Correlation among Composition, Microstructure and Hardness of 7xxx Aluminum Alloy Using Original Statistical Spatial-Mapping Method

Abstract

:1. Introduction

2. Materials and Method

2.1. Experimental Samples

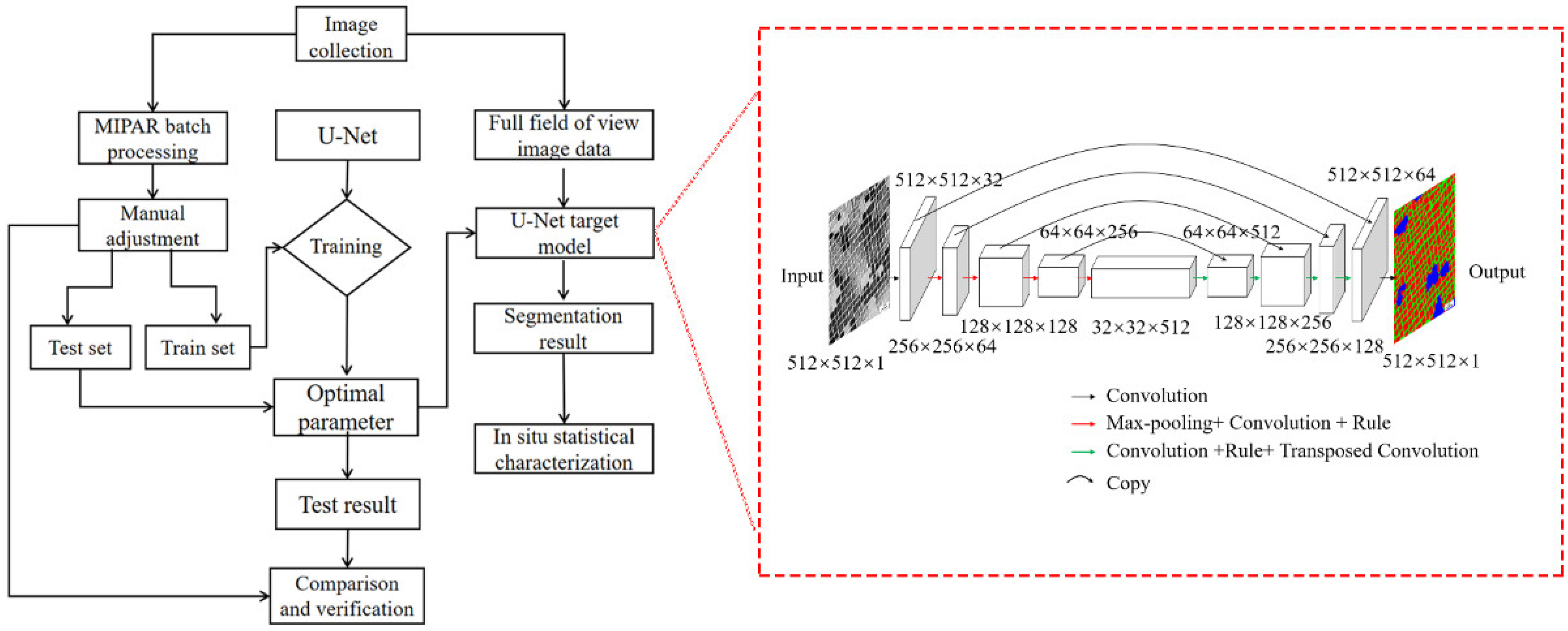

2.2. Quantitative Method of Insoluble Phases Using High Throughput Scanning Electron Microscope

2.3. Quantitative Method of Gray Value Using Optical Microscopy

2.4. Instruments and Conditions of Composition Test

2.5. Instruments and Conditions of Hardness Test

2.6. Instruments and Conditions of Electron Back Scattered Diffraction (EBSD)

3. Experimental Results

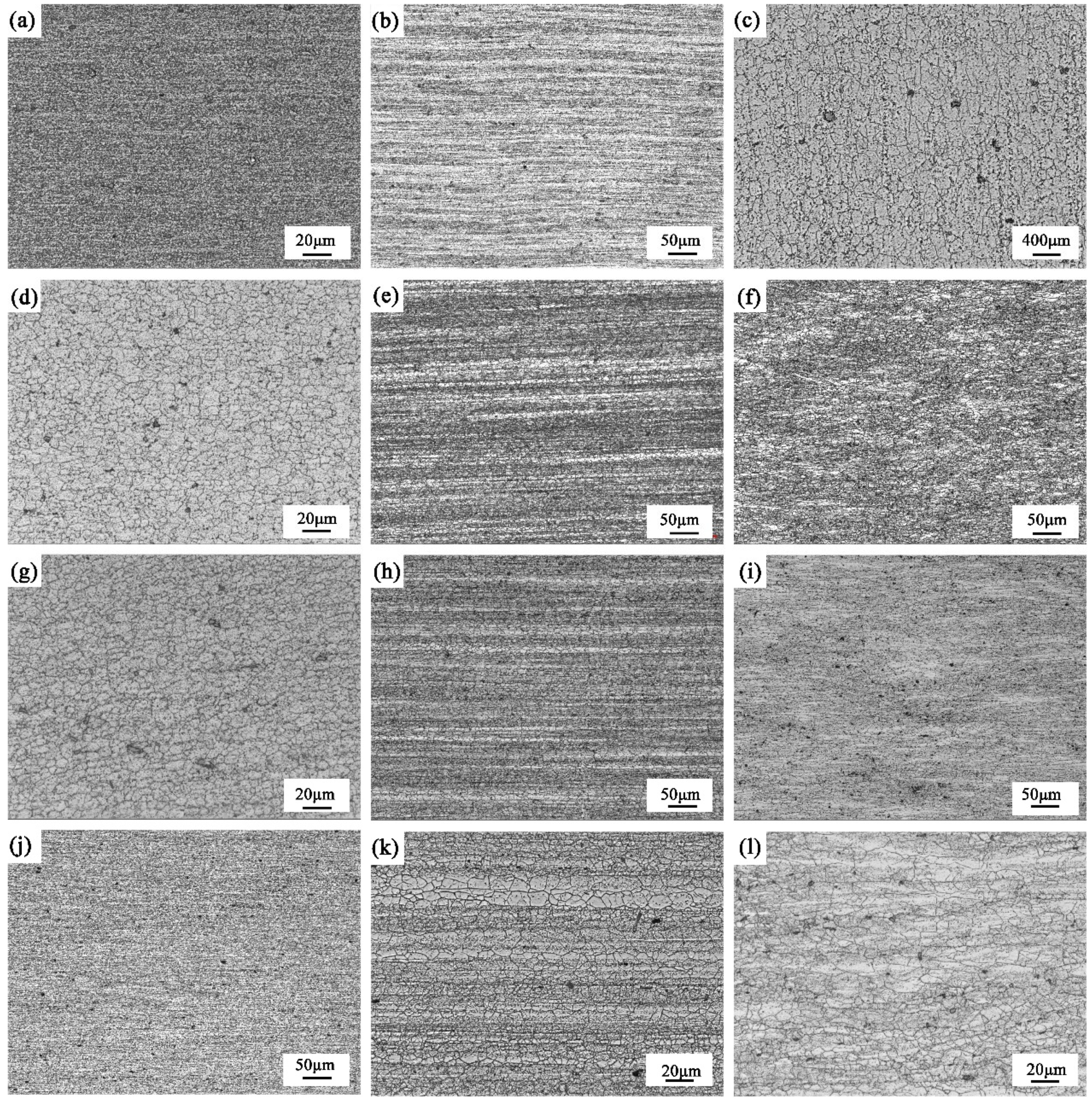

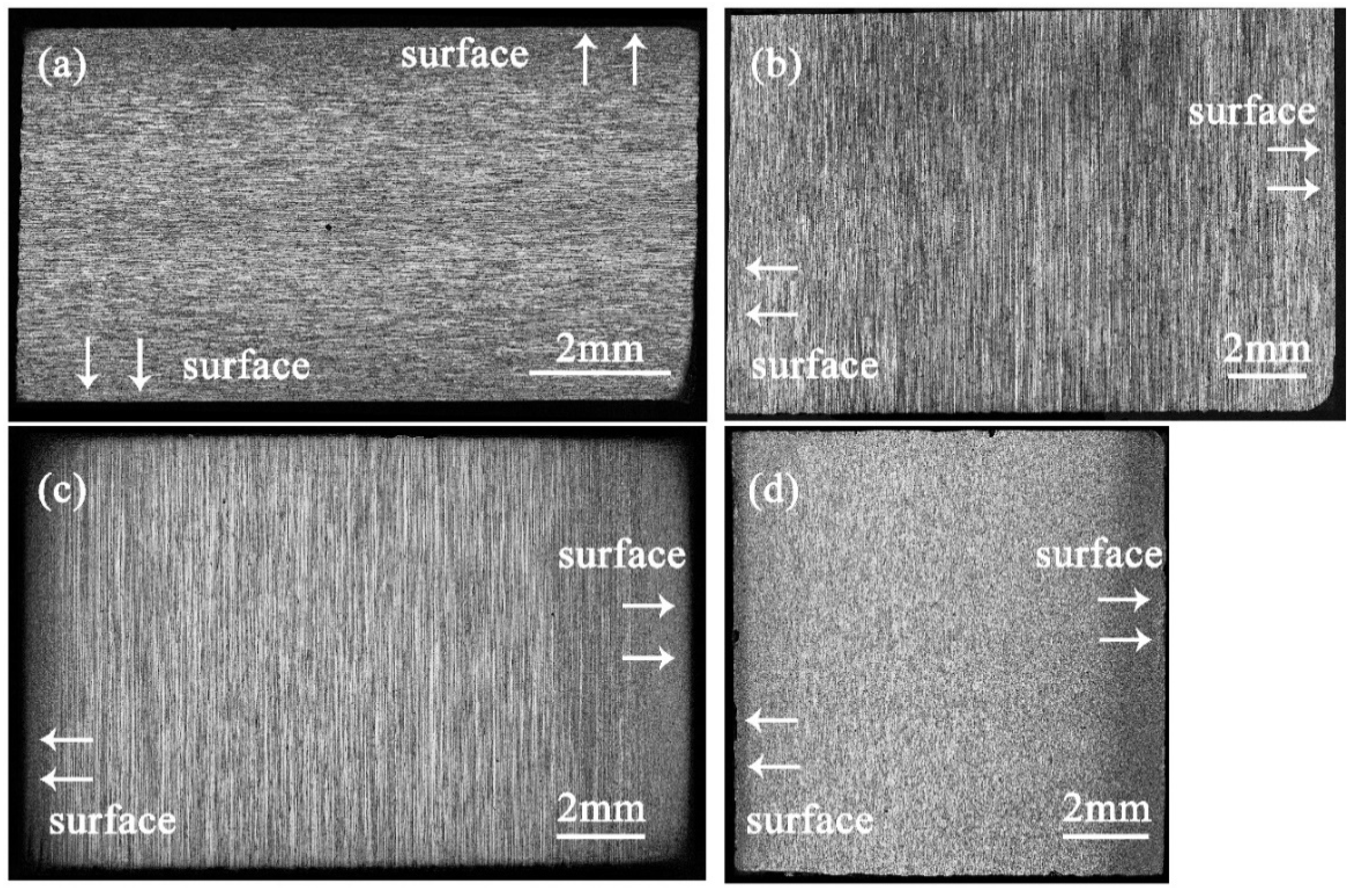

3.1. Microscopic Morphology and Characteristics of Aluminum Alloy

