Properties of Blended Cement Containing Iron Tailing Powder at Different Curing Temperatures

Abstract

:1. Introduction

2. Materials and Methods

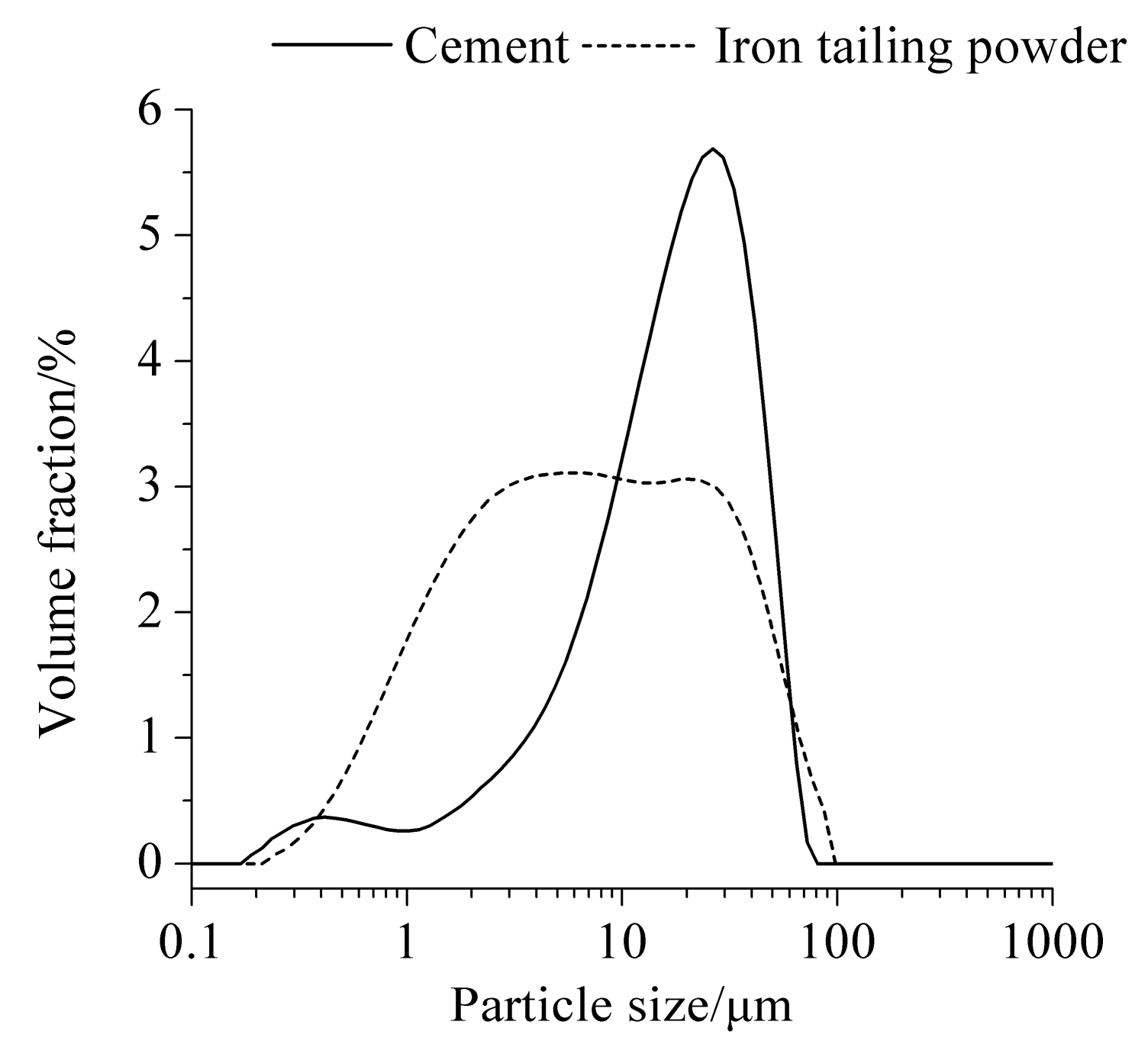

2.1. Raw Materials

2.2. Mix Proportions

2.3. Test Methods

3. Results and Discussion

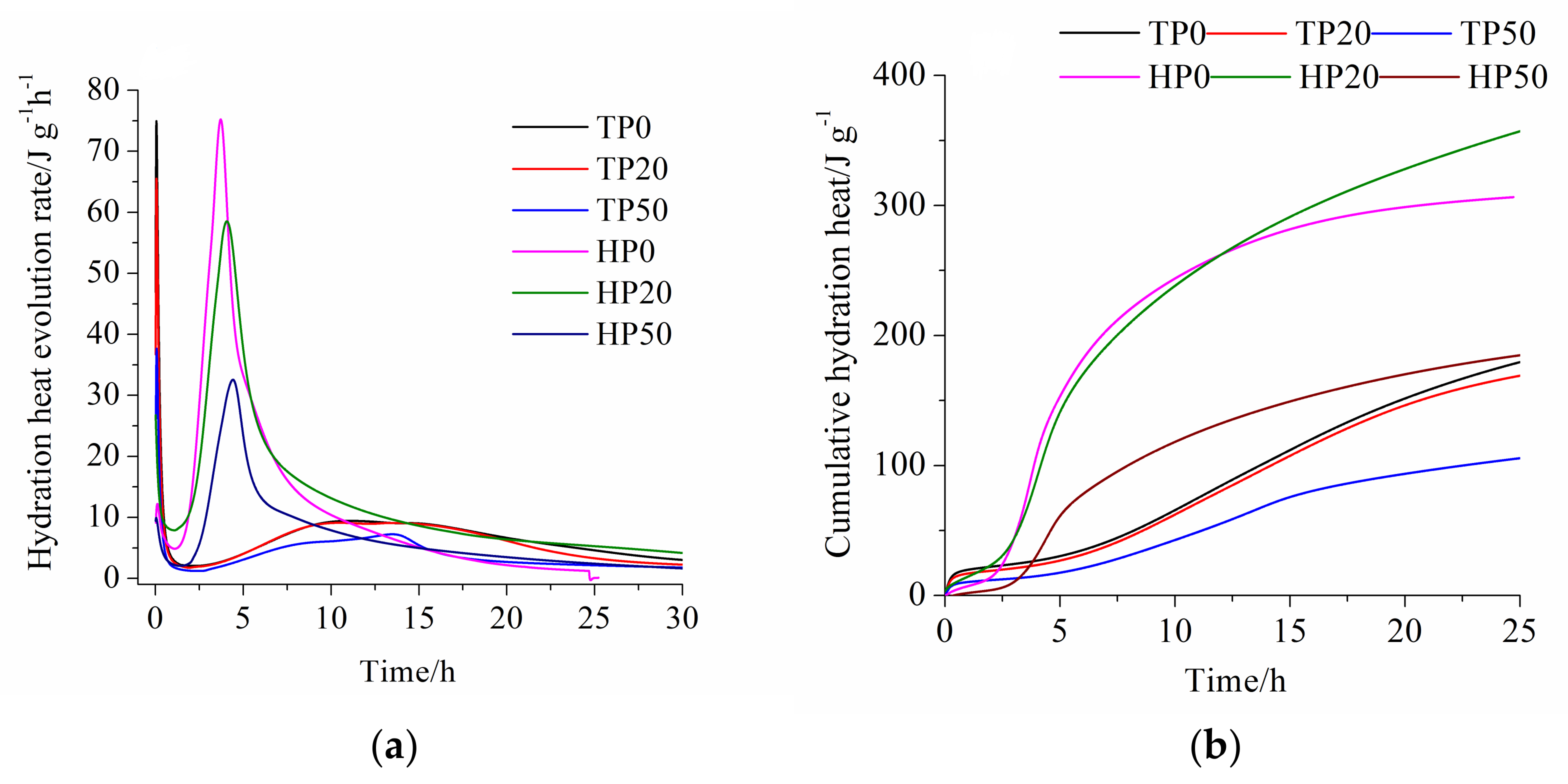

3.1. Hydration Heat

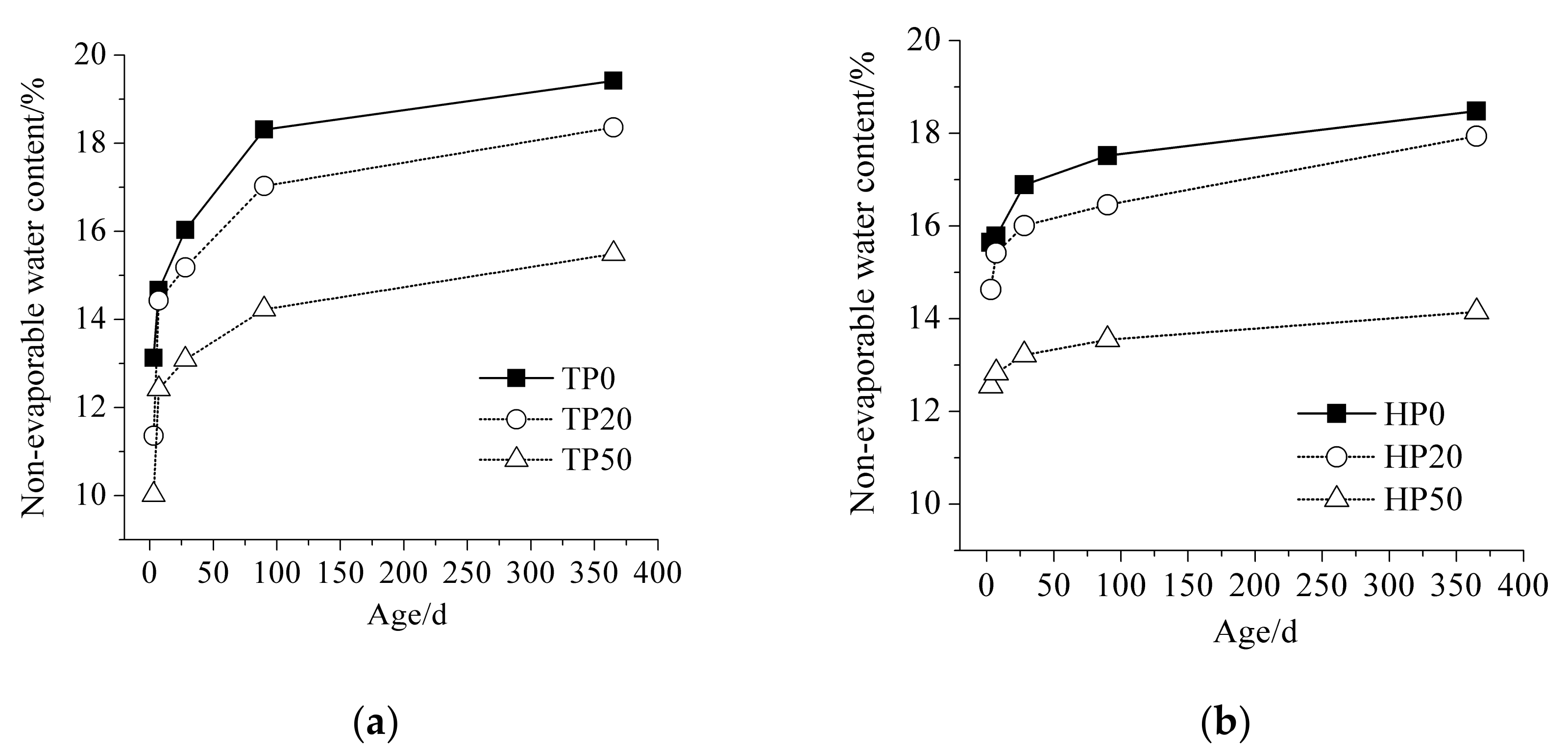

3.2. Non-Evaporable Water Content

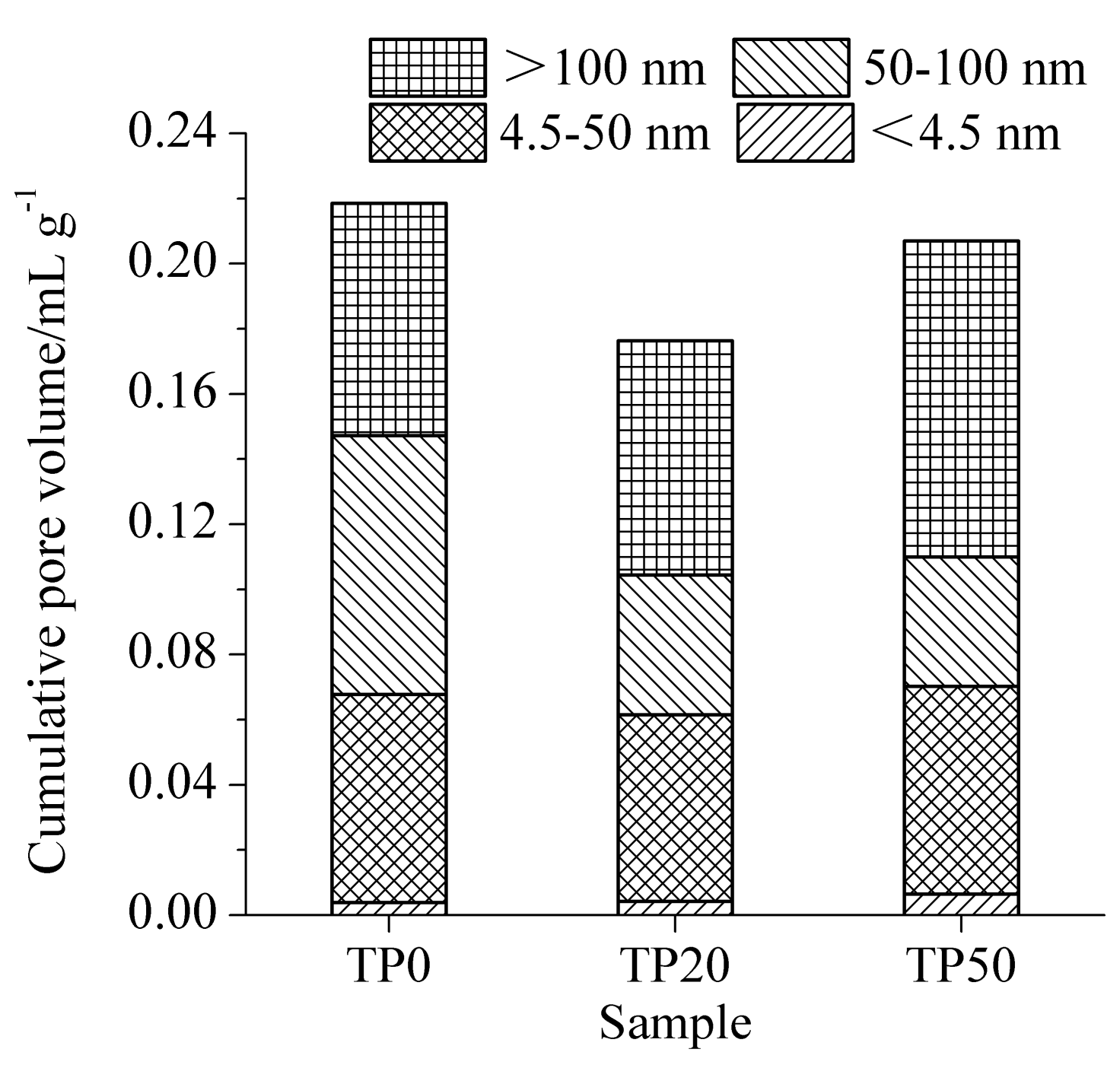

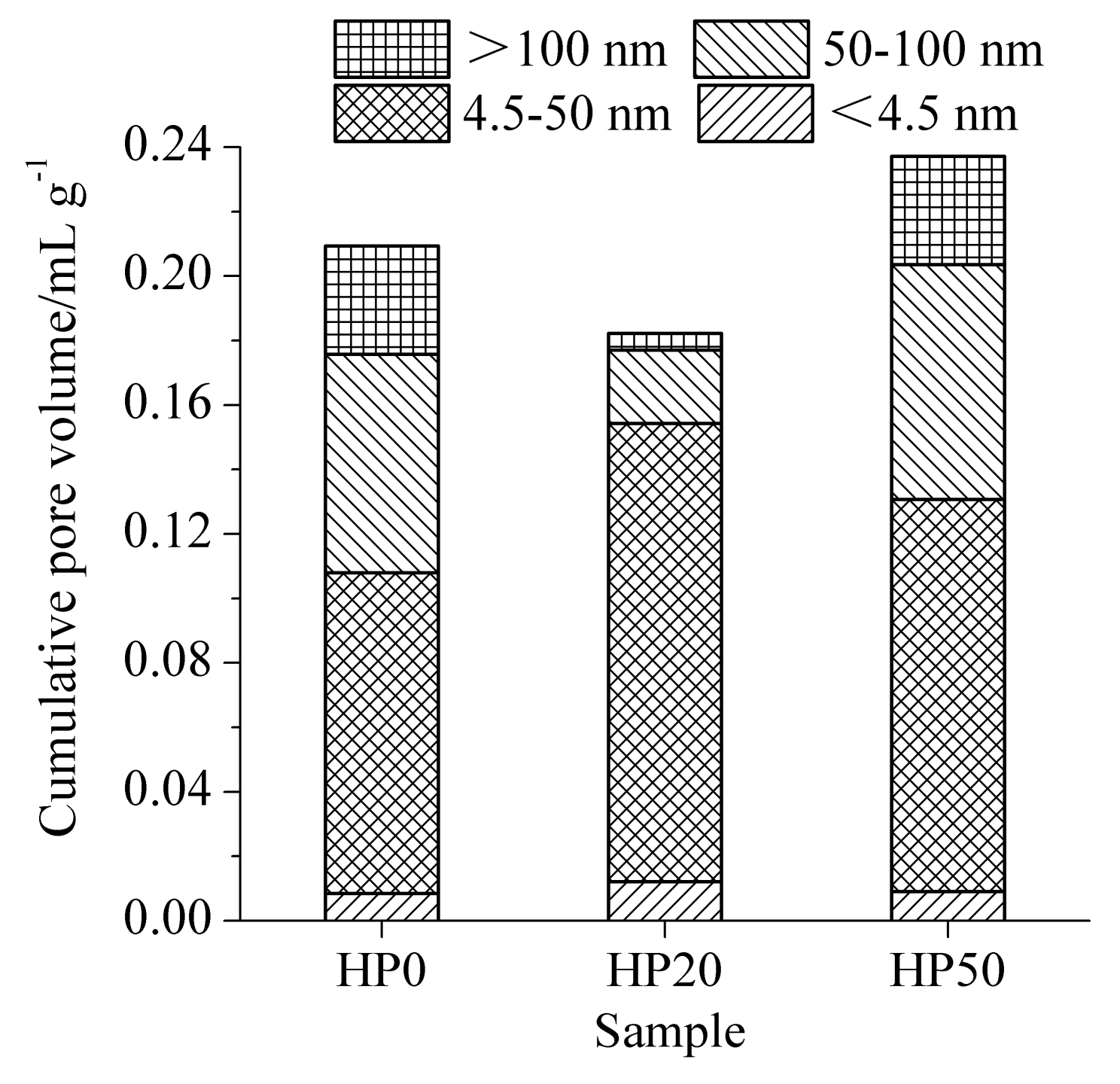

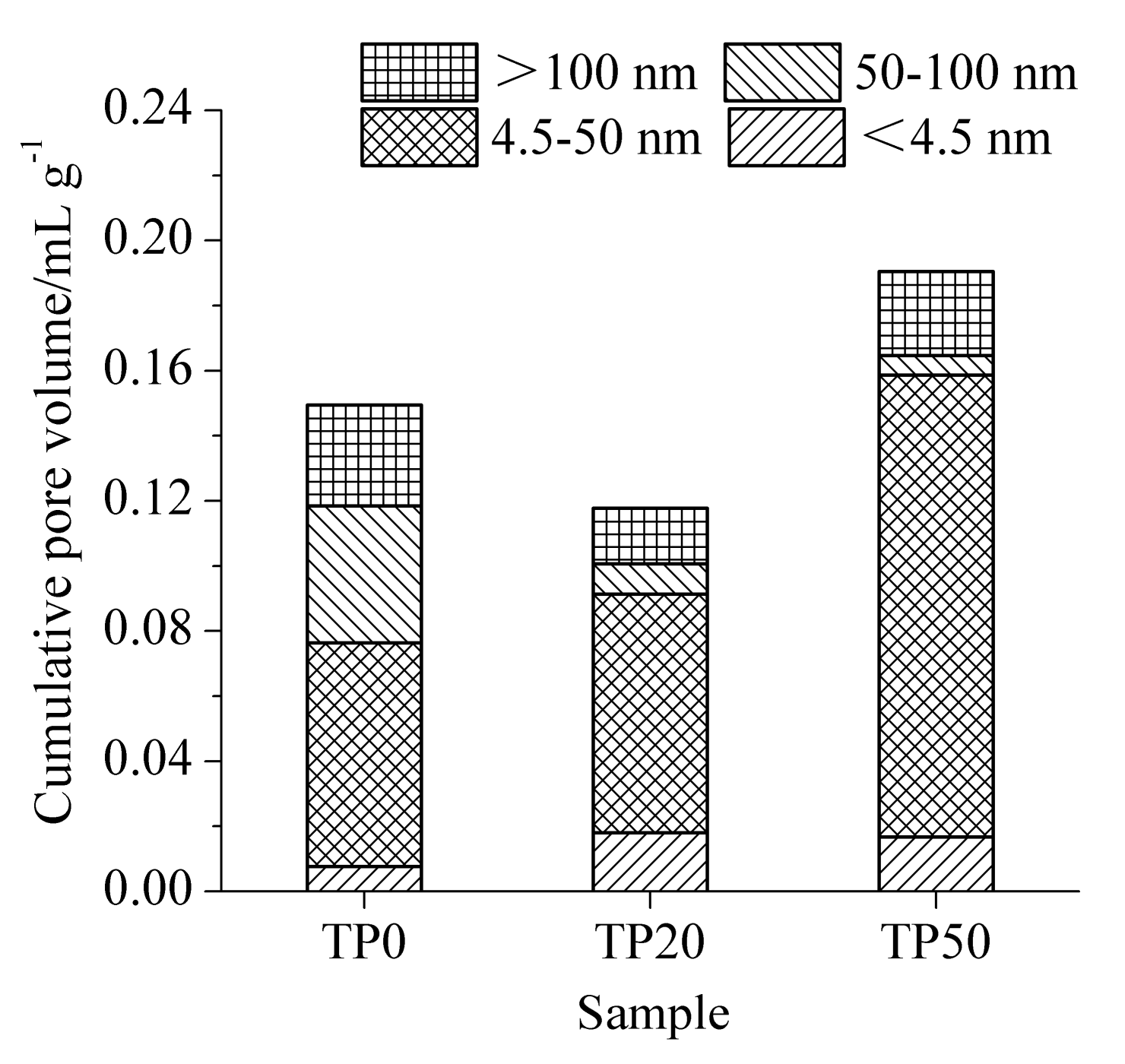

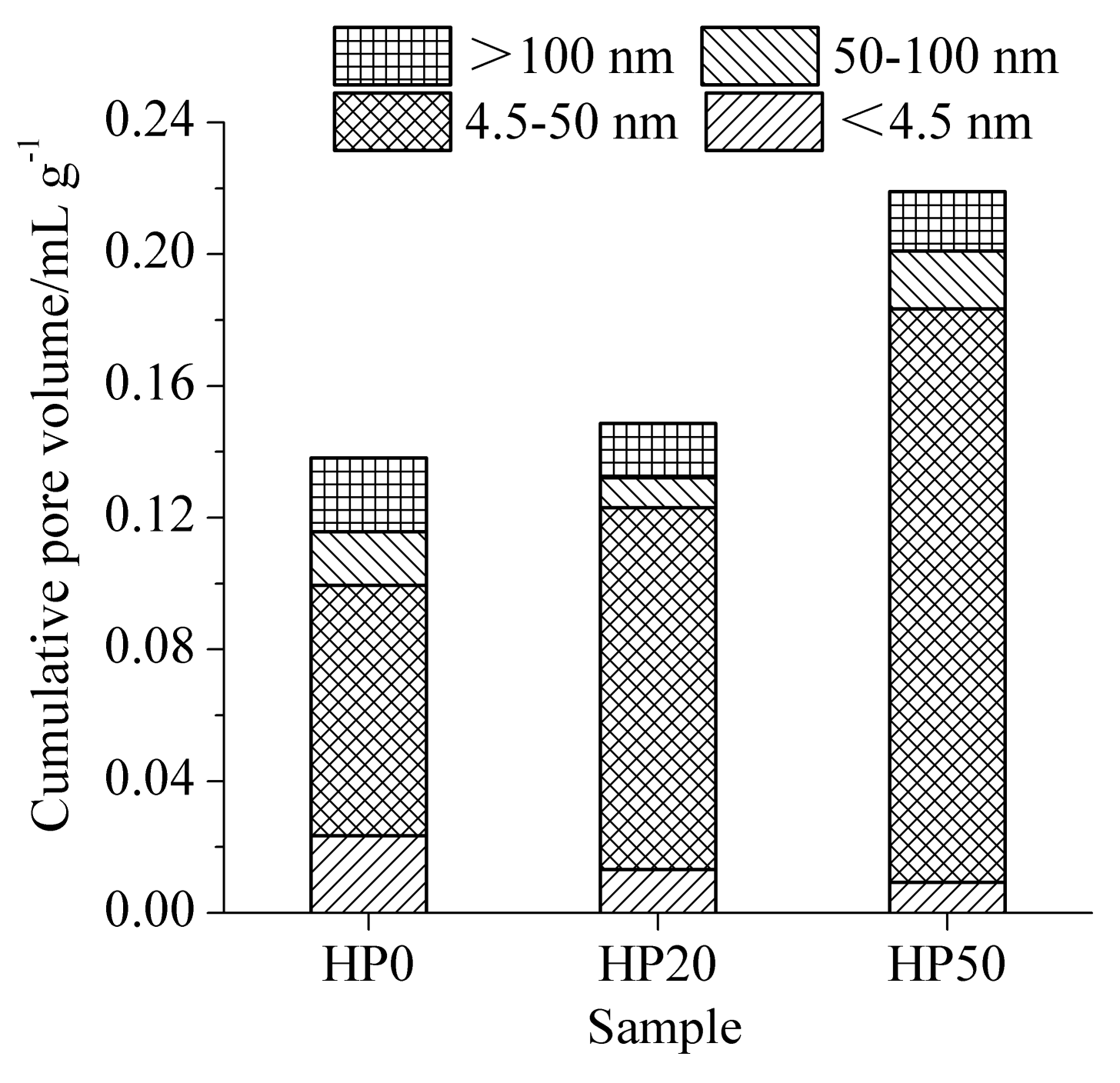

3.3. Pore Structure

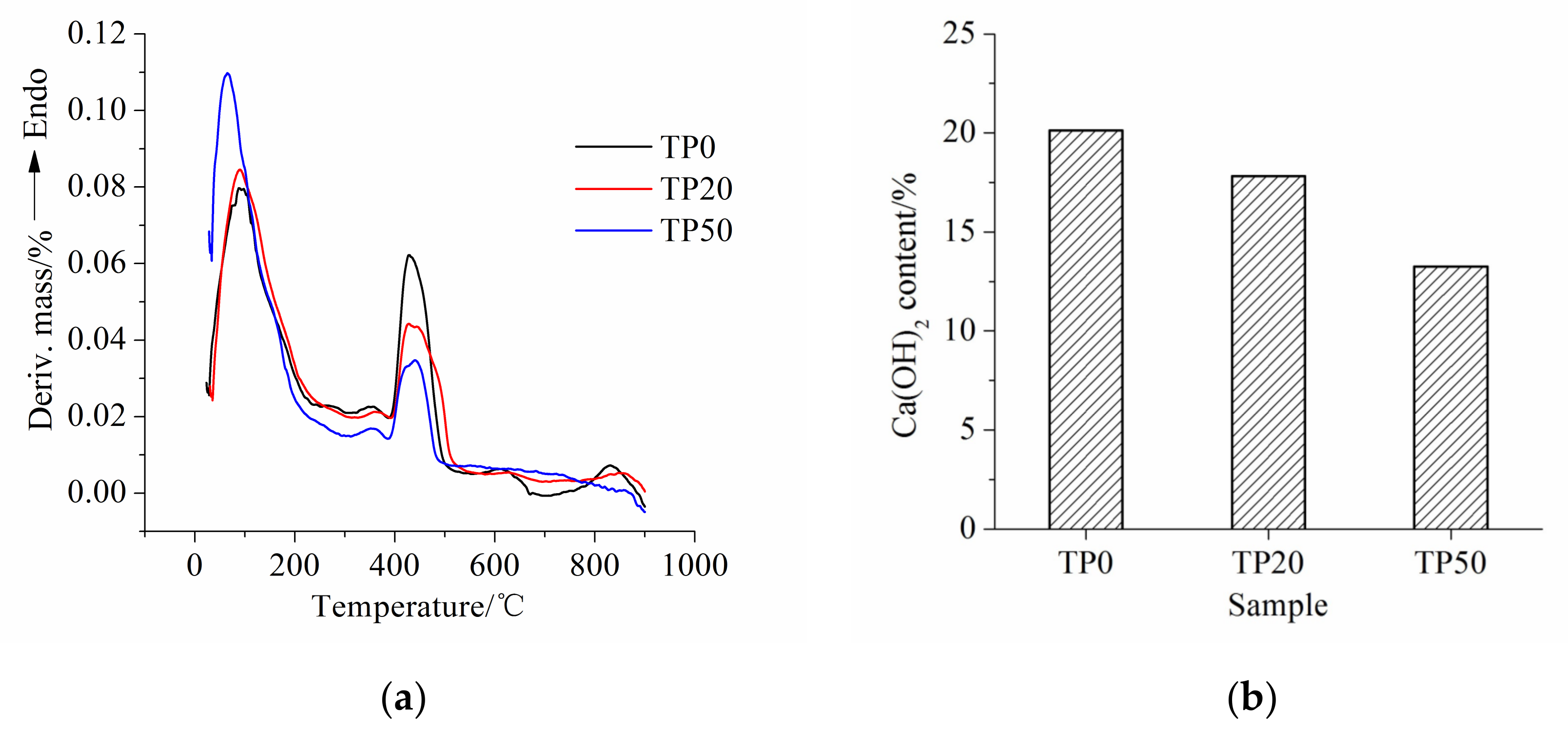

