Experimental Study of a Compact Microwave Applicator for Evaporation of Airflow-Entrained Droplets

Abstract

:1. Introduction

2. Materials and Methods

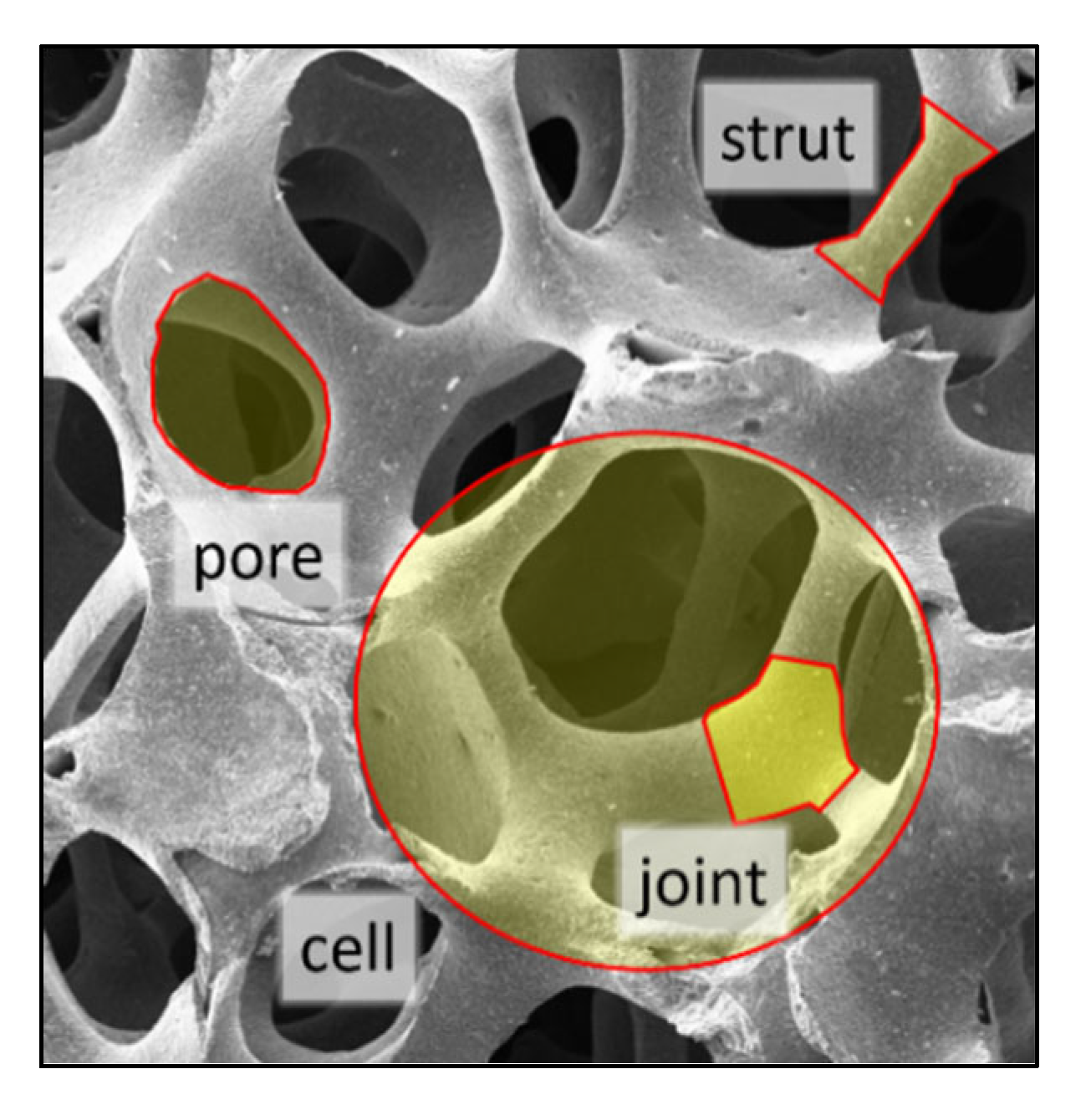

2.1. Open-Cell Ceramic Foams

2.2. Pressure Drop and Droplet Residence Time

