Effect of Waste Basalt Fines and Recycled Concrete Components on Mechanical, Water Absorption, and Microstructure Characteristics of Concrete

Abstract

:1. Introduction

2. Research Importance

3. Experimental Work

3.1. Material Properties

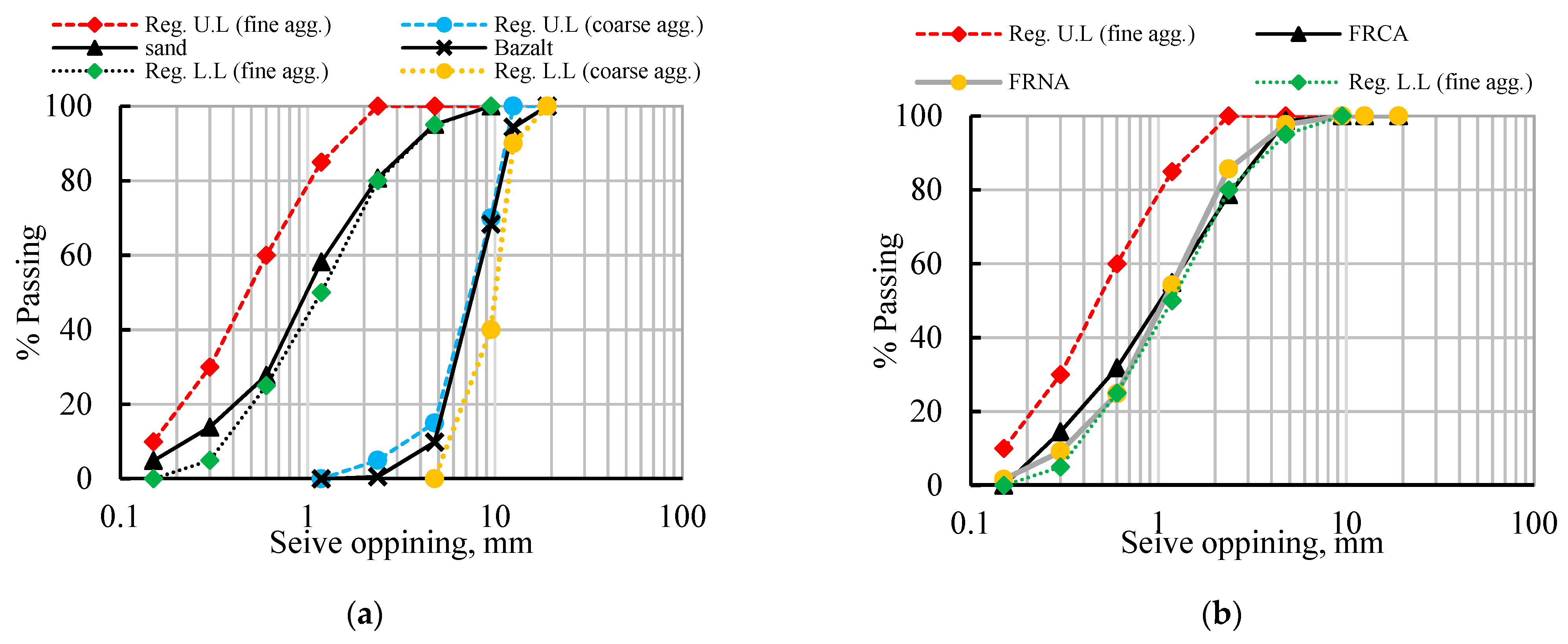

3.1.1. Aggregates

3.1.2. Cement and Pozzolanic Materials

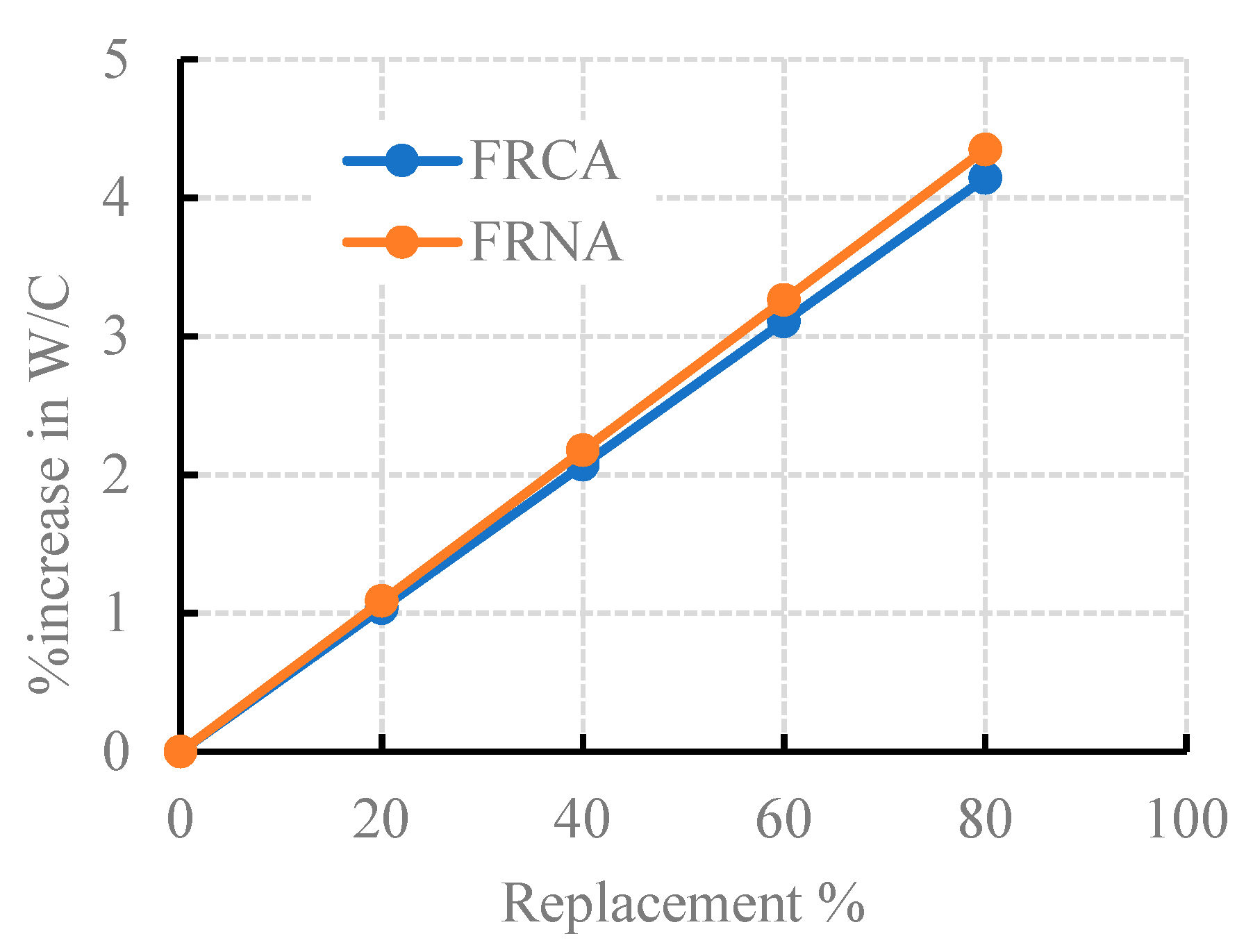

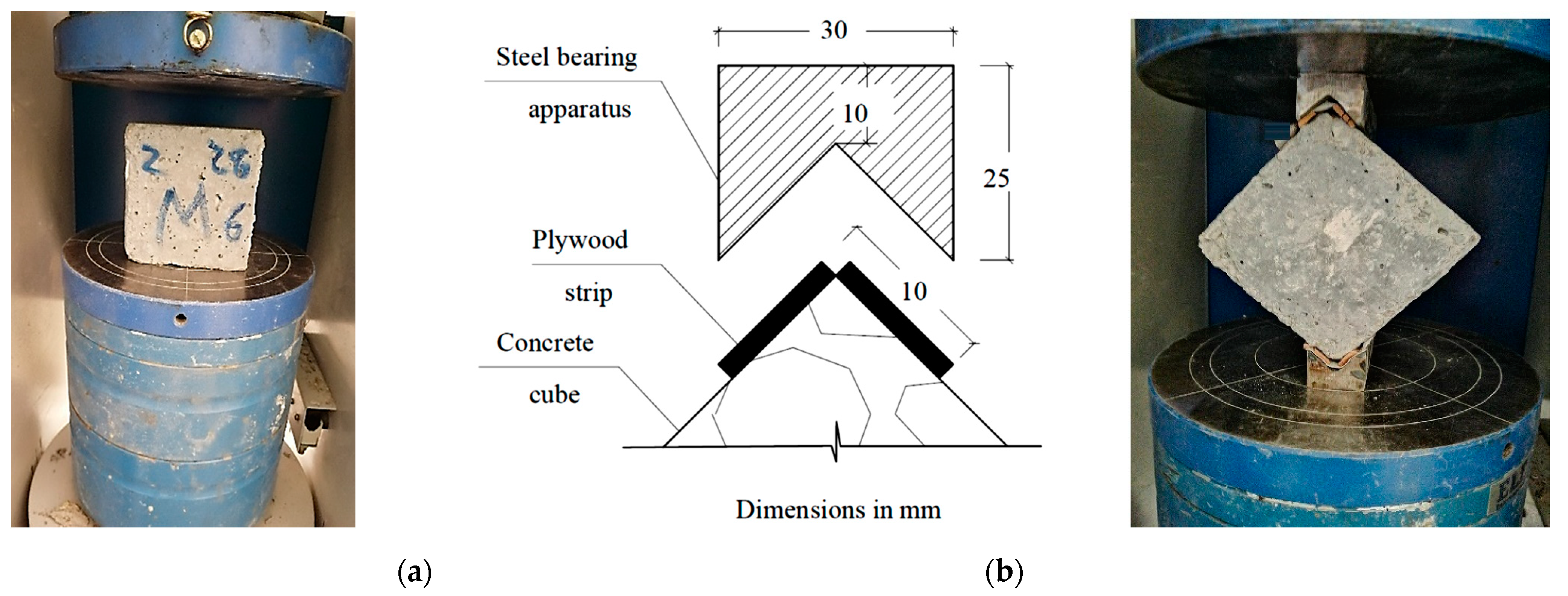

3.2. Mix Design, Specimens, and Testing Methods

4. Results and Discussions

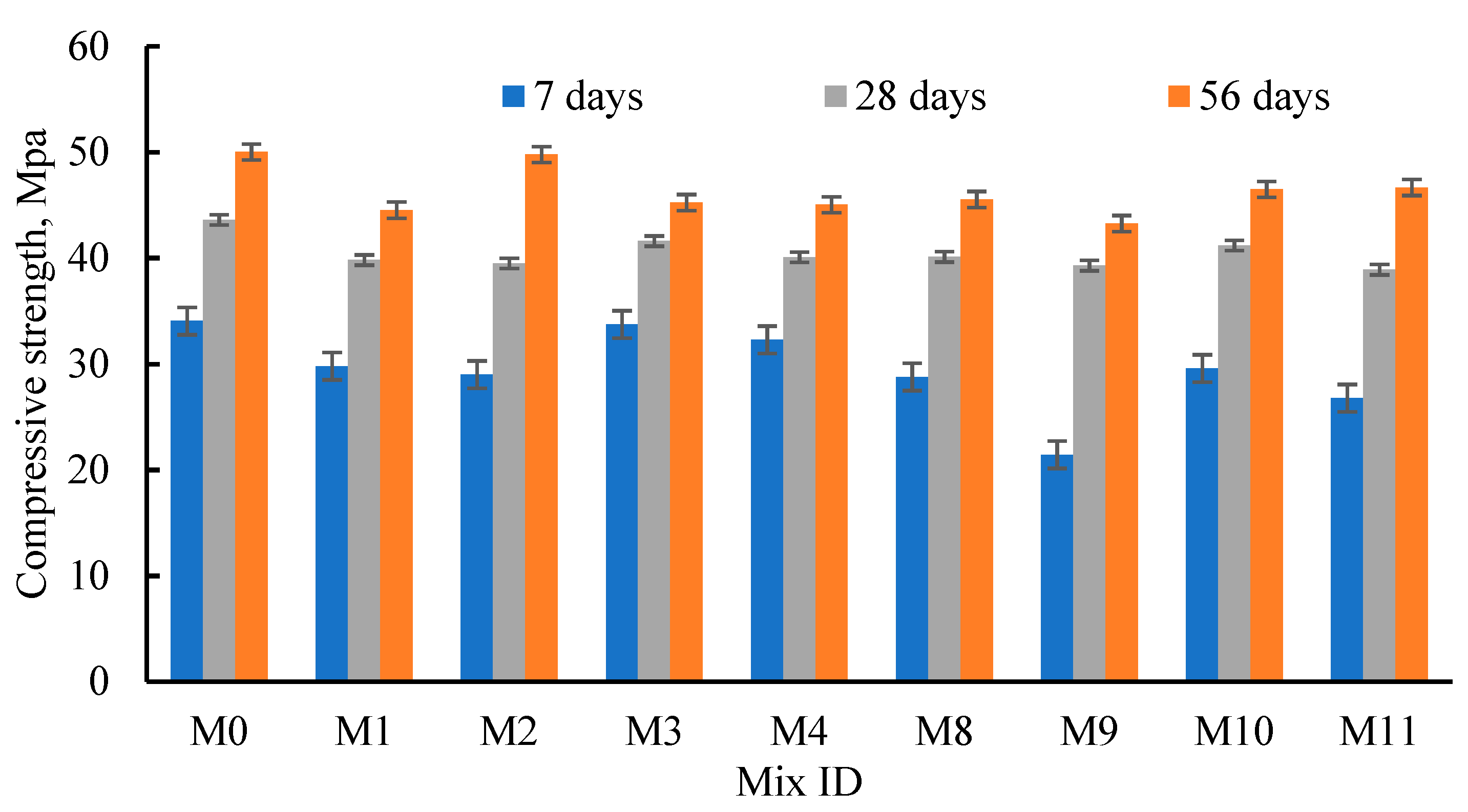

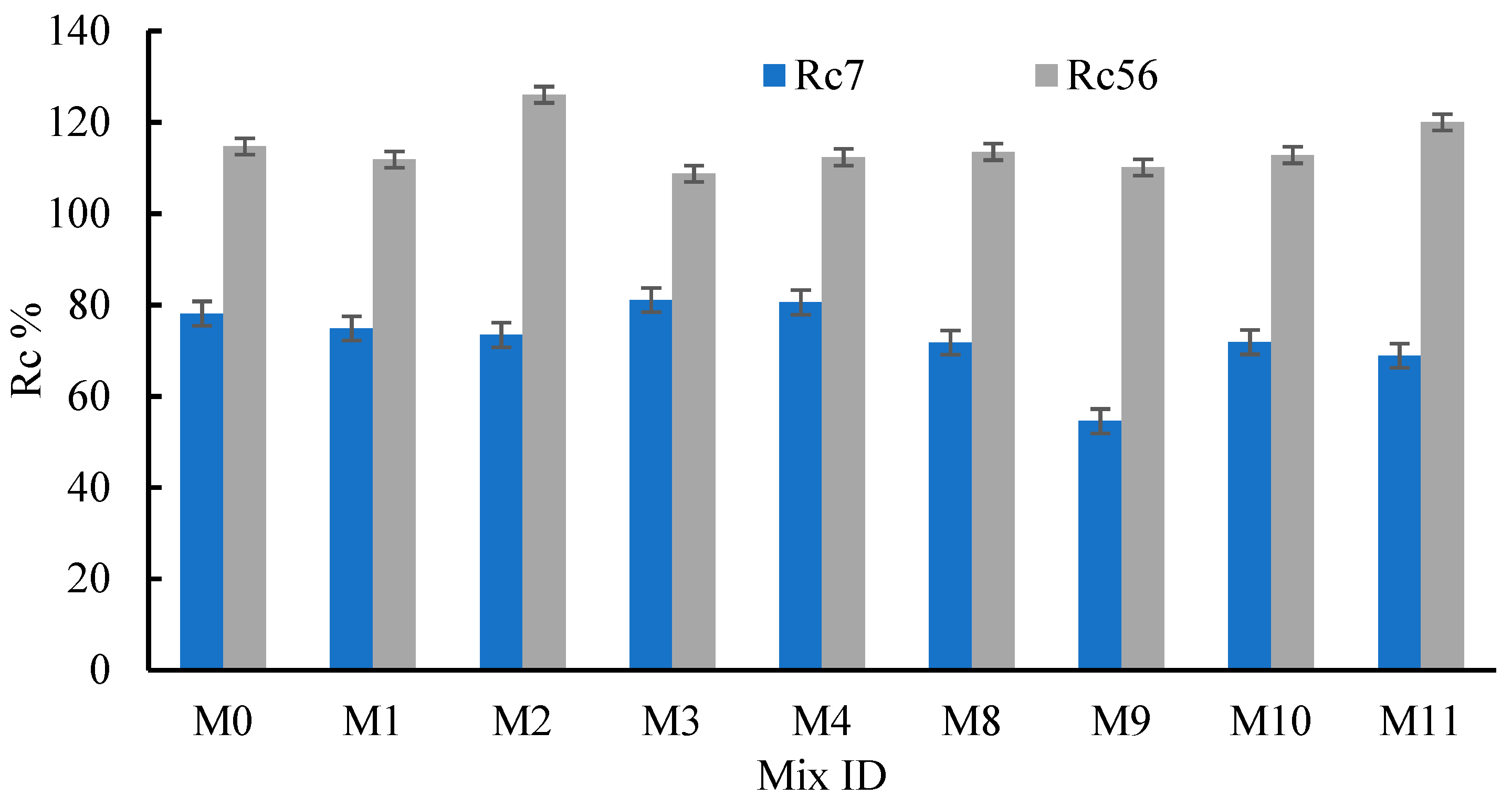

4.1. Compressive Strength

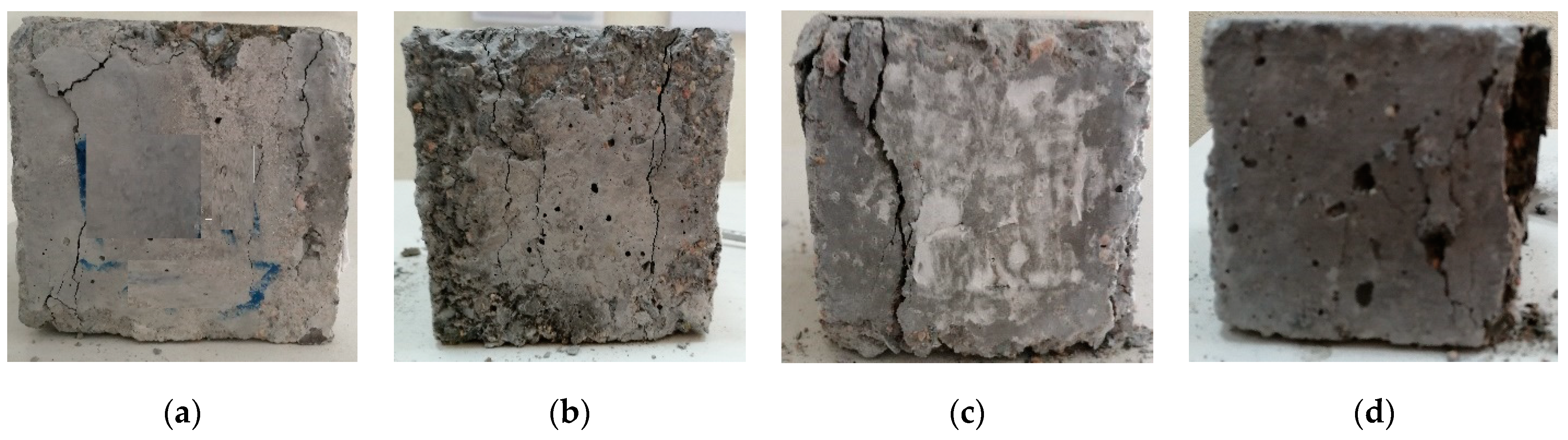

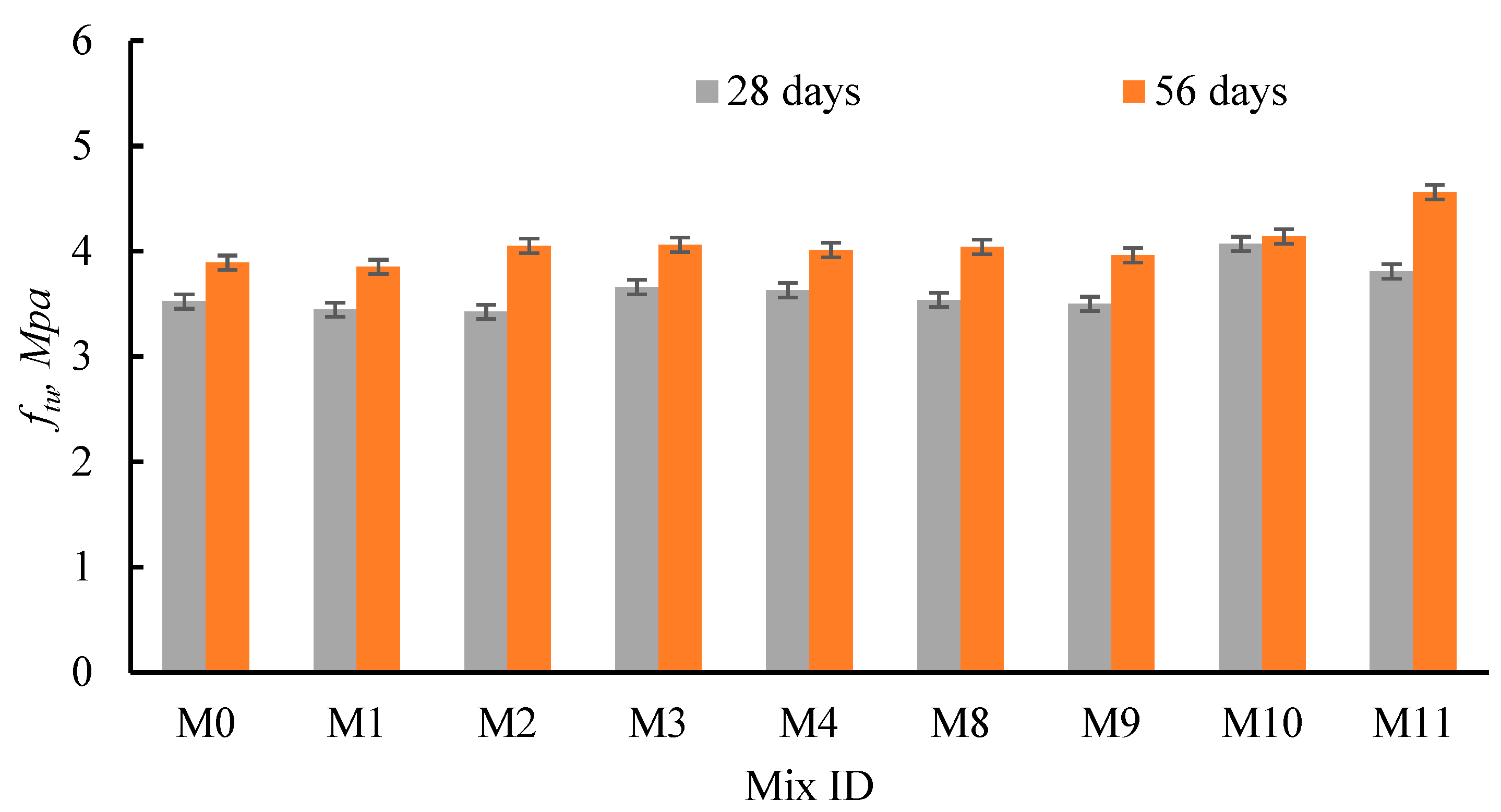

4.2. Tensile Strength

4.3. Discussion of the Results

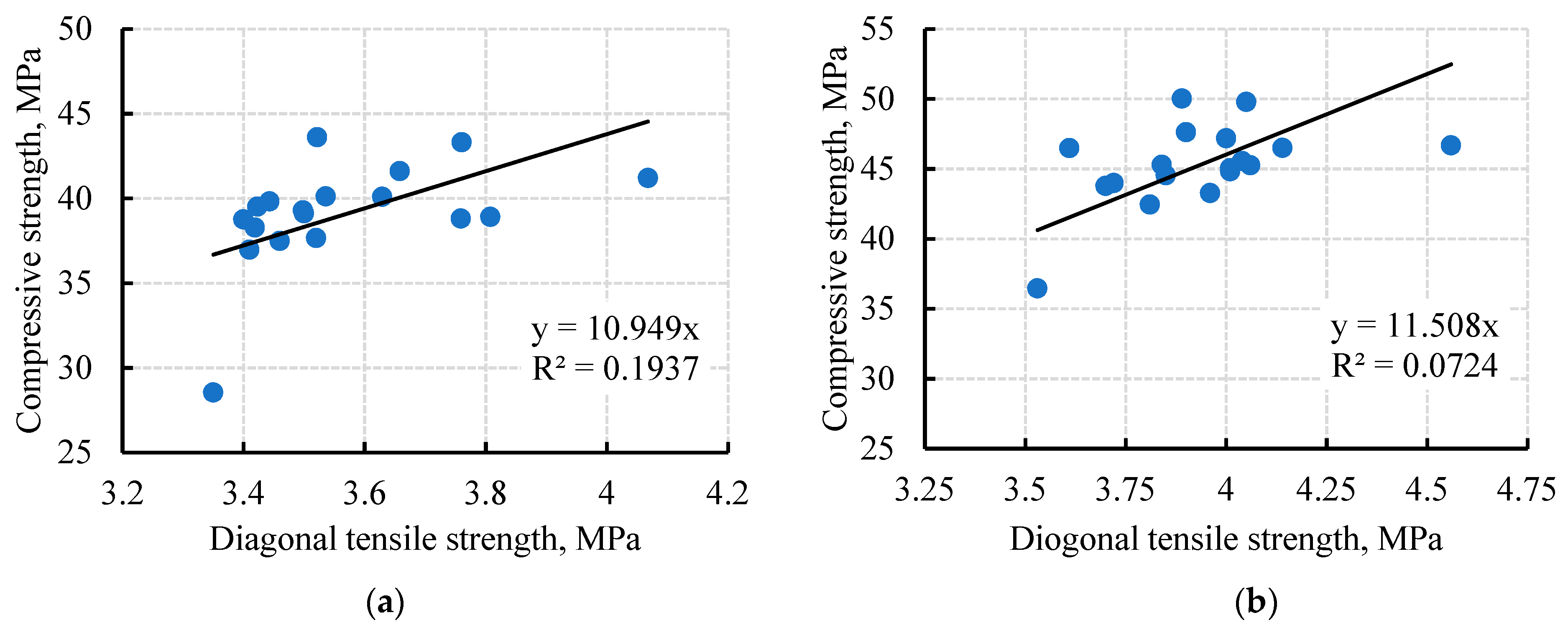

4.4. Correlation between Tensile and Compressive Strengths

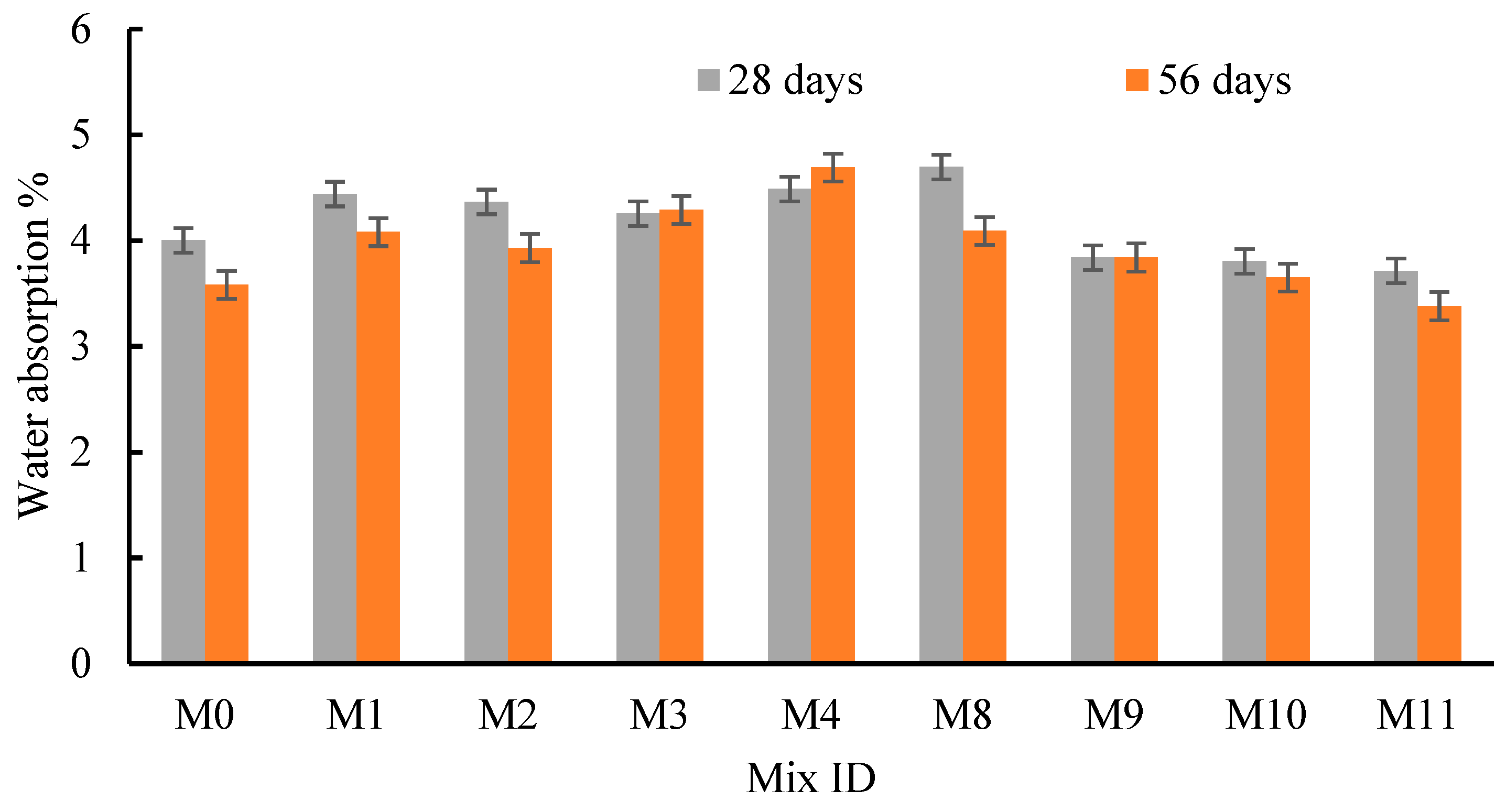

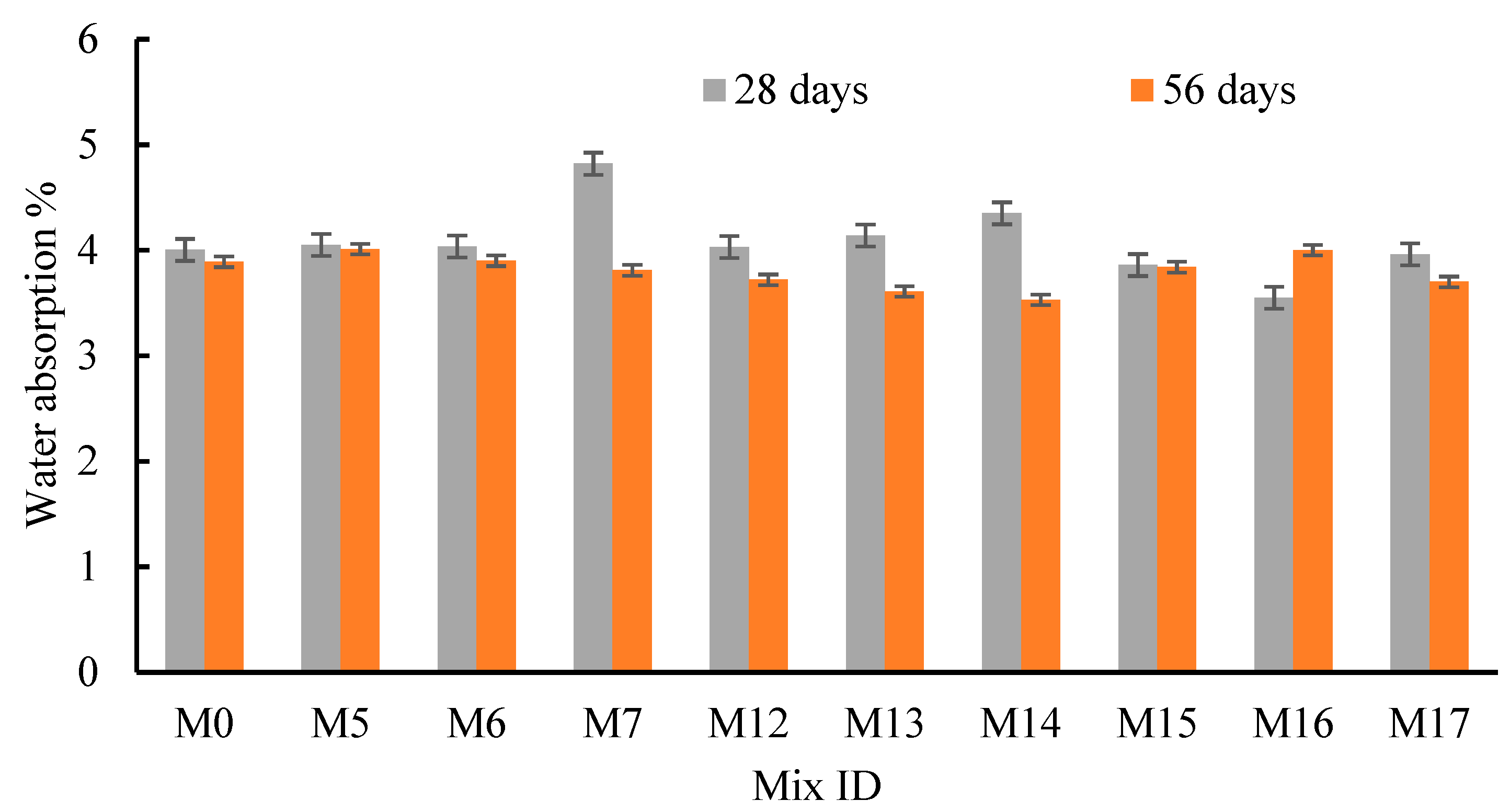

4.5. Water Absorption

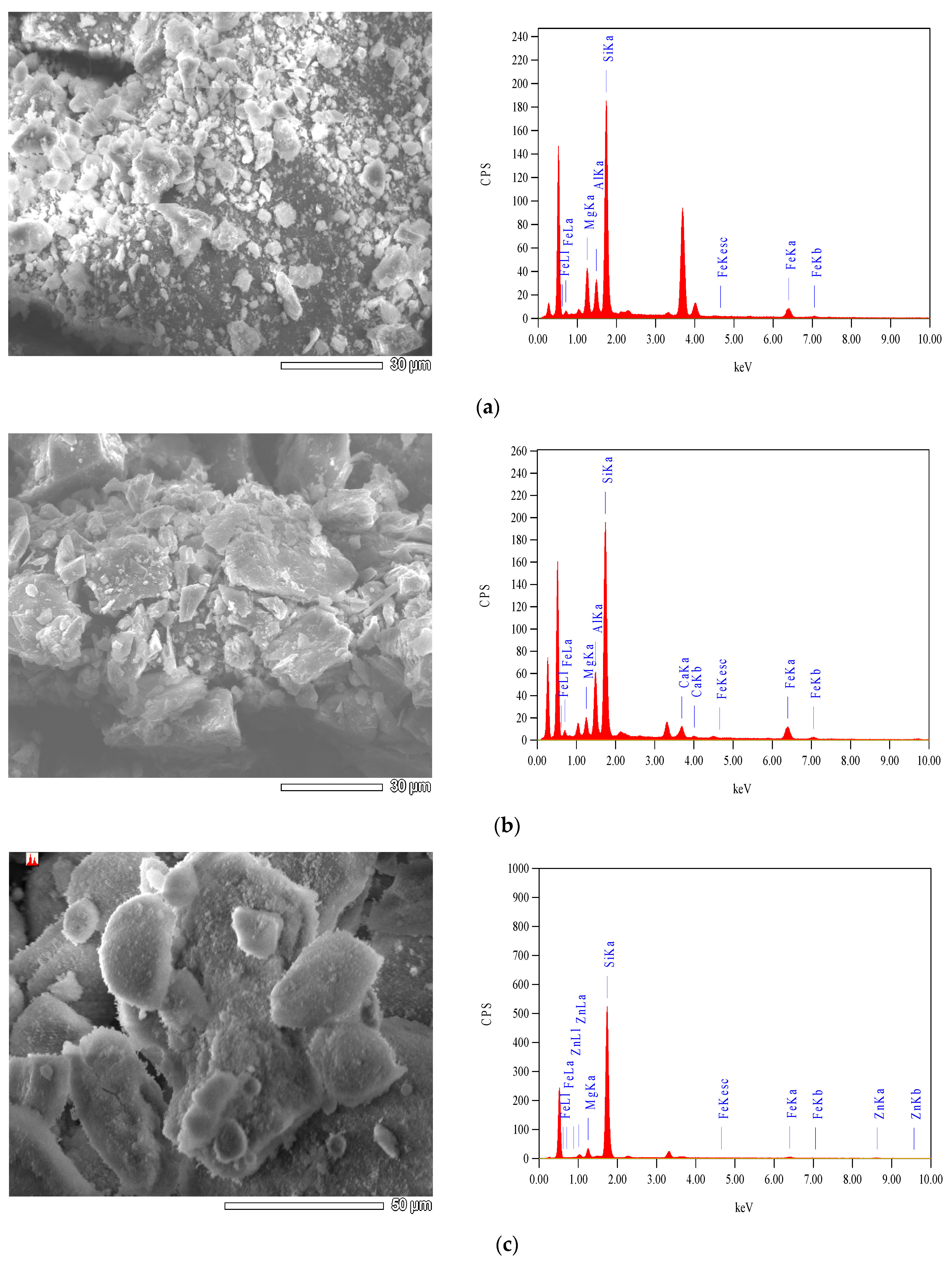

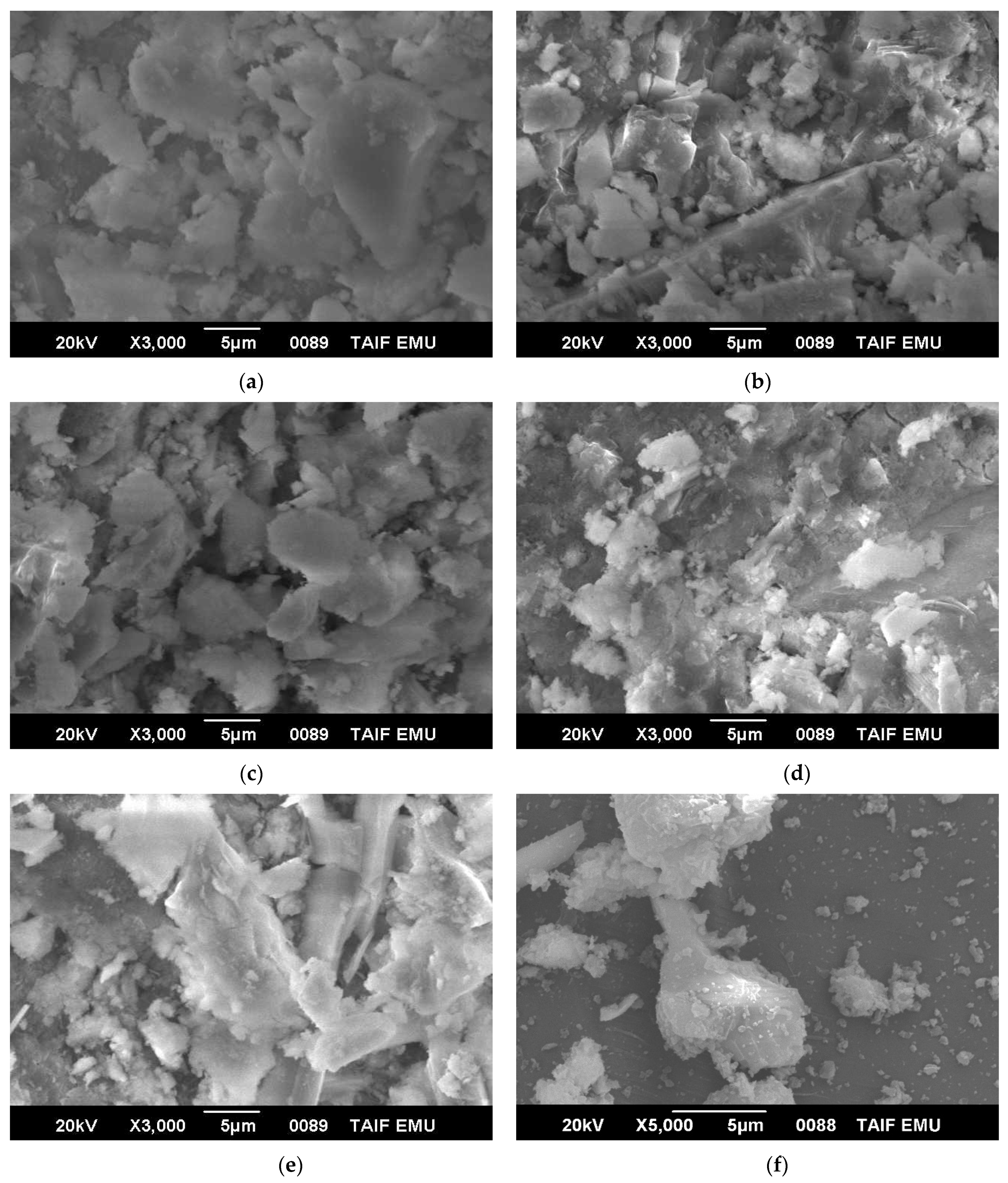

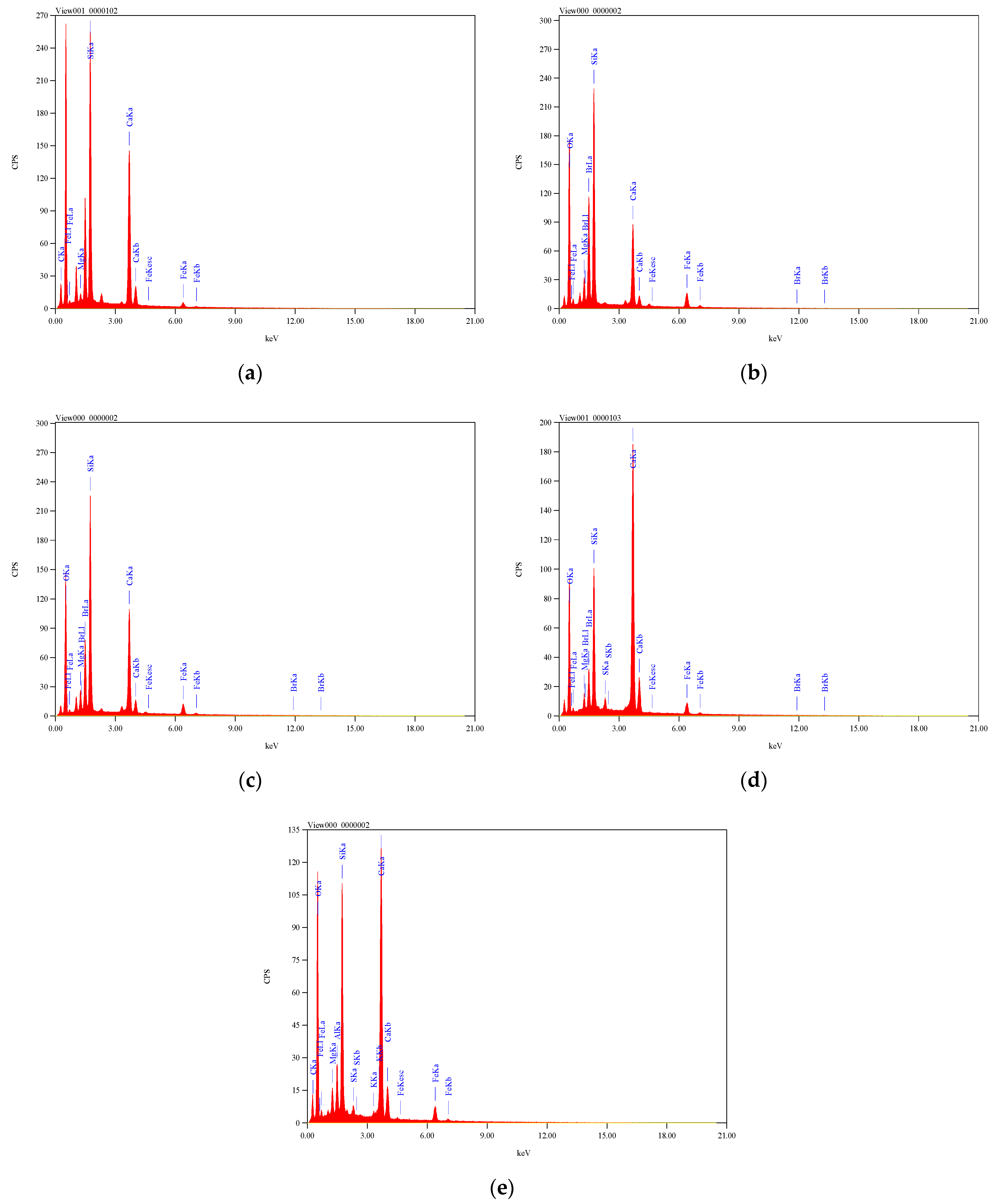

4.6. SEM and EDS Analysis

