Diffusion Bonding of Al-Mg-Si Alloy and 301L Stainless Steel by Friction Stir Lap Welding Using a Zn Interlayer

Abstract

:1. Introduction

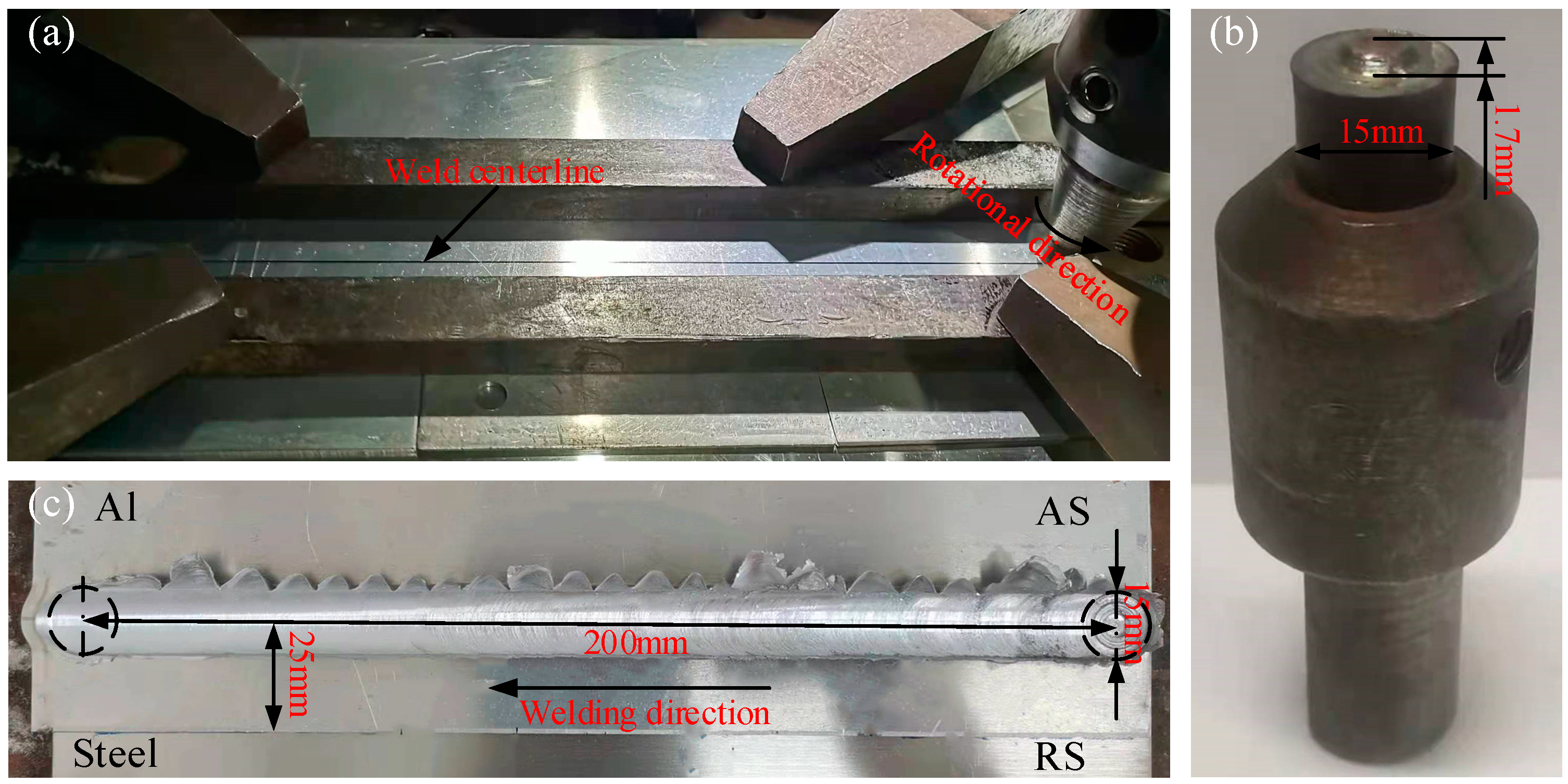

2. Materials and Methods

