Effect of Phosphorus Slag Admixture on the Properties and Hydration Mechanism of Circulating Fluidized Bed Fly Ash-Based Multi-Solid Waste Cementitious Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Physicochemical Performances of Raw Materials

2.1.1. Source of Raw Materials

2.1.2. Chemical Compositions

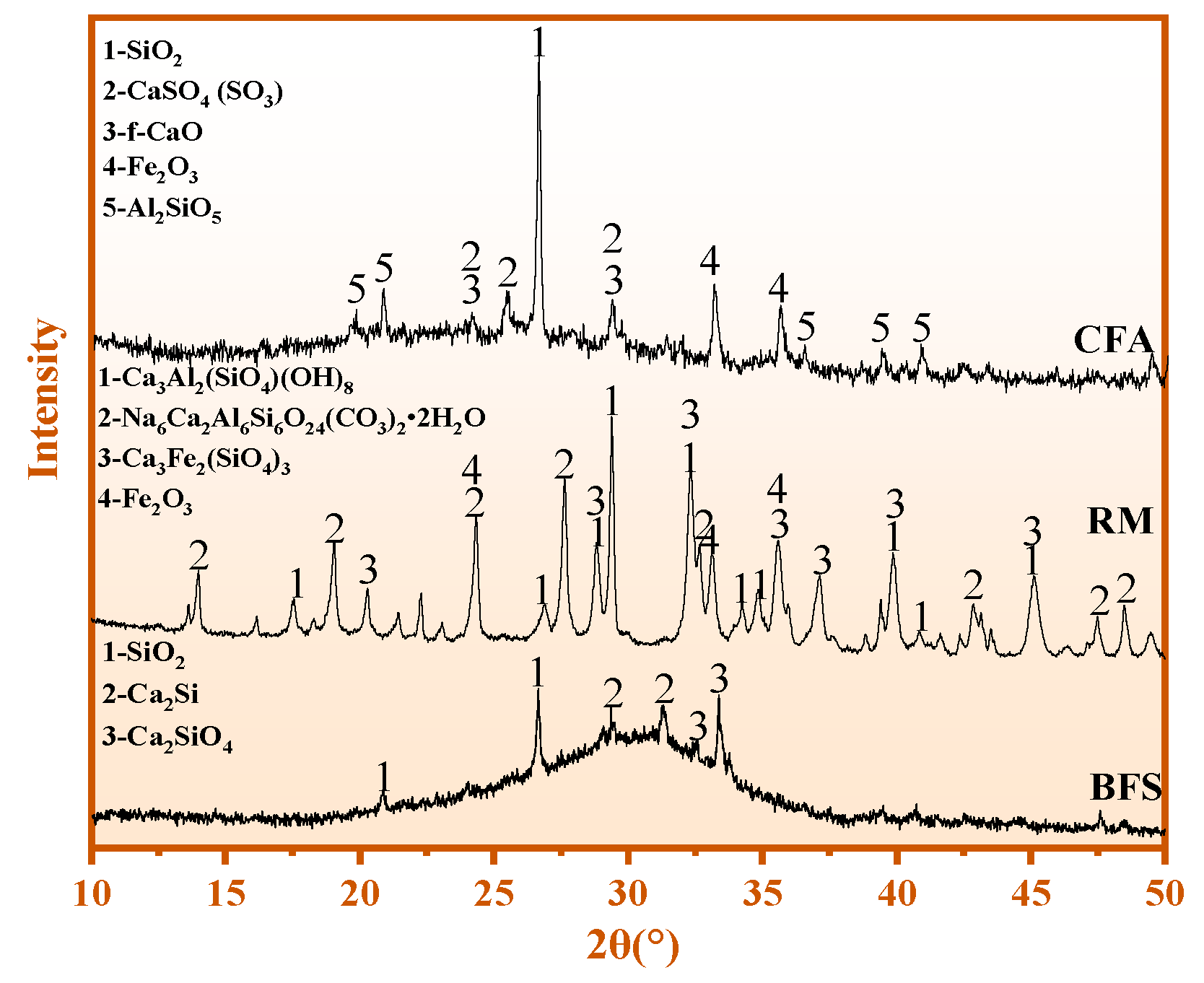

2.1.3. Phase Composition

