Mechanical Strength and Thermal Properties of Cement Concrete Containing Waste Materials as Substitutes for Fine Aggregate

Abstract

1. Introduction

- The aggregate from recycling the concrete paving;

- The aggregate from crushing the wastes created by ceramic brick production;

- The aggregate from burning the sewage sludges in the municipal water treatment plant.

2. Materials and Methods

2.1. Materials

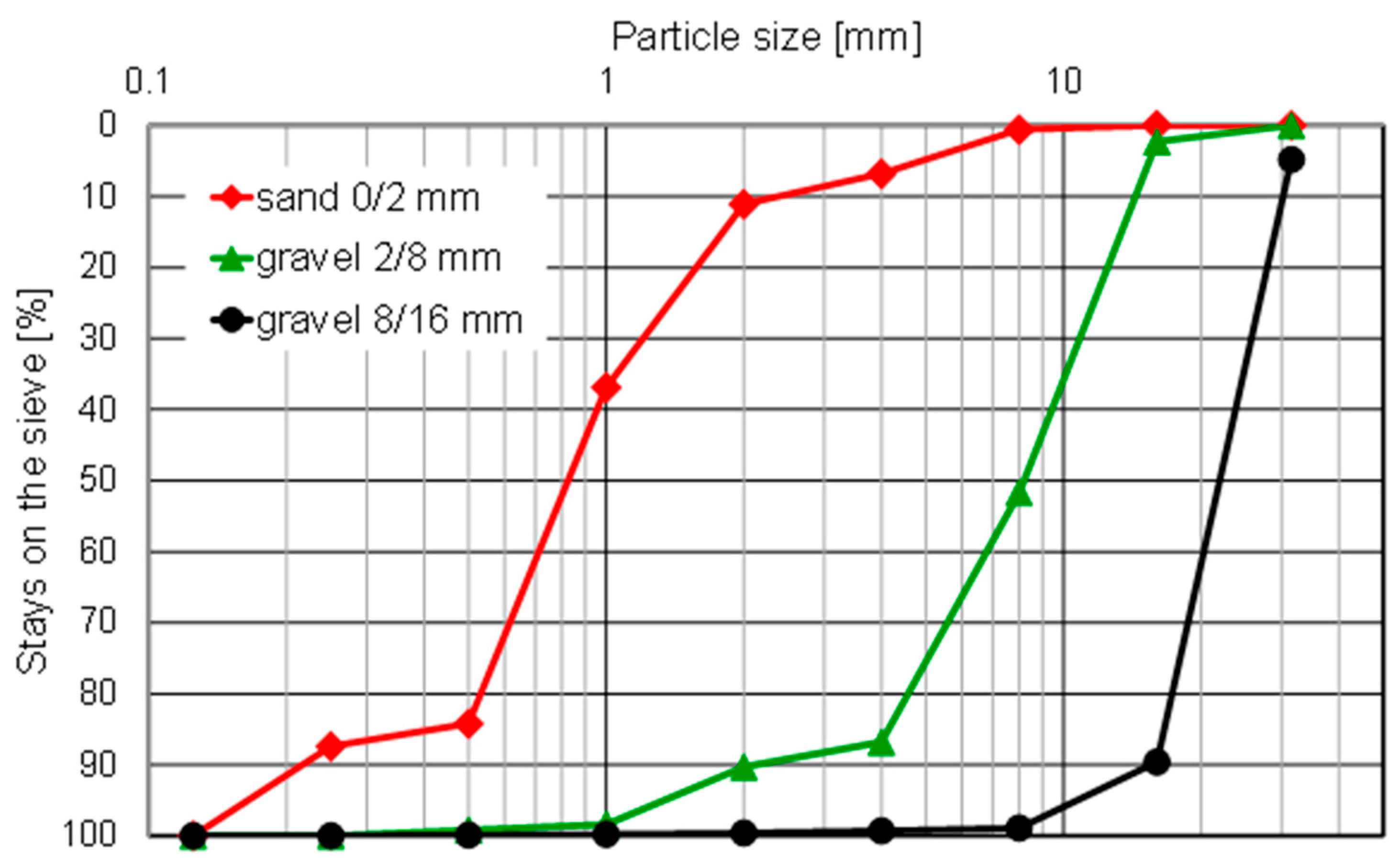

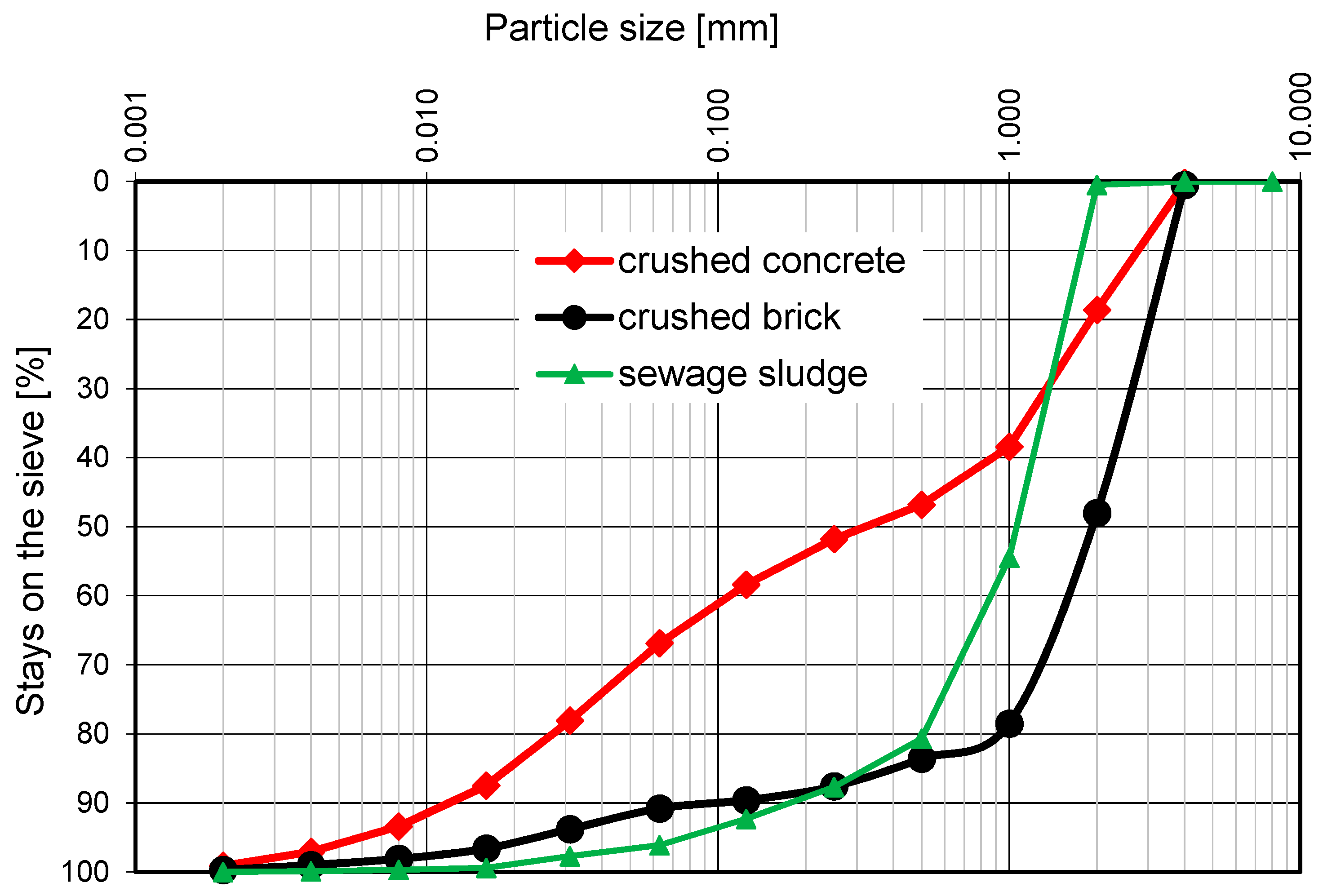

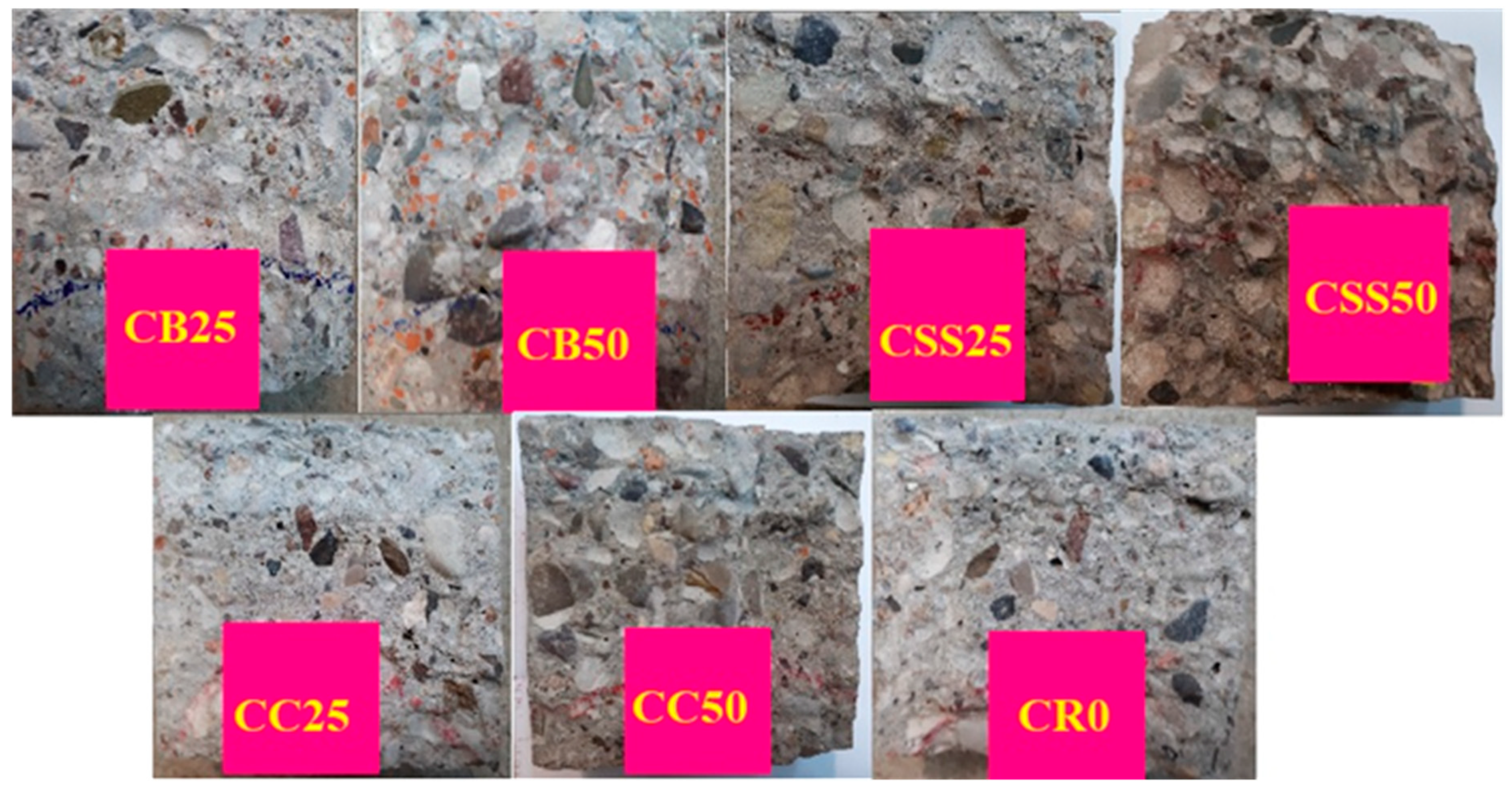

- Aggregate from concrete paving recycling; the paving was initially crushed, and the fractions larger than 2 mm were sifted on the construction sieves (Figure 2a). The concrete mixes containing this aggregate are marked CC25 and CC50. The bulk density of this aggregate was 0.75 g/cm3 and after compaction 0.93 g/cm3;

