Effects of Capsule Type on the Characteristics of Cement Mortars Containing Powder Compacted Capsules

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing Process of PCCs

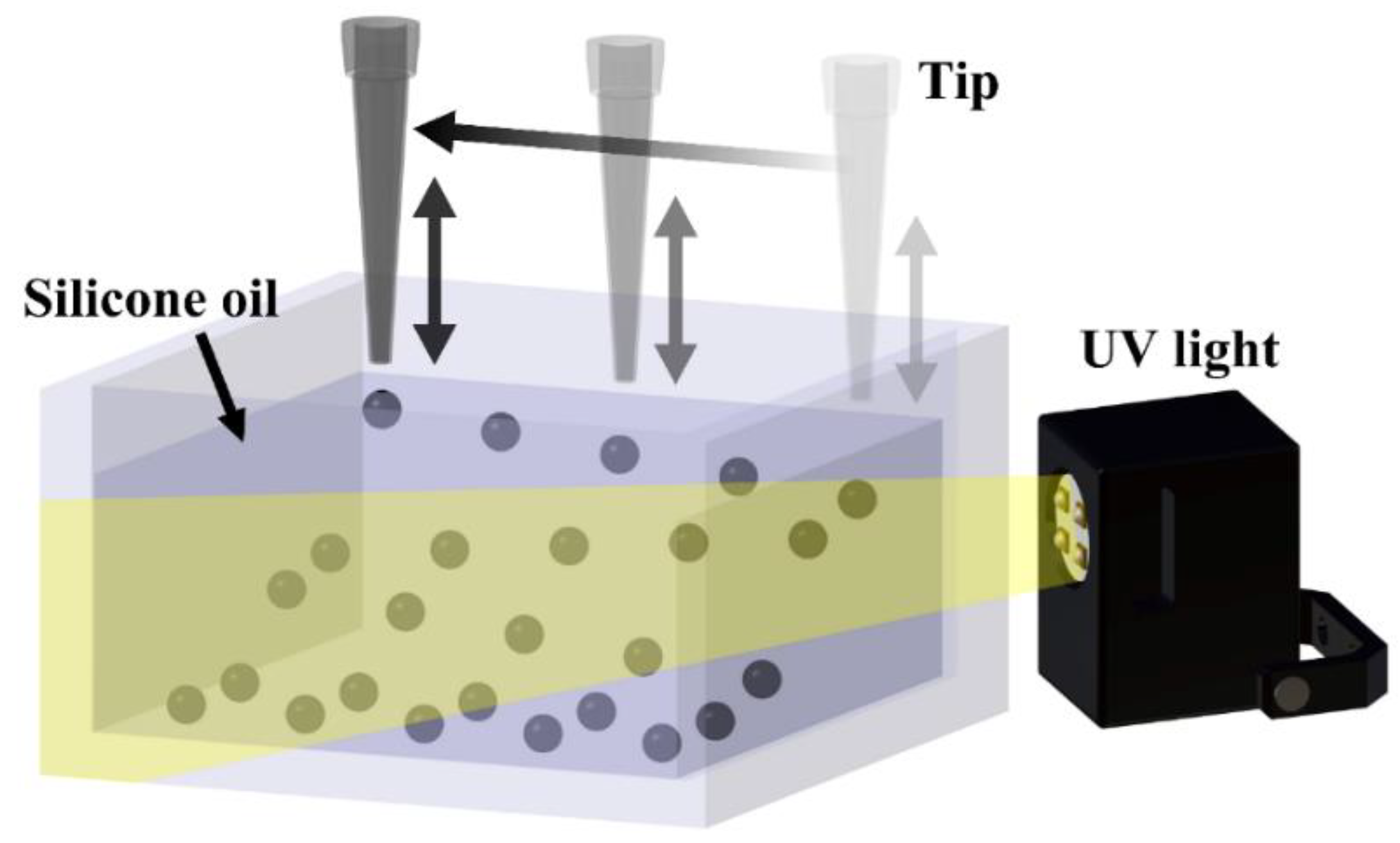

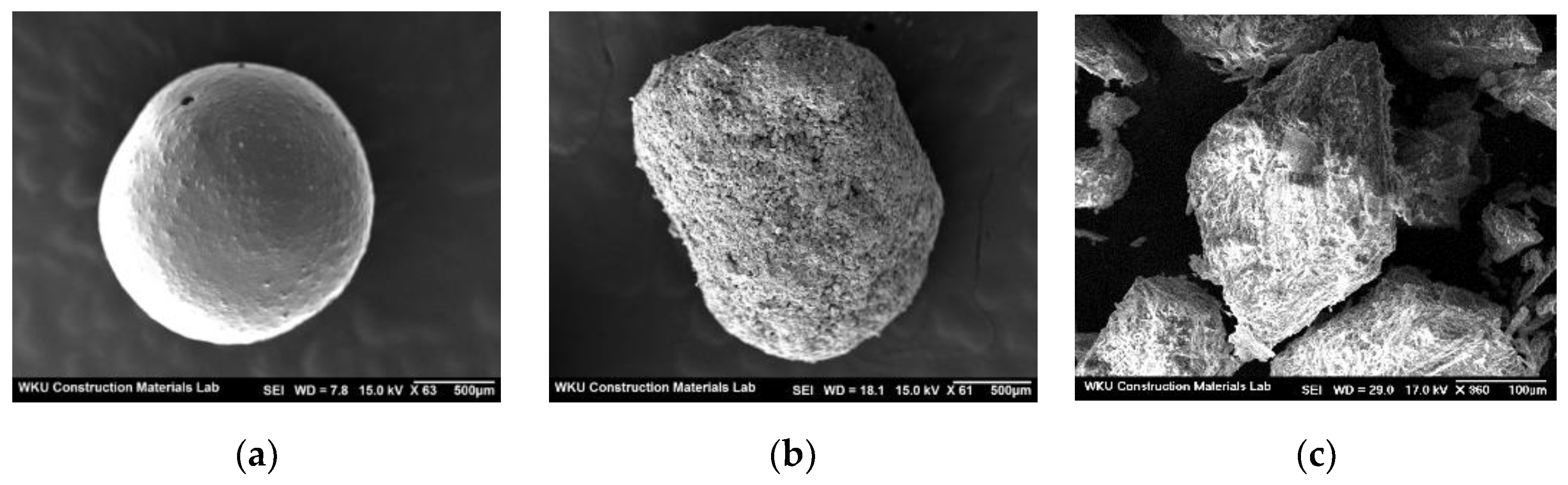

2.2.1. Droplet-PCC (D-PCC)

2.2.2. Blended-PCC (B-PCC)

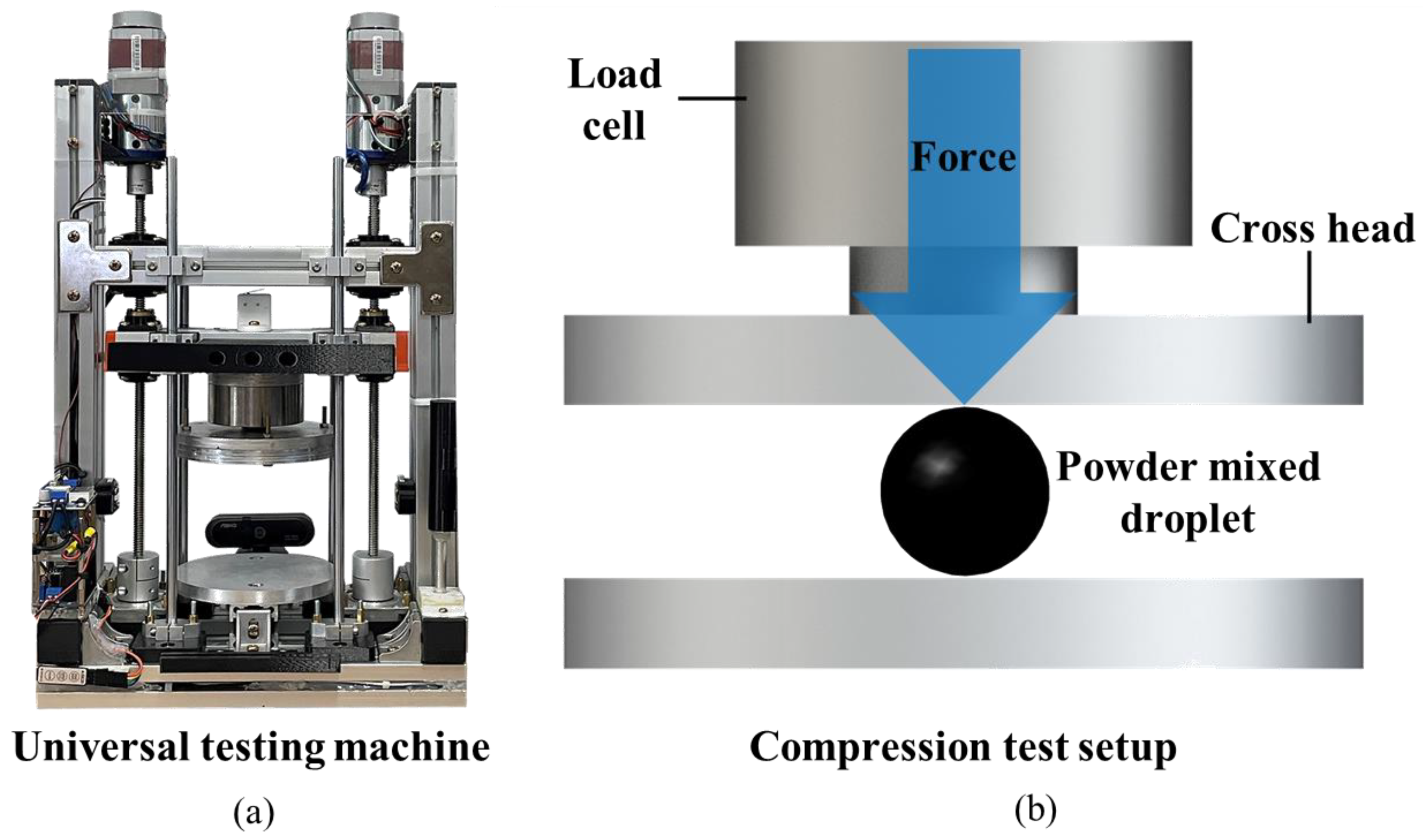

