Mechanical Properties and Damage Layer Thickness of Green Concrete under a Low-Temperature Environment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design of Mix Ratio

Preparation and Curing of the Test Pieces

2.3. Experimental Methods

2.3.1. Low-Temperature Test

2.3.2. Mechanical Properties

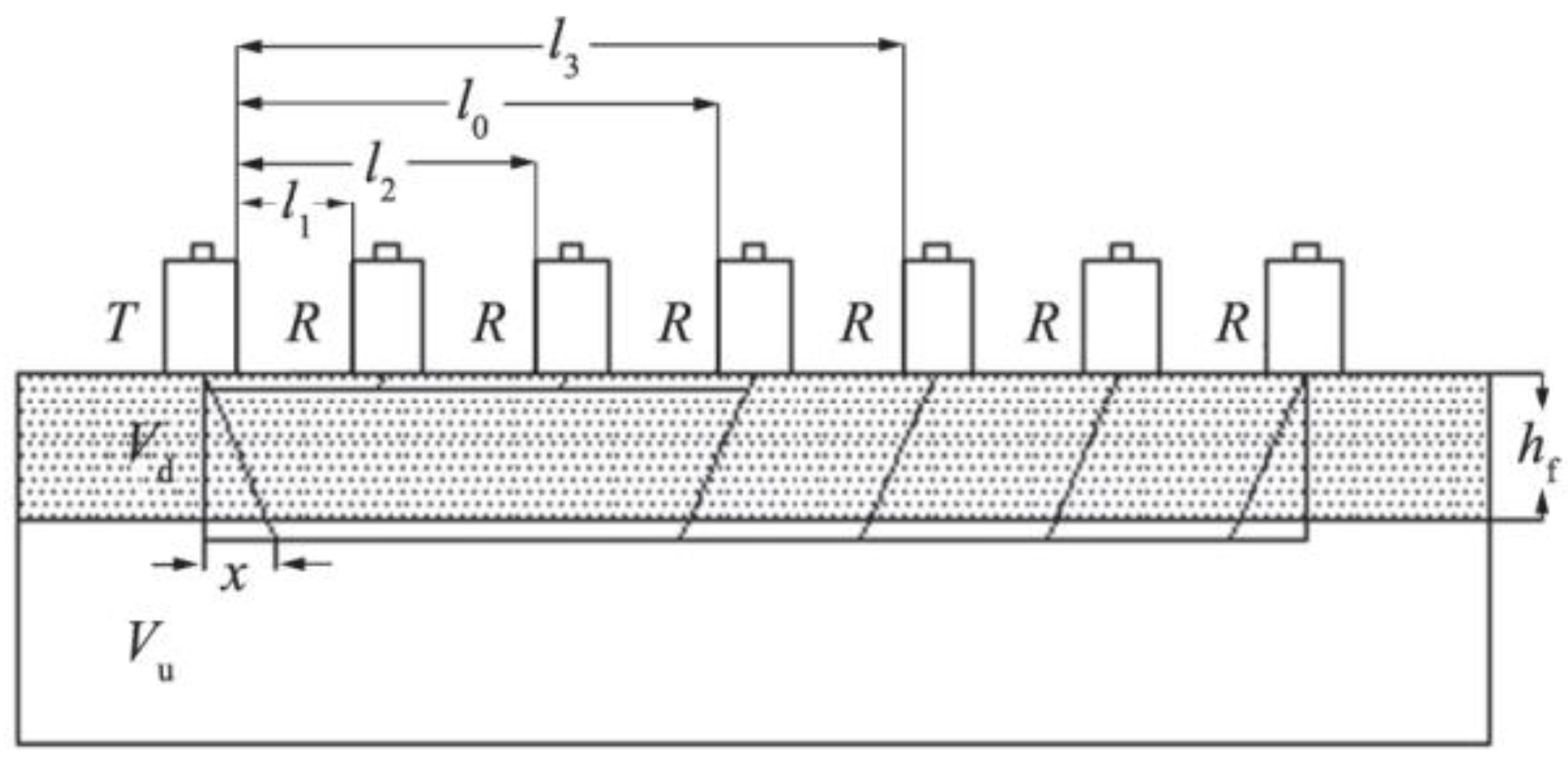

2.3.3. Damaged Layer Detection

3. Results

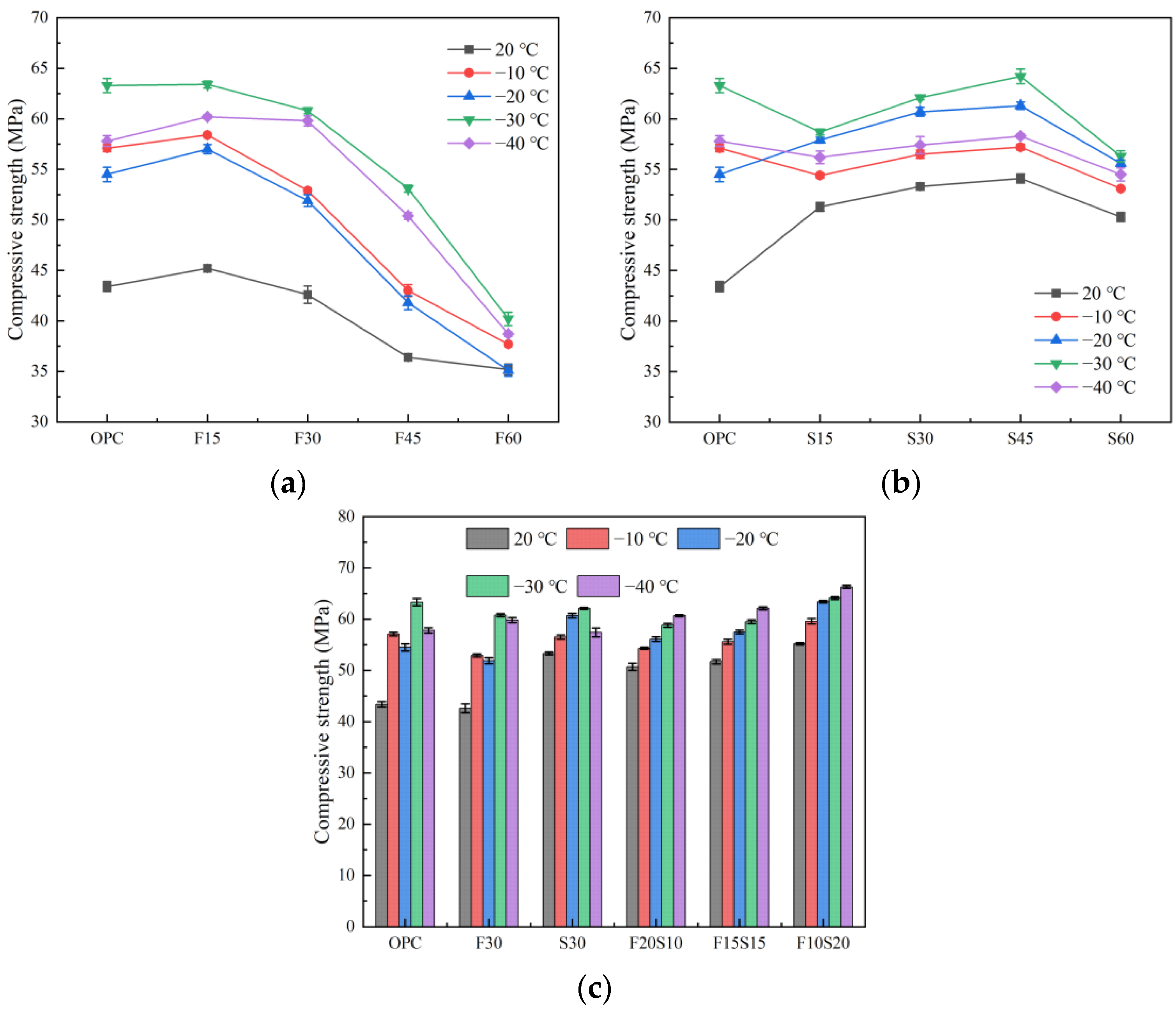

3.1. Compressive Strength

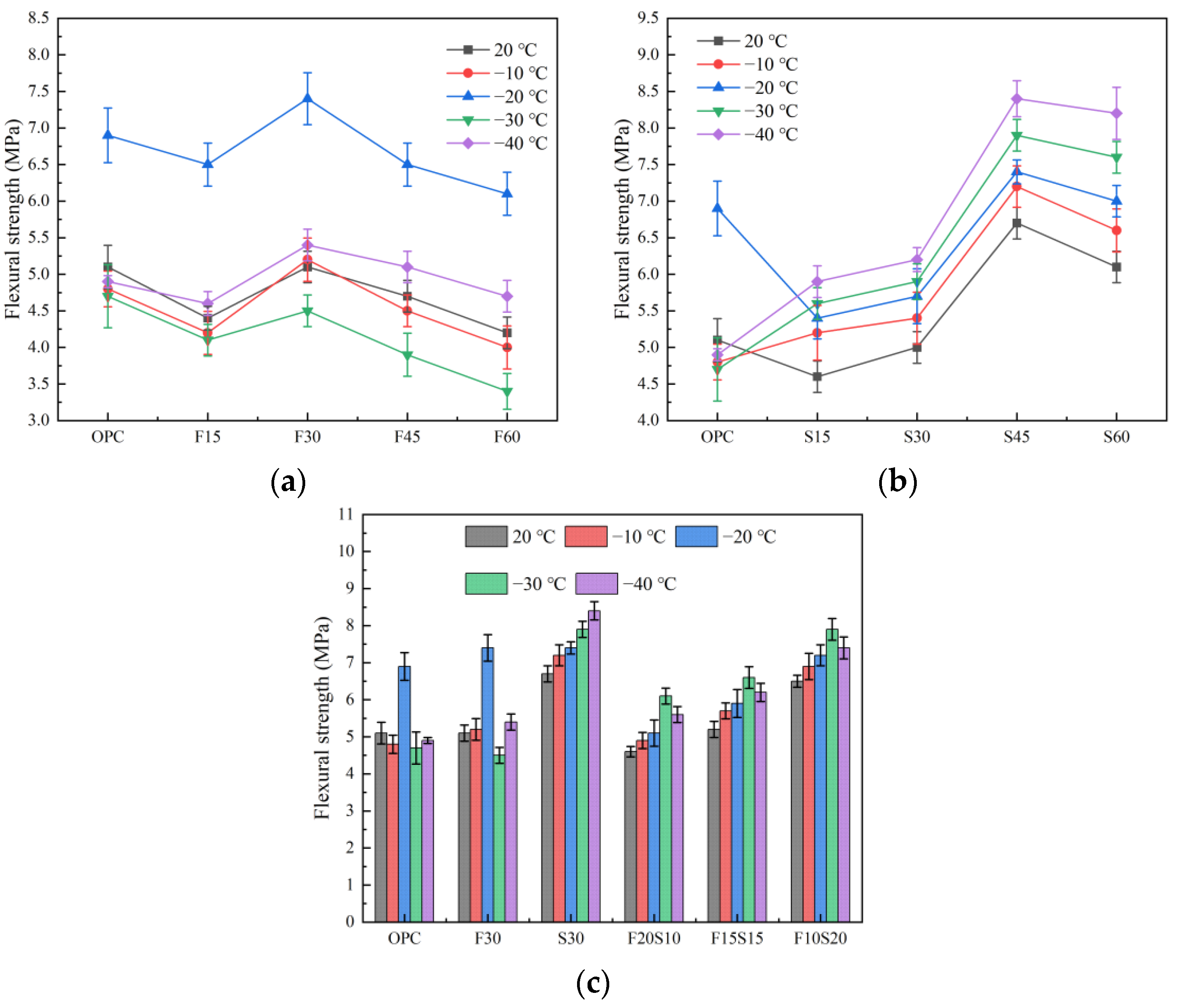

3.1.1. Flexural Strength

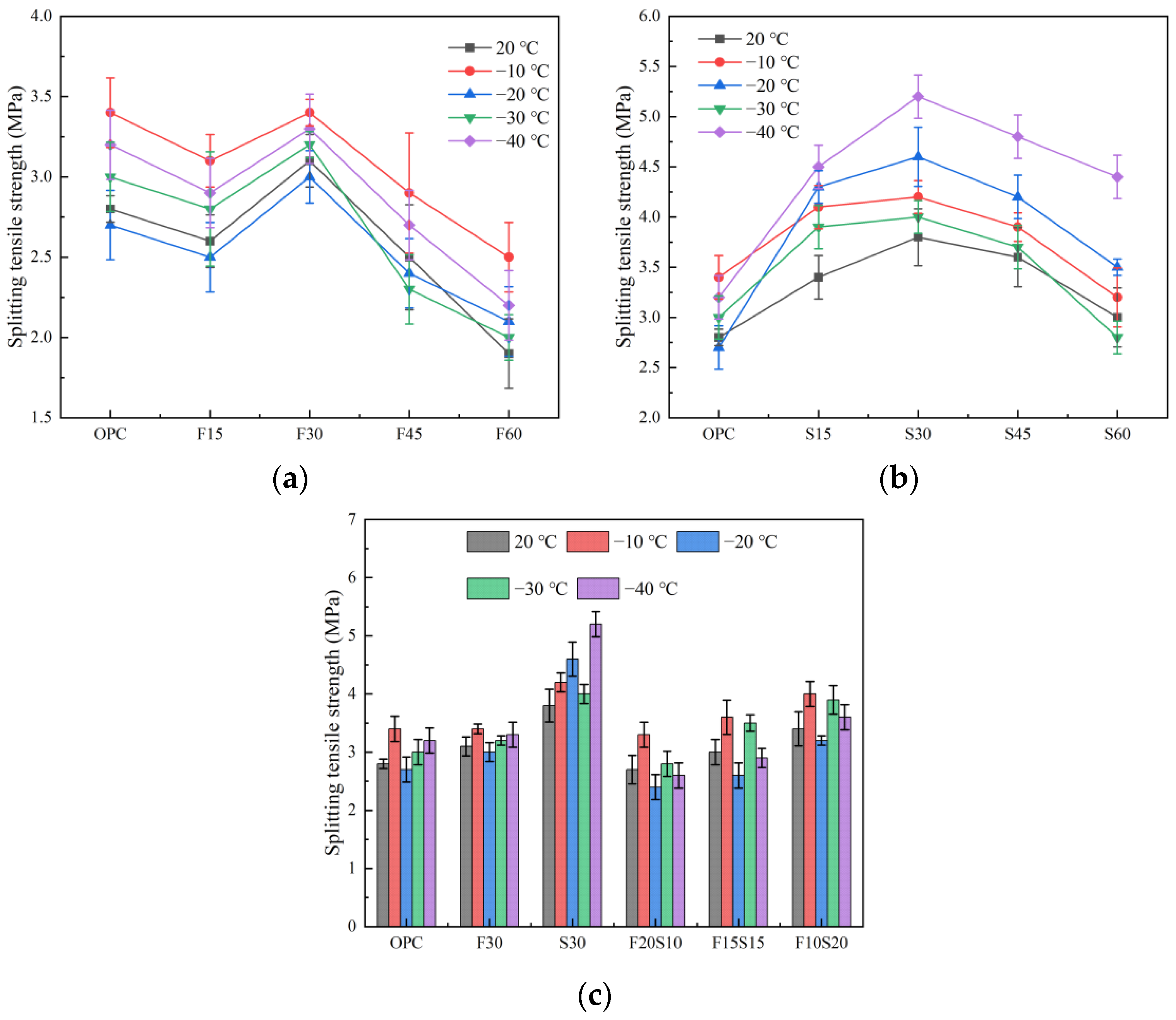

3.1.2. Splitting Tensile Strength