- Aggregate from the wastes created during ceramic bricks production (Figure 2b). The fractions of 1–4 mm dominated in this aggregate. The concrete mixes containing this aggregate are marked CB25 and CB50. The bulk density of this aggregate was 1.12 g/cm3 and after compaction 1.21 g/cm3;

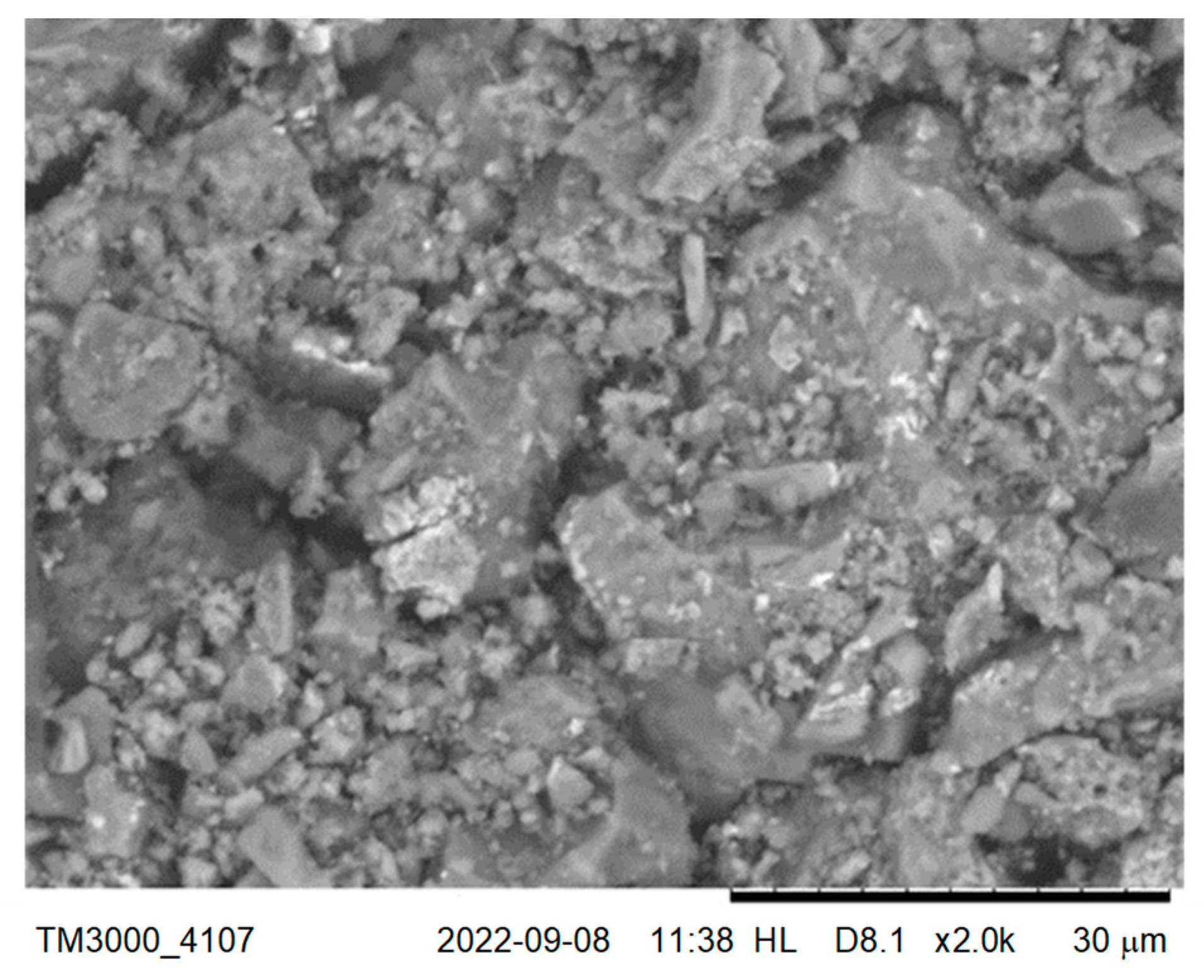

- Aggregate from Pomorzany Water Treatment Plant (Szczecin, Poland) in the form of slag (SS), created during thermal deactivation of the sewage sludges (Figure 2c). The slag is manufactured by drying in the contact dryer and burning in the moving grate boiler [36]. The material is porous with a significant content of open pores [37]; thus, it has low mechanical strength and high water absorbability, which was demonstrated by the worsening of the consistency of the tested concrete mixes. The slag fractions of 0.5–2 mm were selected for preparing concrete mixes. The concrete mixes containing this aggregate are marked CSS25 and CSS50. The bulk density of this aggregate was 0.54 g/cm3 and after compaction 0.64 g/cm3.

