Tribocorrosion Behavior of NiTi Biomedical Alloy Processed by an Additive Manufacturing Laser Beam Directed Energy Deposition Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Tribocorrosion Measurements

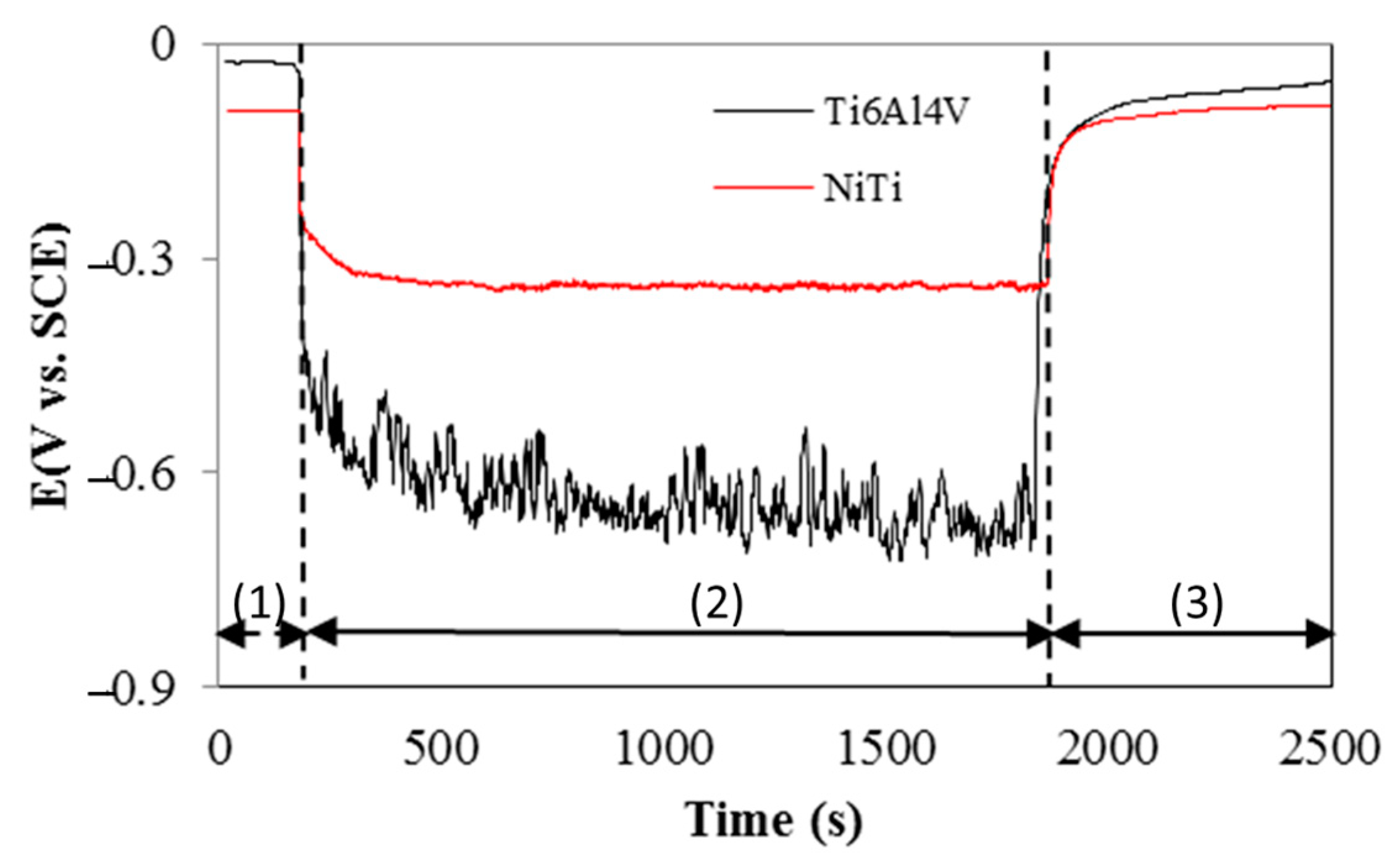

- (1)

- OCP measurement before sliding (passivation step). Before each reciprocating sliding wear test, the OCP was measured in situ for a minimum of 60 min.

- (2)

- OCP measurement during the reciprocating sliding wear test (removal of the passive layer step). The reciprocating wear sliding tests were performed at 1 N normal load, 1 Hz, and at the 3 mm total stroke length for 30 min. Both the OCP and coefficient of friction (COF) were measured during the sliding.

- (3)

- OCP measurement after sliding (repassivation step). At finishing the sliding tests, the OCP was measured for another 60 min.

