Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material

Abstract

:1. Introduction

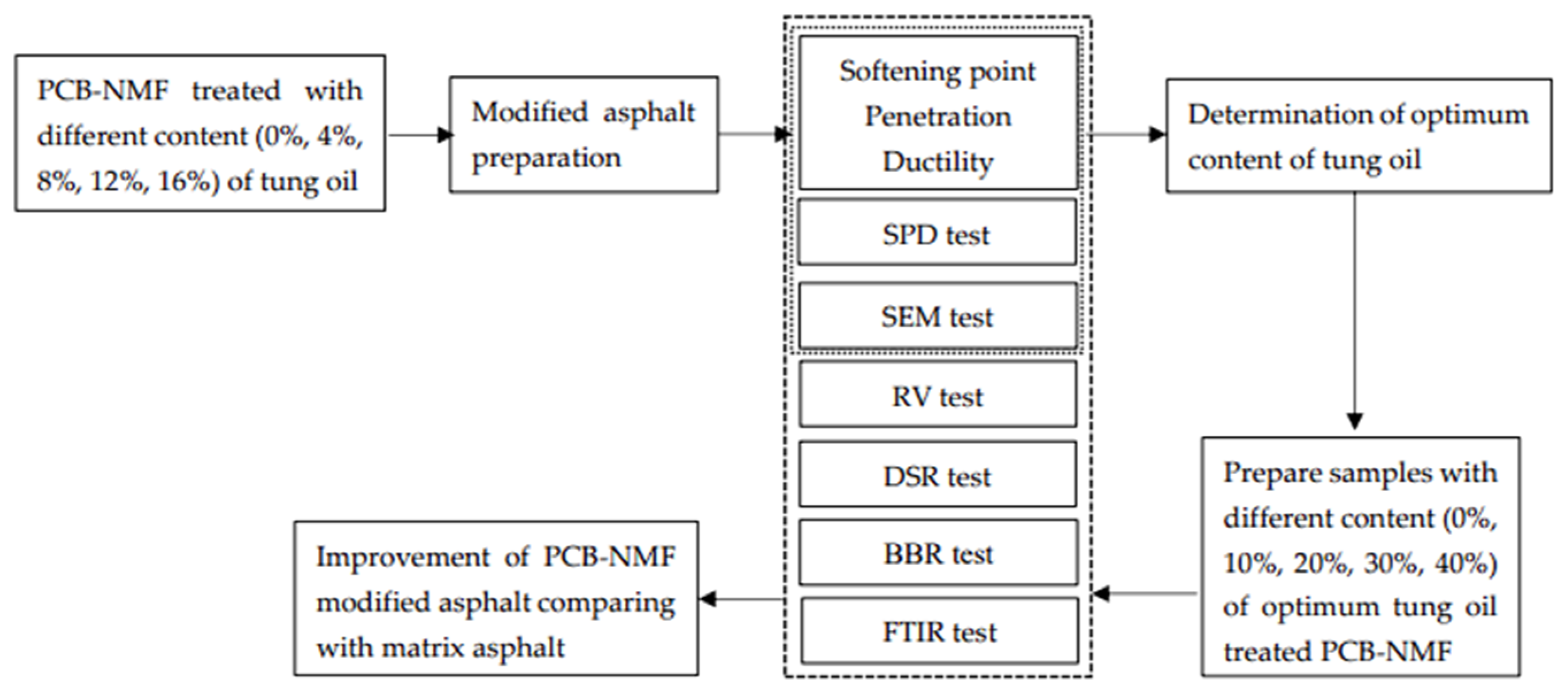

2. Materials and Methodologies

2.1. Materials

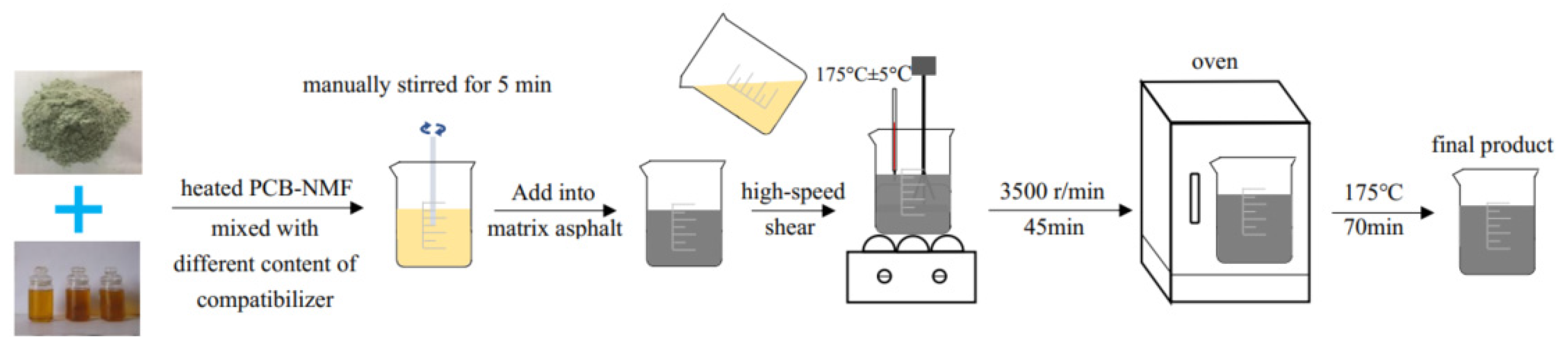

2.2. Preparation Process of NMF-Modified Asphalt

2.3. Test Methods

3. Results and Discussions

3.1. Compatibilizer Content Affection Analysis

3.1.1. Determination of Optimum Compatibilizer Content

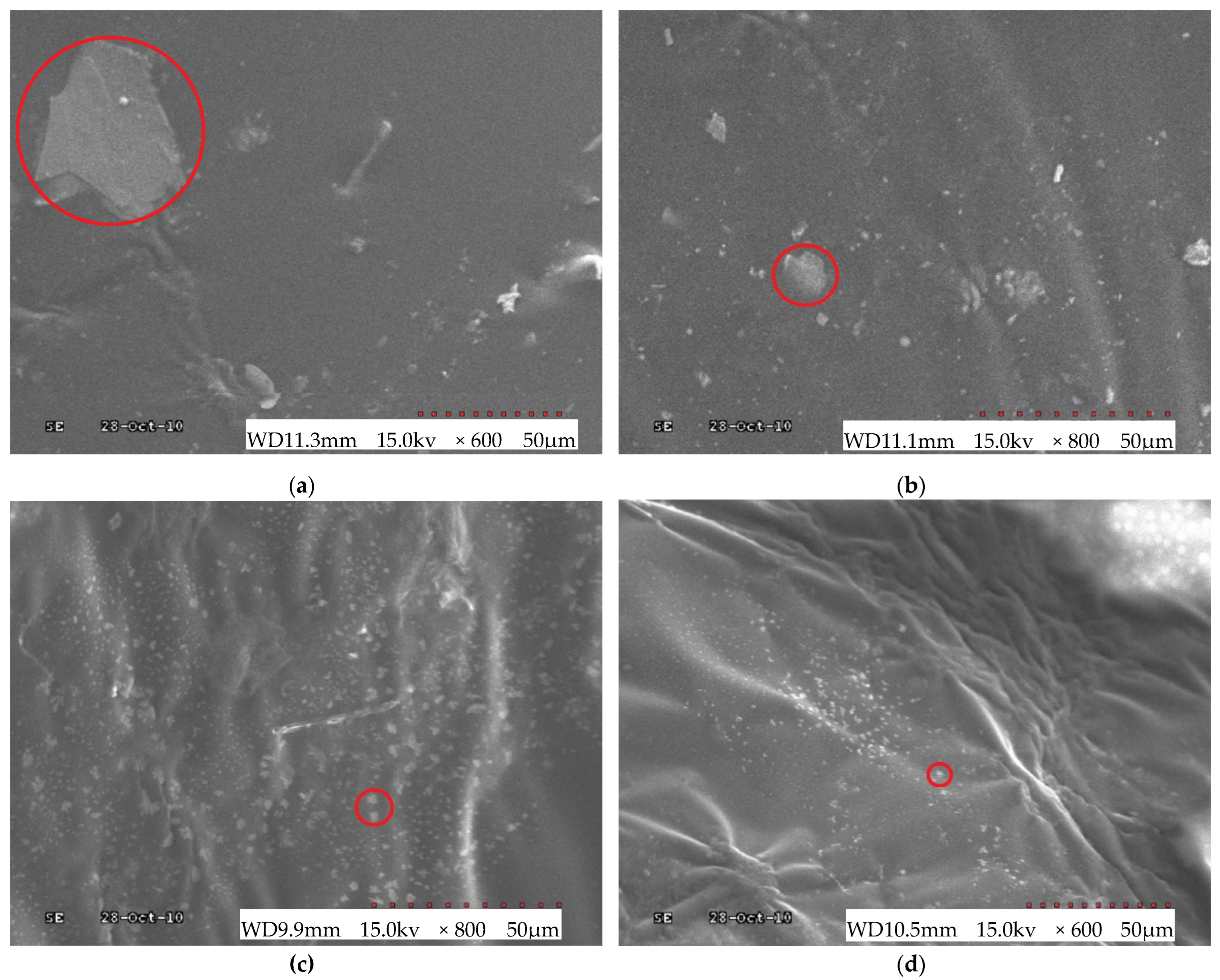

3.1.2. SEM Analysis

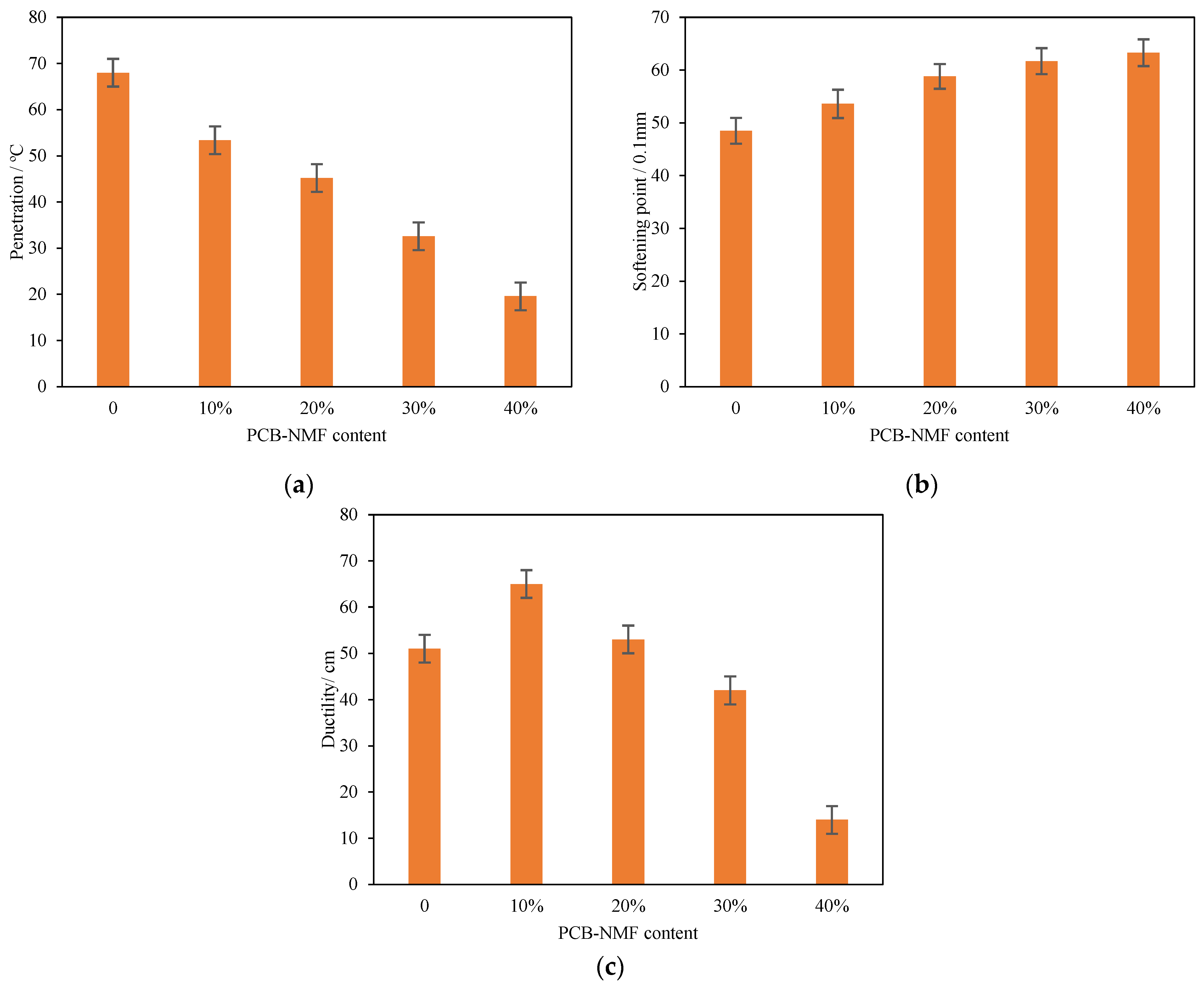

3.2. Basic Properties Analysis

3.3. Storage Stabilities

3.4. Rheology Analysis

3.5. Low-Temperature Performance

3.6. FTIR Analysis

4. Conclusions

- (1)

- A compatibilizer consisting of tung oil and glycerin can help disperse the PCB-NMF powder particles in asphalt materials, improving the compatibility of PCB-NMF powder and asphalt. The optimum compatibilizer content is determined as 8% by the weight of PCB-NMF.