3.1.1. Morphology and Characteristics of Crystallography

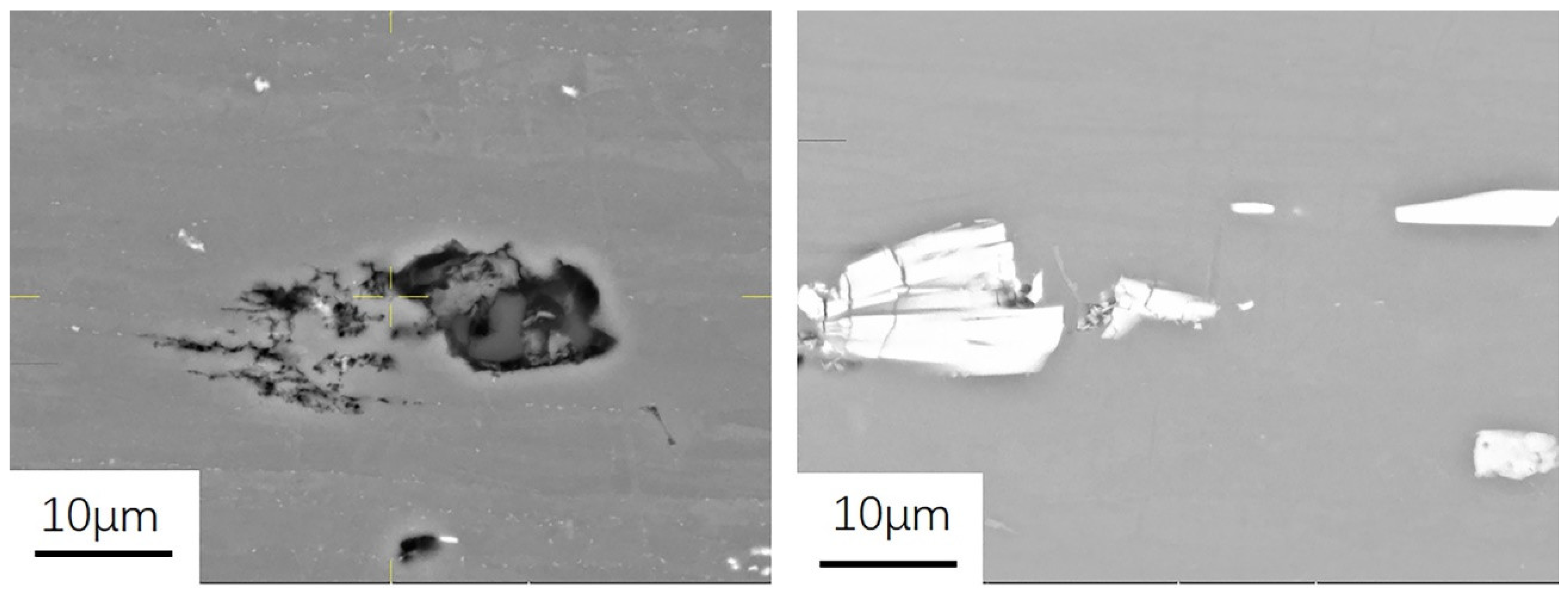

3.1.2. Morphology and Characteristics of Insoluble Phase

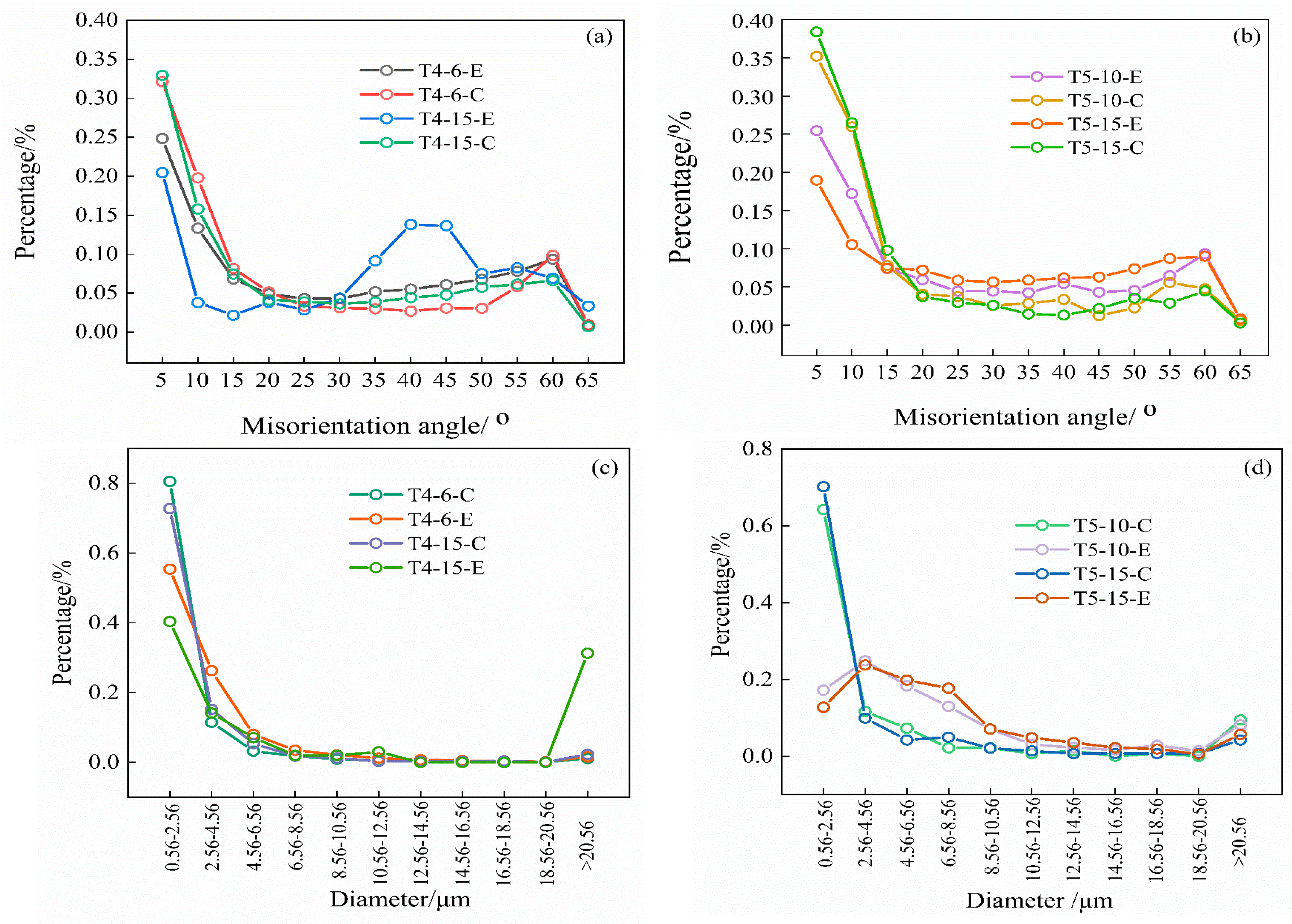

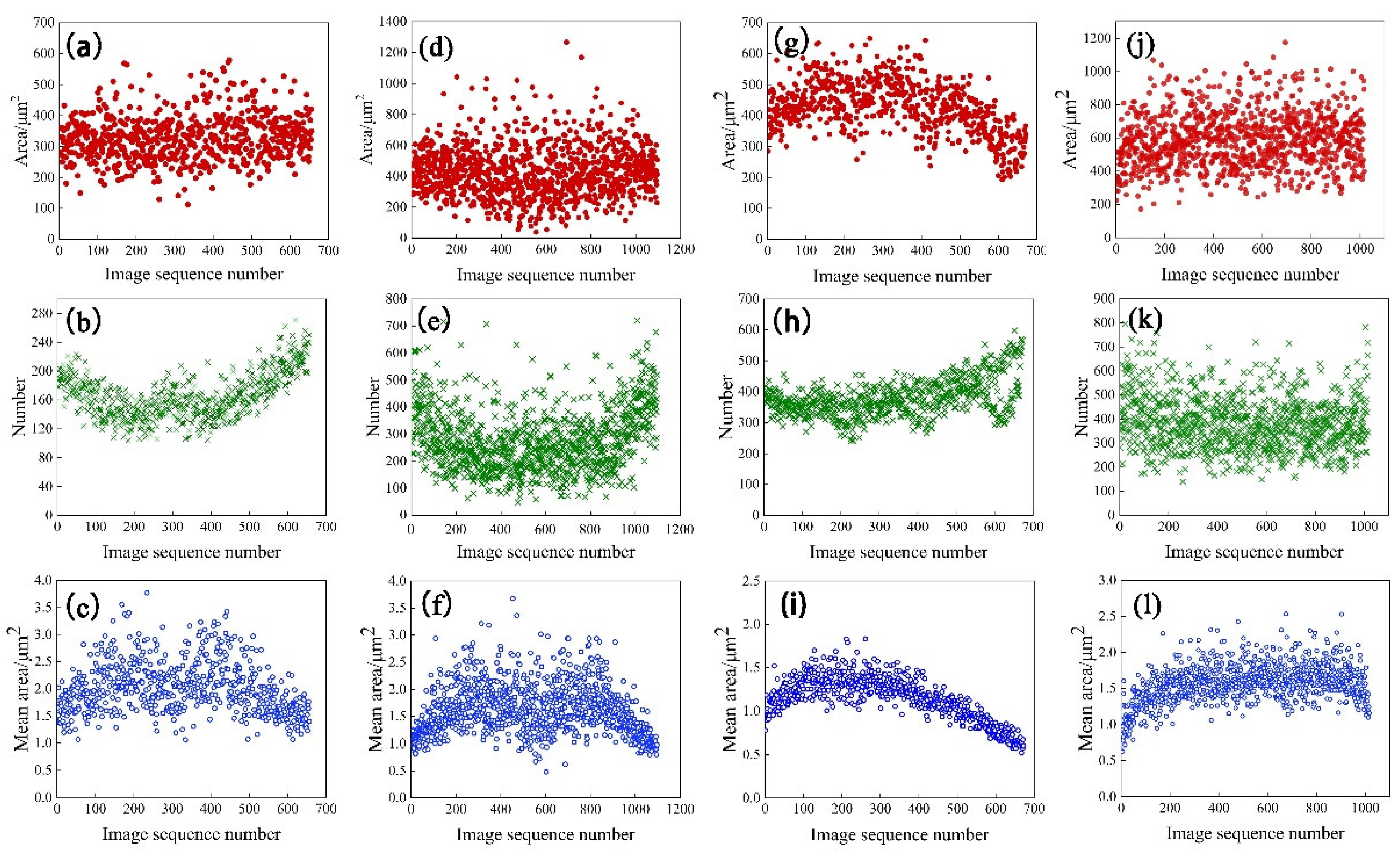

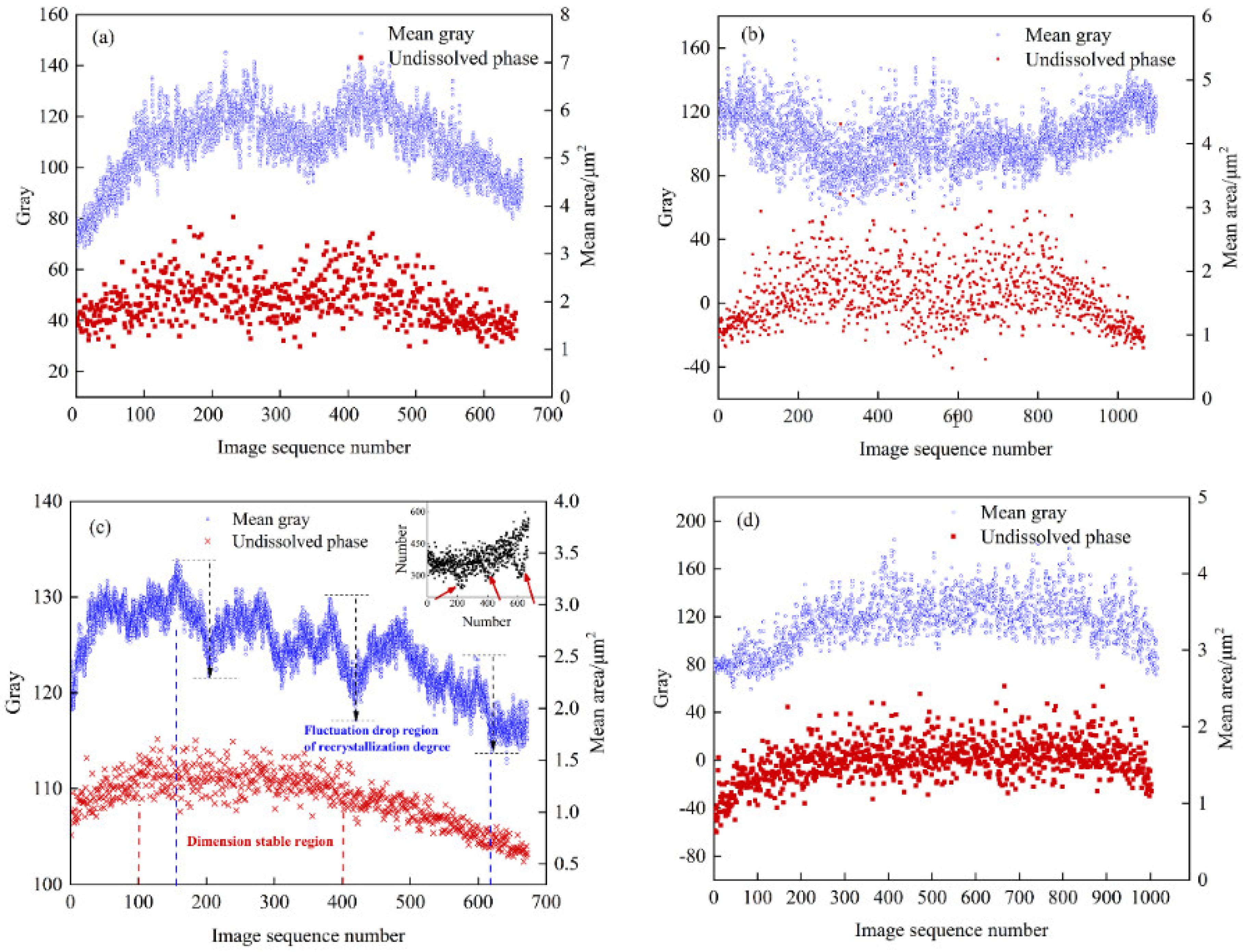

3.2. Statistical Results of Second Phase Distribution

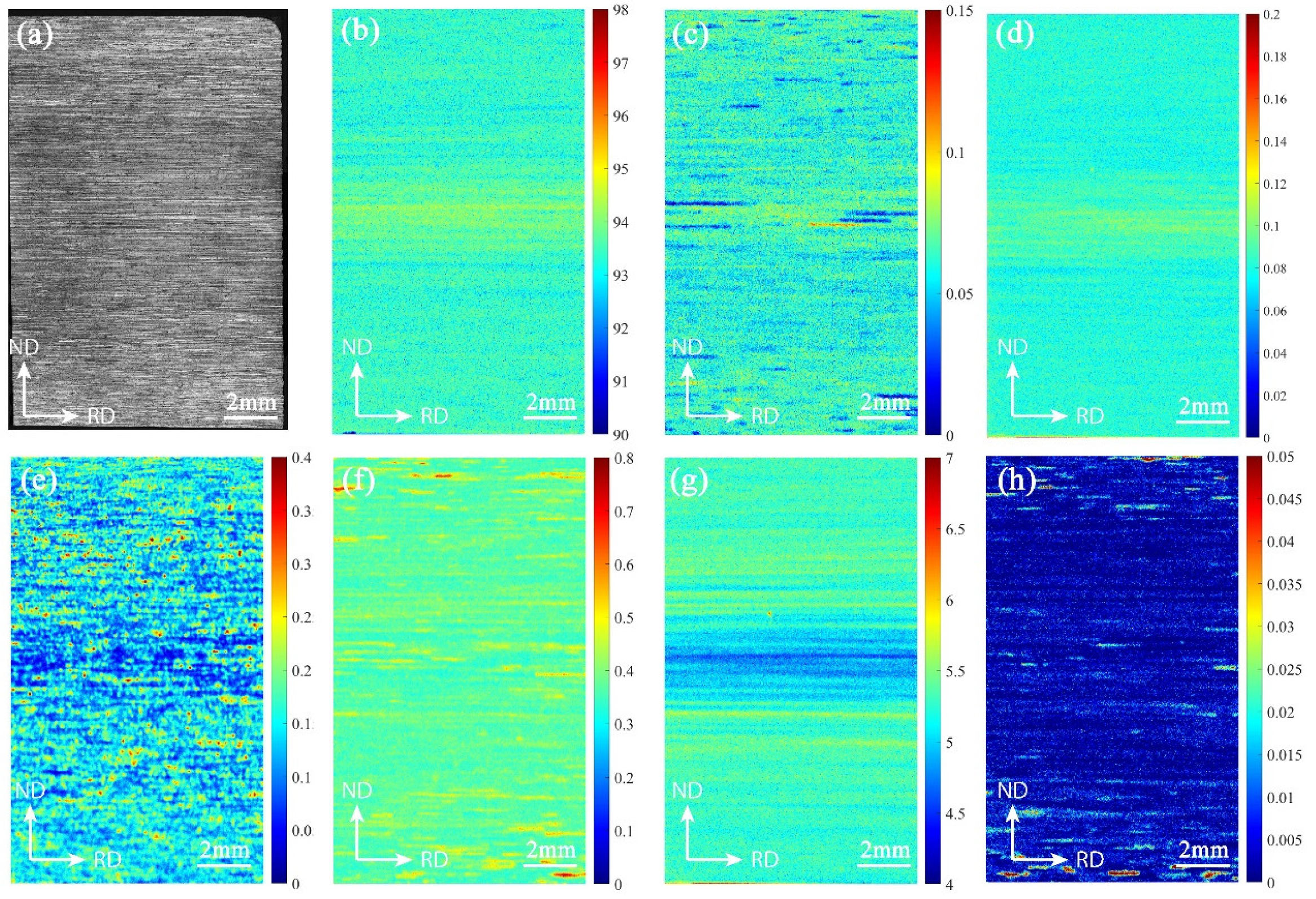

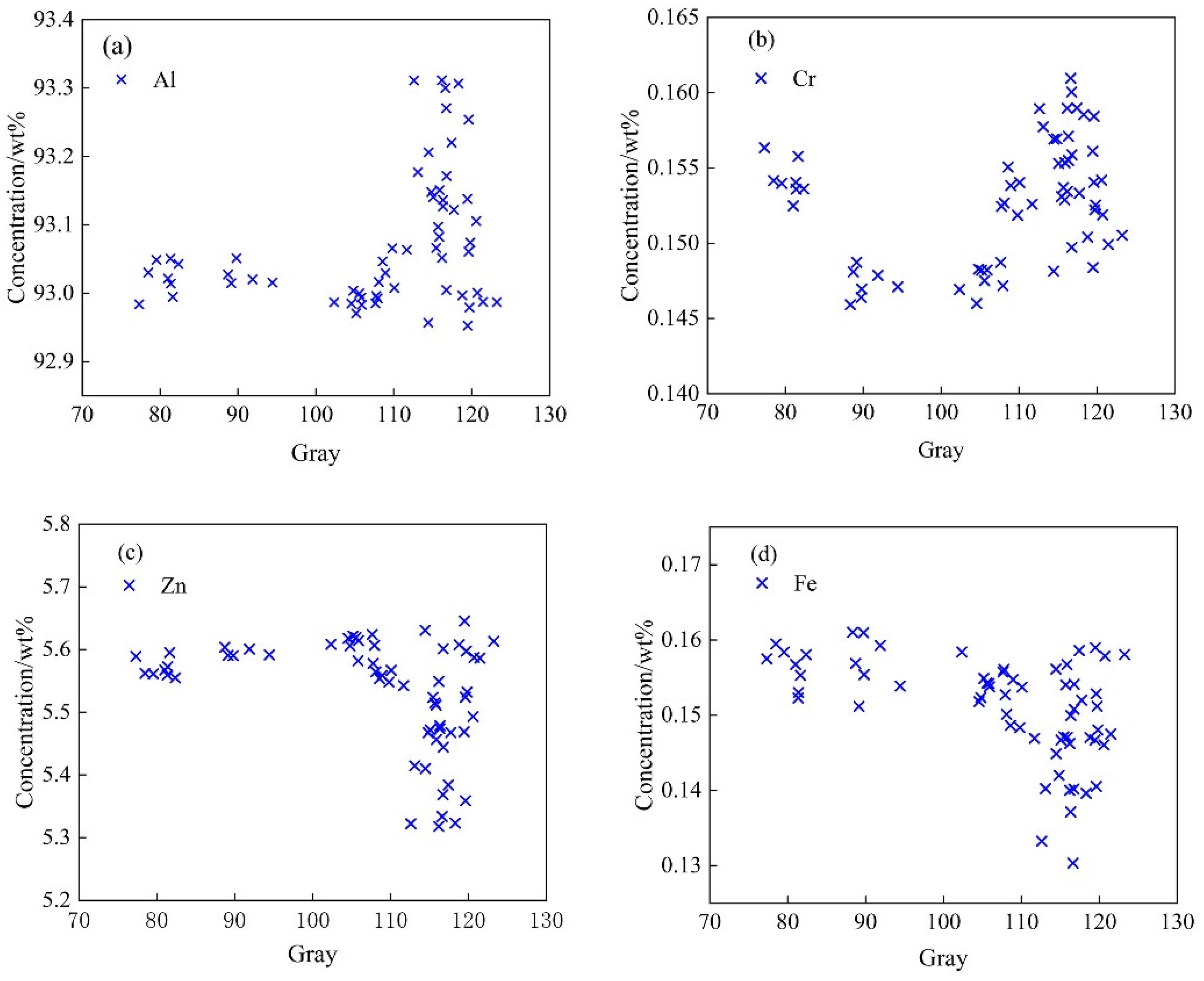

3.3. Statistical Results of Element Distribution

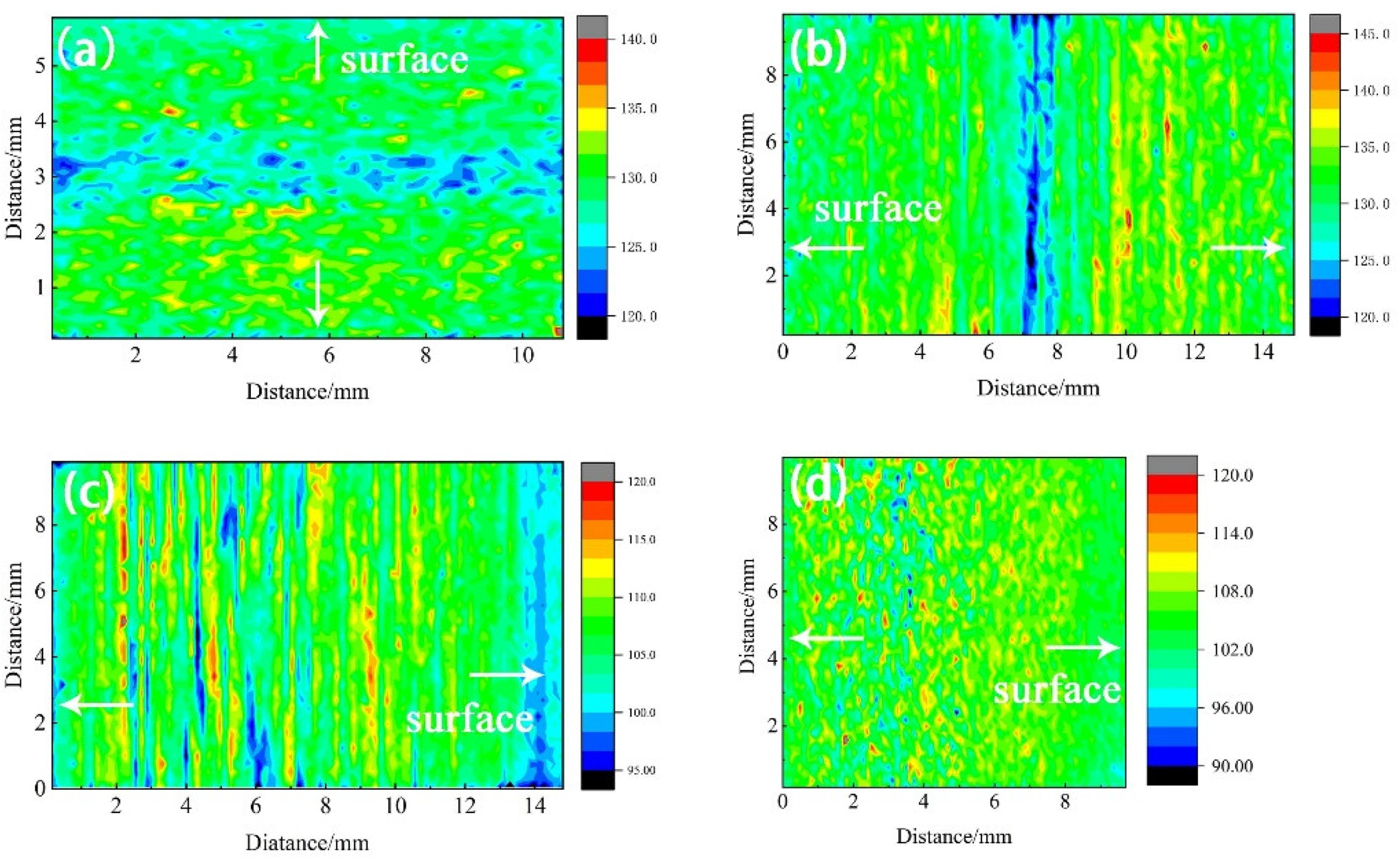

3.4. Statistical Results of Hardness Distribution

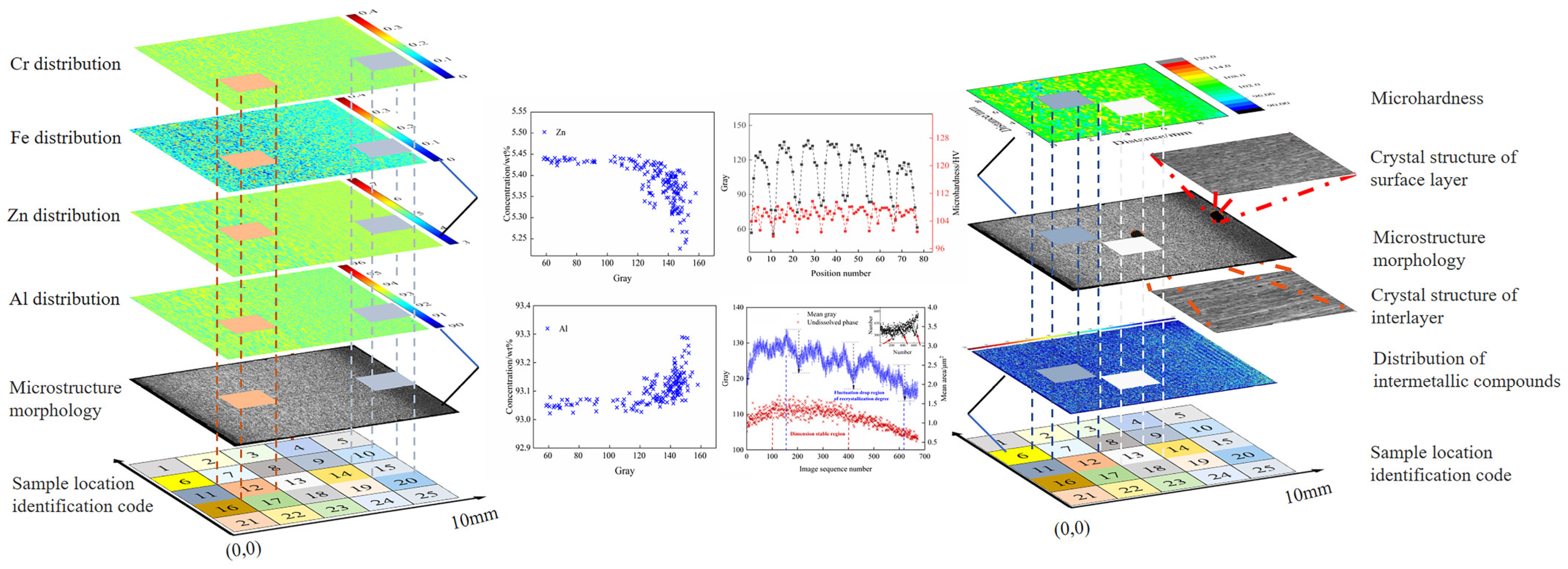

4. Statistical Mapping Trend Analysis

4.1. Analysis of Insoluble Phase-Structure Statistical Mapping Trend

4.2. Analysis of Structure-Composition Statistical Mapping Trend