2.3. Surface Characteristics

3. Results and Discussion

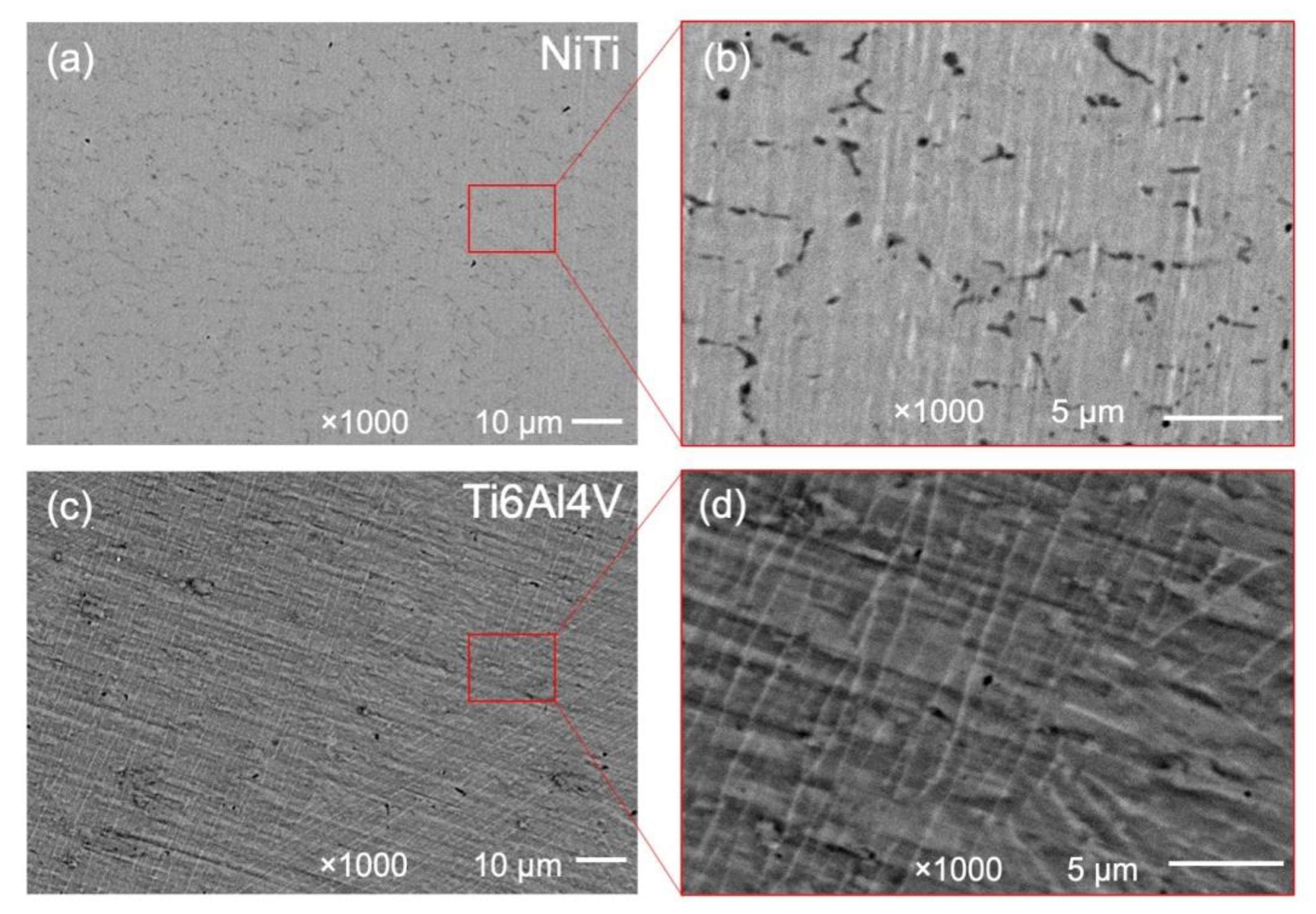

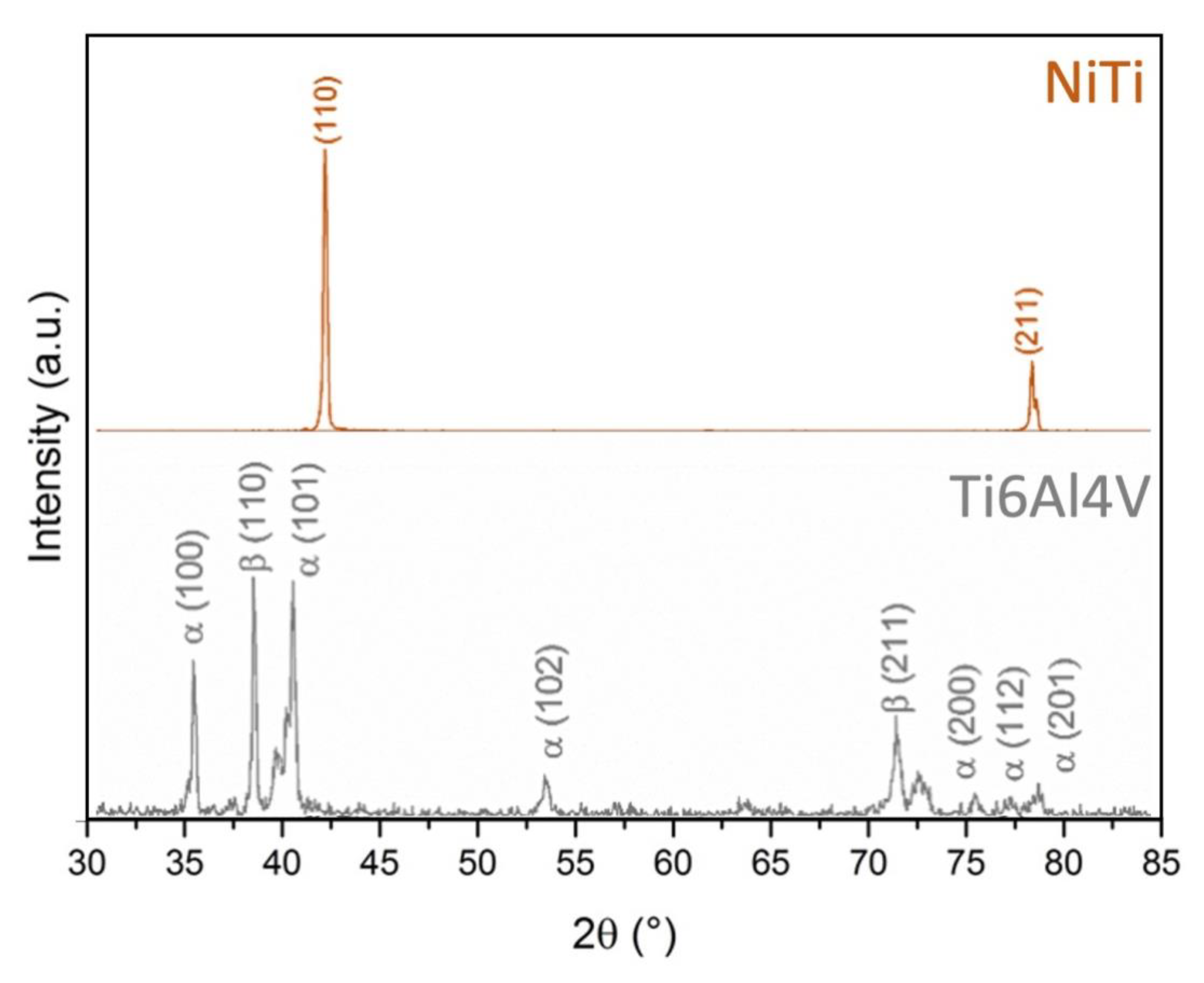

3.1. Microstructural Characterization and Phase Analysis

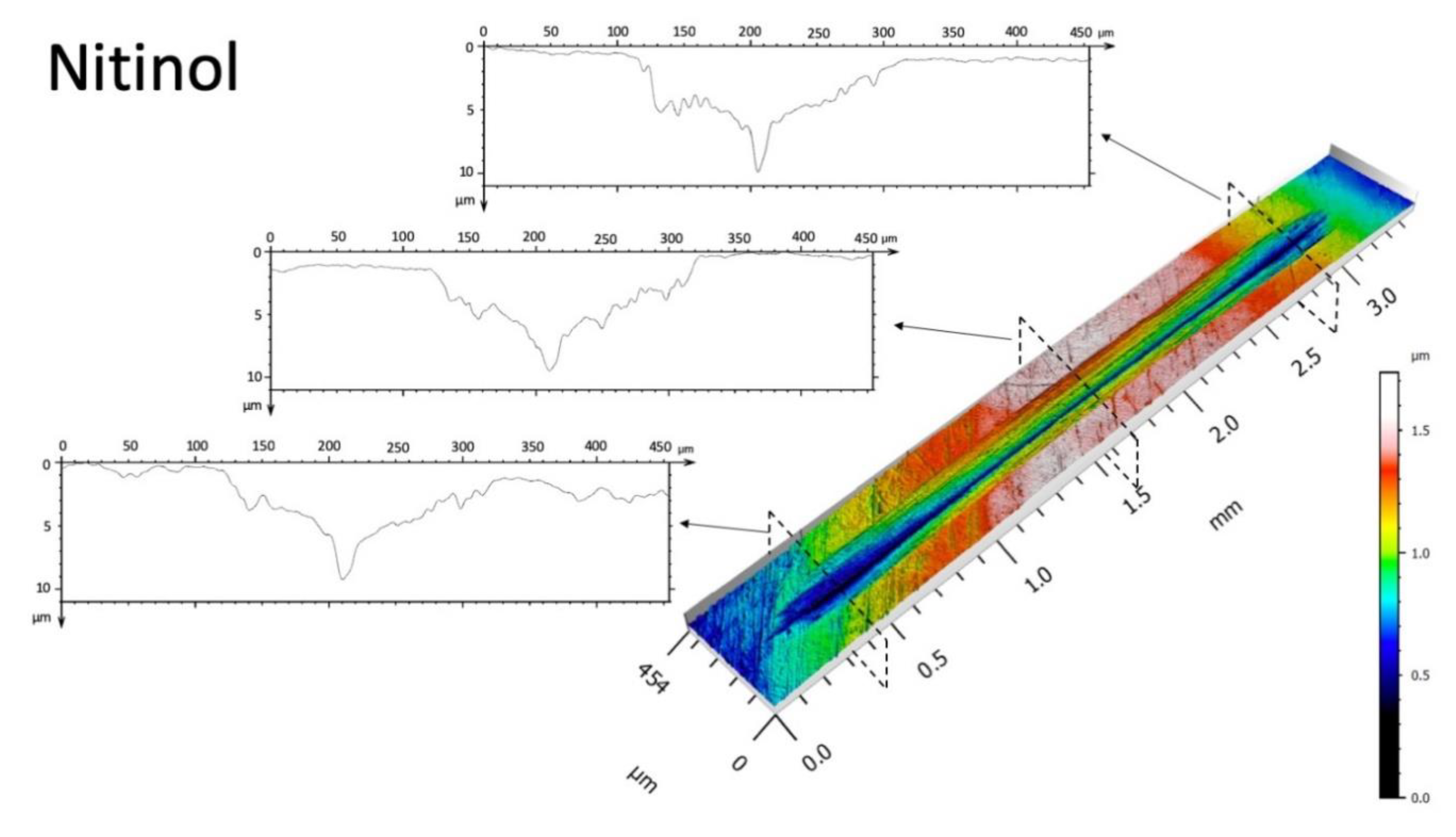

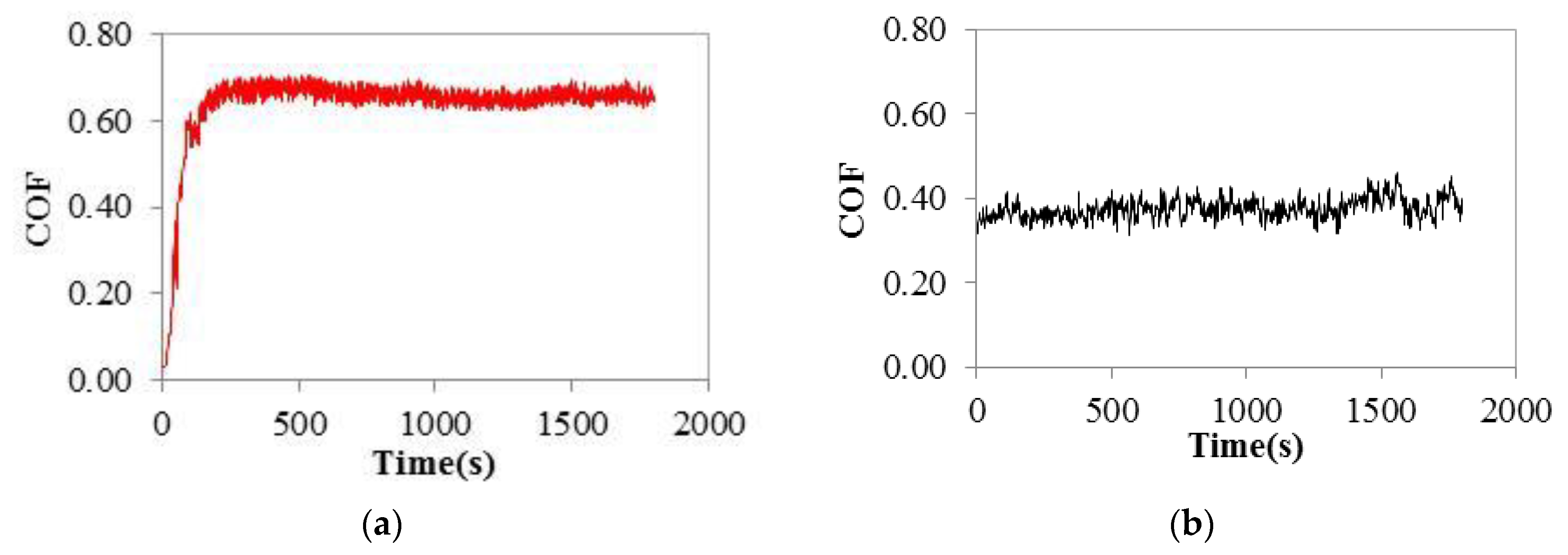

3.2. Wear Volume Loss and Coefficient of Friction (COF) Measurements

3.3. Open Circuit Potential (OCP) Measurements

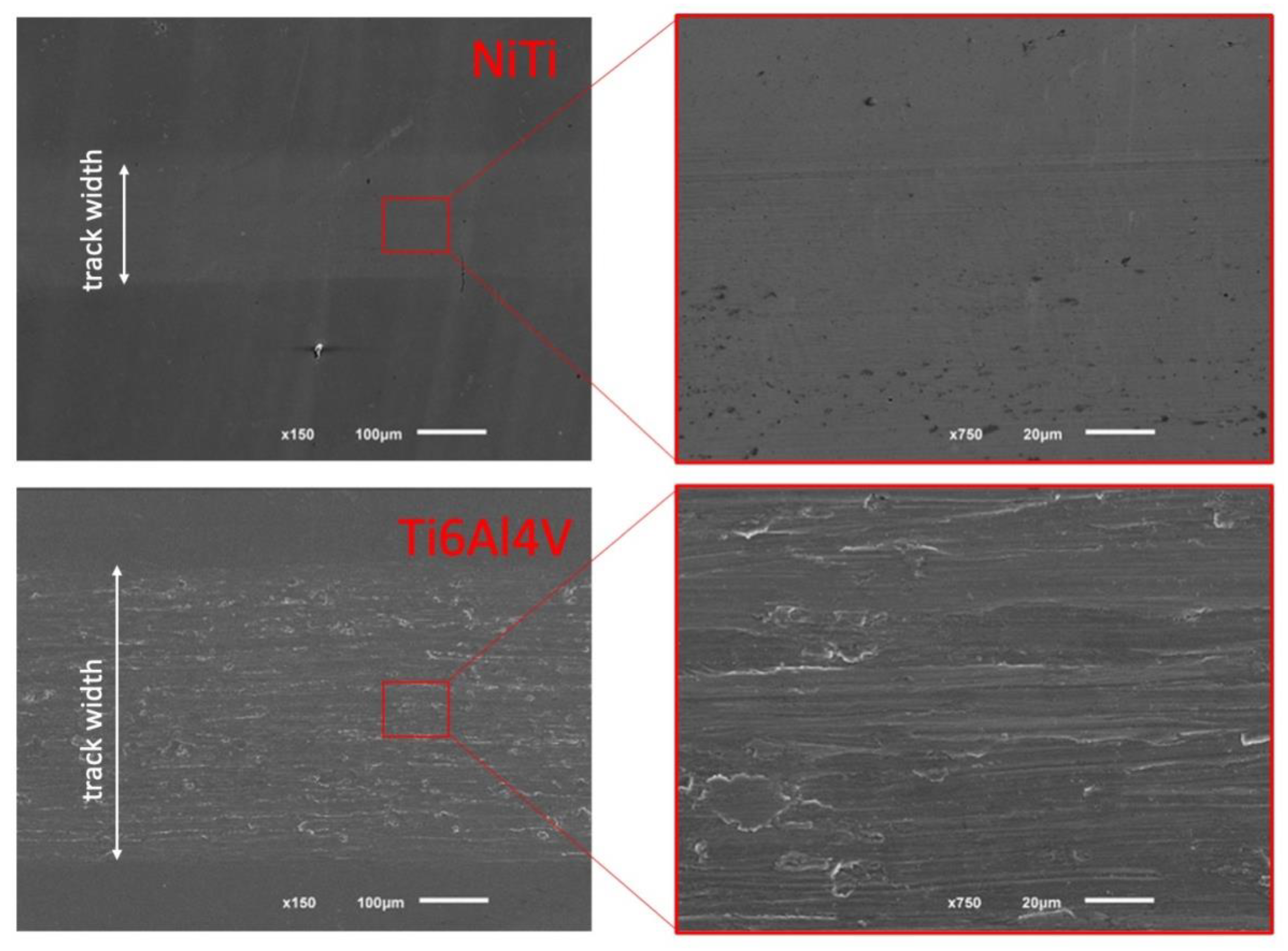

3.4. Surface Morphologies