3. Results and Discussion

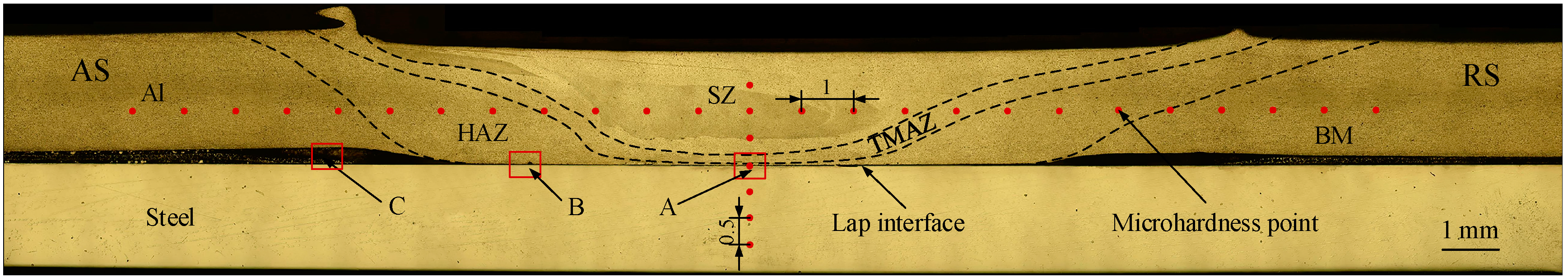

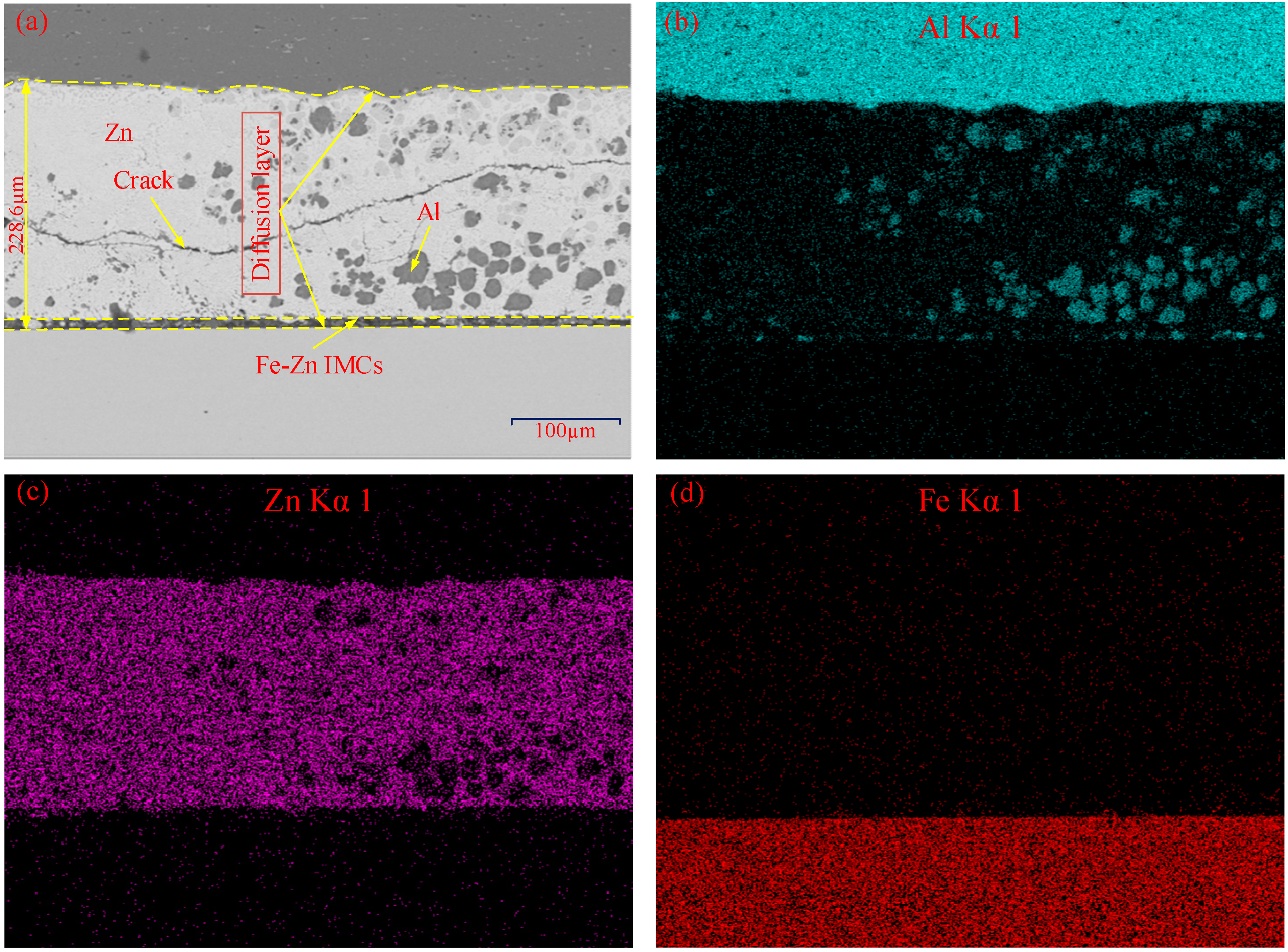

3.1. Cross Section Feature and EDS Analysis

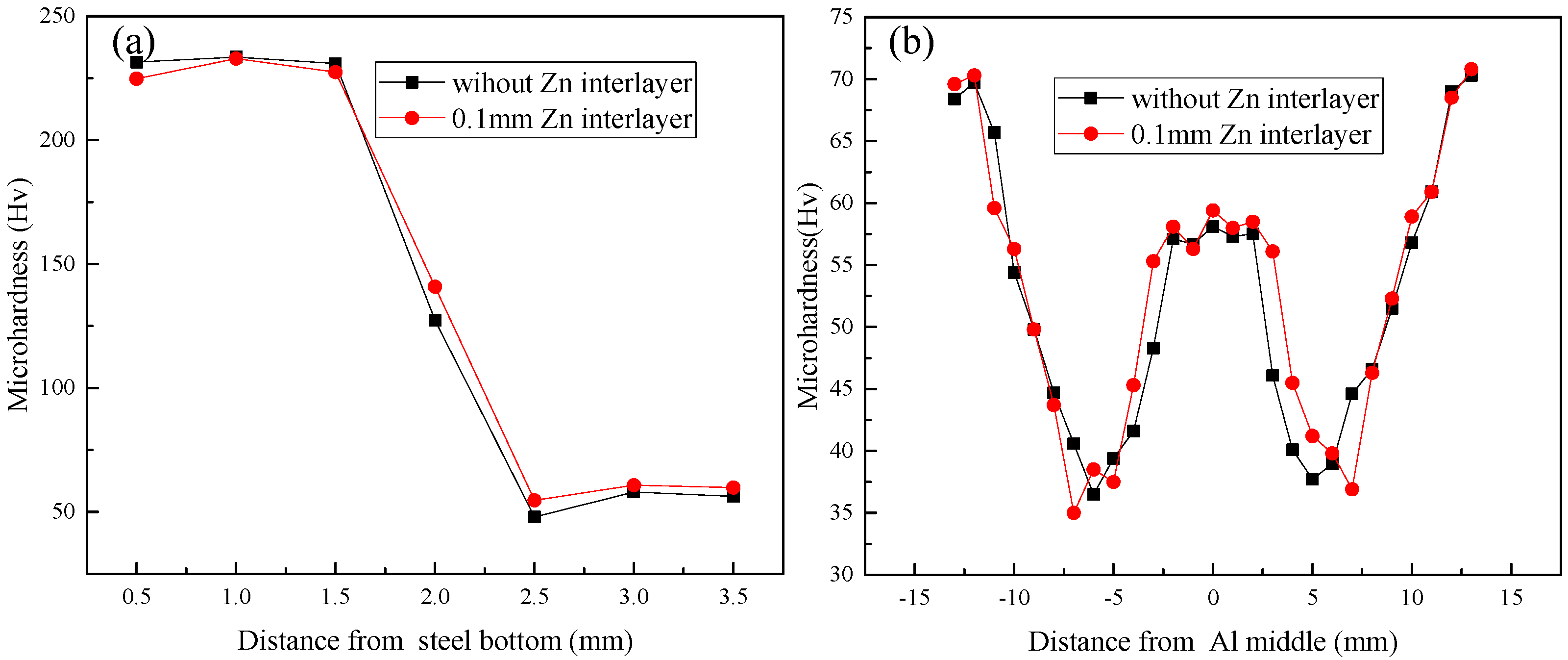