2.3. Dielectric Properties

2.4. Governing Equations

2.5. Design of the Microwave Applicator

2.6. Mesh Size and Boundary Conditions

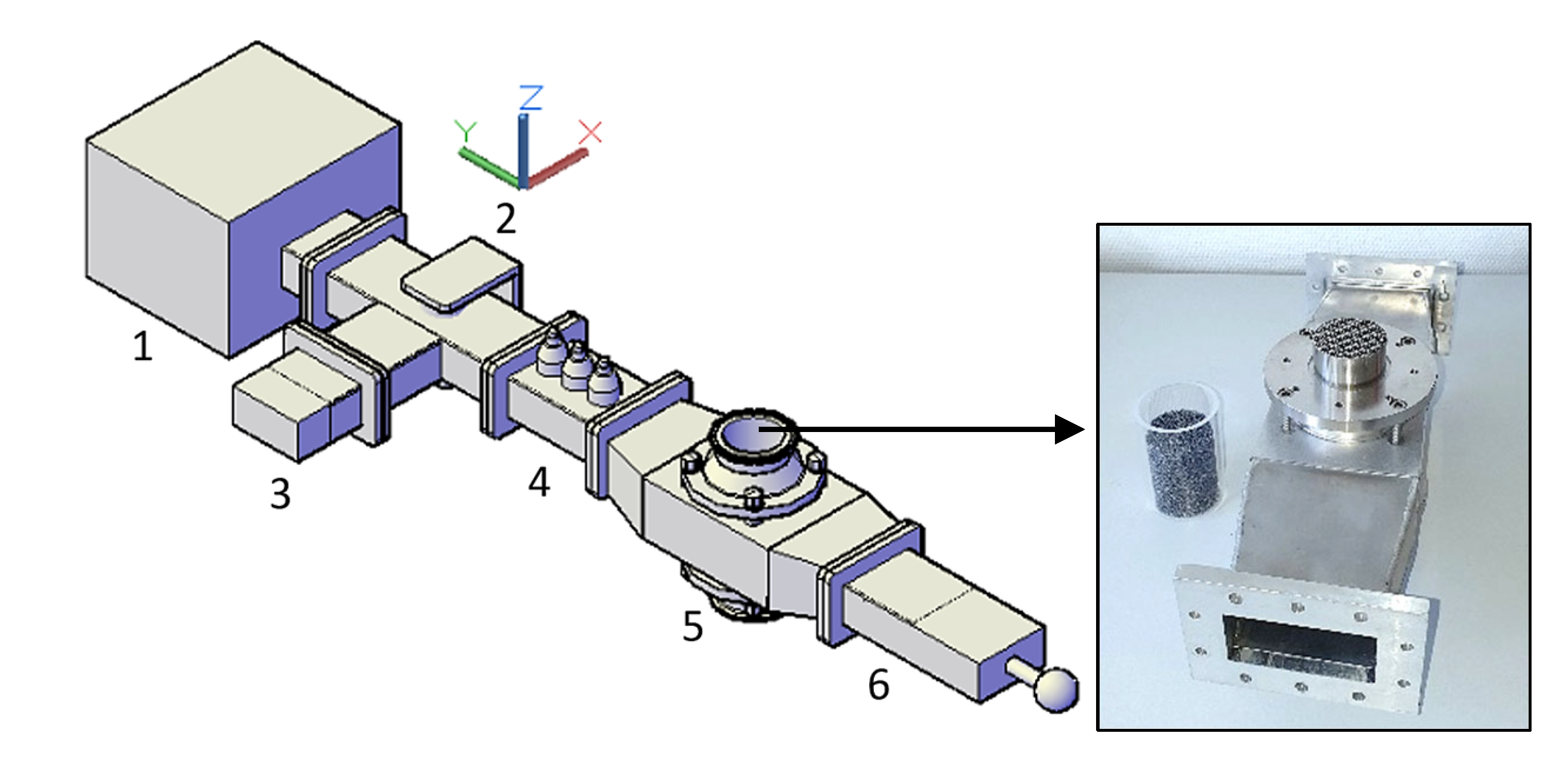

2.7. Experimental Setup

3. Results and Discussion

3.1. Electric Field Distribution

