Effect of Stiffening the Printed Circuit Board in the Fatigue Life of the Solder Joint

Abstract

:1. Introduction

2. Methods and Experiments

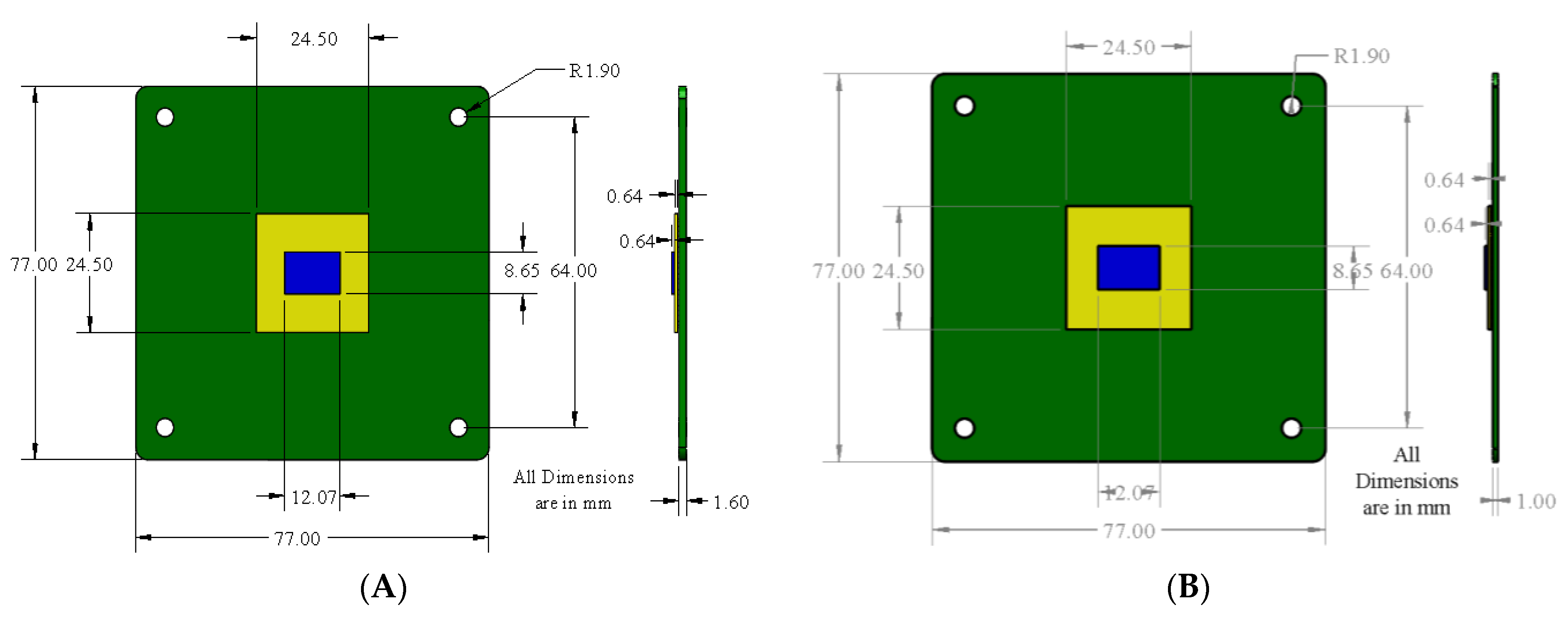

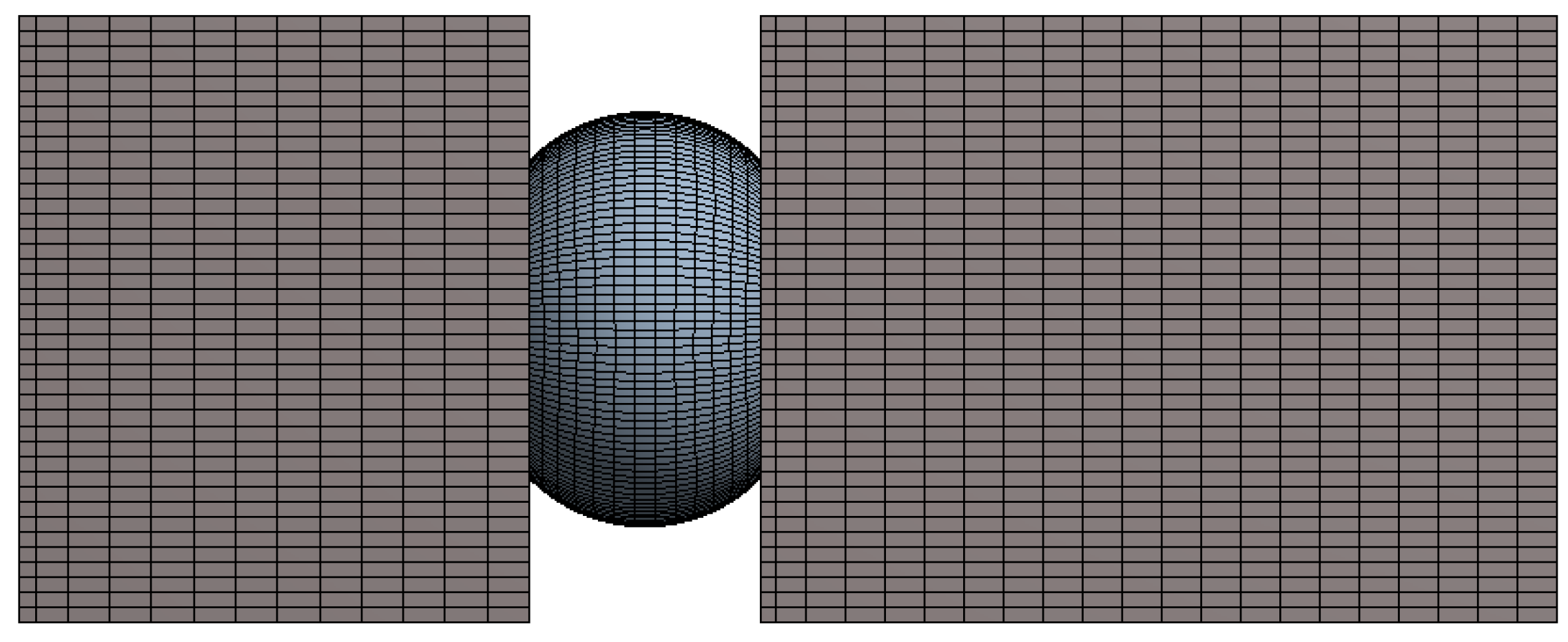

2.1. Finite Element Model

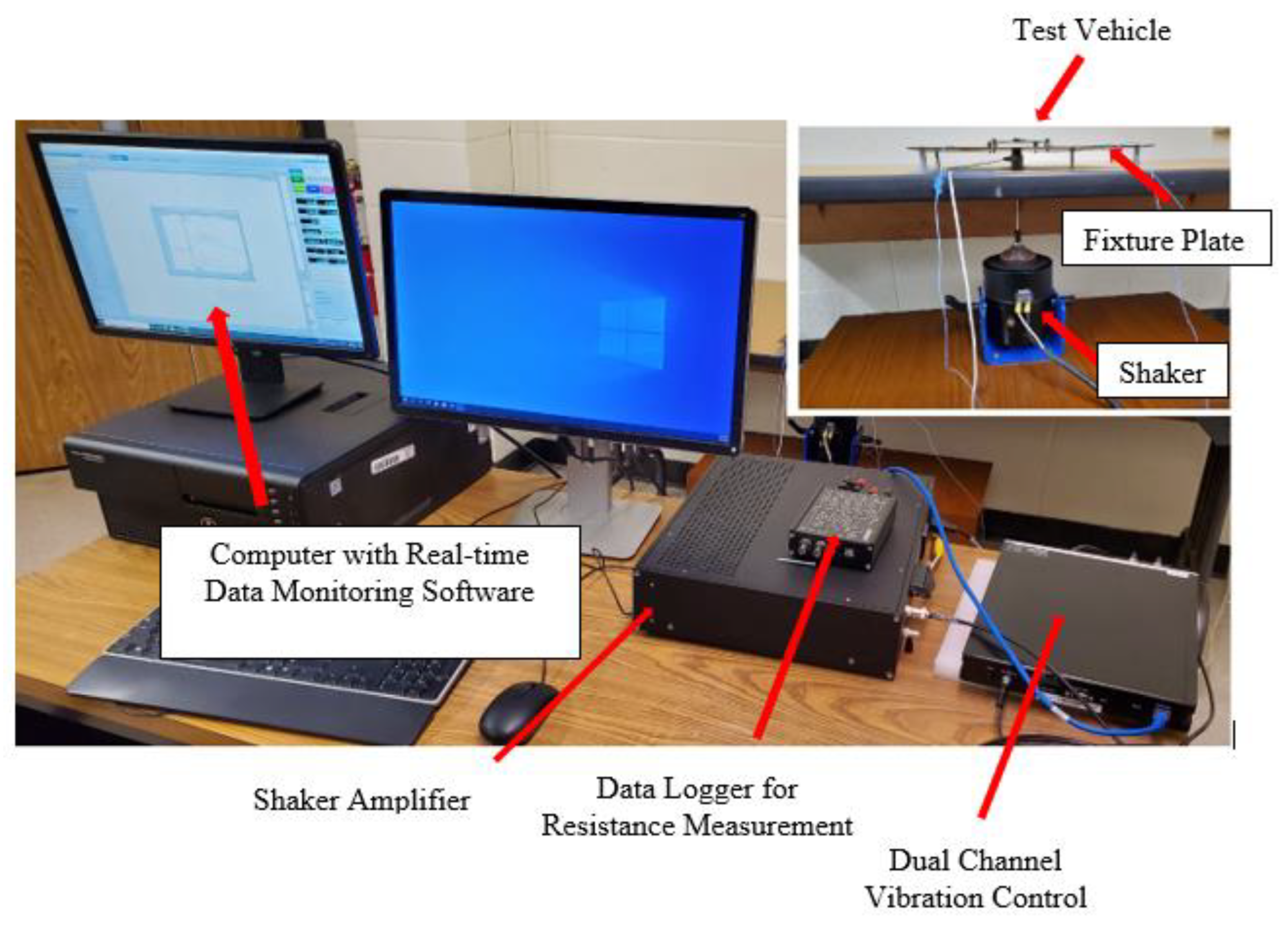

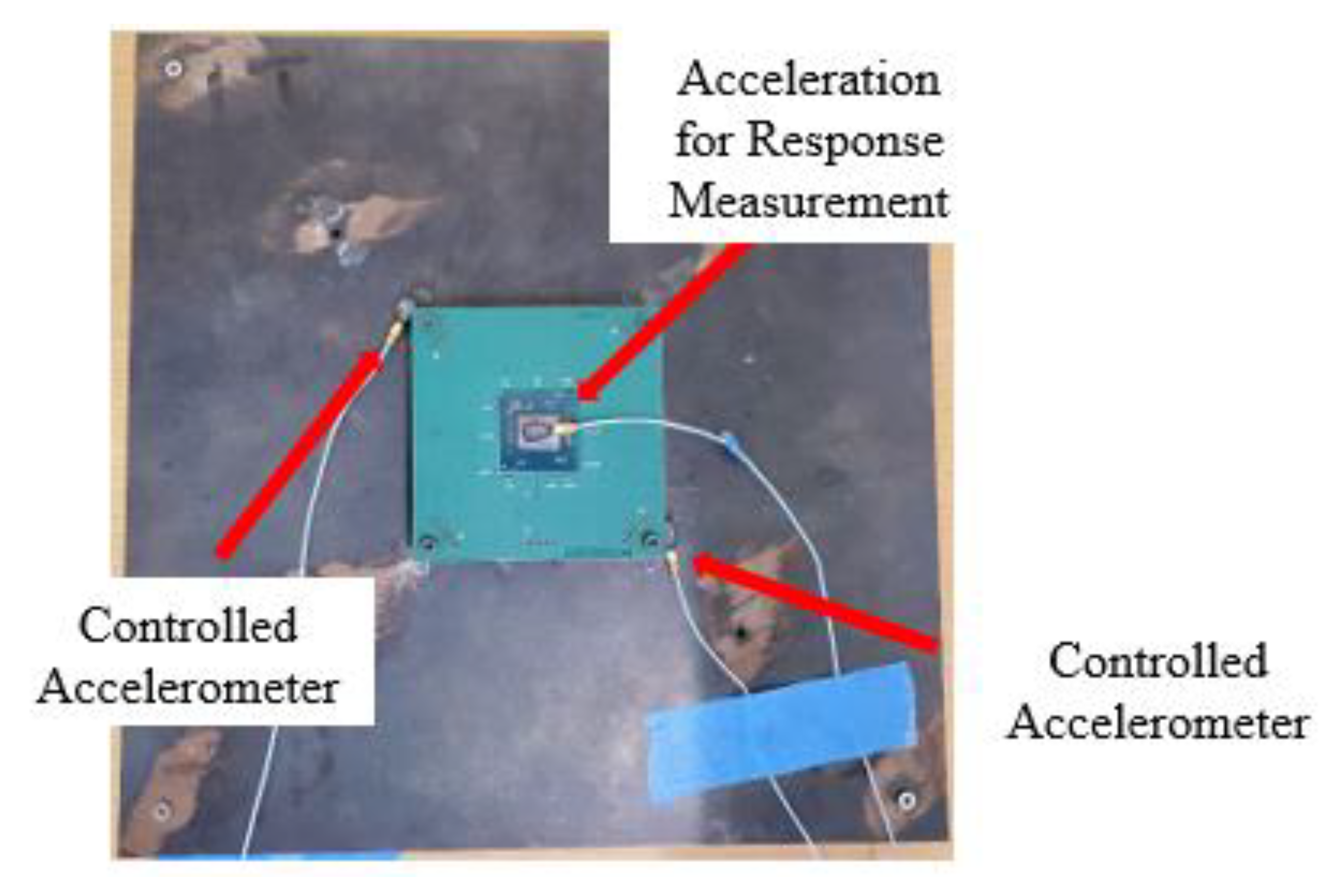

2.2. Experimental Setup

3. Results from Experiments and Simulations

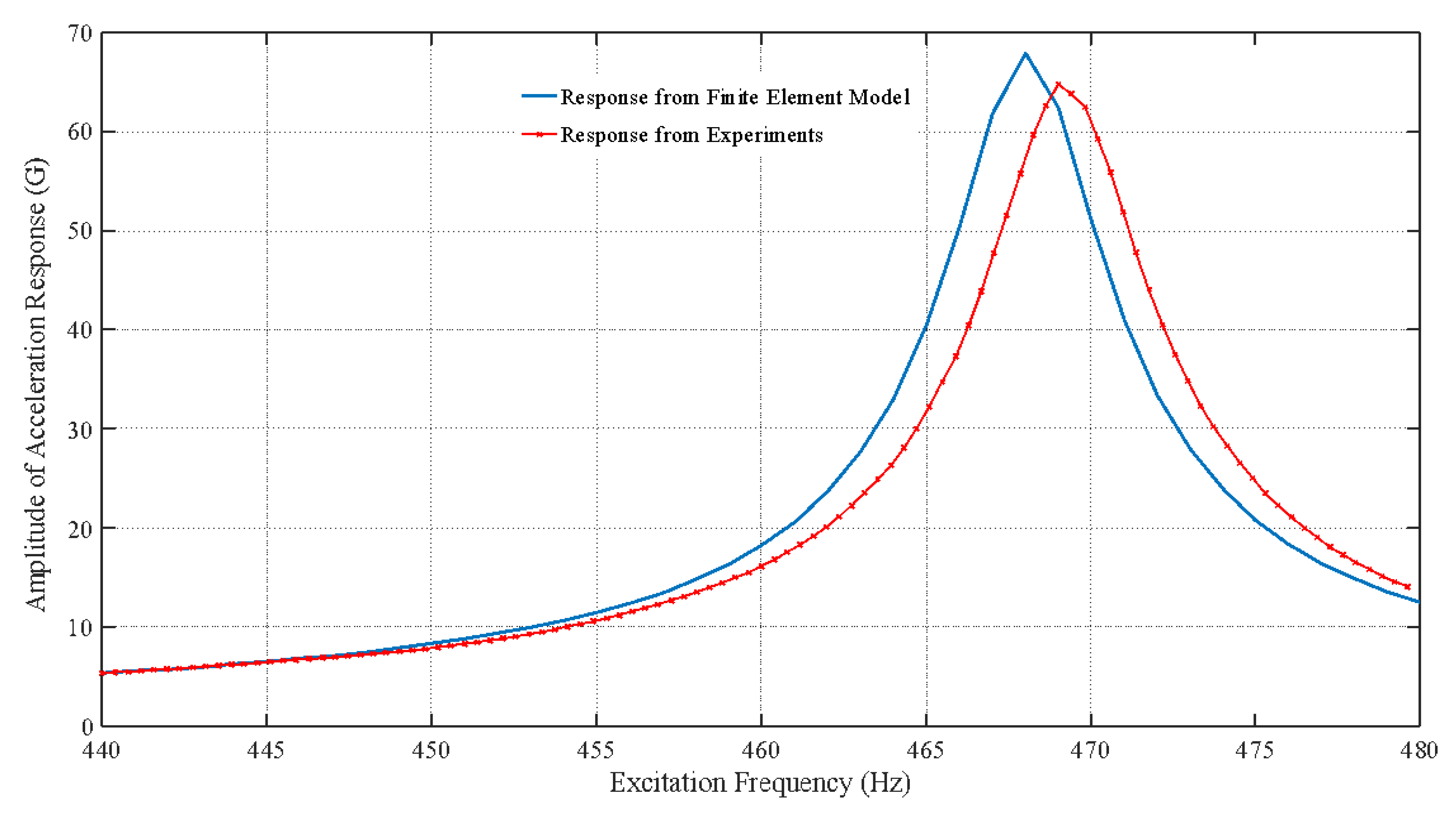

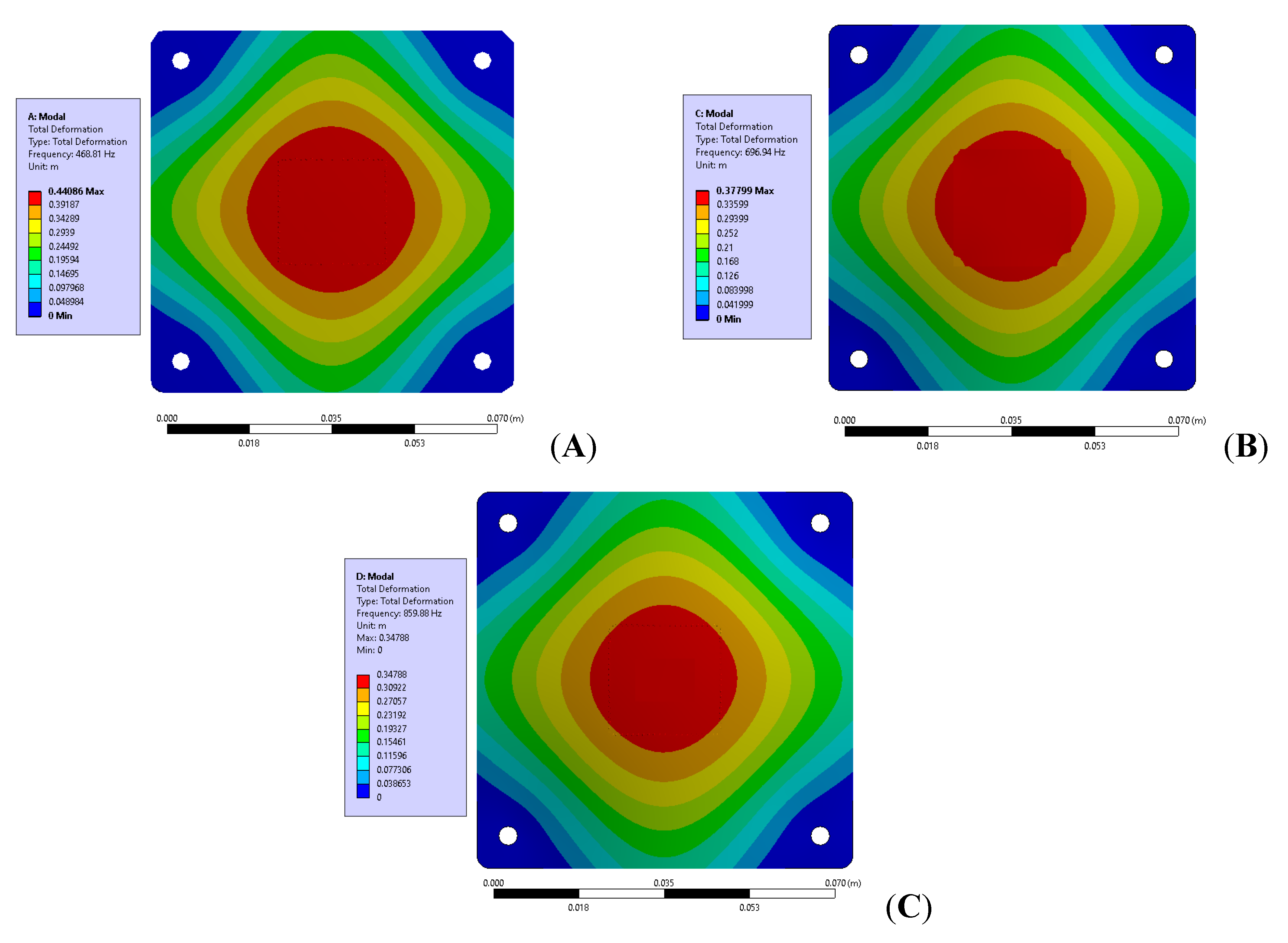

3.1. Sine Sweep and Stepped Sine Testing