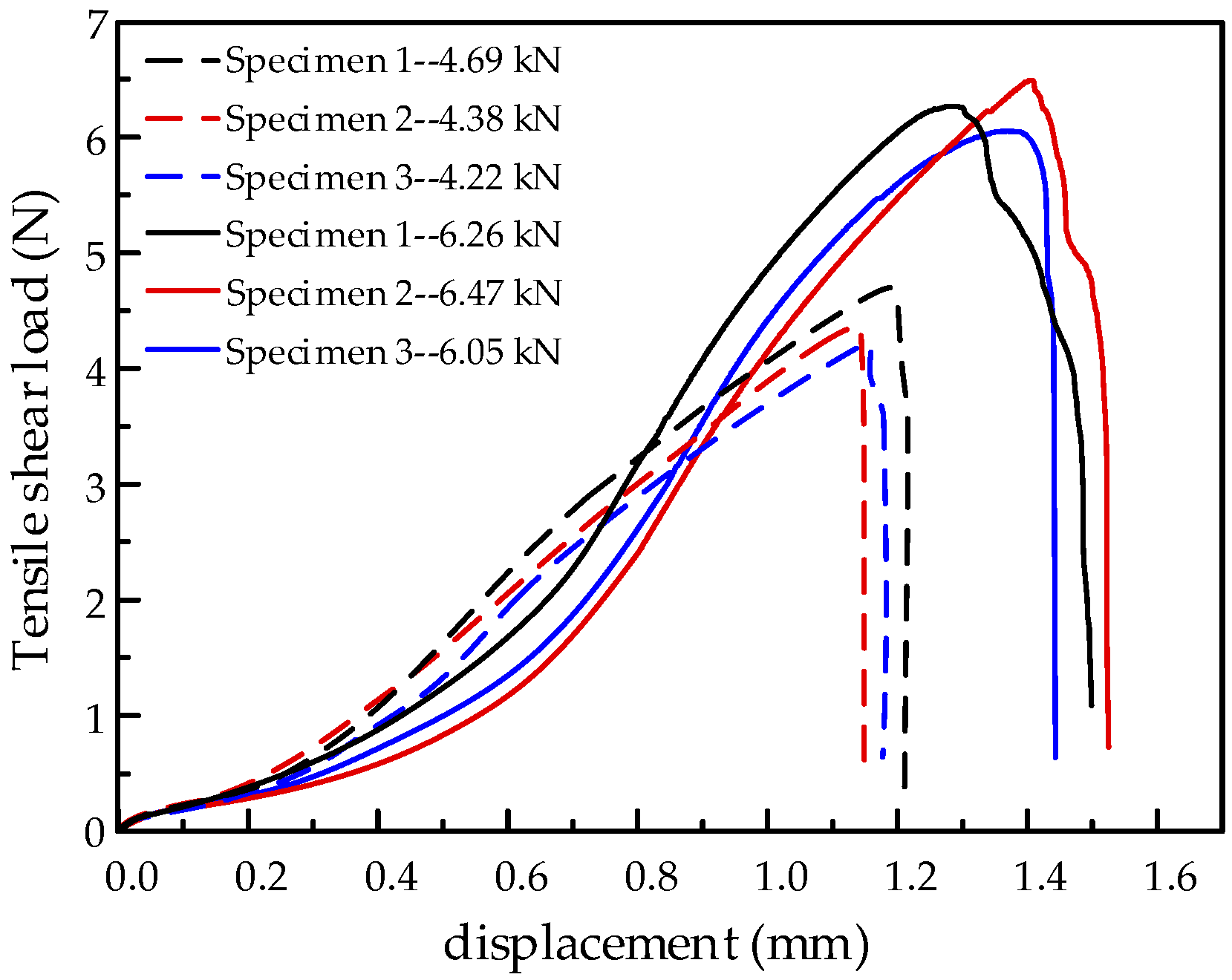

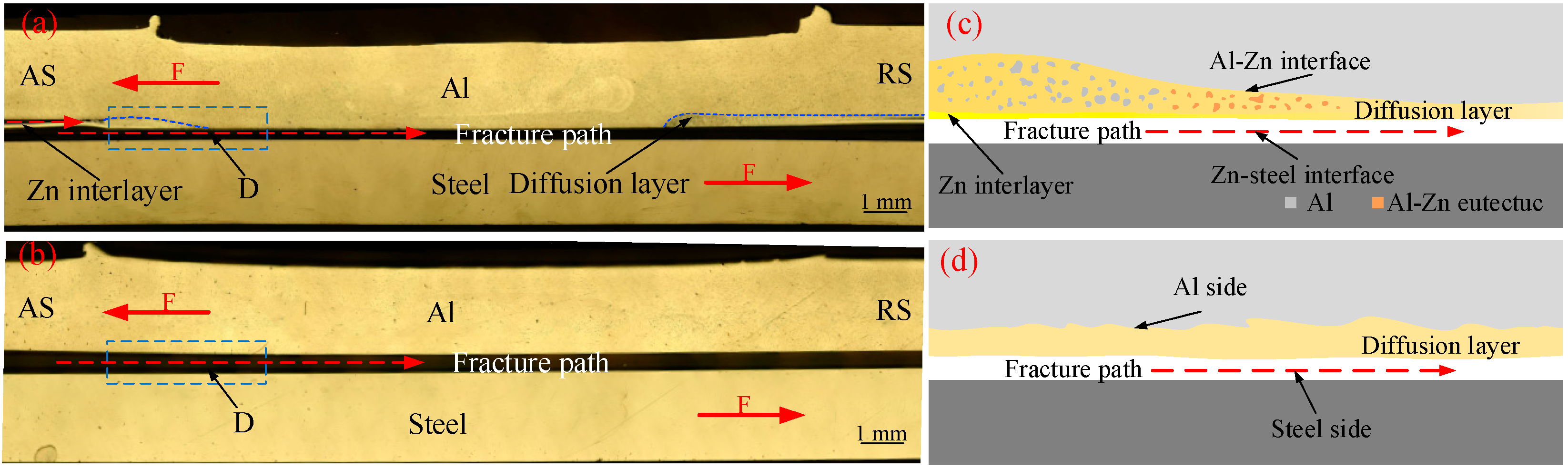

3.2. Mechanical Properties

4. Conclusions

- (1)

- The diffusion layer between the aluminum and steel sheets was changed from the continuous distribution to the uneven and segmented distribution. Compared to the single Fe-Al IMCs in the diffusion layer of the Zn-not-added joint, the Fe-Zn IMCs and Al-Zn eutectic are formed in the Zn-added joint. When a 0.1 mm thick Zn interlayer was adopted, the uneven and segmented diffusion layer owned the significantly changed thickness and compositions.