2.1.4. Specific Surface Area

2.2. Experimental Design of CWM

2.3. Preparation of CWM

2.4. Test Methods

2.4.1. Performance Test

2.4.2. Microstructure Analysis

3. Results and Discussion

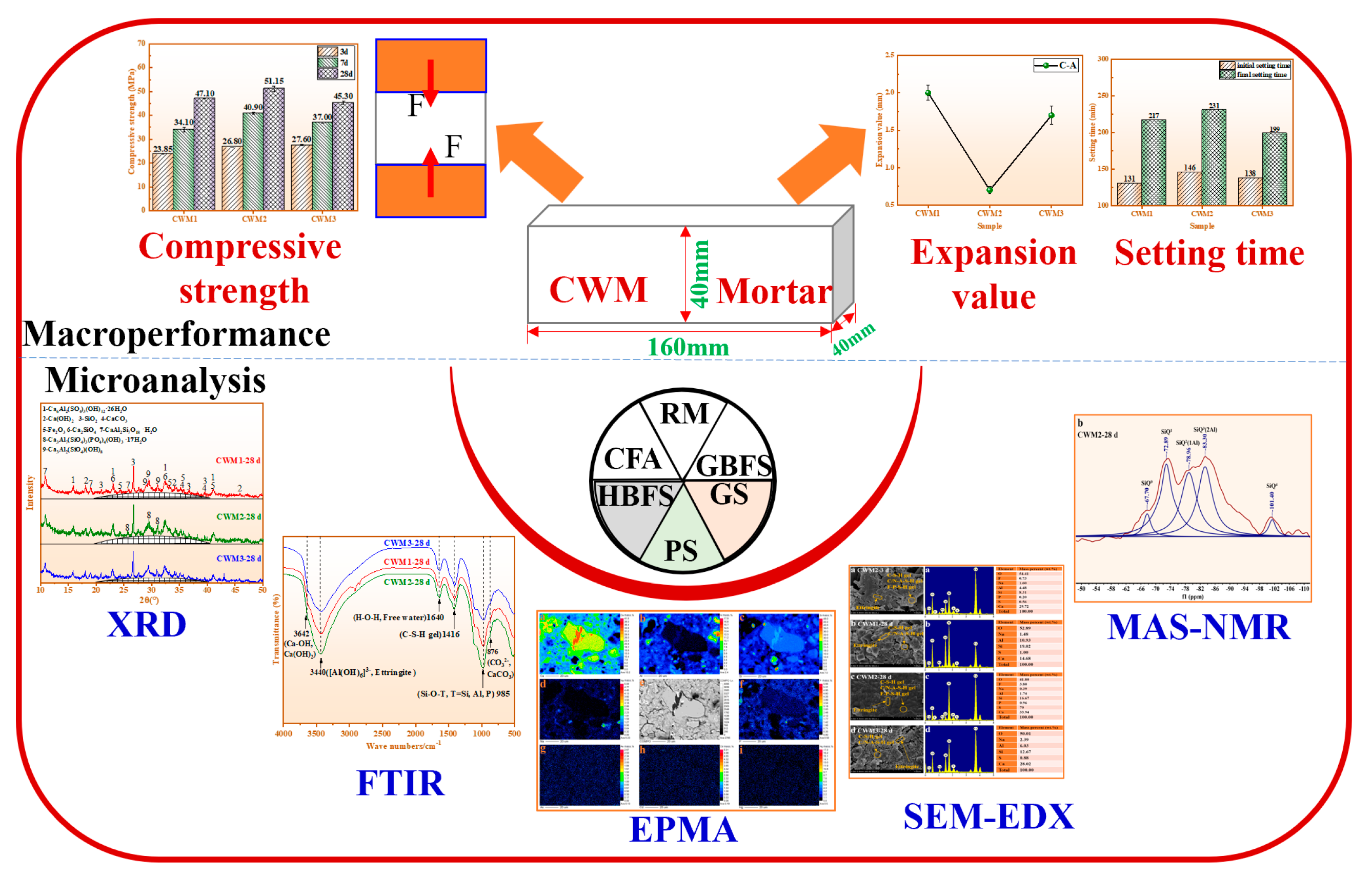

3.1. Macroperformance of CWM

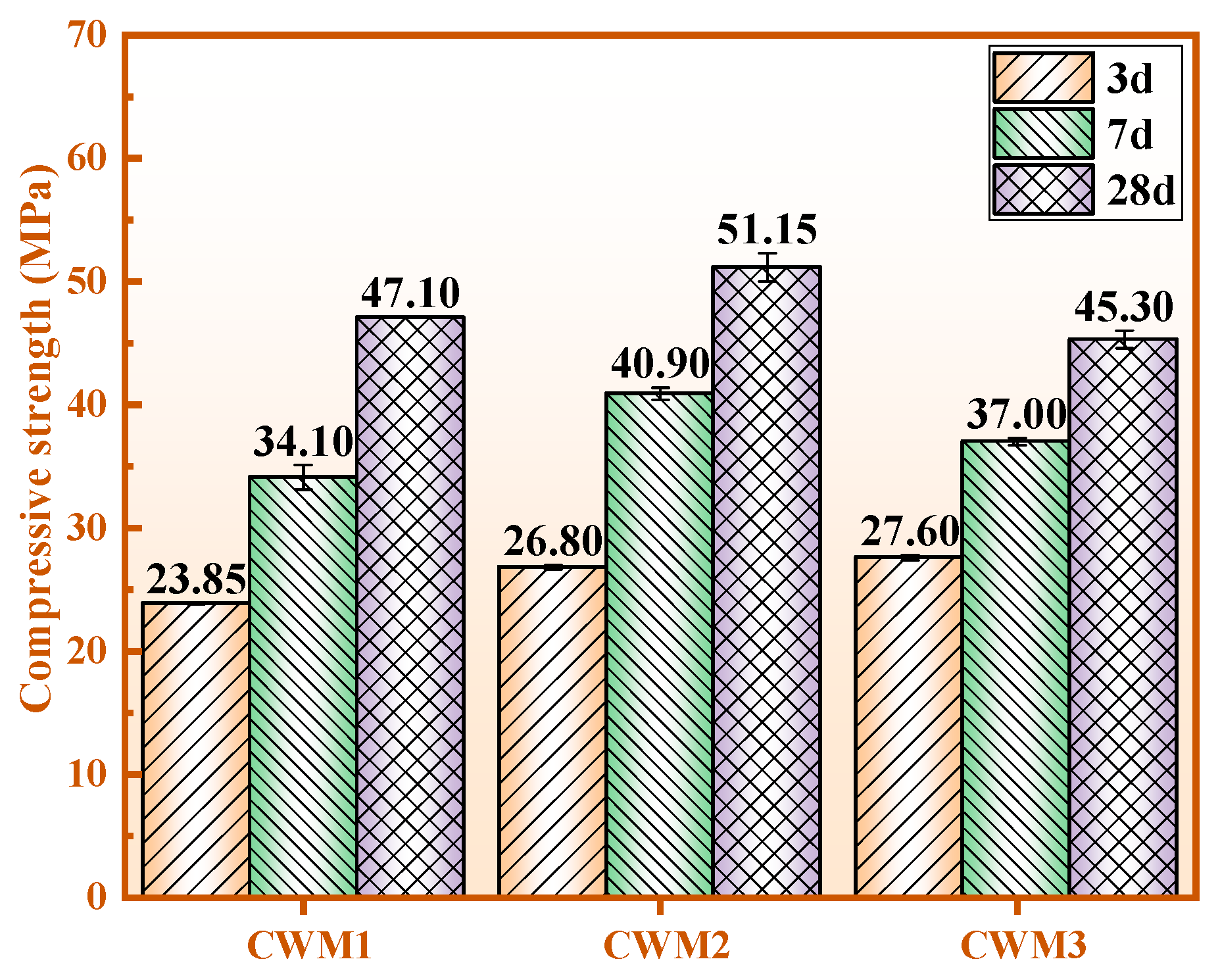

3.1.1. Compressive Strength

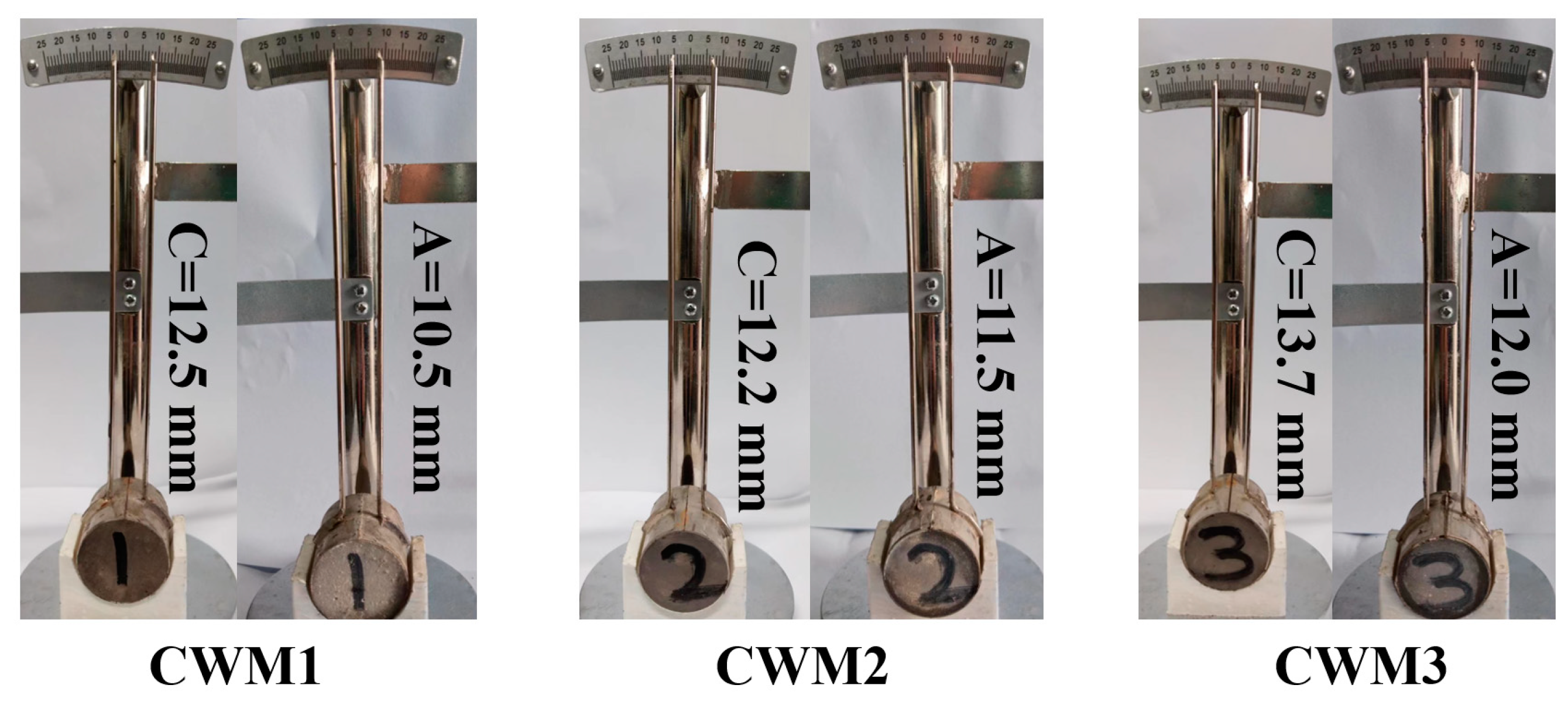

