Time-Dependent Seismic Performance of Coastal Bridges Reinforced with Hybrid FRP and Steel Bars

Abstract

:1. Introduction

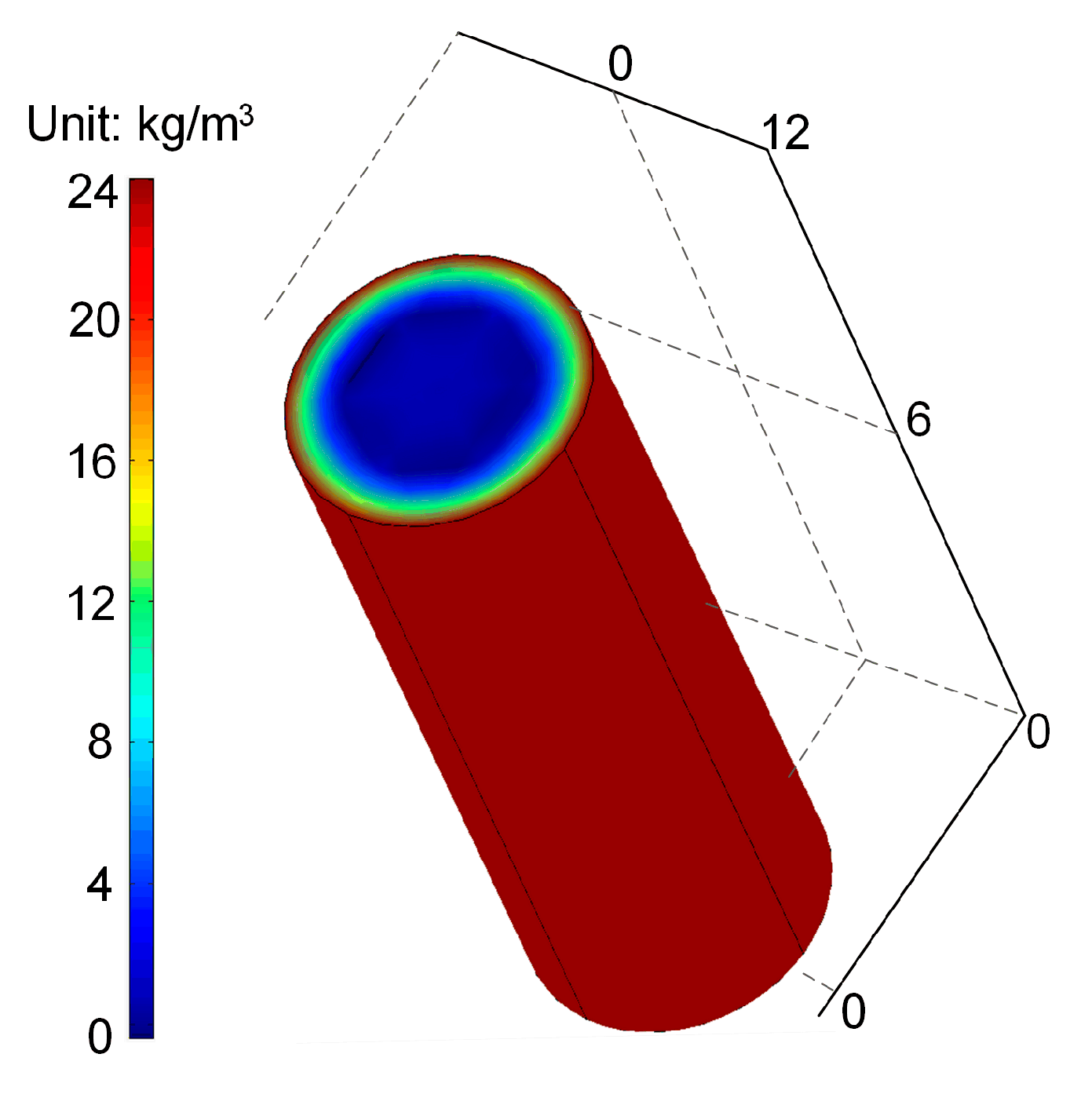

2. Material Deterioration Models

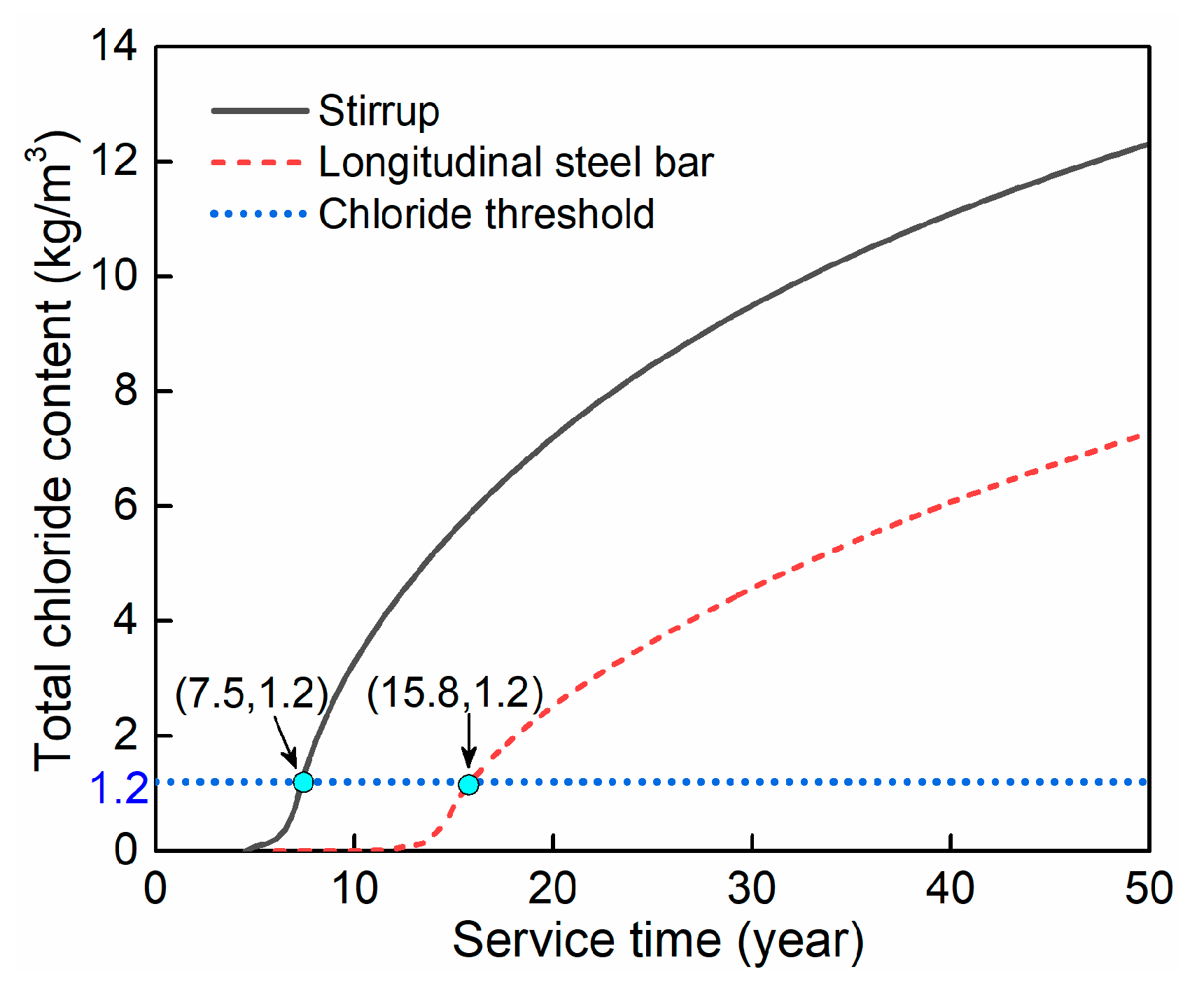

2.1. Steel Bar Deterioration

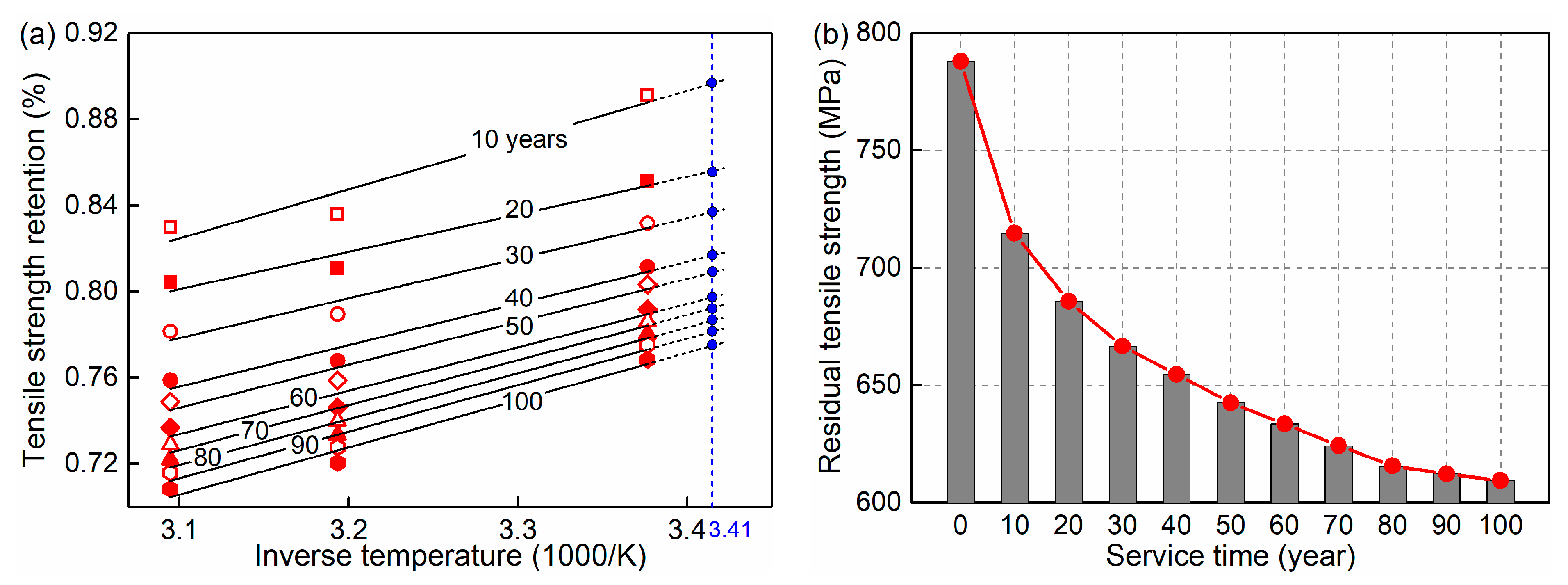

2.2. FRP Bar Deterioration

3. HRC Bridge Column Assessment

3.1. Time-Dependent Finite Element Models

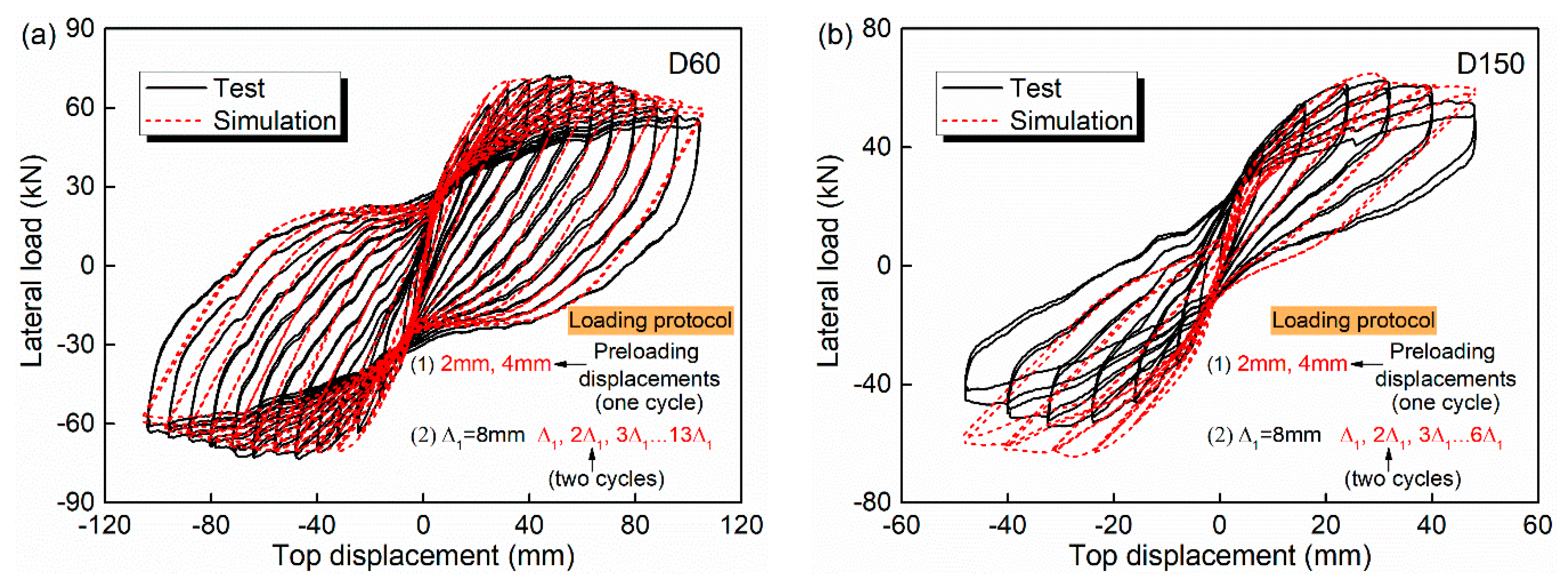

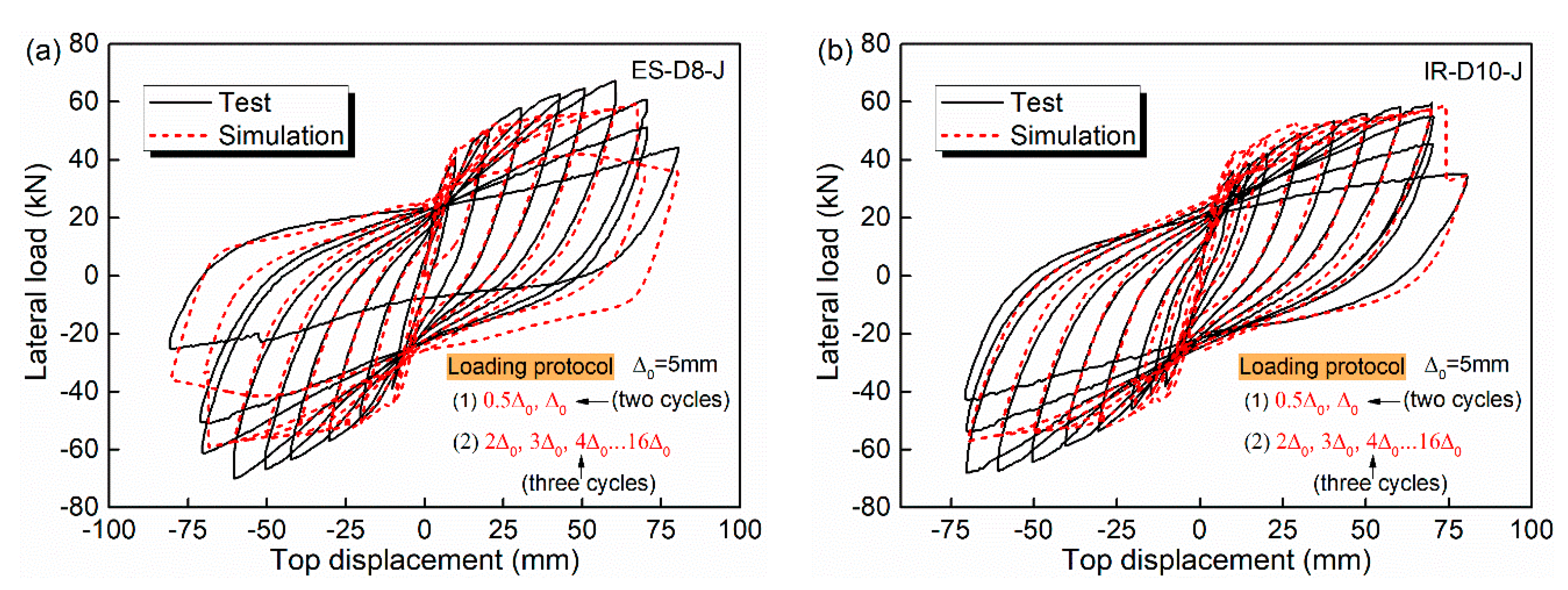

