Mechanical Properties and Durability Performance of Recycled Aggregate Concrete Containing Crumb Rubber

Abstract

:1. Introduction

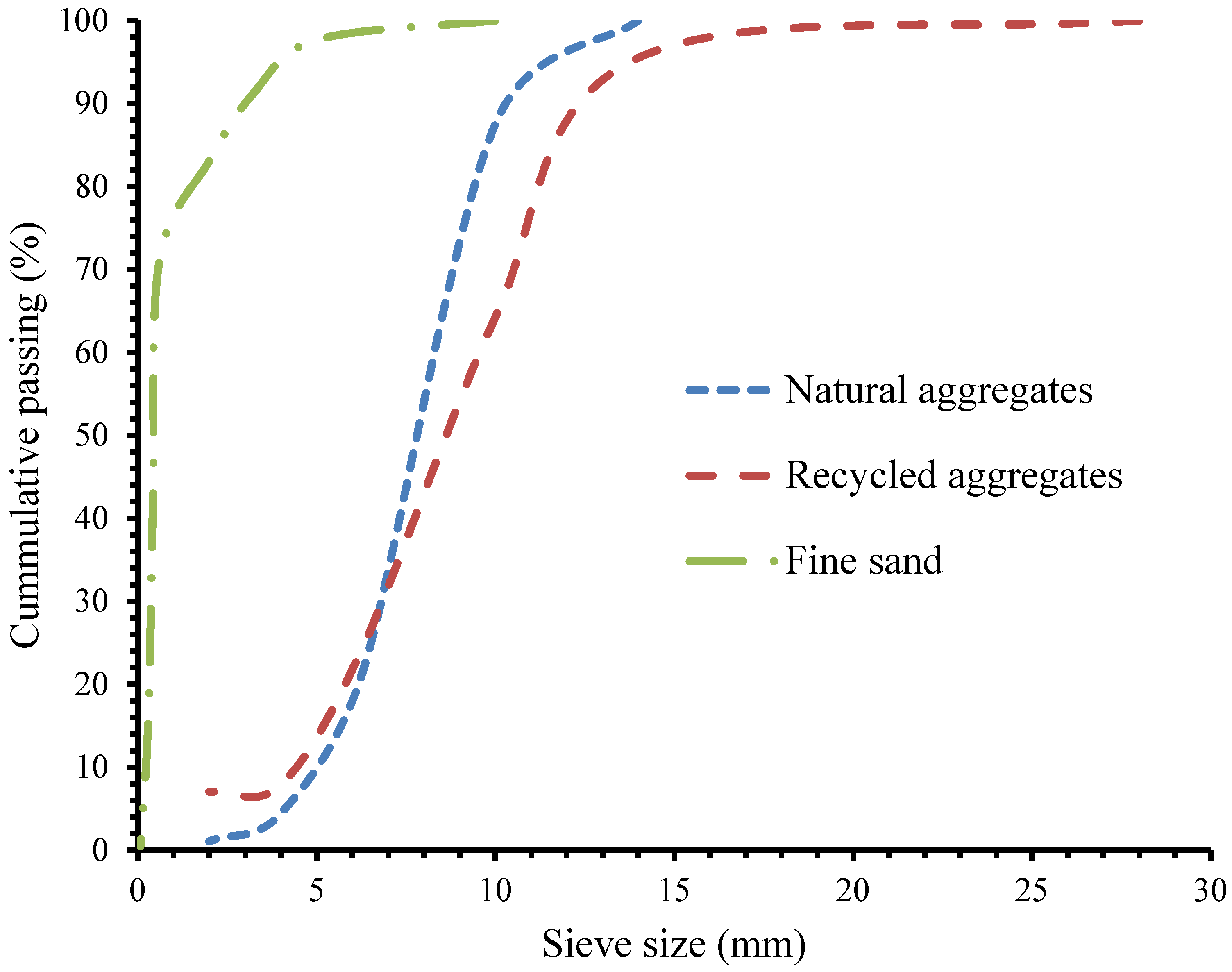

2. Materials

2.1. Material Used

2.2. Concrete Mix and Specimen Preparation

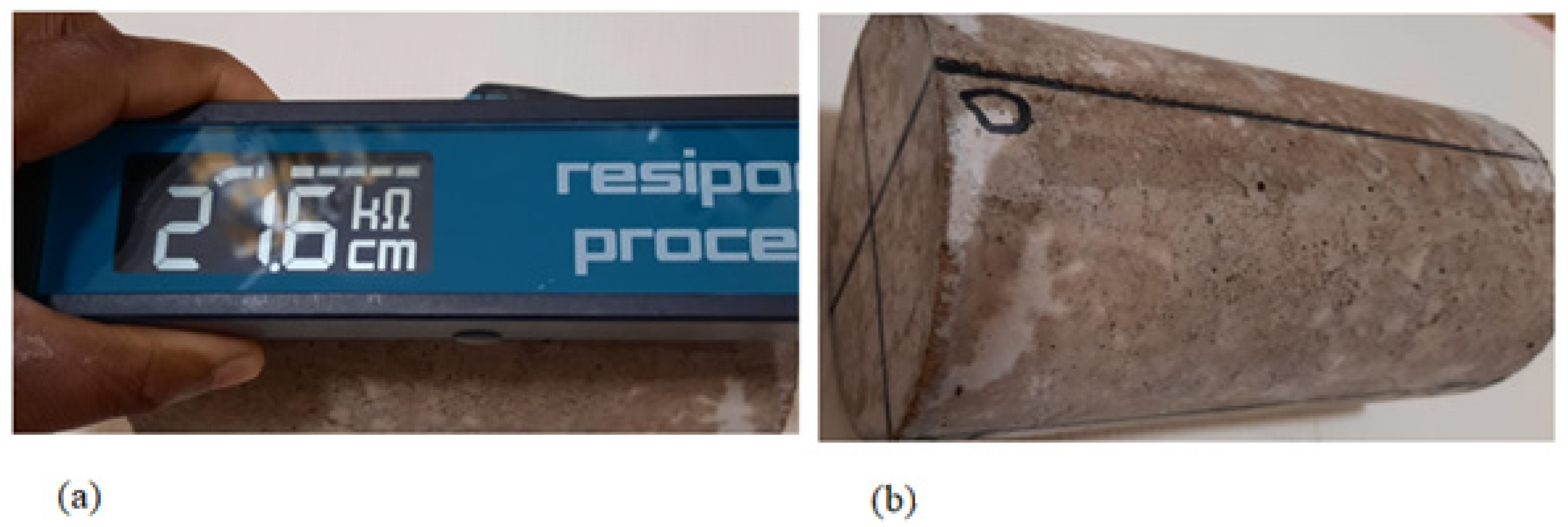

2.3. Concrete Resistivity of Specimens

3. Experimental Results

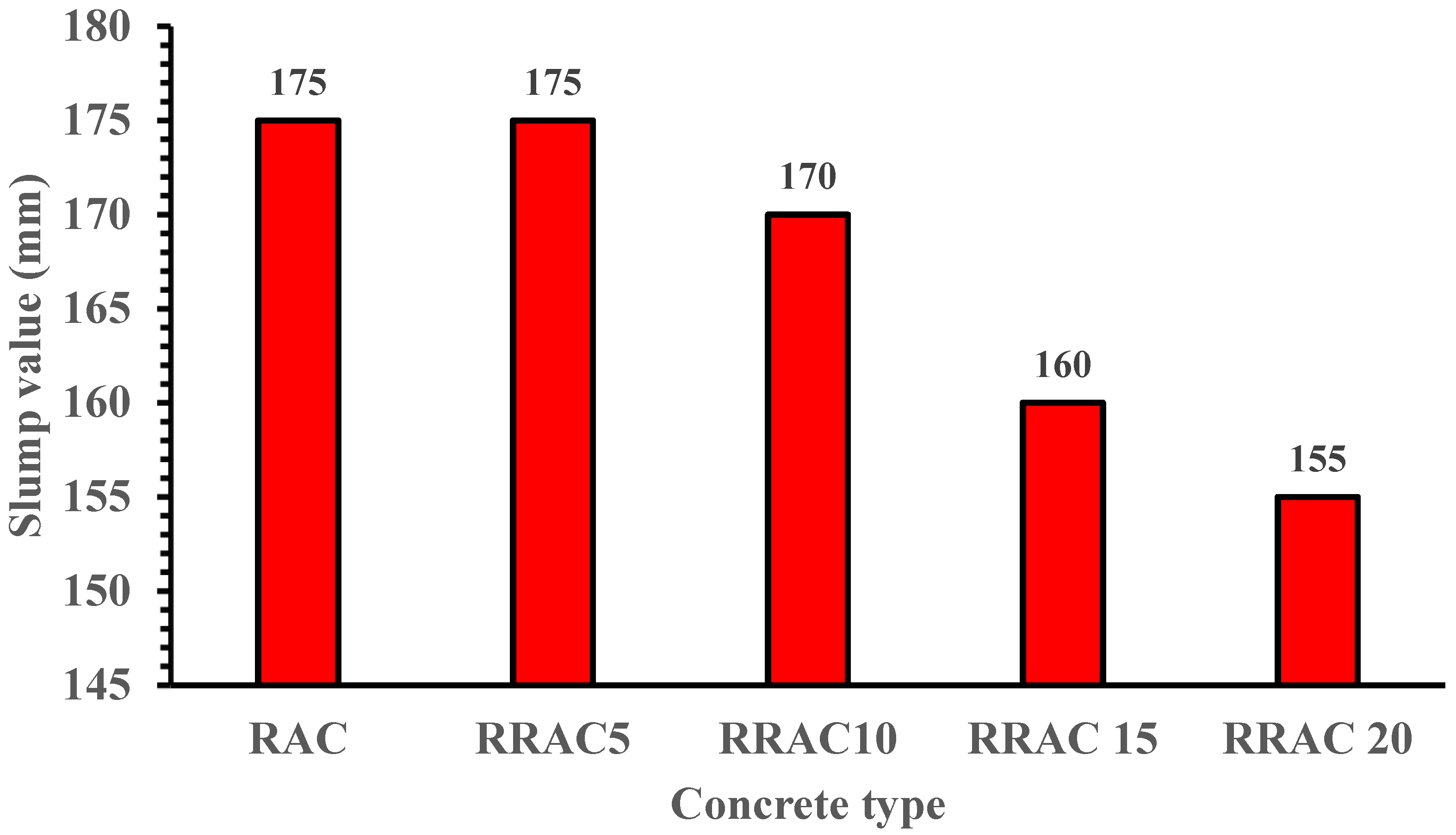

3.1. Fresh Properties

