Flash Sintered Potassium Sodium Niobate: High-Performance Piezoelectric Ceramics at Low Thermal Budget Processing

Abstract

:1. Introduction

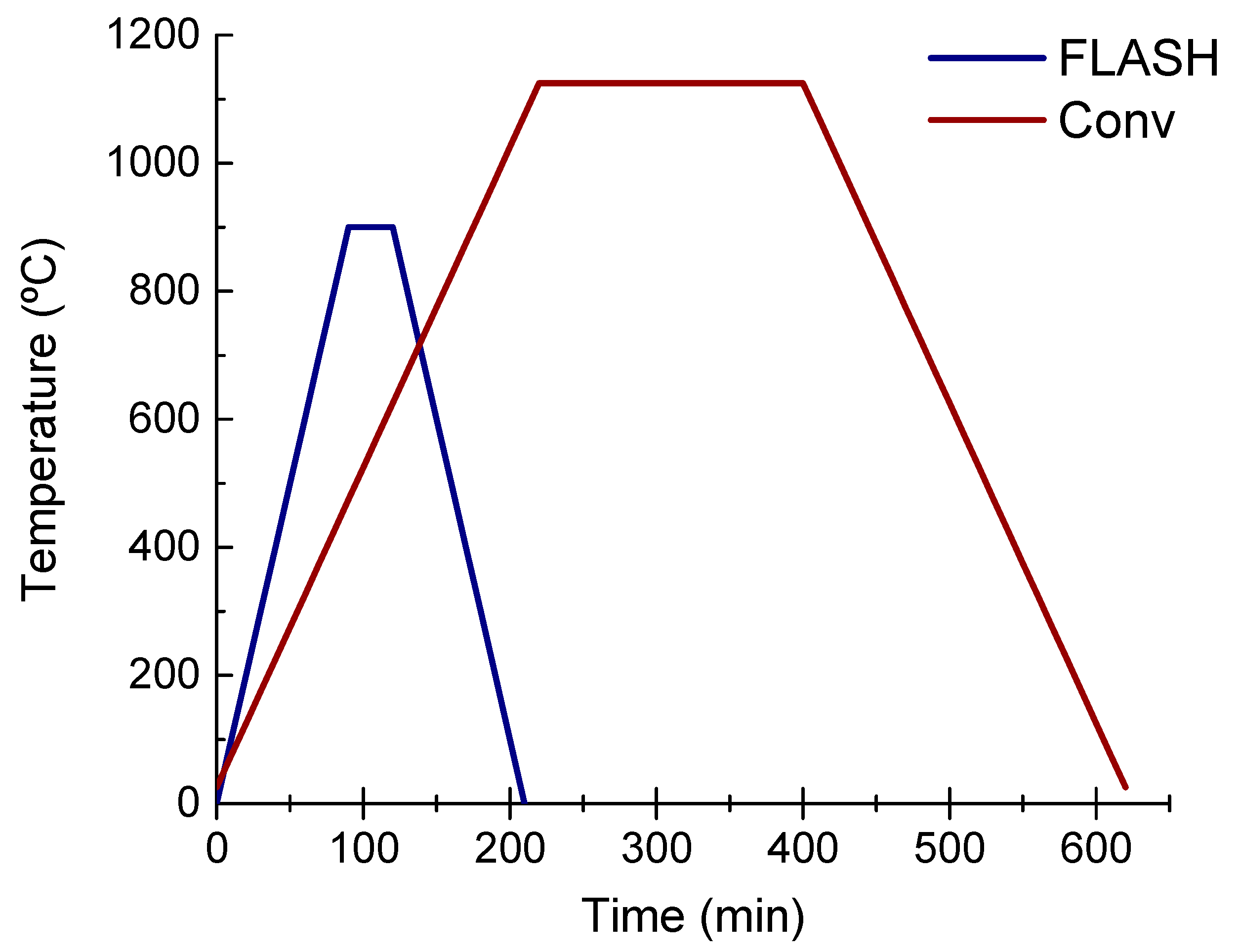

2. Materials and Methods

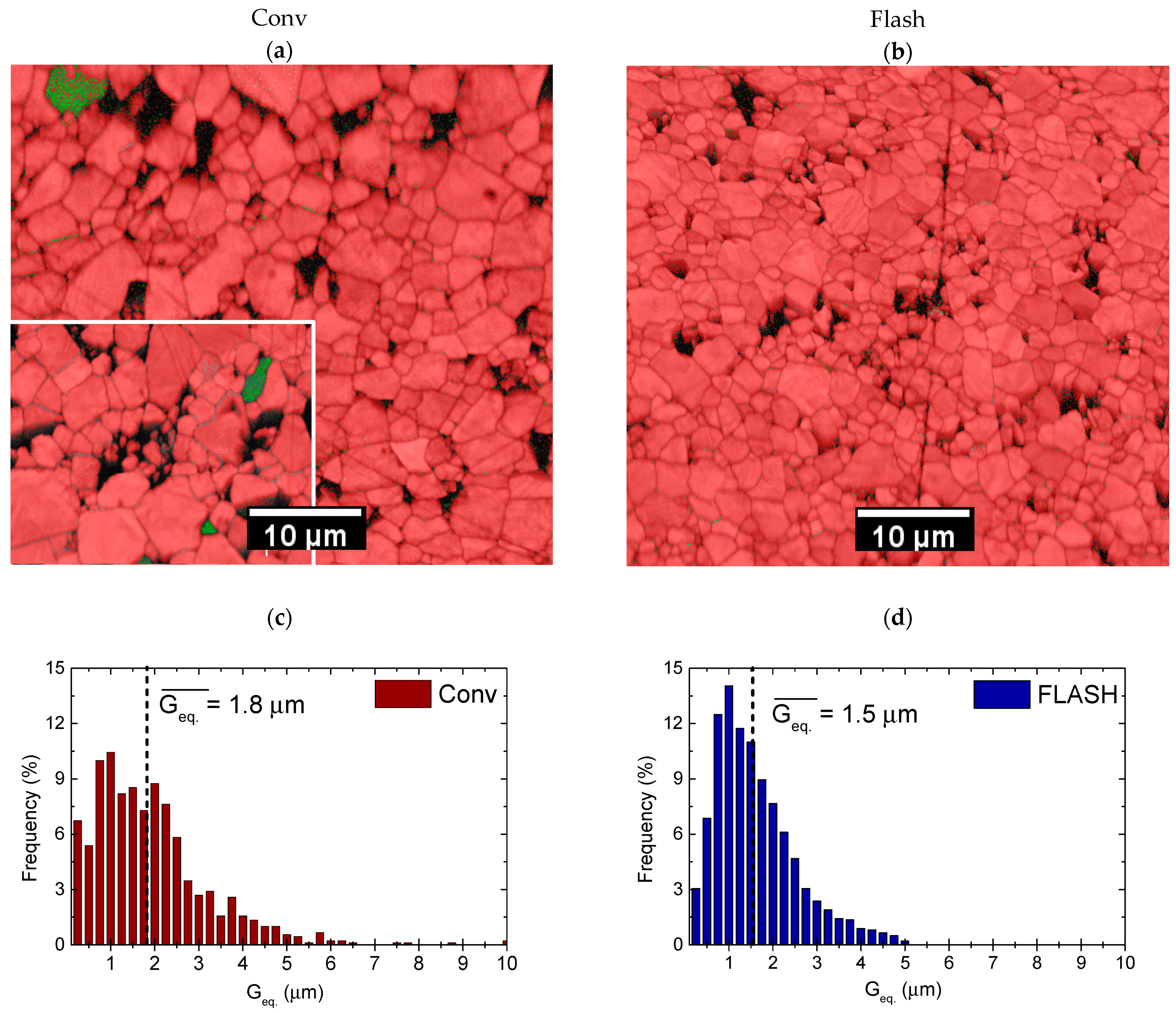

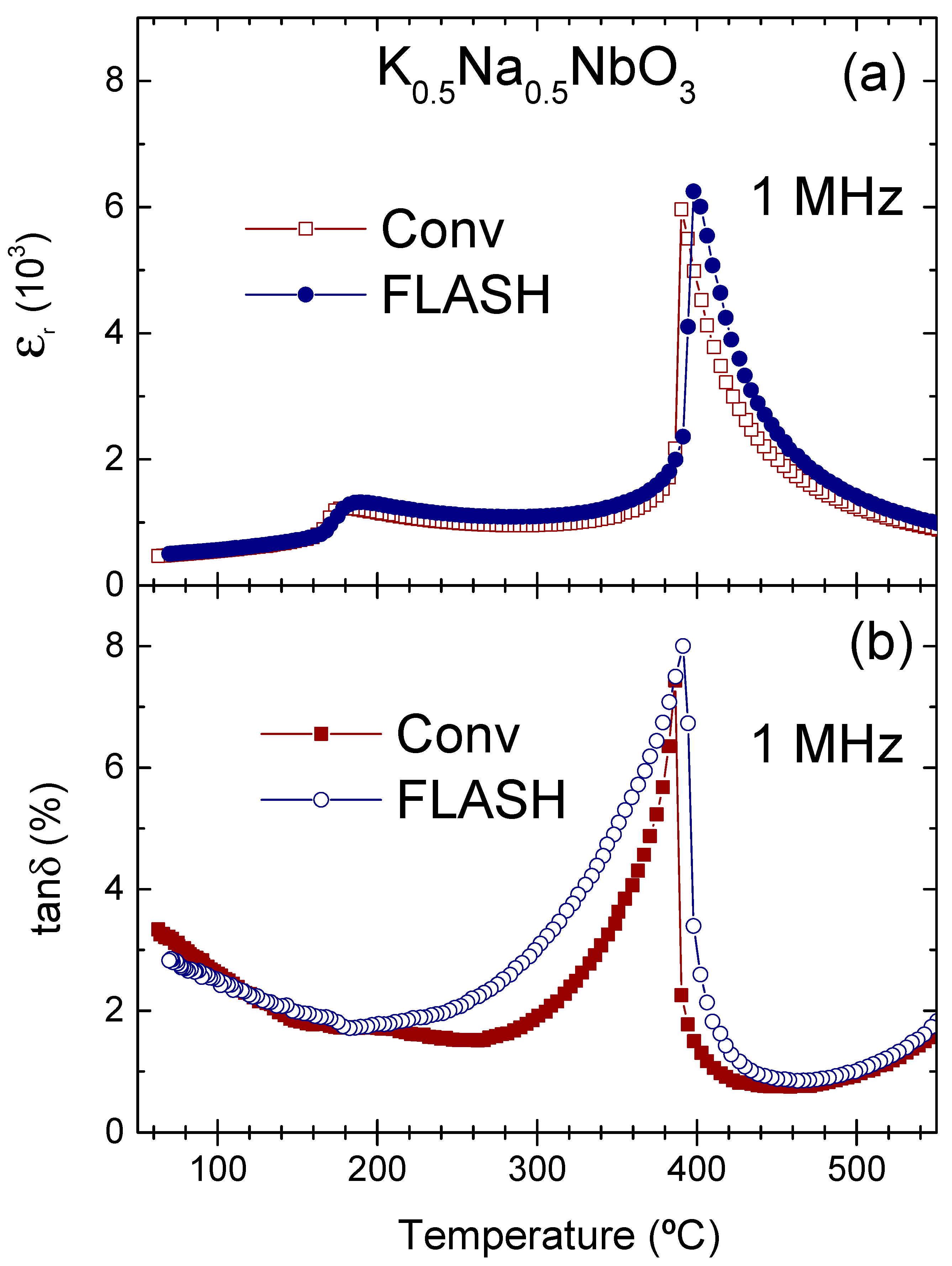