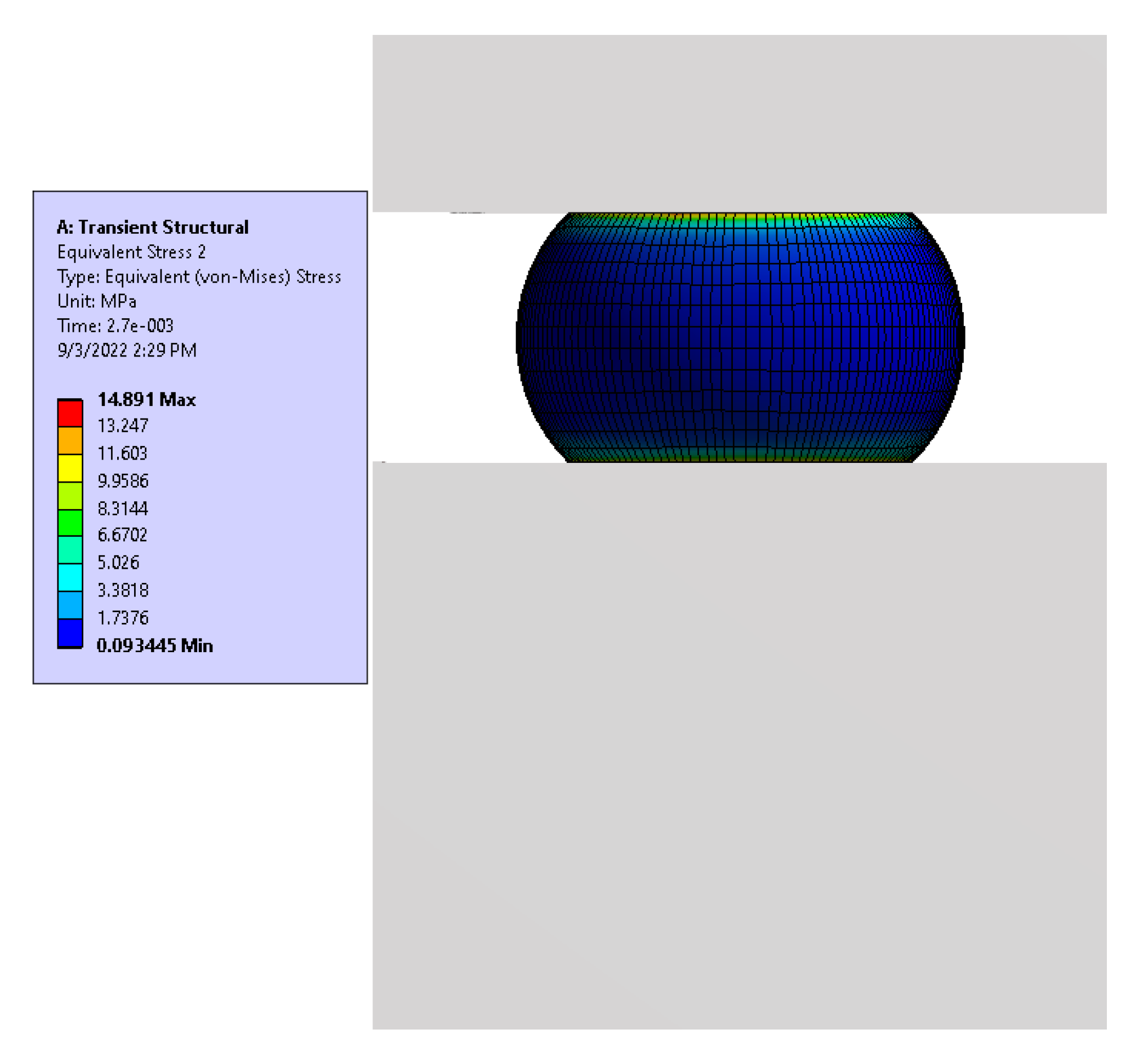

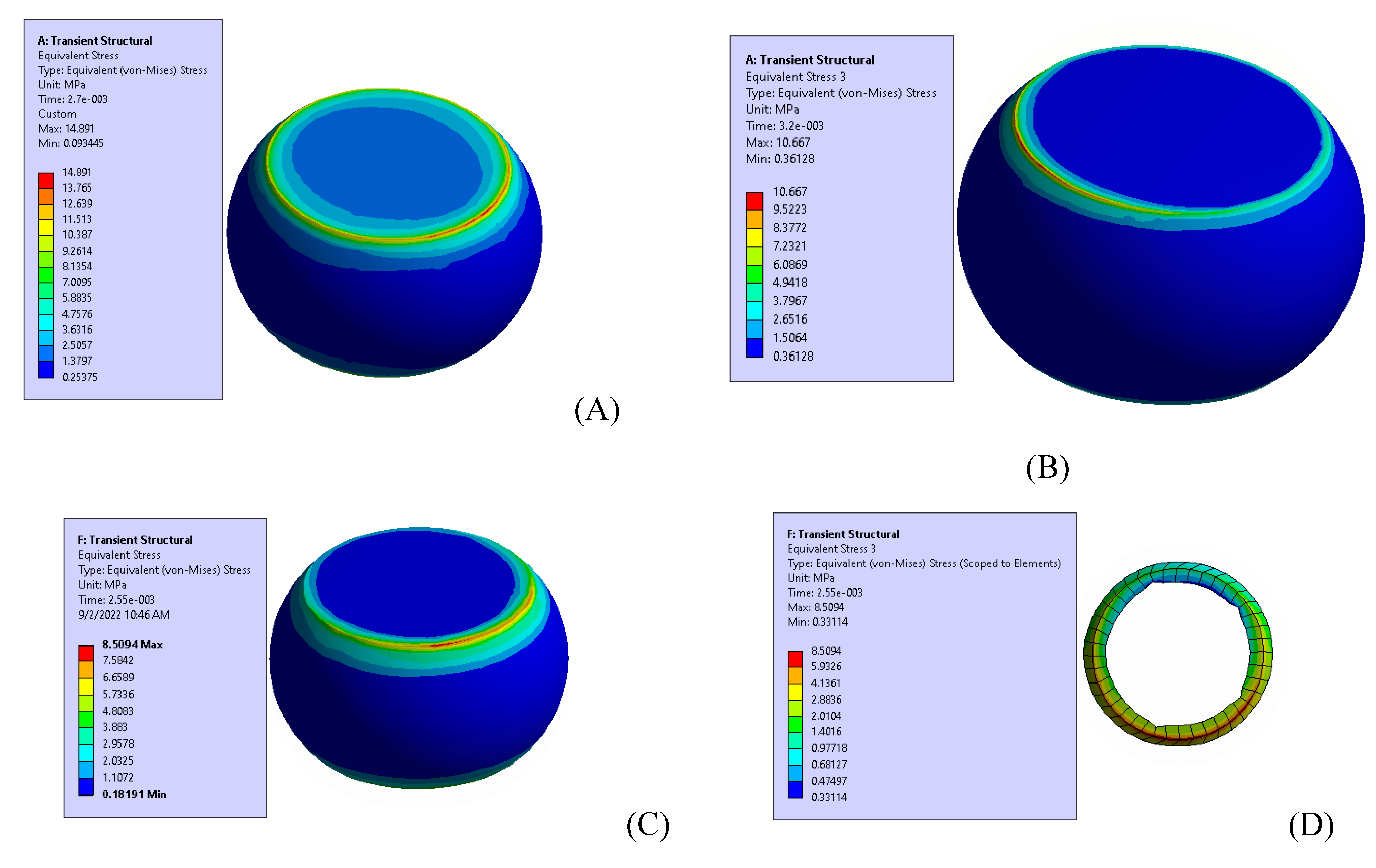

3.2. Fatigue Test (FE Model) Results

3.3. Experimental Observation of Fatigue Life

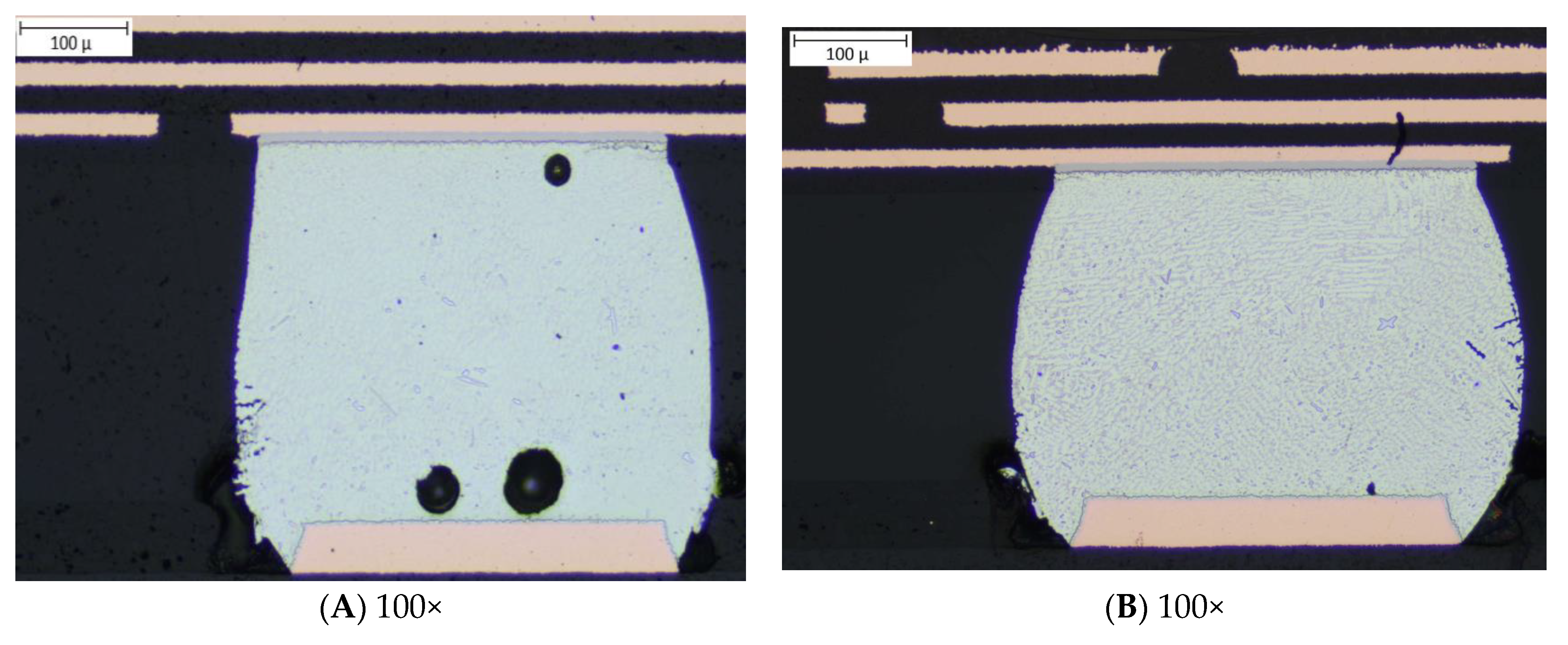

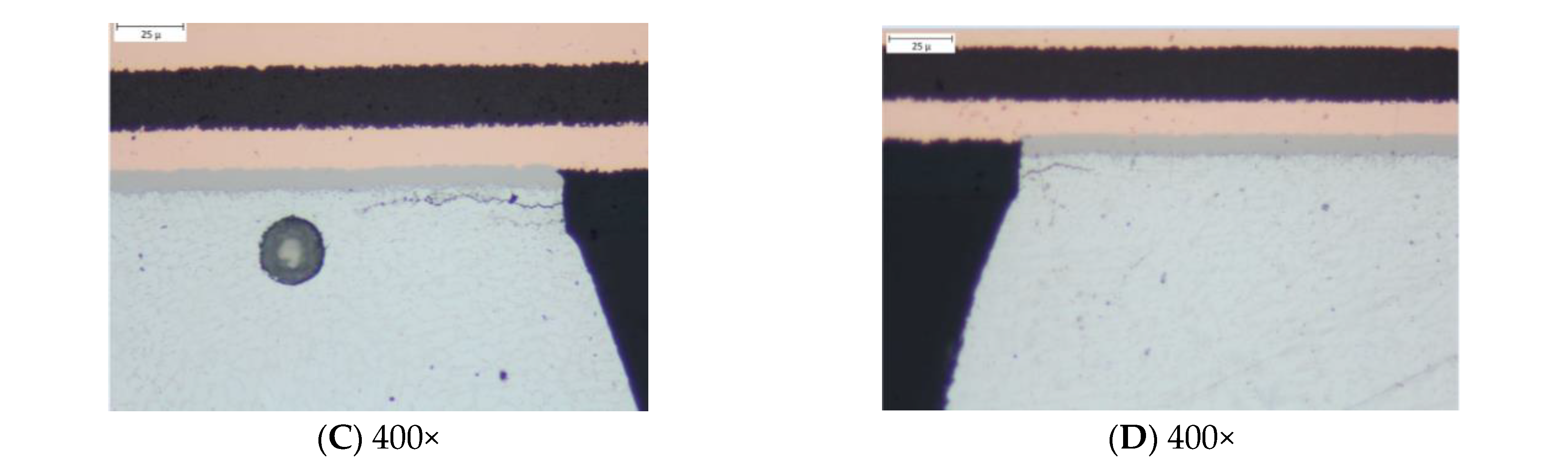

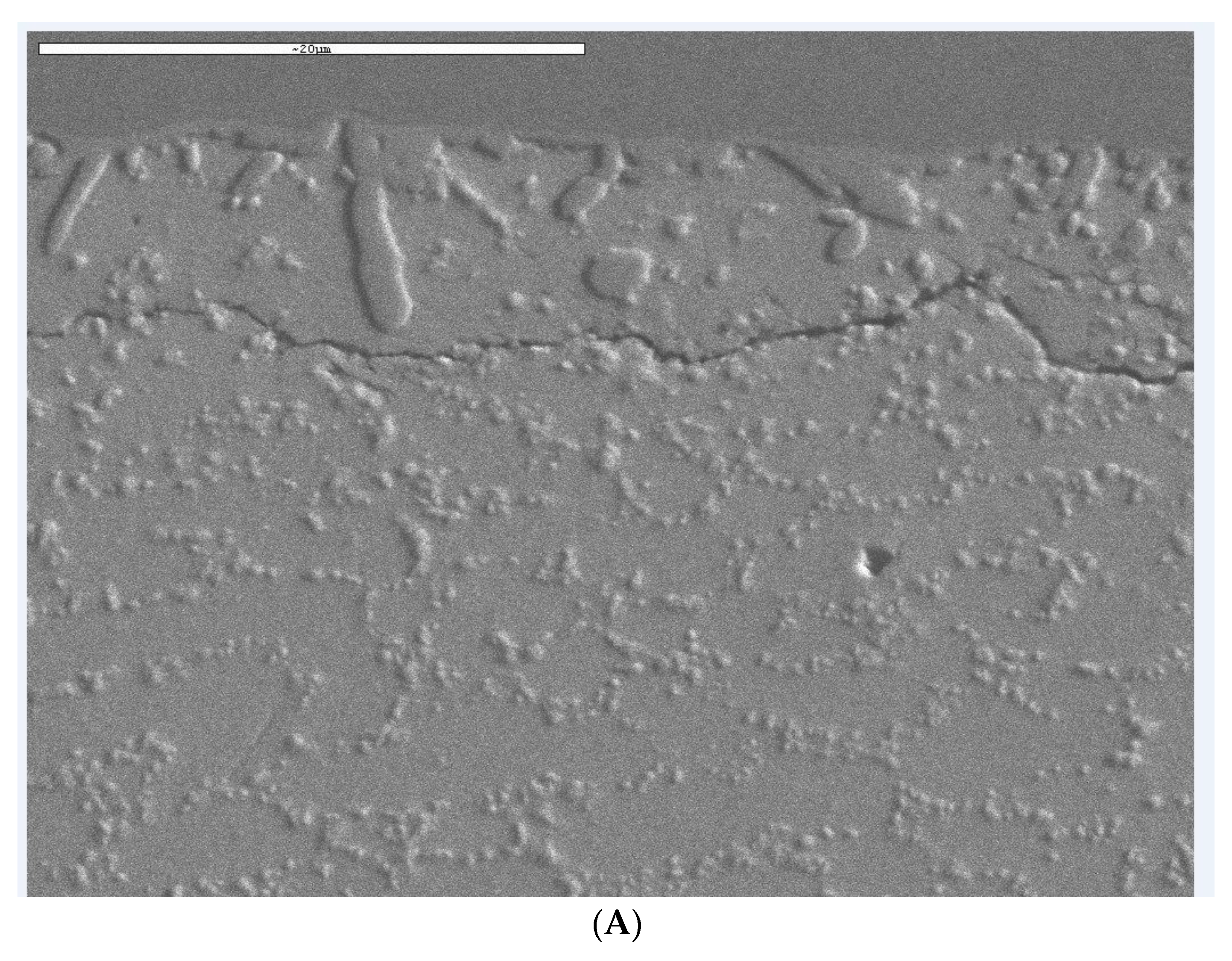

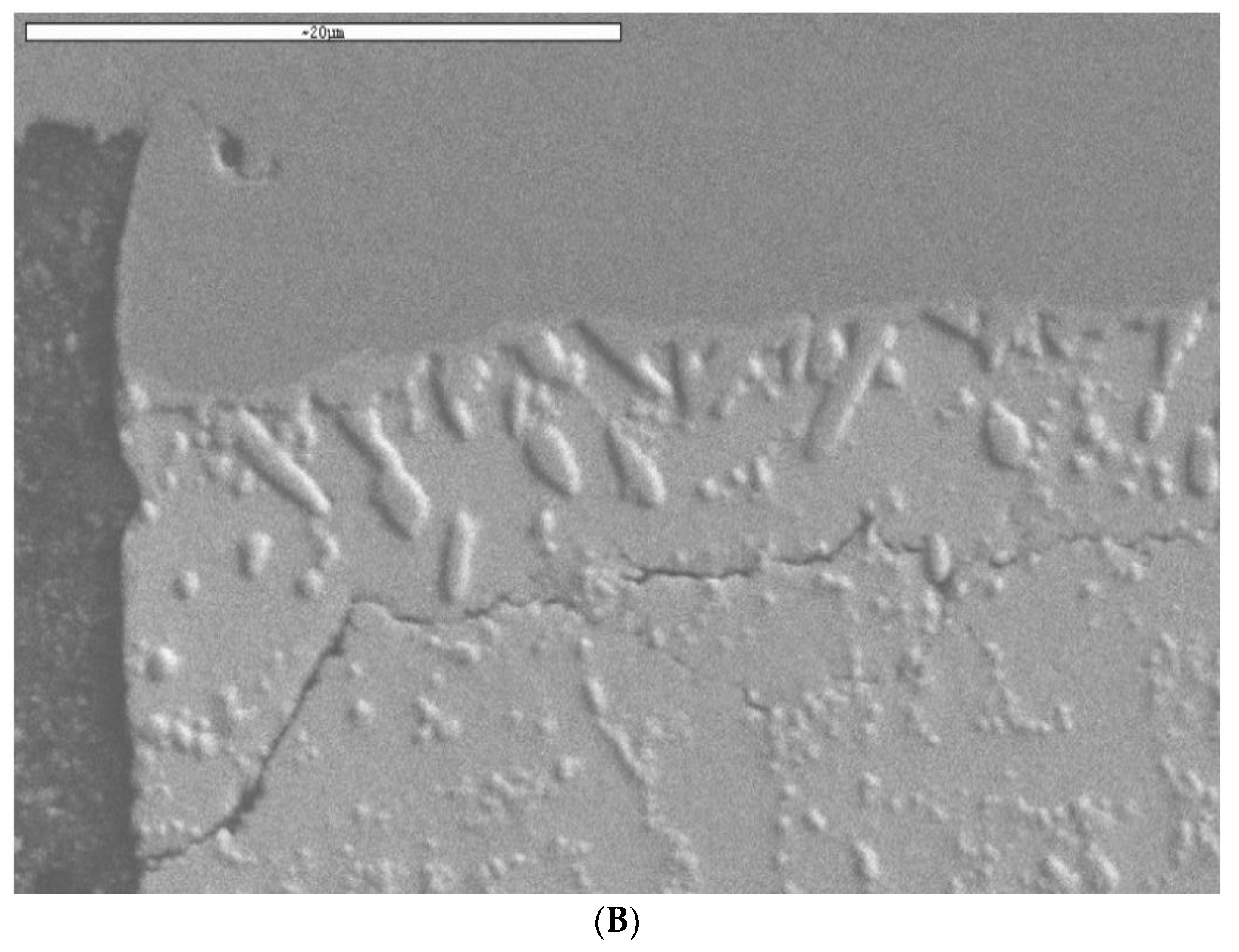

3.4. Failure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, S.; Huang, C.-M.; Pecht, M. A review of lead-free solders for electronics applications. Microelectron. Reliab. 2017, 75, 77–95. [Google Scholar] [CrossRef]