2.3. Experimental Methods for Measuring Mechanical Properties of PCC

2.4. Mixing Proportions and Specimen Preparation

3. Results and Discussion

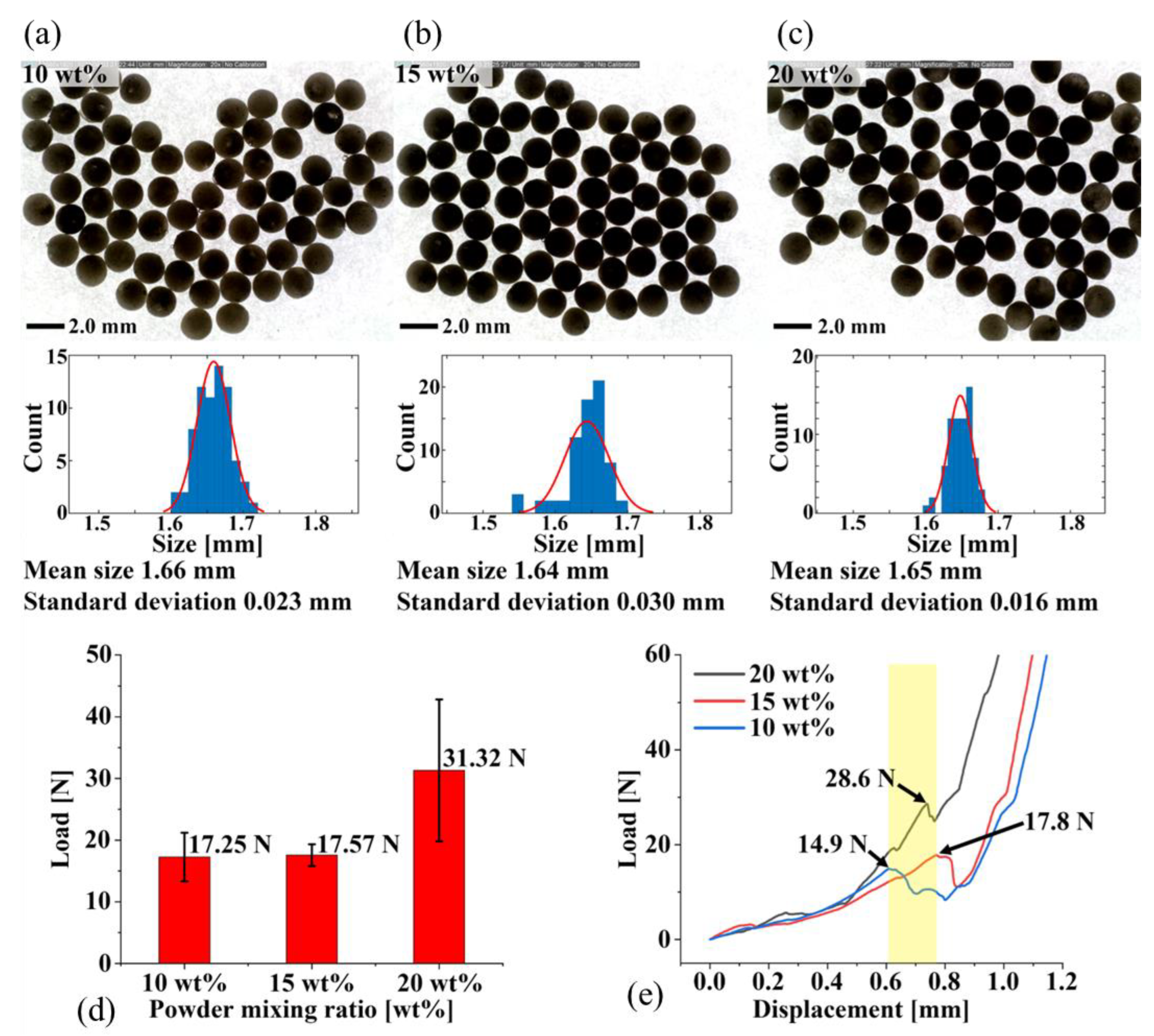

3.1. Mechanical Properties of PCCs

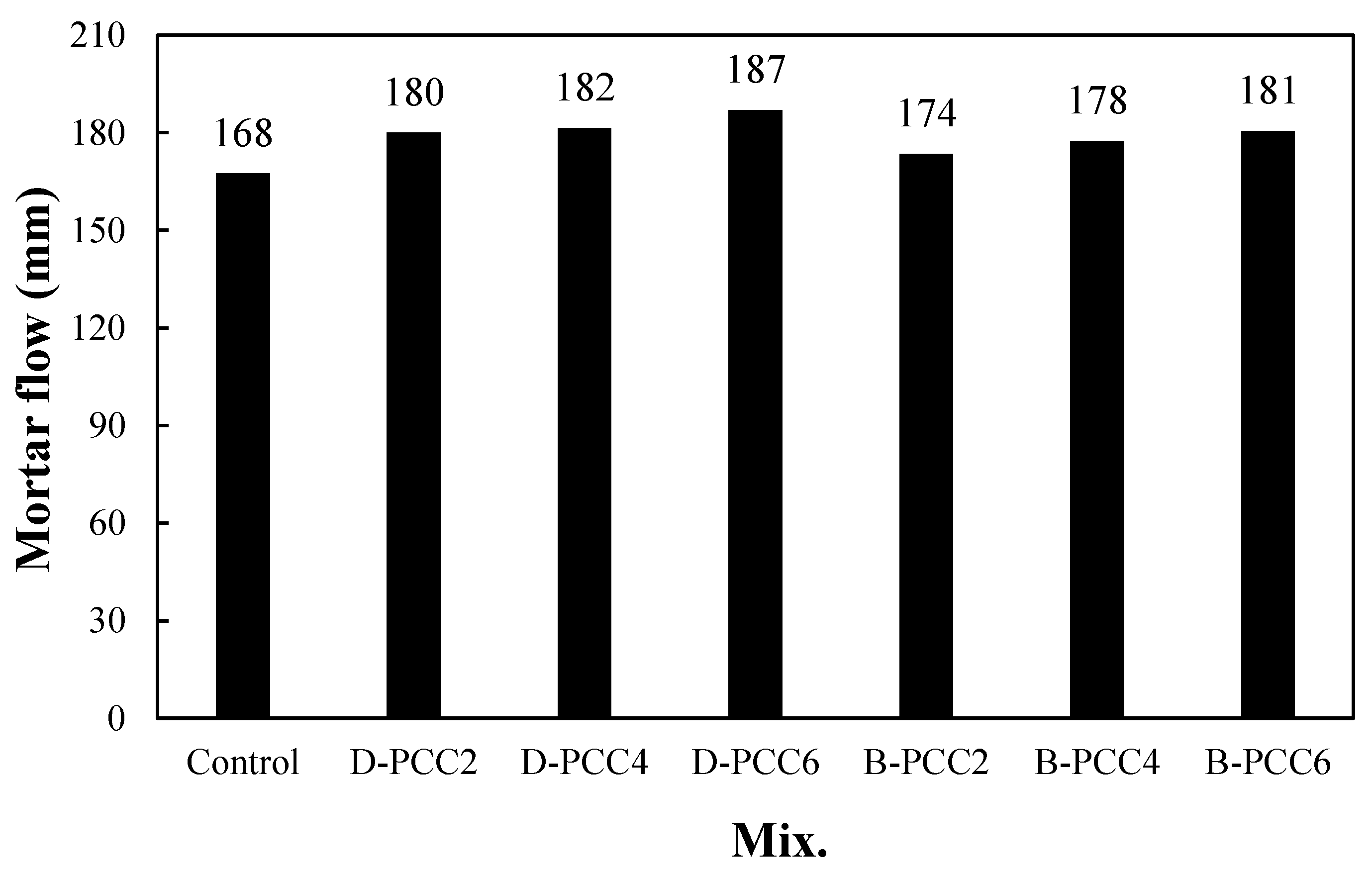

3.2. Mortar Flow

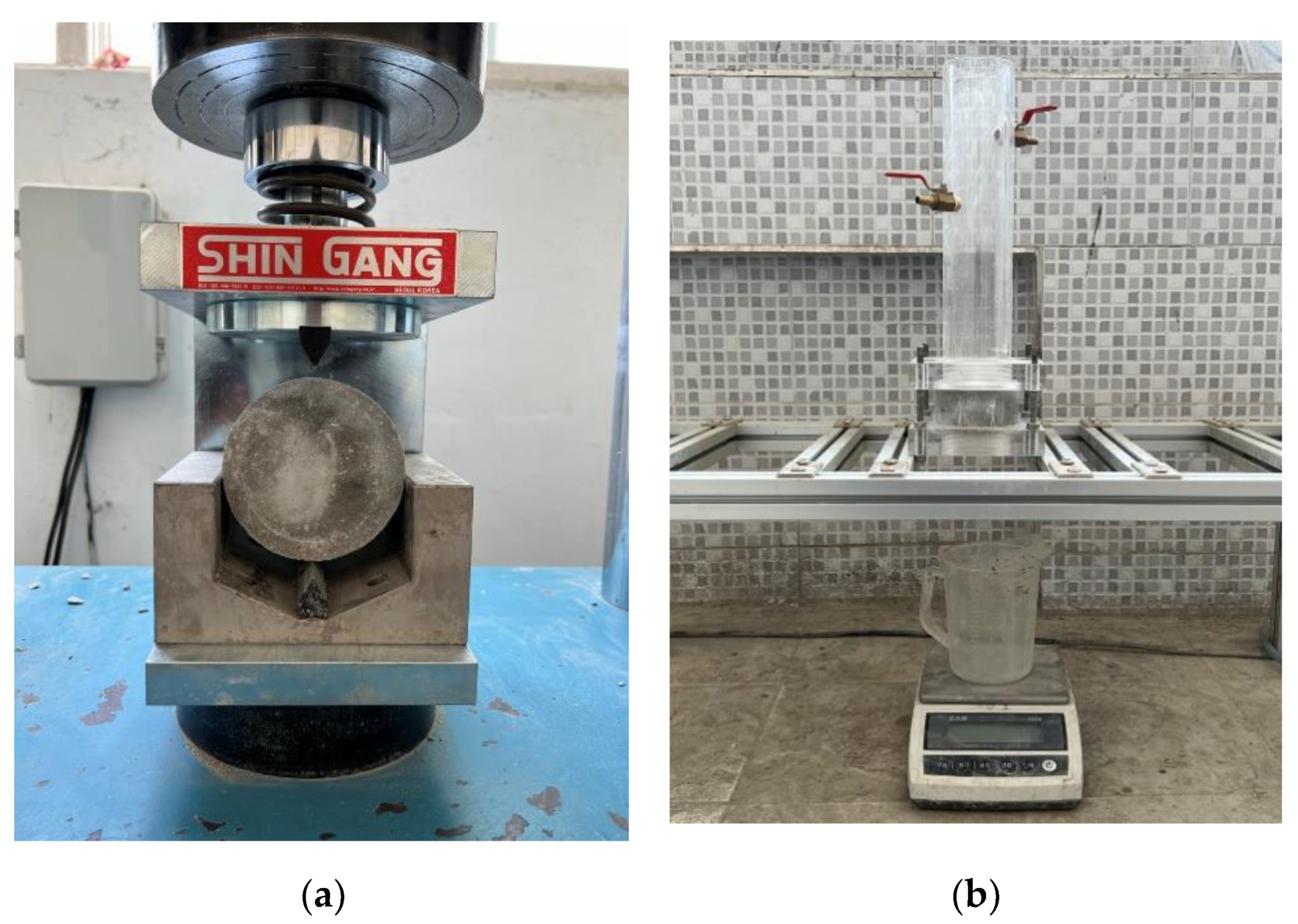

3.3. Compressive Strength