- (2)

- The tensile shear load of the Zn-added joint was 6.26 kN, presenting an obvious increase of 41.3% compared with the Zn-not-added joint. These two joints presented the shear fracture along the lap interface, and the diffusion layers both peel off from the steel side. The heightened tensile shear strength by adding Zn interlayer mainly resulted from the rationally reduced and modified diffusion layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Granum, H.; Myhr, O.R.; Brvik, T.; Odd, S.H. Effect of pre-stretching on the mechanical behaviour of three artificially aged 6xxx series aluminium alloys. Mater. Today Commun 2021, 27, 102408. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, Q.; Wang, S.; Han, X.; David, S.A. Effect of adhesive sealant on resistance spot welding of 301L stainless steel. J. Manuf. Process. 2020, 51, 62–72. [Google Scholar] [CrossRef]

- Kaushik, P.; Dwivedi, D.K. Effect of tool geometry in dissimilar Al-Steel Friction Stir Welding. J. Manuf. Process. 2020, 68, 198–208. [Google Scholar] [CrossRef]

- Liu, J.L.; Hao, Z.L.; Xie, Y.M.; Meng, X.C.; Huang, Y.X.; Wan, L. Interface stability and fracture mechanism of Al/Steel friction stir lap joints by novel designed tool. J. Mater. Process. Technol. 2022, 300, 117425. [Google Scholar] [CrossRef]

- Alhazaa, A.; Haneklaus, N. Diffusion bonding and transient liquid phase (TLP) bonding of type 304 and 316 austenitic stainless steel—a review of similar and dissimilar material joints. Metals 2020, 10, 613. [Google Scholar] [CrossRef]

- Hasanniah, A.; Movahedi, M. Gas tungsten arc lap welding of aluminum/steel hybrid structures. Mar. Struct. 2019, 64, 295–304. [Google Scholar] [CrossRef]

- Js, A.; Ksa, B.; Dks, A. Lap weld-brazing of aluminum to steel using novel cold metal transfer process. J. Mater. Process. Technol. 2020, 283, 116728. [Google Scholar]

- Florence, P.L.; Narayanaswamy, K.S.; Sai, P.; Devaraj, S. Impact of friction stir welding tool profile on the strength of dissimilar aluminum and stainless steel welded joints. Mater. Today Proc. 2021, 46, 583–585. [Google Scholar] [CrossRef]

- Yasui, T.; Tian, W.B.; Hanai, A.; Mori, T.; Fukumoto, M. Friction stir girth welding between aluminum and steel rods. Procedia Manuf. 2018, 15, 1376–1381. [Google Scholar] [CrossRef]

- Yasui, T.; Tian, W.B.; Hanai, A.; Mori, T.; Fukumoto, M. Mechanism of intermetallic compound formation during the dissimilar friction stir welding of aluminum and steel. J. Mater. Sci. 2020, 55, 3064–3072. [Google Scholar]

- Wan, L.; Huang, Y.X. Microstructure and mechanical properties of Al/steel friction stir lap weld. Metals 2017, 7, 542. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.X.; Meng, X.C.; Xie, Y.M.; Wan, L.; Lv, Z.L. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Huang, Y.X.; Wan, L.; Meng, X.C.; Xie, Y.M.; Lv, Z.L.; Zhou, L. Probe shape design for eliminating the defects of friction stir lap welded dissimilar materials. J. Manuf. Process. 2018, 35, 420–427. [Google Scholar] [CrossRef]

- Pourali, M.; Abdollah-Zadeh, A.; Saeid, T.; Kargar, F. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J. Alloys Compd. 2017, 715, 1–8. [Google Scholar] [CrossRef]

- Kar, A.; Vicharapu, B.; Morisada, Y.; Fujii, H. Elucidation of interfacial microstructure and properties in friction stir lap welding of aluminium alloy and mild steel. Mater. Charact. 2020, 168, 110572. [Google Scholar] [CrossRef]

