Impact of WO3-Nanoparticles on Silicone Rubber for Radiation Protection Efficiency

Abstract

:1. Introduction

2. Materials and Method

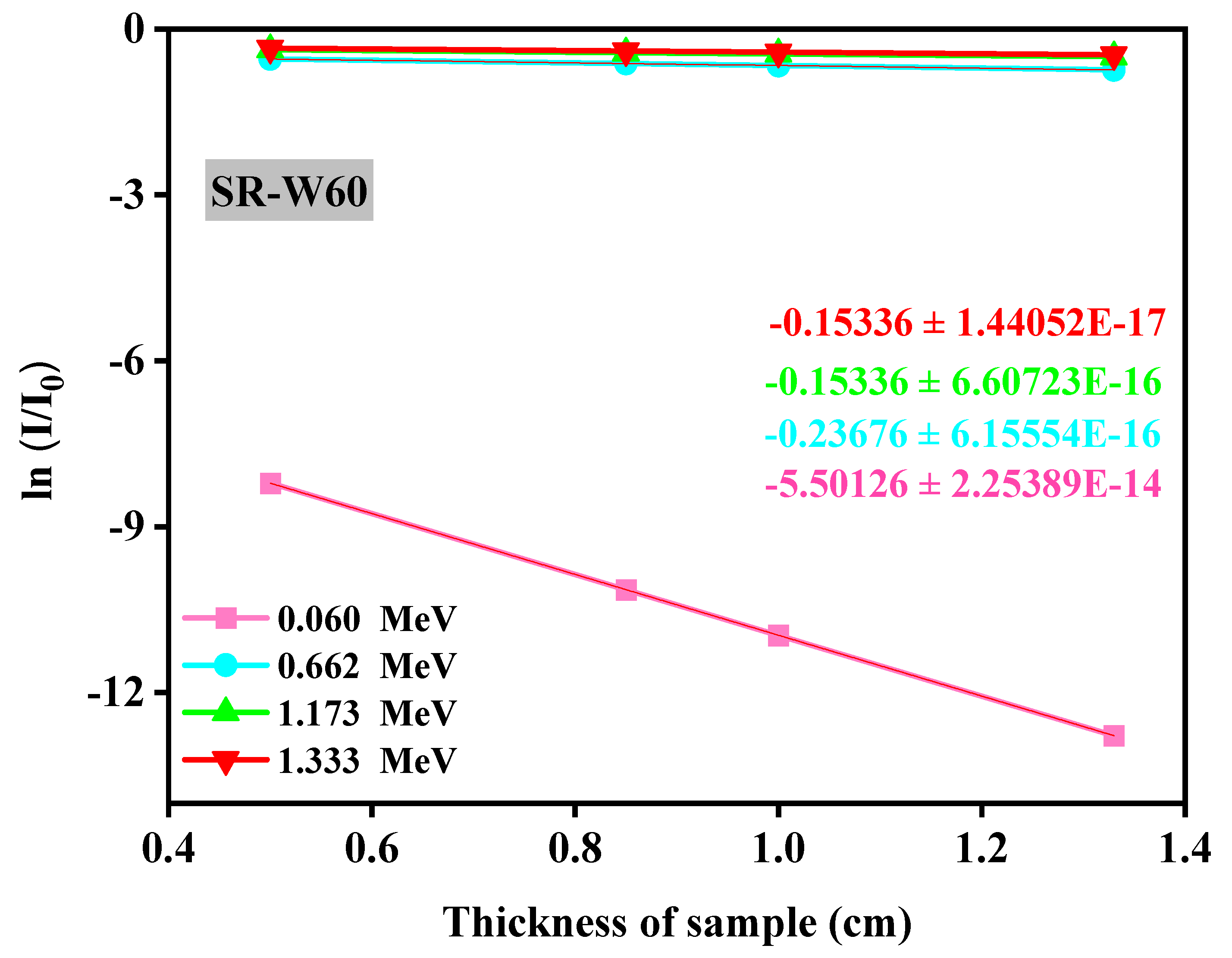

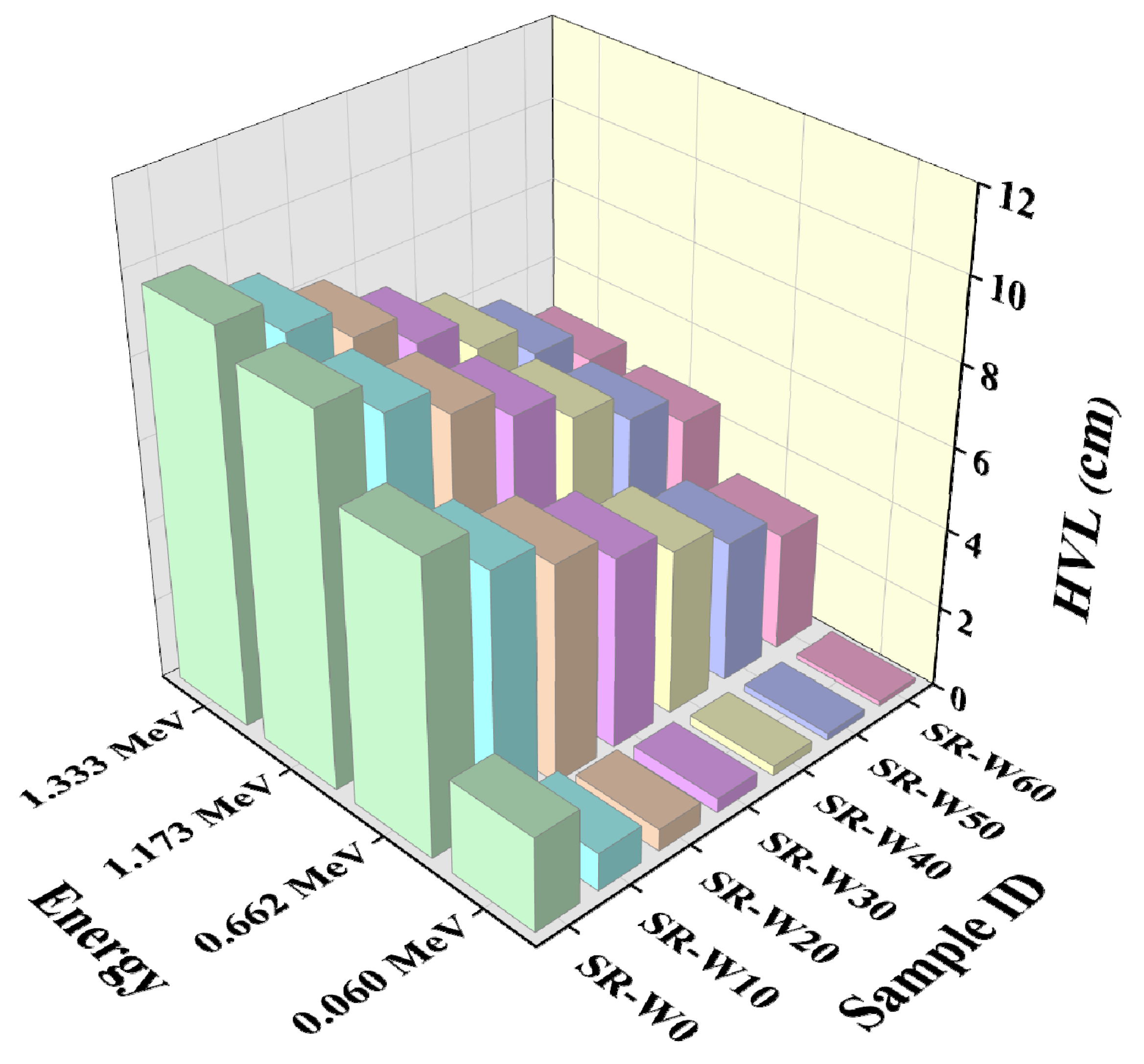

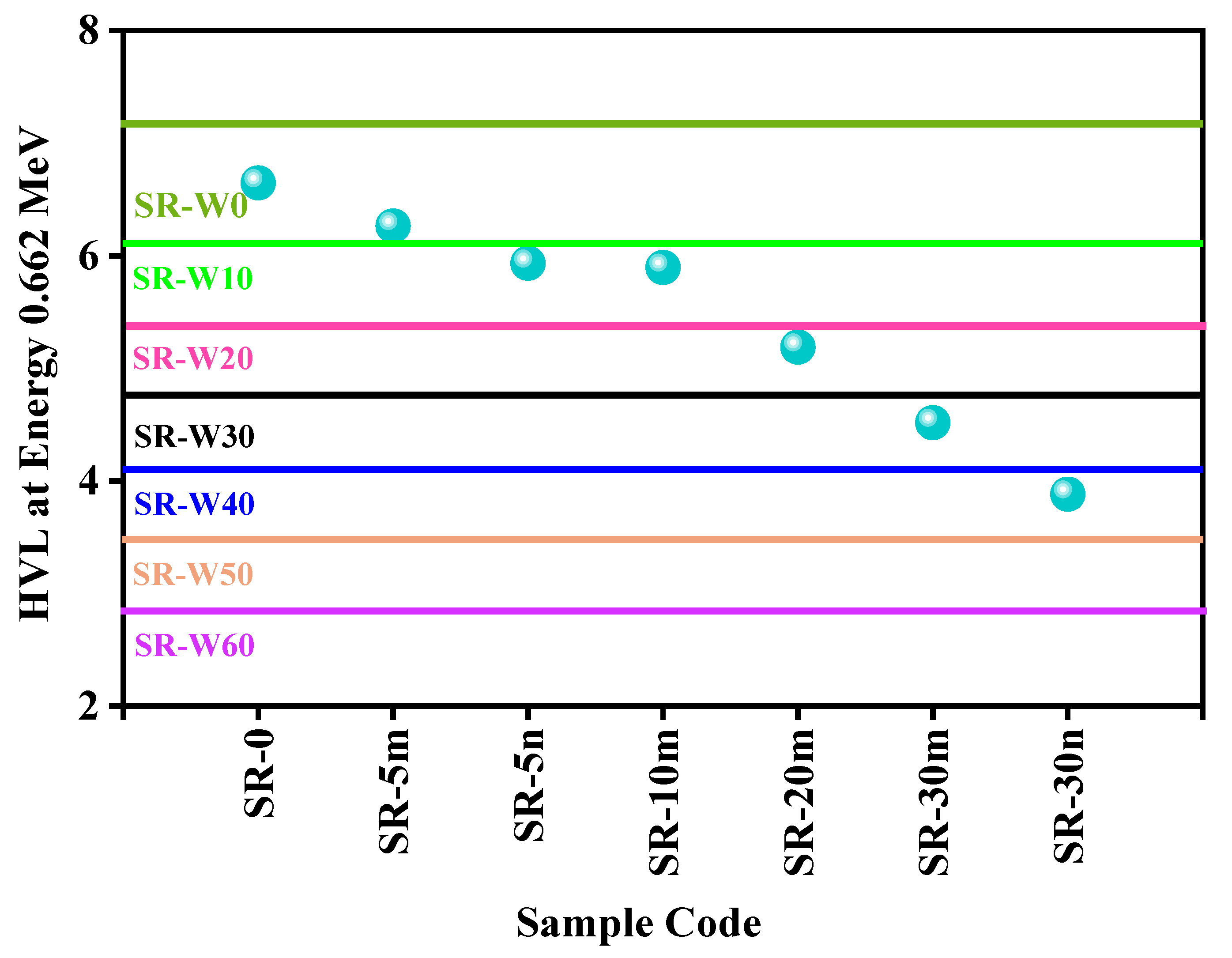

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, M.; Xue, X.; Yang, H.; Li, Z. Highly cost-effective shielding composite made from vanadium slag and boron-rich slag and its properties. Radiat. Phys. Chem. 2017, 141, 239–244. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, S.; Xue, X.; Feng, X.; Yang, H.; Sayyed, M.; Tishkevich, D.; Trukhanov, A.; Almousa, N. Upcycling of boron bearing blast furnace slag as highly cost-effective shield for protection of neutron radiation hazard: An innovative way and proposal of shielding mechanism. J. Clean. Prod. 2022, 355, 131817. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.I.; Barasheed, A.Z.; Ahmed, M.; Elsafi, M. Fabrication of Lead Free Borate Glasses Modified by Bismuth Oxide for Gamma Ray Protection Applications. Materials 2022, 15, 789. [Google Scholar] [CrossRef]