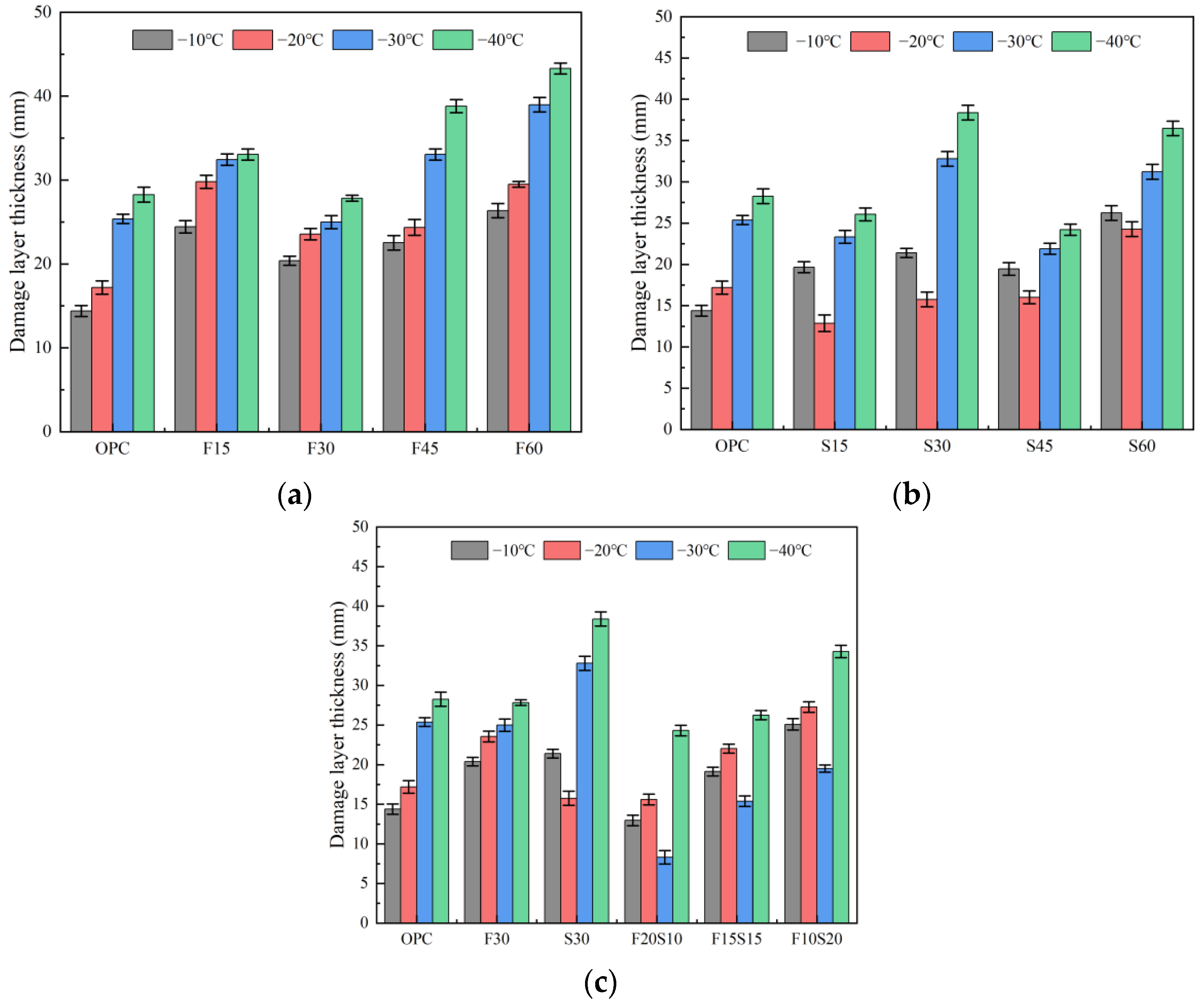

3.2. Damage Layer Thickness

4. Conclusions

- (1)

- As the fly ash content was increased (1560%), the compressive strength of the concrete gradually decreased, and the strength of the concrete (F15) was maximal when the content was 15%. The flexural strength and the splitting tensile strength of the concrete increased first and then decreased as the fly ash content was increased, and the strength was maximal when the fly ash content was 30% (F30). With the decrease in temperature, the strength of the fly ash concrete fluctuated greatly. In terms of the compressive