2.2. Preparation of Concrete Mixes and Concrete Specimens

2.3. Test Methods

3. Results and Discussion

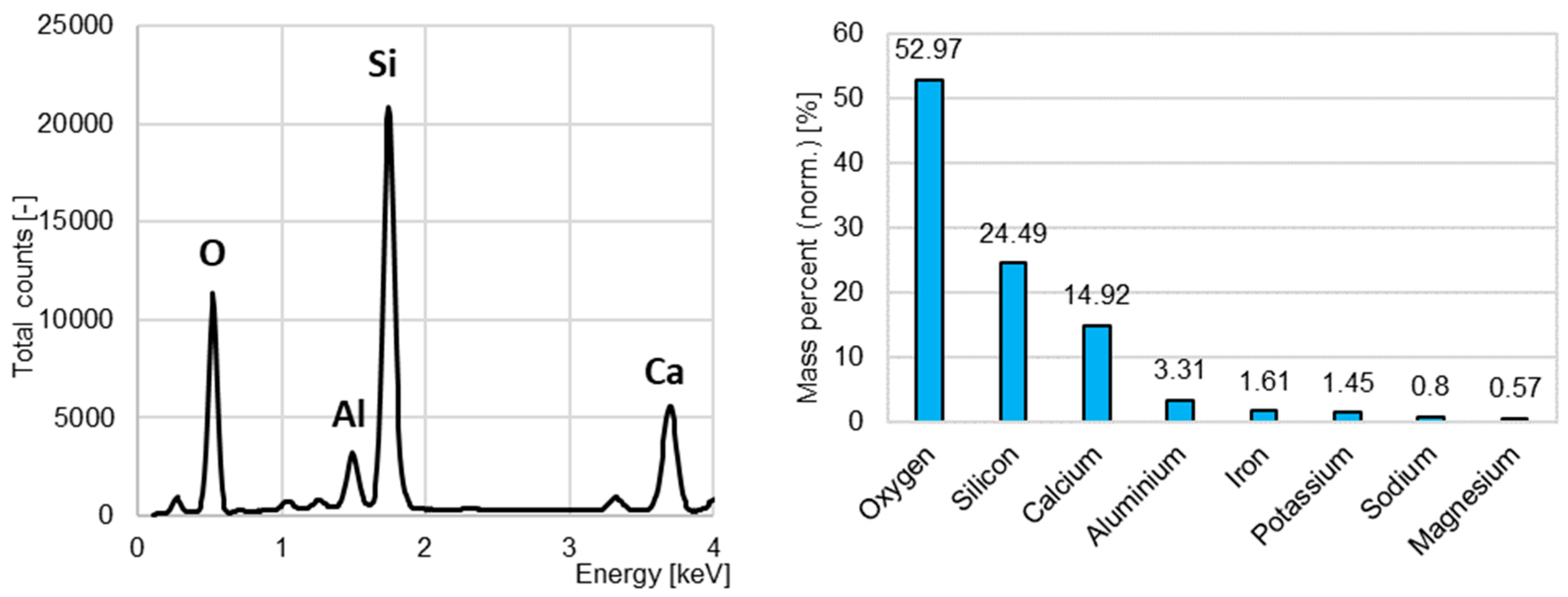

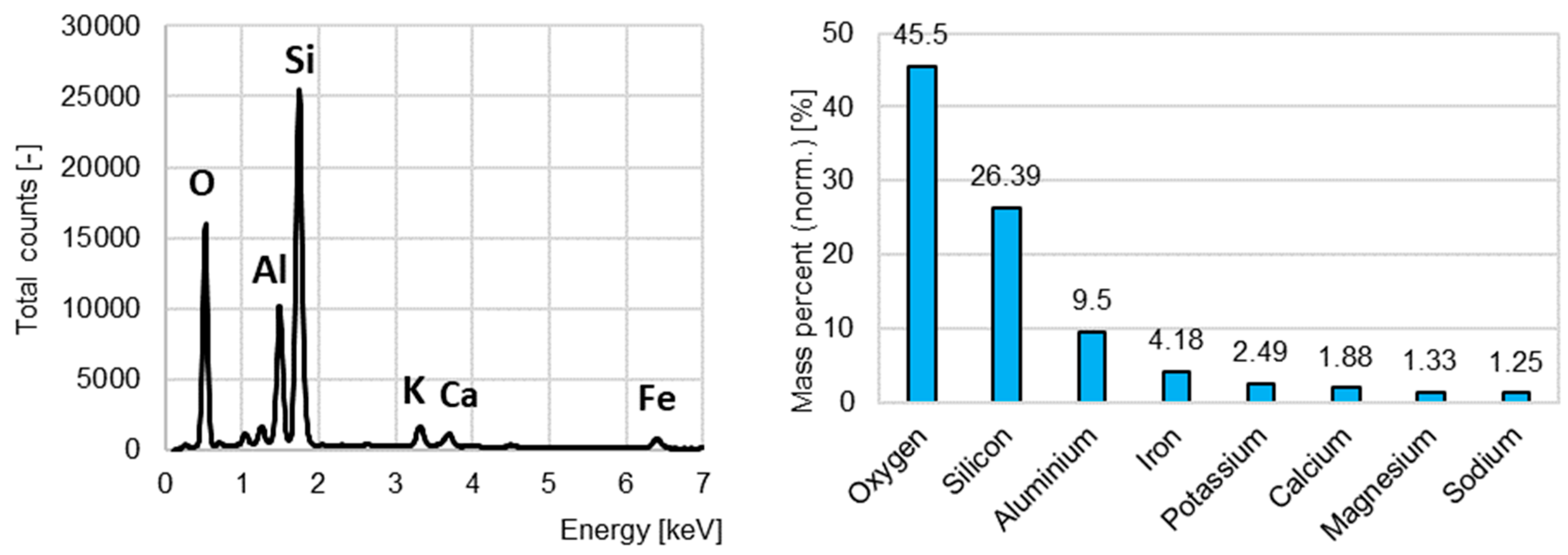

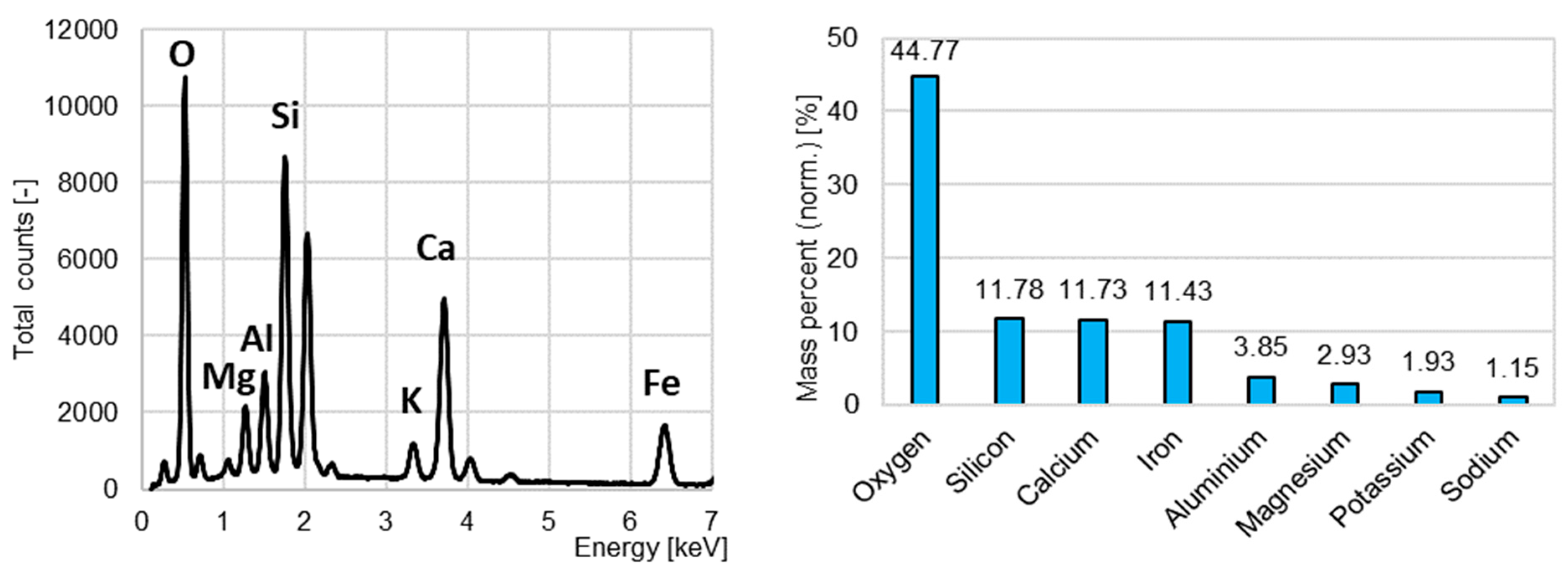