5. Conclusions

- Increasing the curing time (Tc) augmented the compressive and tensile strengths regardless of the concrete components. The concrete strength increased at a high rate until 28 days had passed, then the rate decreased afterward because the cement was highly hydrated during the first 28 days.

- The source, type, and content of the recycled fine basaltic aggregate and powders had a great effect on the concrete’s properties. Consequently, as RFCA replaced sand by 40%, the RFCA achieved about 99.5% of the M0 compressive strength at 56 days as RFCA may integrate more basaltic and cement powders than RFNA.

- As RCP, AMF, and SF were partially replaced with cement, the compressive strength was reduced by dissimilar percentages, depending on the additional amount of C-S-H gel produced in the mix. At 28 days, for the 10% RCP mix, the compressive strength was about 99.3% that of the M0 sample strength.

- The tensile strength greatly depended on the source, type, and percentage of the fine recycled aggregates and powders, apart from the curing ages. As the RFCA and RFNA replaced the sand, the tensile strength was augmented. Conversely, as the RCP, AMF, and SF replaced the cement, the tensile strength was enhanced.

- The WA diminished with the increased curing time or testing ages. The WA of the AMF mixes decreased as the RFNA percentage increased, while the RFCA mixes showed the opposite trend. Moreover, compared to M0, the mixes integrating RCP, AMF, and SF generally showed small WA differences. Furthermore, mixes integrating 10% and 20% SF experienced the lowest values of WA.

- The SEM analysis showed that the C-S-H did not completely cover the basalt particle surface for all mixes. The mixes integrating RFCA had the densest nature, in terms of the ITZ.

- The RCP and AMF had the same potential pozzolanic reactivity as SF, but they retarded the hydration reaction. The basaltic RCP and AMF contents could consume Ca(OH)2 and produce additional C-S-H gel.

- Comparing the magnesium, calcium, and silicate contents in the tested mixes showed that the 40% RFCA mixes diffused the highest contents of both calcium and silicate. The high calcium and silicate contents enhanced the ITZ and enhanced the concrete properties, compared to the other tested mixes.

