Superplastic Deformation of Alumina Composites Reinforced with Carbon Nanofibers and with Graphene Oxide Sintered by SPS—Experimental Testing and Theoretical Interpretation

Abstract

1. Introduction

2. Background Theory

- (a)

- The relative velocity between two sliding grains is proportional to the difference between the shear stress and the threshold stress .

- (b)

- The relative velocity increases linearly with the shear stress, and jumps from zero to the proper value when it is higher than .

3. Experimental Validation and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Yan, H.; Reece, M.J.; Jiang, K. Toughening of zirconia/alumina composites by the addition of graphene platelets. J. Eur. Ceram. Soc. 2012, 32, 4185–4193. [Google Scholar] [CrossRef]

- Ahmad, I.; Cao, H.; Chen, H.; Zhao, H.; Kennedy, A.; Zhu, Y.Q. Carbon nanotube toughened aluminium oxide nanocomposite. J. Eur. Ceram. Soc. 2010, 30, 865–873. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Ball, A. Superplasticity in the aluminium-zinc eutectoid—An early model revisited. Mater. Sci. Eng. A 1997, 234–236, 365–369. [Google Scholar] [CrossRef]

- Fukuyo, H.; Tsai, H.C.; Oyama, T.; Sherby, O.D. Superplasticity and Newtonian-viscous flow in fine-grained class I solid solution alloys. ISIJ Int. 1991, 31, 76–85. [Google Scholar] [CrossRef][Green Version]

- Gittus, J.H. Theory of Superplastic Flow in Two-Phase Materials: Roles of Interphase-Boundary Dislocations, Ledges, and Diffusion. J. Eng. Mater. Technol. 1977, 99, 244–251. [Google Scholar] [CrossRef]

- Kaibyshev, O.A.; Valiev, R.Z.; Emaletdinov, A.K. Deformation mechanisms and the theory of structural superplasticity of metals. Phys. Status Solidi 1985, 90, 197–206. [Google Scholar] [CrossRef]

- Langdon, T.G. Grain boundary sliding as a deformation mechanism during creep. Philos. Mag. 2006, 22, 689–700. [Google Scholar] [CrossRef]

- Mukherjee, A.K. The rate controlling mechanism in superplasticity. Mater. Sci. Eng. 1971, 8, 83–89. [Google Scholar] [CrossRef]

- Gifkins, R.C. Grain-boundary sliding and its accommodation during creep and superplasticity. Metall. Trans. A 1976, 7, 1225–1232. [Google Scholar] [CrossRef]

- Arieli, A.; Mukherjee, A.K. A model for the rate-controlling mechanism in superplasticity. Mater. Sci. Eng. 1980, 45, 61–70. [Google Scholar] [CrossRef]

- Hayden, H.W.; Floreen, S.; Goodell, P.D. The deformation mechanisms of superplasticity. Metall. Mater. Trans. B 1972, 3, 833–842. [Google Scholar] [CrossRef]

- Ashby, M.F.; Verrall, R.A. Diffusion-accommodated flow and superplasticity. Acta Metall. 1973, 21, 149–163. [Google Scholar] [CrossRef]

- Gómez-García, D.; Zapata-Solvas, E.; Domínguez-Rodríguez, A.; Kubin, L.P. Diffusion-driven superplasticity in ceramics: Modeling and comparison with available data. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 80, 214107. [Google Scholar] [CrossRef]

- Sakuma, T.; Yoshida, H. High temperature grain boundary plasticity in ceramics. Mater. Trans. 2009, 50, 229–235. [Google Scholar] [CrossRef]

- Lagos, M. Elastic Instability of Grain Boundaries and the Physical Origin of Superplasticity. Phys. Rev. Lett. 2000, 85, 2335. [Google Scholar] [CrossRef]

- Lagos, M. Theory of superplasticity in polycrystalline materials: Stress-induced structural instabilities of grain boundaries. PhRvB 2005, 71, 224117. [Google Scholar] [CrossRef]

- Lagos, M. Theory of ductility: From brittle to superplastic behavior of polycrystals. Phys. Rev. B Condens. Matter Mater. Phys. 2006, 73, 224107. [Google Scholar] [CrossRef]

- Lagos, M.; Retamal, C. A theoretical approach to finite strain superplasticity and some of its applications. Phys. Scr. 2010, 81, 055601. [Google Scholar] [CrossRef]