3.1. Chemical Composition of the Tested Aggregates

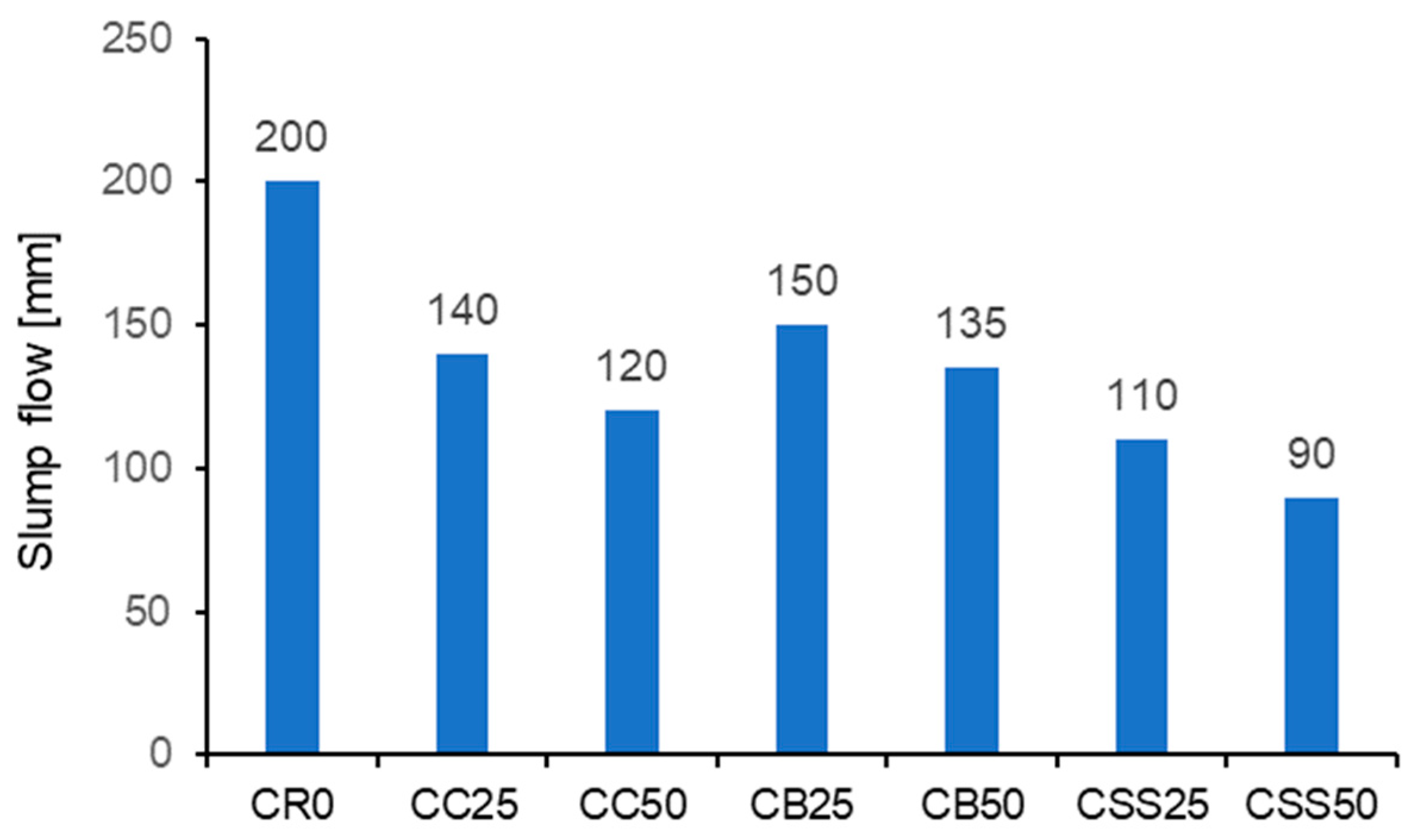

3.2. Consistency and Apparent Density of Concrete Mixes

3.3. Mechanical Performance of Concrete

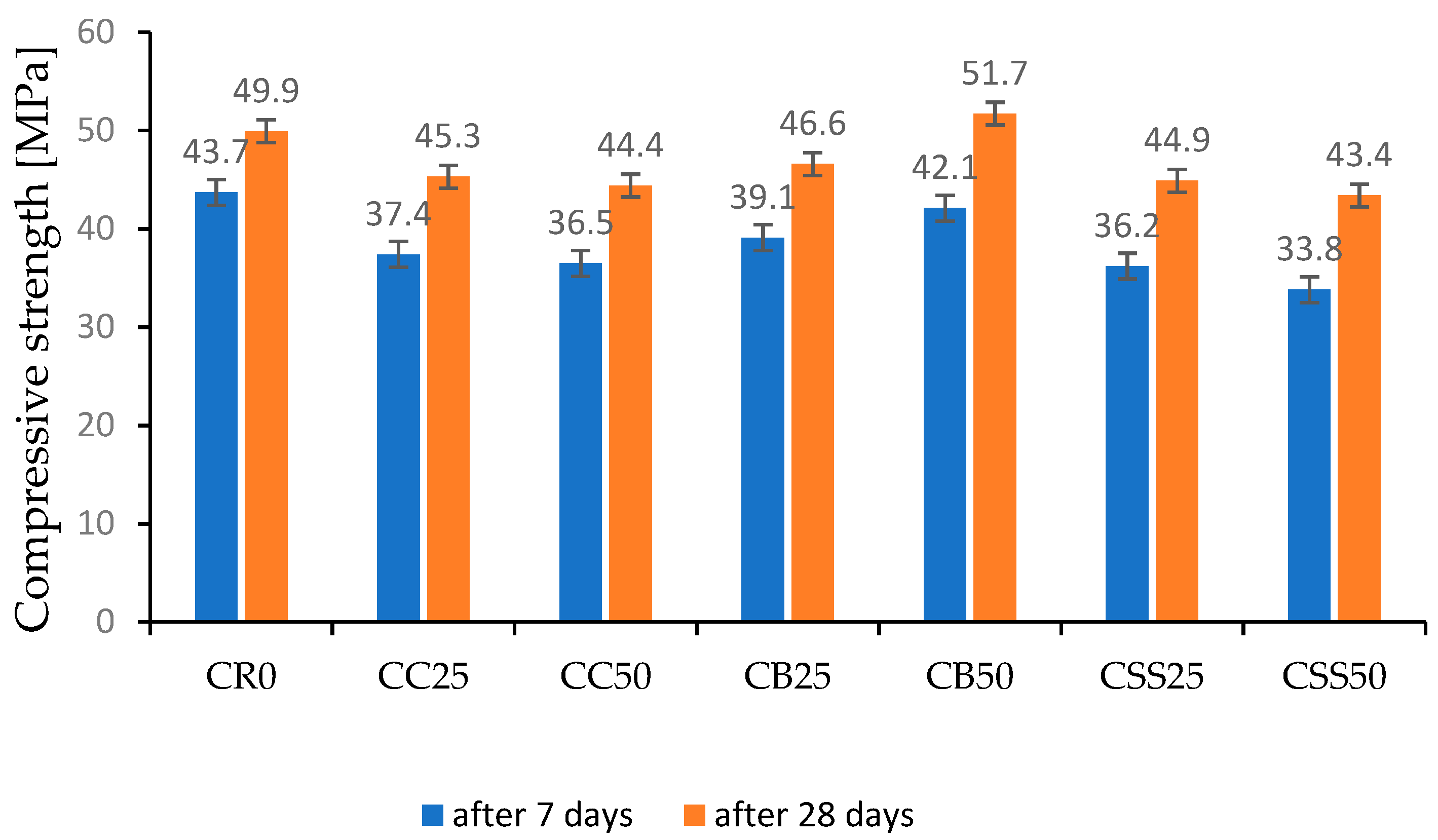