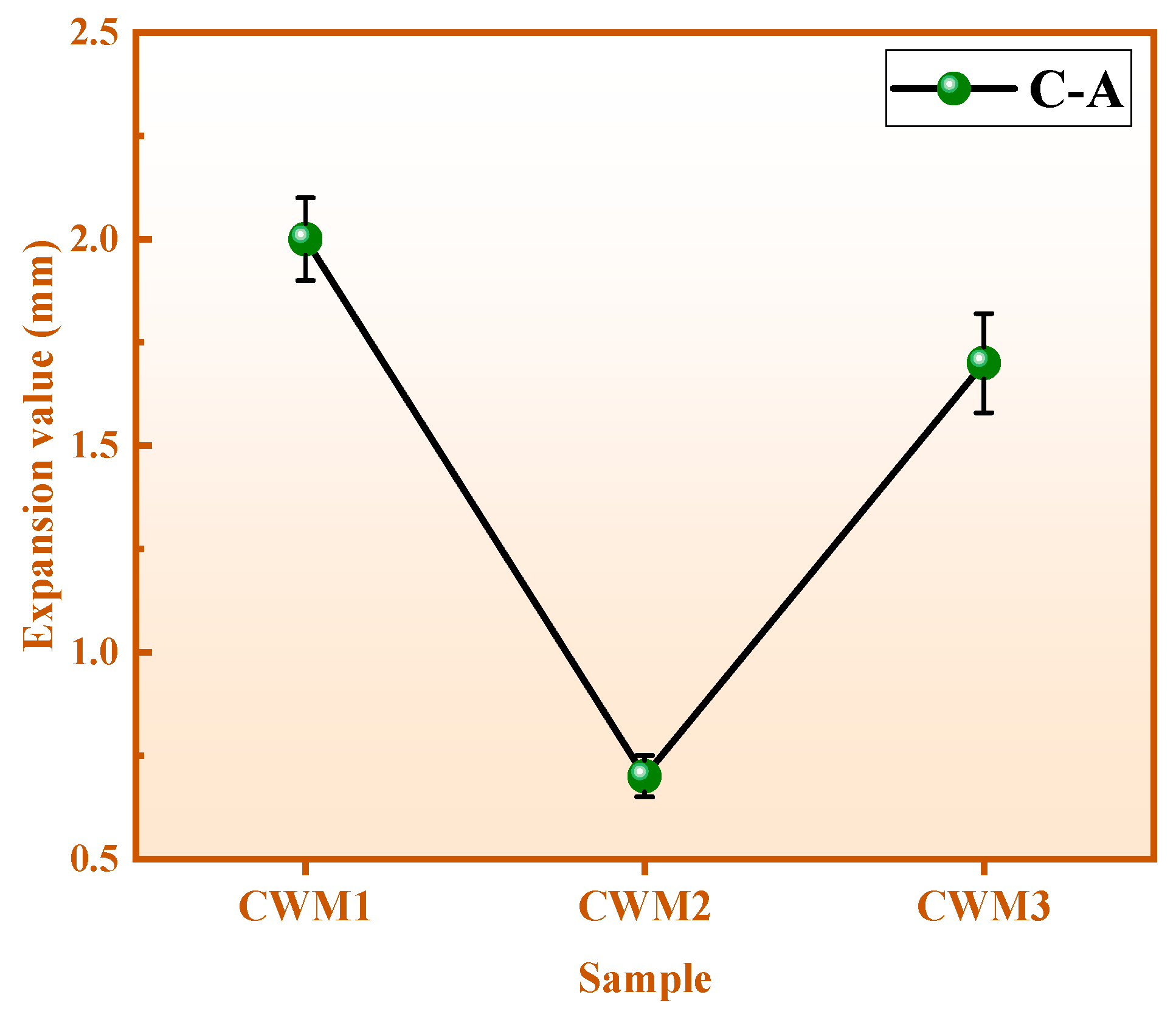

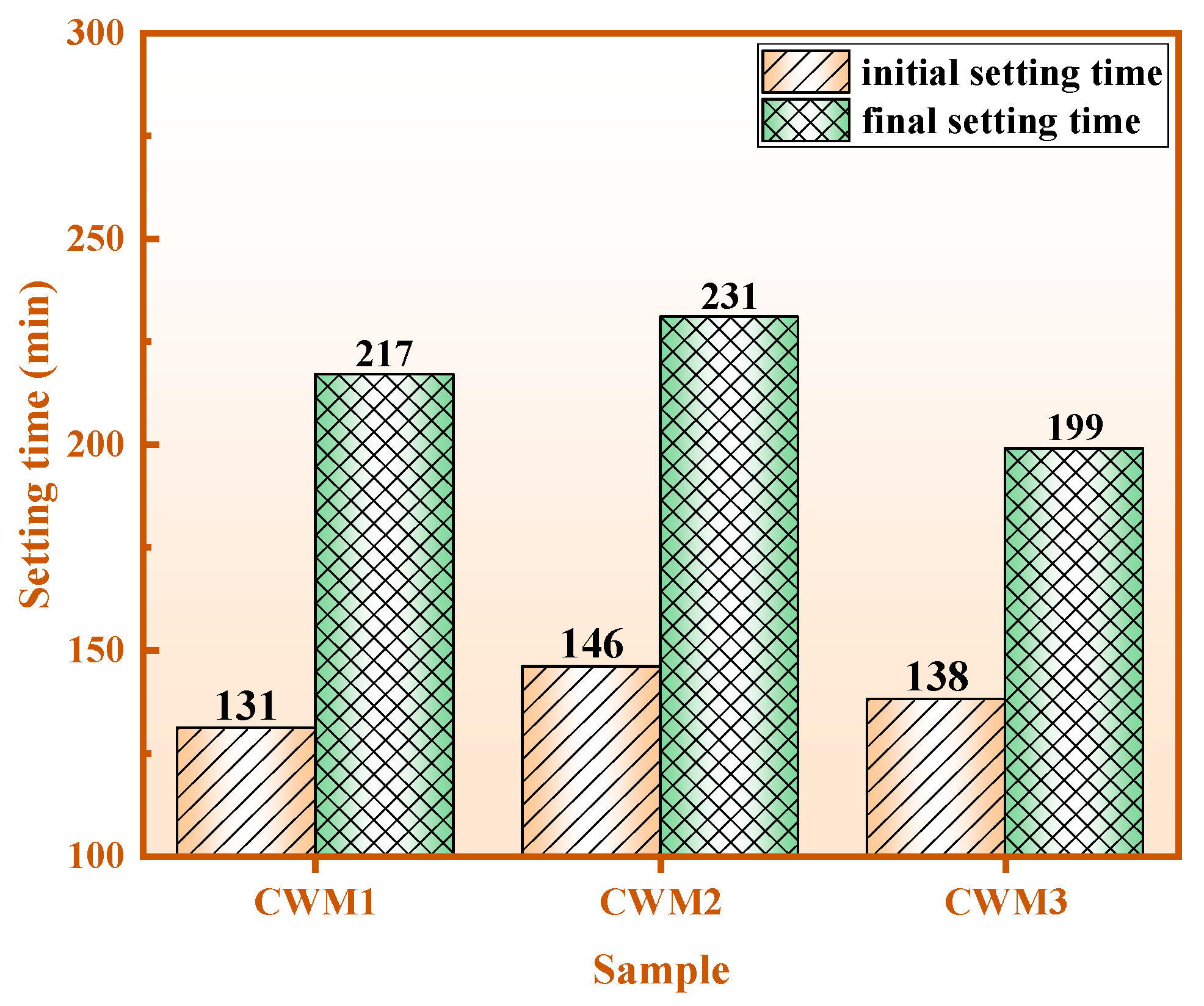

3.1.2. Volume Stability and Setting Time

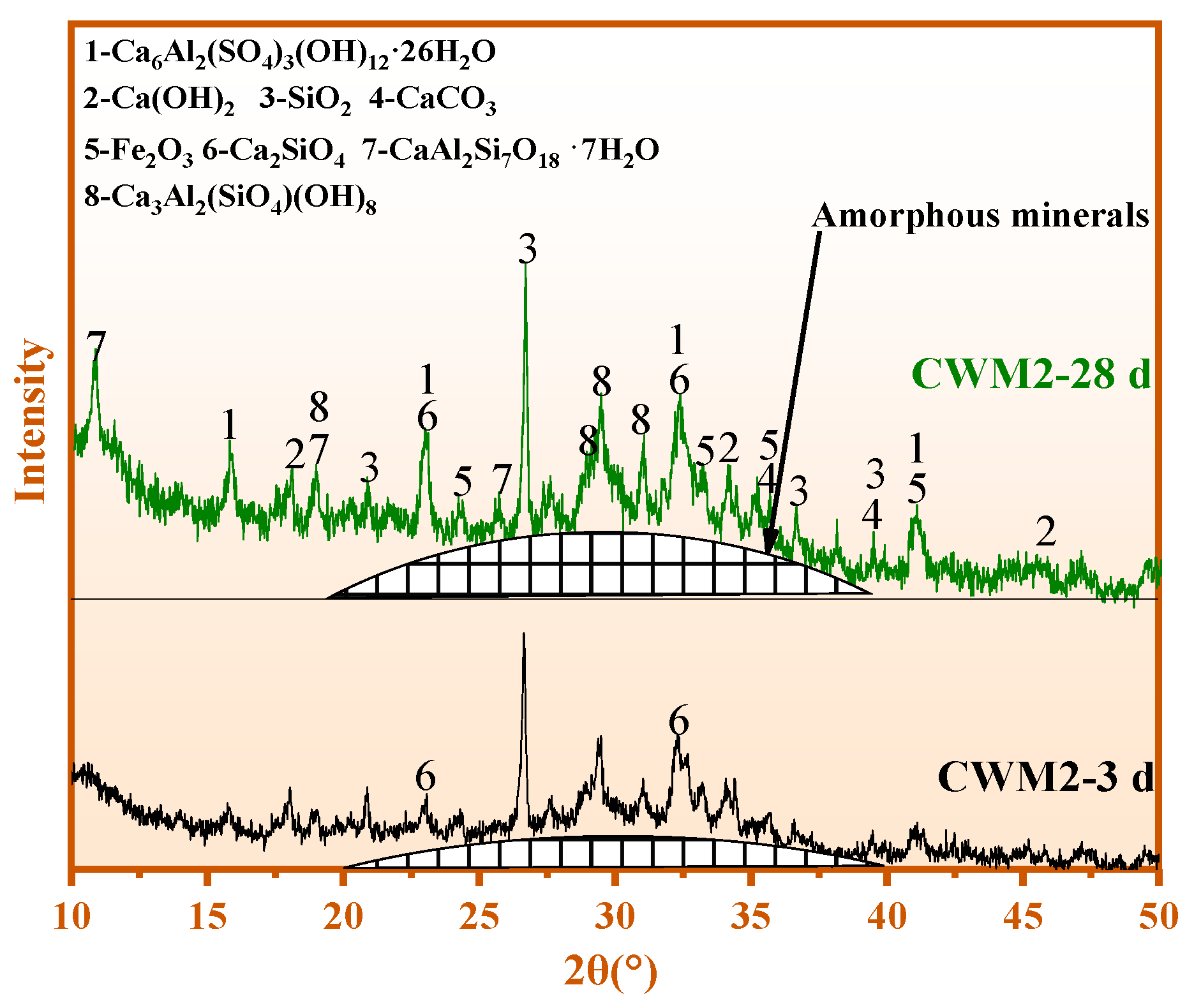

3.2. Mineral Composition Analysis

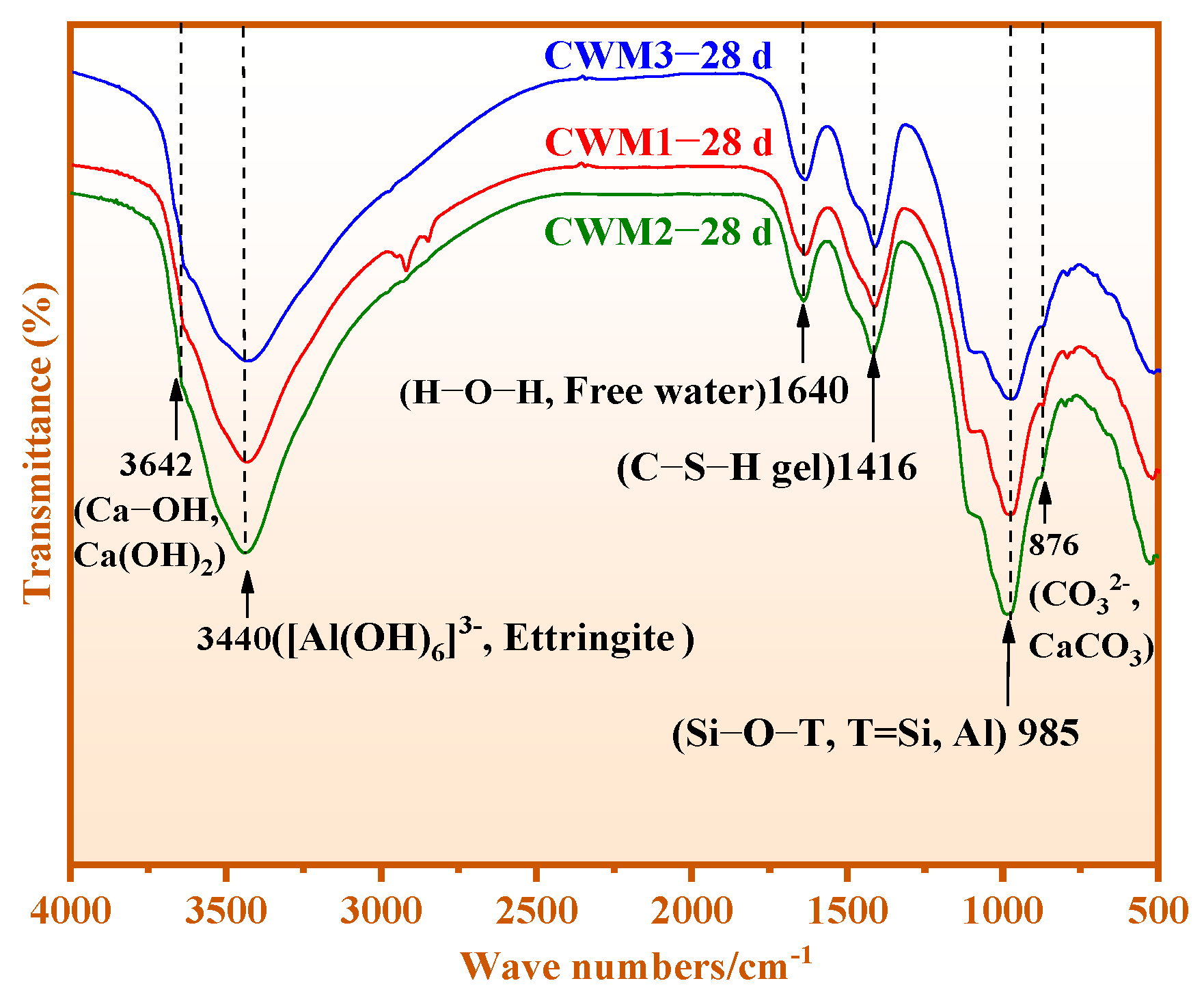

3.3. Chemical Bond Analysis

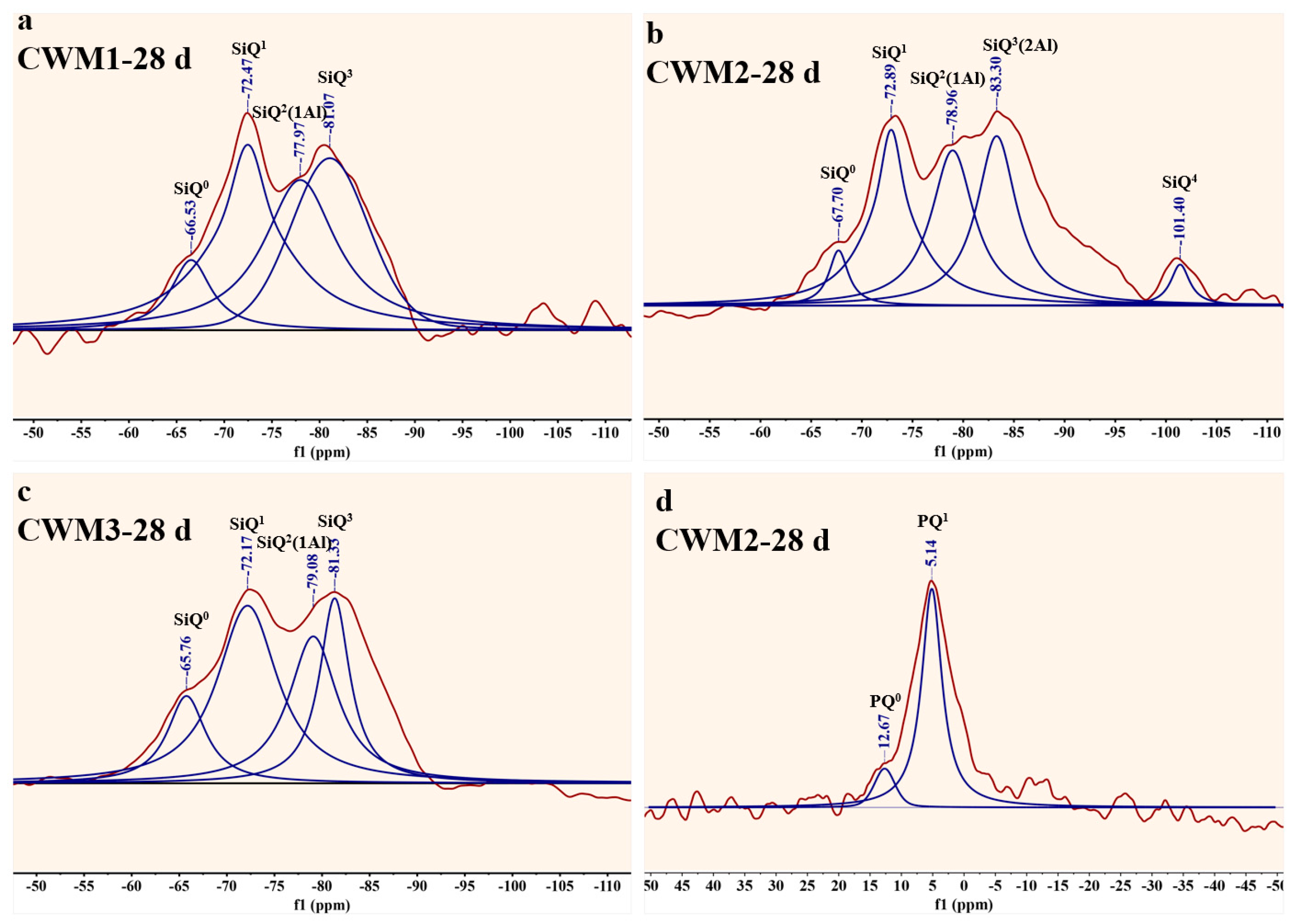

3.4. Molecular Structure Analysis