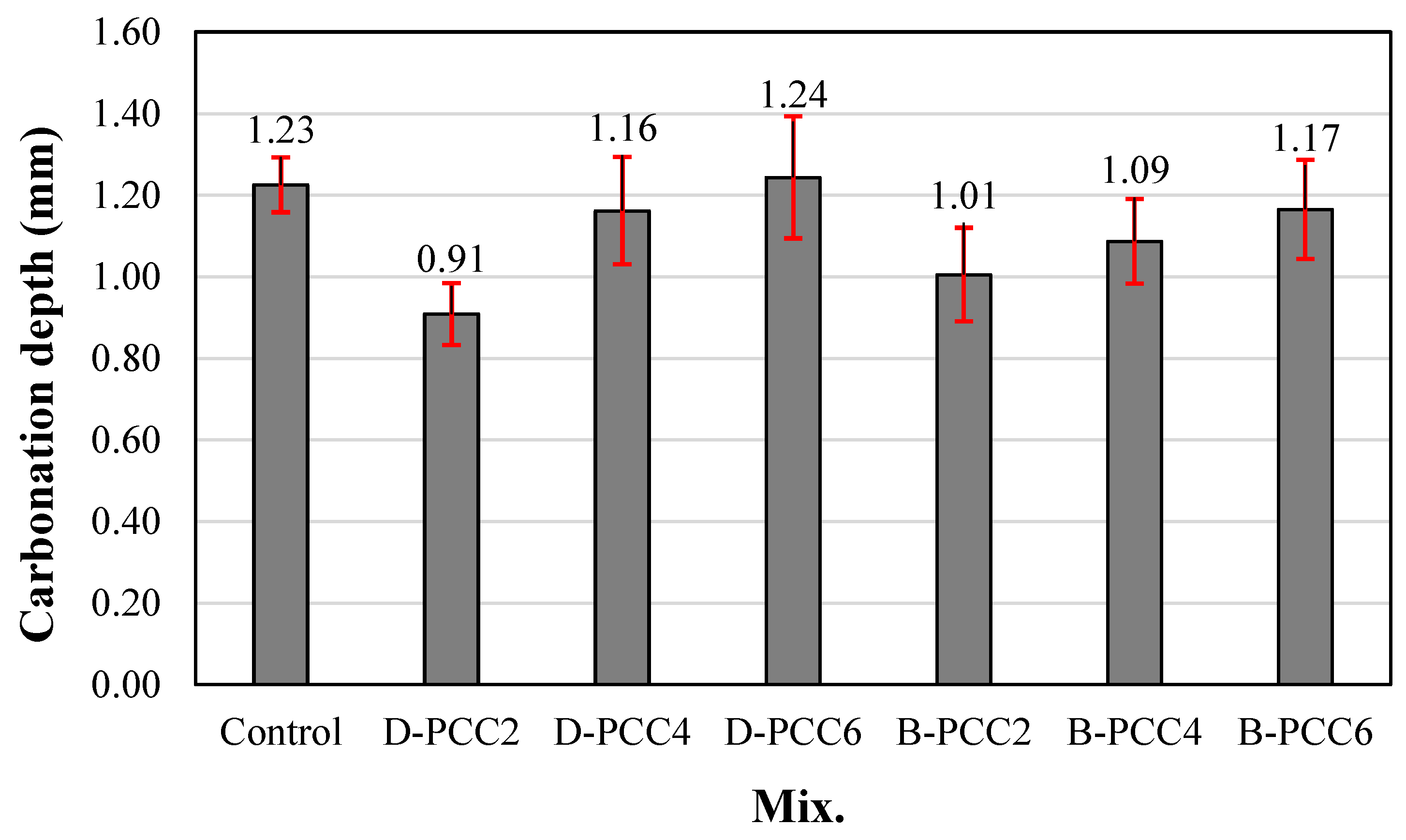

3.4. Carbonation Depth

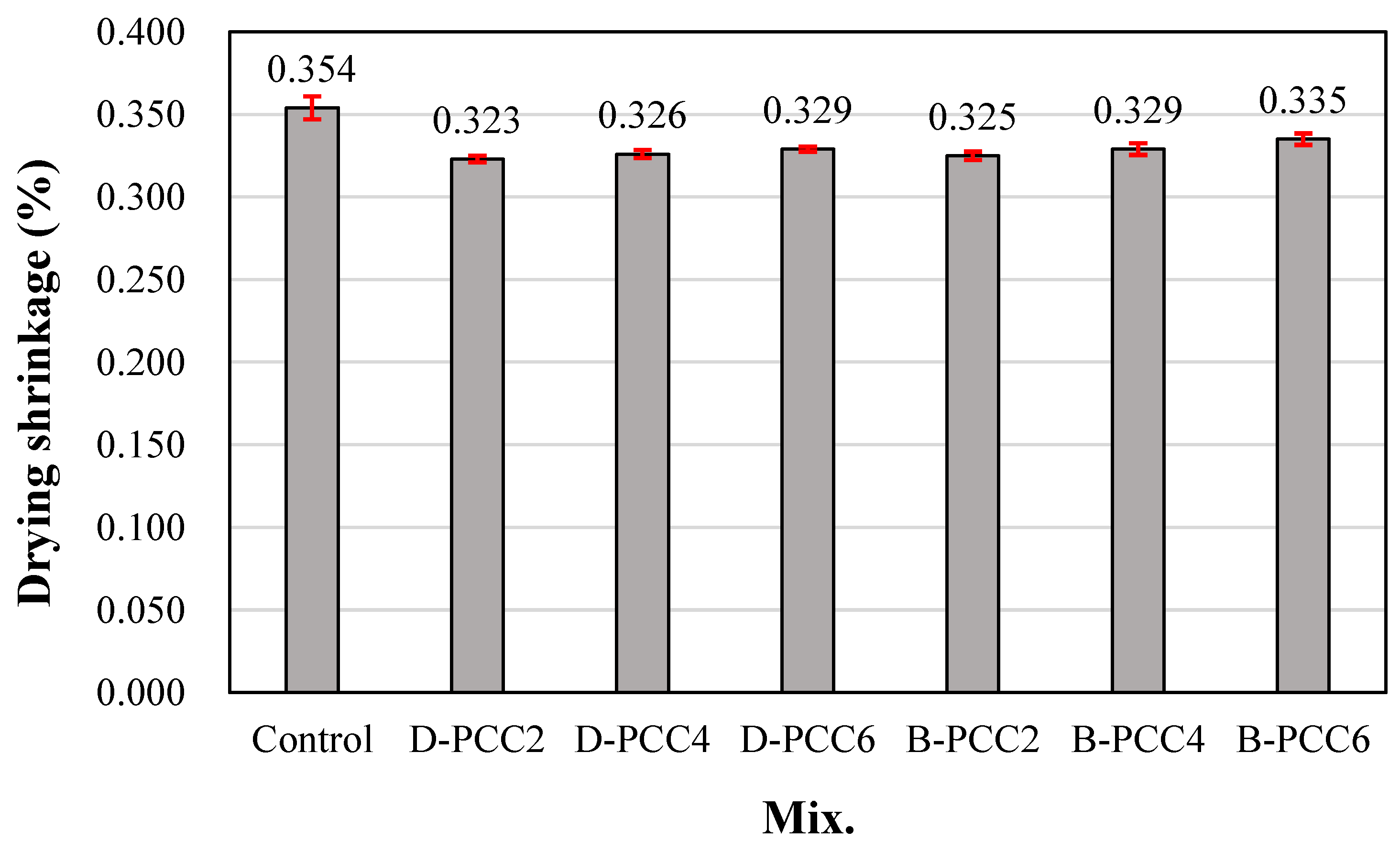

3.5. Drying Shrinkage

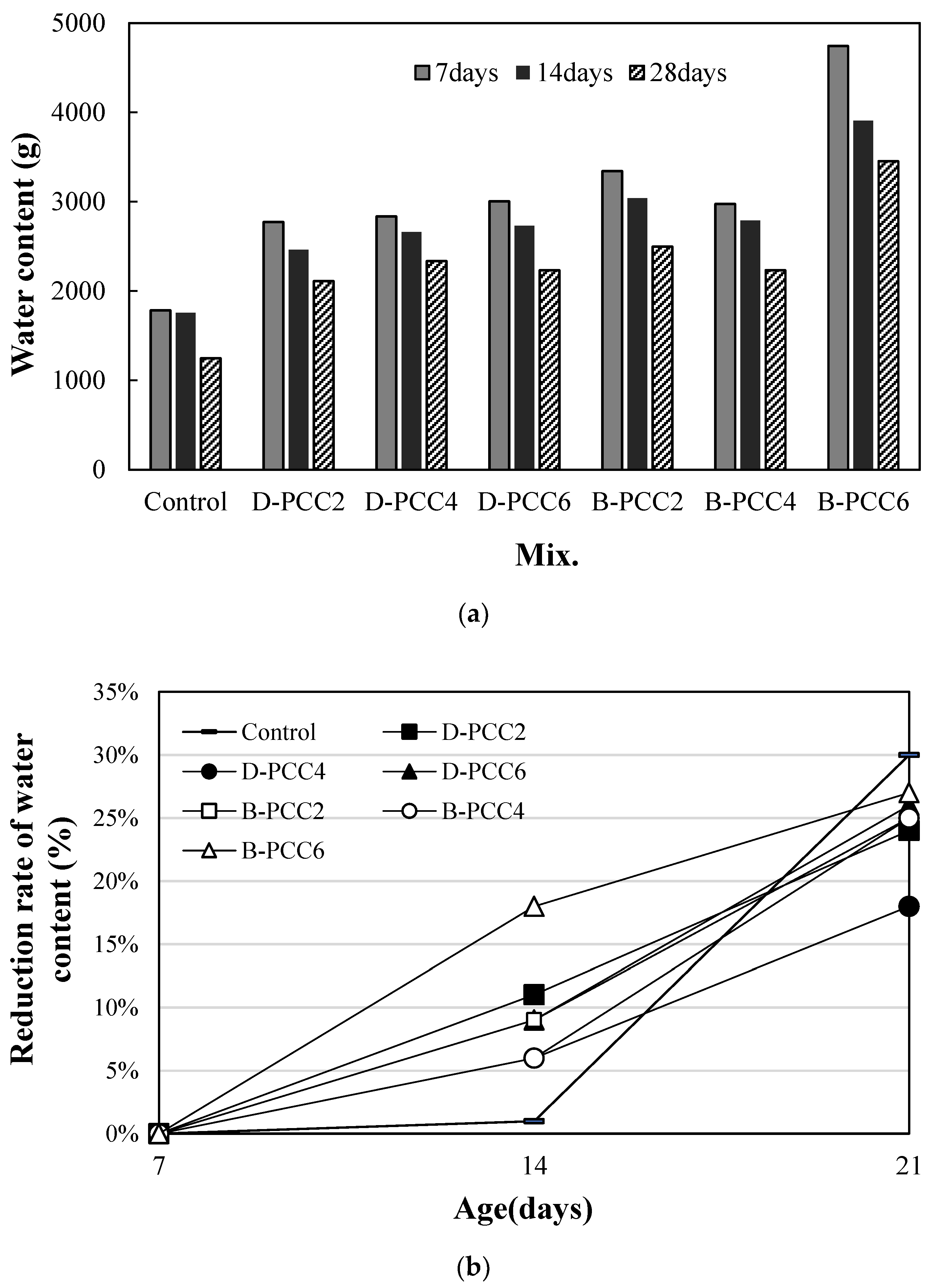

3.6. Water Permeability Test Result

4. Conclusions

- (1)

- The powder droplet manufacturing system can easily change droplet size by controlling the flow rate. Therefore, it provides high precision and uniformity for droplet fabrication. Furthermore, mass production can be performed using this simple manufacturing method. Moreover, this method has considerable economic advantages.

- (2)

- Droplets containing 10 wt% and 15 wt% of powder showed similar properties in the compressive strength test. By contrast, droplets containing 20 wt% powder showed a high compressive strength of at least 14 N. The average load of the B-PCC was approximately 32.75 N, relatively higher than that of the D-PCC.

- (3)

- In the mortar samples using the same amount of PCC, the flow of the mortar sample using D-PCC was slightly higher than that of the mortar using B-PCC. This is probably because the surfaces of the D-PCC particles are smoother than those of the B-PCC particles.

- (4)

- The compressive strength of the mortar sample with B-PCC was generally higher than that of the mortar sample with D-PCC. The compressive strength of the B-PCC2 sample with 0.2% of B-PCC was the highest at all curing ages. Therefore, the use of an appropriate PCC was effective in improving the compressive strength of the mortar.

