Synthesis of P-/N-Containing Bamboo-Activated Carbon toward Enhanced Thermal Stability and Flame Retardancy of Polylactic Acid

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Sample Preparation

2.2.1. Synthesis of P-/N-Grafted Bamboo-Activated Carbon

2.2.2. Preparation of PLA Composite

2.3. Measurements and Characterizations

2.3.1. BAC Characterization

2.3.2. Mechanical Properties

2.3.3. Thermal Performance

2.3.4. Combustion Performance

2.3.5. Residue Carbon Analysis

3. Results and Discussion

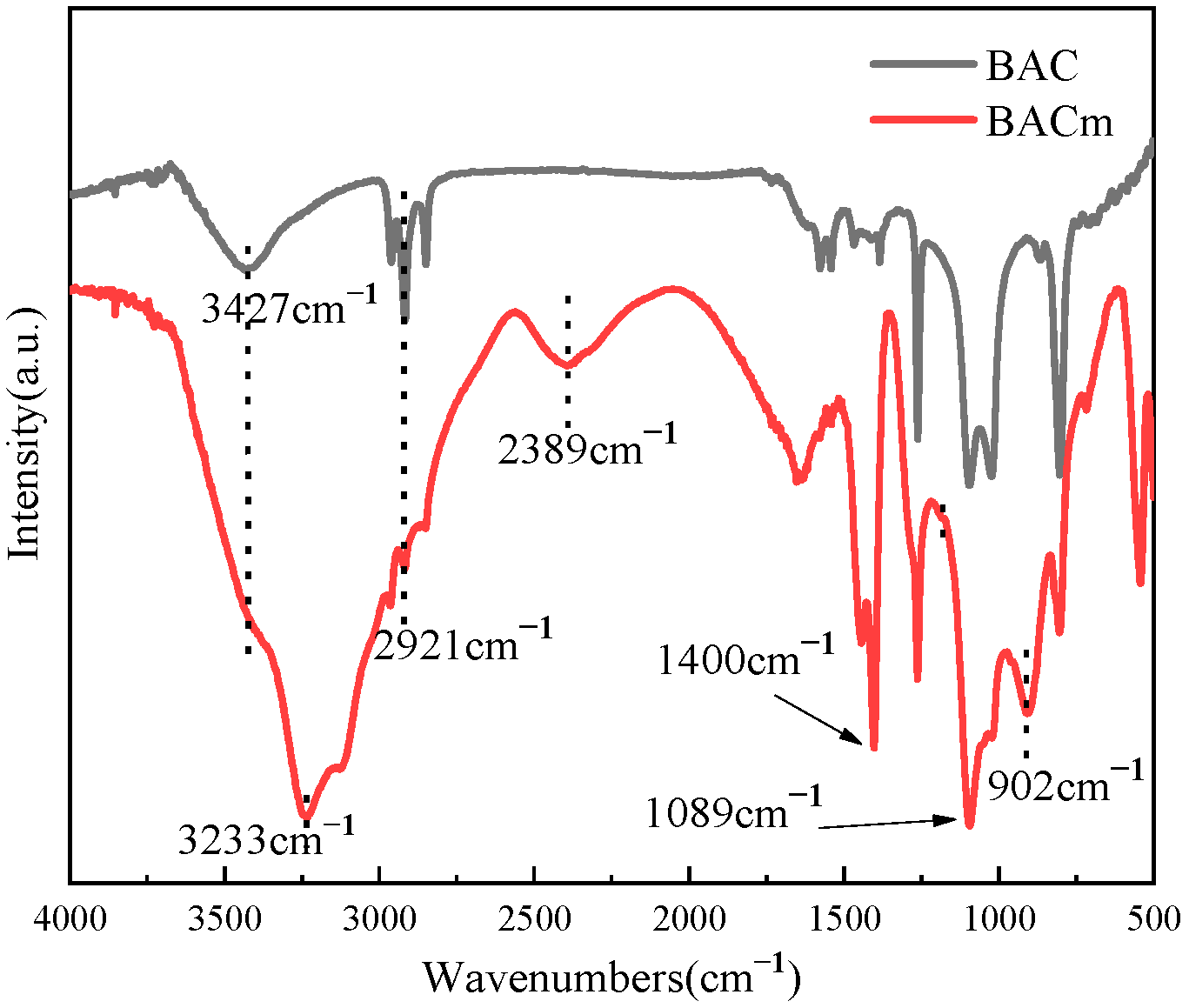

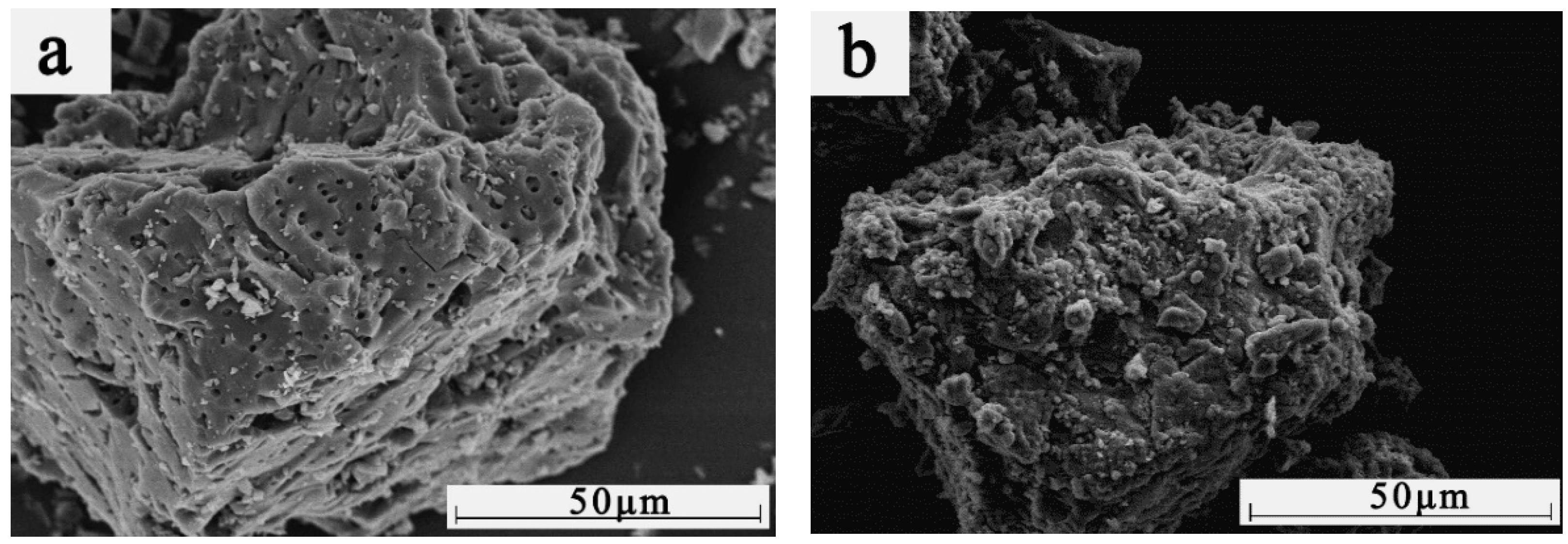

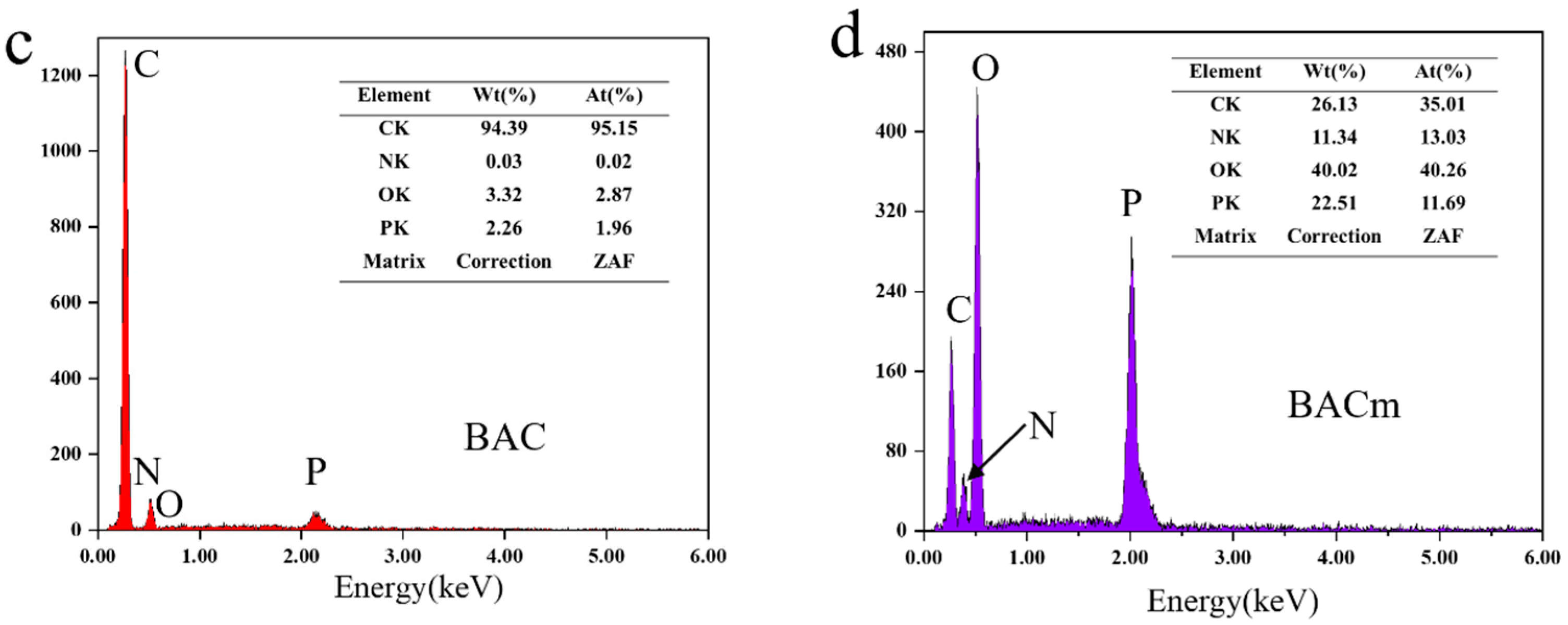

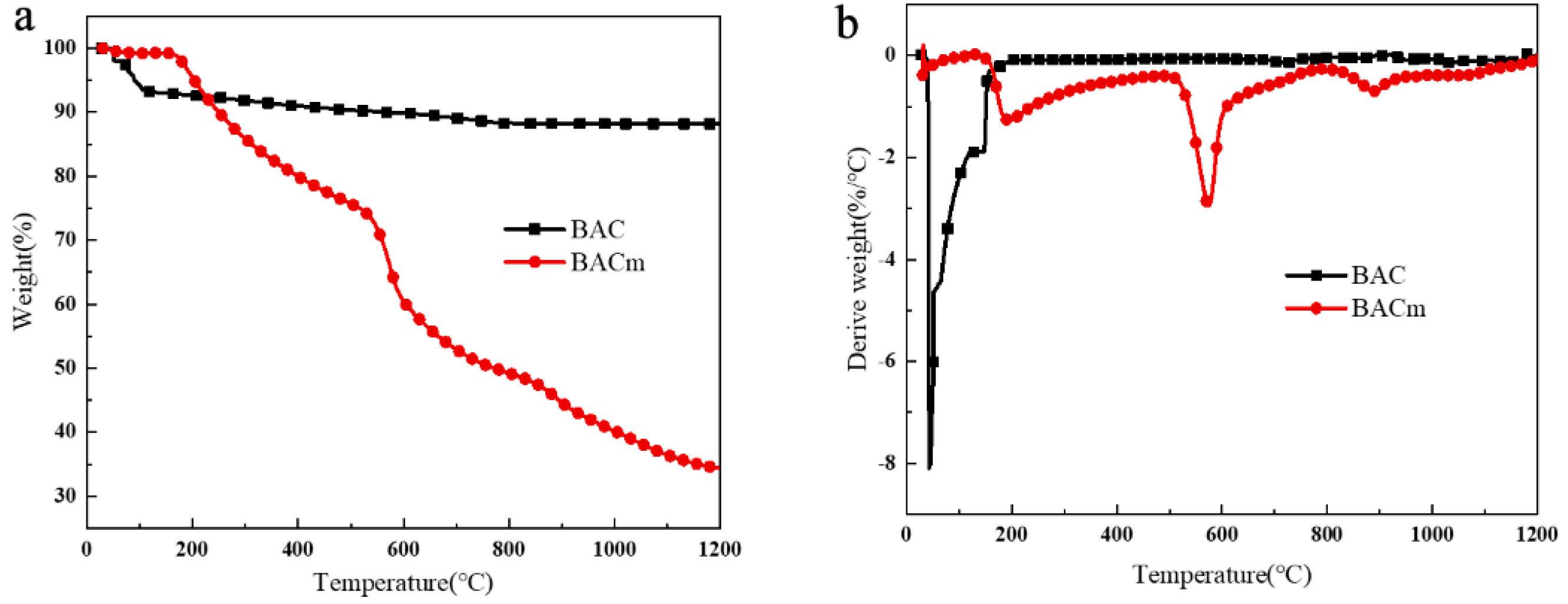

3.1. Characterization of BAC and BACm

3.2. Mechanical Properties

3.3. Combustion Performance

3.3.1. LOI and UL94 Measurements

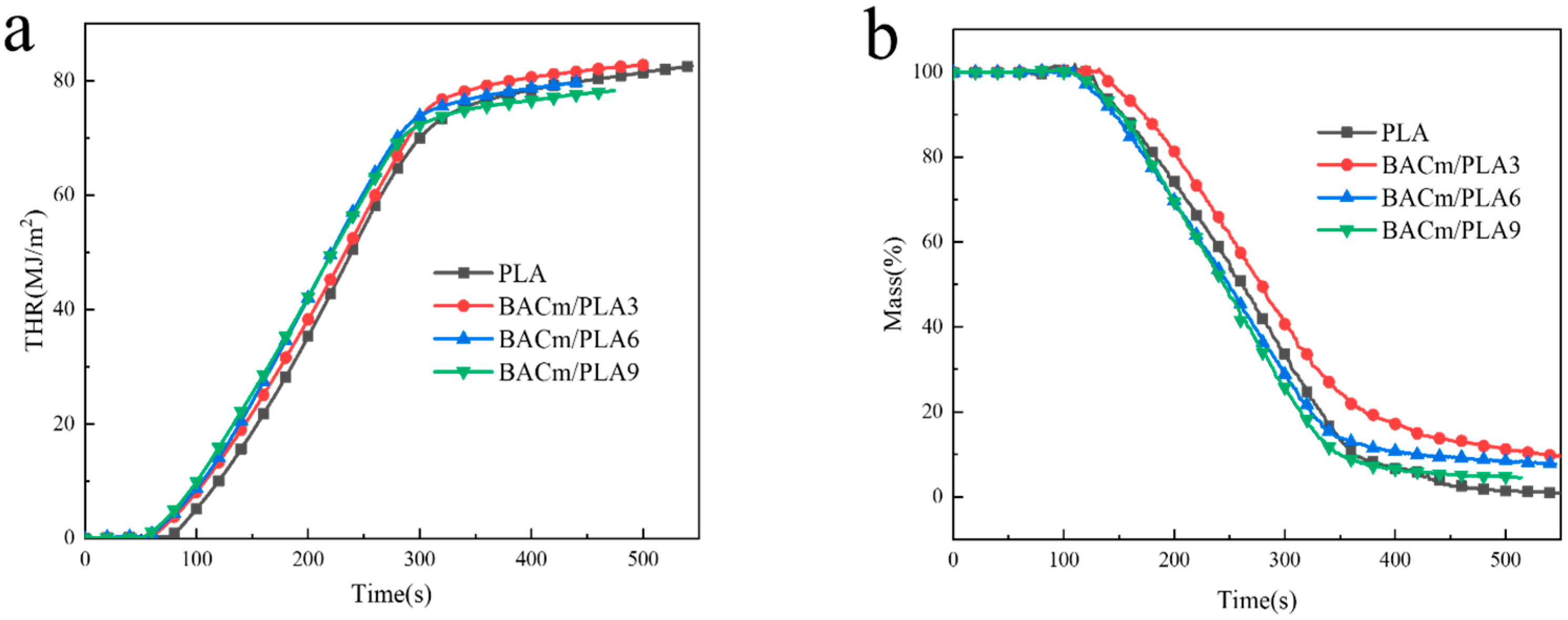

3.3.2. Cone Measurement

3.4. Thermal Stability