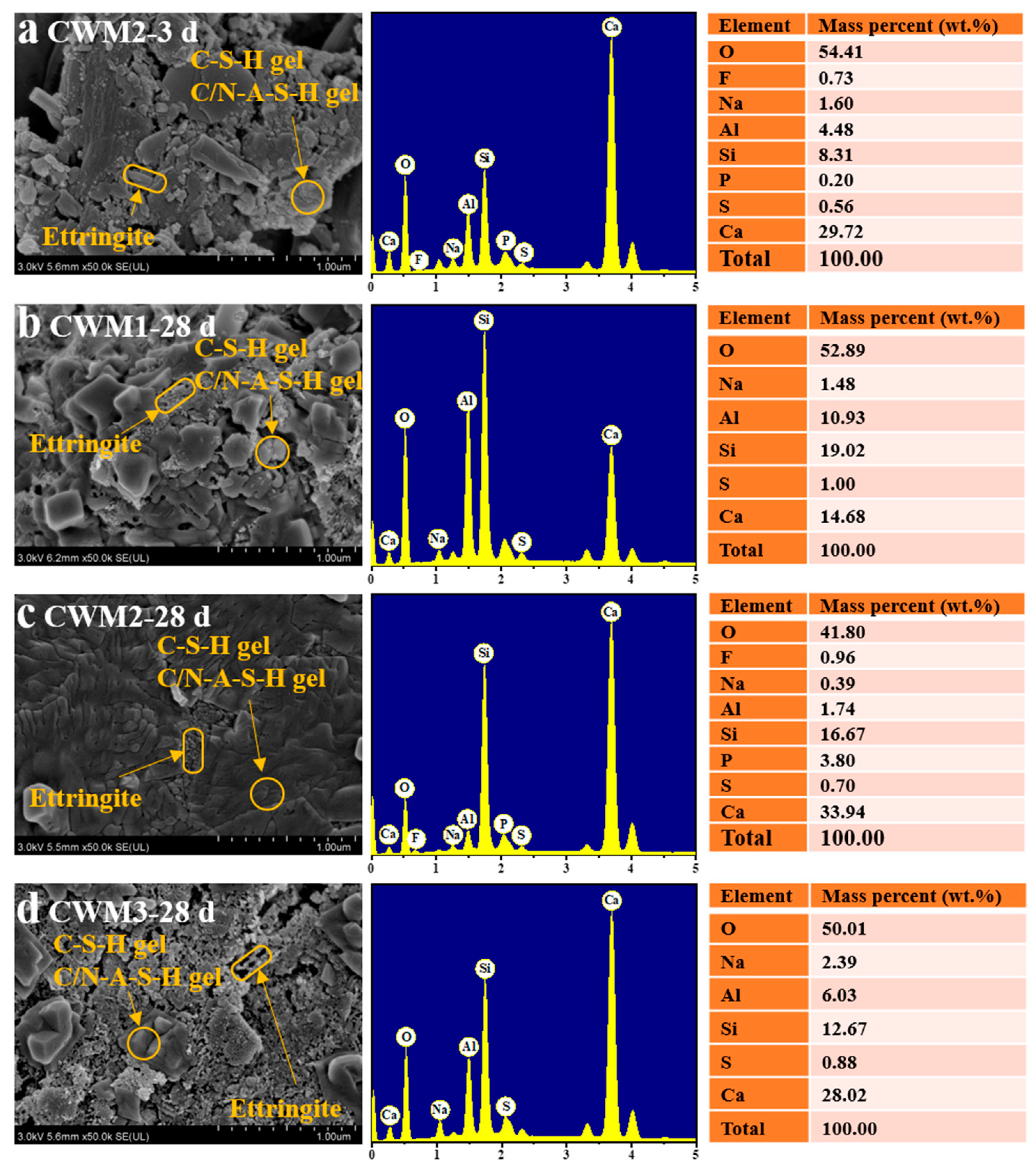

3.5. Micromorphology Analysis

3.6. Environmental Performance

3.6.1. Leaching Results

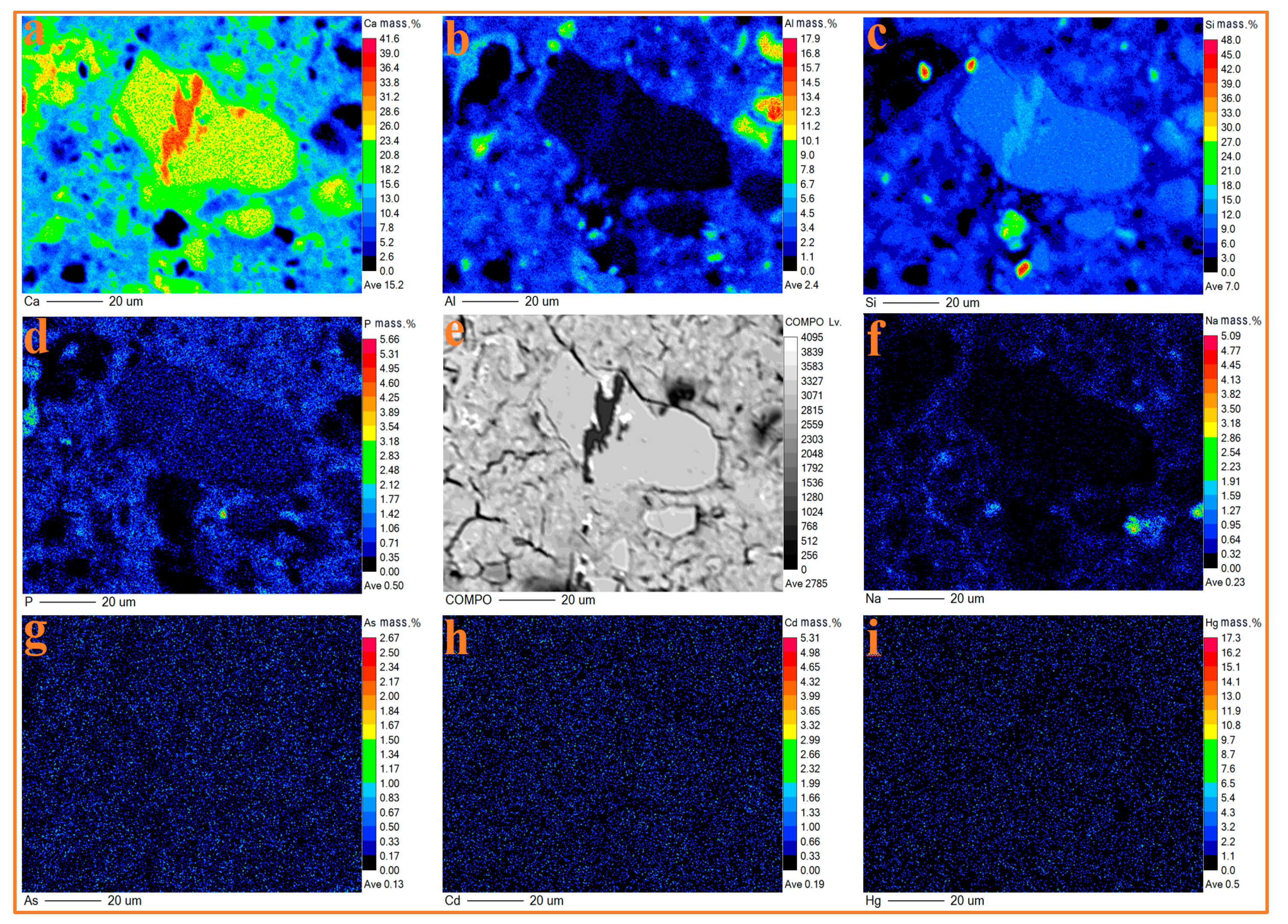

3.6.2. Consolidation Mechanism

4. Conclusions

- (1)

- PS as an admixture is more beneficial for improving the performance of CWM systems compared with gasification slag (GS) and blast furnace slag with a high specific surface area (HBFS). The dosage of total solid waste is increased to 70 wt.% in cementitious materials.

- (2)

- The compressive strength of CWM2 is optimal (51.15 MPa) and the expansion value is the lowest (0.70 mm). Moreover, the contents of SO3 and MgO are 2.61 wt.% and 2.56 wt.%, respectively, which can reach the level of P. F 42.5. The performances of CWM2 are superior to those of other CWMs under the action of PS admixture.

- (3)

- The main hydration products are C-S-H gel, C/N-A-S-H gel, and ettringite in CWM, which are useful to improve the compactness of the micromorphology. The polymerization degree of CWM2-28 d is the optimal (51.57%) because its polymerization structure is improved by the combination of [PO4] and [SiO4].