3.3.1. Compressive Strength

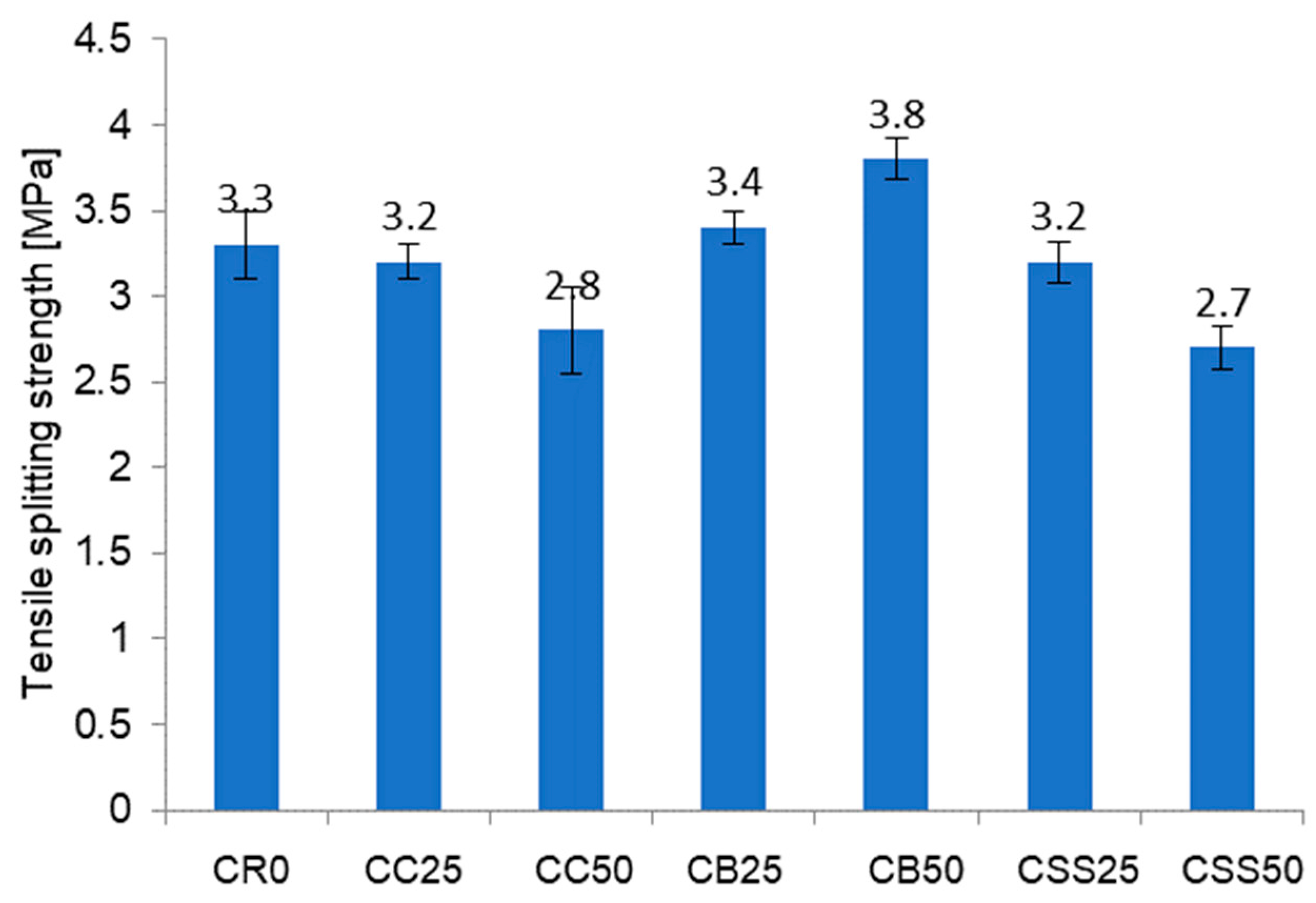

3.3.2. Tensile Strength

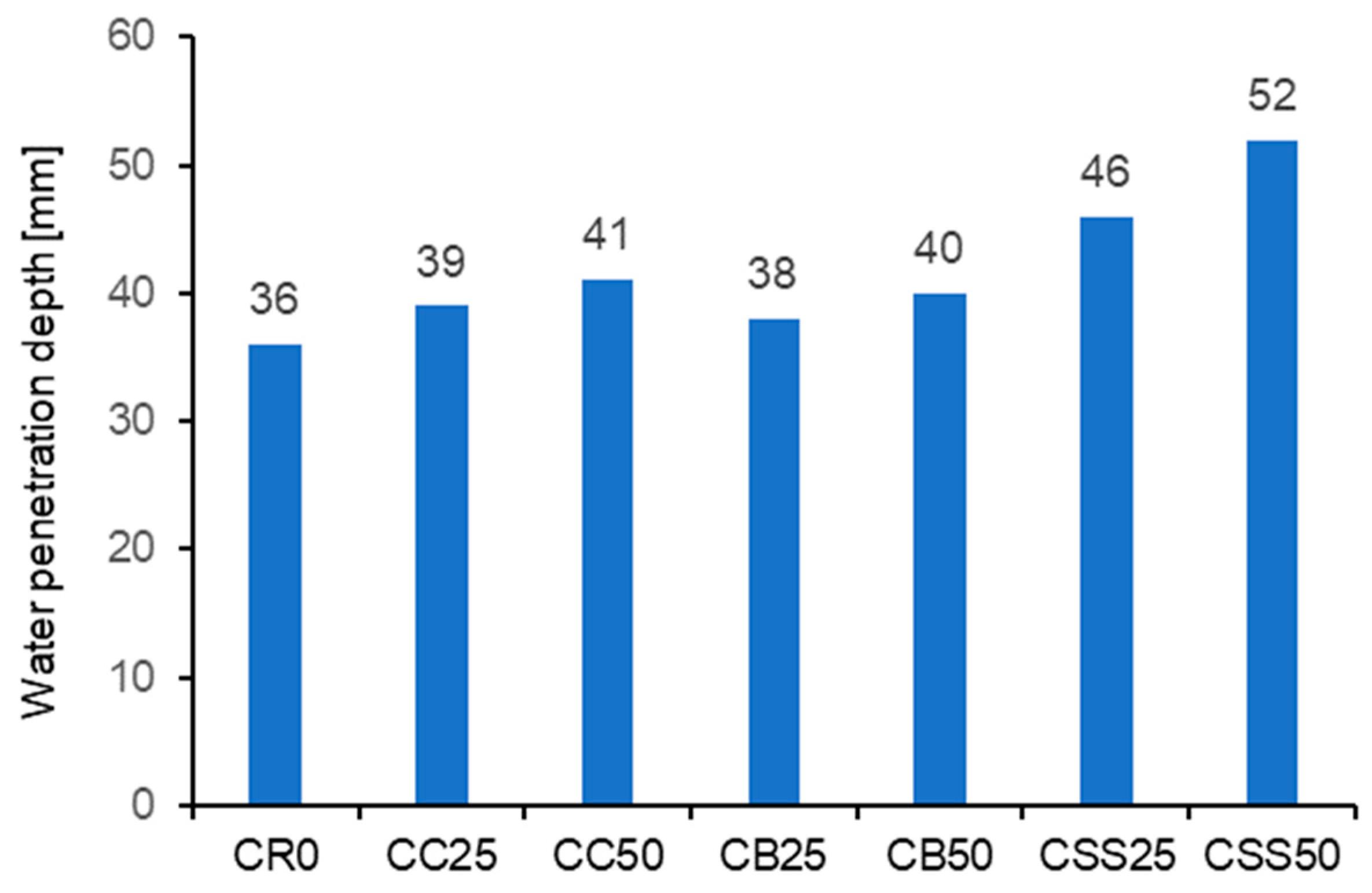

3.4. Depth of Water Penetration

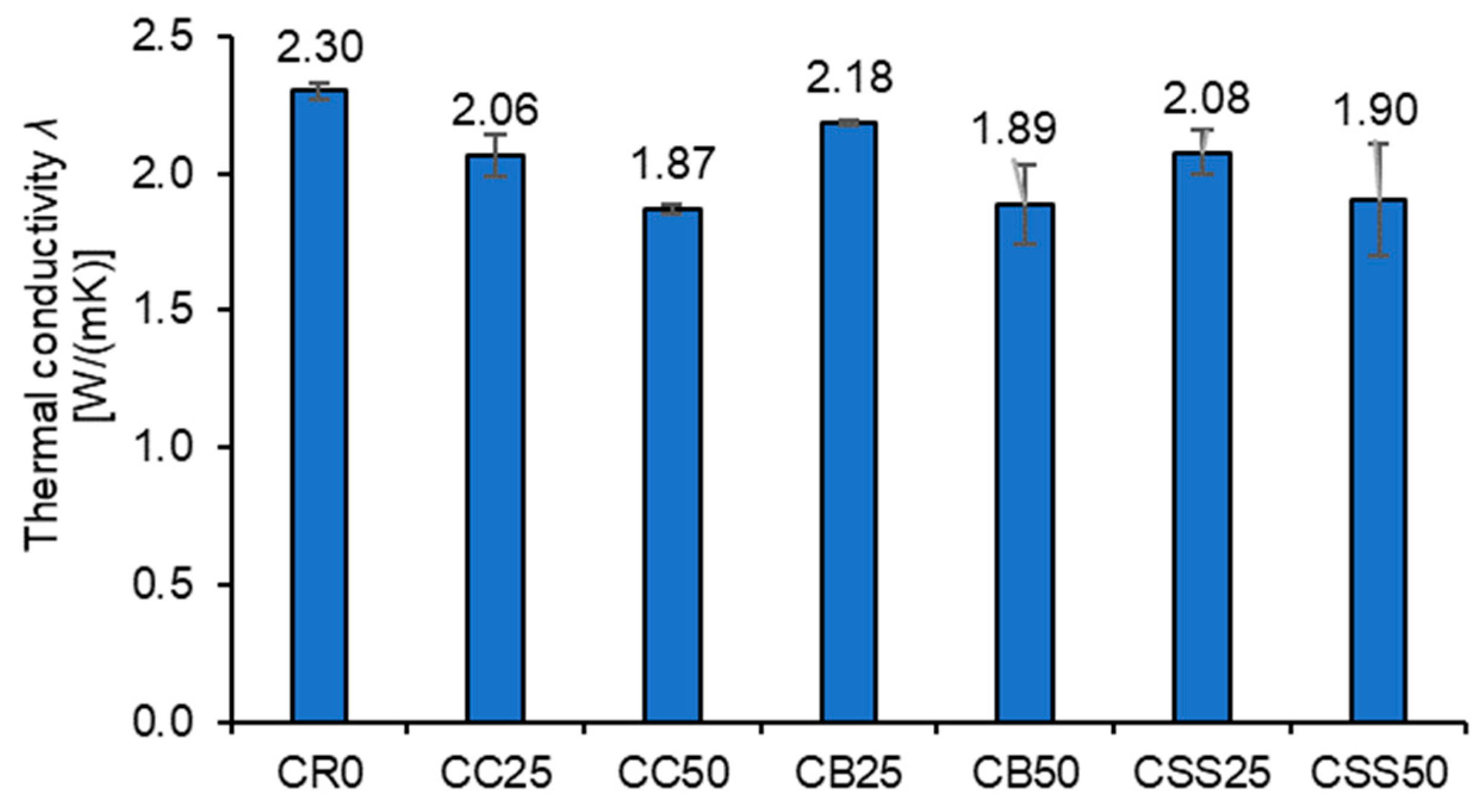

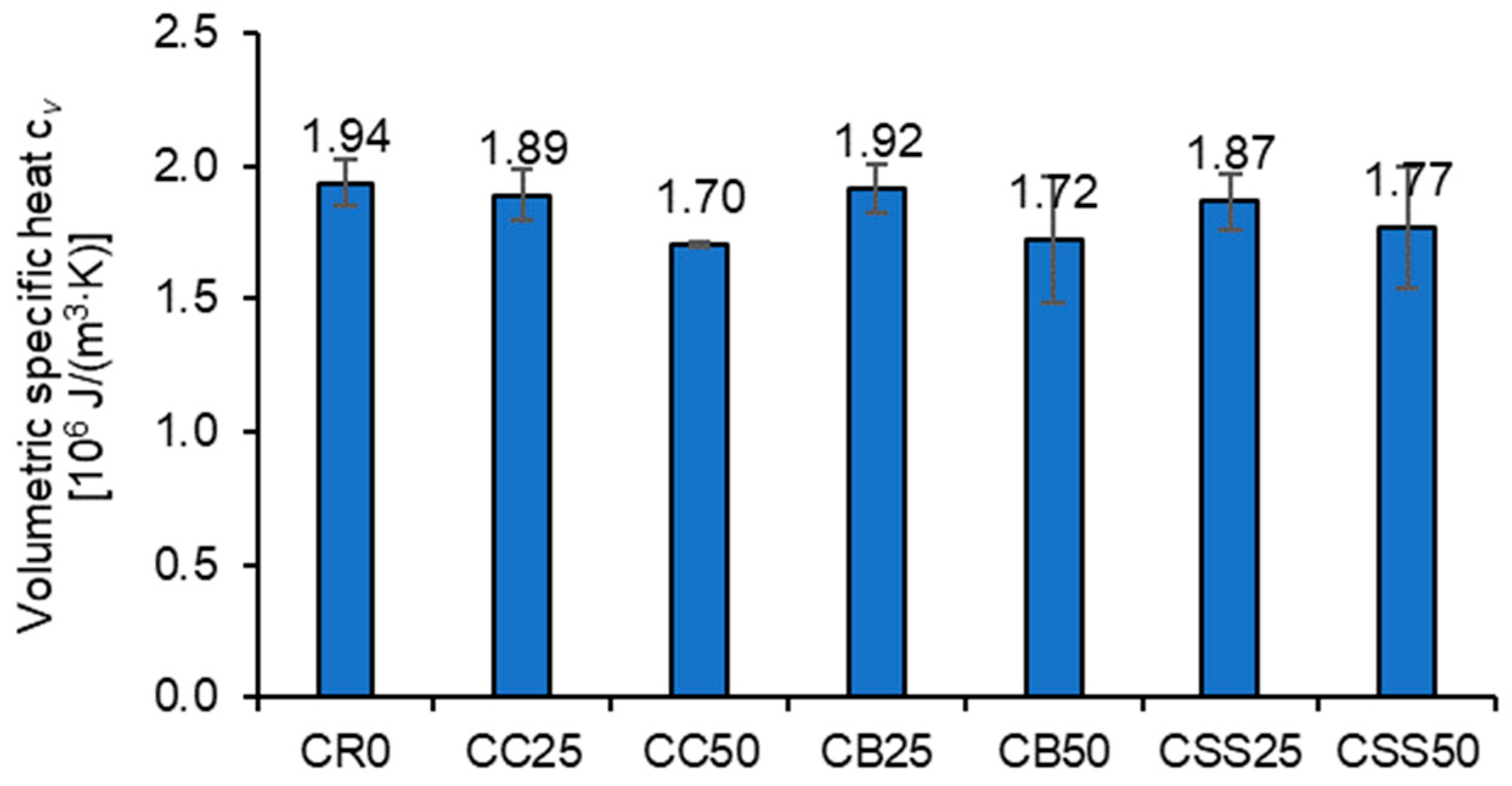