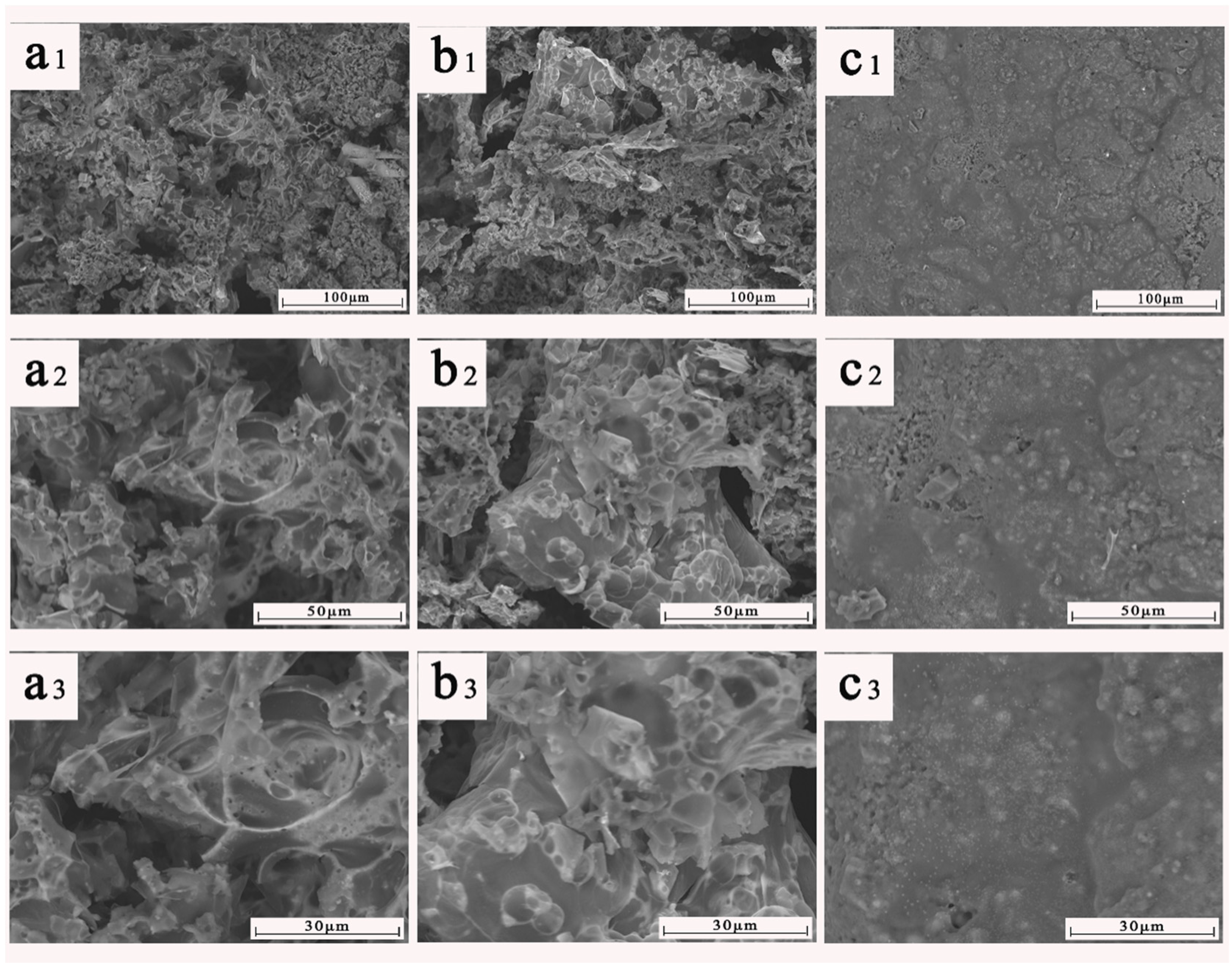

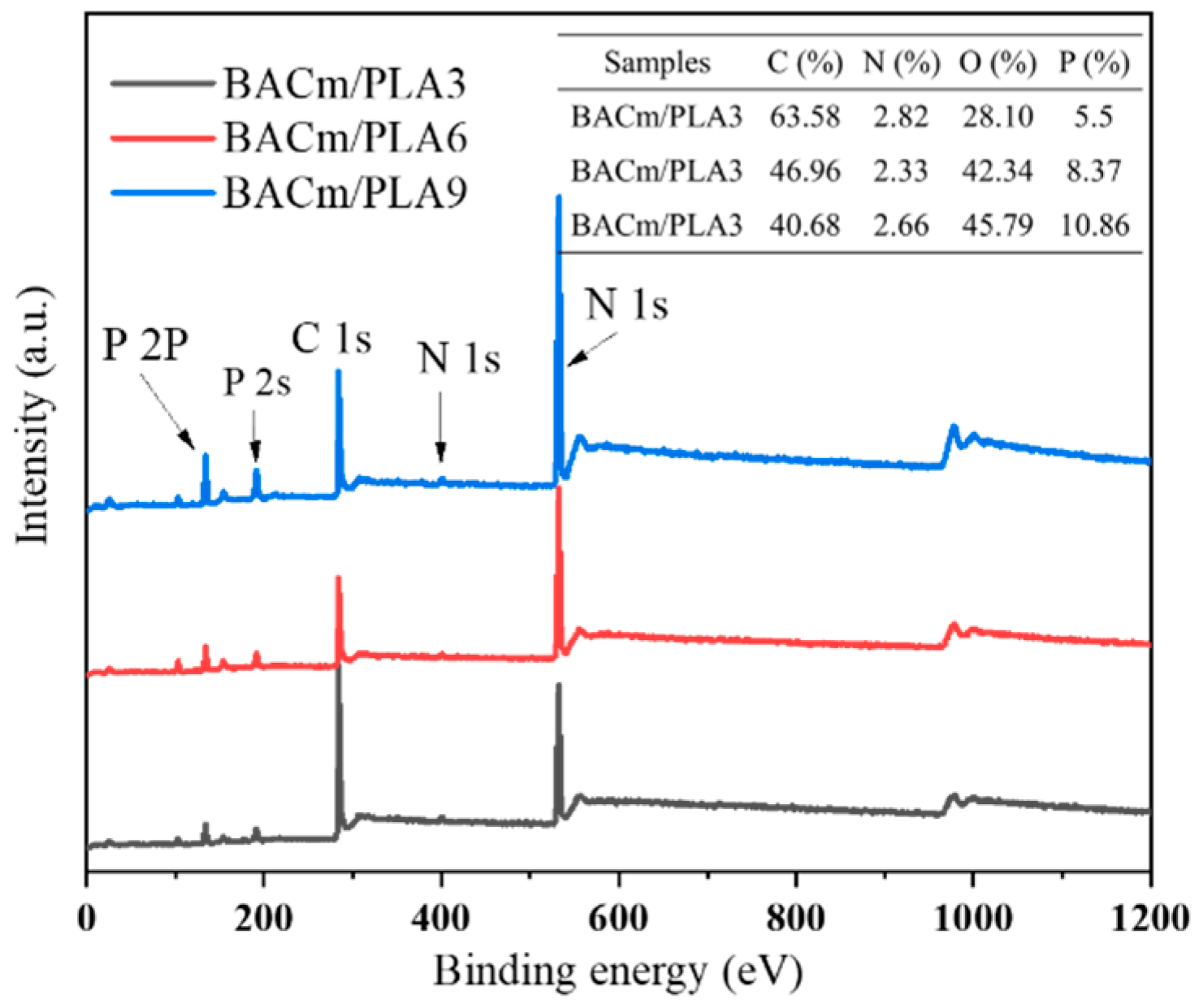

3.5. Residual Carbon Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Müller, C.; Townsend, K.; Matschullat, J. Experimental degradation of polymer shopping bags (standard and degradable plastic, and biodegradable) in the gastrointestinal fluids of sea turtles. Sci. Total Environ. 2012, 416, 464–467. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, G.; Uchida, N.; Tanaka, K.; Matsukami, H.; Kunisue, T.; Takahashi, S.; Viet, P.H.; Kuramochi, H.; Osako, M. Mechanical recycling of plastic waste as a point source of microplastic pollution. Environ. Pollut. 2022, 303, 119114. [Google Scholar] [CrossRef]

- Zhou, X.; Li, J.; Wu, Y. Synergistic effect of aluminum hypophosphite and intumescent flame retardants in polylactide. Polym. Adv. Technol. 2015, 26, 255–265. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.; Chai, W.; Yin, N.; Semple, K.; Li, L.; Zhang, W.; Dai, C. Enhancement of flame retardancy and mechanical properties of polylactic acid with a biodegradable fire-retardant filler system based on bamboo charcoal. Polymers 2021, 13, 2167. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, Y.; Qi, Y.; Wang, H.; Liu, B.; Zhao, Q.; Zhang, J.; Duan, J.; Zhang, L.; Sun, Z. Improved mechanical properties and flame retardancy of wood/PLA all-degradable biocomposites with novel lignin-based flame retardant and TGIC. Macromol. Mater. Eng. 2020, 305, 1900840. [Google Scholar] [CrossRef]

- Yi, L.; Luo, S.; Shen, J.; Guo, S.; Sue, H.-J. Bioinspired polylactide based on the multilayer assembly of shish-kebab structure: A strategy for achieving balanced performances. ACS Sustain. Chem. Eng. 2017, 5, 3063–3073. [Google Scholar] [CrossRef]

- Jia, Y.-W.; Zhao, X.; Fu, T.; Li, D.-F.; Guo, Y.; Wang, X.-L.; Wang, Y.-Z. Synergy effect between quaternary phosphonium ionic liquid and ammonium polyphosphate toward flame retardant PLA with improved toughness. Compos. Part B Eng. 2020, 197, 108192. [Google Scholar] [CrossRef]

- Bourbigot, S.; Fontaine, G. Flame retardancy of polylactide: An overview. Polym. Chem. 2010, 1, 1413–1422. [Google Scholar] [CrossRef]

- Shabanian, M.; Kang, N.-J.; Wang, D.-Y.; Wagenknecht, U.; Heinrich, G. Synthesis of aromatic–aliphatic polyamide acting as adjuvant in polylactic acid (PLA)/ammonium polyphosphate (APP) system. Polym. Degrad. Stab. 2013, 98, 1036–1042. [Google Scholar] [CrossRef]

- Kiuchi, Y.; Iji, M.; Yanagisawa, T.; Shukichi, T. Flame-retarding polylactic-acid composite formed by dual use of aluminum hydroxide and phenol resin. Polym. Degrad. Stab. 2014, 109, 336–342. [Google Scholar] [CrossRef]

- Sun, Q.; Ding, Y.; Stoliarov, S.I.; Sun, J.; Fontaine, G.; Bourbigot, S. Development of a pyrolysis model for an intumescent flame retardant system: Poly (lactic acid) blended with melamine and ammonium polyphosphate. Compos. Part B Eng. 2020, 194, 108055. [Google Scholar] [CrossRef]

- Arslan, F.; Dilsiz, N. Flame resistant properties of LDPE/PLA blends containing halogen-free flame retardant. J. Appl. Polym. Sci. 2020, 137, 48960. [Google Scholar] [CrossRef]

- Reti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2008, 19, 628–635. [Google Scholar] [CrossRef]

- Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Fierro, V.; Celzard, A. PLA with intumescent system containing lignin and ammonium polyphosphate for flame retardant textile. Polymers 2016, 8, 331. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zeng, J.; Liu, W.; Qiu, X.; Qian, Y.; Zhang, H.; Yang, Y.; Liu, M.; Yang, D. Pristine lignin as a flame retardant in flexible PU foam. Green Chem. 2021, 23, 5972–5980. [Google Scholar] [CrossRef]