- Zhang, L.; Han, J.-G.; He, C.-W.; Guo, Y.-H. Reliability behavior of lead-free solder joints in electronic components. J. Mater. Sci. Mater. Electron. 2013, 24, 172–190. [Google Scholar] [CrossRef]

- Zhou, Q.; Lee, T.-K.; Bieler, T.R. In-situ characterization of solidification and microstructural evolution during interrupted thermal fatigue in SAC305 and SAC105 solder joints using high energy X-ray diffraction and post-mortem EBSD analysis. Mater. Sci. Eng. A 2021, 802, 140584. [Google Scholar] [CrossRef]

- Cinar, Y.; Jang, J.; Jang, G.; Kim, S.; Jang, J. Effect of solder pads on the fatigue life of FBGA memory modules under harmonic excitation by using a global–local modeling technique. Microelectron. Reliab. 2013, 53, 2043–2051. [Google Scholar] [CrossRef]

- Zhou, S.; Lin, Z.; Qiu, B.; Wang, H.; Xiong, J.; He, C.; Zhou, B.; Pan, Y.; Huang, R.; Bao, Y.; et al. Evaluation of Solder Joint Reliability in 3D Packaging Memory Devices under Thermal Shock. Electronics 2022, 11, 2556. [Google Scholar] [CrossRef]