3.2. Hardened Properties

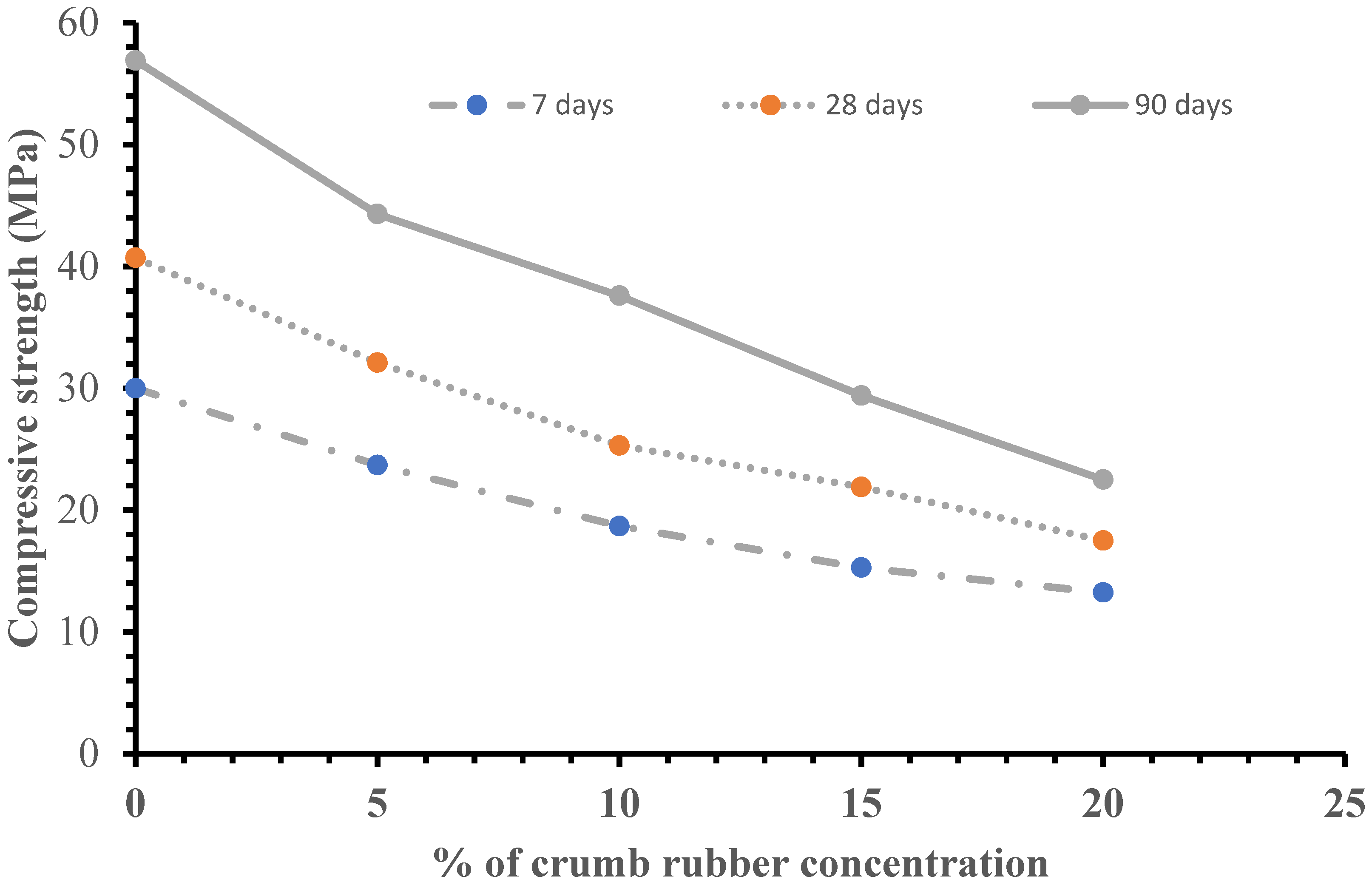

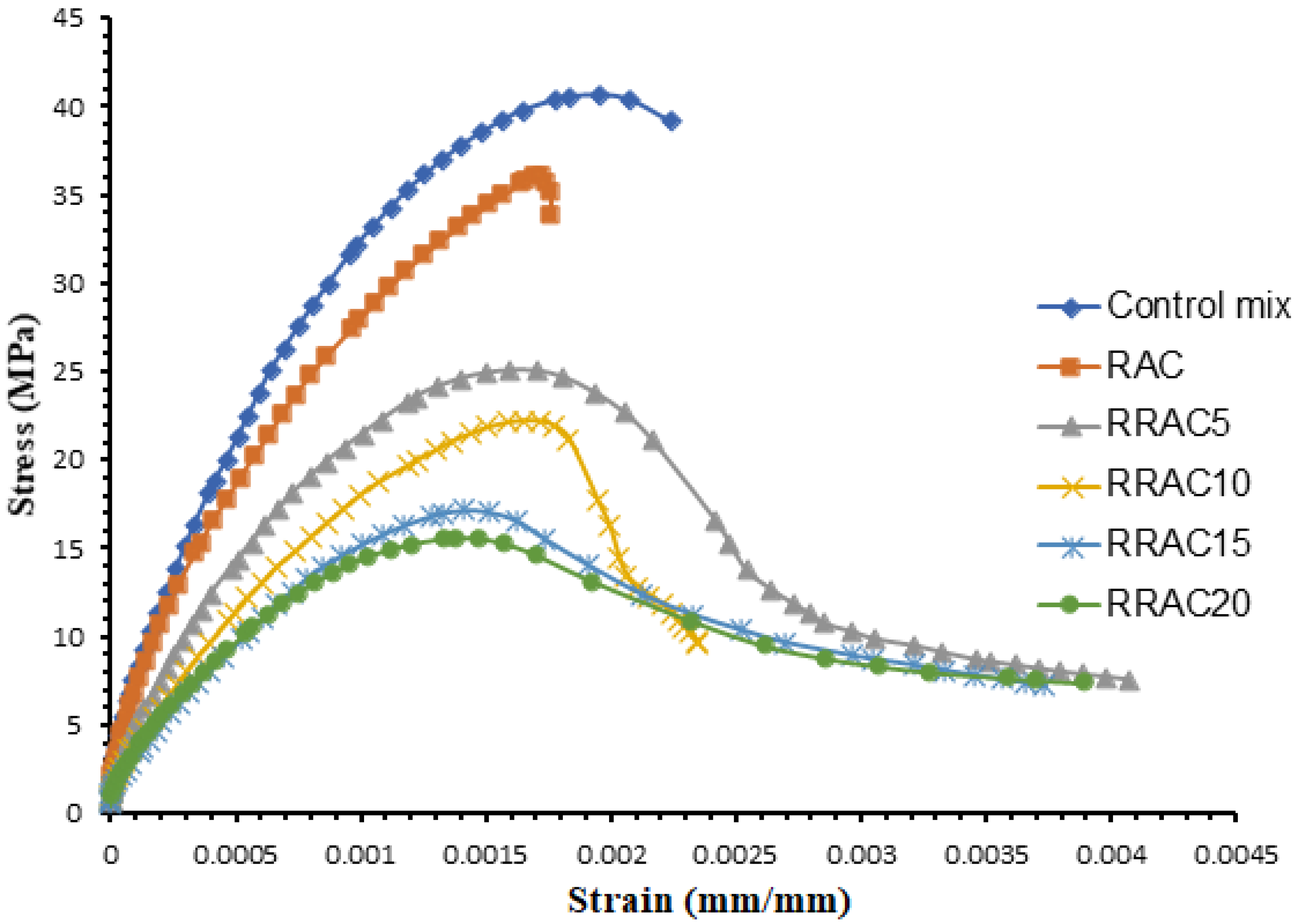

3.2.1. Compressive Strength

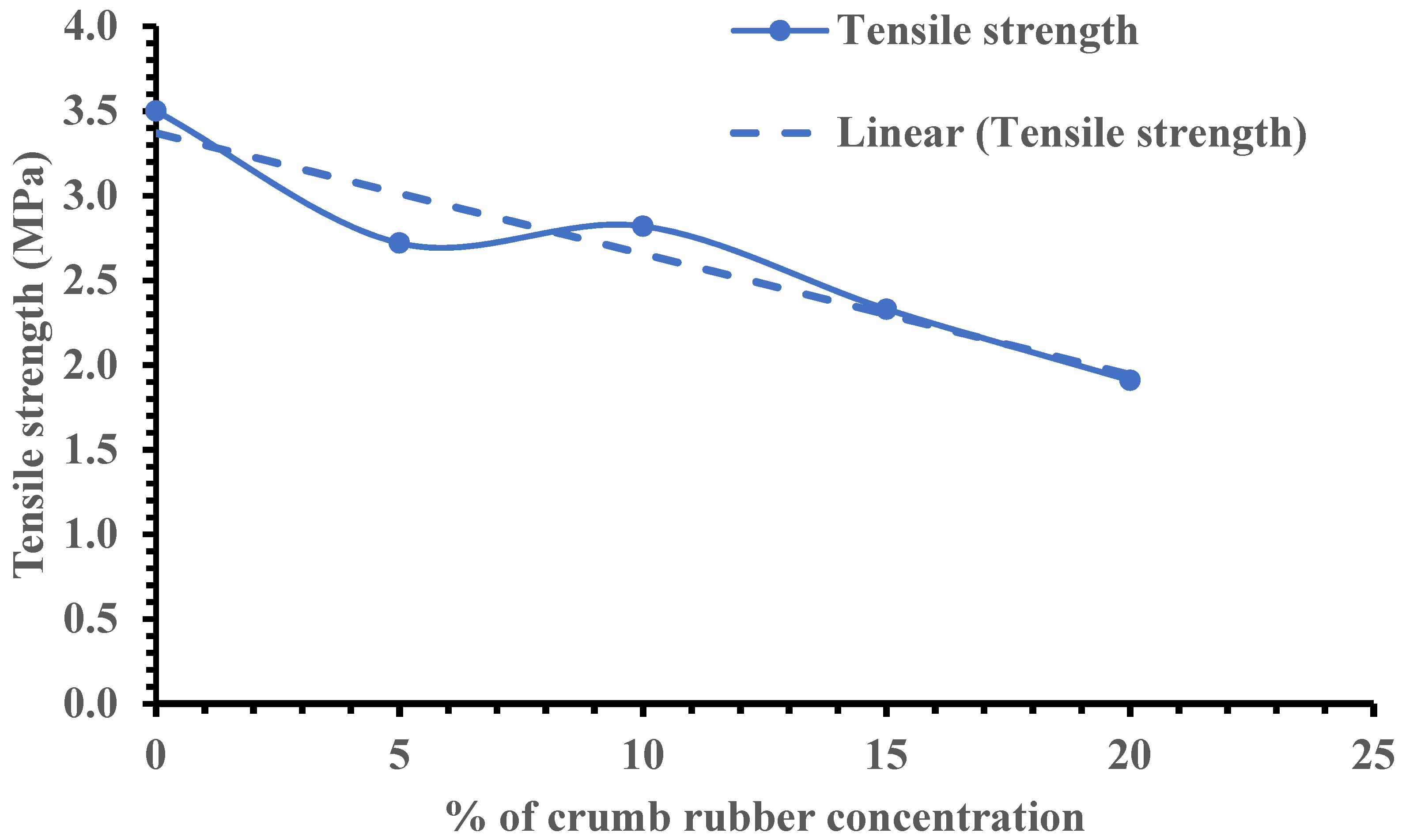

3.2.2. Tensile Strength

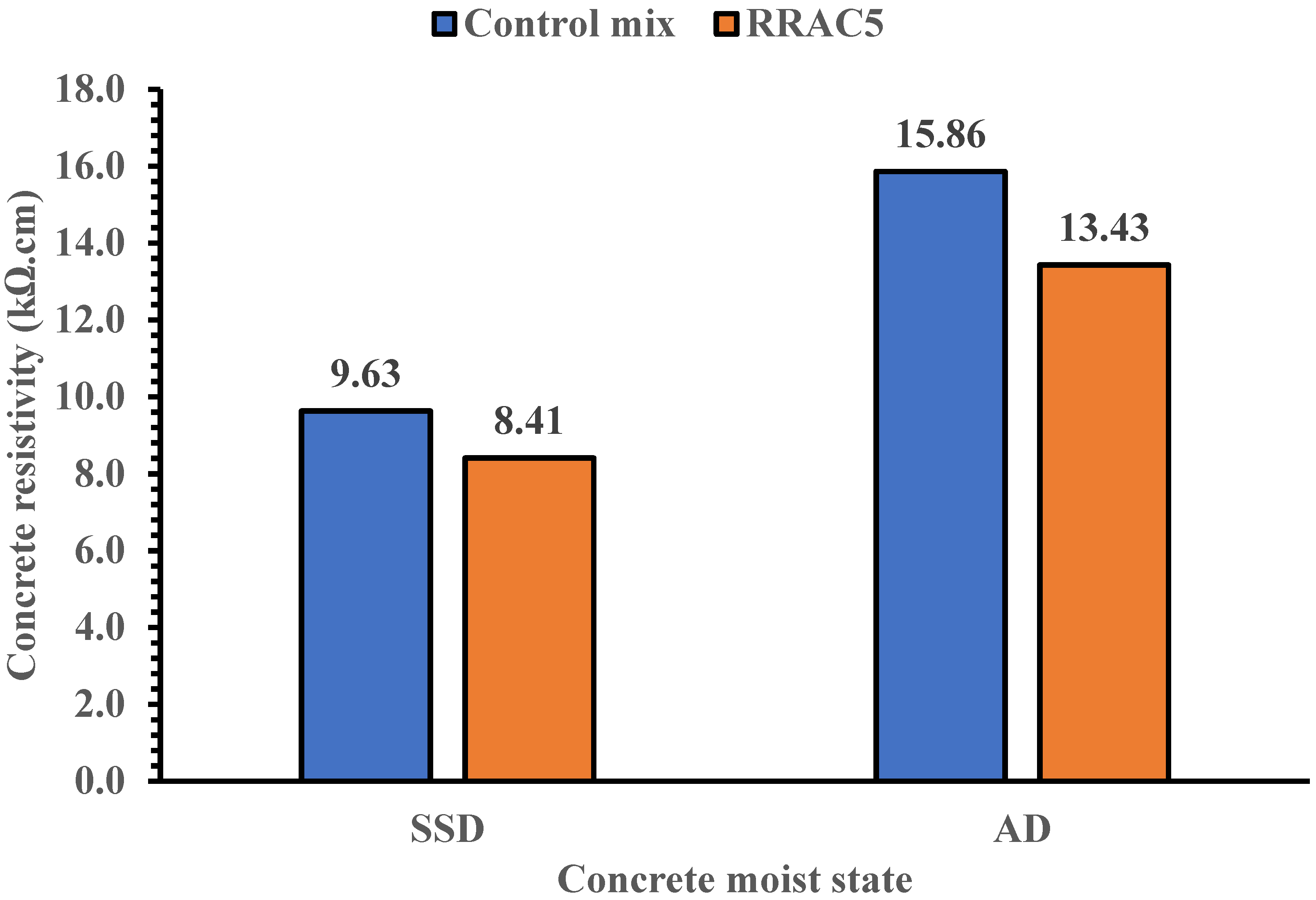

3.3. Durability of the Recycled Aggregate Concrete with Crumb Rubber

4. Conclusions

Further Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- WBCSD. Tire Industry Project, “End-of-Life Tires: A Framework for Effective Management Systems”; World Business Council for Sustainable Development: Geneva, Switzerland, 2010. [Google Scholar]

- Department for Environment, Food and Rural Affairs. UK Statistics on Waste; Government Statistical Service: London, UK, 2021.

- Arezoumandi, M.; Smith, A.; Volz, J.S.; Khayat, K.H. An experimental study on shear strength of reinforced concrete beams with 100% recycled concrete aggregate. Constr. Build. Mater. 2014, 53, 612–620. [Google Scholar] [CrossRef]

- Ismail, K.M.; Hassan, A.A.A.; Hussein, A.A. Structural behaviour of reinforced concrete beams containing crumb rubber and steel fibres. Mag. Concr. Res. 2017, 69, 939–953. [Google Scholar] [CrossRef]

- Xiao, J.; Xie, H.; Yang, Z. Shear transfer across a crack in recycled aggregate concrete. Cem. Concr. Res. 2012, 42, 700–709. [Google Scholar] [CrossRef]

- Tamanna, K.; Tiznobaik, M.; Banthia, N.; Alam, M.S. Mechanical Properties of Rubberized Concrete Containing Recycled Concrete Aggregate. ACI Mater. J. 2020, 117, 169–180. [Google Scholar]

- Henry, M.; Yamashita, H.; Nishimura, T.; Kato, Y. Properties and mechanical–environmental efficiency of concrete combining recycled rubber with waste materials. Int. J. Sustain. Eng. 2011, 5, 66–75. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Muselin, G. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Short and long-term behavior of structural concrete with recycled concrete aggregate. Cem. Concr. Compos. 2013, 37, 312–318. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Bolouri Bazaz, J.; Khayati, M. Properties and Performance of Concrete Made with Recycled Low-Quality Crushed Brick. J. Mater. Civ. Eng. 2012, 24, 330–338. [Google Scholar] [CrossRef]