- Maqsood, M.; Seide, G. Improved thermal processing of polylactic acid/oxidized starch composites and flame-retardant behavior of intumescent non-wovens. Coatings 2020, 10, 291. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, H.; Duan, R.; Zhang, K.; Meng, W.; Li, Y.; Qu, H. Graphene doped Sn flame retardant prepared by ball milling and synergistic with hexaphenoxy cyclotriphosphazene for epoxy resin. J. Mater. Res. Technol. 2022, 17, 774–788. [Google Scholar] [CrossRef]

- Tomiak, F.; Rathberger, K.; Schöffel, A.; Drummer, D. Expandable Graphite for Flame Retardant PA6 Applications. Polymers 2021, 13, 2733. [Google Scholar] [CrossRef]

- Santos, L.P.; da Silva, D.S.; Morari, T.H.; Galembeck, F. Environmentally Friendly, High-Performance Fire Retardant Made from Cellulose and Graphite. Polymers 2021, 13, 2400. [Google Scholar] [CrossRef]

- Cao, X.; Chi, X.; Deng, X.; Sun, Q.; Gong, X.; Yu, B.; Yuen, A.C.Y.; Wu, W.; Li, R.K.Y. Facile synthesis of phosphorus and cobalt co-doped graphitic carbon nitride for fire and smoke suppressions of polylactide composite. Polymers 2020, 12, 1106. [Google Scholar] [CrossRef]

- Gao, M.; Li, J.; Zhou, X. A flame retardant rigid polyurethane foam system including functionalized graphene oxide. Polym. Compos. 2019, 40, E1274–E1282. [Google Scholar] [CrossRef]

- Wu, W.; Xu, Y.; Wu, H.; Chen, J.; Li, M.; Chen, T.; Hong, J.; Dai, L. Synthesis of modified graphene oxide and its improvement on flame retardancy of epoxy resin. J. Appl. Polym. Sci. 2020, 137, 47710. [Google Scholar] [CrossRef]

- Ming, G.; Li, J.; Zhang, X.; Yue, L.; Chai, Z. The flame retardancy of epoxy resin including the modified graphene oxide and ammonium polyphosphate. Combust. Sci. Technol. 2018, 190, 1126–1140. [Google Scholar] [CrossRef]

- Wang, J. Synthesis and characterization of flame-retardant-wrapped carbon nanotubes and its flame retardancy in epoxy nanocomposites. Polym. Polym. Compos. 2021, 29, S835–S843. [Google Scholar] [CrossRef]

- Kong, Q.; Wu, T.; Tang, Y.; Xiong, L.; Liu, H.; Zhang, J.; Guo, R.; Zhang, F. Improving thermal and flame retardant properties of epoxy resin with organic NiFe-layered double hydroxide-carbon nanotubes hybrids. Chin. J. Chem. 2017, 35, 1875–1880. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, W.; Gong, X.; Sun, Q.; Cao, X.; Su, Y.; Yu, B.; Li, R.K.; Vellaisamy, R.A. Surface decoration of halloysite nanotubes with POSS for fire-safe thermoplastic polyurethane nanocomposites. J. Mater. Sci. Technol. 2022, 101, 107–117. [Google Scholar] [CrossRef]

- Li, S.; Wang, H.; Chen, C.; Li, X.; Deng, Q.; Li, D. Mechanical, electrical, and thermal properties of highly filled bamboo charcoal/ultra-high molecular weight polyethylene composites. Polym. Compos. 2018, 39, E1858–E1866. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly (lactic acid) biocomposites reinforced with ultrafine bamboo-char: Morphology, mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2016, 133, 23425. [Google Scholar] [CrossRef]

- Sheng, K.; Zhang, S.; Qian, S.; Lopez, C.A.F. High-toughness PLA/Bamboo cellulose nanowhiskers bionanocomposite strengthened with silylated ultrafine bamboo-char. Compos. Part B Eng. 2019, 165, 174–182. [Google Scholar] [CrossRef]

- Kumar, S.V.; Subramanian, J.; Giridharan, A.; Gupta, M.; Adhikari, A.; Gayen, M. Processing and characterization of organic PU foam reinforced with nano particles. Mater. Today Proc. 2021, 46, 1077–1084. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Semple, K.; Zhang, M.; Zhang, W.; Dai, C. Development of biodegradable flame-retardant bamboo charcoal composites, Part I: Thermal and elemental analyses. Polymers 2020, 12, 2217. [Google Scholar] [CrossRef]

- Zhang, L.; Chai, W.; Li, W.; Semple, K.; Yin, N.; Zhang, W.; Dai, C. Intumescent-grafted bamboo charcoal: A natural nontoxic fire-retardant filler for polylactic acid (PLA) composites. ACS Omega 2021, 6, 26990–27006. [Google Scholar] [CrossRef]

- Pamphile, N.; Xuejiao, L.; Guangwei, Y.; Yin, W. Synthesis of a novel core-shell-structure activated carbon material and its application in sulfamethoxazole adsorption. J. Hazard. Mater. 2019, 368, 602–612. [Google Scholar] [CrossRef] [PubMed]

- Patra, C.; Gupta, R.; Bedadeep, D.; Narayanasamy, S. Surface treated acid-activated carbon for adsorption of anionic azo dyes from single and binary adsorptive systems: A detail insight. Environ. Pollut. 2020, 266, 115102. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.; Tian, N.; Liu, J.; Yao, K.; Jiang, Z.; Chen, X.; Wen, X.; Mijowska, E.; Tang, T. Synergistic effect of activated carbon and Ni2O3 in promoting the thermal stability and flame retardancy of polypropylene. Polym. Degrad. Stab. 2014, 99, 18–26. [Google Scholar] [CrossRef]