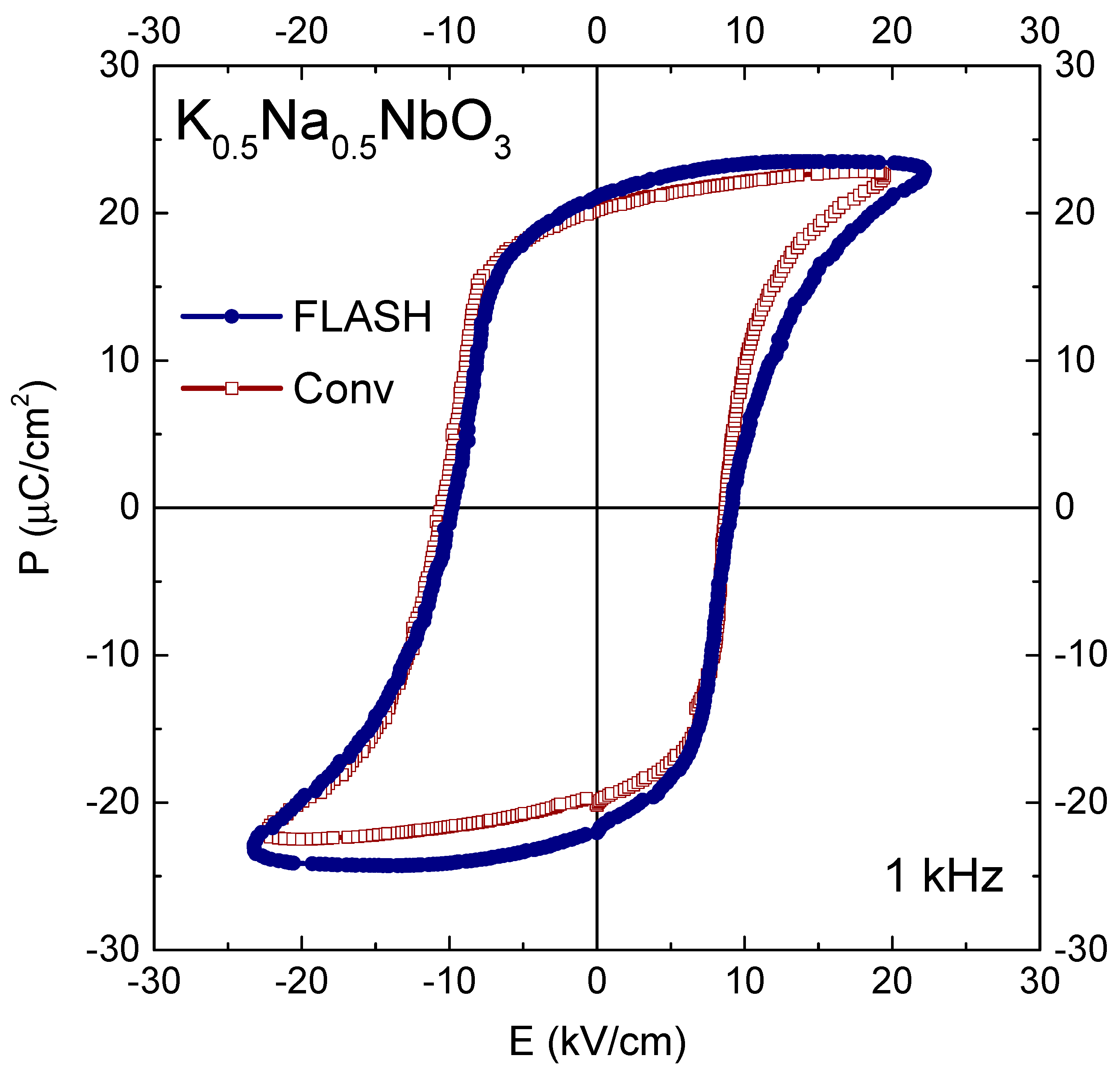

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.F.; Wang, K.; Zhu, F.Y.; Cheng, L.Q.; Yao, F.Z. (K,Na)NbO3-based lead-free piezoceramics: Fundamental aspects, processing technologies, and remaining challenges. J. Am. Ceram. Soc. 2013, 96, 3677–3696. [Google Scholar] [CrossRef]