4. Conclusions

- -

- for the processing parameters used in this study, the LB-DED NiTi alloy exhibited better wear and corrosion performance as compared to the LB-DED Ti-6Al-4V alloy;

- -

- a significant reduction in the wear volume loss of the LB-DED NiTi alloy was obtained as compared with the LB-DED Ti-6Al-4V alloy; however, the COF values in the case of the NiTi alloy processed by LENS were found to still be higher than the Ti-6Al-4V alloy;

- -

- when no mechanical load is applied, the LB-DED Ti-6Al-4V alloy showed a slightly better corrosion behavior as compared to the LB-DED NiTi alloy;

- -

- the drop observed on the OCP value at the beginning of the reciprocating sliding test (when the mechanical load was applied) was smaller for the LB-DED NiTi alloy as compared to the LB-DED Ti-6Al-4V alloy, which means that the NiTi alloy processed by LENS has a lower tendency to corrosion;

- -

- both alloys have the repassivation ability after the sliding is ceased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mocnik, P.; Kosec, T. Tribo-corrosion properties of a NiTi dental wire. Mater. Technol. 2014, 48, 467–472. [Google Scholar]

- Chaubey, A.K.; Mishra, S.K.; Chowdhary, R. Positive Material Identification testing of dental implant to correlate their compositions with allergic conditions. J. Oral Biol. Craniofacial Res. 2019, 9, 294–298. [Google Scholar] [CrossRef]