strength, the strength of fly-ash concrete at different low temperatures was higher than that of the concrete at room temperature, especially at −30 °C, followed by those at −40, −10, and −20 °C. In terms of the flexural strength, the strength of the fly ash concrete at −20 °C was significantly higher than that at other temperatures. For the −40 ℃ variant, the flexural strength and splitting tensile strength attained the maximum peak.

- (2)

- The positive influence of the slag on the mechanical properties of the concrete was considerable. When the slag amount was 30% (S30) within the test range, the splitting tensile strength was maximal, and when the slag amount was 45% (S45), the compressive strength and flexural strength of the concrete were the highest. Slag concrete, exposed to a low temperature of −30 °C, yielded the maximum compressive strength; for the −40 °C variant, the flexural strength and splitting tensile strength attained the maximum peak.

- (3)

- Under the condition of the double mixing of the fly ash and slag, the concrete strength at room temperature was greatly improved, compared with the OPC due to the synergistic effect of the fly ash and slag. When fly ash: slag = 2:1 (F10S20), the mechanical properties are superior to the rest, and the compressive strength is maximal, which is 127.2, 129.6, and 103.6% of the OPC, F30 and S30, respectively. The compressive strength at different temperatures was higher than that of the F30 and S30 groups, and the optimum temperature was −40 °C. However, its flexural strength at different temperatures was lower than that of the S30 group, but the flexural strength at other temperatures was higher than that of F30 group, except at −20 °C. Notably, its splitting strength is less than that of the S30 group at different temperatures.