4.3. Analysis of Structure-Hardness Statistical Mapping Trend

4.4. Correlation among Composition, Hardness and Microstructure Using Original Statistical Spatial-Mapping Method

5. Conclusions

- (1)

- The number of insoluble phases in T4 and T5 has the same variation trend, with more in the surface layer and fewer in the middle. The average area of the insoluble phase in two T4 materials increases from 1.5 and 1 μm2 in the surface layer, to 3 μm2 in the center layer. The anomalous decrease in the insoluble phase area near the center is related to the center segregation. The growth in the insoluble phase of T5 materials is synchronized with the growth process of recrystallization.

- (2)

- The surface of the rolled sheet has a high degree of solid solution, and the composition is evenly distributed; for T5 material, there is positive segregation of Al, Cr, Ti and Zr, and negative segregation of Zn, Cu and Fe in the recrystallized grains of the middle segregation zone; T4 material has genetic center segregation caused by casting and hot rolling process.

- (3)

- The hardness value of the surface composed of equiaxed and coarse recrystallized grains is small and the distribution is uniform; the band-like hardness distribution in the T5 intermediate layer is related to the recrystallization proportion and the size of the recrystallized grains. The coarse grain in the T4 intermediate layer is smaller than that of the T5 material; therefore, there is no low-hardness zone