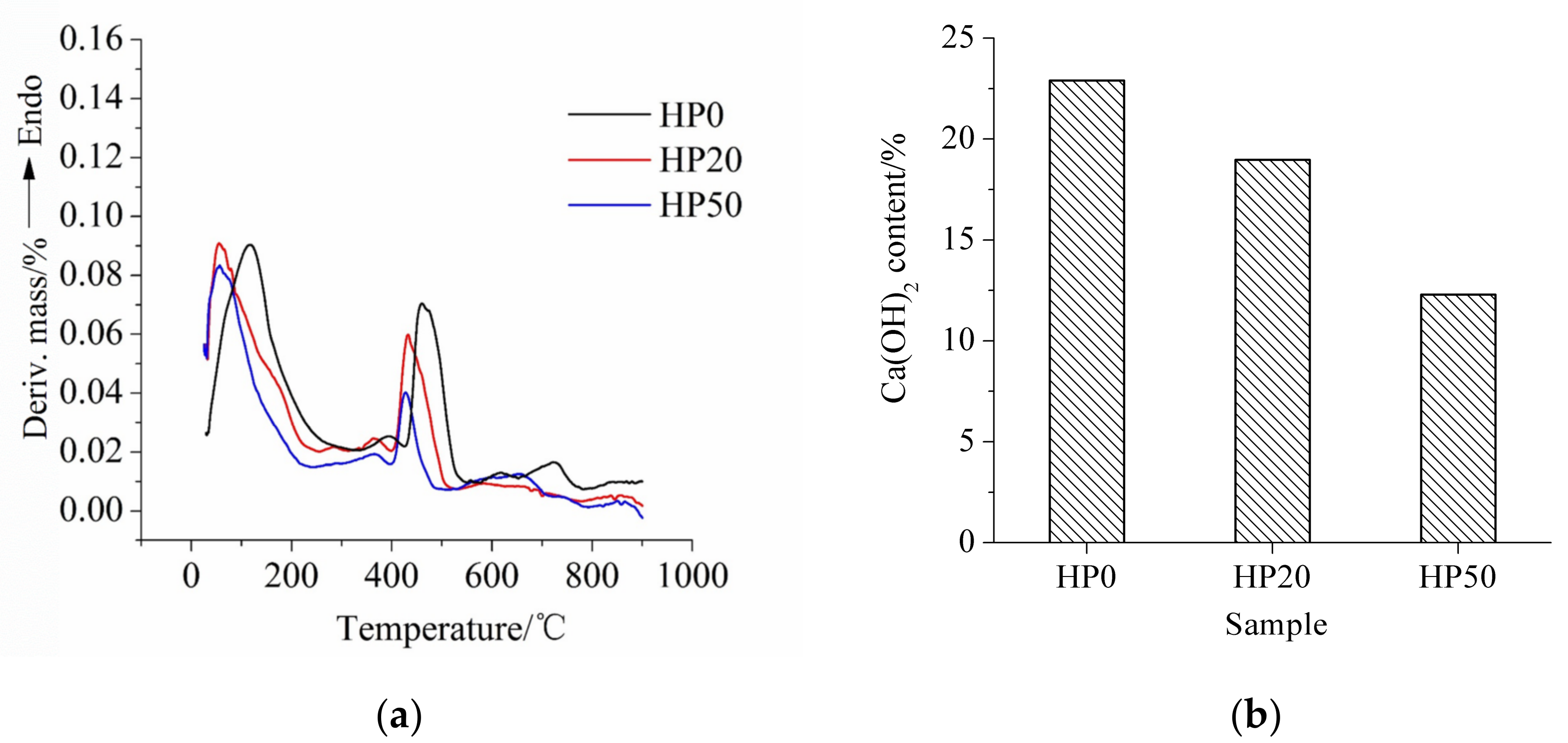

3.4. Thermogravimetric Analysis

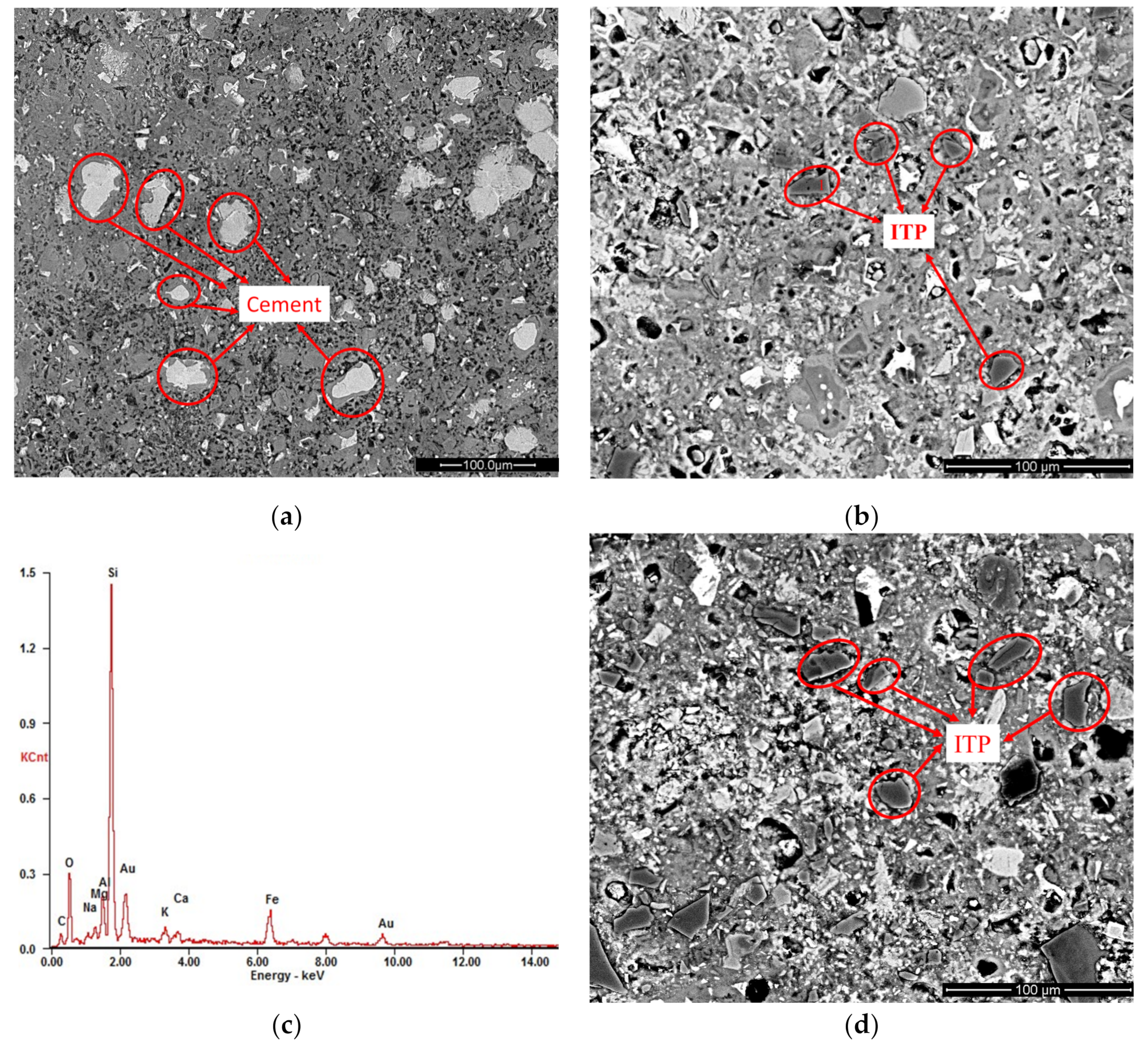

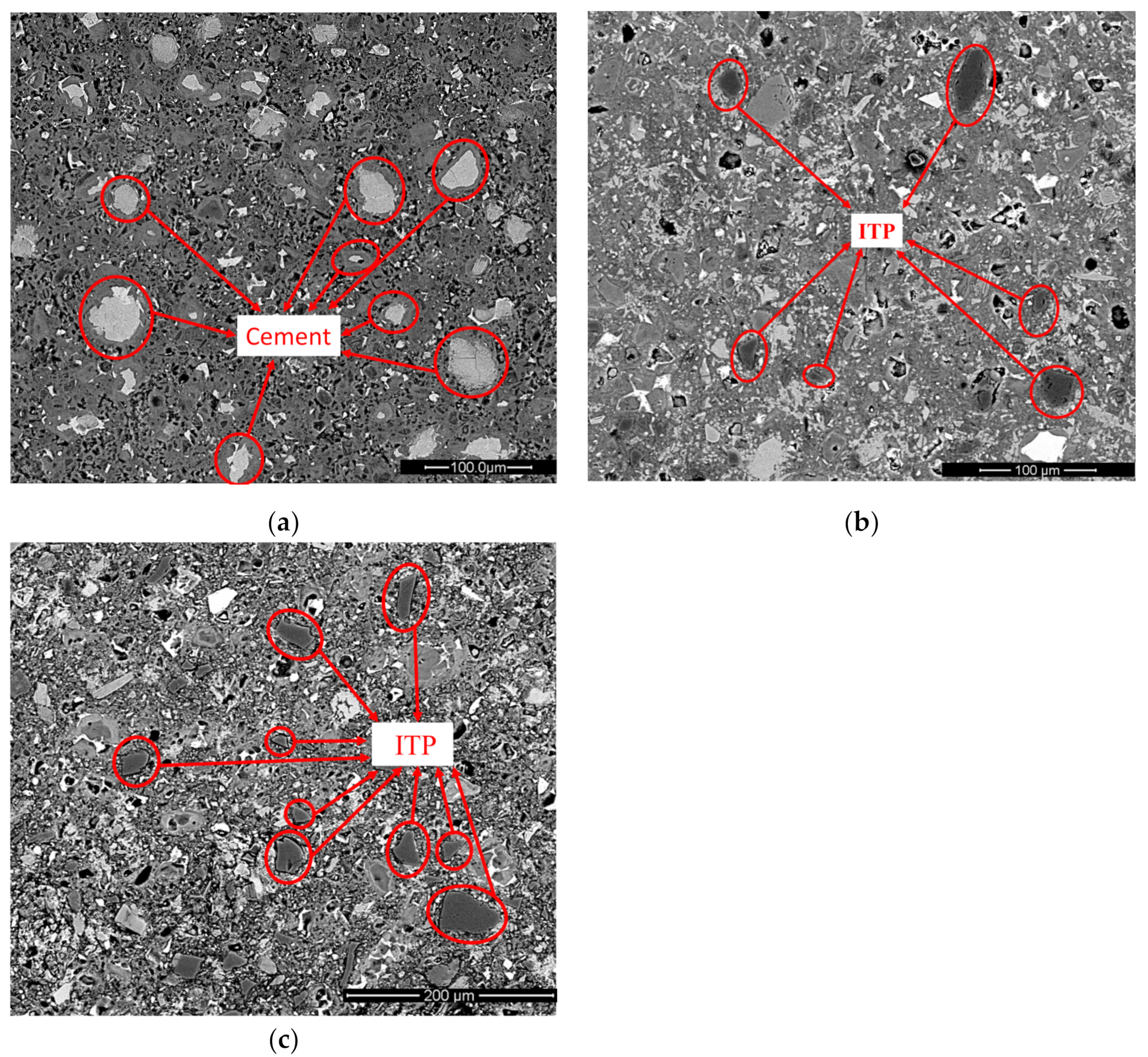

3.5. BSE Images Analysis

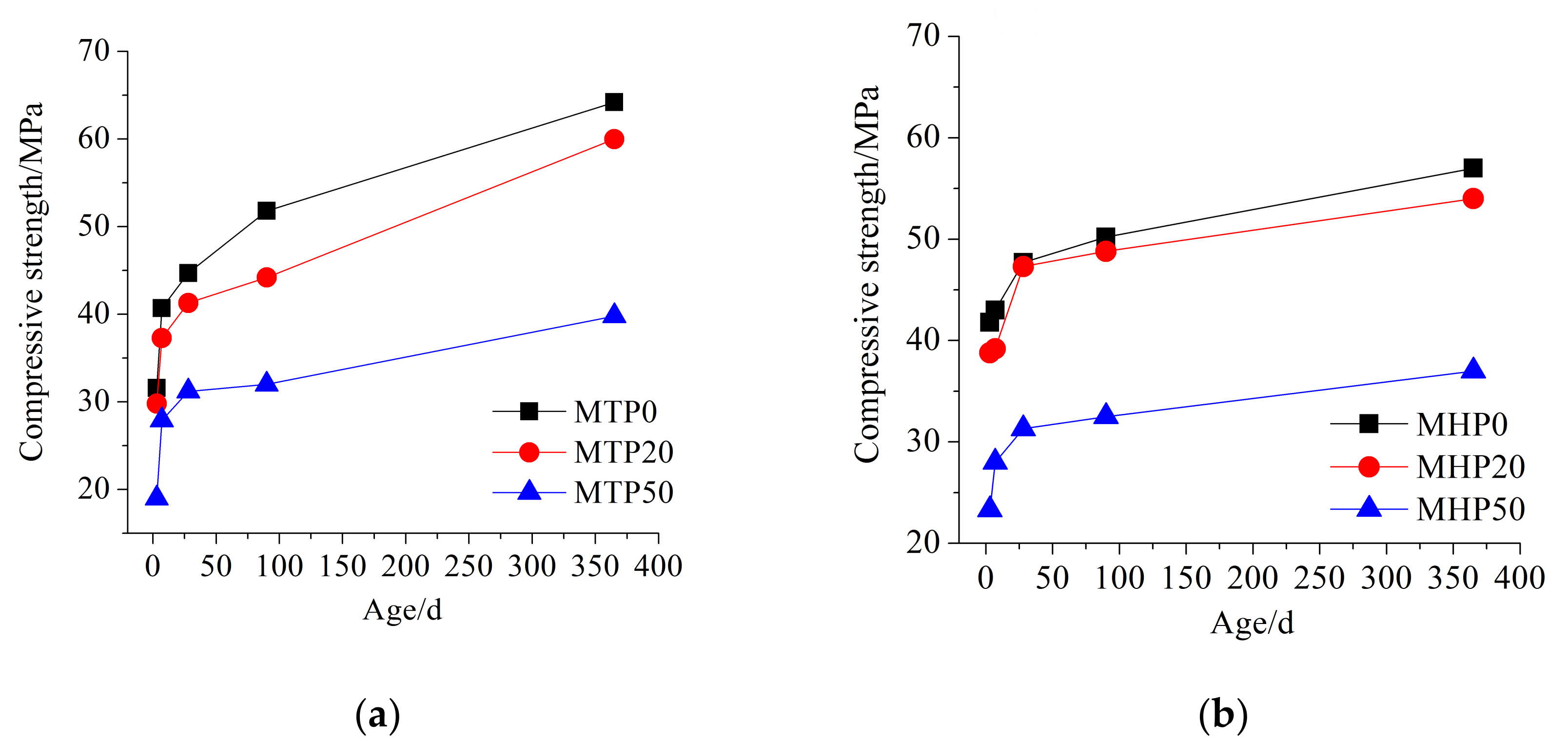

3.6. Compressive Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.S.; Ni, K.; Su, Y.P.; Shi, Y.X. An evaluation of iron ore tailings characteristics and iron ore tailings concrete properties. Constr. Build. Mater. 2021, 286, 122968. [Google Scholar] [CrossRef]

- Zhang, N.; Tang, B.W.; Liu, X.M. Cementitious activity of iron ore tailing and its utilization in cementitious materials, bricks and concrete. Constr. Build. Mater. 