- (4)

- During low temperatures, the thermal stress will be generated in the concrete. During thermal stress, the damage layer thickness of the concrete will increase as the temperature decreases. For the single fly ash blending, the maximum value of the damage layer thickness is 43.3 mm at −40 °C. As the slag content increases, the damage layer thickness first decreases and then increases, and as the temperature decreases, the damage layer thickness of the concrete increases. For the concrete specimen containing both the fly ash and slag, when the fly ash-to-slag ratio is 1:1 (F15S15), the damage layer thickness is the smallest, and is superior to the OPC, F30, and S30. At −30 °C, the damage layer thickness of the concrete is 8.31 mm, which is 32.8%, 33.3%, and 25.3% of the OPC, F30 and S30, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, X.J.; Chen, W.Z.; Wang, H.; Zhao, W.S. Research on temperature control technology of tunnel secondary lining concrete in winter. Chin. J. Rock. Mech. Eng. 2013, 32, 150–160. (In Chinese) [Google Scholar]

- Tian, Y. Influence of admixture on strength development of concrete at low temperature. Constr. Design. Proj. 2015, 4, 59–61. (In Chinese) [Google Scholar]

- Sun, S.W.; Ding, S.Q.; Han, B.G.; Dong, S.F.; Yu, X.; Zhou, D.B.; Ou, J.P. Multi-layer graphene-engineered cementitious composites with multifunctionality/intelligence. Compos. Part B Eng. 2017, 129, 221–232. [Google Scholar] [CrossRef]

- Dong, W.K.; Li, W.G.; Wang, K.J.; Han, B.G.; Sheng, D.C.; Shah, S.P. Investigation on physicochemical and piezoresistive properties of smart MWCNT/cementitious composite exposed to elevated temperatures. Cem. Concr. Compos. 2020, 112, 103675. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Ahmad, A.; Ostrowski, K.A.; Maślak, M.; Farooq, F.; Mehmood, I.; Nafees, A. Comparative study of supervised machine learning algorithms for predicting the compressive strength of concrete at high temperature. Materials 2021, 14, 4222. [Google Scholar] [CrossRef]

- Ahmad, M.; Hu, J.-L.; Ahmad, F.; Tang, X.-W.; Amjad, M.; Iqbal, M.; Asim, M.; Farooq, A. Supervised Learning Methods for Modeling Concrete Compressive Strength Prediction at High Temperature. Materials 2021, 14, 1983. [Google Scholar] [CrossRef]

- Lin, H.; Han, Y.; Liang, S.; Gong, F.; Han, S.; Shi, C.; Feng, P. Effects of low temperatures and cryogenic freeze-thaw cycles on concrete mechanical properties: A literature review. Constr. Build. Mater. 2022, 345, 128287. [Google Scholar] [CrossRef]

- Dahmani, L.; Khenane, A.; Kaci, S. Behavior of the reinforced concrete at cryogenic temperatures. Cryogenics 2007, 47, 517–525. [Google Scholar] [CrossRef]

- Yamane, A.; Zhao, K. Ultra-low temperature concrete. Low Temp. Archit. Technol. 1980, 01, 57–60. (In Chinese) [Google Scholar]

- MacLean, T.J.; Lloyd, A. Compressive stress–strain response of concrete exposed to low temperatures. J. Cold. Red. Eng. 2019, 33, 04019014. [Google Scholar] [CrossRef]

- Miura, T. The properties of concrete at very low temperature. Mater. Struct. 1989, 22, 243–254. [Google Scholar] [CrossRef]

- Okada, T.; Iguro, M. Bending behaviour of prestressed concrete beams under low temperature. Concr. Eng. Assoc. 1978, 208, 15–17. [Google Scholar]

- Luis, A.M.; John, E.S.; Mervyn, J.K. Cyclic response of reinforced concrete members at low temperatures. Cold. Reg. Engrg. 2008, 22, 79. [Google Scholar]

- Korhonen, C.J.; Ryan, R. New Low-temperature Admixtures. Concr. Int. 2000, 22, 33–39. [Google Scholar]