- Ahtee, M.; Newat, A.W. Structural phase transitions in sodium-potassium niobate solid solutions by neutron powder diffraction. Acta Cryst. A 1978, 34, 309–317. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 111–124. [Google Scholar] [CrossRef]

- Zuo, R.; Rödel, J.; Chen, R.; Li, L. Sintering and electrical properties of lead-free Na0.5K0.5NbO3 piezoelectric ceramics. J. Am. Ceram. Soc. 2006, 89, 2010–2015. [Google Scholar] [CrossRef]

- Malič, B.; Koruza, J.; Hreščak, J.; Bernard, J.; Wang, K.; Fisher, J.G.; Benčan, A. Sintering of lead-free piezoelectric sodium potassium niobate ceramics. Materials 2015, 8, 8116–8146. [Google Scholar] [CrossRef] [PubMed]

- Matsubara, M.; Yamaguchi, T.; Kikuta, K.; Hirano, S.I. Sinterability and piezoelectric properties of (K,Na)NbO3 ceramics with novel sintering aid. Jpn. J. Appl. Phys. 2004, 43, 7159–7163. [Google Scholar] [CrossRef]

- Shirane, G.; Newnham, R.; Pepinsky, R. Dielectric properties and phase transitions of NaNbO3 and (Na,K)NbO3. Phys. Rev. 1954, 96, 581–588. [Google Scholar] [CrossRef]

- Pavlič, J.; Malič, B.; Rojac, T. Microstructural, structural, dielectric and piezoelectric properties of potassium sodium niobate thick films. J. Eur. Ceram. Soc. 2014, 34, 285–295. [Google Scholar] [CrossRef]

- Pinho, R.; Tkach, A.; Zlotnik, S.; Costa, M.E.; Noudem, J.; Reaney, I.M.; Vilarinho, P.M. Spark plasma texturing: A strategy to enhance the electro-mechanical properties of lead-free potassium sodium niobate ceramics. Appl. Mater. Today 2020, 19, 100566. [Google Scholar] [CrossRef]

- Biesuz, M.; Grasso, S.; Sglavo, V.M. What’s new in ceramics sintering? A short report on the latest trends and future prospects. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100868. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Flash sintering of ceramics. J. Eur. Ceram. Soc. 2019, 39, 115–143. [Google Scholar] [CrossRef]

- Corapcioglu, G.; Gulgun, M.A.; Kisslinger, K.; Sturm, S.; Jha, S.K.; Raj, R. Microstructure and microchemistry of flash sintered K0.5Na0.5NbO3. J. Ceram. Soc. Jpn. 2016, 124, 321–328. [Google Scholar] [CrossRef]

- Serrazina, R.; Senos, A.M.O.R.; Pereira, L.; Dean, J.S.; Reaney, I.M.; Vilarinho, P.M. The Role of Particle Contact in Densification of FLASH Sintered Potassium Sodium Niobate. Eur. J. Inorg. Chem. 2020, 2020, 3720–3728. [Google Scholar] [CrossRef]

- Serrazina, R.; Dean, J.S.; Reaney, I.M.; Pereira, L.; Vilarinho, P.M.; Senos, A.M.O.R. Mechanism of densification in low-temperature FLASH sintered lead free Potassium Sodium Niobate (KNN) piezoelectrics. J. Mater. Chem. C 2019, 7, 14334–14341. [Google Scholar] [CrossRef]

- Serrazina, R.; Ribeiro, C.; Costa, M.E.; Pereira, L.; Vilarinho, P.M.; Senos, A.M.O.R. Particle characteristics influence on FLASH sintering of Potassium Sodium Niobate: A relationship with conduction mechanisms. Materials 2021, 14, 1321. [Google Scholar] [CrossRef] [PubMed]