- Araz, A.; Kavaz, E.; Durak, R. Neutron and photon shielding competences of aluminum open-cell foams filled with different epoxy mixtures: An experimental study. Radiat. Phys. Chem. 2021, 182, 109382. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, S.; Xue, X.; Feng, X.; Sayyed, M.I.; Khandaker, M.U.; Bradley, D.A. The potential use of boron containing resources for protection against nuclear radiation. Radiat. Phys. Chem. 2021, 188, 109601. [Google Scholar] [CrossRef]

- Kamislioglu, M. An investigation into gamma radiation shielding parameters of the (Al:Si) and (Al+Na):Si-doped international simple glasses (ISG) used in nuclear waste management, deploying Phy-X/PSD and SRIM software. J. Mater. Sci. Mater. Electron. 2021, 32, 12690–12704. [Google Scholar] [CrossRef]

- Abouhaswa, A.S.; Kavaz, E. Bi2O3 effect on physical, optical, structural and radiation safety characteristics of B2O3-Na2O-ZnO-CaO glass system. J. Non-Cryst. Solids 2020, 535, 119993. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, S.; Xue, X.; Sayyed, M.; Tishkevich, D.; Trukhanov, A.; Wang, C. Study of comprehensive shielding behaviors of chambersite deposit for neutron and gamma ray. Prog. Nucl. Energy 2022, 146, 104155. [Google Scholar] [CrossRef]

- Naseer, K.A.; Sathiyapriya, G.; Marimuthu, K.; Piotrowski, T.; Alqahtani, M.S.; Yousef, E.S. Optical, elastic, and neutron shielding studies of Nb2O5 varied Dy3+ doped barium-borate glasses. Optik 2021, 251, 168436. [Google Scholar] [CrossRef]

- Rajesh, M.; Kavaz, E.; Deva Prasad Raju, B. Photoluminescence, radiative shielding properties of Sm3+ ions doped fluoroborosilicate glasses for visible (reddish-orange) display and radiation shielding applications. Mater. Res. Bull. 2021, 142, 111383. [Google Scholar] [CrossRef]

- Hannachi, E.; Sayyed, M.I.; Slimani, Y.; Elsafi, M. Experimental investigation on the physical properties and radiation shielding efficiency of YBa2Cu3Oy/M@M3O4 (M= Co, Mn) ceramic composites. J. Alloy. Compd. 2022, 904, 164056. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Yang, H.; Liu, D.; Wang, C.; Li, Z. A novel comprehensive utilization of vanadium slag: As gamma ray shielding material. J. Hazard. Mater. 2016, 318, 751–757. [Google Scholar] [CrossRef] [PubMed]

- Nagaraj, N.; Manjunatha, H.; Vidya, Y.; Seenappa, L.; Sridhar, K.; Gupta, P.D. Investigations on Lanthanide polymers for radiation shielding purpose. Radiat. Phys. Chem. 2022, 199, 110310. [Google Scholar] [CrossRef]

- Ekinci, N.; Mahmoud, K.; Sarıtaş, S.; Aygün, B.; Hessien, M.; Bilici, I.; Rammah, Y. Development of Tincal based polypropylene polymeric materials for radiation shielding applications: Experimental, theoretical, and Monte Carlo investigations. Mater. Sci. Semicond. Process. 2022, 146, 106696. [Google Scholar] [CrossRef]

- Almurayshid, M.; Alsagabi, S.; Alssalim, Y.; Alotaibi, Z.; Almsalam, R. Feasibility of polymer-based composite materials as radiation shield. Radiat. Phys. Chem. 2021, 183, 109425. [Google Scholar] [CrossRef]

- Kim, S.; Ahn, Y.; Song, S.H.; Lee, D. Tungsten nanoparticle anchoring on boron nitride nanosheet-based polymer nanocomposites for complex radiation shielding. Compos. Sci. Technol. 2022, 221, 109353. [Google Scholar] [CrossRef]