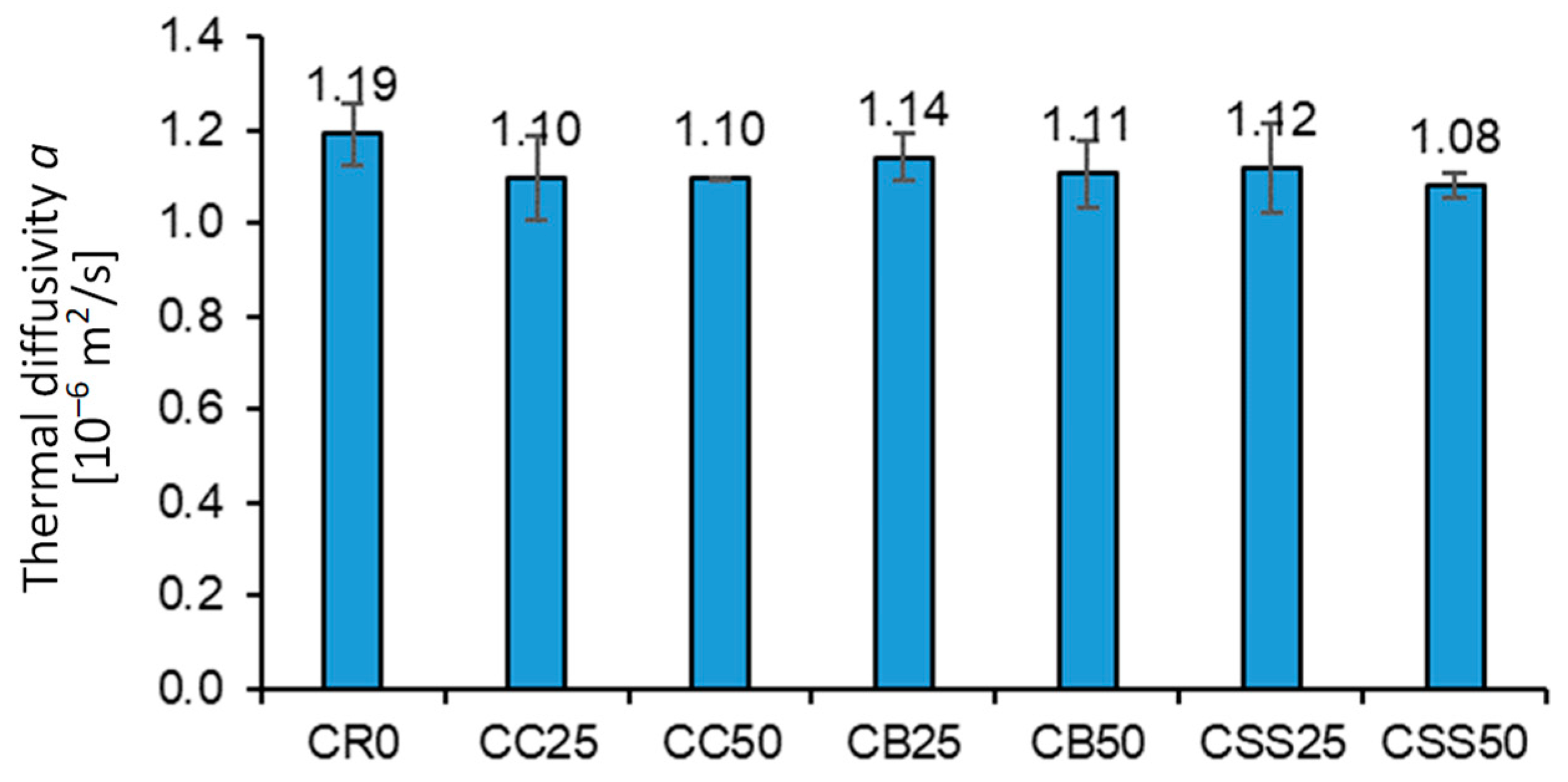

3.5. Thermal Conductivity

4. Conclusions

- The presence of chlorides or heavy metals, which could exclude the recycled aggregate as a building material component, was not detected.