- Obaidat, M.; Hamasha, S.; Jaradat, Y.; Qasaimeh, A.; Arfaei, B.; Anselm, M.; Borgesen, P. Effects of varying amplitudes on the fatigue life of lead free solder joints. In Proceedings of the 2013 IEEE 63rd Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2013. [Google Scholar]

- Ma, H.; Lee, T.-K. Effects of Board Design Variations on the Reliability of Lead-Free Solder Joints. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 3, 71–78. [Google Scholar] [CrossRef]

- Ghaderi, D.; Pourmahdavi, M.; Samavatian, V.; Mir, O.; Samavatian, M. Combination of thermal cycling and vibration loading effects on the fatigue life of solder joints in a power module. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1753–1763. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.; Liu, X.; Lu, G.Q. Effect of substrate flexibility on solder joint reliability. Part II: Finite element modeling. Microelectron. Reliab. 2005, 45, 143–154. [Google Scholar] [CrossRef]

- Deshpande, A.; Jiang, Q.; Dasgupta, A.; Becker, U. Role of Nominal Stress State on Cyclic Fatigue Durability of SAC305 Grain-Scale Solder Joints. J. Electron. Packag. 2022, 144, 1–42. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, B.; Lu, F.; Jiao, X.; Hu, J.; Chen, Y. Study on Failure Simulation and Fatigue Life Prediction of BGA Solder Joint Under Random Vibration. In Proceedings of the 2018 Prognostics and System Health Management Conference (PHM-Chongqing), Chongqing, China, 26–28 October 2018. [Google Scholar]