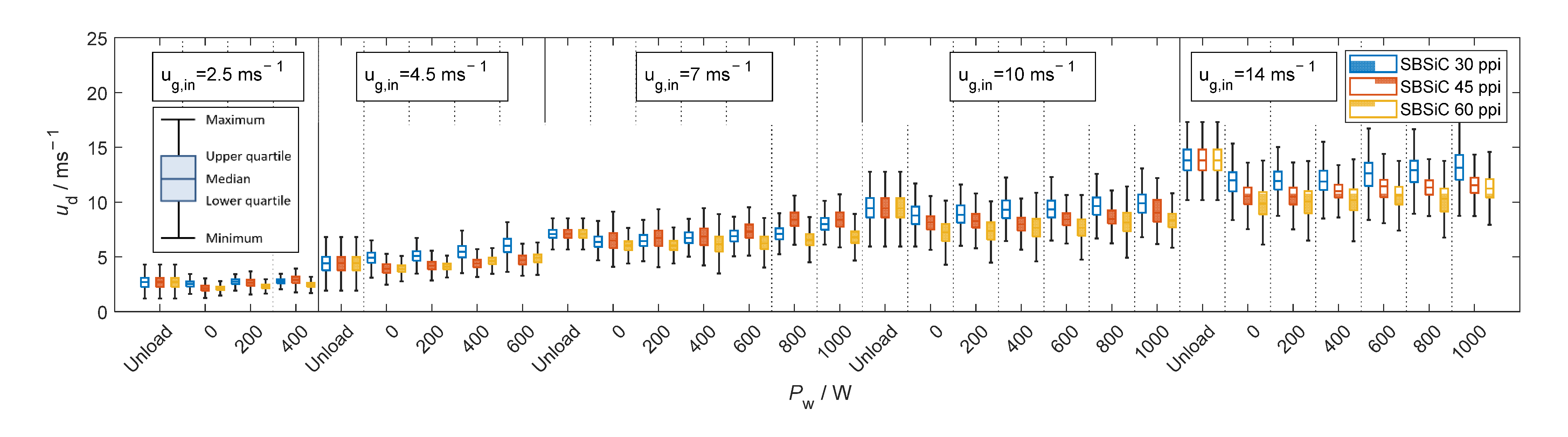

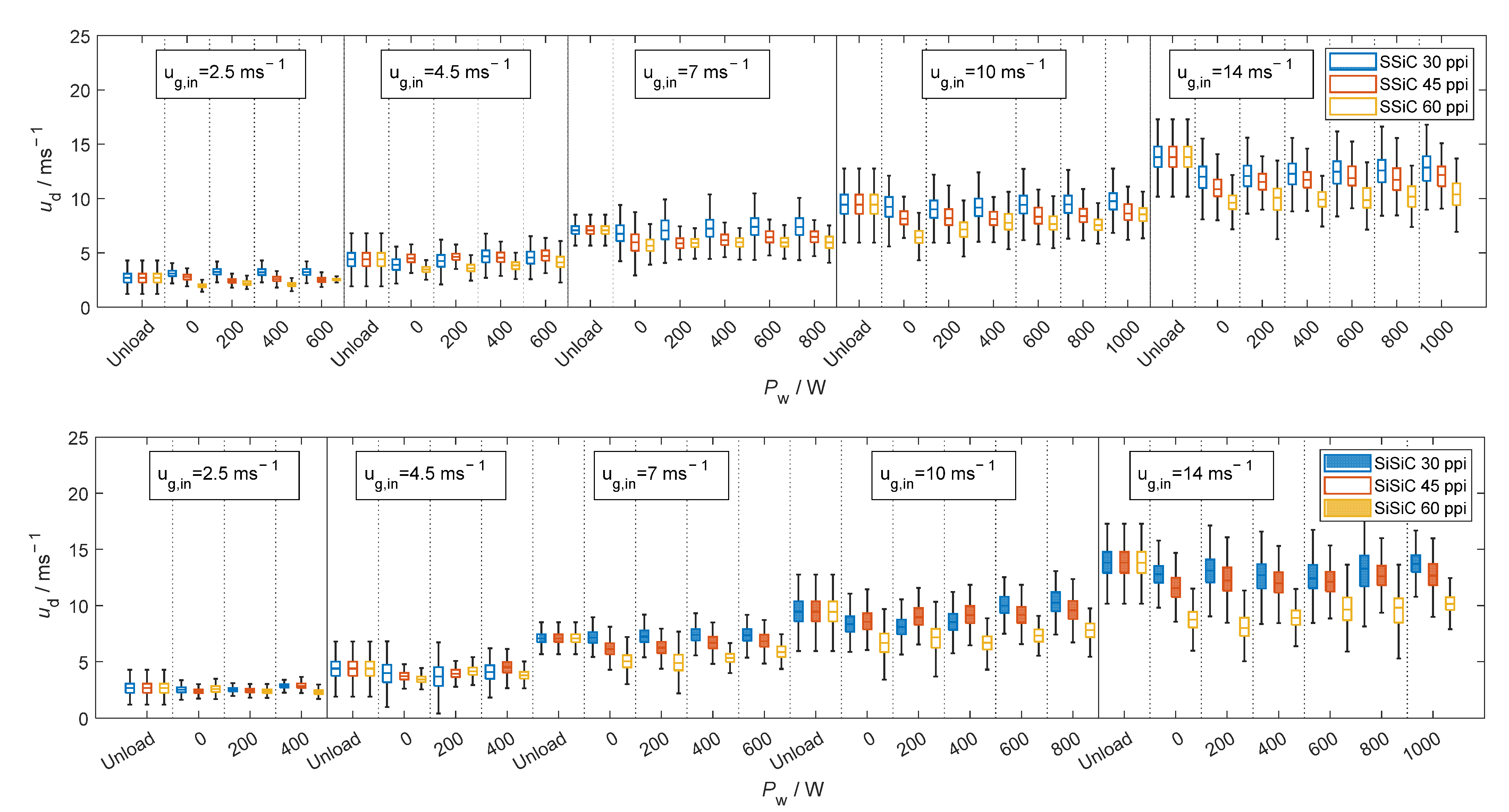

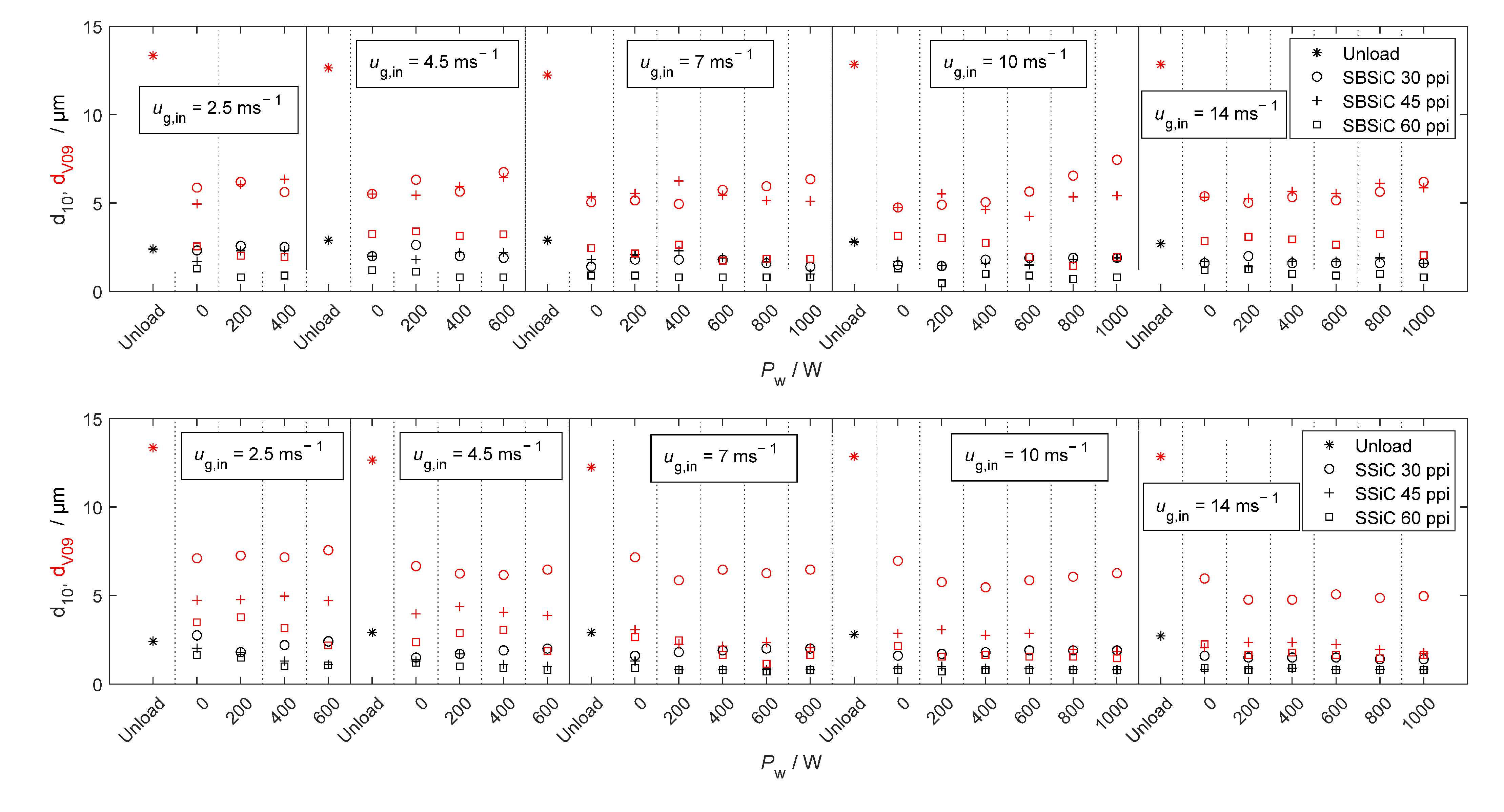

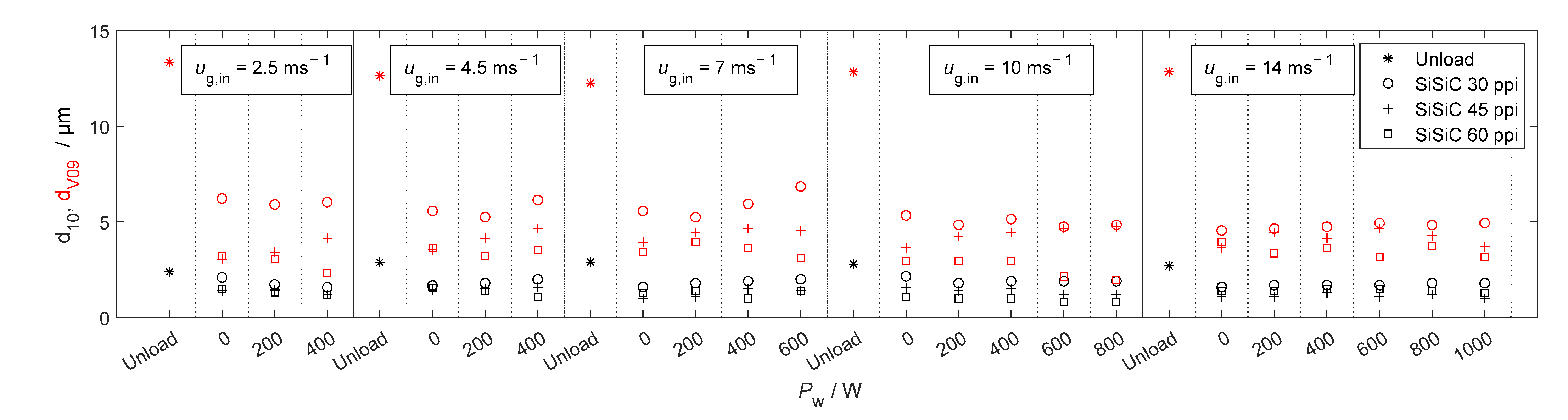

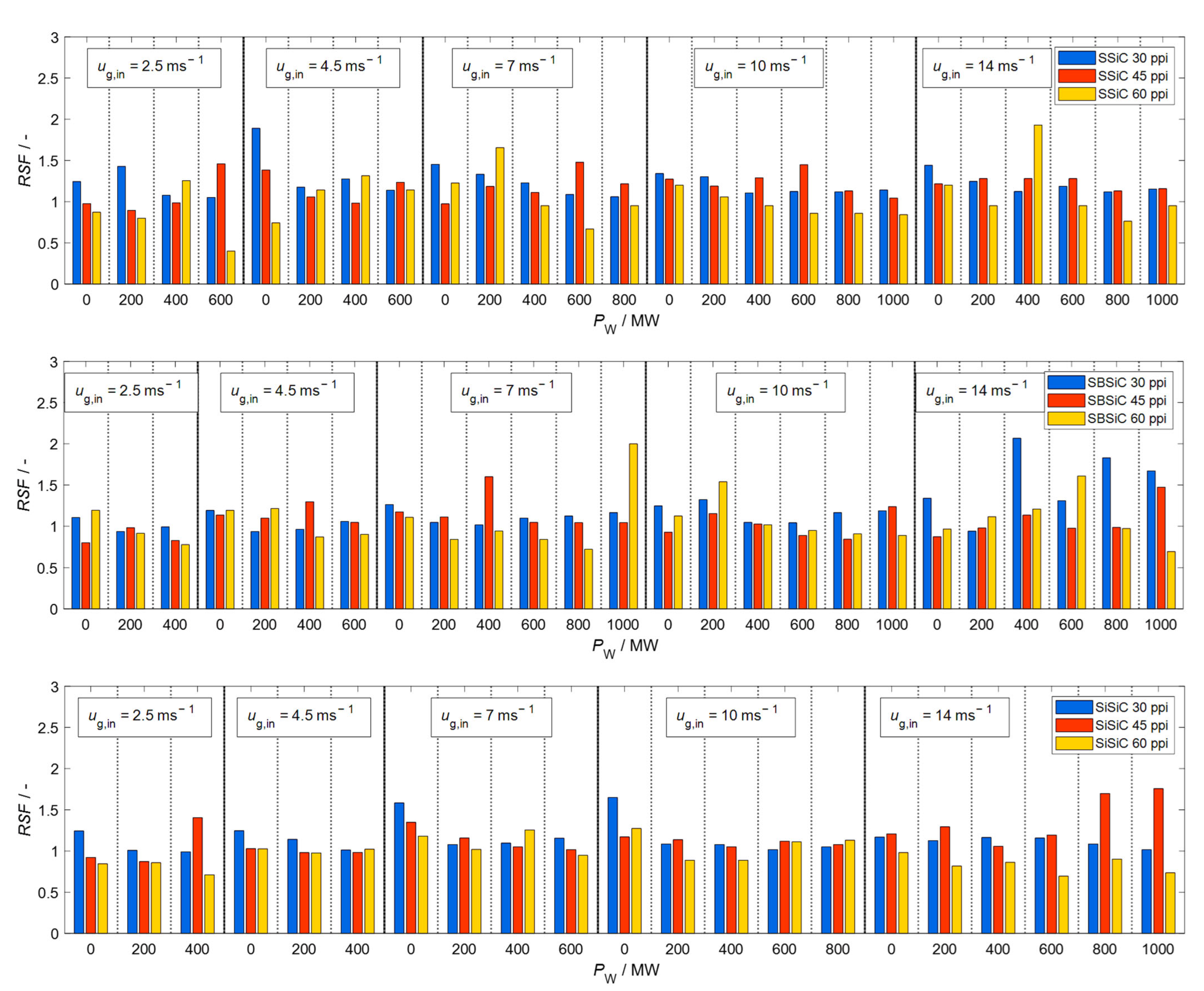

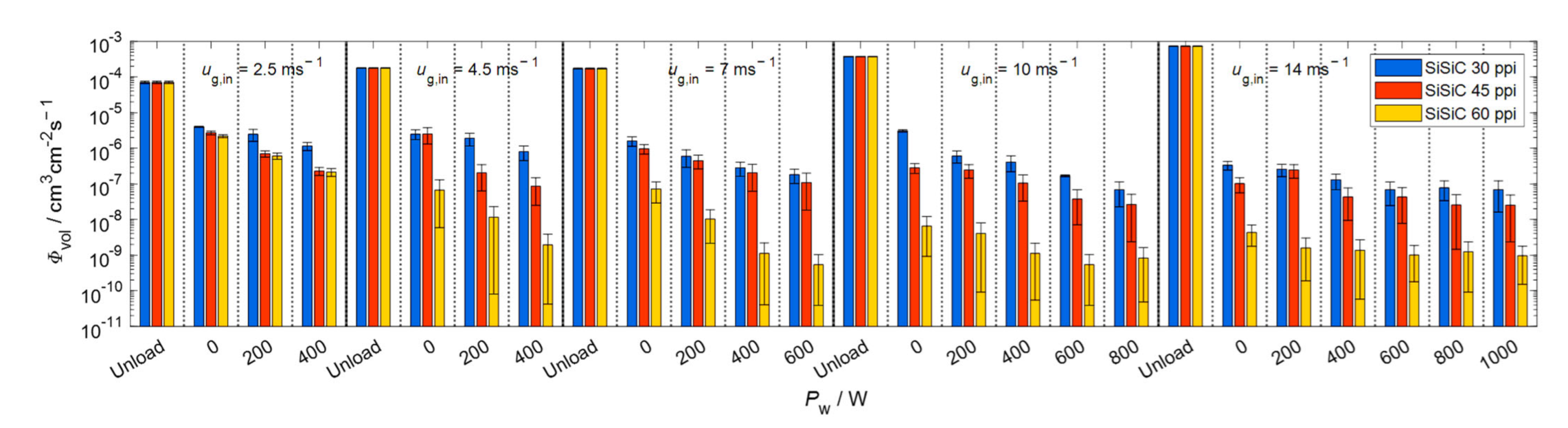

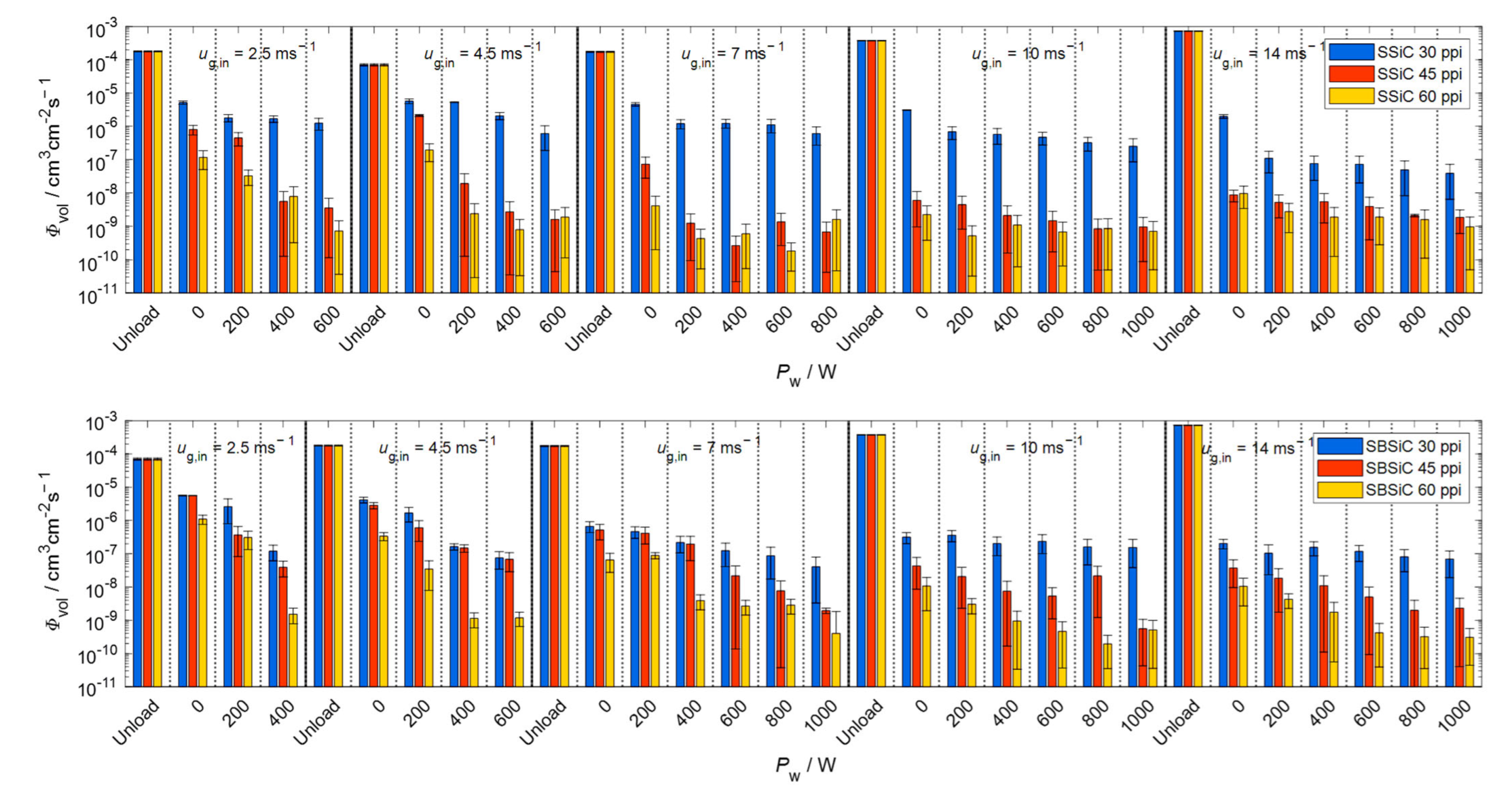

3.2. Microwave-Assisted Droplet Removal

4. Conclusions

- The volumetric flow of droplets is found to decrease as much as ~99.9% by using the open-cell foams as filter media, while microwave-heated foams result in a further reduction up to ~99.99%. The major contribution to droplet removal is due to mechanical filtration and not due to microwave selective heating.

- Increasing the microwave input power causes a higher temperature in the open-cell foams, which in turn decreases the droplet volumetric flow via evaporation.

- High temperatures in open-cell foams under microwave heating are found to prevent structure-borne liquid accumulations. Thus, the device presented has proven to be a compact solution for droplet removal in pipeline installations that combines primary and secondary droplet separation in a single step.