- Beltran, M.G.; Barbudo, A.; Agrela, F.; Galvín, A.P.; Jiménez, J.R. Effect of cement addition on the properties of recycled concretes to reach control concretes strengths. J. Clean. Prod. 2014, 79, 124–133. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

- Barbudo, A.; De Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Ignjatović, I.S.; Marinković, S.B.; Mišković, Z.M.; Savić, A.R. Flexural behavior of reinforced recycled aggregate concrete beams under short-term loading. Mater. Struct. 2012, 46, 1045–1059. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Toutanji, H.A. The Use of Rubber Tire Particles in Concrete to replace mineral aggregates. Cem. Concr. Compos. 1995, 18, 135–139. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire-rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef] [PubMed]

- Moustafa, A.; ElGawady, M.A. Mechanical properties of high strength concrete with scrap tire rubber. Constr. Build. Mater. 2015, 93, 249–256. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Measurement and Prediction of the Strength of Rubberized Concrete. Cem. Concr. Compos. 1994, 16, 287–298. [Google Scholar] [CrossRef]

- Shah, S.F.A.; Naseer, A.; Shah, A.A.; Ashraf, M. Evaluation of Thermal and Structural Behavior of Concrete Containing Rubber Aggregate. Arab. J. Sci. Eng. 2014, 39, 6919–6926. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Barluenga, G. Fire performance of recycled rubber-filled high-strength concrete. Cem. Concr. Res. 2004, 34, 109–117. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E. Strength development and chloride penetration in rubberized concretes with and without silica fume. Mater. Struct. 2007, 40, 953–964. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K. Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J. Clean. Prod. 2014, 82, 125–131. [Google Scholar] [CrossRef]

- Yilmaz, A.; Degirmenci, N. Possibility of using waste tire rubber and fly ash with Portland cement as construction materials. Waste Manag. 2009, 29, 1541–1546. [Google Scholar] [CrossRef]

- Ma, Q.W.; Yue, J.C. Effect on Mechanical Properties of Rubberized Concrete due to Pretreatment of Waste Tire Rubber with NaOH. Appl. Mech. Mater. 2013, 357, 897–904. [Google Scholar] [CrossRef]

- Su, H.; Yang, J.; Ling, T.C.; Ghataora, G.S.; Dirar, S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 2015, 91, 288–296. [Google Scholar] [CrossRef] [Green Version]

- Najim, K.B.; Hall, M.R. Workability and mechanical properties of crumb-rubber concrete. Proc. ICE—Constr. Mater. 2013, 166, 7–17. [Google Scholar] [CrossRef]

- Pham, T.M.; Elchalakani, M.; Hao, H.; Lai, J.; Ameduri, S.; Tran, T.M. Durability characteristics of lightweight rubberized concrete. Constr. Build. Mater. 2019, 224, 584–599. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 2009, 23, 1084–1092. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; Composition, Specifications and Conformity Criteria for Common Cements. BSI Standards Publication: London, UK, 2011.

- BS EN 12620; Aggregates for Concrete. BSI Standards Publication: London, UK, 2013.

- Ling, T.C.; Nor, H.M.; Lim, S.K. Using recycled waste tyres in concrete paving blocks. In Proceedings of the ICE—Waste and Resource Management; ICE Virtual Library: London, UK, 2010; Volume 163, pp. 37–45. [Google Scholar]

- Yadav, S.; Pathak, S. Durability Aspects of Recycled Aggregate Concrete: An Experimental Study. Int. J. Civ. Environ. Eng. 2018, 12, 313–323. [Google Scholar]

- AASHTO-TP95; Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- ACI228–2R; Report on Nondestructive Test Methods for Evaluation of Concrete in Structures. ACI: Farmington Hills, MI, USA, 2013.

- Layssi, H.; Ghods, P.; Alizadeh, A.R.; Salehi, M. Electrical Resistivity of Concrete: Concepts, applications, and measurement techniques. Concr. Int. 2015, 37, 41–46. [Google Scholar]

- BS-EN12350–2-2009; Testing Fresh Concrete—Part 2: Slump-Test. British Standard Publications: London, UK, 2009.

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Matias, D.; De Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates—Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef]

- Moo-Young, H.; Sellasie, K.; Zeroka, D.; Sabnis, G. Physical and Chemical Properties of Recycled Tire Shreds for Use in Construction. J. Environ. Eng. 2003, 129. [Google Scholar] [CrossRef]

- BS-EN12390–3-2009; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. British standard publications: London, UK, 2009.