- The recycled aggregates worsen the concrete mixes’ consistency. The reason for this phenomenon is high porosity and, in the case of the aggregates made by crushing and grinding, high content of the dust fractions. The downfall of the consistency can be limited by the initial saturation of the recycled aggregate with water before mixing the dry components [48,63].

- The recycled aggregates, due to their porous structure, cause a decrease in the compressive strength of the concrete. The only exception was the concrete containing the crushed bricks, which, after 28 days, demonstrated slightly higher (by 3.6%) compressive strength compared to the reference concrete. The downfall of compressive strength is decreased with time, and after 56 or 90 days of curing, the compressive strength can be close to the reference concrete, as demonstrated in [48].

- The tensile splitting strength is the highest for concrete with crushed bricks as a recycled aggregate. Using the other tested aggregates led to a tensile strength similar to the reference concrete.

- Using the recycled aggregates worsens the tightness of the concrete, which manifests itself by increasing water penetration depth.

- The thermal properties of concrete are slightly affected by the type and content of the recycled aggregate. The thermal conductivity is slightly decreased, while the specific heat and thermal diffusivity are not significantly influenced.

- The obtained test results and the analysis of the available literature data show that considering the concrete mix’s and hardened concrete’s performance, the sewage sludge’s content in the fine aggregate should not exceed 25%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Characterization of eco-friendly steel fiber-reinforced concrete containing waste coconut shell as coarse aggregates and fly ash as partial cement replacement. Struct. Concr. 2020, 21, 437–447. [Google Scholar] [CrossRef]

- Yadav, M.; Sinha, S. Waste to wealth: Overview of waste and recycled materials in construction industry. Mater. Today Proc. 2022, 65, 2042–2052. [Google Scholar] [CrossRef]

- Prakash, R.; Raman, S.N.; Divyah, N.; Subramanian, C.; Praveenkumar, S. Fresh and mechanical characteristics of roselle fibre reinforced self-compacting concrete incorporating fly ash and metakaolin. Constr. Build. Mater. 2021, 290, 123209. [Google Scholar] [CrossRef]

- Ahmad, T.; Ahmad, K.; Alam, M. Sustainable management of water treatment sludge through 3‘R’ concept. J. Clean. Prod. 2016, 124, 1–13. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, R.; Awe, O.W.; Yang, Y.; Shen, C. Acceptability of land application of alum-based water treatment residuals—An explicit and comprehensive review. Chem. Eng. J. 2018, 353, 717–726. [Google Scholar] [CrossRef]

- Rutkowska, G.; Ogrodnik, P.; Żółtowski, M.; Powęzka, A.; Kucharski, M.; Krejsa, M. Fly Ash from the Thermal Transformation of Sewage Sludge as an Additive to Concrete Resistant to Environmental Influences in Communication Tunnels. Appl. Sci. 2022, 12, 1802. [Google Scholar] [CrossRef]

- Basu, D.; Pal, P.; Prakash, A. Utilization of waste sludge in cementitious matrix: A feasibility study. Mater. Today Proc. 2022, 65, 1375–1381. [Google Scholar] [CrossRef]

- Tabsh, W.S.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Jarosiński, A. Mineral and Chemical Composition of Fly Ashes Deriving from Co-Combustion of Biomass with Coal and Its Application. Inż. Miner. J. Pol. Miner. Eng. Soc. 2013, 14, 141–148. [Google Scholar]

- Zerihun, B.; Yehualaw, M.D.; Vo, D.-H. Effect of Agricultural Crop Wastes as Partial Replacement of Cement in Concrete Production. Adv. Civ. Eng. 2022, 2022, 1–31. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, Y.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomas s from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Dachowski, R.; Kostrzewa, P. The Use of Waste Materials in the Construction Industry. Procedia Eng. 2016, 161, 754–758. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Infuence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Koga, H.; Katahira, H.; Shimata, A. The introduction of recycled-aggregate concrete specifcations in Japan and the research into the freezing–thawing resistance of recycled-aggregate concrete. J. Mater. Cycles Waste 2022, 24, 1207–1215. [Google Scholar] [CrossRef]

- de Brito, J.; Agrela, F.; Silva, R.V. Legal regulations of recycled aggregate concrete in buildings and roads. In New Trends in Ecoefcient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 509–526. [Google Scholar]

- Rudnicki, T.; Jurczak, R. Recycling of a Concrete Pavement after over 80 Years in Service. Materials 2020, 13, 2262. [Google Scholar] [CrossRef]

- Tomaszewska, J. Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability Performance of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Sosa, M.E.; Villagrán Zaccardi, Y.A.; Zega, C.J. A Critical Review of the Resulting Effective Water-to-Cement Ratio of Fine Recycled Aggregate Concrete. Constr. Build. Mater. 2021, 313, 125536. [Google Scholar] [CrossRef]

- Arredondo-Rea, S.P.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Gámez-García, D.C.; Bernal-Camacho, J.M.; Rosas-Casarez, C.A.; Ungsson-Nieblas, M.J. Durability Parameters of Reinforced Recycled Aggregate Concrete: Case Study. Appl. Sci. 2019, 9, 617. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of Microstructure of ITZ on Compressive Strength of Concrete Prepared with Recycled Aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Nedeljkovic, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of Fine Recycled Concrete Aggregates in Concrete: A Critical Review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Courard, L.; Rondeux, M.; Zhao, Z.; Michel, F. Use of Recycled Fine Aggregates from C&DW for Unbound Road Sub-Base. Materials 2020, 13, 2994. [Google Scholar] [CrossRef]

- Ge, Z.; Feng, Y.; Zhang, H.; Xiao, J.; Sun, R.; Liu, X. Use of Recycled Fine Clay Brick Aggregate as Internal Curing Agent for Low Water to Cement Ratio Mortar. Constr. Build. Mater. 2020, 264, 120280. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Pang, S.D.; Zhao, S. Durability and Microstructural Properties of Concrete with Recycled Brick as Fine Aggregates. Constr. Build. Mater. 2020, 262, 120032. [Google Scholar] [CrossRef]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-Related Performance of Concrete Containing Fine Recycled Aggregates from Crushed Bricks and Sanitary Ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- Kim, J.; Kim, N. Recycling Waste Paver Blocks in the Manufacture of New Concrete Paver Blocks and Building Bricks. Appl. Sci. 2022, 12, 10970. [Google Scholar] [CrossRef]

- Pavlu, T.; Khanapur, N.V.; Fortová, K.; Mariaková, D.; Tripathi, B.; Chandra, T.; Hájek, P. Design of Performance-Based Concrete Using Sand Reclaimed from Construction and Demolition Waste–Comparative Study of Czechia and India. Materials 2022, 15, 7873. [Google Scholar] [CrossRef]

- Oliveira, R.; de Brito, J.; Veiga, R. Incorporation of Fine Glass Aggregates in Renderings. Constr. Build. Mater. 2013, 44, 329–341. [Google Scholar] [CrossRef]

- Neno, C.; de Brito, J.; Veiga, R. Using Fine Recycled Concrete Aggregate for Mortar Production. Mater. Res. 2014, 17, 168–177. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. Quality Improvement of Recycled Concrete Aggregate by Removal of Residual Mortar: A Comprehensive Review of Approaches Adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Nili, M.; Sasanipour, H.; Aslani, F. The Effect of Fine and Coarse Recycled Aggregates on Fresh and Mechanical Properties of Self-Compacting Concrete. Materials 2019, 12, 1120. [Google Scholar] [CrossRef]

- EN 12350-2; Testing Fresh Concrete—Part 2: Slump Test. European Committee for Standardization: Bruxelles, Belgium, 2019.

- Yang, Z.; Zhang, Y.; Liu, L.; Seetharaman, S.; Wang, X.; Zhang, Z. Integrated Utilization of Sewage Sludge and Coal Gangue for Cement Clinker Products: Promoting Tricalcium Silicate Formation and Trace Elements Immobilization. Materials 2016, 9, 275. [Google Scholar] [CrossRef]

- Kiper, J.; Głowacka, A.; Rucińska, T. Analysis of the Variability of the Composition of Sewage Sludge Before and After Drying Treatment—SEM Studies. J. Ecol. Eng. 2019, 20, 45–52. [Google Scholar] [CrossRef]

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: Bruxelles, Belgium, 2019.

- EN 12390-6; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. European Committee for Standardization: Bruxelles, Belgium, 2022.