- As the concrete properties obtained from both recycled and natural aggregates are nearly the same, the use of recycled aggregate to partially replace the natural ones reduces the extraction energy needed. Conversely, using concrete micro fines to partially replace OPC lessens the CO2 emissions that result from OPC production. Therefore, using recycled materials to replace both natural aggregate and cement is an effective way to lessen construction costs and their environmental impact.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martínez-García, R.; de Rojas, M.I.S.; Del Pozo, J.M.M.; Fraile-Fernández, F.J.; Juan-Valdés, A. Evaluation of mechanical characteristics of cement mortar with fine recycled concrete aggregates (FRCA). Sustainability 2021, 13, 414. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. High tech startup creation for energy efficient built environment. Renew. Sustain. Energy Rev. 2017, 71, 618–629. [Google Scholar] [CrossRef] [Green Version]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Xuan, D.; Poon, C.S.; Zheng, W. Management and sustainable utilization of processing wastes from ready-mixed concrete plants in construction: A review. Resour. Conserv. Recycl. 2018, 136, 238–247. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular economy on construction and demolition waste: A literature review on material recovery and production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- Yu, B.; Wang, J.; Li, J.; Lu, W.; Li, C.Z.; Xu, X. Quantifying the potential of recycling demolition waste generated from urban renewal: A case study in Shenzhen, China. J. Clean. Prod. 2020, 247, 119127. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Kua, H.W.; Yu, L.N.; Chung, J.K.H. Fresh Properties of Cementitious Materials Containing Rice Husk Ash for Construction 3D Printing. J. Mater. Civ. Eng. 2020, 32, 04020195. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Rheological behavior of high volume fly ash mixtures containing micro silica for digital construction application. Mater. Lett. 2019, 237, 348–351. [Google Scholar] [CrossRef]

