Investigation of Tensile Properties of Different Infill Pattern Structures of 3D-Printed PLA Polymers: Analysis and Validation Using Finite Element Analysis in ANSYS

Abstract

:1. Introduction

2. Materials and Methods

2.1. Printer Setting

2.2. Tensile Test

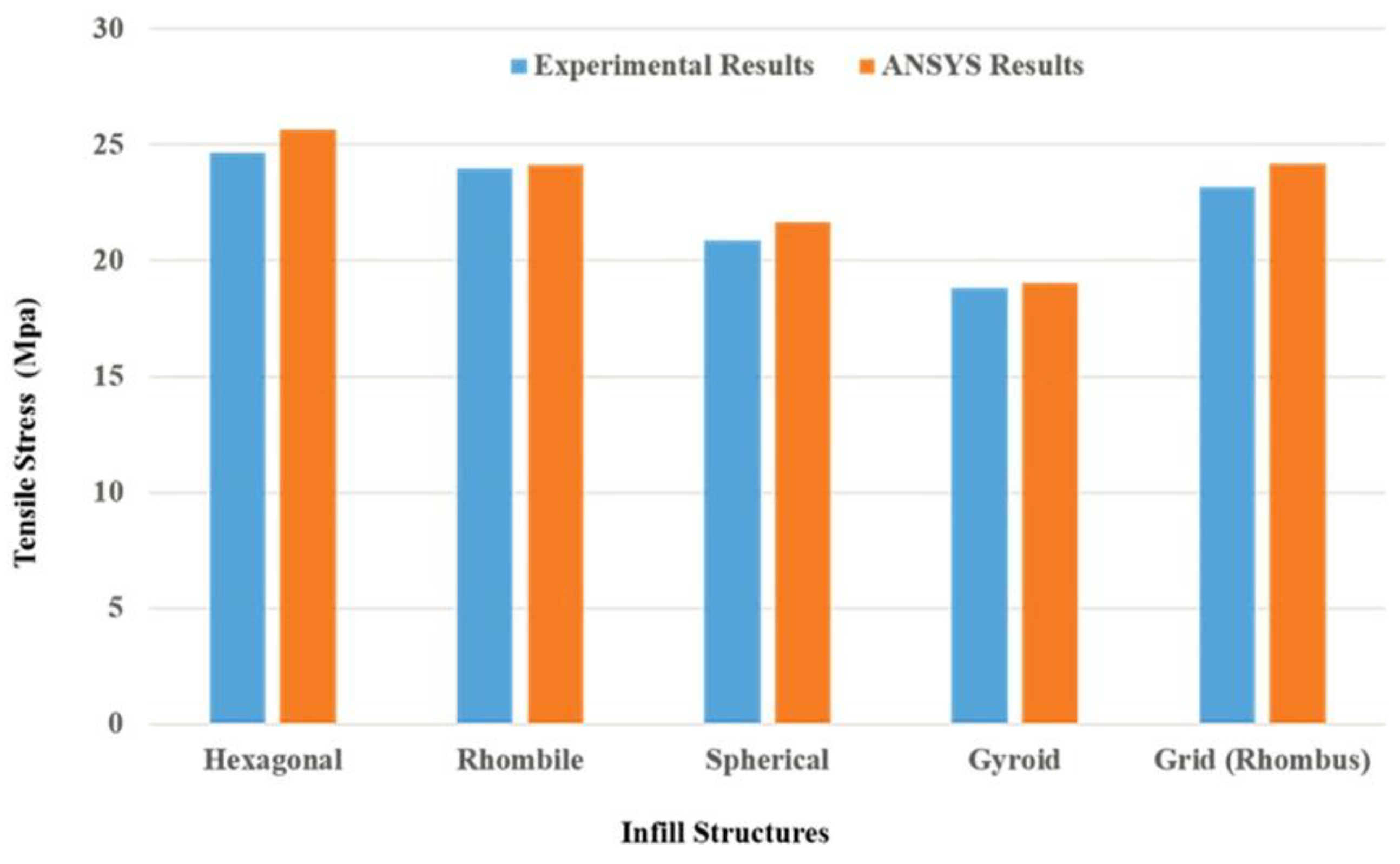