- Chaturvedi, T.P. An overview of the corrosion aspect of dental implants (titanium and its alloys). Indian J. Dent. Res. 2009, 20, 91–98. [Google Scholar] [CrossRef]

- Buciumeanu, M.; Bagheri, A.; Shamsaei, N.; Thompson, S.M.; Silva, F.S.; Henriques, B. Tribocorrosion behavior of additive manufactured Ti-6Al-4V biomedical alloy. Tribol. Int. 2018, 119, 381–388. [Google Scholar] [CrossRef]

- Vijayaraghavan, V.; Sabane, A.V.; Tejas, K. Hypersensitivity to titanium: A less explored area of research. J. Indian Prosthodont. Soc. 2012, 12, 201–207. [Google Scholar] [CrossRef]

- Hosoki, M.; Nishigawa, K.; Miyamoto, Y.; Ohe, G.; Matsuka, Y. Allergic contact dermatitis caused by titanium screws and dental implants. J. Prosthodont. Res. 2016, 60, 213–219. [Google Scholar] [CrossRef] [Green Version]

- Buciumeanu, M.; Araujo, A.; Carvalho, O.; Miranda, G.; Souza, J.C.M.; Silva, F.S.; Henriques, B. Study of the tribocorrosion behaviour of Ti6Al4V–HA biocomposites. Tribol. Int. 2017, 107, 77–84. [Google Scholar] [CrossRef]

- Manhabosco, T.M.; Tamborim, S.M.; dos Santos, C.B.; Müller, I.L. Tribological, electrochemical and tribo-electrochemical characterization of bare and nitrided Ti6Al4V in simulated body fluid solution. Corros. Sci. 2011, 53, 1786–1793. [Google Scholar] [CrossRef] [Green Version]

- Blanco-Dalmau, L.; Carrasquillo-Alberty, H.; Silva-Parra, J. A study of nickel allergy. J. Prosthet. Dent. 1984, 52, 116–119. [Google Scholar] [CrossRef]

- Es-Souni, M.; Es-Souni, M.; Fischer-Brandies, H. Assessing the biocompatibility of NiTi shape memory alloys used for medical applications. Anal. Bioanal. Chem. 2005, 381, 557–567. [Google Scholar] [CrossRef] [PubMed]

- Akhras, G. Smart Materials and Smart Systems for the Future. Can. Mil. J. 2000, 1, 25–32. [Google Scholar]

- Mahtabi, M.J.; Shamsaei, N.; Mitchell, M.R. Fatigue of Nitinol: The state-of-the-art and ongoing challenges. J. Mech. Behav. Biomed. Mater. 2015, 50, 228–254. [Google Scholar] [CrossRef]

- Bansiddhi, A.; Sargeant, T.D.; Stupp, S.I.; Dunand, D.C. Porous NiTi for bone implants: A review. Acta Biomater. 2008, 4, 773–782. [Google Scholar] [CrossRef] [Green Version]

- Hang, R.; Ma, S.; Ji, V.; Chu, P.K. Corrosion behavior of NiTi alloy in fetal bovine serum. Electrochim. Acta 2010, 55, 5551–5560. [Google Scholar] [CrossRef]

- Mocnik, P.; Kosec, T.; Kovac, J.; Bizjak, M. The effect of pH, fluoride and tribocorrosion on the surface properties of dental archwires. Mater. Sci. Eng. C 2017, 78, 682–689. [Google Scholar] [CrossRef]

- Andani, M.T.; Anderson, W.; Elahinia, M. Design, modeling and experimental evaluation of a minimally invasive cage for spinal fusion surgery utilizing superelastic Nitinol hinges. J. Intell. Mater. Syst. Struct. 2015, 26, 631–638. [Google Scholar] [CrossRef]

- Cases, C. Implant biomaterials: A comprehensive review. World J. Clin. Cases 2015, 3, 52–57. [Google Scholar] [CrossRef]

- Wittenberg, R.H.; Steffen, R.; Windhagen, H.; Bücking, P.; Wilcke, A.; Elisabeth-krankenhaus, S.; Klinik, O. Five-year results of a cementless short-hip-stem prosthesis. Orthop. Rev. 2013, 5, e4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Waghmare, D.T.; Padhee, C.K.; Prasad, R.; Masanta, M. NiTi coating on Ti-6Al-4V alloy by TIG cladding process for improvement of wear resistance: Microstructure evolution and mechanical performances. J. Mater. Process. Technol. 2018, 262, 551–561. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Ma, C.; Taheri, M.; Qin, H.; Shayesteh, N.; Ibrahim, H.; Jahadakbar, A.; Amerinatanzi, A.; Ren, Z. Improving surface fi nish and wear resistance of additive manufactured nickel-titanium by ultrasonic nano-crystal surface modi fi cation. J. Mater. Process. Technol. 2017, 249, 433–440. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Elahinia, M. Laser welding of NiTi shape memory alloy: A review. J. Manuf. Process. 2018, 31, 162–186. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-khanlou, A.; Heckmann, A.; Fuchs, B.; Buchkremer, H.P. Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater. Sci. Eng. A 2002, 337, 254–263. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Silva, F.S.; Carvalho, O.; Miranda, G. Wear behavior of Ti6Al4V biomedical alloys processed by selective laser melting, hot pressing and conventional casting. Trans. Nonferrous Met. Soc. China 2017, 27, 829–838. [Google Scholar] [CrossRef]