- (4)

- The consolidation capacity of Na, As, Cd, and Hg in CWM2 is higher than that of other CWMs under the action of the PS admixture. The harmful elements of CWM2 are consolidated by physical encapsulation and charge balance, which meet the drinking water requirements of the WHO. Therefore, this work provides a novel idea for the application of PS as an admixture in CFA-based multi-solid waste cementitious material, which is beneficial to the utilization of various solid wastes in building materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, R.; Wang, Q.; Luo, T. Understanding the workability of alkali-activated phosphorus slag pastes: Effects of alkali dose and silicate modulus on early-age hydration reactions. Cem. Concr. Compos. 2022, 133, 104649. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A.; Dong, P.; Bassim, N.; Mahinroosta, M. Resistance of red clay brick waste/phosphorus slag-based geopolymer mortar to acid solutions of mild concentration. J. Build. Eng. 2020, 34, 102066. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, R.; Hu, W.; Jiang, X.; Zhang, X.; Huang, B. Effect of granulated phosphorus slag on physical, mechanical and microstructural characteristics of Class F fly ash based geopolymer. Constr. Build. Mater. 2021, 291, 123287. [Google Scholar] [CrossRef]

- Hassankhani-Majd, Z.; Anbia, M. Recovery of valuable materials from phosphorus slag using nitric acid leaching followed by precipitation method. Resour. Conserv. Recycl. 2021, 169, 105547. [Google Scholar] [CrossRef]

- Chen, Q.; Ding, W.; Sun, H.; Peng, T. Mineral carbonation of yellow phosphorus slag and characterization of carbonated product. Energy 2019, 188, 116102. [Google Scholar] [CrossRef]

- Huang, X.-F.; Yang, X.-B.; Zhao, D.; Ma, L.-P.; Bao, Y.-Z. Effect of BaF2 and CaF2 on properties of Tb3+-doped yellow phosphorus slag luminescent glass-ceramics. Opt. Mater. 2022, 126, 112134. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, X.; Qian, G.; Gong, X.; Nie, X. Evaluation of phosphorus slag (PS) content and particle size on the performance modification effect of asphalt. Constr. Build. Mater. 2020, 256, 119334. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q. Influence behavior of phosphorus slag and fly ash on the interface transition zone in concrete prepared by cement-red mud. J. Build. Eng. 2022, 49, 104017. [Google Scholar] [CrossRef]

- Mehdizadeh, H.; Shao, X.; Mo, K.H.; Ling, T.-C. Enhancement of early age cementitious properties of yellow phosphorus slag via CO2 aqueous carbonation. Cem. Concr. Compos. 2022, 133, 104702. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Q.; Yang, J. Hydration mechanisms of composite binders containing phosphorus slag at different temperatures. Constr. Build. Mater. 2017, 147, 720–732. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Li, L.; Wang, J.; Zhou, Y.; Wang, D. One-step high efficiency crystallization of zeolite A from ultra-fine circulating fluidized bed fly ash by hydrothermal synthesis method. Fuel 2019, 257, 116043. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Ran, J.; Lin, H.; Kang, W.; Zhu, J. Research progress on the performance of circulating fluidized bed combustion ash and its utilization in China. J. Build. Eng. 2022, 52, 104350. [Google Scholar] [CrossRef]

- He, P.; Zhang, X.; Chen, H.; Zhang, Y. Waste-to-resource strategies for the use of circulating fluidized bed fly ash in construction materials: A mini review. Powder Technol. 2021, 393, 773–785. [Google Scholar] [CrossRef]

- Liang, G.; Li, H.; Zhu, H.; Liu, T.; Chen, Q.; Guo, H. Reuse of waste glass powder in alkali-activated metakaolin/fly ash pastes: Physical properties, reaction kinetics and microstructure. Resour. Conserv. Recycl. 2021, 173, 105721. [Google Scholar] [CrossRef]

- Li, D.; Sun, R.; Wang, D.; Ren, C.; Fang, K. Study on the pozzolanic activity of ultrafine circulating fluidized-bed fly ash prepared by jet mill. Fuel 2021, 291, 120220. [Google Scholar] [CrossRef]

- Li, D.; Wang, D.; Ren, C.; Rui, Y. Investigation of rheological properties of fresh cement paste containing ultrafine circulating fluidized bed fly ash. Constr. Build. Mater. 2018, 188, 1007–1013. [Google Scholar] [CrossRef]

- Zahedi, M.; Jafari, K.; Rajabipour, F. Properties and durability of concrete containing fluidized bed combustion (FBC) fly ash. Constr. Build. Mater. 2020, 258, 119663. [Google Scholar] [CrossRef]

- Chen, X.; Gao, J.; Yan, Y.; Liu, Y. Investigation of expansion properties of cement paste with circulating fluidized bed fly ash. Constr. Build. Mater. 2017, 157, 1154–1162. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Zhang, Z.; Li, Y.; Gu, J. Synergic effects of circulating fluidized bed fly ash-red mud-blast furnace slag in green cementitious materials: Hydration products and environmental performance. J. Build. Eng. 2022, 58, 105007. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Zhang, Z.; Li, Y.; Gu, J.; Wang, Y.; Xue, Y. Circulating fluidized bed fly ash-blast furnace slag based cementitious materials: Hydration behaviors and performance. Constr. Build. Mater. 2022, 342, 128006. [Google Scholar] [CrossRef]

- Zhang, N.; Tang, B.; Liu, X. Cementitious activity of iron ore tailing and its utilization in cementitious materials, bricks and concrete. Constr. Build. Mater. 2021, 288, 123022. [Google Scholar] [CrossRef]

- GB 175-2007, Common Portland Cement. 2007. Available online: https://www.antpedia.com/standard/5156435.html (accessed on 11 November 2007).

- GB/T 17671-2021, Test Method of Cement Mortar Strength (IOS Method). 2021. Available online: http://www.doc88.com/p-08773985826297.html (accessed on 1 July 2022).

- EN 451-1-2017, Method of Testing Fly Ash—Part 1: Determination of Free Calcium Oxide Content. 2017. Available online: https://www.doc88.com/p-9189147009468.html (accessed on 3 May 2017).

- Wu, Y.; Zhang, Q.; Li, L. Effect of phosphorus slag on retarding properties of ordinary portland cement. Bull. Chin. Ceram. Soc. 2019, 38, 1177. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, J.; Zhou, X.; Li, Y.; Wang, Y.; Xue, Y.; Liu, X. Circulating fluidized bed fly ash based multi-solid wastes road base materials: Hydration characteristics and utilization of SO3 and f-CaO. J. Clean. Prod. 2021, 316, 128355. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Wang, Y.; Li, Z.; Li, Y.; Ren, Y. Binary reaction behaviors of red mud based cementitious material: Hydration characteristics and Na+ utilization. J. Hazard. Mater. 2021, 410, 124592. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhao, X.; Yin, H.; Chen, J.; Zhang, N. Intermediate-calcium based cementitious materials prepared by MSWI fly ash and other solid wastes: Hydration characteristics and heavy metals solidification behavior. J. Hazard. Mater. 2018, 349, 262–271. [Google Scholar] [CrossRef]

- Liu, X.; Yang, S.; Liu, S.; Yang, Y. Performance and mechanism of phosphorus removal by slag ceramsite filler. Process Saf. Environ. Prot. 2021, 148, 858–866. [Google Scholar] [CrossRef]

- Hao, X.; Liu, X.; Zhang, Z.; Zhang, W.; Lu, Y.; Wang, Y.; Yang, T. In-depth insight into the cementitious synergistic effect of steel slag and red mud on the properties of composite cementitious materials. J. Build. Eng. 2022, 52, 104449. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, H.; Sun, Y.; Zhang, N. Correlation between ~(29)Si polymerization and cementitious activity of coal gangue. J. Zhejiang Univ. 2009, 10, 1334–12240. [Google Scholar] [CrossRef]

- Szumera, M. Structural investigations of silicate–phosphate glasses containing MoO3 by FTIR, Raman and 31P MAS NMR spectroscopies. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 130, 1–6. [Google Scholar] [CrossRef]

- Cody, G.D.; Mysen, B.; Sághi-Szabó, G.; A Tossell, J. Silicate-phosphate interactions in silicate glasses and melts: I. A multinuclear (27Al,29Si,31P) MAS NMR and ab initio chemical shielding (31P) study of phosphorous speciation in silicate glasses. Geochim. Cosmochim. Acta 2001, 65, 2395–2411. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, R.; Zhao, X.; Jia, J.; Min, Y. Quantification of phosphorus structures in CaO–SiO2–P2O5 glasses via Raman spectroscopy. J. Non-Cryst. Solids 2021, 557, 120579. [Google Scholar] [CrossRef]

- Mysen, B.O.; Ryerson, F.; Virgo, D. The structural role of phosphorus in silicate melts. Am. Mineral. 1981, 66, 106–117. Available online: http://www.minsocam.org/ammin/AM66/AM66_106.pdf (accessed on 1 February 1981).