- Najim, K.B.; Hall, M.R. Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Constr. Build. Mater. 2012, 27, 521–530. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Sandrolini, F. Tyre rubber waste recycling in self-compacting concrete. Cem. Concr. Res. 2006, 36, 735–739. [Google Scholar] [CrossRef]

- Emiroglu, M.; Kelestemur, M.H.; Yildiz, S. An investigation on ITZ microstructure of the concrete containing waste vehicles tire. In Proceedings of the 8th International Fracture Conference, Istanbul, Turkey, 8 November 2007. [Google Scholar]

- BS1881–203:1986; Testing Concrete—Part 203: Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete. British Standard Publications: London, UK, 1986.

- BS-EN12390-6-2000; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. British Standard Publications: London, UK, 2000.

| Composition | Proportion |

|---|---|

| Natural aggregates | |

| Quartzite | 79% |

| Sandstone | 6% |

| Basalt | 5% |

| Others | 10% |

| Recycled Aggregates | |

| Recycled Aggregates | 81% |

| Bricks | 13% |

| Dust | 6% |

| Type | Apparent Particle Density | Particle Density on Oven Dry Bases | Particle Density on Saturated and Oven Dry Bases | Water Absorption (%) |

|---|---|---|---|---|

| Natural aggregate | 2.69 | 2.62 | 2.65 | 1.05 |

| Recycled aggregates (RA) | 2.61 | 2.27 | 2.40 | 5.77 |

| Mix Type | Cement (kg) | Water (kg) | w/c | Sand (kg) | Coarse Aggregates (kg) |

|---|---|---|---|---|---|

| NAC | 550 | 220 | 0.4 | 626 | 939 |

| Specimen | Natural Aggregates | Recycled Aggregates (RA) | Crumb Rubber | Sand |

|---|---|---|---|---|

| Designation | (% by Weight) | (% by Weight) | (% by RA Weight) | (% by Weight) |

| NAC | 100 | - | - | 100 |

| RAC | - | 100 | - | 100 |

| RRAC5 | - | 100 | 5 | 100 |

| RRAC10 | - | 100 | 10 | 100 |

| RRAC 15 | - | 100 | 15 | 100 |

| RRAC 20 | - | 100 | 20 | 100 |

| Specimen | Compressive Strength (MPa) | Tensile | Ultrasonic Pulse | ||

|---|---|---|---|---|---|

| Type | 7 days | 28 days | 90 days | Strength MPa | Velocity (KM/s) |

| NAC | 34.6 | 47.8 | 60.4 | 4.11 | 4.19 |

| RAC | 30 | 40.7 | 56.9 | 3.50 | 3.90 |

| RRAC5 | 23.7 | 32.1 | 44.3 | 2.72 | 3.72 |

| RRAC10 | 18.69 | 25.3 | 37.6 | 2.82 | 3.61 |

| RRAC 15 | 15.28 | 21.9 | 29.4 | 2.33 | 3.54 |

| RRAC 20 | 13.24 | 17.5 | 22.5 | 1.91 | 3.41 |

| Ultrasonic Pulse Velocity (m/s) | Concrete Classification |

|---|---|

| V > 4575 | Excellent |

| 4575 > V > 3660 | Good |

| 3660 > V > 3050 | Questionable |

| 3050 > V > 2135 | Poor |

| V < 2135 | Very poor |

| Chloride Ion Penetrability | AASHTO TP 95, kΩ.cm | ASTM C1202, Coulombs |

|---|---|---|

| High | <12 | >4000 |

| Moderate | 12 to 21 | 2000 to 4000 |

| Low | 21 to 37 | 1000 to 2000 |

| Very Low | 37 to 254 | 100 to 1000 |

| Negligible | >254 | <100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ataria, R.B.; Wang, Y.C. Mechanical Properties and Durability Performance of Recycled Aggregate Concrete Containing Crumb Rubber. Materials 2022, 15, 1776. https://doi.org/10.3390/ma15051776

Ataria RB, Wang YC. Mechanical Properties and Durability Performance of Recycled Aggregate Concrete Containing Crumb Rubber. Materials. 2022; 15(5):1776. https://doi.org/10.3390/ma15051776

Chicago/Turabian StyleAtaria, Robert B., and Yong C. Wang. 2022. "Mechanical Properties and Durability Performance of Recycled Aggregate Concrete Containing Crumb Rubber" Materials 15, no. 5: 1776. https://doi.org/10.3390/ma15051776

APA StyleAtaria, R. B., & Wang, Y. C. (2022). Mechanical Properties and Durability Performance of Recycled Aggregate Concrete Containing Crumb Rubber. Materials, 15(5), 1776. https://doi.org/10.3390/ma15051776