- (2)

- Through a series of tests, it was found that the addition of PCB-NMF can increase the dynamic modulus, viscosity, and softening point. The appropriate content of PCB-NMF significantly improves the stiffness, rutting resistance, and temperature sensitivity of asphalt materials.

- (3)

- By comprehensively checking the effects of PCB-NMF powder on penetration, softening point, ductility viscosity, and dynamic shear properties of modified asphalt, the optimum content of PCB-NMF is determined as 30% by the weight of the asphalt.

- (4)

- The BBR test demonstrates that PCB-NMF increases the creep stiffness and decreases the m-value of the binder. Although the asphalt modified with 30% PCB-NMF meets the low-temperature criterion at −12 °C, the low-temperature performance is weakened.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, Y.; Wu, Y.; Xu, M.; Mu, X.; Zuo, T. Waste electrical and electronic equipment (WEEE) recycling for a sustainable resource supply in the electronics industry in China. J. Clean. Prod. 2016, 127, 331–338. [Google Scholar] [CrossRef]

- The Global E-Waste Monitor 2020: Quantities, Flows, and the Circular Economy Potential. Available online: https://globalewaste.org (accessed on 15 September 2020).

- Li, J.; Shrivastava, P.; Gao, Z.; Zhang, H. Printed circuit board recycling: A state-of-the-art survey. IEEE Trans. Electron. Packag. Manuf. 2004, 27, 33–42. [Google Scholar]

- Silvia, A.; Marina, C.C.; Manuel, B.; Martinez, F.O. Green pavements: Reuse of plastic waste in asphalt mixtures. Mater. Struct. 2015, 49, 1655–1665. [Google Scholar]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Lakusic, S. Use of e-plastic waste in bituminous pavements. J. Croat. Assoc. Civ. Eng. 2018, 70, 607–615. [Google Scholar] [CrossRef]

- Hayat, U.; Rahim, A.; Khan, A.H.; Rehman, Z.U. Use of Plastic Wastes and Reclaimed Asphalt for Sustainable Development. Balt. J. Road Bridge Eng. 2020, 15, 182–196. [Google Scholar] [CrossRef]

- De Almeida Júnior, A.F.; Battistelle, R.A.; Bezerra, B.S.; De Castro, R. Use of scrap tire rubber in place of SBS in modified asphalt as an environmentally correct alternative for Brazil. J. Clean. Prod. 2012, 33, 236–238. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Arinina, M.P.; Mamulat, Y.S.; Malkin, A.Y.; Kulichikhin, V.G. Rheological properties of road bitumens modified with polymer and solid nanosized additives. Colloid J. 2014, 76, 425–434. [Google Scholar] [CrossRef]

- Lv, S.; Xia, C.; Yang, Q.; Guo, S.; You, L.; Guo, Y.; Zheng, J. Improvements on high-temperature stability, rheology, and stiffness of asphalt binder modified with waste crayfish shell powder. J. Clean. Prod. 2020, 264, 121745. [Google Scholar] [CrossRef]