3.2. Model Validation

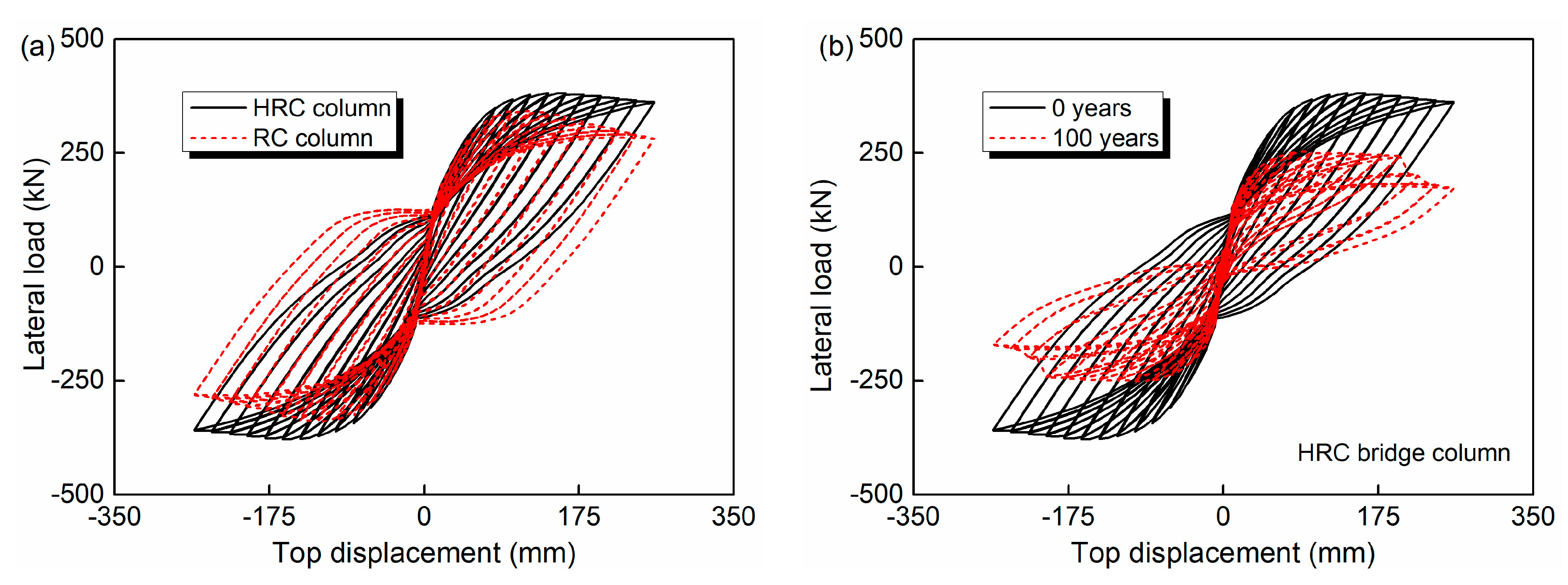

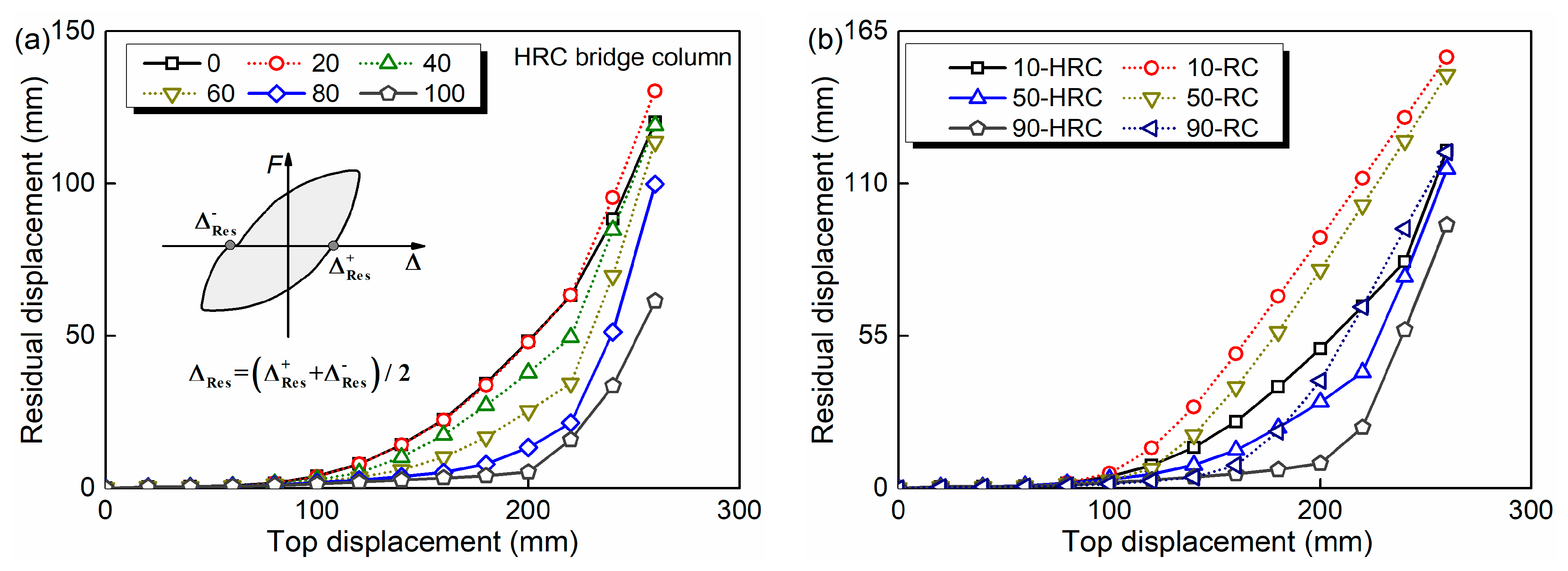

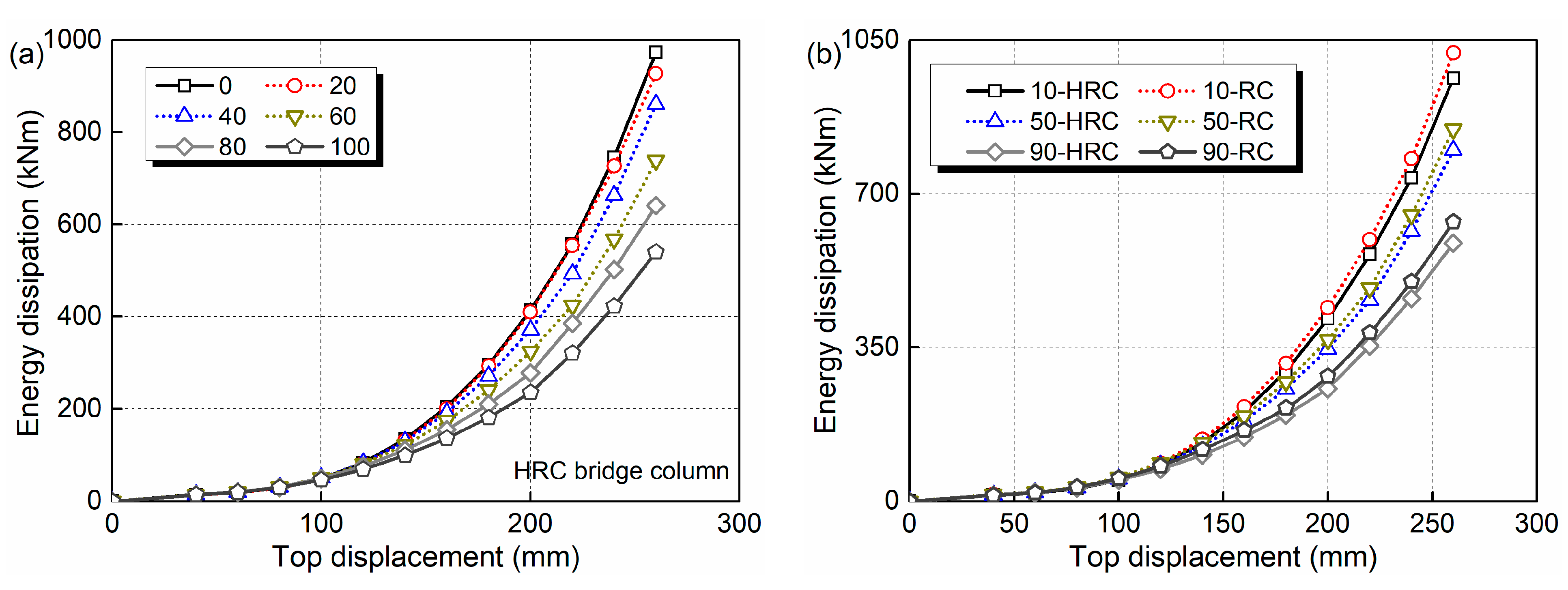

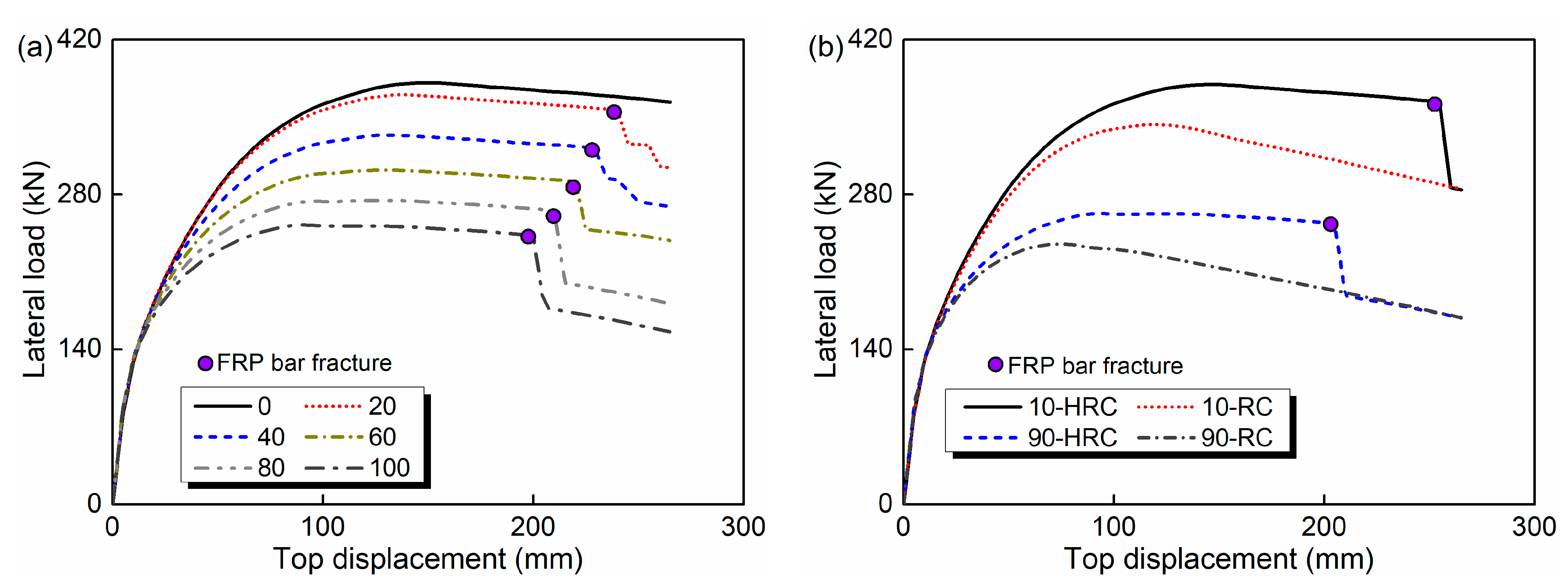

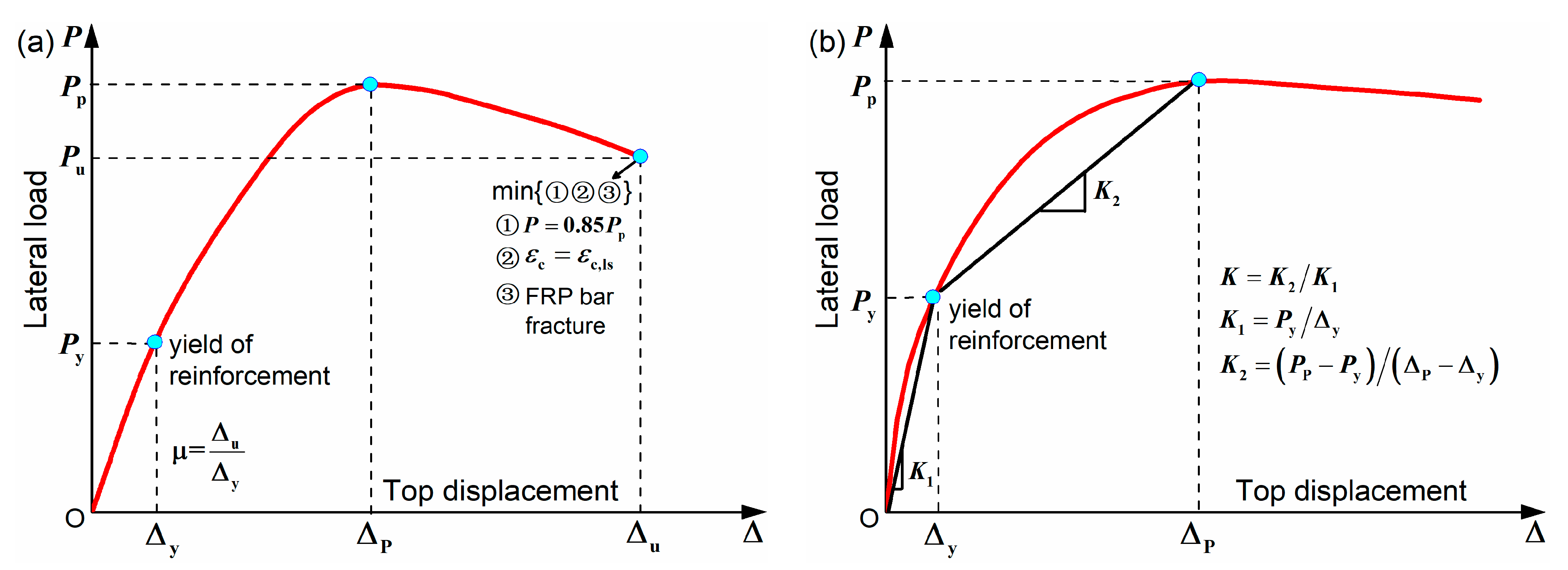

3.3. Seismic Performance Analysis

4. HRC Bridge Assessment

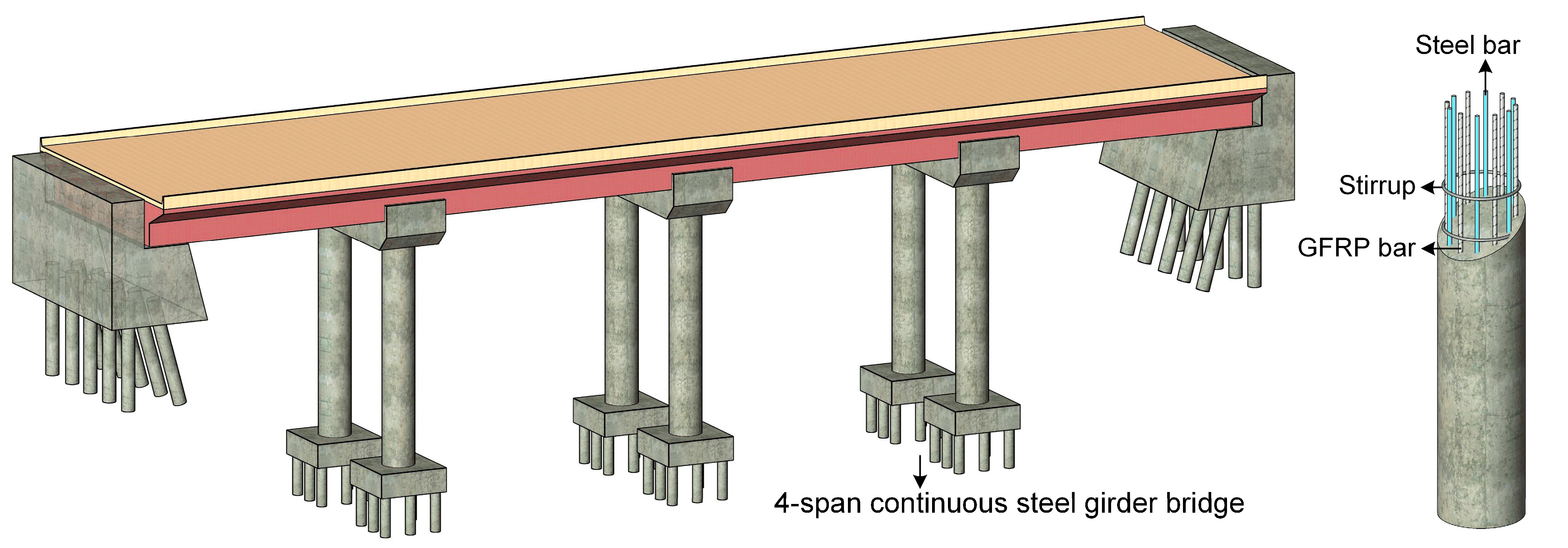

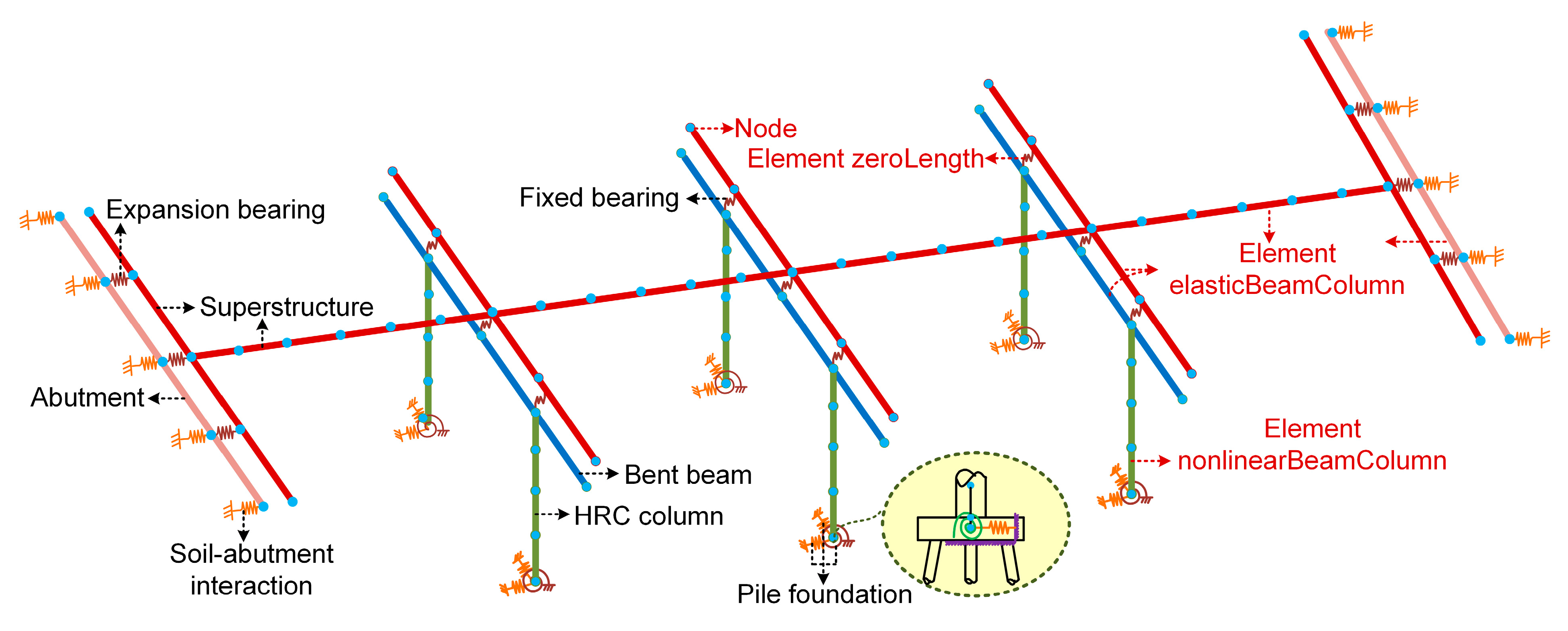

4.1. HRC Bridge Model

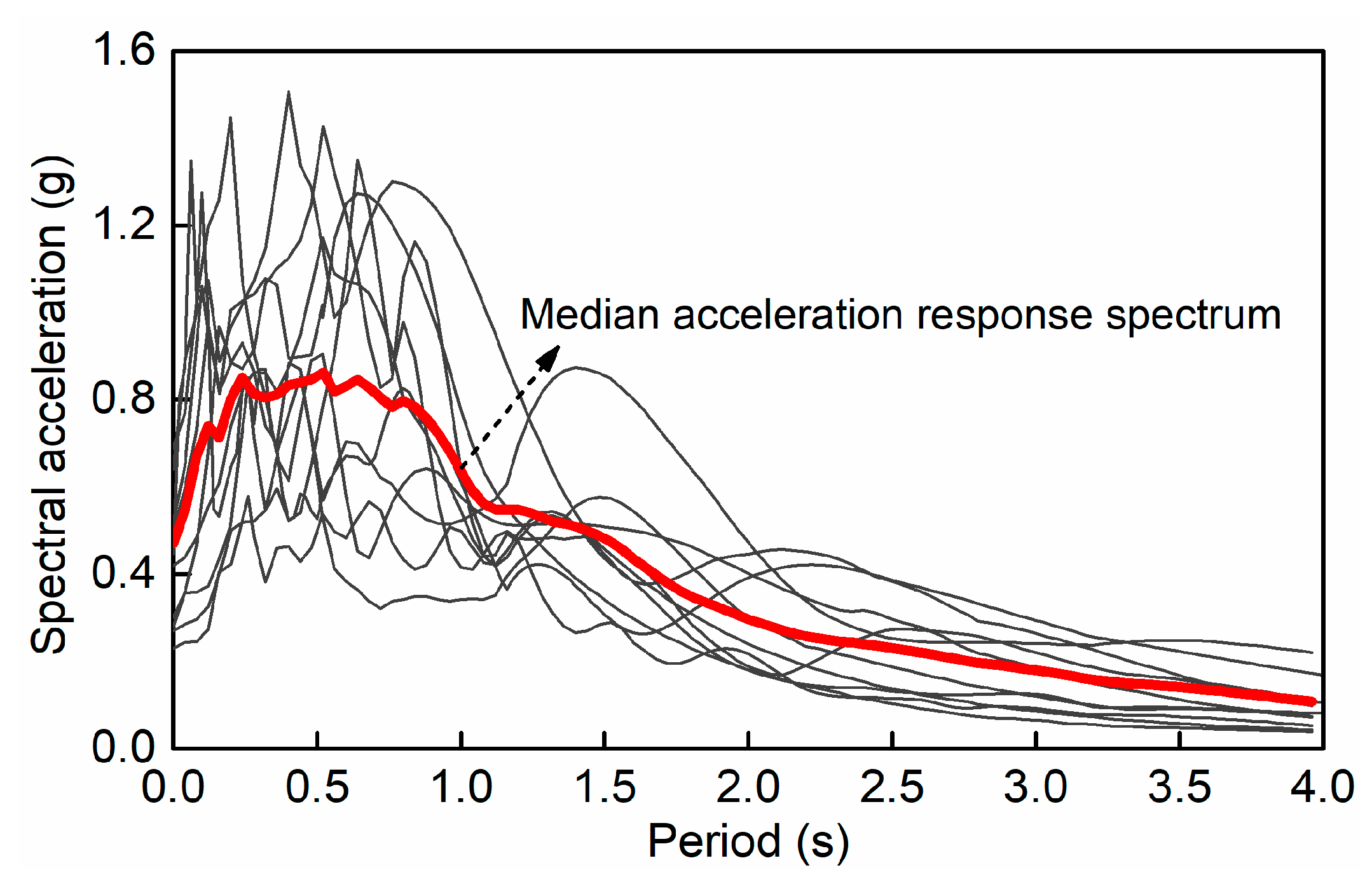

4.2. Ground Motion Selection