- Malešev, M.; Radonjanin, V.; Marinković, S. Recycled concrete as aggregate for structural concrete production. Sustainability 2010, 2, 1204–1225. [Google Scholar] [CrossRef] [Green Version]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Casuccio, M.; Torrijos, M.C.; Giaccio, G.; Zerbino, R. Failure mechanism of recycled aggregate concrete. Constr. Build. Mater. 2008, 22, 1500–1506. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of parent concrete on the performance of recycled aggregate concrete. Sustainability 2020, 12, 9399. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N. Properties of Concrete Incorporating Coal Fly Ash and Coal Bottom Ash. J. Inst. Eng. Ser. A 2019, 100, 459–469. [Google Scholar] [CrossRef]

- Satpathy, H.P.; Patel, S.K.; Nayak, A.N. Development of sustainable lightweight concrete using fly ash cenosphere and sintered fly ash aggregate. Constr. Build. Mater. 2019, 202, 636–655. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Dinis Silvestre, J.; de Brito, J.; Duarte Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Life cycle assessment and life cycle costing toward eco-efficiency concrete waste management in Malaysia. J. Clean. Prod. 2018, 172, 3415–3427. [Google Scholar] [CrossRef]

- Wijayasundara, M.; Mendis, P.; Crawford, R.H. Net incremental indirect external benefit of manufacturing recycled aggregate concrete. Waste Manag. 2018, 78, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Braga, A. Comparative Analysis of the Life Cycle Assessment of Conventional and Recycled Aggregate Concrete; Instituto Superior Tecnico—University of Lisbon: Lisbon, Portuguese, 2015. [Google Scholar]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of concrete prepared with crushed fine stone, furnace bottom ash and fine recycled aggregate as fine aggregates. Constr. Build. Mater. 2009, 23, 2877–2886. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Fan, C.C.; Huang, R.; Hwang, H.; Chao, S.J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Dapena, E.; Alaejos, P.; Lobet, A.; Pérez, D. Effect of Recycled Sand Content on Characteristics of Mortars and Concretes. J. Mater. Civ. Eng. 2011, 23, 414–422. [Google Scholar] [CrossRef]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr. Build. Mater. 2015, 81, 179–186. [Google Scholar] [CrossRef]

- Gholampour, A.; Zheng, J.; Ozbakkaloglu, T. Development of waste-based concretes containing foundry sand, recycled fine aggregate, ground granulated blast furnace slag and fly ash. Constr. Build. Mater. 2021, 267, 121004. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Constr. Build. Mater. 2021, 269, 121242. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. Comparison of alkali and silica sources in one-part alkali-activated blast furnace slag mortar. J. Clean. Prod. 2018, 187, 171–179. [Google Scholar] [CrossRef]

- Ashish, D.K. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J. Clean. Prod. 2018, 211, 716–729. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. Determination of optimum mixture design method for self-compacting concrete: Validation of method with experimental results. Constr. Build. Mater. 2019, 217, 664–678. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. Cementing Efficiency of Flash and Rotary-Calcined Metakaolin in Concrete. J. Mater. Civ. Eng. 2019, 31, 04019307. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Toutanji, H.; Delatte, N.; Aggoun, S.; Duval, R.; Danson, A. Effect of supplementary cementitious materials on the compressive strength and durability of short-term cured concrete. Cem. Concr. Res. 2004, 34, 311–319. [Google Scholar] [CrossRef] [Green Version]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Zaidi, K.A.; Ram, S.; Gautam, M.K. Utilisation of glass powder in high strength copper slag concrete. Adv. Concr. Constr. 2017, 5, 65–74. [Google Scholar] [CrossRef]

- Chen, G.; Lee, H.; Young, K.L.; Yue, P.L.; Wong, A.; Tao, T.; Choi, K.K. Glass recycling in cement production—An innovative approach. Waste Manag. 2002, 22, 747–753. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Çakir, O. Experimental analysis of properties of recycled coarse aggregate (RCA) concrete with mineral additives. Constr. Build. Mater. 2014, 68, 17–25. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of sustainable concrete using recycled coarse aggregate and ground granulated blast furnace slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N. Bond, durability and microstructural characteristics of ground granulated blast furnace slag based recycled aggregate concrete. Constr. Build. Mater. 2019, 212, 578–595. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, B. Hydration and Properties of Slag Cement Activated by Alkali and Sulfate. J. Mater. Civ. Eng. 2017, 29, 04017091. [Google Scholar] [CrossRef]

- Acharya, P.K.; Patro, S.K. Effect of lime and ferrochrome ash (FA) as partial replacement of cement on strength, ultrasonic pulse velocity and permeability of concrete. Constr. Build. Mater. 2015, 94, 448–457. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N. Production of sustainable concrete utilising high-volume blast furnace slag and recycled aggregate with lime activator. J. Clean. Prod. 2020, 255, 120188. [Google Scholar] [CrossRef]

- He, H.; Wang, Y.; Wang, J. Effects of aggregate micro fines (AMF), aluminum sulfate and polypropylene fiber (PPF) on properties of machine-made sand concrete. Appl. Sci. 2019, 9, 2250. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Che, Y. Recycling of aggregate micro fines as a partial replacement for fly ash in 3D printing cementitious materials. Constr. Build. Mater. 2022, 321, 126372. [Google Scholar] [CrossRef]

- Yuli, W.; Hang, H.; Xiaoxing, L. Influences of aggregate micro fines on the packing of fresh mortar and the performances of mortar. Compos. Part B Eng. 2019, 164, 493–498. [Google Scholar] [CrossRef]

- He, H.; Wang, Y.; Wang, J. Compactness and hardened properties of machine-made sand mortar with aggregate micro fines. Constr. Build. Mater. 2020, 250, 118828. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E. Upcycling waste seashells with cement: Rheology and early-age properties of Portland cement paste. Resour. Conserv. Recycl. 2020, 155, 104680. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 2019, 220, 235–252. [Google Scholar] [CrossRef]

- Uncik, S.; Kmecova, V. The effect of basalt powder on the properties of cement composites. Procedia Eng. 2013, 65, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Shahrour, N.; Allouzi, R. Shear behavior of captive- and short- column effects using different basalt aggregate contents. J. Build. Eng. 2020, 32, 101508. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; He, J.; Sun, M.; Yang, J.; Li, L. Combined use of silica fume and steel fibre to improve fracture properties of recycled aggregate concrete exposed to elevated temperature. J. Mater. Cycles Waste Manag. 2020, 22, 862–877. [Google Scholar] [CrossRef]

- Laibao, L.; Yunsheng, Z.; Wenhua, Z.; Zhiyong, L.; Lihua, Z. Investigating the influence of basalt as mineral admixture on hydration and microstructure formation mechanism of cement. Constr. Build. Mater. 2013, 48, 434–440. [Google Scholar] [CrossRef]

- Ponzi, G.G.D.; dos Santos, V.H.J.M.; Martel, R.B.; Pontin, D.; e Stepanha, A.S.d.G.; Schütz, M.K.; Menezes, S.C.; Einloft, S.M.O.; Vecchia, F.D. Basalt powder as a supplementary cementitious material in cement paste for CCS wells: Chemical and mechanical resistance of cement formulations for CO2 geological storage sites. Int. J. Greenh. Gas Control 2021, 109, 103337. [Google Scholar] [CrossRef]

- Saraya, M.E.S.I. Study physico-chemical properties of blended cements containing fixed amount of silica fume, blast furnace slag, basalt and limestone, a comparative study. Constr. Build. Mater. 2014, 72, 104–112. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Schindler, A.K.; Pichór, W. Mechanical properties and interfacial transition zone microstructure of concrete with waste basalt powder addition. Constr. Build. Mater. 2018, 177, 222–229. [Google Scholar] [CrossRef]

- Sharaky, I.; Issa, U.; Alwetaishi, M.; Abdelhafiz, A.; Shamseldin, A.; Al-Surf, M.; Al-Harthi, M.; Balabel, A. Strength and Water Absorption of Sustainable Concrete Produced with Recycled Basaltic Concrete Aggregates and Powder. Sustainability 2021, 13, 6277. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003.

- American Concrete Institute. ACI 211.1 Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete (ACI 211.1-91); American Concrete Institute: Farmington Hills, MI, USA, 2002. [Google Scholar]

- BS EN 12390-3:2009; Testing Hardened Concrete, Part 3: Compressive Strength of Test Specimens. British Standard Institution: London, UK, 2009.

- Ince, R. Determination of concrete fracture parameters based on peak-load method with diagonal split-tension cubes. Eng. Fract. Mech. 2012, 82, 100–114. [Google Scholar] [CrossRef]

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- BS 1881: Part 122: 1983; Testing Concrete-Method for Determination of Water Absorption. British Standard Institution: London, UK, 2009.