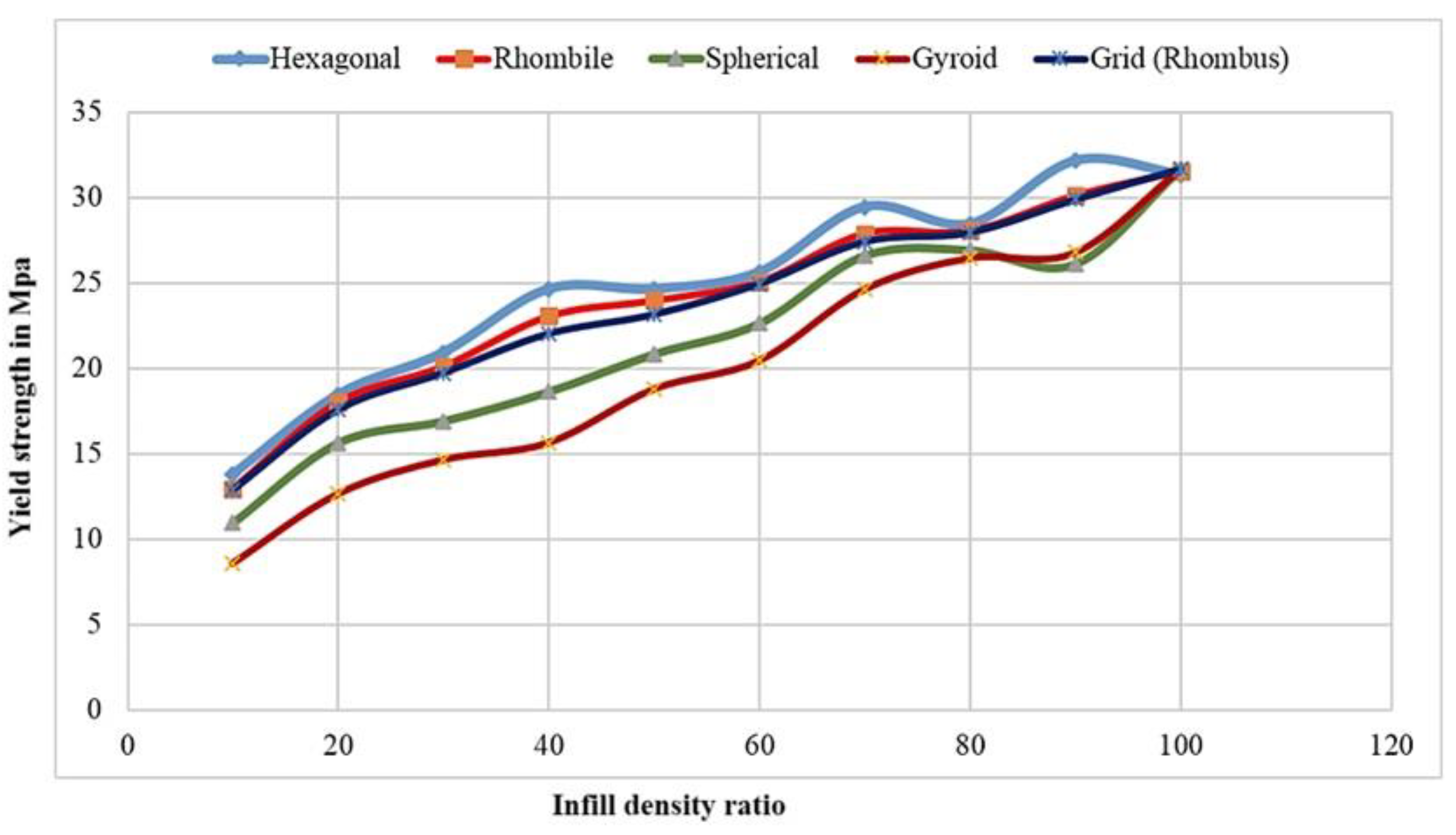

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Srinivasan, R.; Ruban, W.; Deepanraj, A.; Bhuvanesh, R.; Bhuvanesh, T. Effect on infill density on mechanical properties of PETG part fabricated by fused deposition modelling. Mater. Today Proc. 2020, 27, 1838–1842. [Google Scholar] [CrossRef]