- By evaporating structure-borne liquid accumulations, microwave heating is found to prevent water clogging in the fine droplet separator.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LTNE | Local thermal nonequilibrium |

| PEEK | Polyetheretherketone |

| PID | Phase Doppler interferometry |

| SBSiC | Silicon-bonded silicon carbide |

| SiSiC | Silicon infiltrated silicon carbide |

| SSiC | Pressureless sintered silicon carbide |

Nomenclature

| Coefficients of the polynomials for calculating and | |

| Heat capacity | |

| Diameter | |

| Electric field | |

| Gravity acceleration constant | |

| Volumetric heat transfer coefficient | |

| Heat rate | |

| Relative humidity | |

| Complex number | |

| Thermal conductivity | |

| Molar mass | |

| Porosity | |

| Relative span factor | |

| Specific surface area | |

| T | Temperature |

| Time | |

| Velocity | |

| Volume domain | |

| Inclusion-size parameter | |

| Droplets residence time distribution | |

| Flux | |

| Volume fraction | |

| Fitting parameters for a modified Dagum distribution | |

| Wavelength | |

| Fitting geometrical parameter representing Platonic foams | |

| Real and imaginary parts of q, respectively | |

| Complex permittivity | |

| Dielectric constant and dielectric loss, respectively | |

| Dynamic viscosity | |

| Density | |

| Angular frequency | |

| Rotational relaxation time of the molecules | |

| Summation of the viscous stress tensor and turbulence tensor | |

| Pressure drop | |

| Enthalpy |

Subscripts

| boil | Boiling |

| d | Droplets |

| eff | Effective |

| f | Medium filling the voids of open-cell foam |

| foam | Open-cell foam |

| g | Gas |

| in | Incident radiation |

| inlet | Position corresponding to the inlet |

| icl | Inclusion |

| m | Slope value of the linear expression of q |

| MW | Microwave |

| s | Solid |

| st | Static, equivalent to a wave with a frequency equal to zero |

| vap | Evaporation |

| vol | Volumetric |

| Optical, equivalent to a wave with a frequency equal to infinite | |

| V01, V05, V09 | Total sprayed volume corresponding to 10%, 50% and 90%. |

| 0 | Ordinate-intercept value of the linear expression of q |

References

- Wahba, E.M.; Nawar, H. Multiphase flow modeling and optimization for online wash systems of gas turbines. Appl. Math. Model. 2013, 37, 7549–7560. [Google Scholar] [CrossRef]

- Fan, S.; Wang, Y.; Yao, K.; Fan, Y.; Wan, J.; Gu, W. Research on Water Droplet Movement Characteristics in the Last Two Stages of Low-Pressure Cylinder of Steam Turbine Under Low Load Conditions. Front. Energy Res. 2021, 9, 798305. [Google Scholar] [CrossRef]

- Wines, T.H.; Mokhatab, S. Contamination Control in the Natural Gas Industry, 1st ed.; Gulf Professional Publishing: Oxford, UK, 2021. [Google Scholar]

- Mokhatab, S.; Poe, W.A.; Mak, A.P. Handbook of Natural Gas Transmission and Processing: Principles and Practices, 3rd ed.; Gulf Professional Publishing: Oxford, UK, 2019. [Google Scholar]

- Droplet Separators—Functional Principle. Available online: https://www.lechler.com/de-en/technology/basics-nozzle-technology/droplet-separators-functional-principle. (accessed on 19 June 2022).

- O’Rourke, P.J.; Amsden, A.A. A Spray/Wall Interaction Submodel for the KIVA-3 Wall Film Model; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Mundo, C.; Sommerfeld, M.; Tropea, C. Droplet-wall collisions: Experimental studies of the deformation and breakup process. Int. J. Multiph. Flow. 1995, 21, 151. [Google Scholar] [CrossRef]

- Almohammadi, H.; Amirfazli, A. Droplet impact: Viscosity and wettability effects on splashing. J. Colloid Interface Sci. 2019, 553, 22. [Google Scholar] [CrossRef]

- Gipperich, A.; Lembach, A.N.; Roisman, I.V.; Tropea, C. On the splashing threshold of a single droplet impacting onto rough and porous surfaces. In Proceedings of the ILASS—Europe 2010, 23rd Annual Conference on Liquid Atomization and Spray Systems, Brno, Czech Republic, 6–8 September 2010. [Google Scholar]

- El-Dessouky, H.T.; Alatiqi, I.M.; Ettouney, H.M.; Al-Deffeeri, N.S. Performance of wire mesh mist eliminator. Chem. Eng. Process. 2000, 39, 129–139. [Google Scholar] [CrossRef]

- Manabe, J.; Kasahara, J.; Fujita, I.; Kojima, T. Recent moisture separator reheater design technologies. J. Eng. Gas Turbines Power 2010, 132, 102905. [Google Scholar] [CrossRef]

- Behrend, R.; Dorn, C.; Uhlig, V.; Krause, H. Investigations on container materials in high temperature microwave applications. Energy Procedia 2017, 120, 417–423. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Zalucky, J.; Wagner, M.; Schubert, M.; Lange, R.; Hampel, U. Hydrodynamics of Descending Gas-Liquid Flows in Solid Foams: Liquid Holdup, Multiphase Pressure Drop and Radial Dispersion. Chem. Eng. Sci. 2017, 168, 480. [Google Scholar] [CrossRef]

- Hernandez, J.N.C.; Lecrivain, G.; Schubert, M.; Hampel, U. Droplet retention time and pressure drop in SiSiC open-cell foams used as droplet separation devices: A numerical approach. Ind. Eng. Chem. Res. 2019, 59, 4093–4107. [Google Scholar] [CrossRef]