with a band-like distribution. The low hardness region with a value below 125 in T4 is mainly caused by the negative segregation of alloying elements. Values below 100 are basically distributed in this area.

- (4)

- The original statistical spatial-mapping method demonstrated the feasibility of analyzing the correlation among massive multi-source heterogeneous data, including for composition–microstructure–performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Guo, F.B.; Zhu, B.H.; Jin, L.B.; Guo, F.-B.; Zhu, B.-H.; Jin, L.-B.; Wang, G.-J.; Yan, H.-W.; Li, Z.-H.; Zhang, Y.-A.; et al. Microstructure and mechanical properties of 7A56 aluminum alloy after solution treatment. Rare Met. 2021, 40, 168–175. [Google Scholar] [CrossRef]

- Dai, X.; Xia, C.; Peng, X.; Ma, K. Structure and properties of an ultra-high strength 7xxx aluminum alloy contained Sc and Zr. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2018, 15, 276–279. [Google Scholar] [CrossRef]

- Srinivasa Rao, T.; Madhusudhan Reddy, G.; Koteswara Rao, S.R. Microstructure and mechanical properties of friction stir welded AA7075–T651 aluminum alloy thick plates. Trans. Nonferrous Met. Soc. China 2015, 25, 1770–1778. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Cepeda-Jiménez, C.; Orozco-Caballero, A.; Ruano, O.; Carreño, F. Evolution of the microstructure, texture and creep properties of the 7075 aluminium alloy during hot accumulative roll bonding. Mater. Sci. Eng. A 2014, 606, 434–442. [Google Scholar] [CrossRef] [Green Version]