- Mentz, J.; Frenzel, J.; Wagner, M.F.; Neuking, K.; Eggeler, G.; Peter, H.; St, D. Powder metallurgical processing of NiTi shape memory alloys with elevated transformation temperatures. Mater. Sci. Eng. A 2008, 491, 270–278. [Google Scholar] [CrossRef]

- Bagheri, A.; Mahtabi, M.J.; Shamsaei, N. Fatigue behavior and cyclic deformation of additive manufactured NiTi. J. Mater. Process. Technol. 2018, 252, 440–453. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Zhou, Q.; Dilawer, M.; Chen, G.; Cai, S.; Qu, X. Selective electron beam melting of NiTi: Microstructure, phase transformation and mechanical properties. Mater. Sci. Eng. A 2019, 744, 290–298. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Singh, A.K.; Datta, S.; Das, M.; Balla, V.K.; Bontha, S.; Kalpathy, S.K. Microstructure and corrosion behavior of laser processed NiTi alloy. Mater. Sci. Eng. C 2015, 57, 309–313. [Google Scholar] [CrossRef]

- Abedini, M.; Ghasemi, H.M.; Ahmadabadi, M.N. Tribological behavior of NiTi alloy in martensitic and austenitic states. Mater. Des. 2009, 30, 4493–4497. [Google Scholar] [CrossRef]

- Abedini, M.; Ghasemi, H.M.; Ahmadabadi, M.N. Tribological behavior of NiTi alloy against 52100 steel and WC at elevated temperatures. Mater. Charact. 2010, 61, 689–695. [Google Scholar] [CrossRef]

- Li, D.Y.; Liu, R. The mechanism responsible for high wear resistance of Pseudo-elastic TiNi alloy—A novel tribo-material. Wear 1999, 225–229, 777–783. [Google Scholar] [CrossRef]

- Figueira, N.; Silva, T.M.; Carmezim, M.J.; Fernandes, J.C.S. Corrosion behaviour of NiTi alloy. Electrochim. Acta 2009, 54, 921–926. [Google Scholar] [CrossRef]

- Sun, X.T.; Kang, Z.X.; Zhang, X.L.; Jiang, H.J.; Guan, R.F.; Zhang, X.P. A comparative study on the corrosion behavior of porous and dense NiTi shape memory alloys in NaCl solution. Electrochim. Acta 2011, 56, 6389–6396. [Google Scholar] [CrossRef]

- Zhang, C.; Farhat, Z.N. Sliding wear of superelastic TiNi alloy. Wear 2009, 267, 394–400. [Google Scholar] [CrossRef]

- Ye, H.Z.; Liu, R.; Li, D.Y.; Eadie, R.L. Wear and friction of a new wear-resistant material: TiNi-based composites. Compos. Sci. Technol. 2001, 61, 987–994. [Google Scholar] [CrossRef]

- Neupane, R.; Farhat, Z. Wear mechanisms of nitinol under reciprocating sliding contact. Wear 2014, 315, 25–30. [Google Scholar] [CrossRef]

- Kosec, T.; Mocnik, P.; Andraz, L. The tribocorrosion behaviour of NiTi alloy. Appl. Surf. Sci. 2014, 288, 727–735. [Google Scholar] [CrossRef]

- Tan, L.; Dodd, R.A.; Crone, W.C. Corrosion and wear-corrosion behavior of NiTi modified by plasma source ion implantation. Biomaterials 2003, 24, 3931–3939. [Google Scholar] [CrossRef]

- Bagheri, A.; Thompson, S.M.; Shamsaei, N. Microstructure and mechanical properties of Ti-6Al-4V parts fabricated by laser engineered net shaping. In ASME International Mechanical Engineering Congress and Exposition; The American Society of Mechanical Engineers: New York, NY, USA, 2015. [Google Scholar]

- Mahtabi, M.J.; Shamsaei, N.; Rutherford, B. Mean Strain Effects on the Fatigue Behavior of Superelastic Nitinol Alloys: An Experimental Investigation. Procedia Eng. 2015, 133, 646–654. [Google Scholar] [CrossRef] [Green Version]

- Mahtabi, M.J.; Shamsaei, N. A modified energy-based approach for fatigue life prediction of superelastic NiTi in presence of tensile mean strain and stress. Int. J. Mech. Sci. 2016, 117, 321–333. [Google Scholar] [CrossRef] [Green Version]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Lowe, T.C. Advances in metals and alloys for joint replacement. Prog. Mater. Sci. 2017, 88, 232–280. [Google Scholar] [CrossRef]