- Lagos, M.; Retamal, C. Grain dynamics and plastic properties of highly refined materials. Phys. Scr. 2010, 82, 065603. [Google Scholar] [CrossRef]

- Zapata-Solvas, E.; Gómez-García, D.; García-Gañán, C.; Domínguez-Rodríguez, A. High temperature creep behaviour of 4 mol% yttria tetragonal zirconia polycrystals (4-YTZP) with grain sizes between 0.38 and 1.15 μm. J. Eur. Ceram. Soc. 2007, 27, 3325–3329. [Google Scholar] [CrossRef]

- Retamal, C.; Lagos, M.; Moshtaghioun, B.M.; Cumbrera, F.L.; Domínguez-Rodríguez, A.; Gómez-García, D. A new approach to the grain-size dependent transition of stress exponents in yttria tetragonal zirconia polycrystals. The theoretical limit for superplasticity in ceramics. Ceram. Int. 2016, 42, 4918–4923. [Google Scholar] [CrossRef]

- Cano-Crespo, R.; Malmal Moshtaghioun, B.; Gómez-García, D.; Domínguez-Rodríguez, A.; Moreno, R. High-temperature creep of carbon nanofiber-reinforced and graphene oxide-reinforced alumina composites sintered by spark plasma sintering. Ceram. Int. 2017, 43, 7136–7141. [Google Scholar] [CrossRef]

- Gómez-García, D.; Devincre, B.; Kubin, L. Dislocation dynamics in confined geometry. J. Comput. Mater. Des. 1999, 6, 157–164. [Google Scholar] [CrossRef]

- Bellon, P.; Averback, R.S. Non equilibrium roughening of interfaces in crystals under shear: Application to ball milling. Phys. Rev. Lett. 1995, 74, 1819–1822. [Google Scholar] [CrossRef]

- Fukutomi, H.; Yamamoto, T.; Nonomura, K.; Takada, K. Examination of Dislocation Mechanism on Grain Boundary Sliding in High Angle Grain Boundaries by Stress Change Test. Interface Sci. 1999, 2, 141–146. [Google Scholar] [CrossRef]

- Qi, Y.; Krajewski, P.E. Molecular dynamics simulations of grain boundary sliding: The effect of stress and boundary misorientation. Acta Mater. 2007, 5, 1555–1563. [Google Scholar] [CrossRef]

- Lagos, M.; Retamal, C. Theory of finite strain superplasticity. Mater. Sci. 2009, arXiv:0911.3649. [Google Scholar]

- Lagos, M.; Conte, V. Mathematical model for the plastic flow of a polycrystalline material medium. Scr. Mater. 2012, 65, 1053–1056. [Google Scholar] [CrossRef]

- Domínguez-Rodríguez, A.; Gómez-García, D.; Wakai, F. High temperature plasticity in yttria stabilised tetragonal zirconia polycrystals (Y-TZP). Int. Mater. Rev. 2013, 58, 399–417. [Google Scholar] [CrossRef]

- Karato, S.I.; Jung, H. Effects of pressure on high-temperature dislocation creep in olivine. Philos. Mag. 2003, 83, 401–414. [Google Scholar] [CrossRef]