- Ambika, M.R.; Nagaiah, N.; Harish, V.; Lokanath, N.K.; Sridhar, M.A.; Renukappa, N.M.; Suman, S.K. Preparation and characterisation of Isophthalic-Bi2O3 polymer composite gamma radiation shields. Radiat. Phys. Chem. 2017, 130, 351–358. [Google Scholar] [CrossRef]

- Özdemir, T.; Güngör, A.; Akbay, I.; Uzun, H.; Babucçuoglu, Y. Nano lead oxide and epdm composite for development of polymer based radiation shielding material: Gamma irradiation and attenuation tests. Radiat. Phys. Chem. 2018, 144, 248–255. [Google Scholar] [CrossRef]

- Belgin, E.E.; Aycik, G.; Kalemtas, A.; Pelit, A.; Dilek, D.; Kavak, M. Preparation and characterization of a novel ionizing electromagnetic radiation shielding material: Hematite filled polyester based composites. Radiat. Phys. Chem. 2015, 115, 34–48. [Google Scholar] [CrossRef]

- Al Hassan, M.; Wang, Z.; Liu, W.-B.; Wang, J.; Zhigang, Y.; Khan, M.; Ali, M.M.; Geldiyev, R.; Diaby, M.; Derradji, M. Thermal stability and gamma ray shielding properties of tungsten borides/epoxy micro-composites. Radiat. Phys. Chem. 2021, 189, 109769. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Mousavi, S.M.; Faghihi, R.; Arjmand, M.; Sina, S.; Amani, A.M. Lead oxide-decorated graphene oxide/epoxy composite towards X-Ray radiation shielding. Radiat. Phys. Chem. 2018, 146, 77–85. [Google Scholar] [CrossRef]

- Şahin, N.; Bozkurt, M.; Karabul, Y.; Kılıç, M.; Özdemir, Z.G. Low cost radiation shielding material for low energy radiation applications: Epoxy/Yahyali Stone composites. Prog. Nucl. Energy 2021, 135, 103703. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; El-Khatib, A.M.; Badawi, M.S.; Rashad, A.R.; El-Sharkawy, R.M.; Thabet, A.A. Fabrication, characterization and gamma rays shielding properties of nano and micro lead oxide-dispersed-high density polyethylene composites. Radiat. Phys. Chem. 2018, 145, 160–173. [Google Scholar] [CrossRef]

- Abbas, M.I.; El-Khatib, A.M.; Dib, M.F.; Mustafa, H.E.; Sayyed, M.I.; Elsafi, M. The Influence of Bi2O3 Nanoparticle Content on the γ-ray Interaction Parameters of Silicon Rubber. Polymers 2022, 14, 1048. [Google Scholar] [CrossRef] [PubMed]

- Sayyed, M.I.; Al-Ghamdi, H.; Almuqrin, A.H.; Yasmin, S.; Elsafi, M. A Study on the Gamma Radiation Protection Effectiveness of Nano/Micro-MgO-Reinforced Novel Silicon Rubber for Medical Applications. Polymers 2022, 14, 2867. [Google Scholar] [CrossRef]

- Buyuk, B. Gamma-Ray Attenuation Properties of Flexible Silicone Rubber Materials while using Cs-137 as Radioactive Source. Eur. J. Sci. Technol. 2019, 15, 28–35. [Google Scholar] [CrossRef]

- Elsafi, M.; Koraim, Y.; Almurayshid, M.; I Almasoud, F.; Sayyed, M.I.; Saleh, I.H. Investigation of Photon Radiation Attenuation Capability of Different Clay Materials. Materials 2021, 14, 6702. [Google Scholar] [CrossRef]

- Aloraini, D.A.; Almuqrin, A.H.; Sayyed, M.I.; Al-Ghamdi, H.; Kumar, A.; Elsafi, M. Experimental Investigation of Radiation Shielding Competence of Bi2O3-CaO-K2O-Na2O-P2O5 Glass Systems. Materials 2021, 14, 5061. [Google Scholar] [CrossRef]