- Wu, M.-L. Vibration-induced fatigue life estimation of ball grid array packaging. J. Micromech. Microeng. 2009, 19, 065005. [Google Scholar] [CrossRef]

- Yoon, S.W.; Hong, J.K.; Kim, H.J.; Byun, K.Y. Board-level reliability of Pb-free solder joints of TSOP and various CSPs. IEEE Trans. Electron. Packag. Manuf. 2005, 28, 168–175. [Google Scholar] [CrossRef]

- Ma, H.; Suhling, J.C. A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 2009, 44, 1141–1158. [Google Scholar] [CrossRef]

- Lau, J.H.; Lee, S.-W.R. Modeling and analysis of 96.5 Sn-3.5 Ag lead-free solder joints of wafer level chip scale package on buildup microvia printed circuit board. IEEE Trans. Electron. Packag. Manuf. 2002, 25, 51–58. [Google Scholar] [CrossRef]

- Cinar, Y.; Jang, J.; Jang, G.; Kim, S.; Jang, J.; Chang, J.; Jun, Y. Failure mechanism of FBGA solder joints in memory module subjected to harmonic excitation. Microelectron. Reliab. 2012, 52, 735–743. [Google Scholar] [CrossRef]

- Hohne, R.; Meier, K.; Dasgupta, A.; Leslie, D.; Bock, K.-H. Improved Damage Modeling for Solder Joints under Combined Vibration and Temperature Cycling Loading. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June–4 July 2021. [Google Scholar]

- Xu, F.; Li, C.; Jiang, T.; Zhang, D. Fatigue Life Prediction for PBGA under Random Vibration Using Updated Finite Element Models. Exp. Tech. 2016, 40, 1421–1435. [Google Scholar] [CrossRef]

- Jayesh, S.; Elias, J. Finite element modeling and random vibration analysis of BGA electronic package soldered using lead free solder alloy − Sn-1Cu-1Ni-1Ag. Int. J. Simul. Multidiscip. Des. Optim. 2019, 10, A11. [Google Scholar] [CrossRef]

- Qiu, B.; Xiong, J.; Wang, H.; Zhou, S.; Yang, X.; Lin, Z.; Liu, M.; Cai, N. Survey on Fatigue Life Prediction of BGA Solder Joints. Electronics 2022, 11, 542. [Google Scholar] [CrossRef]

- Chen, Y.S.; Wang, C.S.; Yang, Y.J. Combining vibration test with finite element analysis for the fatigue life estimation of PBGA components. Microelectron. Reliab. 2008, 48, 638–644. [Google Scholar] [CrossRef]

- Yu, D.; Al-Yafawi, A.; Nguyen, T.T.; Park, S.; Chung, S. High-cycle fatigue life prediction for Pb-free BGA under random vibration loading. Microelectron. Reliab. 2011, 51, 649–656. [Google Scholar] [CrossRef]

- Steinberg, D.S. Vibration Analysis for Electronic Equipment, 3rd ed.; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar]

- Depiver, J.A. Thermo-Mechanical Reliability Studies of Lead-Free Solder Interconnects. Ph.D. Thesis, University of Derby, Derby, UK, 2021. [Google Scholar]

- An, T.; Qin, F. Effects of the intermetallic compound microstructure on the tensile behavior of Sn3. 0Ag0. 5Cu/Cu solder joint under various strain rates. Microelectron. Reliab. 2014, 54, 932–938. [Google Scholar] [CrossRef]

- Libot, J.B.; Arnaud, L.; Dalverny, O.; Alexis, J.; Milesi, P.; Dulondel, F. Mechanical fatigue assessment of SAC305 solder joints under harmonic and random vibrations. In Proceedings of the 2016 17th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Montpellier, France, 18–20 April 2016. [Google Scholar]

| SN | Materials | Young’s Modulus (GPa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|---|

| 1 | PCB | 15.6 | 0.39 | 1950 |

| 2 | Solder Ball | 51 | 0.3 | 7400 |

| 3 | Substrate | 15 | 0.35 | 1900 |

| 4 | Silicon Chip | 60 | 0.25 | 2330 |

| Sample Number | Board Dimensions (mm) | Board 1 First Natural Frequency (Hz) | Board 2 First Natural Frequency (Hz) |

|---|---|---|---|

| Sample 1 | 77 × 77 × 1 | 469.2 | 459.76 |

| Sample 2 | 77 × 77 × 1.6 | 696.58 | 699.3 |

| Material Constant | Material Type | Numerical Values | Reference |

|---|---|---|---|

| (MPa) | SAC 305 | 64.8 | [22] |

| −0.1443 |

| SN | PCB Dimensions | Solder Alloy | Input Excitation | Life to Failure |

|---|---|---|---|---|

| Sample 1 | 77 × 77 × 1 | SAC 305 | 0.5 G | 108 h, 27 min |

| Sample 2 | 77 × 77 × 1.6 | SAC 305 | 0.5 G | 450 h, 48 min |

| Experimental Results | Simulation Results | % Error | |||

|---|---|---|---|---|---|

| Time to Failure | Mean Time to Failure | Time To Failure | |||

| Sample 1 | Test Vehicle 1 | 140 h, 26 min | 137 h, 4 min | 108 h, 27 min | 20.87 |

| Test Vehicle 2 | 133 h, 38 min | ||||

| Sample 2 | Test Vehicle 1 | 530 h, 19 min | 540 h, 32 min | 450 h, 48 min | 16.60 |

| Test Vehicle 2 | 549 h, 43 min | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doranga, S.; Schuldt, M.; Khanal, M. Effect of Stiffening the Printed Circuit Board in the Fatigue Life of the Solder Joint. Materials 2022, 15, 6208. https://doi.org/10.3390/ma15186208

Doranga S, Schuldt M, Khanal M. Effect of Stiffening the Printed Circuit Board in the Fatigue Life of the Solder Joint. Materials. 2022; 15(18):6208. https://doi.org/10.3390/ma15186208

Chicago/Turabian StyleDoranga, Sushil, Matthew Schuldt, and Mukunda Khanal. 2022. "Effect of Stiffening the Printed Circuit Board in the Fatigue Life of the Solder Joint" Materials 15, no. 18: 6208. https://doi.org/10.3390/ma15186208

APA StyleDoranga, S., Schuldt, M., & Khanal, M. (2022). Effect of Stiffening the Printed Circuit Board in the Fatigue Life of the Solder Joint. Materials, 15(18), 6208. https://doi.org/10.3390/ma15186208