- Wen, X.; Gong, J.; Yu, H.; Liu, Z.; Wan, D.; Liu, J.; Jiang, Z.; Tang, T. Catalyzing carbonization of poly (L-lactide) by nanosized carbon black combined with Ni2O3 for improving flame retardancy. J. Mater. Chem. 2012, 22, 19974–19980. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, W.; He, S.; Wang, X.; Jiao, Y.; Qu, H.; Xu, J. Synergistic flame retardant effects of activated carbon and molybdenum oxide in poly (vinyl chloride). Polym. Int. 2018, 67, 445–452. [Google Scholar] [CrossRef]

- Song, X.-Y.; Wang, M.; Weng, Y.-X.; Huang, Z.-G. Effect of bamboo flour grafted lactide on the interfacial compatibility of polylactic acid/bamboo flour composites. Polymers 2017, 9, 323. [Google Scholar] [CrossRef]

- Shao, Z.-B.; Deng, C.; Tan, Y.; Yu, L.; Chen, M.-J.; Chen, L.; Wang, Y.-Z. Ammonium polyphosphate chemically-modified with ethanolamine as an efficient intumescent flame retardant for polypropylene. J. Mater. Chem. A 2014, 2, 13955–13965. [Google Scholar] [CrossRef]

- Ni, J.; Chen, L.; Zhao, K.; Hu, Y.; Song, L. Preparation of gel-silica/ammonium polyphosphate core-shell flame retardant and properties of polyurethane composites. Polym. Adv. Technol. 2011, 22, 1824–1831. [Google Scholar] [CrossRef]

- Takagi, H.; Maruyama, K.; Yoshizawa, N.; Yamada, Y.; Sato, Y. XRD analysis of carbon stacking structure in coal during heat treatment. Fuel 2004, 83, 2427–2433. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, B.; Yuan, S.; Wu, X.; Chen, J.; Wang, L. Adsorptive removal of chloramphenicol from wastewater by NaOH modified bamboo charcoal. Bioresour. Technol. 2010, 101, 7661–7664. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.; Qu, D.; Yang, D.; Nie, B.; Zhao, Y.; Fan, H.; Sun, Z. Synthesis of carbon dots with multiple color emission by controlled graphitization and surface functionalization. Adv. Mater. 2018, 30, 1704740. [Google Scholar] [CrossRef]

- Tang, C.-M.; Tian, Y.-H.; Hsu, S.-H. Poly (vinyl alcohol) nanocomposites reinforced with bamboo charcoal nanoparticles: Mineralization behavior and characterization. Materials 2015, 8, 4895–4911. [Google Scholar] [CrossRef]

- Song, M.; Jin, B.; Xiao, R.; Yang, L.; Wu, Y.; Zhong, Z.; Huang, Y. The comparison of two activation techniques to prepare activated carbon from corn cob. Biomass Bioenergy 2013, 48, 250–256. [Google Scholar] [CrossRef]

- Yu, K.; Zhu, H.; Qi, H.; Liang, C. High surface area carbon materials derived from corn stalk core as electrode for supercapacitor. Diam. Relat. Mater. 2018, 88, 18–22. [Google Scholar] [CrossRef]

- Lin, H.; Yan, H.; Liu, B.; Wei, L.; Xu, B. The influence of KH-550 on properties of ammonium polyphosphate and polypropylene flame retardant composites. Polym. Degrad. Stab. 2011, 96, 1382–1388. [Google Scholar] [CrossRef]

- Liu, G.; Liu, X.; Yu, J. Ammonium polyphosphate with crystalline form V by ammonium dihydrogen phosphate process. Ind. Eng. Chem. Res. 2010, 49, 5523–5529. [Google Scholar] [CrossRef]

- Xu, B.-R.; Deng, C.; Li, Y.-M.; Lu, P.; Zhao, P.-P.; Wang, Y.-Z. Novel amino glycerin decorated ammonium polyphosphate for the highly-efficient intumescent flame retardance of wood flour/polypropylene composite via simultaneous interfacial and bulk charring. Compos. Part B Eng. 2019, 172, 636–648. [Google Scholar] [CrossRef]

- Wen, P.; Wang, X.; Xing, W.; Feng, X.; Yu, B.; Shi, Y.; Tang, G.; Song, L.; Hu, Y.; Yuen, R.K. Synthesis of a novel triazine-based hyperbranched char foaming agent and the study of its enhancement on flame retardancy and thermal stability of polypropylene. Ind. Eng. Chem. Res. 2013, 52, 17015–17022. [Google Scholar] [CrossRef]

- Jing, J.; Zhang, Y.; Tang, X.; Zhou, Y.; Li, X.; Kandola, B.K.; Fang, Z. Layer by layer deposition of polyethylenimine and bio-based polyphosphate on ammonium polyphosphate: A novel hybrid for simultaneously improving the flame retardancy and toughness of polylactic acid. Polymer 2017, 108, 361–371. [Google Scholar] [CrossRef]

- Tang, G.; Wang, X.; Xing, W.; Zhang, P.; Wang, B.; Hong, N.; Yang, W.; Hu, Y.; Song, L. Thermal degradation and flame retardance of biobased polylactide composites based on aluminum hypophosphite. Ind. Eng. Chem. Res. 2012, 51, 12009–12016. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.-M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Liu, T.; Jing, J.; Zhang, Y.; Fang, Z. Synthesis of a novel polyphosphate and its application with APP in flame retardant PLA. RSC Adv. 2018, 8, 4483–4493. [Google Scholar] [CrossRef]