- Celis, J.; Ponthiaux, P.; Wenger, F. Tribo-corrosion of materials: Interplay between chemical, electrochemical, and mechanical reactivity of surfaces. Wear 2006, 261, 939–946. [Google Scholar] [CrossRef]

- Buciumeanu, M.; Bagheri, A.; Souza, J.C.M.; Silva, F.S.; Henriques, B. Tribocorrosion behavior of hot pressed CoCrMo alloys in artificial saliva. Tribol. Int. 2016, 97, 423–430. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Balla, V.K.; Das, M.; Bontha, S.; Kalpathy, S.K. Effect of heat treatment on microstructure, corrosion, and shape memory characteristics of laser deposited NiTi alloy. J. Alloys Compd. 2018, 744, 337–346. [Google Scholar] [CrossRef]

- Levintant-Zayonts, N.; Starzynski, G.; Kopec, M.; Kucharski, S. Characterization of NiTi SMA in its unusual behaviour in wear tests. Tribol. Int. 2019, 137, 313–323. [Google Scholar] [CrossRef]

- Yan, Y. Bio-Tribocorrosion in Biomaterials and Medical Implants; Woodhead Publishing Series in Biomaterials; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780857095404. [Google Scholar]

- Dalmau, A.; Buch, A.R.; Rovira, A.; Navarro-Laboulais, J.; Muñoz, A.I. Wear model for describing the time dependence of the material degradation mechanisms of the AISI 316L in a NaCl solution. Wear 2018, 394–395, 166–175. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.J.; Gao, Y.; Gui, Y.; Zhu, M. Corrosion behaviour of nanocrystalline 304 stainless steel prepared by equal channel angular pressing. Corros. Sci. 2012, 54, 60–67. [Google Scholar] [CrossRef]

- López-Ortega, A.; Arana, J.L.; Bayón, R. Tribocorrosion of Passive Materials: A Review on Test Procedures and Standards. Int. J. Corros. 2018, 2018, 7345346. [Google Scholar] [CrossRef]

- Ponthiaux, P.; Wenger, F.; Drees, D.; Celis, J.P. Electrochemical techniques for studying tribocorrosion processes. Wear 2004, 256, 459–468. [Google Scholar] [CrossRef]

- Rondelli, G.; Vicentini, B. Evaluation by electrochemical tests of the passive film stability of equiatomic Ni-Ti alloy also in presence of stress-induced martensite. J. Biomed. Mater. Res. 2000, 51, 47–54. [Google Scholar] [CrossRef]

- Yoshida, A.; Yokoyama, K.; Inaba, T.; Mutoh, K.; Sakai, J. Fracture and corrosion behaviors of Ni-Ti superelastic alloy under sustained tensile loading in neutral fluoride solution containing hydrogen peroxide. J. Alloys Compd. 2012, 544, 24–29. [Google Scholar] [CrossRef]

| Element | O | Al | C | Fe | H | N | Cr | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Weight percent (%) | 0.10 | 0.009 | 0.017 | 0.009 | 0.002 | 0.008 | 0.19 | 55.0 | 43.0 |

| Material | Powder Feed Rate (g/s) | Traverse/Scan Speed (cm/s) | Laser Output Power (W) | Layer Thickness (mm) | Hatch Spacing (mm) |

|---|---|---|---|---|---|

| NiTi | 0.06 | 8.47 | 280 | 0.02 | 0.02 |

| Ti-6Al-4V | 0.156 | 0.85, 1.27 or 1.69 | 350 | 0.02 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buciumeanu, M.; Bagheri, A.; Silva, F.S.; Henriques, B.; Lasagni, A.F.; Shamsaei, N. Tribocorrosion Behavior of NiTi Biomedical Alloy Processed by an Additive Manufacturing Laser Beam Directed Energy Deposition Technique. Materials 2022, 15, 691. https://doi.org/10.3390/ma15020691

Buciumeanu M, Bagheri A, Silva FS, Henriques B, Lasagni AF, Shamsaei N. Tribocorrosion Behavior of NiTi Biomedical Alloy Processed by an Additive Manufacturing Laser Beam Directed Energy Deposition Technique. Materials. 2022; 15(2):691. https://doi.org/10.3390/ma15020691

Chicago/Turabian StyleBuciumeanu, Mihaela, Allen Bagheri, Filipe Samuel Silva, Bruno Henriques, Andrés F. Lasagni, and Nima Shamsaei. 2022. "Tribocorrosion Behavior of NiTi Biomedical Alloy Processed by an Additive Manufacturing Laser Beam Directed Energy Deposition Technique" Materials 15, no. 2: 691. https://doi.org/10.3390/ma15020691

APA StyleBuciumeanu, M., Bagheri, A., Silva, F. S., Henriques, B., Lasagni, A. F., & Shamsaei, N. (2022). Tribocorrosion Behavior of NiTi Biomedical Alloy Processed by an Additive Manufacturing Laser Beam Directed Energy Deposition Technique. Materials, 15(2), 691. https://doi.org/10.3390/ma15020691