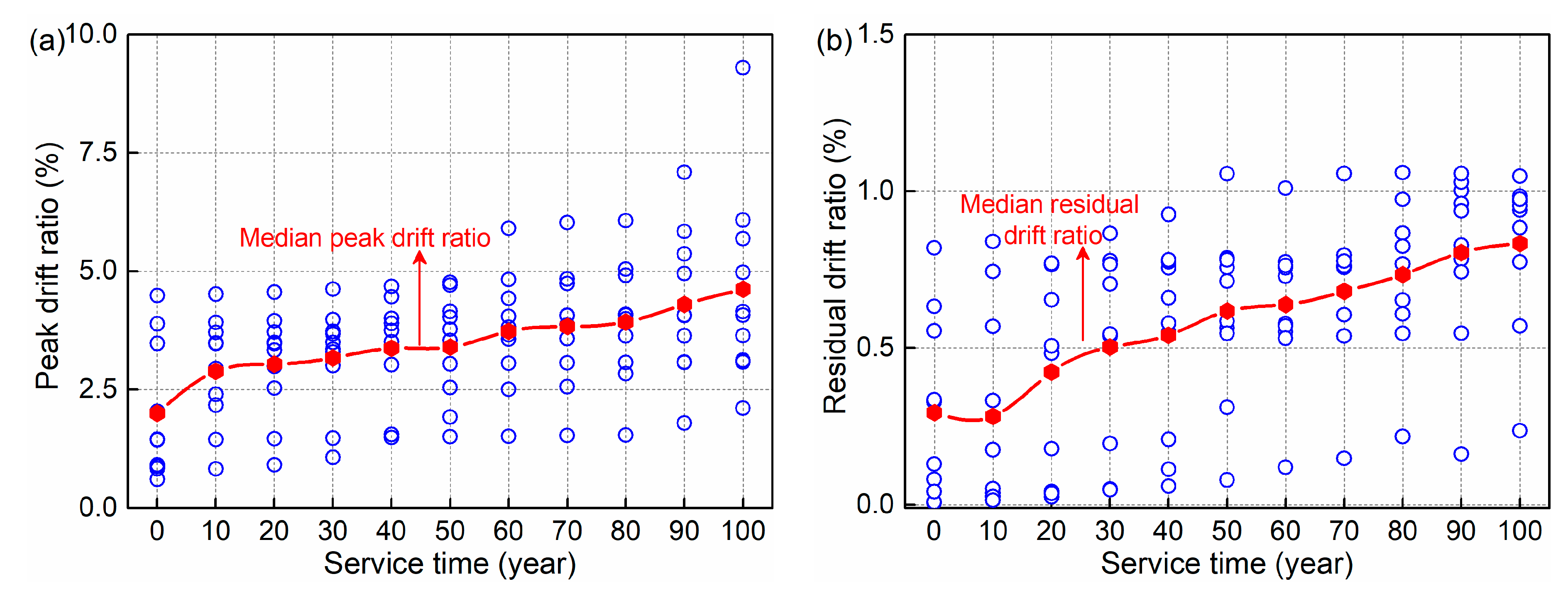

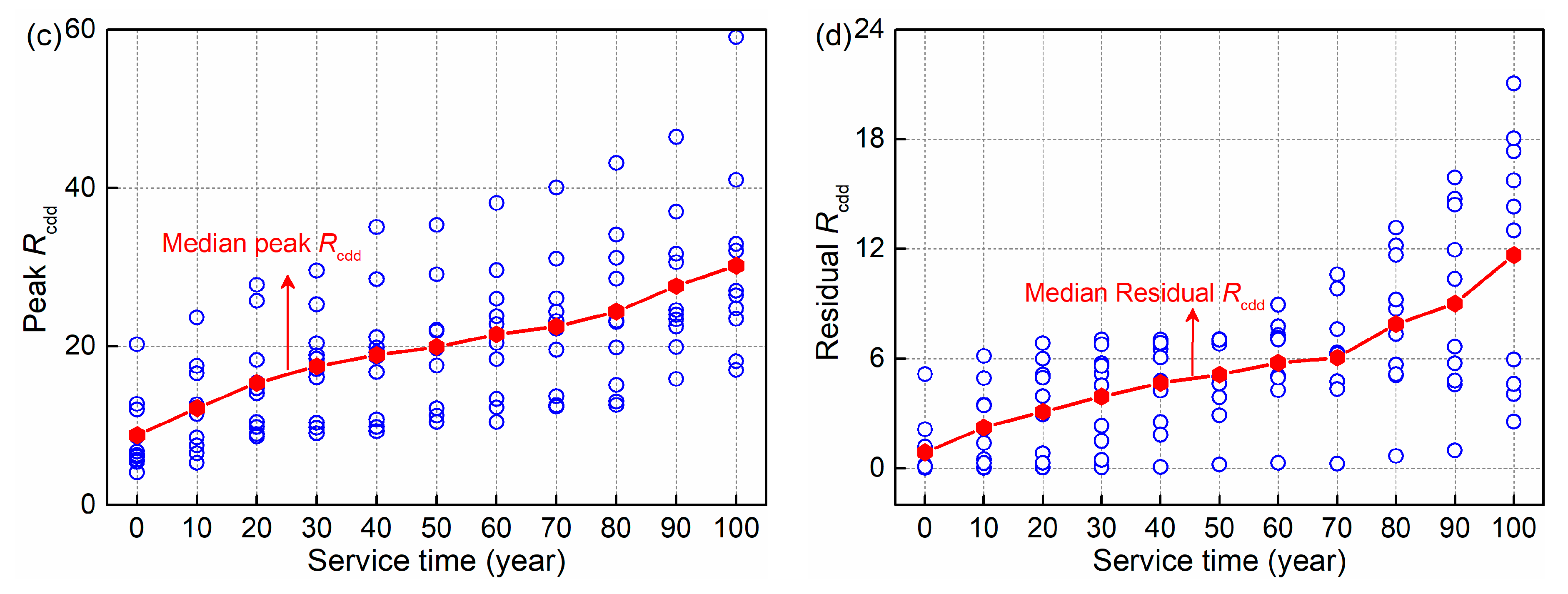

4.3. Seismic Demand and Damage Evolution

5. Conclusions

- (1)

- The cover depth significantly influences the corrosion initiation time of steel bars. Therefore, the decrease of diameter and yield strength is more severe for steel stirrups than the longitudinal steel bars. Main feature of corrosion deterioration of GFRP bars is reduction of tensile strength, which exhibits a relatively fast rate in the early 30 years and then gradually slows down.

- (2)

- The compression and tension behavior, as well as the fracture failure phenomenon of the GFRP bars, are critical for numerical simulation of the HRC columns and structures. The finite element modeling method proposed in this paper has a high precision in predicting structural seismic response.

- (3)

- The energy dissipation capacity, displacement ductility, bearing capacity and residual displacement of the HRC bridge column decrease with the service time. Furthermore, it is found when the hybrid ratio (area of GFRP bars/ area of steel bars) increases from 25.8% to 54.2% due to corrosion, the post-yield stiffness ratio of HRC columns increases from 0.174 to 0.240. In addition, compared to RC bridge columns, the bearing capacity of the HRC column increases by as much as 12.6%, and the residual displacement decreases by as much as 40.2%.

- (4)

- Under ground motion excitations, the peak and residual drift ratio/curvature ductility demand ratio of the HRC bridge columns have the positive correlation with the exposure time, indicating the gradually increasing damage. The abutment is a less vulnerable component in the HRC bridge structure, and the probability of less than extensive damage at 100 years is 90%. In the whole life cycle, the expansion bearing shows a 32% increase in maximum deformation, while the 76% decrease is obtained for the fixed bearing.