- Wang, H.L.; Wang, J.J.; Sun, X.Y.; Jin, W.L. Improving performance of recycled aggregate concrete with superfine pozzolanic powders. J. Cent. South Univ. 2013, 20, 3715–3722. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Evaluation of high-performance concrete with recycled aggregates: Use of densified silica fume as cement replacement. Constr. Build. Mater. 2017, 147, 803–814. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Gorjinia, A.; Shafigh, P.; Moghimi, M.; Bin, H. The role of 0–2 mm fine recycled concrete aggregate on the compressive and splitting tensile strengths of recycled concrete aggregate concrete. J. Mater. 2014, 64, 345–354. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem. Concr. Compos. 2016, 71, 97–109. [Google Scholar] [CrossRef] [Green Version]

- Karthikeyan, B.; Dhinakaran, G. Influence of ultrafine TiO2 and silica fume on performance of unreinforced and fiber reinforced concrete. Constr. Build. Mater. 2018, 161, 570–576. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2015, 19, 825–849. [Google Scholar] [CrossRef]

- Hasan-Nattaj, F.; Nematzadeh, M. The effect of forta-ferro and steel fibers on mechanical properties of high-strength concrete with and without silica fume and nano-silica. Constr. Build. Mater. 2017, 137, 557–572. [Google Scholar] [CrossRef]

- Sari, M.; Prat, E.; Labastire, J.F. High strength self-compacting concrete original solutions associating organic and inorganic admixtures. Cem. Concr. Res. 1999, 29, 813–818. [Google Scholar] [CrossRef]

- Lawrence, P.; Cyr, M.; Ringot, E. Mineral admixtures in mortars effect of type, amount and fineness of fine constituents on compressive strength. Cem. Concr. Res. 2005, 35, 1092–1105. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P.M. Strength and durability of concrete containing recycled concrete aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Tasong, W.; Cripps, J.; Lynsdale, C. Aggregate-cement chemical interactions. Cem. Concr. Res. 1998, 28, 1037–1048. [Google Scholar] [CrossRef]

- Goldman, A.; Bentur, A. Bond Effects in High-Strength Silica Fume Concretes. ACI Mater. J. 1989, 86, 440–447. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Mehta, P.K. Chemical and Physical Effects of Silica Fume on the Mechanical Behavior of Concrete. ACI Mater. J. 1989, 86, 609–614. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Liu, C.; Liu, L.; Tang, K. Study on microstructure and bond strength of interfacial transition zone between cement paste and high-performance lightweight aggregates prepared from ferrochromium slag. Constr. Build. Mater. 2017, 142, 31–41. [Google Scholar] [CrossRef]

- Kuroda, M.; Watanabe, T.; Terashi, N. Increase of bond strength at interfacial transition zone by the use of fly ash. Cem. Concr. Res. 2000, 30, 253–258. [Google Scholar] [CrossRef]

- Hu, J.; Stroeven, P. Properties of the interfacial transition zone in model concrete. Interface Sci. 2004, 12, 389–397. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

| Physical Properties | Crushed Basalt | Sand | RFCA | RFNA |

|---|---|---|---|---|

| Apparent specific gravity (kg/m3) | 2.85 | 2.63 | 2.64 | 2.83 |

| Bulk specific gravity (SSD) (gr/cm3) | 2.76 | 2.28 | 2.15 | 2.78 |

| Bulk specific gravity (GD), (gr/cm3) | 2.71 | 2.03 | 1.86 | 2.74 |

| Water absorption (%) | 1.77 | 10.96 | 13.82 | 13.83 |

| Moisture content (%) | 0.93 | 2.73 | 2.37 | 2.22 |

| Item | OPC * | RCP | AMF | SF * |

|---|---|---|---|---|

| SiO2 | 21.28 | 66.23 | 60.42 | 90.2 |

| CaO | 64.64 | - | 4.59 | - |

| AL2O3 | 5.60 | 9.61 | 15.57 | 1.2 |

| Fe2O3 | 3.42 | 11.84 | 14.60 | 1.8 |

| MgO | 2.06 | 12.32 | 4.83 | 6.2 |

| SO3 | 2.12 | - | - | - |

| L.O.I | 0.88 | - | - | 0.6 |

| Group | Mix ID | RCA (%) | SF (%) | RCP (%) | AMF (%) | Aggregates (kg) | Water (kg) | Add. Water (kg) | Cement (kg) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sand | Basalt | RFCA or RFNA | |||||||||

| Control | M0 | 0 | 0 | 0 | 0 | 692 | 1094 | 0 | 215 | 0 | 430 |

| Recycled concrete wastes | |||||||||||

| RFCA | M1 | 20 | 0 | 0 | 0 | 553.6 | 1094 | 138.0 | 215 | 4.1 | 430 |

| M2 | 40 | 0 | 0 | 0 | 415.2 | 1094 | 275.8 | 215 | 8.3 | 430 | |

| M3 | 60 | 0 | 0 | 0 | 276.8 | 1094 | 413.6 | 215 | 12.4 | 430 | |

| M4 | 80 | 0 | 0 | 0 | 138.4 | 1094 | 551.5 | 215 | 16.6 | 430 | |

| RCP | M5 | 0 | 0 | 5 | 0 | 692 | 1094 | 0 | 215 | 0 | 409 |

| M6 | 0 | 0 | 10 | 0 | 692 | 1094 | 0 | 215 | 0 | 387 | |

| M7 | 0 | 0 | 20 | 0 | 692 | 1094 | 0 | 215 | 0 | 344 | |

| Recycled natural basalt wastes | |||||||||||

| RFNA | M8 | 20 | 0 | 0 | 0 | 553.6 | 1094 | 128.6 | 215 | 4.3 | 430 |

| M9 | 40 | 0 | 0 | 0 | 415.2 | 1094 | 257.2 | 215 | 8.7 | 430 | |

| M10 | 60 | 0 | 0 | 0 | 276.8 | 1094 | 385.8 | 215 | 13.0 | 430 | |

| M11 | 80 | 0 | 0 | 0 | 138.4 | 1094 | 514.4 | 215 | 17.4 | 430 | |

| AMF | M12 | 0 | 0 | 0 | 5 | 692 | 1094 | 0 | 215 | 0 | 409 |

| M13 | 0 | 0 | 0 | 10 | 692 | 1094 | 0 | 215 | 0 | 387 | |

| M14 | 0 | 0 | 0 | 20 | 692 | 1094 | 0 | 215 | 0 | 344 | |

| Industrial wastes | |||||||||||

| SF | M15 | 0 | 5 | 0 | 0.5 | 692 | 1094 | 0 | 215 | 0 | 409 |

| M16 | 0 | 10 | 0 | 0.5 | 692 | 1094 | 0 | 215 | 0 | 387 | |

| M17 | 0 | 20 | 0 | 0.5 | 692 | 1094 | 0 | 215 | 0 | 344 | |

| Group | Mix ID | Specimen No. | fcu,7 MPa | Mean (σµ) MPa | µ7 % | fcu,28 MPa | Mean (σµ) MPa | µ28 % | fcu,56 MPa | Mean (σµ) MPa | µ56 % | µ28/7 % | µ56/28 % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | M0 | 1 | 35.6 | 34.1 (±1.34) | 0.0 | 43.5 | 43.6 (±0.10) | 0.0 | 52.5 | 50.0 (±2.72) | 0.0 | 28.0 | 14.7 |

| 2 | 33.1 | 43.7 | 50.5 | ||||||||||

| 3 | 33.5 | 43.6 | 47.1 | ||||||||||

| Recycled concrete wastes | |||||||||||||

| RFCA | M1 | 1 | 30.6 | 29.8 (±0.80) | 12.5 | 40.54 | 39.8 (±1.22) | 8.7 | 42.8 | 44.5 (±0.00) | 11.0 | 33.6 | 11.8 |

| 2 | 29.0 | 40.50 | 45.5 | ||||||||||

| 3 | 29.8 | 38.40 | 45.2 | ||||||||||

| M2 | 1 | 29.8 | 29.0 (±0.80) | 14.8 | 39.63 | 39.5 (±0.21) | 9.4 | 47.9 | 49.8 (±0.00) | 0.50 | 36.1 | 26.0 | |

| 2 | 28.2 | 39.61 | 54.7 | ||||||||||

| 3 | 29.0 | 39.26 | 46.5 | ||||||||||

| M3 | 1 | 32.5 | 33.7 (±1.20) | 1.0 | 40.64 | 41.6 (±2.46) | 4.6 | 46.5 | 45.3 (±1.28) | 9.50 | 23.3 | 8.8 | |

| 2 | 34.9 | 44.40 | 43.9 | ||||||||||

| 3 | 33.8 | 39.77 | 45.3 | ||||||||||

| M4 | 1 | 32.4 | 32.3 (±0.10) | 5.2 | 39.98 | 40.1 (±0.57) | 8.1 | 45.7 | 45.0 (±1.32) | 10.0 | 24.1 | 12.4 | |

| 2 | 32.3 | 40.70 | 43.5 | ||||||||||

| 3 | 32.2 | 39.58 | 45.9 | ||||||||||

| M5 | 1 | 32.02 | 32.0 (±0.06) | 6.0 | 38.73 | 38.8 (±0.50) | 11.0 | 44.6 | 44.8 (±0.55) | 10.4 | 21.2 | 8.7 | |

| 2 | 31.95 | 39.33 | 45.4 | ||||||||||

| 3 | 32.07 | 38.34 | 44.4 | ||||||||||

| RCP | M6 | 1 | 22.34 | 22.9 (±0.84) | 32.7 | 43.39 | 43.3 (±0.32) | 0.70 | 46.9 | 47.6 (±0.67) | 4.8 | 88.8 | 11.1 |

| 2 | 23.90 | 43.57 | 48.2 | ||||||||||

| 3 | 22.56 | 42.94 | 47.7 | ||||||||||

| M7 | 1 | 22.89 | 21.6 (±1.24) | 36.7 | 39.70 | 38.3 (±2.32) | 12.2 | 41.2 | 42.4 (±1.07) | 15.2 | 77.4 | 11.4 | |

| 2 | 20.42 | 39.52 | 43.0 | ||||||||||

| 3 | 21.41 | 35.59 | 43.0 | ||||||||||

| Natural aggregate wastes | |||||||||||||

| RFNA | M8 | 1 | 29.0 | 28.8 (±4.79) | 15.5 | 39.4 40.8 40.1 | 40.1 (±0.73) | 8.0 | 45.7 | 45.5 (±0.67) | 9.0 | 39.3 | 14.3 |