- Caivano, R.; Tridello, A.; Paolino, D.; Chiandussi, G. Topology and fibre orientation simultaneous optimisation: A design methodology for fibre-reinforced composite components. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1267–1279. [Google Scholar] [CrossRef]

- Lubombo, C.; Huneault, M.A. Effect of infill patterns on the mechanical performance of lightweight 3D-printed cellular PLA parts. Mater. Today Commun. 2018, 17, 214–228. [Google Scholar] [CrossRef]

- Hlinka, M. Non-destructive Testing for the Influence of Infill Pattern Geometry on Mechanical Stiffness of 3D Printing Materials. Ph.D. Thesis, Florida Atlantic University, Boca Raton, FL, USA, 2020. [Google Scholar]

- Ranjan, R.; Ayas, C.; Langelaar, M.; van Keulen, F. Topology Optimisation Techniques. In Precision Metal Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2020; pp. 11–34. [Google Scholar]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Clausen, A.; Sigmund, O. Minimum compliance topology optimization of shell–infill composites for additive manufacturing. Comput. Methods Appl. Mech. Eng. 2017, 326, 358–375. [Google Scholar] [CrossRef] [Green Version]

- Gupta, P.; Krishnamoorthy, B.; Dreifus, G. Continuous toolpath planning in a graphical framework for sparse infill additive manufacturing. Comput. Aided Des. 2020, 127, 102880. [Google Scholar] [CrossRef]

- Kumar, S.A.; Narayan, Y.S. Tensile testing and evaluation of 3D-printed PLA specimens as per ASTM D638 type IV standard. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering (I-DAD 2018); Springer: Singapore, 2019; pp. 79–95. [Google Scholar]

- Culbreath, C.J.; Gaerke, B.; Taylor, M.S.; McCullen, S.D.; Mefford, O.T. Effect of Infill on Resulting Mechanical Properties of Additive Manufactured Bioresorbable Polymers for Medical Devices. Materialia 2020, 12, 100732. [Google Scholar] [CrossRef]

- Alhazmi, M.W.; Backar, A.H. Influence of Infill density and Orientation on the Mechanical Response of PLA+ Specimens Produced using FDM 3D Printing. Int. J. Adv. Sci. Technol. 2020, 29, 3362–3371. [Google Scholar]

- Alvarez, C.; Kenny, L.; Lagos, C.; Rodrigo, F.; Aizpun, M. Investigating the influence of infill percentage on the mechanical properties of fused deposition modelled ABS parts. Ing. E Investig. 2016, 36, 110–116. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Wang, L.; Ma, G. Mechanical improvement of continuous steel microcable reinforced geopolymer composites for 3D printing subjected to different loading conditions. Compos. Part B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Wang, J.; Sama, S.R.; Lynch, P.C.; Manogharan, G. Design and topology optimization of 3D-Printed wax patterns for rapid investment casting. Procedia Manuf. 2019, 34, 683–694. [Google Scholar] [CrossRef]

- Yang, C.; Xu, P.; Xie, S.; Yao, S. Mechanical performances of four lattice materials guided by topology optimisation. Scr. Mater. 2019, 178, 339–345. [Google Scholar] [CrossRef]

- Wu, J.; Aage, N.; Westermann, R.; Sigmund, O. Infill Optimization for Additive Manufacturing—Approaching Bone-Like Porous Structures. IEEE Trans. Vis. Comput. Graph. 2017, 24, 1127–1140. [Google Scholar] [CrossRef] [Green Version]

- Kain, S.; Ecker, J.V.; Haider, A.; Musso, M.; Petutschnigg, A. Effects of the infill pattern on mechanical properties of fused layer modeling (FLM) 3D printed wood/polylactic acid (PLA) composites. Eur. J. Wood Wood Prod. 2020, 78, 65–74. [Google Scholar] [CrossRef]

- Aloyaydi, B.; Sivasankaran, S.; Mustafa, A. Investigation of infill-patterns on mechanical response of 3D printed poly-lactic-acid. Polym. Test. 2020, 87, 106557. [Google Scholar] [CrossRef]

- García-Domínguez, A.; Claver, J.; Sebastián, M.A. Infill optimization for pieces obtained by 3D printing. Procedia Manuf. 2019, 41, 193–199. [Google Scholar] [CrossRef]