- Mahto, R.P.; Kumar, R.; Pal, S.K.; Panda, S.K. A comprehensive study on force, temperature, mechanical properties, and micro-structural characterizations in friction stir lap welding of dissimilar materials (AA6061-T6 & AISI304). J. Manuf. Process. 2018, 31, 624–639. [Google Scholar]

- Sr, A.; Rkrs, B.; Klak, A. Artificial intelligent approach for process parameters modeling of friction stir processing. Mater. Today Proc. 2021, 43, 326–334. [Google Scholar]

- Taher, A.S.; Mohamed, A.; Ammar, H.E.; Zhou, J.X. Modeling of friction stir welding process using adaptive neuro-fuzzy inference system integrated with harris hawks optimizer. J. Mater. Res. Technol. 2019, 8, 5882–5892. [Google Scholar]

- Waheed, S.; Mohamed, A.E.; Emad, I.G.; Essam, B.M.; Ammar, H.E. A new fine-tuned random vector functional link model using hunger games search optimizer for modeling friction stir welding process of polymeric materials. J. Mater. Res. Technol. 2021, 14, 1482–1493. [Google Scholar]

- Kumar, M.; Das, A.; Ballav, R. Influence of interlayer on microstructure and mechanical properties of friction stir welded dissimilar joints: A review. Mater. Today Proc. 2020, 26, 2123–2129. [Google Scholar] [CrossRef]

- Zheng, Q.; Feng, X.; Shen, Y.; Huang, G.; Zhao, P. Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal. J. Alloys Compd. 2016, 686, 693–701. [Google Scholar] [CrossRef]

- Ahmed, E.; Makoto, T.; Kenji, I. Friction-stir-welded lap joint of aluminum to zinc-coated steel. Q. J. Jpn Weld. Soc. 2005, 23, 186–193. [Google Scholar]

- Akca, E.; Gursel, A. The importance of interlayers in diffusion welding—A review. Period. Eng. Nat. Sci. 2015, 3, 12–16. [Google Scholar] [CrossRef]

- Li, W.Y.; Liu, J.F.; Zhang, Z.H.; Gao, D.L.; Wang, W.B. Improving mechanical properties of pinless friction stir spot welded joints by eliminating hook defect. Mater. Des. 2014, 62, 247–254. [Google Scholar] [CrossRef]

- Huang, Y.X.; Wan, L.; Si, X.Q.; Huang, T.F.; Meng, X.C.; Xie, Y.M. Achieving high-quality Al/Steel joint with ultrastrong interface. Metall. Mater. Trans. A 2019, 50, 295–299. [Google Scholar] [CrossRef]

- Haghshenas, M.; Abdel-Gwad, A.; Omran, A.M.; Goekce, B.; Sahraeinejad, S.; Gerlich, A.P. Friction stir weld assisted diffusion bonding of 5754 aluminum alloy to coated high strength steels. Mater. Des. 2014, 55, 442–449. [Google Scholar] [CrossRef]

- Mahto, R.P.; Bhoje, R.; Pal, S.K.; Joshi, H.S.; Das, S. A study on mechanical properties in friction stir lap welding of AA 6061-T6 and AISI 304. Mater. Sci. Eng. A 2016, 652, 136–144. [Google Scholar] [CrossRef]

- Ratanathavorn, W.; Melander, A. Influence of zinc on intermetallic compounds formed in friction stir welding of AA5754 aluminum alloy to galvanised ultra-high strength steel. Sci. Technol. Weld. Join. 2017, 22, 673–680. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Reihani, S.M.S.; Cheng, W.J.; Wang, C.J. Effect of annealing treatment on joint strength of aluminum/steel friction stir lap weld. Mater Des. 2013, 44, 487–492. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Reihani, S.M.S.; Najafi, H. Effect of tool travel and rotation speeds on weld zone defects and joint strength of aluminum steel lap joints made by friction stir welding. Sci. Technol. Join. 2012, 17, 162–167. [Google Scholar] [CrossRef]