- Xu, B.; Ma, W.; Shao, L.; Qian, L.; Qiu, Y. Enhancement of an organic–metallic hybrid charring agent on flame retardancy of ethylene-vinyl acetate copolymer. R. Soc. Open Sci. 2019, 6, 181413. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Semple, K.; Zhang, M.; Zhang, W.; Dai, C. Development of biodegradable flame-retardant bamboo charcoal composites, Part II: Thermal degradation, gas phase, and elemental analyses. Polymers 2020, 12, 2238. [Google Scholar] [CrossRef]

| Sample | Ingredients (wt.%) | ||

|---|---|---|---|

| PLA | BAC | BACm | |

| Neat PLA | 100.0 | 0 | 0 |

| BAC/PLA3 | 97.0 | 3.0 | 0 |

| BAC/PLA6 | 94.0 | 6.0 | 0 |

| BAC/PLA9 | 91.0 | 9.0 | 0 |

| BACm/PLA3 | 97.0 | 0 | 3.0 |

| BACm/PLA6 | 94.0 | 0 | 6.0 |

| BACm/PLA9 | 91.0 | 0 | 9.0 |

| Sample | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|

| Neat PLA | 75.19 ± 2.64 | 602.49 ± 128.7 | 104.51 ± 2.22 | 2.3 ± 0.91 |

| BAC/PLA3 | 58.98 ± 4.52 | 549.25 ± 94.28 | 87.5 ± 2.86 | 3.32 ± 0.52 |

| BAC/PLA6 | 71.04 ± 1.32 | 579.17 ± 108.38 | 98.18 ± 2.69 | 3.63 ± 0.27 |

| BAC/PLA9 | 67.78 ± 2.74 | 525.04 ± 101.47 | 93.12 ± 6.56 | 2.79 ± 0.57 |

| BACm/PLA3 | 67.48 ± 2.25 | 498.93 ± 135.07 | 93.77 ± 4.80 | 2.56 ± 0.81 |

| BACm/PLA6 | 63.75 ± 1.75 | 422.37 ± 94.14 | 99.53 ± 0.93 | 2.29 ± 0.78 |

| BACm/PLA9 | 61.3 ± 1.2 | 375.56 ± 112.1 | 90.76 ± 6.04 | 1.82 ± 0.14 |

| Samples | LOI (%) | UL-94 | |

|---|---|---|---|

| Dripping | Rating | ||

| Neat PLA | 20.1 | Yes | NR |

| BAC/PLA3 | 20.9 | Yes | NR |

| BAC/PLA6 | 21.6 | Yes | NR |

| BAC/PLA9 | 23.1 | Yes | V-2 |

| BACm/PLA3 | 28.0 | Yes | V-2 |

| BACm/PLA6 | 30.8 | Yes | V-2 |

| BACm/PLA9 | 31.7 | No | V-0 |

| Sample | TTI (s) | THR (MJ/m2) | pHRR (kW/m2) | pMLR (g/s) | RM (%) |

|---|---|---|---|---|---|

| Neat PLA | 67 | 82.63 | 402.29 | 0.59 | 0.92% |

| BACm/PLA3 | 47 | 82.78 | 386.29 | 0.63 | 4.56% |

| BACm/PLA6 | 45 | 79.76 | 390.45 | 0.68 | 7.74% |

| BACm/PLA9 | 42 | 78.26 | 366.16 | 0.45 | 7.99% |

| Sample | T5% (°C) | Tmax (°C) | Carbon Residue Rate (wt.%) | ||

|---|---|---|---|---|---|

| 400 (°C) | 600 (°C) | 800 (°C) | |||

| Neat PLA | 334 | 363 | 2.28 | 1.63 | 1.35 |

| BAC | 90 | 45 | 90.97 | 89.85 | 88.28 |

| BACm | 203 | 574 | 79.98 | 60.49 | 49.25 |

| BAC/PLA3 | 332 | 367 | 2.88 | 2.36 | 1.78 |

| BAC/PLA6 | 313 | 368 | 4.01 | 3.16 | 1.81 |

| BAC/PLA9 | 328 | 358 | 7.62 | 4.66 | 2.13 |

| BACm/PLA3 | 329 | 364 | 5.77 | 5.15 | 4.44 |

| BACm/PLA6 | 324 | 357 | 8.71 | 7.41 | 6.42 |

| BACm/PLA9 | 323 | 363 | 10.59 | 9.78 | 8.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, N.; Zhong, J.; Tian, H.; Zhou, Z.; Ying, W.; Dai, J.; Li, W.; Zhang, W. Synthesis of P-/N-Containing Bamboo-Activated Carbon toward Enhanced Thermal Stability and Flame Retardancy of Polylactic Acid. Materials 2022, 15, 6802. https://doi.org/10.3390/ma15196802

Yin N, Zhong J, Tian H, Zhou Z, Ying W, Dai J, Li W, Zhang W. Synthesis of P-/N-Containing Bamboo-Activated Carbon toward Enhanced Thermal Stability and Flame Retardancy of Polylactic Acid. Materials. 2022; 15(19):6802. https://doi.org/10.3390/ma15196802

Chicago/Turabian StyleYin, Ningning, Jinhuan Zhong, Huayu Tian, Zenan Zhou, Weijun Ying, Jinfeng Dai, Wenzhu Li, and Wenbiao Zhang. 2022. "Synthesis of P-/N-Containing Bamboo-Activated Carbon toward Enhanced Thermal Stability and Flame Retardancy of Polylactic Acid" Materials 15, no. 19: 6802. https://doi.org/10.3390/ma15196802

APA StyleYin, N., Zhong, J., Tian, H., Zhou, Z., Ying, W., Dai, J., Li, W., & Zhang, W. (2022). Synthesis of P-/N-Containing Bamboo-Activated Carbon toward Enhanced Thermal Stability and Flame Retardancy of Polylactic Acid. Materials, 15(19), 6802. https://doi.org/10.3390/ma15196802