- Schmitt, M.; Mehta, R.M.; Kim, I.Y. Additive manufacturing infill optimization for automotive 3D-printed ABS components. Rapid Prototyp. J. 2020, 26, 89–99. [Google Scholar] [CrossRef]

- Qiu, W.; Jin, P.; Jin, S.; Wang, C.; Xia, L.; Zhu, J.; Shi, T. An evolutionary design approach to shell-infill structures. Addit. Manuf. 2020, 34, 101382. [Google Scholar] [CrossRef]

- Alexandersen, J.; Andreasen, C.S. A review of topology optimisation for fluid-based problems. Fluids 2020, 5, 29. [Google Scholar] [CrossRef] [Green Version]

- Al-Tamimi, A.A.; Almeida, H.; Bartolo, P. Structural optimisation for medical implants through additive manufacturing. Prog. Addit. Manuf. 2020, 5, 95–110. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núnez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Carneau, P.; Mesnil, R.; Roussel, N.; Baverel, O. Additive manufacturing of cantilever-From masonry to concrete 3D printing. Autom. Constr. 2020, 116, 103184. [Google Scholar] [CrossRef] [Green Version]

- Maurya, S.; Malik, B.; Sharma, P.; Singh, A.; Chalisgaonkar, R. Investigation of different parameters of cube printed using PLA by FDM 3D printer. Mater. Today Proc. 2022, 1–6. [Google Scholar] [CrossRef]

- Monogarov, K.A.; Fomenkov, I.V.; Pivkina, A.N. FDM 3D printing of combustible structures: First results. Mendeleev Commun. 2022, 32, 228–230. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Kern, F.; Dufner, L.; Antonowicz, M.; Matus, K. Alumina and Zirconia-Reinforced Polyamide PA-12 Composites for Biomedical Additive Manufacturing. Materials 2021, 14, 6201. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Singh, S.K.; Deshmukh, S. Printing parameters and materials affecting mechanical properties of FDM-3D printed Parts: Perspective and prospects. Mater. Today Proc. 2021, 50, 2269–2275. [Google Scholar] [CrossRef]

- Singh, R.; Singh, N. Effect of hybrid reinforcement of SiC and Al2O3 in Nylon-6 matrix on mechanical properties of feed stock filament for FDM. Adv. Mater. Process. Technol. 2017, 3, 353–361. [Google Scholar] [CrossRef]

- Saniman, M.N.F.; Bidin, M.F.; Nasir, R.M.; Shariff, J.M. Flexural Properties Evaluation of Additively Manufactured Components with Various Infill Patterns. Int. J. Adv. Sci. Technol. 2020, 29, 4646–4657. [Google Scholar]

- Tho, N.H.; Minh, T.C.; Tai, N.P. The effect of infill pattern, infill density, printing speed and temperature on the additive manufacturing process based on the FDM technology for the hook-shaped components. J. Polimesin 2020, 18, 1–6. [Google Scholar]

- Kuppuswamy, H.; Ganesan, A. Structural, mechanical and in vitro studies on pulsed laser deposition of hydroxyapatite on additive manufactured polyamide substrate. Int. J. Bioprinting 2016, 2, 84. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.A.; Khan, S.Z.; Asif, M.; Khan, K.A.; Saquib, A.N.; Mansoor, M.S.; Mujtaba, A. Prediction of crack depth and fatigue life of an Acrylonitrile Butadiene Styrene cantilever beam using dynamic response. J. Test. Eval. 2020, 48, 1520–1536. [Google Scholar] [CrossRef]

- Kumar, M.V.; Padmanaban, G.; Balasubramanian, V. Role of tool pin profiles on wear characteristics of friction stir processed magnesium alloy ZK60/silicon carbide surface composites. Mater. Und Werkst. 2020, 51, 140–152. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Zeng, X.; Nierstrasz, V. Stress, strain and deformation of poly-lactic acid filament deposited onto polyethylene terephthalate woven fabric through 3D printing process. Sci. Rep. 2019, 9, 1–18. [Google Scholar]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Al-Tamimi, A.A.; Quental, C.; Folgado, J.; Peach, C.; Bartolo, P. Stress analysis in a bone fracture fixed with topology-optimised plates. Biomech. Modeling Mechanobiol. 2020, 19, 693–699. [Google Scholar] [CrossRef] [Green Version]