- Liu, M.; Zhao, Y.; Yu, Z.; Cao, Z. Impact of Ni(Ⅱ) and Cd(Ⅱ) on the hydration and microstructure of cement pastes for immobilization: C-A-S-H composition and binding characteristic. Constr. Build. Mater. 2021, 310, 125284. [Google Scholar] [CrossRef]

| Oxide | CFA | RM | BFS | CC | Admixture | ||

|---|---|---|---|---|---|---|---|

| HBFS | PS | GS | |||||

| T-CaO | 12.73 | 21.09 | 34.14 | 63.87 | 39.74 | 46.67 | 26.41 |

| f-CaO | 4.10 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| SiO2 | 34.15 | 19.02 | 34.64 | 22.75 | 29.19 | 36.79 | 34.79 |

| Al2O3 | 24.04 | 22.46 | 18.64 | 5.76 | 15.02 | 2.93 | 15.96 |

| SO3 | 6.67 | 0.29 | 1.66 | 0.38 | 2.73 | 1.30 | 0.49 |

| Fe2O3 | 5.31 | 15.15 | 0.86 | 3.17 | 0.82 | 0.13 | 9.53 |

| MgO | 1.25 | 0.46 | 6.96 | 2.06 | 9.38 | 1.32 | 0.98 |

| TiO2 | 0.76 | 4.33 | 0.77 | 0.24 | 0.81 | 0.20 | 0.89 |

| P2O5 | 0.23 | 0.67 | 0.04 | 0.19 | 0.02 | 3.34 | 0.07 |

| F | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 3.04 | 0.00 |

| K2O | 0.82 | 0.57 | 0.63 | 0.82 | 0.50 | 0.69 | 0.70 |

| Na2O | 0.20 | 6.01 | 0.62 | 0.33 | 0.47 | 0.98 | 4.89 |

| LOI | 10.38 | 8.84 | 0.50 | 0.03 | 0.60 | 1.85 | 3.94 |

| Total | 96.54 | 98.89 | 99.46 | 99.6 | 99.28 | 99.24 | 98.65 |

| Sample | CFA | RM | BFS | CC | Admixture | (Ca + Na)/(Si + Al) Mass Ratio |

|---|---|---|---|---|---|---|

| CWM1 | 30 | 10 | 20 | 30 | 10 (HBFS) | 0.81 |

| CWM2 | 30 | 10 | 20 | 30 | 10 (PS) | 0.84 |

| CWM3 | 30 | 10 | 20 | 30 | 10 (GS) | 0.78 |

| NO. | Compressive Strength (MPa) | Setting Time (min) | Expansion Value (mm) | SO3 (wt.%) | MgO (wt.%) | ||

|---|---|---|---|---|---|---|---|

| 3 Days | 28 Days | Initial | Final | ||||

| CWM1 | 23.85 | 47.10 | 131 | 217 | 2.00 | 2.75 | 3.37 |

| CWM2 | 26.80 | 51.15 | 146 | 231 | 0.70 | 2.61 | 2.56 |

| CWM3 | 27.60 | 45.30 | 138 | 199 | 1.70 | 2.52 | 2.53 |

| GB 175–2007 [22] | 17.00 | 42.50 | ≥45 | ≤600 | ≤5.00 | ≤3.50 | ≤6.00 |

| Sample | Peak Position (ppm) | Assign | Relative | Polymerization Degree of RBO |

|---|---|---|---|---|

| CWM1-28 d | −66.53 | SiQ0 | 18.50 | 46.34% |

| −72.47 | SiQ1 | 100.00 | ||

| −77.97 | SiQ2(1Al) | 71.68 | ||

| −81.07 | SiQ3(2Al) | 65.32 | ||

| CWM2-28 d | −67.7 | SiQ0 | 14.89 | 51.57% |

| −72.89 | SiQ1 | 100.00 | ||

| −78.96 | SiQ2(1Al) | 95.74 | ||

| −83.30 | SiQ3(2Al) | 97.87 | ||

| −101.40 | SiQ4 | 10.64 | ||

| CWM3-28 d | −65.76 | SiQ0 | 31.78 | 44.75% |

| −72.17 | SiQ1 | 100.00 | ||

| −79.08 | SiQ2(1Al) | 68.22 | ||

| −81.33 | SiQ3(2Al) | 53.49 |

| Sample | Na | As | Cd | Hg |

|---|---|---|---|---|

| CFA | 5.2753 | 0.0441 | 0.0015 | <0.0001 |

| RM | 685.6372 | 0.0491 | 0.0016 | 0.0022 |

| PS | 12.5648 | 0.0007 | <0.0001 | <0.0001 |

| GS | 37.3006 | 0.0046 | 0.0005 | <0.0001 |

| CWM1-28 d | 70.9931 | 0.0004 | 0.0004 | 0.0002 |

| CWM2-28 d | 56.6467 | 0.0001 | 0.0002 | <0.0001 |

| CWM3-28 d | 66.0012 | 0.0006 | 0.0004 | 0.0001 |

| Requirements of the WHO | 200.0000 | 0.0100 | 0.0030 | 0.00100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wei, C.; Liu, X.; Zhang, Z. Effect of Phosphorus Slag Admixture on the Properties and Hydration Mechanism of Circulating Fluidized Bed Fly Ash-Based Multi-Solid Waste Cementitious Material. Materials 2022, 15, 6774. https://doi.org/10.3390/ma15196774

Zhang W, Wei C, Liu X, Zhang Z. Effect of Phosphorus Slag Admixture on the Properties and Hydration Mechanism of Circulating Fluidized Bed Fly Ash-Based Multi-Solid Waste Cementitious Material. Materials. 2022; 15(19):6774. https://doi.org/10.3390/ma15196774

Chicago/Turabian StyleZhang, Wei, Chao Wei, Xiaoming Liu, and Zengqi Zhang. 2022. "Effect of Phosphorus Slag Admixture on the Properties and Hydration Mechanism of Circulating Fluidized Bed Fly Ash-Based Multi-Solid Waste Cementitious Material" Materials 15, no. 19: 6774. https://doi.org/10.3390/ma15196774

APA StyleZhang, W., Wei, C., Liu, X., & Zhang, Z. (2022). Effect of Phosphorus Slag Admixture on the Properties and Hydration Mechanism of Circulating Fluidized Bed Fly Ash-Based Multi-Solid Waste Cementitious Material. Materials, 15(19), 6774. https://doi.org/10.3390/ma15196774