- (5)

- The carbonation resistance of the mortar sample containing PCC was better than that of the control sample. The carbonation resistances of the D-PCC2 and B-PCC2 samples using 0.2% PCC were higher than those of the samples using 0.4% and 0.6% PCC.

- (6)

- The amount of water passing through the cracks in all samples decreased with age. The reduction rate of the water content of all the samples using PCC was approximately 6–18%, larger than that of the control sample. Therefore, a crack healing effect was observed in the samples with PCC, regardless of the PCC type. The effect was the greatest in the B-PCC6 sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, S.H.; Choi, E.K.; Park, W.J.; Yi, C.K.; Chung, N.H. Effectiveness of expanded clay as a bacteria carrier for self-healing concrete. Appl. Biol. Chem. 2019, 62, 19. [Google Scholar] [CrossRef]

- Choi, S.J.; Bae, S.H.; Lee, J.I.; Bang, E.J.; Ko, H.M. Strength, carbonation resistance, and chloride-ion penetrability of cement mortars containing catechol-functionalized chitosan polymer. Materials 2021, 14, 6395. [Google Scholar] [CrossRef] [PubMed]

- Menon, R.R.; Luo, J.; Chen, X.; Zhou, H.; Liu, Z.; Zhou, G.; Zhang, N.; Jin, C. Screening of fungi for potential application of self-healing concrete. Sci. Rep. 2019, 9, 2075. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Van Tittelboom, K.; De Belie, N.; Verstraete, W. Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr. Build. Mater. 2012, 26, 532–540. [Google Scholar] [CrossRef]

- Xu, J.; Peng, C.; Wang, G.; Wang, P.-G. A multi-phase scale simulation of electrochemical chloride extraction in crack-self-healing concrete. Struct. Concr. 2021, 23, 805–821. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Al-Tabbaa, A.; Litina, C.; Giannaros, P.; Kanellopoulos, A.; Souza, L. First UK field application and performance of microcapsule-based self-healing concrete. Constr. Build. Mater. 2019, 208, 669–685. [Google Scholar] [CrossRef]

- Hilloulin, B.; Van Tittelboom, K.; Gruyaert, E.; De Belie, N.; Loukili, A. Design of polymeric capsules for self-healing concrete. Cem. Concr. Compos. 2015, 55, 298–307. [Google Scholar] [CrossRef]

- Hu, Z.-X.; Hu, X.M.; Cheng, W.-M.; Zhao, Y.; Wu, M.Y. Performance optimization of one-component polyurethane healing agent for self-healing concrete. Constr. Build. Mater. 2018, 179, 151–159. [Google Scholar] [CrossRef]

- Qian, C.; Zheng, T.; Zhang, X.; Su, Y. Application of microbial self-healing concrete: Case study. Constr. Build. Mater. 2021, 290, 123226. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Constr. Build. Mater. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Palmer, D.; Kerr, A.; Al-Tabbaa, A. Polymeric microcapsules with switchable mechanical properties for self-healing concrete: Synthesis, characterization and proof of concept. Smart Mater. Struct. 2017, 26, 45025. [Google Scholar] [CrossRef]

- Milla, J.; Hassan, M.M.; Rupnow, T.; Al-Ansari, M.; Arce, G. Effect of self-healing calcium nitrate microcapsules on concrete properties. Transp. Res. Rec. 2016, 2577, 69–77. [Google Scholar] [CrossRef]

- Dong, B.; Ding, W.; Qin, S.; Han, N.; Fang, G.; Liu, Y.; Xing, F.; Hong, S. Chemical self-healing system with novel microcapsules for corrosion inhibition of rebar in concrete. Cem. Concr. Compos. 2018, 85, 83–91. [Google Scholar] [CrossRef]

- Oh, S.R.; Lee, K.M.; Choi, S.; Choi, Y.W. Fundamental properties and self-healing performance of repair mortar with solid capsules made using inorganic reactive powder. Materials 2022, 15, 1710. [Google Scholar] [CrossRef]

- Papaioannou, S.; Amenta, M.; Kilikogloua, V.; Gournis, D.; Karatasios, I. Synthesis and integration of cement-based capsules modified with sodium silicate for developing self-healing cements. Constr. Build. Mater. 2020, 17, 125803. [Google Scholar] [CrossRef]

- Nam, E.J.; Oh, S.R.; Kim, C.G.; Choi, Y.W. An experimental study on the self-healing performance of solid capsules according to the composition ratio of crystal growth type inorganic materials. J. Korea Inst. Struct. Maint. Inspect. 2021, 25, 16–22. [Google Scholar]

- Fang, X.; Pan, Z.; Chen, A. Analytical models to estimate the efficiency of capsule-based self-healing cementitious materials considering the effect of capsule shell thickness. Constr. Build. Mater. 2021, 274, 121999. [Google Scholar] [CrossRef]

- Wu, M.; Hu, X.; Zhang, Q.; Cheng, W.; Xue, D.; Zhao, Y. Application of bacterial spores coated by a green inorganic cementitious material for the self-healing of concrete cracks. Cem. Concr. Compos. 2020, 113, 103718. [Google Scholar] [CrossRef]

- Ren, J.; Wang, X.; Li, D.; Xu, S.; Dong, B.; Xing, F. Performance of temperature adaptive microcapsules in self-healing cementitious materials under different mixing temperatures. Constr. Build. Mater. 2021, 299, 124254. [Google Scholar] [CrossRef]

- Xu, J.H.; Li, S.W.; Tan, J.; Wang, Y.J.; Luo, G.S. Preparation of highly monodisperse droplet in a T-junction microfluidic device. AIChE J. 2006, 52, 3005–3010. [Google Scholar] [CrossRef]

- Li, X.B.; Li, F.C.; Yang, J.-C.; Kinoshita, H.; Oishi, M.; Oshima, M. Study on the mechanism of droplet formation in T-junction microchannel. Chem. Eng. Sci. 2012, 69, 340–351. [Google Scholar] [CrossRef]