- Saniman, M.N.F.; Hashim, M.H.M.; Mohammad, K.A.; Wahid, K.A.A.; Muhamad, W.M.W.; Mohamed, N.H.N. Tensile Characteristics of Low Density Infill Patterns for Mass Reduction of 3D Printed Polylactic Parts. Int. J. Automot. Mech. Eng. 2020, 17, 7927–7934. [Google Scholar] [CrossRef]

- Reddy, A.P.; Krishna, P.V.; Rao, R.N. Mechanical and Wear Properties of Aluminum-Based Nanocomposites Fabricated through Ultrasonic Assisted Stir Casting. J. Test. Evaluation 2018, 48. [Google Scholar]

- Ball, D.L.; Martinez, M.; Baldassarre, A.; Dubowski, D.M.; Carlson, S.S. Analytical and Experimental Investigation of Elastic–Plastic Strain Distributions at 2-D Notches. J. Test. Eval. 2020, 49. [Google Scholar] [CrossRef]

- Vigneshkumar, M.; Padmanaban, G.; Balasubramanian, V. Influence of Tool Rotational Speed on the Formation of Friction Stir Processing Zone in Cast Zk60/SiCp Magnesium Alloy Surface Composites. Mater. Perform. Charact. 2018, 7, 579–590. [Google Scholar] [CrossRef]

- Nemati, R.; Dave, E.V.; Sias, J.E. Statistical evaluation of the effects of mix design properties on performance indices of asphalt mixtures. J. Test. Eval. 2020, 48, 72–87. [Google Scholar] [CrossRef]

- Parab, S.; Zaveri, N. Investigating the Influence of Infill Pattern on the Compressive Strength of Fused Deposition Modelled PLA Parts. In Proceedings of the International Conference on Intelligent Manufacturing and Automation; Springer: Singapore, 2020; pp. 239–247. [Google Scholar]

- Thirumalaikumarasamy, D.; Balasubramanian, V.; Sabari, S.S. Prediction and optimization of process variables to maximize the Young’s modulus of plasma sprayed alumina coatings on AZ31B magnesium alloy. J. Magnes. Alloy. 2017, 5, 133–145. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganeshkumar, S.; Kumar, S.D.; Magarajan, U.; Rajkumar, S.; Arulmurugan, B.; Sharma, S.; Li, C.; Ilyas, R.A.; Badran, M.F. Investigation of Tensile Properties of Different Infill Pattern Structures of 3D-Printed PLA Polymers: Analysis and Validation Using Finite Element Analysis in ANSYS. Materials 2022, 15, 5142. https://doi.org/10.3390/ma15155142

Ganeshkumar S, Kumar SD, Magarajan U, Rajkumar S, Arulmurugan B, Sharma S, Li C, Ilyas RA, Badran MF. Investigation of Tensile Properties of Different Infill Pattern Structures of 3D-Printed PLA Polymers: Analysis and Validation Using Finite Element Analysis in ANSYS. Materials. 2022; 15(15):5142. https://doi.org/10.3390/ma15155142

Chicago/Turabian StyleGaneshkumar, S., S. Dharani Kumar, U. Magarajan, S. Rajkumar, B. Arulmurugan, Shubham Sharma, Changhe Li, R. A. Ilyas, and Mohamed Fathy Badran. 2022. "Investigation of Tensile Properties of Different Infill Pattern Structures of 3D-Printed PLA Polymers: Analysis and Validation Using Finite Element Analysis in ANSYS" Materials 15, no. 15: 5142. https://doi.org/10.3390/ma15155142

APA StyleGaneshkumar, S., Kumar, S. D., Magarajan, U., Rajkumar, S., Arulmurugan, B., Sharma, S., Li, C., Ilyas, R. A., & Badran, M. F. (2022). Investigation of Tensile Properties of Different Infill Pattern Structures of 3D-Printed PLA Polymers: Analysis and Validation Using Finite Element Analysis in ANSYS. Materials, 15(15), 5142. https://doi.org/10.3390/ma15155142