2021, 288, 123022. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Qiu, J.P.; Ma, Z.Y. Temperature-dependent rheological, mechanical and hydration properties of cement paste blended with iron tailing. Powder Technol. 2021, 381, 82–91. [Google Scholar] [CrossRef]

- Saedi, A.; Jameshidi-Zanjani, A.; Darban, A.K. A review on different methods of activating tailings to improve their cementitious property as cemented paste and reusability. J. Environ. Manag. 2020, 270, 110881. [Google Scholar] [CrossRef]

- Lv, X.D.; Shen, W.G.; Wang, L.; Dong, Y.; Zhang, J.F.; Xie, Z.Q. A comparative study on the practical utilization of iron tailings as a complete replacement of normal aggregates in dam concrete with different gradation. J. Clean. Prod. 2019, 211, 704–715. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Protasio, F.N.M.; de Avillez, R.R.; Letichevsky, S.; de Andrade Silva, F. The use of iron ore tailings obtained from the Germano dam in the production of a sustainable concrete. J. Clean. Prod. 2021, 278, 123929. [Google Scholar] [CrossRef]

- Zhang, W.F.; Gu, X.W.; Qiu, J.P.; Liu, J.P.; Zhao, Y.Q.; Li, X.H. Effects of iron ore tailings on the compressive strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2020, 260, 119917. [Google Scholar] [CrossRef]