- (5)

- The study conducted in this paper is focused on the time-dependent performance deterioration of the coastal bridges induced by the chloride corrosion. The influence of fatigue damage, creep phenomenon and carbonization are not being considered. For future research, the seismic performance of the coastal structures under the action of multiple factors will be investigated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alipour, A.; Shafei, B.; Shinozuka, M. Performance evaluation of deteriorating highway bridges located in high seismic areas. J. Bridge Eng. 2011, 16, 597–611. [Google Scholar] [CrossRef]

- Bhargava, K.; Ghosh, A.K.; Mori, Y.; Ramanujam, S. Corrosion-induced bond strength degradation in reinforced concrete-Analytical and empirical models. Nucl. Eng. Des. 2007, 237, 1140–1157. [Google Scholar] [CrossRef]

- Hanjari, K.Z.; Coronelli, D.; Lundgren, K. Bond capacity of severely corroded bars with corroded stirrups. Mag. Concr. Res. 2011, 63, 953–968. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.L.; Su, R.K.L. Experimental investigation of the process of corrosion-caused cover cracking. Constr. Build. Mater. 2020, 253, 119166. [Google Scholar] [CrossRef]

- American Concrete Institute. Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Zeng, J.J.; Zhuge, Y.; Liang, S.D.; Bai, Y.L.; Liao, J.J.; Zhang, L.H. Durability assessment of PEN/PET FRP composites based on accelerated aging in alkaline solution/seawater with different temperatures. Constr. Build. Mater. 2022, 327, 126992. [Google Scholar] [CrossRef]

- Benmokrane, B.; Hassan, M.; Robert, M.; Vijay, P.V.; Manalo, A. Effect of different constituent fiber, resin, and sizing combinations on alkaline resistance of basalt, carbon, and glass FRP bars. J. Compos. Constr. 2020, 24, 04020010. [Google Scholar] [CrossRef]

- Lu, C.H.; Ni, M.Z.; Chu, T.S.; He, L.Y. Comparative investigation on tensile performance of FRP bars after exposure to water, seawater, and alkaline solutions. J. Mater. Civ. Eng. 2020, 32, 04020170. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; El-Gamal, S.; Almusallam, T.H.; Alsayed, S.H.; Aqel, M. Effect of harsh environmental conditions on the tensile properties of GFRP bars. Compos. Part B Eng. 2013, 45, 835–844. [Google Scholar] [CrossRef]

- Wu, G.; Dong, Z.Q.; Wang, X.; Zhu, Y.; Wu, Z.S. Prediction of long-term performance and durability of BFRP bars under the combined effect of sustained load and corrosive solutions. J. Compos. Constr. 2015, 19, 04014058. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Combined effects of saline solution and moist concrete on long-term durability of GFRP reinforcing bars. Constr. Build. Mater. 2013, 38, 274–284. [Google Scholar] [CrossRef]

- Ding, L.I.; Lei, M.K.; Wang, X.; Shi, Y.W.; Zhu, Z.G.; Yu, P.C.; Wu, Z.S. Durability of concrete members reinforced with steel-FRP composite bars under dry-wet cycles of seawater. Structures 2021, 33, 2273–2283. [Google Scholar] [CrossRef]

- Bank, L.C.; Gentry, T.R.; Thompson, B.P.; Russell, J.S. A model specification for FRP composites for civil engineering structures. Constr. Build. Mater. 2003, 17, 405–437. [Google Scholar] [CrossRef]

- Beddows, J.; Purnell, P.; Mottram, J.T. Application of GRC accelerated ageing rationales to pultruded structural GRP. In FRC 2002: 9th International Conference on Fibre Reinforced Composites; Conference Design Consultants: Hobart, Australia, 2002; pp. 215–221. [Google Scholar]

- Phani, K.K.; Bose, N.R. Temperature-dependence of hydrothermal aging of CSM-laminate during water immersion. Compos. Sci. Technol. 1987, 29, 79–87. [Google Scholar] [CrossRef]

- Litherland, K.L.; Oakley, D.R.; Proctor, B.A. The use of accelerated aging procedures to predict the long-term strength of GRC composites. Cem. Concr. Res. 1981, 11, 455–466. [Google Scholar] [CrossRef]

- Hales, T.A.; Pantelides, C.P.; Reaveley, L.D. Experimental evaluation of slender high-strength concrete columns with GFRP and Hybrid reinforcement. J. Compos. Constr. 2016, 20, 04016050. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Wu, G.; Zhang, J.; Zeng, Y.H.; Xiao, W.C. Experimental study on concrete columns reinforced by hybrid steel-fiber reinforced polymer (FRP) bars under horizontal cyclic loading. Constr. Build. Mater. 2017, 130, 202–211. [Google Scholar] [CrossRef]

- Yuan, F.; Chen, M.C.; Pan, J.L. Experimental study on seismic behaviours of hybrid FRP-steel-reinforced ECC-concrete composite columns. Compos. Part B Eng. 2019, 176, 107272. [Google Scholar] [CrossRef]

- Chellapandian, M.; Prakash, S.S.; Sharma, A. Axial compression-bending interaction behavior of severely damaged RC columns rapid repaired and strengthened using hybrid FRP composites. Constr. Build. Mater. 2019, 195, 390–404. [Google Scholar] [CrossRef]

- Cai, Z.K.; Yuan, W.; Wang, Z.Y.; Smith, S.T. Seismic behavior of precast segmental bridge columns reinforced with hybrid FRP-steel bars. Eng. Struct. 2021, 228, 111484. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F.; Al-Rahmani, A. Structural performance and serviceability of concrete beams reinforced with hybrid (GFRP and steel) bars. Constr. Build. Mater. 2015, 96, 518–529. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P.; Nguyen, T.Q. Flexural behavior of geopolymer-concrete beams longitudinally reinforced with GFRP and steel hybrid reinforcements. Eng. Struct. 2019, 182, 141–152. [Google Scholar] [CrossRef]

- Ghosh, J.; Padgett, J.E. Aging considerations in the development of time-dependent seismic fragility curves. J. Struct. Eng. 2010, 136, 1497–1511. [Google Scholar] [CrossRef]

- Lu, C.H.; Jin, W.L.; Liu, R.G. Probabilistic lifetime assessment of marine reinforced concrete with steel corrosion and cover cracking. China Ocean Eng. 2011, 25, 305–318. [Google Scholar] [CrossRef]

- Ou, Y.C.; Fan, H.D.; Nguyen, D.N. Long-term seismic performance of reinforced concrete bridges under steel reinforcement corrosion due to chloride attack. Earthq. Eng. Struct. Dyn. 2013, 42, 2113–2127. [Google Scholar] [CrossRef]

- Martin-Perez, B.; Zibara, H.; Hooton, R.D.; Thomas, M.D.A. A study of the effect of chloride binding on service life predictions. Cem. Concr. Res. 2000, 30, 1215–1223. [Google Scholar] [CrossRef]

- Martin-Perez, B.; Pantazopoulou, S.J.; Thomas, M.D.A. Numerical solution of mass transport equations in concrete structures. Comput. Struct. 2001, 79, 1251–1264. [Google Scholar] [CrossRef] [Green Version]

- Kong, J.S.; Ababneh, A.N.; Frangopol, D.M.; Xi, Y.P. Reliability analysis of chloride penetration in saturated concrete. Probabilistic Eng. Mech. 2002, 17, 305–315. [Google Scholar] [CrossRef]

- Xi, Y.P.; Bazant, Z.P. Modeling chloride penetration in saturated concrete. J. Mater. Civil. Eng. 1999, 11, 58–65. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Najjar, L.J. Nonlinear water diffusion in unsaturated concrete. Mater. Struct. 1972, 5, 3–20. [Google Scholar] [CrossRef]

- Saetta, A.V.; Schrefler, B.A.; Vitaliani, R.V. The carbonation of the concrete and the mechanism of moisture, heat, and carbon dioxide flow through porous material. Cem. Concr. Res. 1993, 23, 761–772. [Google Scholar] [CrossRef]

- Bentz, E.C.; Tomas, M.D.A. Life-365 Service Life Prediction Model and Computer Program for Predicting the Service Life and Life-Cycle Cost of Reinforced Concrete Exposed to Chlorides; Life-365 Consortium II: Scottsdale, AZ, USA, 2012. [Google Scholar]

- Andrade, C.; Alonso, C.; Molina, F.J. Cover cracking as a function of bar corrosion: Part I-Experimental test. Mater. Struct. 1993, 26, 453–464. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Residual capacity of corroded reinforcing bars. Mag. Concr. Res 2005, 57, 135–147. [Google Scholar] [CrossRef]