| d = 0.30 µm | d = 0.38 µm | d = 0.45 µm | ||||

|---|---|---|---|---|---|---|

| Model A | Model B | Model A | Model B | Model A | Model B | |

| ξ2 | 0.1189 | 0.0561 | 0.0007 | 0.0001 | 0.0045 | 0.0013 |

| R2 | 0.9122 | 0.9586 | 0.9978 | 0.9996 | 0.9918 | 0.9977 |

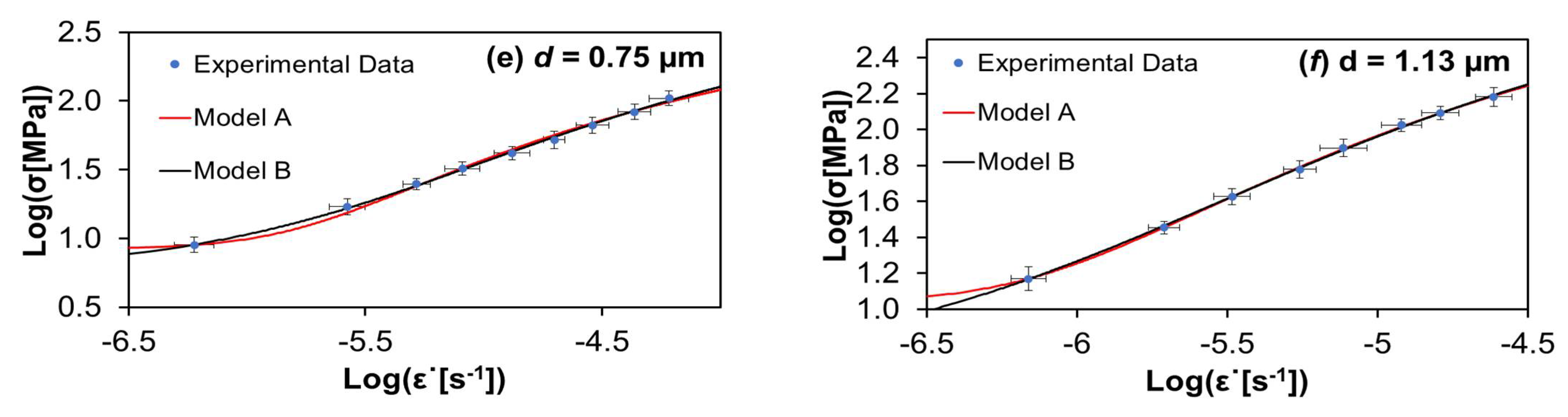

| d = 0.60 µm | d = 0.75 µm | d = 1.13 µm | ||||

|---|---|---|---|---|---|---|

| Model A | Model B | Model A | Model B | Model A | Model B | |

| ξ2 | 0.0091 | 0.0033 | 0.0026 | 0.0007 | 0.0002 | 0.0003 |

| R2 | 0.9844 | 0.9943 | 0.9937 | 0.9983 | 0.9994 | 0.9990 |

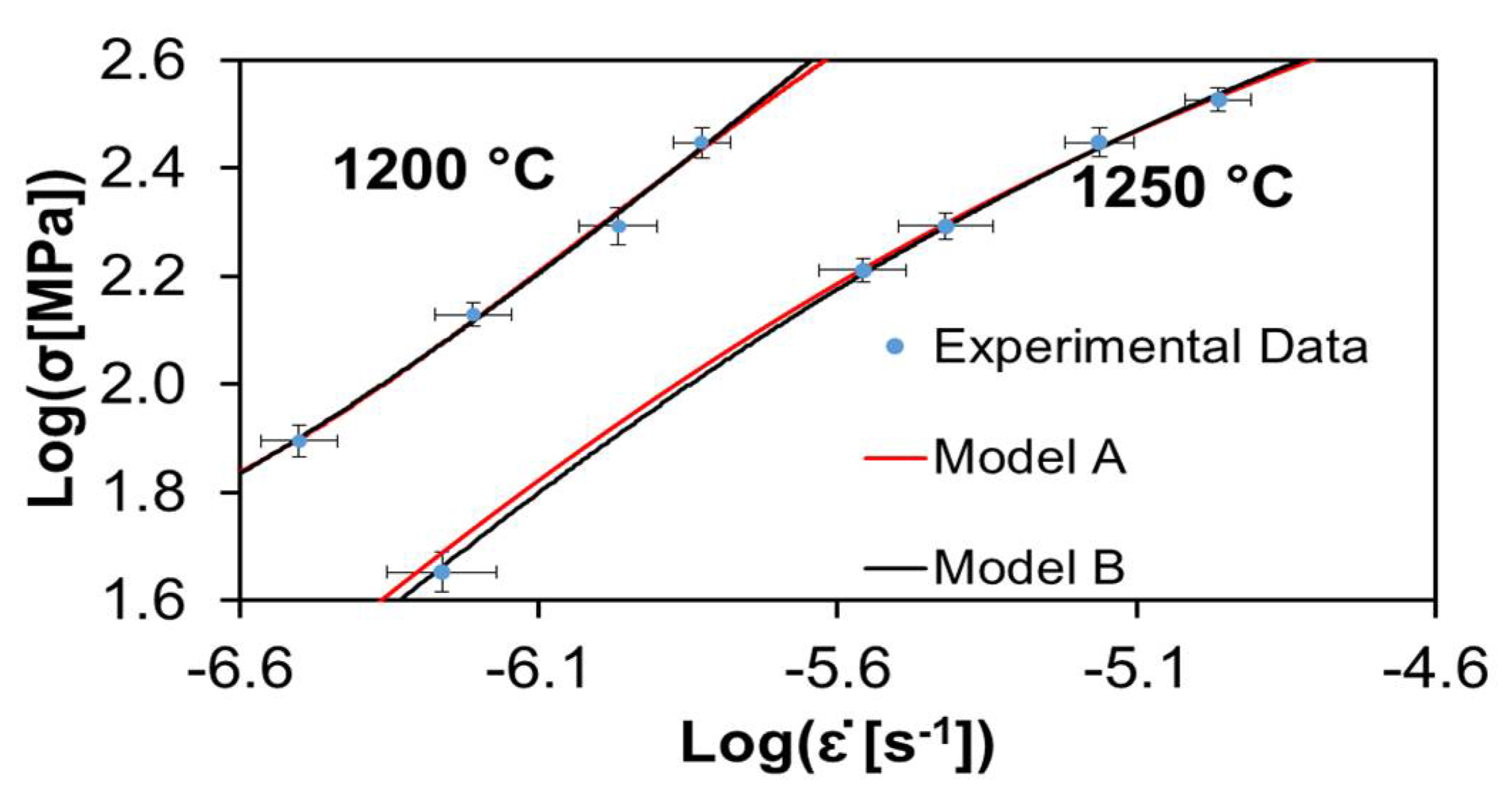

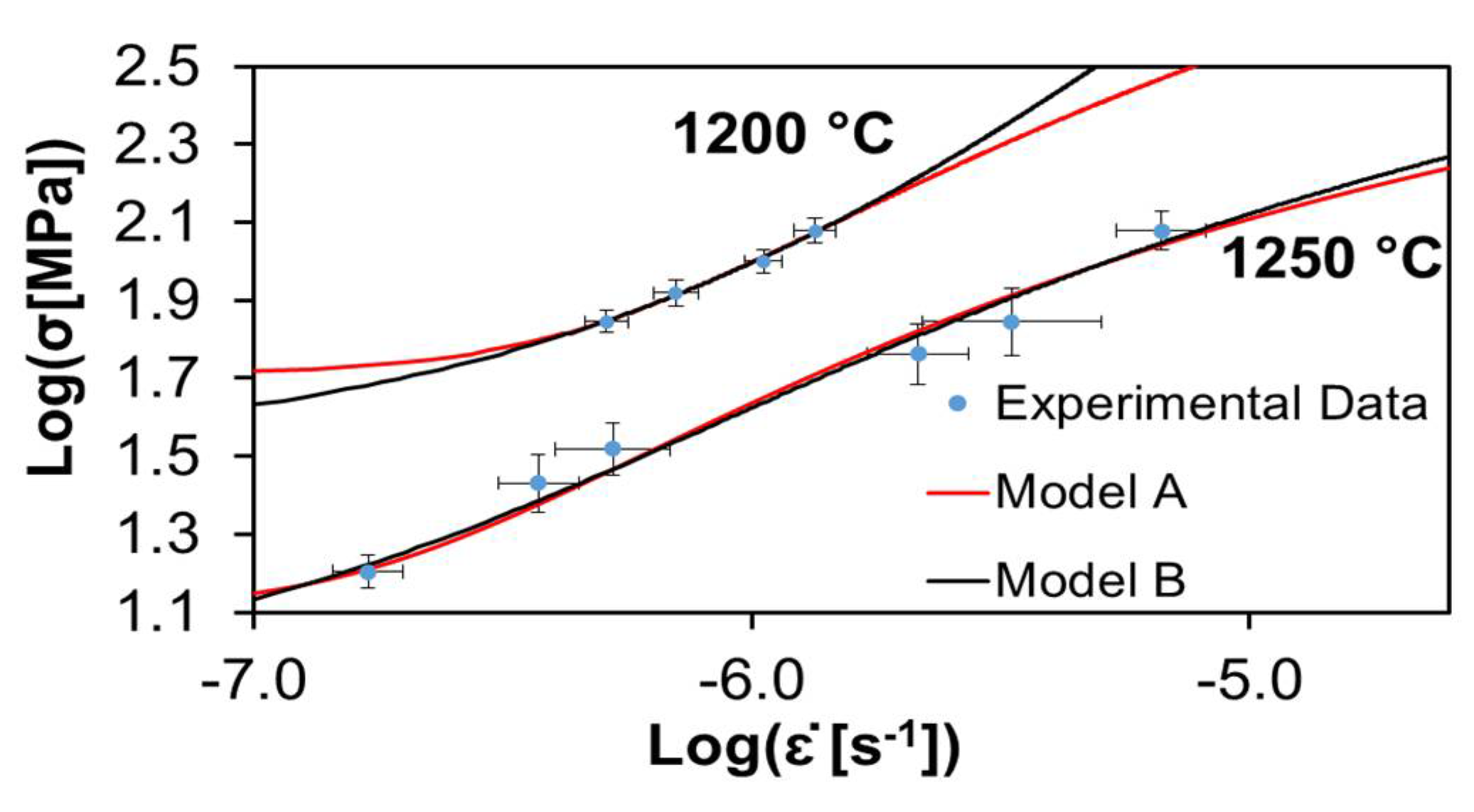

| 1200 °C A | 1250 °C A | 1200 °C A-GO | 1250 °C A-GO | 1200 °C A-CNF | 1250 °C A-CNF | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | A | B | |

| ξ2 | 0.0008 | 0.0007 | 0.0012 | 0.0005 | 0.0003 | 0.0003 | 0.0191 | 0.0149 | 0.0022 | 0.000001 | 0.0005 | 0.0007 |

| R2 | 0.9893 | 0.9913 | 0.9950 | 0.9979 | 0.9887 | 0.9909 | 0.9501 | 0.9611 | 0.9600 | 0.9999 | 0.9978 | 0.9965 |