- Li, T.; Wang, S.L.; Xu, F.; Meng, X.Y.; Li, B.B.; Zhan, M. Study of the basic mechanical properties and degradation mechanism of recycled concrete with tailings before and after carbonation. J. Clean. Prod. 2020, 259, 120923. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.L.; Li, T.; Liu, B.; Zhao, N.; Liu, K.N. The mechanical properties and resistance against the coupled deterioration of sulfate attack and freeze-thaw cycles of tailing recycled aggregate concrete. Constr. Build. Mater. 2021, 269, 121273. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.L.; Li, T.; Liu, B.; Li, B.B.; Zhou, Y. The mechanical properties of tailing recycled aggregate concrete and its resistance to the coupled deterioration of sulfate attack and wetting-drying cycles. Structures 2020, 27, 2208–2216. [Google Scholar] [CrossRef]

- Chen, Y.H.; Huang, F.; Li, W.C.; Liu, R.; Li, G.L.; Wei, J.M. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Constr. Build. Mater. 2016, 118, 164–170. [Google Scholar] [CrossRef]

- Yao, G.; Wang, Q.; Su, Y.W.; Wang, J.X.; Qiu, J.; Lyu, X.J. Mechanical activation as an innovative approach for the preparation of pozzolan from iron ore tailings. Min. Eng. 2020, 145, 106068. [Google Scholar] [CrossRef]

- Yao, G.; Wang, Q.; Wang, Z.M.; Wang, J.X.; Lyu, X.J. Activation of hydration properties of iron ore tailings and their application as supplementary cementitious materials in cement. Powder Technol. 2020, 360, 863–871. [Google Scholar] [CrossRef]

- Wu, C.R.; Hong, Z.Q.; Yin, Y.H.; Kou, S.C. Mechanical activated waste magnetite tailing as pozzolanic material substitute for cement in the preparation of cement products. Constr. Build. Mater. 2020, 252, 119129. [Google Scholar] [CrossRef]

- Yang, M.J.; Sun, J.H.; Dun, C.Y.; Duan, Y.J.; Meng, Z.L. Cementitious activity optimization studies of iron tailings powder as a concrete admixture. Constr. Build. Mater. 2020, 265, 120760. [Google Scholar] [CrossRef]