- Ahmadi, F.; Samlali, K.; Vo, P.Q.N.; Shih, S.C.C. An integrated droplet-digital microfluidic system for on-demand droplet creation, mixing, incubation, and sorting. Lab Chip 2019, 19, 524–535. [Google Scholar] [CrossRef] [PubMed]

- Shojaeian, M.; Hardt, S. Fast electric control of the droplet size in a microfluidic T-junction droplet generator. Appl. Phys. Lett. 2018, 112, 194102. [Google Scholar] [CrossRef]

- Choi, Y.W.; Oh, S.R.; Kim, C.G.; Nam, E.J. A study on crack healing properties of cement composites mixed with self-healing microcapsules. J. Korea Inst. Struct. Maint. Inspect. 2019, 23, 113–121. [Google Scholar]

- KS L 5105; Testing Method for Compressive Strength of Hydraulic Cement Mortars. Korea Industrial Standards: Seoul, Korea; Korean Standards & Certification Information Center: Seoul, Korea, 2007; p. 5.

- KS F 2424; Standard Test Method for Length Change of Mortar and Concrete. Korea Industrial Standards: Seoul, Korea; Korean Standards & Certification Information Center: Seoul, Korea, 2015.

- KS F 2584; Standard Test Method for Accelerated Carbonation of Concrete. Korea Industrial Standards: Seoul, Korea; Korean Standards & Certification Information Center: Seoul, Korea, 2015.

- Hou, S.; Li, K.; Wu, Z.; Li, F.; Shi, C. Quantitative evaluation on self-healing capacity of cracked concrete by water permeability test: A review. Cem. Concr. Struct. 2022, 127, 104404. [Google Scholar] [CrossRef]

- Lee, K.M.; Kim, H.S.; Lee, D.K.; Shin, K.J. Self-healing performance evaluation of concrete incorporating inorganic materials based on a water permeability test. Materials 2021, 14, 3202. [Google Scholar] [CrossRef]

- Vivian, W.Y.T.; Gao, X.F.; Tam, C.M. Carbonation around near aggregate regions of old hardened concrete cement paste. Cem. Concr. Res. 2005, 35, 1180–1186. [Google Scholar] [CrossRef]

- Geng, J.; Sun, J. Characteristics of the carbonation resistance of recycled fine aggregate concrete. Constr. Build. Mater. 2013, 49, 814–820. [Google Scholar] [CrossRef]

| Type | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Blaine (cm2/g) | Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| Cement | 17.43 | 6.50 | 3.57 | 64.40 | 2.55 | 1.17 | 3430 | 3.15 |

| Blast furnace slag powder | 30.61 | 13.98 | 0.32 | 40.71 | 6.43 | 0.60 | 4210 | 2.93 |

| Fly ash | 64.88 | 20.56 | 6.06 | 2.58 | 0.80 | 1.45 | 3710 | 2.21 |

| Mix | D-PCC (S*%) | B-PCC (S*%) | W/C (%) | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | PCC (kg/m3) |

|---|---|---|---|---|---|---|---|

| Control | - | - | 50 | 170 | 340 | 739.0 | - |

| D-PCC2 | 0.2 | - | 340 | 737.5 | 1.5 | ||

| D-PCC4 | 0.4 | - | 340 | 736.0 | 3.0 | ||

| D-PCC6 | 0.6 | - | 340 | 734.5 | 4.5 | ||

| B-PCC2 | - | 0.2 | 340 | 737.5 | 1.5 | ||

| B-PCC4 | - | 0.4 | 340 | 736.0 | 3.0 | ||

| B-PCC6 | - | 0.6 | 340 | 734.5 | 4.5 |

| Powder Ratio (wt%) | Test 1 (N) | Test 2 (N) | Test 3 (N) | Test 4 (N) |

|---|---|---|---|---|

| 10 | 14.9 | 13 | 19.9 | 21.2 |

| 15 | 17.8 | 19.9 | 16.7 | 15.9 |

| 20 | 28.6 | 48.2 | 26 | 22.5 |

| Sample No. | Displacement (mm) | Load (N) |

|---|---|---|

| Sample 1 | 0.297 | 28.33 |

| Sample 2 | 0.519 | 34.95 |

| Sample 3 | 0.289 | 31.53 |

| Sample 4 | 0.333 | 45.67 |

| Sample 5 | 0.154 | 16.69 |

| Sample 6 | 0.128 | 22.91 |

| Sample 7 | 0.220 | 34.55 |

| Sample 8 | 0.122 | 13.85 |

| Sample 9 | 0.298 | 78.33 |

| Sample 10 | 0.218 | 20.75 |

| Average | 0.258 | 32.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-J.; Bae, S.-H.; Ji, D.-M.; Kim, S.-H. Effects of Capsule Type on the Characteristics of Cement Mortars Containing Powder Compacted Capsules. Materials 2022, 15, 6773. https://doi.org/10.3390/ma15196773

Choi S-J, Bae S-H, Ji D-M, Kim S-H. Effects of Capsule Type on the Characteristics of Cement Mortars Containing Powder Compacted Capsules. Materials. 2022; 15(19):6773. https://doi.org/10.3390/ma15196773

Chicago/Turabian StyleChoi, Se-Jin, Sung-Ho Bae, Dong-Min Ji, and Sung-Hoon Kim. 2022. "Effects of Capsule Type on the Characteristics of Cement Mortars Containing Powder Compacted Capsules" Materials 15, no. 19: 6773. https://doi.org/10.3390/ma15196773

APA StyleChoi, S.-J., Bae, S.-H., Ji, D.-M., & Kim, S.-H. (2022). Effects of Capsule Type on the Characteristics of Cement Mortars Containing Powder Compacted Capsules. Materials, 15(19), 6773. https://doi.org/10.3390/ma15196773