- Elsafi, M.; Alrashedi, M.; Sayyed, M.; Al-Hamarneh, I.; El-Nahal, M.; El-Khatib, M.; Khandaker, M.; Osman, H.; Askary, A. The Potentials of Egyptian and Indian Granites for Protection of Ionizing Radiation. Materials 2021, 14, 3928. [Google Scholar] [CrossRef] [PubMed]

- Al-Harbi, N.; Sayyed, M.I.; Al-Hadeethi, Y.; Kumar, A.; Elsafi, M.; Mahmoud, K.A.; Khandaker, M.U.; Bradley, D.A. A novel CaO–K2O–Na2O–P2O5 glass systems for radiation shielding applications. Radiat. Phys. Chem. 2021, 188, 109645. [Google Scholar] [CrossRef]

- Mhareb, M.H.A.; Zeama, M.; Elsafi, M.; Alajerami, Y.S.; Sayyed, M.I.; Saleh, G.; Hamad, R.M.; Hamad, M.K. Radiation shielding features for various tellurium-based alloys: A comparative study. J. Mater. Sci. Mater. Electron. 2021, 32, 26798–26811. [Google Scholar] [CrossRef]

- Kim, J.; Seo, D.; Lee, B.C.; Seo, Y.S.; Miller, W.H. Nano-W Dispersed Gamma Radiation Shielding Materials. Adv. Eng. Mater. 2014, 16, 1083–1089. [Google Scholar] [CrossRef]

- Gavrish, V.M.; Baranov, G.A.; Chayka, T.V.; Derbasova, N.M.; Lvov, A.V.; Matsuk, Y.M. Tungsten nanoparticles influence on radiation protection properties of polymers. IOP Conf. Ser. Mater. Sci. Eng. 2016, 110, 012028. [Google Scholar] [CrossRef]

| Codes | Chemical Compositions (wt%) | Density (g/cm3) | |

|---|---|---|---|

| Silicone Rubber | WO3-Nanoparticles | ||

| SR-W0 | 100 | 0 | 1.180 ± 0.008 |

| SR-W10 | 90 | 10 | 1.293 ± 0.011 |

| SR-W20 | 80 | 20 | 1.421 ± 0.008 |

| SR-W30 | 70 | 30 | 1.580 ± 0.009 |

| SR-W40 | 60 | 40 | 1.779 ± 0.007 |

| SR-W50 | 50 | 50 | 2.032 ± 0.008 |

| SR-W60 | 40 | 60 | 2.375 ± 0.009 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ghamdi, H.; Hemily, H.M.; Saleh, I.H.; Ghataas, Z.F.; Abdel-Halim, A.A.; Sayyed, M.I.; Yasmin, S.; Almuqrin, A.H.; Elsafi, M. Impact of WO3-Nanoparticles on Silicone Rubber for Radiation Protection Efficiency. Materials 2022, 15, 5706. https://doi.org/10.3390/ma15165706

Al-Ghamdi H, Hemily HM, Saleh IH, Ghataas ZF, Abdel-Halim AA, Sayyed MI, Yasmin S, Almuqrin AH, Elsafi M. Impact of WO3-Nanoparticles on Silicone Rubber for Radiation Protection Efficiency. Materials. 2022; 15(16):5706. https://doi.org/10.3390/ma15165706

Chicago/Turabian StyleAl-Ghamdi, Hanan, Hanaa M. Hemily, I. H. Saleh, Z. F. Ghataas, A. A. Abdel-Halim, M. I. Sayyed, Sabina Yasmin, Aljawhara H. Almuqrin, and Mohamed Elsafi. 2022. "Impact of WO3-Nanoparticles on Silicone Rubber for Radiation Protection Efficiency" Materials 15, no. 16: 5706. https://doi.org/10.3390/ma15165706

APA StyleAl-Ghamdi, H., Hemily, H. M., Saleh, I. H., Ghataas, Z. F., Abdel-Halim, A. A., Sayyed, M. I., Yasmin, S., Almuqrin, A. H., & Elsafi, M. (2022). Impact of WO3-Nanoparticles on Silicone Rubber for Radiation Protection Efficiency. Materials, 15(16), 5706. https://doi.org/10.3390/ma15165706