- Han, F.H.; Song, S.M.; Liu, J.H.; Wu, R.D. Effect of water/binder ratio and temperature on the hydration heat and properties of ternary blended cement containing slag and iron tailing powder. J. Therm. Anal. Calorim. 2021, 144, 1115–1128. [Google Scholar] [CrossRef]

- Han, F.H.; Zhou, Y.; Zhang, Z.Q. Effect of gypsum on the properties of composite binder containing high-volume slag and iron tailing powder. Constr. Build. Mater. 2020, 252, 119023. [Google Scholar] [CrossRef]

- Chen, Y.H.; Huang, F.; Qi, S.S.; Li, W.C.; Liu, R.; Li, G. Durability of concrete incorporated with siliceous iron tailings. Constr. Build. Mater. 2020, 242, 118147. [Google Scholar] [CrossRef]

- Xiong, C.S.; Li, W.H.; Jiang, L.H.; Wang, W.; Guo, Q.X. Use of grounded iron ore tailings (GIOTs) and BaCO3 to improve sulfate resistance of pastes. Constr. Build. Mater. 2017, 150, 66–76. [Google Scholar] [CrossRef]

- Han, F.H.; Luo, A.; Liu, J.H.; Zhang, Z.H. Properties of high-volume iron tailing powder concrete under different curing conditions. Constr. Build. Mater. 2020, 241, 118108. [Google Scholar] [CrossRef]

- Han, F.H.; Li, L.; Song, S.M.; Liu, J.H. Early-age hydration characteristics of composite binder containing iron tailing powder. Powder Technol. 2017, 315, 322–331. [Google Scholar] [CrossRef]

- Ramadan, M.; EI-Gamal, S.M.A.; Selim, F.A. Mechanical properties, radiation mitigation and fire resistance of OPC-recycled glass powder composites containing nanoparticles. Constr. Build. Mater. 2020, 251, 118703. [Google Scholar] [CrossRef]

- AI-Tersawy, S.H.; EI-Sadany, R.A.; Sallam, H.E.M. Long-term behavior of normal weight concrete containing hybrid nanoparticles subjected to gamma radiation. Arch. Civ. Mech. Eng. 2021, 21, 9. [Google Scholar] [CrossRef]

- Han, F.H.; Liu, J.H.; Yan, P.Y. Comparative study of reaction degree of mineral admixture by selective dissolution and image analysis. Constr. Build. Mater. 2016, 114, 946–955. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Liu, S.H.; Xie, G.S.; Wang, S. Effect of curing temperature on hydration properties of waste glass powder in cement-based materials. J. Therm. Anal. Calorim. 2015, 119, 47–55. [Google Scholar] [CrossRef]

- Han, F.H.; Liu, J.H.; Yan, P.Y. Effect of temperature on hydration of composite binder containing slag. J. Chin. Ceram. Soc. 2015, 43, 1331–1340. [Google Scholar]

- Liu, J.; Guo, R.H.; Shi, P.C.; Huang, L. Hydration mechanisms of composite binders containing copper slag at different temperatures. J. Therm. Anal. Calorim. 2019, 137, 1919–1928. [Google Scholar] [CrossRef]

- Gallucci, E.; Zhang, X.; Scrivener, K.L. Effect of temperature on the microstructure of calcium silicate hydrate (C-S-H). Cem. Concr. Res. 2013, 53, 185–195. [Google Scholar] [CrossRef]

- Metha, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties and Materials; McGraw Hill: New York, NY, USA, 2005. [Google Scholar]

- Berodier, E.; Scrivener, K. Evolution of pore structure in blended systems. Cem. Concr. Res. 2015, 73, 25–35. [Google Scholar] [CrossRef] [Green Version]

- Deschner, F.; Winnefeld, F.; Lothenbach, B.; Seufert, S.; Schwesig, P.; Dittrich, S.; Goetz-Neunhoeffer, F.; Neubauer, J. Hydration of Portland cement with high replacement by siliceous fly ash. Cem. Concr. Res. 2012, 42, 1389–1400. [Google Scholar] [CrossRef]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement: The effect of the secondary component on the hydration of Portland cement: Part I. A fine non-hydraulic filler. Cem. Concr. Res. 1990, 20, 778–782. [Google Scholar] [CrossRef]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement: The effect of the secondary component on the hydration of Portland cement: Part 2: Fine hydraulic binders. Cem. Concr. Res. 1990, 20, 853–861. [Google Scholar] [CrossRef]

- Wang, D.Q.; Wang, Q.; Huang, Z.X. New insights into the early reaction of NaOH-activated slag in the presence of CaSO4. Compos. Part B Eng. 2020, 198, 108207. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Wang, Q.; Chen, H.H. Properties of high-volume limestone powder concrete under standard curing and steam-curing conditions. Powder Technol. 2016, 301, 16–25. [Google Scholar] [CrossRef]

- Yan, P.Y.; Mi, G.D.; Wang, Q. A comparison of early hydration properties of cement-steel slag binder and cement-limestone powder binder. J. Therm. Anal. Calorim. 2014, 115, 193–200. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2Oeq | f-CaO | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 20.55 | 4.59 | 3.27 | 62.50 | 2.61 | 2.93 | 0.53 | 0.83 | 2.08 |

| ITP | 67.29 | 8.49 | 8.95 | 3.63 | 4.80 | 0.45 | 2.90 | - | 2.39 |

| Sample | Water/Binder Ratio | Early Curing Temperature | Mass Fraction (%) | |

|---|---|---|---|---|

| Cement | Iron Tailing Powder | |||

| TP0 | 0.4 | 20 °C | 100 | 0 |

| TP20 | 80 | 20 | ||

| TP50 | 50 | 50 | ||

| HP0 | 0.4 | 60 °C | 100 | 0 |

| HP20 | 80 | 20 | ||

| HP50 | 50 | 50 | ||

| Sample | w/b Ratio | Early Curing Temperature | Mass (g) | ||

|---|---|---|---|---|---|

| Cement | ITP | ISO Standard Sand | |||

| MTP0 | 0.4 | 20 °C | 450 | 0 | 1350 |

| MTP20 | 360 | 90 | |||

| MTP50 | 225 | 225 | |||

| MHP0 | 0.4 | 60 °C | 450 | 0 | 1350 |

| MHP20 | 360 | 90 | |||

| MHP50 | 225 | 225 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Han, F.; Pu, S.; Zhang, H. Properties of Blended Cement Containing Iron Tailing Powder at Different Curing Temperatures. Materials 2022, 15, 693. https://doi.org/10.3390/ma15020693

Wang H, Han F, Pu S, Zhang H. Properties of Blended Cement Containing Iron Tailing Powder at Different Curing Temperatures. Materials. 2022; 15(2):693. https://doi.org/10.3390/ma15020693

Chicago/Turabian StyleWang, Heng, Fanghui Han, Shaochang Pu, and Hongbo Zhang. 2022. "Properties of Blended Cement Containing Iron Tailing Powder at Different Curing Temperatures" Materials 15, no. 2: 693. https://doi.org/10.3390/ma15020693

APA StyleWang, H., Han, F., Pu, S., & Zhang, H. (2022). Properties of Blended Cement Containing Iron Tailing Powder at Different Curing Temperatures. Materials, 15(2), 693. https://doi.org/10.3390/ma15020693