- Engler, O.; Crumbach, M.; Li, S. Alloy-dependent rolling texture simulation of aluminium alloys with a grain-interaction model. Acta Mater. 2005, 53, 2241–2257. [Google Scholar] [CrossRef]

- She, X.-W.; Jiang, X.-Q.; Wang, P.-Q.; Tang, B.-B.; Chen, K.; Liu, Y.-J.; Cao, W.-N. Relationship between microstructure and mechanical properties of 5083 aluminum alloy thick plate. Trans. Nonferrous Met. Soc. China 2020, 30, 1780–1789. [Google Scholar] [CrossRef]

- Ao, M.; Dong, C.; Li, N.; Wang, L.; Ji, Y.; Yue, L.; Sun, X.; Zou, S.; Xiao, K.; Li, X. Unexpected Stress Corrosion Cracking Improvement Achieved by Recrystallized Layer in Al-Zn-Mg Alloy. J. Mater. Eng. Perform. 2021, 30, 6258–6268. [Google Scholar] [CrossRef]

- Ji, Y.; Dong, C.; Chen, L.; Xiao, K.; Li, X. High-throughput computing for screening the potential alloying elements of a 7xxx aluminum alloy for increasing the alloy resistance to stress corrosion cracking. Corros. Sci. 2021, 183, 109304–109314. [Google Scholar] [CrossRef]

- Liu, P.; Hu, L.; Zhao, X.; Zhang, Q.; Yu, Z.; Hu, J.; Chen, Y.; Wu, F.; Cao, F. Investigation of microstructure and corrosion behavior of weathering steel in aqueous solution containing different anions for simulating service environments. Corros. Sci. 2020, 170, 108686–108700. [Google Scholar] [CrossRef]

- Deschamps, A.; Ringeval, S.; Texier, G.; Delfaut-Durut, L. Quantitative characterization of the microstructure of an electron-beam welded medium strength Al–Zn–Mg alloy. Mater. Sci. Eng. A 2009, 517, 361–368. [Google Scholar] [CrossRef]

- Luo, R.; Cao, Y.; Bian, H.; Chen, L.; Peng, C.-T.; Cao, F.; Ouyang, L.; Qiu, Y.; Xu, Y.; Chiba, A.; et al. Hot workability and dynamic recrystallization behavior of a spray formed 7055 aluminum alloy. Mater. Charact. 2021, 178, 11203–11215. [Google Scholar] [CrossRef]

- Huo, M.S.; Zhao, J.W.; Xie, H.B.; Jia, F.; Li, S.; Zhang, H.; Jiang, Z. Effects of micro flexible rolling and annealing on microstructure, microhardness and texture of aluminium alloy. Mater. Charact. 2019, 148, 142–155. [Google Scholar] [CrossRef]

- Han, B.; Sun, D.D.; Wan, W.H.; Wang, H.; Dong, C.C.; Zhao, L.; Wang, H.Z. Element Segregation of Cast-Rolled 7B05 Aluminum Alloy Basedon Microbeam X-Ray Fluorescence. Spectrosc. Spectr. Anal. 2022, 42, 1413–1419. [Google Scholar]

- Li, D.-L.; Liu, Z.-X.; Zhao, L.; Shen, X.-J.; Wang, H.-Z. Characterization of the elemental distribution of superalloy composite powders by micro beam X-ray fluorescence and laser-induced breakdown spectroscopy. Spectrochim. Acta Part B At. Spectrosc. 2020, 169, 105896–105910. [Google Scholar] [CrossRef]

- Wang, H.; Jia, Y.; Li, Y.; Zhao, L.; Yang, C.; Cheng, D. Rapid analysis of content and particle sizes of aluminum inclusions in low and middle alloy steel by laser-induced breakdown spectroscopy. Spectrochim. Acta Part B At. Spectrosc. 2020, 171, 105927–105934. [Google Scholar] [CrossRef]

- Azimi, S.M.; Britz, D.; Engstler, M.; Fritz, M.; Mücklich, F. Advanced Steel Microstructural Classification by Deep Learning Methods. Sci. Rep. 2018, 8, 2128–2142. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, A.; Kautz, E.; Yener, B.; Lewis, D. Image driven machine learning methods for microstructure recognition. Comput. Mater. Sci. 2016, 123, 176–187. [Google Scholar] [CrossRef] [Green Version]

- Staniewicz, L.; Midgley, P.A. Machine learning as a tool for classifying electron tomographic reconstructions. Adv. Struct. Chem. Imaging 2015, 1, 9. [Google Scholar] [CrossRef] [Green Version]

- Bulgarevich, D.S.; Tsukamoto, S.; Kasuya, T.; Demura, M.; Watanabe, M. Pattern recognition with machine learning on optical microscopy images of typical metallurgical microstructures. Sci. Rep. 2018, 8, 2078–2086. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, L.; Jiang, L.; Wang, H. Microstructure and properties of Cu-rGO composites prepared by microwave sintering. Materials 2021, 14, 4899. [Google Scholar] [CrossRef]

- Chen, X.B.; Zhao, L.; Li, D.L.; Jiang, L.; Wang, H. Characteristic of microwave melting H13 steel powder with different tungsten contents. Mater. Lett. 2021, 294, 129803–129808. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.L.; Dominguez-Lopez, I.; Lopez-Jimenez, L.; Barceinas-Sanchez, J.O. Comparative quantification and statistical analysis of η′ and η precipitates in aluminum alloy AA7075-T651 by TEM and AFM. Mater. Charact. 2014, 87, 116–124. [Google Scholar] [CrossRef]

- Albuquerque, V.H.C.; Silva, C.; Menezes, T.I.D.S.; Farias, J.P.; Tavares, J.M.R.S. Automatic Evaluation of Nickel alloy secondary phases from SEM images. Microsc. Res. Tech. 2011, 74, 36–46. [Google Scholar] [CrossRef] [PubMed]

- Wan, W.H.; Li, D.L.; Wang, H.Z.; Zhao, L.; Shen, X.; Sun, D.; Chen, J.; Xiao, B. Automatic identification and quantitative characterization of primary dendrite microstructure based on machine learning. Craystals 2021, 11, 1060. [Google Scholar] [CrossRef]

- Li, W.; Li, W.; Qin, Z.; Tan, L.; Huang, L.; Liu, F.; Xiao, C. Deep Transfer Learning for Ni-Based Superalloys Microstructure Recognition on ϒ′ Phases. Materials 2022, 15, 4251. [Google Scholar] [CrossRef]

- Wan, W.H.; Li, D.L.; Zhou, Q.Q.; Zang, Q.; Xue, X.; Shi, H.; Wang, H. Quantitative characterization of the ϒ′ phases distribution in the large-scale area of the Second-Generation Nickon-based single crystal blade DD5. Craystals 2021, 11, 1399. [Google Scholar] [CrossRef]

- Xie, F.; Yan, X.; Ding, L.; Zhang, F.; Chen, S.; Chu, M.G.; Chang, Y. A study of microstructure and microsegregation of aluminum 7050 alloy. Mater. Sci. Eng. A 2003, 355, 144–153. [Google Scholar] [CrossRef]

- Eskin, D.G.; Nadella, R.; Katgerman, L. Effect of different grain structures on centerline macrosegregation during direct-chill casting. Acta Mater. 2008, 56, 1358–1365. [Google Scholar] [CrossRef] [Green Version]