- Reginald, B.; Iyengar, S.; Grasley, Z.C.; Masad, E.A.; Zollinger, D.G. A review of concrete properties at cryogenic temperatures: Towards direct LNG containment. Constr. Build. Mater. 2013, 47, 760–770. [Google Scholar] [CrossRef]

- Lu, Z.; Feng, Z.G.; Yao, D.; Li, X.; Ji, H. Freeze-thaw resistance of Ultra-High performance concrete: Dependence on concrete composition. Constr. Build. Mater. 2021, 293, 123523. [Google Scholar] [CrossRef]

- Jiang, Z.; He, B.; Zhu, X.; Ren, Q.; Zhang, Y. State-of-the-art review on properties evolution and deterioration mechanism of concrete at cryogenic temperature. Constr. Build. Mater. 2020, 257, 119456. [Google Scholar] [CrossRef]

- Krstulovic-Opara, N. Liquefied natural gas storage: Material behavior of concrete at cryogenic temperatures. ACI Mater. J. 2007, 104, 297–306. Available online: https://www.researchgate.net/publication/283749780_Liquefied_natural_gas_storage_Material_behavior_of_concrete_at_cryogenic_temperatures (accessed on 24 September 2022).

- Medina, C.; de Rojas, M.I.S.; Frías, M. Freeze-thaw durability of recycled concrete containing ceramic aggregate. J. Clean. Prod. 2013, 40, 151–160. [Google Scholar] [CrossRef]

- Rahman, S.; Grasley, Z. A poromechanical model of freezing concrete to elucidate damage mechanisms associated with substandard aggregates. Cem. Concr. Res. 2014, 55, 88–101. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, Y.; Zhang, S.; Xu, F.; Zhu, X.; Jiang, X.; Zhou, L.; Shen, Y.; Chen, Q.; Yan, Z.; et al. Research progress of the thermophysical and mechanical properties of concrete subjected to freeze-thaw cycles. Constr. Build. Mater. 2022, 330, 127254. [Google Scholar] [CrossRef]

- Chang, Z.; Zhang, W.; Zhao, G.; Dong, F.; Geng, X. Aging Stability Analysis of Slope Considering Cumulative Effect of Freeze–Thaw Damage—A Case Study. Minerals 2022, 12, 598. [Google Scholar] [CrossRef]

- Yuan, L.; Niu, G.; Jiang, L.; Sun, Y.; Fei, Q. Study on concrete damage under the combined action of sulfate erosion and freeze-thaw cycle. Bull. Chin. Ceram. Soc. 2013, 32, 1171–1176. [Google Scholar] [CrossRef]

- Chu, H.Y.; Chen, J.K. Evolution of viscosity of concrete under sulfate attack. Constr. Build. Mater. 2013, 39, 46–50. [Google Scholar] [CrossRef]

- Ould, N.S.; Gou, M.; Piwakowski, B.; Buyle-Bodin, F. Detection of chemical damage in concrete using ultrasound. Ultrasonics 2002, 40, 247–251. [Google Scholar] [CrossRef]

- BS EN 12390-4; Testing Hardened Concrete, Part 4: Specification for Compressive Strength Testing Machines. BSI: London, UK, 2019.

- Sun, C.; Niu, G.; Yuan, C.; Gai, Q. Study on the relationship between kinetic elastic modulus of concrete and ultrasonic sound velocity and compressive strength. Concrete 2010, 04, 14–16. (In Chinese) [Google Scholar]

- Guan, X.; Chen, J.; Qiu, J.; Gao, Y.; Gao, J. Damage evaluation method based on ultrasound technique for gangue concrete under freezing-thawing cycles. Constr. Build. Mater. 2020, 246, 118437. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Q.; Mao, M.; Li, J. Carbonation performance of concrete with fly ash as fine aggregate after stress damage and high temperature exposure. Constr. Build. Mater. 2020, 242, 118125. [Google Scholar] [CrossRef]

- Zhang, D.; Mao, M.; Zhang, S.; Yang, Q. Influence of stress damage and high temperature on the freeze–thaw resistance of concrete with fly ash as fine aggregate. Constr. Build. Mater. 2019, 229, 116845. [Google Scholar] [CrossRef]

- Ding, X.; Zhou, R.; Wang, Y. Effect of silica ash on the frost resistance of concrete and its pore structure. Concrete 2017, 02, 53–55. (In Chinese) [Google Scholar]