| 1200 °C A | 1250 °C A | 1200 °C A-GO | 1250 °C A-GO | 1200 °C A-CNF | 1250 °C A-CNF | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | A | B | |

| Q (J) | 9.5 · 10−19 | 9.5 · 10−19 | 9.5 · 10−19 | 9.5 · 10−19 | 1.0 · 10−18 | 1.0 · 10−18 | 1.0 · 10−18 | 1.0 · 10−18 | 9.9 · 10−19 | 9.9 · 10−19 | 9.9 · 10−19 | 9.9 · 10−19 |

| C0 (s−1) | 3.46 · 1014 | 2.61 · 1015 | 3.10 · 1013 | 3.69 · 1013 | 3.43 · 1015 | 6.24 · 1019 | 2.68 · 1014 | 5.34 · 1014 | 8.53 · 1020 | 1.63 · 1015 | 1.06 · 1014 | 1.47 · 1014 |

| 1200 °C A | 1250 °C A | 1200 °C A-GO | 1250 °C A-GO | 1200 °C A-CNF | 1250 °C A-CNF | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | A | B | |

| τc (MPa) | 19.84 | 7.92 | 0.25 | 3.05 · 10−15 | 25.68 | 15.83 | 6.32 | 3.58 | 13.28 | 3.85 | 6.78 | 2.63 |

| Ω* (m3) | 4.9 · 10−23 | 8.3 · 10−24 | 2.5 · 10−22 | 2.3 · 10−22 | 2.1 · 10−22 | 2.5 · 10−26 | 8.7 · 10−22 | 6.7 · 10−22 | 1.2 · 10−27 | 4.5 · 10−22 | 1.1 · 10−21 | 1.0 · 10−21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano-Crespo, R.; Retamal, C.; Lagos, M.; Cumbrera, F.L. Superplastic Deformation of Alumina Composites Reinforced with Carbon Nanofibers and with Graphene Oxide Sintered by SPS—Experimental Testing and Theoretical Interpretation. Materials 2022, 15, 1396. https://doi.org/10.3390/ma15041396

Cano-Crespo R, Retamal C, Lagos M, Cumbrera FL. Superplastic Deformation of Alumina Composites Reinforced with Carbon Nanofibers and with Graphene Oxide Sintered by SPS—Experimental Testing and Theoretical Interpretation. Materials. 2022; 15(4):1396. https://doi.org/10.3390/ma15041396

Chicago/Turabian StyleCano-Crespo, Rafael, César Retamal, Miguel Lagos, and Francisco Luis Cumbrera. 2022. "Superplastic Deformation of Alumina Composites Reinforced with Carbon Nanofibers and with Graphene Oxide Sintered by SPS—Experimental Testing and Theoretical Interpretation" Materials 15, no. 4: 1396. https://doi.org/10.3390/ma15041396

APA StyleCano-Crespo, R., Retamal, C., Lagos, M., & Cumbrera, F. L. (2022). Superplastic Deformation of Alumina Composites Reinforced with Carbon Nanofibers and with Graphene Oxide Sintered by SPS—Experimental Testing and Theoretical Interpretation. Materials, 15(4), 1396. https://doi.org/10.3390/ma15041396