| 2 | 28.6 | 44.8 | |||||||||||

| 3 | 20.5 | 46.1 | |||||||||||

| M9 | 1 | 21.5 | 21.4 (±0.60) | 37.1 | 39.5 | 39.3 (±1.54) | 9.9 | 43.3 | 43.3 (±0.34) | 13.5 | 83.3 | 13.2 | |

| 2 | 20.8 | 37.7 | 43.6 | ||||||||||

| 3 | 22.0 | 40.7 | 42.9 | ||||||||||

| M10 | 1 | 32.9 | 29.6 (±3.46) | 13.1 | 40.8 | 41.2 (±0.38) | 5.5 | 47.3 | 46.5 (±1.12) | 7.1 | 39.2 | 11.9 | |

| 2 | 31.2 | 41.6 | 45.2 | ||||||||||

| 3 | 26.3 | 41.2 | 46.9 | ||||||||||

| M11 | 1 | 26.0 | 26.8 (±0.78) | 21.3 | 39.3 | 38.9 (±0.12) | 10.8 | 45.1 | 46.7 (±1.47) | 6.7 | 45.2 | 19.8 | |

| 2 | 26.9 | 39.3 | 48.0 | ||||||||||

| 3 | 27.5 | 39.1 | 46.9 | ||||||||||

| AMF | M16 | 1 | 35.36 | 31.82 (±4.88) | 6.6 | 39.46 | 39.11 (±0.55) | 10.3 | 42.87 | 43.98 (±0.97) | 12.1 | 22.91 | 11.2 |

| 2 | 25.60 | 39.40 | 44.71 | ||||||||||

| 3 | 30.50 | 38.48 | 44.35 | ||||||||||

| M17 | 1 | 26.70 | 26.50 (±1.21) | 22.2 | 38.85 | 38.75 (±0.52) | 11.5 | 48.70 | 46.47 (±2.25) | 7.1 | 46.23 | 12.2 | |

| 2 | 27.60 | 38.23 | 44.21 | ||||||||||

| 3 | 25.20 | 38.64 | 46.50 | ||||||||||

| M18 | 1 | 15.93 | 17.45 (±2.13) | 58.5 | 32.89 | 28.54 (±0.94) | 34.3 | 36.35 | 36.45 (±0.51) | 27.1 | 63.55 | 12.8 | |

| 2 | 16.54 | 31.11 | 36.00 | ||||||||||

| 3 | 19.88 | 31.48 | 37.00 | ||||||||||

| Industrial wastes | |||||||||||||

| SF | M19 | 1 | 27.78 | 27.67 (±0.32) | 18.8 | 37.70 | 37.66 (±0.14) | 13.6 | 45.00 | 45.27 (±1.42) | 9.5 | 73.5 | 20.2 |

| 2 | 27.31 | 37.50 | 44.00 | ||||||||||

| 3 | 27.92 | 37.78 | 46.80 | ||||||||||

| M20 | 1 | 26.58 | 26.54 (±0.28) | 22.1 | 36.81 | 36.96 (±1.86) | 15.2 | 47.70 | 47.17 (±0.50) | 5.7 | 71.8 | 27.6 | |

| 2 | 26.24 | 38.89 | 46.70 | ||||||||||

| 3 | 26.80 | 35.19 | 47.10 | ||||||||||

| M21 | 1 | 18.60 | 18.20 (±0.53) | 46.6 | 35.79 | 37.48 (±0.1.81) | 42.00 | 43.77 (±1.59) | 12.5 | 48.6 | 16.8 | ||

| 2 | 17.60 | 37.26 | 14.0 | 44.20 | |||||||||

| 3 | 18.40 | 39.39 | 45.10 | ||||||||||

| Group | Mix ID | Specimen No. | ftu,28 MPa | Mean (σµ) MPa | µt28 % | ftu,56 MPa | Mean (σµ) MPa | µt56 % | µt56/28 % | ftu,28/fcu,28 % | ftu,56/fcu,56 % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | M0 | 1 | 3.48 | 3.52 (±0.05) | 0.00 | 3.92 | 3.89 (±0.03) | 0.00 | 10.45 | 8.08 | 7.78 |

| 2 | 3.58 | 3.88 | |||||||||

| 3 | 3.51 | 3.87 | |||||||||

| Recycled concrete wastes | |||||||||||

| FRCA | M5 | 1 | 3.66 | 3.44 (±0.20) | −2.24 | 4.00 | 3.85 (±0.13) | 0.26 | 13.27 | 8.65 | 8.76 |

| 2 | 3.29 | 3.78 | |||||||||

| 3 | 3.38 | 3.78 | |||||||||

| M6 | 1 | 3.27 | 3.42 (±0.20) | −2.88 | 3.87 | 4.05 (±0.18) | 5.40 | 19.78 | 8.67 | 8.24 | |

| 2 | 3.34 | 4.24 | |||||||||

| 3 | 3.65 | 4.05 | |||||||||

| M7 | 1 | 3.67 | 3.66 (±0.04) | 3.87 | 4.25 | 4.06 (±0.17) | 5.40 | 12.08 | 8.79 | 9.06 | |

| 2 | 3.61 | 3.96 | |||||||||

| 3 | 3.70 | 3.96 | |||||||||

| M8 | 1 | 3.21 | 3.63 (±0.36) | 3.05 | 4.20 | 4.01 (±0.17) | 3.09 | 10.49 | 9.05 | 8.90 | |

| 2 | 3.95 | 3.86 | |||||||||

| 3 | 3.73 | 3.96 | |||||||||

| RCP | M9 | 1 | 3.88 | 3.76 (±0.11) | 6.81 | 4.02 | 4.01 (±0.03) | 3.09 | 6.68 | 9.69 | 8.95 |

| 2 | 3.66 | 3.99 | |||||||||

| 3 | 3.74 | 4.03 | |||||||||

| M10 | 1 | 3.90 | 3.76 (±0.16) | 6.81 | 3.88 | 3.90 (±0.07) | 0.26 | 3.72 | 8.68 | 8.19 | |

| 2 | 3.58 | 3.97 | |||||||||

| 3 | 3.79 | 3.83 | |||||||||

| M11 | 1 | 3.24 | 3.42 (±0.16) | −2.92 | 3.87 | 3.81 (±0.09) | −2.05 | 11.44 | 8.93 | 8.98 | |

| 2 | 3.47 | 3.85 | |||||||||

| 3 | 3.54 | 3.70 | |||||||||

| Natural aggregate wastes | |||||||||||

| FRNA | M12 | 1 | 3.54 | 3.54 (±0.04) | 0.40 | 4.13 | 4.04 (±0.08) | 3.86 | 14.3 | 8.82 | 8.87 |

| 2 | 3.57 | 3.97 | |||||||||

| 3 | 3.50 | 4.03 | |||||||||

| M13 | 1 | 3.88 | 3.50 (±0.31) | −0.68 | 4.05 | 3.96 (±0.08) | 1.80 | 13.2 | 8.90 | 9.15 | |

| 2 | 3.25 | 3.93 | |||||||||

| 3 | 3.56 | 3.90 | |||||||||

| M14 | 1 | 4.28 | 4.07 (±0.19) | 15.50 | 4.07 | 4.14 (±0.11) | 6.43 | 1.80 | 9.88 | 8.91 | |

| 2 | 4.00 | 4.26 | |||||||||

| 3 | 3.92 | 4.08 | |||||||||

| M15 | 1 | 3.77 | 3.81 (±0.10) | 8.11 | 4.62 | 4.56 (±0.07) | 17.23 | 19.8 | 9.79 | 9.77 | |

| 2 | 3.73 | 4.47 | |||||||||

| 3 | 3.92 | 4.58 | |||||||||

| RNP | M16 | 1 | 3.50 | 3.50 (±0.04) | −0.56 | 3.61 | 3.72 (±0.36) | −4.37 | 6.30 | 8.95 | 8.46 |

| 2 | 3.46 | 3.43 | |||||||||

| 3 | 3.53 | 4.11 | |||||||||

| M17 | 1 | 3.35 | 3.40 (±0.04) | −3.50 | 3.48 | 3.61 (±0.12) | −7.19 | 6.20 | 8.77 | 7.77 | |

| 2 | 3.40 | 3.72 | |||||||||

| 3 | 3.44 | 3.62 | |||||||||

| M18 | 1 | 3.98 | 3.35 (±0.59) | −4.80 | 3.34 | 3.53 (±0.19) | −9.25 | 5.40 | 11.74 | 9.68 | |

| 2 | 2.81 | 3.71 | |||||||||

| 3 | 3.27 | 3.53 | |||||||||

| Industrial wastes | |||||||||||

| SF | M19 | 1 | 3.52 | 3.52 (±0.01) | 3.86 | 3.84 (±0.03) | |||||

| 2 | 3.53 | 0.00 | 3.81 | −1.3 | 8.90 | 9.35 | 8.48 | ||||

| 3 | 3.53 | 3.85 | |||||||||

| M20 | 1 | 3.31 | 3.41 (±0.09) | 4.00 | 4.00 (±0.03) | ||||||

| 2 | 3.49 | −3.30 | 3.98 | 2.9 | 17.5 | 9.23 | 8.48 | ||||

| 3 | 3.42 | 4.03 | |||||||||

| M21 | 1 | 3.35 | 3.61 | 3.70 (±0.32) | |||||||

| 2 | 3.59 | 3.46 (±0.12) | −1.90 | 3.43 | −5.0 | 7.00 | 9.23 | 8.45 | |||

| 3 | 3.43 | 4.05 | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharaky, I.A.; Elamary, A.S.; Alharthi, Y.M. Effect of Waste Basalt Fines and Recycled Concrete Components on Mechanical, Water Absorption, and Microstructure Characteristics of Concrete. Materials 2022, 15, 4385. https://doi.org/10.3390/ma15134385

Sharaky IA, Elamary AS, Alharthi YM. Effect of Waste Basalt Fines and Recycled Concrete Components on Mechanical, Water Absorption, and Microstructure Characteristics of Concrete. Materials. 2022; 15(13):4385. https://doi.org/10.3390/ma15134385

Chicago/Turabian StyleSharaky, Ibrahim A., Ahmed S. Elamary, and Yasir M. Alharthi. 2022. "Effect of Waste Basalt Fines and Recycled Concrete Components on Mechanical, Water Absorption, and Microstructure Characteristics of Concrete" Materials 15, no. 13: 4385. https://doi.org/10.3390/ma15134385

APA StyleSharaky, I. A., Elamary, A. S., & Alharthi, Y. M. (2022). Effect of Waste Basalt Fines and Recycled Concrete Components on Mechanical, Water Absorption, and Microstructure Characteristics of Concrete. Materials, 15(13), 4385. https://doi.org/10.3390/ma15134385