- Monteiro, P.J.M.; Rashed, A.I.; Bastacky, J.; Hayes, T.L. Ice in cement paste as analyzed in the low-temperature scanning electron microscope. Cem. Concr. Res. 1989, 19, 306–314. [Google Scholar] [CrossRef]

- Wang, Y.R.; Cao, Y.B.; Zhang, P.; Ma, Y.W.; Zhao, T.J.; Wang, H.; Zhang, Z.H. Water absorption and chloride diffusivity of concrete under the coupling effect of uniaxial compressive load and freeze-thaw cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Xu, Y.; Luo, M.; Hei, C.; Song, G. Quantitative evaluation of compactness of concrete-filled fiber-reinforced polymer tubes using piezoceramic transducers and time difference of arrival. Smart Mater. Struct. 2018, 27, 035023. Available online: https://iopscience.iop.org/article/10.1088/1361-665X (accessed on 24 September 2022). [CrossRef]

- Zhang, J.; Lv, T.; Han, Q.; Zhu, Y.; Hou, D.; Dong, B. Effects of fly ash on MgO-based shrinkage-compensating cement: Microstructure and properties. Constr. Bulid. Mater. 2022, 399, 1274. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Liang, H.; Jiang, J.; Yang, Y.; He, Z. Synergistic enhancement of mechanical property of the high replacement low-calcium ultrafine fly ash blended cement paste by multiple chemical activators. J. Build. Eng. 2020, 32, 101520. [Google Scholar] [CrossRef]

- Li, H.; Tong, Y.; Zhang, H.; Zhang, S.; Duan, J. Study on Road Performance of Cement Fly Ash Stabilized Steel Slag-Concrete Recycled Macadam. Materials 2021, 24, 7530. [Google Scholar] [CrossRef]

- Marshall, A.L. Cryogenic concrete. Cryogenics 1982, 22, 555–565. [Google Scholar] [CrossRef]

| Oxide | Al2O3 | SiO2 | Fe2O3 | CaO | Na2O | K2O | SO3 |

|---|---|---|---|---|---|---|---|

| Cement | 7.60 | 22.46 | 5.00 | 57.15 | 0.31 | 0.86 | 2.96 |

| Fly ash | 26.38 | 47.85 | 8.43 | 5.81 | 1.11 | 2.22 | 1.94 |

| Slag | 14.8 | 28.7 | 0.43 | 38.1 | 1.78 | 0.66 | 2.18 |

| Code | Fly Ash | Slag | Cement | Water | Sand | Coarse Aggregate | Super-Plasticiser |

|---|---|---|---|---|---|---|---|

| OPC | 0 | 0 | 400 | 160 | 756 | 1134 | 3 |

| F15 | 60 | 0 | 340 | 4.3 | |||

| F30 | 120 | 0 | 280 | 5.2 | |||

| F45 | 180 | 0 | 220 | 6.1 | |||

| F60 | 240 | 0 | 160 | 7.1 | |||

| S15 | 0 | 60 | 340 | 3.4 | |||

| S30 | 0 | 120 | 280 | 3.9 | |||

| S45 | 0 | 180 | 220 | 4.6 | |||

| S60 | 0 | 240 | 160 | 5.0 | |||

| F20S10 | 80 | 40 | 280 | 4.7 | |||

| F15S15 | 60 | 60 | 280 | 4.4 | |||

| F10S20 | 40 | 80 | 280 | 3.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Zhang, T.; Yang, Q. Mechanical Properties and Damage Layer Thickness of Green Concrete under a Low-Temperature Environment. Materials 2022, 15, 7409. https://doi.org/10.3390/ma15217409

Zhang D, Zhang T, Yang Q. Mechanical Properties and Damage Layer Thickness of Green Concrete under a Low-Temperature Environment. Materials. 2022; 15(21):7409. https://doi.org/10.3390/ma15217409

Chicago/Turabian StyleZhang, Dongsheng, Tianhao Zhang, and Qiuning Yang. 2022. "Mechanical Properties and Damage Layer Thickness of Green Concrete under a Low-Temperature Environment" Materials 15, no. 21: 7409. https://doi.org/10.3390/ma15217409

APA StyleZhang, D., Zhang, T., & Yang, Q. (2022). Mechanical Properties and Damage Layer Thickness of Green Concrete under a Low-Temperature Environment. Materials, 15(21), 7409. https://doi.org/10.3390/ma15217409