- Guo, F.; Wang, X.; Liu, W.; Shang, C.; Misra, R.D.K.; Wang, H.; Zhao, T.; Peng, C. The Influence of Centerline Segregation on the Mechanical Performance and Microstructure of X70 Pipeline Steel. Steel Res. Int. 2018, 89, 1800407. [Google Scholar] [CrossRef]

- Lee, S.; Bi, X.; Reed, R.B.; Ranville, J.F.; Herckes, P.; Westerhoff, P. Nanoparticle Size Detection Limits by Single Particle ICP-MS for 40 Elements. Environ. Sci. Technol. 2014, 48, 10291–10300. [Google Scholar] [CrossRef]

- Stratis, D.N.; Eland, K.L.; Angel, S.M. Enhancement of Aluminum, Titanium, and Iron in Glass Using Pre-ablation Spark Dual-Pulse LIBS. Appl. Spectrosc. 2000, 54, 1719–1726. [Google Scholar] [CrossRef]

- Solé, V.; Papillon, E.; Cotte, M.; Walter, P.; Susini, J. A multiplatform code for the analysis of energy-dispersive X-ray fluorescence spectra. Spectrochim. Acta Part B At. Spectrosc. 2007, 62, 63–68. [Google Scholar] [CrossRef]

- Potts, P.J.; Webb, P.C. X-ray fluorescence spectrometry. J. Geochem. Explor. 2012, 44, 251–296. [Google Scholar] [CrossRef]

- Paunesku, T.; Vogt, S.; Maser, J.; Lai, B.; Woloschak, G. X-ray fluorescence microprobe imaging in biology and medicine. J. Cell. Biochem. 2006, 99, 1489–1502. [Google Scholar] [CrossRef] [PubMed]

- Bahn, C.B.; Kasza, K.E.; Shack, W.J.; Natesan, K.; Klein, P. Evaluation of precipitates used in strainer head loss testing: Part II. Precipitates by in situ aluminum alloy corrosion. Nucl. Eng. Des. 2011, 241, 1926–1936. [Google Scholar] [CrossRef]

- Li, L.L.; Desouza, A.L.; Swain, G.M. In situ pH measurement during the formation of conversion coatings on an aluminum alloy (AA2024). Analyst 2013, 138, 4398–4403. [Google Scholar] [CrossRef]

- Zhao, L.; Jiang, L.; Yang, L.; Wang, H.; Zhang, W.; Ji, G.; Zhou, X.; Curtin, W.; Chen, X.; Liaw, P.; et al. High throughput synthesis enabled exploration of CoCrFeNi-based high entropy alloys. J. Mater. Sci. Technol. 2021, 15, 269–282. [Google Scholar] [CrossRef]

- Cao, Y.; Zhu, P.; Shi, W.; Hua, G.; Wang, H.; Qiu, M. Correlation between X-Ray diffraction pattern and microstructure of surface of E690 high-strength steel induced by laser-shock processing. Vacuum 2021, 195, 110595. [Google Scholar] [CrossRef]

- Zhang, Q.; Cui, Z.; Niu, X.; Geng, S.; Qiao, Y. Image Segmentation with Pyramid Dilated Convolution Based on ResNet and U-Net. In Proceedings of the 24th International Conference, ICONIP 2017, Guangzhou, China, 14–18 November 2017; Volume 10635, pp. 364–372. [Google Scholar] [CrossRef]

- Devalla, S.K.; Renukanand, P.K.; Sreedhar, B.K.; Subramanian, G.; Zhang, L.; Perera, S.; Mari, J.M.; Chin, K.S.; Tun, T.A.; Strouthidis, N.G.; et al. DRUNET: A dilated-residual U-Net deep learning network to segment optic nerve head tissues in optical coherence tomography images. Biomed. Opt. Express 2018, 9, 3244–3265. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.X.; Liu, Q.J. Road Extraction by Deep Residual U-Net. IEEE Geosci. Remote Sens. Lett. 2018, 15, 749–753. [Google Scholar] [CrossRef] [Green Version]

- Norman, B.; Pedoia, V.; Majumdar, S. Use of 2D U-Net Convolutional Neural Networks for Automated Cartilage and Meniscus Segmentation of Knee MR Imaging Data to Determine Relaxometry and Morphometry. Radiology 2018, 288, 177–185. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, H.; Yang, G.; Liu, F.; Mo, Y.; Guo, Y. Automatic Brain Tumor Detection and Segmentation Using U-Net Based Fully Convolutional Networks. In Proceedings of the Annual Conference on Medical Image Understanding and Analysis, Edinburgh, UK, 11–13 July 2017; Springer: Cham, Switzerland, 2017; Volume 723, pp. 506–517. [Google Scholar]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. Med. Image Comput. Comput.-Assist. Interv. 2015, 9351, 234–241. [Google Scholar]

- Han, B.; Wan, W.-H.; Sun, D.-D.; Dong, C.-C.; Zhao, L.; Wang, H.-Z. A deep learning-based method for segmentation and quantitative characterization of microstructures in weathering steel from sequential scanning electron microscope images. J. Iron Steel Res. Int. 2022, 29, 836–845. [Google Scholar] [CrossRef]

| Material | Zn | Mg | Cu | Fe | Si | Mn | Cr | Zr | Ti |

|---|---|---|---|---|---|---|---|---|---|

| T4-6 | 4.53 | 1.1 | 0.23 | 0.17 | 0.088 | 0.34 | 0.18 | 0.12 | 0.046 |

| T4-15 | 4.39 | 1.38 | 0.022 | 0.16 | 0.067 | 0.35 | 0.084 | 0.071 | 0.02 |

| T5-10 | 4.31 | 1.01 | 0.15 | 0.17 | 0.062 | 0.37 | 0.23 | 0.097 | 0.05 |

| T5-15 | 4.23 | 1.09 | 0.16 | 0.17 | 0.058 | 0.37 | 0.22 | 0.11 | 0.048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, B.; Sun, D.; Wan, W.; Dong, C.; Li, D.; Zhao, L.; Wang, H. Correlation among Composition, Microstructure and Hardness of 7xxx Aluminum Alloy Using Original Statistical Spatial-Mapping Method. Materials 2022, 15, 5767. https://doi.org/10.3390/ma15165767

Han B, Sun D, Wan W, Dong C, Li D, Zhao L, Wang H. Correlation among Composition, Microstructure and Hardness of 7xxx Aluminum Alloy Using Original Statistical Spatial-Mapping Method. Materials. 2022; 15(16):5767. https://doi.org/10.3390/ma15165767

Chicago/Turabian StyleHan, Bing, Dandan Sun, Weihao Wan, Caichang Dong, Dongling Li, Lei Zhao, and Haizhou Wang. 2022. "Correlation among Composition, Microstructure and Hardness of 7xxx Aluminum Alloy Using Original Statistical Spatial-Mapping Method" Materials 15, no. 16: 5767. https://doi.org/10.3390/ma15165767

APA StyleHan, B., Sun, D., Wan, W., Dong, C., Li, D., Zhao, L., & Wang, H. (2022). Correlation among Composition, Microstructure and Hardness of 7xxx Aluminum Alloy Using Original Statistical Spatial-Mapping Method. Materials, 15(16), 5767. https://doi.org/10.3390/ma15165767