- Alikin, D.; Turygin, A.; Kholkin, A.; Shur, V. Review ferroelectric domain structure and local piezoelectric properties of lead-free (K0.5Na0.5)NbO3 and BiFeO3-based piezoelectric ceramics. Materials 2017, 10, 47. [Google Scholar] [CrossRef] [PubMed]

- Feizpour, M.; Barzegar Bafrooei, H.; Hayati, R.; Ebadzadeh, T. Microwave-assisted synthesis and sintering of potassium sodium niobate lead-free piezoelectric ceramics. Ceram. Int. 2014, 40, 871–877. [Google Scholar] [CrossRef]

- Birol, H.; Damjanovic, D.; Setter, N. Preparation and characterization of (K0.5Na0.5)NbO3 ceramics. J. Eur. Ceram. Soc. 2006, 26, 861–866. [Google Scholar] [CrossRef]

- Rafiq, M.A.; Costa, M.E.V.; Vilarinho, P.M. Establishing the Domain Structure of (K0.5Na0.5)NbO3 (KNN) Single Crystals by Piezoforce-Response Microscopy. Sci. Adv. Mater. 2014, 6, 426–433. [Google Scholar] [CrossRef]

| KNN | ρrel., % | TO−T, °C | TC, °C | εr | tanδ | Pr, μC/cm2 | Ec, kV/cm | d33, pC/N | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| at TC | at RT | at TC | at RT | |||||||||

| Flash | 93 ± 3 | 1.5 | 190 | 398 | 6249 | 527 | 0.080 | 0.043 | 21 | 10 | 117 ± 2 | This work |

| Conv | 96 ± 2 | 1.8 | 181 | 390 | 5963 | 468 | 0.074 | 0.034 | 20 | 10 | 115 ± 2 | |

| Conv | 95–96 | - | 190 | 400 | ≈5200 | 472 | - | ≈0.04 | 20 | 20 | 110 | [19] |

| Conv | 94 | 6.6 | - | 401 | ≈5500 | 468 | ≈0.9 | 0.031 | 20 | 12 | 88 | [18] |

| MW | 93.8 | 3.8 | - | 398 | ≈5000 | 427 | ≈0.7 | 0.035 | 18 | 12 | 85 | |

| SPS | 96 | 3.0 | 207 | 386 | 4160 | 736 | 0.175 | 0.377 | 17 | 18 | 95 | [10] |

| SPT | 99.8 | 1.4 | 204 | 370 | 4672 | 576 | 0.160 | 0.045 | 20 | 12 | 108 | |

| Single Crystal | - | - | 215 | 429 | 29,100 | ≈300 | - | - | 19 | 11 | 160 | [20] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrazina, R.; Tkach, A.; Pereira, L.; Senos, A.M.O.R.; Vilarinho, P.M. Flash Sintered Potassium Sodium Niobate: High-Performance Piezoelectric Ceramics at Low Thermal Budget Processing. Materials 2022, 15, 6603. https://doi.org/10.3390/ma15196603

Serrazina R, Tkach A, Pereira L, Senos AMOR, Vilarinho PM. Flash Sintered Potassium Sodium Niobate: High-Performance Piezoelectric Ceramics at Low Thermal Budget Processing. Materials. 2022; 15(19):6603. https://doi.org/10.3390/ma15196603

Chicago/Turabian StyleSerrazina, Ricardo, Alexander Tkach, Luis Pereira, Ana M. O. R. Senos, and Paula M. Vilarinho. 2022. "Flash Sintered Potassium Sodium Niobate: High-Performance Piezoelectric Ceramics at Low Thermal Budget Processing" Materials 15, no. 19: 6603. https://doi.org/10.3390/ma15196603

APA StyleSerrazina, R., Tkach, A., Pereira, L., Senos, A. M. O. R., & Vilarinho, P. M. (2022). Flash Sintered Potassium Sodium Niobate: High-Performance Piezoelectric Ceramics at Low Thermal Budget Processing. Materials, 15(19), 6603. https://doi.org/10.3390/ma15196603