- EN 12390-8; Testing Hardened Concrete—Part 8: Depth of Penetration of Water Under Pressure. European Committee for Standardization: Bruxelles, Belgium, 2019.

- EN 12620; Aggregates for Concrete. European Committee for Standardization: Bruxelles, Belgium, 2013.

- Merino, I.; Arévalo, L.F.; Romero, F. Preparation and characterization of ceramic products by thermal treatment of sewage sludge ashes mixed with different additives. Waste Manag. 2007, 27, 1829–1844. [Google Scholar] [CrossRef]

- Park, Y.J.; Moon, S.O.; Heo, J. Crystalline phase control of glass ceramics obtained from sewage sludge fly ash. Ceram. Int. 2003, 29, 223–227. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S. Sewage sludge ash characteristics and potential for use in bricks, tiles and glass ceramics. Water Sci. Technol. 2016, 74, 17–29. [Google Scholar] [CrossRef]

- Lin, D.F.; Luo, H.L.; Cheng, J.F.; Zhuang, M.L. Strengthening tiles manufactured with sewage sludge ash replacement by adding micro-carbon powder. Mater. Struct. 2016, 49, 3559–3567. [Google Scholar] [CrossRef]

- Chakraborty, S.; Jo, B.W.; Jo, J.H.; Baloch, Z. Effectiveness of sewage sludge ash combined with waste pozzolanic minerals in developing sustainable construction material: An alternative approach for waste management. J. Clean. Prod. 2017, 153, 253–263. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wichowski, P.; Fronczyk, J.; Franus, M.; Chalecki, M. Use of fly ashes from municipal sewage sludge combustion in production of ash concretes. Constr. Build. Mater. 2018, 188, 874–883. [Google Scholar] [CrossRef]

- Rucińska, T.; Głowacka, A.; Sidełko, R. The Influence of Incinerated Sewage Sludge as an Aggregate on the Selected Properties of Cement Mortars. Materials 2021, 14, 5846. [Google Scholar] [CrossRef]

- Chen, Z.; Poon, C.S. Comparative studies on the effects of sewage sludge ash and fly ash on cement hydration and properties of cement mortars. Constr. Build. Mater. 2017, 154, 791–803. [Google Scholar] [CrossRef]

- Rutkowska, G.; Chalecki, M.; Żółtowski, M. Fly Ash from Thermal Conversion of Sludge as a Cement Substitute in Concrete Manufacturing. Sustainability 2021, 13, 4182. [Google Scholar] [CrossRef]

- Ing, D.S.; Chin, S.C.; Guan, T.K.; Suil, A. The use of sewage sludge ash (SSA) as partial replacement of cement in concrete. ARPN J. Eng. Appl. Sci. 2016, 11, 3771–3775. [Google Scholar]

- Chen, M.; Blanc, D.; Gautier, M.; Mehu, J.; Gourdon, R. Environmental and technical assessments of the potential utilization of sewage sludge ashes (SSAs) as secondary raw materials in construction. Waste Manag. 2013, 33, 1268–1275. [Google Scholar] [CrossRef]

- Valls, S.; Yague, A.; Vazquez, E.; Mariscal, C. Physical and mechanical properties of concrete with added dry sludge from a sewage treatment plant. Cem. Concr. Res. 2004, 34, 2203–2208. [Google Scholar] [CrossRef]

- Rozporządzenie Ministra Rozwoju z Dnia 21 Stycznia 2016 r. W Sprawie Wymagań Dotyczących Prowadzenia Procesu Termicznego Przekształcania Odpadów Oraz Sposobów Postępowania z Odpadami Powstałymi w Wyniku Tego Procesu. (Dz.U. 2016 poz. 108). Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20160000108 (accessed on 24 April 2019).

- PN-EN 451–2:2017–06; Fly Ash Test Method-Determination of Fineness by Wet Sieving. Polish Committee for Standardization: Warsaw, Poland, 2017.

- PN-EN 197–1:2012; Cement. Part 1: Composition, Requirements and Compliance Criteria for Common Cements. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Głowacka, A.; Rucińska, T.; Kiper, J. The slag original from the process of sewage sludge incineration selected properties characteristic. E3S Web Conf. 2017, 22, 54. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Hakim, M.Y.A.; Osman, S.A.; El-Zeadani, M. Physical and Mechanical Properties of Concrete using Recycled Clay Bricks as Coarse Aggregate. Am. J. Eng. Appl. Sci. 2022, 15, 88–100. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Thornberg, D.; Cohen, Y.; Stiernstrom, S. Utilization of acid-washed sewage sludge ash as sand or cement replacement in concrete. Resour. Conserv. Recycl. 2022, 176, 105943. [Google Scholar] [CrossRef]

- Liang, C.; Le, X.; Fang, W.; Zhao, J.; Fang, L.; Hou, S. The Utilization of Recycled Sewage Sludge Ash as a Supplementary Cementitious Material in Mortar: A Review. Sustainability 2022, 14, 4432. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M. Application of SSA as Partial Replacement of Aggregate in Concrete. Pol. J. Environ. Stud. 2011, 20, 365–370. [Google Scholar]

- Stolarska, A.; Rucińska, T. Evaluation of Physical Characteristics and Sorption of Cement Mortars with Recycled Ceramic Aggregate. Materials 2021, 14, 7852. [Google Scholar] [CrossRef] [PubMed]

- Kępniak, M.; Woyciechowski, P.; Łukowski, P.; Kuziak, J.; Kobyłka, R. The durability of concrete modified by waste limestone powder in the chemically aggressive environment. Materials 2019, 12, 1693. [Google Scholar] [CrossRef] [PubMed]

- Łukowski, P.; Dębska, D. Effect of polymer addition on performance of Portland cement mortar exposed to sulphate attack. Materials 2020, 13, 71. [Google Scholar] [CrossRef]

| Concrete Designation | Cement | Water | Sand 0/2 mm | Crushed Concrete | Crushed Bricks | Sewage Sludge | Gravel 2/8 mm | Gravel 8/16 mm | SP |

|---|---|---|---|---|---|---|---|---|---|

| [kg/m3] | |||||||||

| CR0 | 320 | 176 | 580 | 0 | 0 | 0 | 708 | 560 | 4.8 |

| CC25 | 320 | 176 | 448 | 98 | 0 | 0 | 708 | 560 | 4.8 |

| CC50 | 320 | 176 | 299 | 196 | 0 | 0 | 708 | 560 | 4.8 |

| CB25 | 320 | 176 | 448 | 0 | 63 | 0 | 708 | 560 | 4.8 |

| CB50 | 320 | 176 | 299 | 0 | 126 | 0 | 708 | 560 | 4.8 |

| CSS25 | 320 | 176 | 448 | 0 | 0 | 36 | 708 | 560 | 4.8 |

| CSS50 | 320 | 176 | 299 | 0 | 0 | 72 | 708 | 560 | 4.8 |

| Concrete

Designation | Compressive Strength [MPa] | |

|---|---|---|

| After 7 Days | After 28 Days | |

| CR0 | 43.7 ± 1.3 | 49.9 ± 1.8 |

| CC25 | 37.4 ± 1.4 | 45.3 ± 2.3 |

| CC50 | 36.5 ± 2.1 | 44.4 ± 1.9 |

| CB25 | 39.1 ± 1.6 | 46.6 ± 1.4 |

| CB50 | 42.1 ± 1.3 | 51.7 ± 1.8 |

| CSS25 | 36.2 ± 1.6 | 44.9 ± 2.6 |

| CCSS50 | 33.8 ± 1.8 | 43.4 ± 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łukowski, P.; Horszczaruk, E.; Seul, C.; Strzałkowski, J. Mechanical Strength and Thermal Properties of Cement Concrete Containing Waste Materials as Substitutes for Fine Aggregate. Materials 2022, 15, 8832. https://doi.org/10.3390/ma15248832

Łukowski P, Horszczaruk E, Seul C, Strzałkowski J. Mechanical Strength and Thermal Properties of Cement Concrete Containing Waste Materials as Substitutes for Fine Aggregate. Materials. 2022; 15(24):8832. https://doi.org/10.3390/ma15248832

Chicago/Turabian StyleŁukowski, Paweł, Elżbieta Horszczaruk, Cyprian Seul, and Jarosław Strzałkowski. 2022. "Mechanical Strength and Thermal Properties of Cement Concrete Containing Waste Materials as Substitutes for Fine Aggregate" Materials 15, no. 24: 8832. https://doi.org/10.3390/ma15248832

APA StyleŁukowski, P., Horszczaruk, E., Seul, C., & Strzałkowski, J. (2022). Mechanical Strength and Thermal Properties of Cement Concrete Containing Waste Materials as Substitutes for Fine Aggregate. Materials, 15(24), 8832. https://doi.org/10.3390/ma15248832