- Camacho Hernandez, J.N.; Link, G.; Schubert, M.; Hampel, U. Modeling of the effective permittivity of open-cell ceramic foams inspired by platonic solids. Materials 2021, 14, 7446. [Google Scholar] [CrossRef] [PubMed]

- Camacho Hernandez, J.N.; Link, G.; Soldatov, S.; Füssel, A.; Schubert, M.; Hampel, U. Experimental and numerical analysis of the complex permittivity of open-cell ceramic foams. Ceram. Int. 2020, 46, 26829–26840. [Google Scholar] [CrossRef]

- Raizer, V. Microwave Emission of the Ocean. In Advances in Passive Microwave Remote Sensing of Oceans, 1st ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2017; Volume 1, pp. 120–122. [Google Scholar]

- Ellison, W.J. Permittivity of Pure Water, at Standard Atmospheric Pressure, over the Frequency Range 0–25 THz and the temperature range 0–100 °C. J. Phys. Chem. Ref. Data 2007, 36, 1–18. [Google Scholar] [CrossRef]

- Chistyakov, A.D. The Permittivity of Water and Water Vapor in Saturation States. Russ. J. Phys. Chem. A 2005, 81, 5–8. [Google Scholar] [CrossRef]

- Fernández, D.P.; Goodwin, A.R.H.; Lemmon, E.W.; Levelt Sengers, J.M.H.; Williams, R.C. A Formulation for the Static Permittivity of Water and Steam at Temperatures from 238 K to 873 K at Pressures up to 1200 MPa, Including Derivatives and Debye–Hückel Coefficients. J. Phys. Chem. Ref. Data 1997, 26, 1125–1166. [Google Scholar] [CrossRef]

- Qian, J.; Gu, Q.; Yao, H.; Zeng, W. Dielectric properties of wet steam based on a double relaxation time model. Eur. Phys. 2019, 42, 22. [Google Scholar] [CrossRef] [PubMed]

- Mishchenko, M.I.; Dlugach, J.M.; Liu, L. Applicability of the effective-medium approximation to heterogeneous aerosol particles. J. Quant. Spectrosc. Radiat. Transf. 2016, 178, 284–294. [Google Scholar] [CrossRef]

- Zhao, J.; Sun, M.; Zhang, L.; Hu, C.; Tang, D.; Yang, L.; Song, Y. Forced convection heat transfer in porous structure: Effect of morphology on pressure drop and heat transfer coefficient. J. Therm. Sci. 2021, 30, 363–393. [Google Scholar] [CrossRef]

- Dietrich, B. Heat transfer coefficients for solid ceramic sponges—Experimental results and correlation. Int. J. Heat Mass Transf. 2013, 61, 627–637. [Google Scholar] [CrossRef]

- Mahmoudi, Y.; Hooman, K.; Vafai, K. Convective Heat Transfer in Porous Media, 1st ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 37–52. [Google Scholar]

- Sili, E.; Cambronne, J. A New Empirical Expression of the Breakdown Voltage for Combined Variations of Temperature and Pressure. Int. J. Aerosp. Eng. 2012, 6, 611–616. [Google Scholar]

| Pore Density /ppi | SBSiC | SSiC | SiSiC | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 30 | 45 | 60 | 30 | 45 | 60 | 30 | 45 | 60 | |

| /- | 0.902 | 0.905 | 0.906 | 0.896 | 0.896 | 0.903 | 0.868 | 0.87 | 0.874 |

| Flow Boundary Conditions | |||

|---|---|---|---|

| Interface | Velocity | Pressure | Remarks |

| Inlet | Computed | is the dimensionless wall-thickness parameter | |

| Outlet | |||

| Walls (no slip) | Computed | ||

| Electromagnetic Boundary Conditions | |||

| Interface | Electric Field | Remarks | |

| Walls | Perfect electric conductor | ||

| Ports | Computed | ||

| Heat Transfer Boundary Conditions | |||

| Interface | Heat Flux | Remarks | |

| Inlet | and is the vector normal to the boundary | ||

| Outlet | |||

| Walls | |||

| Foam | ||

|---|---|---|

| SBSiC | 0.90 | 30 |

| SSiC | 0.90 | 25 |

| SiSiC | 0.87 | 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camacho Hernandez, J.N.; Link, G.; Schubert, M.; Hampel, U. Experimental Study of a Compact Microwave Applicator for Evaporation of Airflow-Entrained Droplets. Materials 2022, 15, 6765. https://doi.org/10.3390/ma15196765

Camacho Hernandez JN, Link G, Schubert M, Hampel U. Experimental Study of a Compact Microwave Applicator for Evaporation of Airflow-Entrained Droplets. Materials. 2022; 15(19):6765. https://doi.org/10.3390/ma15196765

Chicago/Turabian StyleCamacho Hernandez, Jesus Nain, Guido Link, Markus Schubert, and Uwe Hampel. 2022. "Experimental Study of a Compact Microwave Applicator for Evaporation of Airflow-Entrained Droplets" Materials 15, no. 19: 6765. https://doi.org/10.3390/ma15196765

APA StyleCamacho Hernandez, J. N., Link, G., Schubert, M., & Hampel, U. (2022). Experimental Study of a Compact Microwave Applicator for Evaporation of Airflow-Entrained Droplets. Materials, 15(19), 6765. https://doi.org/10.3390/ma15196765