- Suresh, S.; Venkatesan, K.; Natarajan, E.; Rajesh, S.; Lim, W.H. Evaluating weld properties of conventional and swept friction stir spot welded 6061-T6 aluminium alloy. Mater. Express 2019, 9, 851–860. [Google Scholar] [CrossRef]

- Shen, Z.; Yang, C.; Haghshenas, M.; Gerlich, A.P. Role of welding parameters on interfacial bonding in dissimilar steel/aluminum friction stir welds. Eng. Sci. Technol. Int. J. 2015, 18, 270–277. [Google Scholar] [CrossRef] [Green Version]

- Zuo, Y.Y.; Liu, H.; Gong, P.; Ji, S.D.; Wu, B.S. Radial additive friction stir repairing of mechanical hole out of dimension tolerance of AZ31 magnesium alloy assisted by stationary shoulder: Process and mechanical properties. Acta Metall. Sin. Engl. Lett. 2021, 34, 1345–1360. [Google Scholar] [CrossRef]

- Boumerzoug, Z.; Helal, Y. Friction stir welding of dissimilar materials aluminum Al6061-T6 to ultralow carbon steel. Metals 2017, 7, 42. [Google Scholar] [CrossRef] [Green Version]

- Zuo, Y.Y.; Kong, L.P.; Liu, Z.L.; Lv, Z.; Wen, H.J. Process parameters optimization of refill friction stir spot welded Al/Cu joint by response surface method. Trans. Indian Inst. Met. 2020, 73, 2975–2984. [Google Scholar] [CrossRef]

- Chitturi, V.; Pedapati, S.R.; Awang, M. Effect of tilt angle and pin depth on dissimilar friction stir lap welded joints of aluminum and steel alloys. Materials 2019, 12, 3901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Chemical Composition(wt. %) | Mechanical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Si | Mg | Cr | Zn | Cu | Mn | Ti | Al | Tensile Strength | Hardness | Elongation |

| 0.08 | 2.62 | 0.19 | 5.81 | 1.59 | 0.01 | 0.02 | Bal. | 355.9 MPa | 99.4 Hv | 7% |

| Chemical Composition(wt. %) | Mechanical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | N | Si | Mn | Ni | Cr | Fe | Tensile Strength | Hardness | Elongation |

| 0.03 | 0.2 | 1.00 | 2.00 | 6.00 | 16.00 | Bal. | 864.4 Mpa | 243.2 Hv | 72% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.-H.; Liu, H.; Ji, S.-D.; Yan, D.-J.; Zhao, H.-X. Diffusion Bonding of Al-Mg-Si Alloy and 301L Stainless Steel by Friction Stir Lap Welding Using a Zn Interlayer. Materials 2022, 15, 696. https://doi.org/10.3390/ma15030696

Dong J-H, Liu H, Ji S-D, Yan D-J, Zhao H-X. Diffusion Bonding of Al-Mg-Si Alloy and 301L Stainless Steel by Friction Stir Lap Welding Using a Zn Interlayer. Materials. 2022; 15(3):696. https://doi.org/10.3390/ma15030696

Chicago/Turabian StyleDong, Ji-Hong, Hua Liu, Shu-De Ji, De-Jun Yan, and Hua-Xia Zhao. 2022. "Diffusion Bonding of Al-Mg-Si Alloy and 301L Stainless Steel by Friction Stir Lap Welding Using a Zn Interlayer" Materials 15, no. 3: 696. https://doi.org/10.3390/ma15030696

APA StyleDong, J.-H., Liu, H., Ji, S.-D., Yan, D.-J., & Zhao, H.-X. (2022). Diffusion Bonding of Al-Mg-Si Alloy and 301L Stainless Steel by Friction Stir Lap Welding Using a Zn Interlayer. Materials, 15(3), 696. https://doi.org/10.3390/ma15030696