- Rodriguez, J.; Andrade, C. A Validated Users Manual for Assessing the Residual Service Life of Concrete Structures; DG Enterprise: Lancaster, OH, USA; GEOCISA: Madrid, Spain, 2001. [Google Scholar]

- Wang, Z.K.; Zhao, X.L.; Xian, G.J.; Wu, G.; Raman, R.K.S.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Davalos, J.F.; Chen, Y.; Ray, I. Long-term durability prediction models for GFRP bars in concrete environment. J. Compos. Mater. 2012, 46, 1899–1914. [Google Scholar] [CrossRef]

- Mazzoni, S.; Mckenna, F.; Scott, M.H.; Fenves, G.L. Opensees Command Language Manual; Pacific Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 2007. [Google Scholar]

- AlNajmi, L.; Abed, F. Evaluation of FRP bars under compression and their performance in RC columns. Materials 2020, 13, 4541. [Google Scholar] [CrossRef] [PubMed]

- Tarawneh, A.N.; Dwairi, H.M.; Almasabha, G.S.; Madalaweyh, S.A. Effect of fiber-reinforced polymer-compression reinforcement in columns subjected to concentric and eccentric loading. ACI Struct. J. 2021, 118, 187–197. [Google Scholar] [CrossRef]

- Tavassoli, A.; Liu, J.; Sheikh, S. Glass fiber-reinforced polymer-reinforced circular columns under simulated seismic loads. ACI Struct. J. 2015, 112, 103–114. [Google Scholar] [CrossRef]

- Urbanski, M. Compressive strength of modified FRP hybrid bars. Materials 2020, 13, 1898. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.K.; Wang, D.Y.; Wang, Z.Y. Full-scale seismic testing of concrete building columns reinforced with both steel and CFRP bars. Compos. Struct. 2017, 178, 195–209. [Google Scholar] [CrossRef]

- Efe, S.; Shokouhian, M.; Head, M.; Chinaka, E. Numerical study on the cyclic response of AFRP reinforced columns with externally unbonded energy dissipaters. Struct. Infrastruct. Eng. 2018, 14, 218–231. [Google Scholar] [CrossRef]

- Kwan, W.P.; Billington, S.L. Unbonded posttensioned concrete bridge piers. I: Monotonic and cyclic analyses. J. Bridge Eng. 2003, 8, 92–101. [Google Scholar] [CrossRef]

- Yuan, W.; Guo, A.X.; Li, H. Experimental investigation on the cyclic behaviors of corroded coastal bridge piers with transfer of plastic hinge due to non-uniform corrosion. Soil Dyn. Earthq. Eng. 2017, 102, 112–123. [Google Scholar] [CrossRef]

- Ibrahim, A.M.A.; Wu, Z.S.; Fahmy, M.F.M.; Kamal, D. Experimental study on cyclic response of concrete bridge columns reinforced by steel and basalt FRP reinforcements. J. Compos. Constr. 2016, 20, 04015062. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Park, R. Strength and ductility of concrete bridge columns under seismic loading. ACI Struct. J. 1987, 84, 61–76. [Google Scholar]

- Nielson, B.G. Analytical Fragility Curves for Highway Bridges in Moderate Seismic Zones. Ph.D. Thesis, School of Civil and Environmental Engineering, Georgia Institute of Technology, Atlanta, GA, USA, 2005. [Google Scholar]

- Bian, J.; Zhou, X.; Ke, K.; Yam, M.C.H.; Wang, Y. Seismic resilient steel substation with BI-TMDI: A theoretical model for optimal design. J. Constr. Steel Res. 2022, 192, 107233. [Google Scholar] [CrossRef]

- Zhang, Z.; Ping, Y.; He, X. Self-centering shape memory alloy-viscoelastic hybrid braces for seismic resilience. Materials 2022, 15, 2349. [Google Scholar] [CrossRef] [PubMed]

- Nielson, B.G.; DesRoches, R. Seismic fragility methodology for highway bridges using a component level approach. Earthq. Eng. Struct. Dyn. 2007, 36, 823–839. [Google Scholar] [CrossRef]

| Function | Assigned Value | Meaning |

|---|---|---|

| = 0.75 | : critical humidity level | |

| = 41,800 | : activation energy : gas constant : reference temperature | |

| = 28 (day); | : reference time : empirical age factor | |

| = 8.366; | , : empirical coefficients |

| Test Specimen | Displacement Amplitude = 40 mm | Displacement Amplitude = 104 mm | |||

|---|---|---|---|---|---|

| D0 | 5.17/5.68 (9.86) | 32.5/35.5 (9.23) | 1.88/1.71 (9.04) | 198/211 (6.57) | 0.61/0.56 (8.20) |

| D30 | 4.51/5.11 (13.3) | 31.9/34.2 (7.21) | 1.87/1.71 (8.56) | 194/210 (8.25) | 0.60/0.54 (10.0) |

| D60 | 4.04/4.29 (6.19) | 31.4/33.1 (5.41) | 1.76/1.65 (6.25) | 187/206 (10.2) | 0.55/0.47 (14.5) |

| D105 | 3.63/3.52 (3.03) | 27.3/24.1 (11.7) | 1.51/1.57 (3.97) | SF | SF |

| D130 | 3.19/3.08 (3.45) | 22.4/19.4 (13.4) | 1.49/1.28 (14.1) | SF | SF |

| D150 | 3.17/2.91 (8.20) | 19.6/15.5 (20.9) | 1.48/1.24 (16.2) | SF | SF |

| Service Time (a) | (mm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 40.1 | 151 | 166 | 257 | 381 | 369 | 4.14 | 0.174 |

| 20 | 40.1 | 141 | 153 | 257 | 370 | 358 | 3.82 | 0.175 |

| 40 | 38.2 | 130 | 131 | 234 | 334 | 324 | 3.43 | 0.178 |

| 60 | 37.5 | 121 | 123 | 219 | 308 | 300 | 3.28 | 0.183 |

| 80 | 36.2 | 105 | 108 | 198 | 275 | 271 | 2.98 | 0.205 |

| 100 | 36.0 | 90 | 102 | 186 | 253 | 245 | 2.83 | 0.240 |

| No. | Event | Station | PGA (g) | |

|---|---|---|---|---|

| 1 | Superstition Hills, 1987 | Parachute Test Site | 0.432 | 0.890 |

| 2 | Landers, 1992 | Yermo Fire Station | 0.245 | 0.498 |

| 3 | Northridge, 1994 | Newhall-W Pico Canyon Rd. | 0.357 | 0.762 |

| 4 | Cape Mendocino, 1992 | Centerville Beach | 0.318 | 0.412 |

| 5 | Northridge, 1994 | Pacoima Kagel Canyon | 0.433 | 1.089 |

| 6 | Parkfield-02_CA, 2004 | Parkfield-Fault Zone 1 | 0.833 | 0.989 |

| 7 | Northridge, 1994 | Sylmar-Converter Sta | 0.623 | 1.321 |

| 8 | Parkfield-02 CA, 2004 | Parkfield-Cholame 2WA | 0.624 | 0.988 |

| 9 | Christchurch, New Zealand, 2011 | Pages Road Pumping Station | 0.569 | 0.638 |

| 10 | Loma Prieta, 1989 | Foster City-APEEL 1 | 0.284 | 0.901 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, W.; Cai, Z.-K.; Pan, X.; Lin, J. Time-Dependent Seismic Performance of Coastal Bridges Reinforced with Hybrid FRP and Steel Bars. Materials 2022, 15, 5293. https://doi.org/10.3390/ma15155293

Yuan W, Cai Z-K, Pan X, Lin J. Time-Dependent Seismic Performance of Coastal Bridges Reinforced with Hybrid FRP and Steel Bars. Materials. 2022; 15(15):5293. https://doi.org/10.3390/ma15155293

Chicago/Turabian StyleYuan, Wei, Zhong-Kui Cai, Xiaolan Pan, and Jun Lin. 2022. "Time-Dependent Seismic Performance of Coastal Bridges Reinforced with Hybrid FRP and Steel Bars" Materials 15, no. 15: 5293. https://doi.org/10.3390/ma15155293

APA StyleYuan, W., Cai, Z.-K., Pan, X., & Lin, J. (2022). Time-Dependent Seismic Performance of Coastal Bridges Reinforced with Hybrid FRP and Steel Bars. Materials, 15(15), 5293. https://doi.org/10.3390/ma15155293