- Li, S.; Huang, Y.; Liu, Z.H. Experimental evaluation of asphalt material for interlayer in rigid–flexible composite pavement. Constr. Build. Mater. 2016, 102, 699–705. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I. Potential application of E-wastes in construction industry: A review. Constr. Build. Mater. 2019, 203, 222–240. [Google Scholar] [CrossRef]

- Colbert, B.W.; You, Z. Properties of Modified Asphalt Binders Blended with Electronic Waste Powders. J. Mater. Civ. Eng. 2012, 24, 1261–1267. [Google Scholar] [CrossRef]

- Mohd Hasan, M.R.; Colbert, B.; You, Z.; Jamshidi, A.; Heiden, P.A.; Hamzah, M.O. A simple treatment of electronic-waste plastics to produce asphalt binder additives with improved properties. Constr. Build. Mater. 2016, 110, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Shahane, H.A.; Bhosale, S.S. E-Waste plastic powder modified bitumen: Rheological properties and performance study of bituminous concrete. Road Mater. Pavement Des. 2019, 22, 682–702. [Google Scholar] [CrossRef]

- Ban, B.; Song, J.; Lim, J.; Wang, S.; An, K.; Kim, D. Studies on the reuse of waste printed circuit board as an additive for cement mortar. J. Environ. Sci. Health Part A Toxic/Hazard. Subst. Environ. Eng. 2005, 40, 645–656. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Che, J.; Liu, S.; Chen, Q. Investigation on compatibility and microstructure of PCBs-modified asphalt. J. Appl. Polym. Sci. 2017, 134, 44798. [Google Scholar] [CrossRef]

- Guo, J.; Guo, J.; Wang, S.; Xu, Z. Asphalt Modified with Nonmetals Separated from Pulverized Waste Printed Circuit Boards. Environ. Sci. Technol. 2009, 43, 503–508. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Sun, S.; Zhong, S.; Li, S.; Yi, W.; Wu, J. Performance of the heavy fraction of pyrolysis oil derived from waste printed circuit boards in modifying asphalt. J. Environ. Manag. 2013, 126, 1–6. [Google Scholar] [CrossRef]

- Yu, X.; Dong, F.; Liang, X.; Ji, Z. Rheological Properties and Microstructure of Printed Circuit Boards Modified Asphalt. China Pet. Process. Petrochem. Technol. 2017, 19, 72–80. [Google Scholar]

- Meng, Y.; Liao, Y.; Liu, Z.; Jing, C.; Yang, X.; Rong, H. Study on Rheological Properties of Bituminous Binders and Mixtures Containing Waste Printed Circuit Boards (PCBs) and SBR Compound Modified Bitumen. Materials 2021, 14, 1697. [Google Scholar] [CrossRef]

- Ghasemi, M.; Marandi, S.M. Performance improvement of a crumb rubber modified bitumen using recycled glass powder. J. Zhejiang Univ. Sci. A 2013, 14, 805–814. [Google Scholar] [CrossRef] [Green Version]

- Androjić, I.; Dimter, S. Properties of hot mix asphalt with substituted waste glass. Mater. Struct. 2014, 49, 249–259. [Google Scholar] [CrossRef]

- Jin, D.; Wang, J.; You, L.; Ge, D.; Liu, C.; Liu, H.; You, Z. Waste cathode-ray-tube glass powder modified asphalt materials: Preparation and characterization. J. Clean. Prod. 2021, 314, 127949. [Google Scholar] [CrossRef]

- Nie, X.; Li, Z.; Yao, H.; Hou, T.; Zhou, X.; Li, C. Waste bio-oil as a compatibilizer for high content SBS modified asphalt. Pet. Sci. Technol. 2019, 38, 316–322. [Google Scholar] [CrossRef]

- Wang, Q.; Ye, Q.; Luo, J.; Xie, C.; Liu, H.; Liu, J.; Qin, M. Effects of Tung Oil Composite Regenerating Agent on Rheological Properties and Microstructures of Reclaimed Asphalt Binder. Materials 2022, 15, 3197. [Google Scholar] [CrossRef]

- JTG E20-2011. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. 2011. Available online: https://www.codeofchina.com/search/default.html?page=1&keyword=JTGE20-2011 (accessed on 1 June 2022).

- Yan, Y.; Xiao, X.; Liu, W.; Zhang, D. Properties of Organic Montmorillonite /Epoxy Resin Composite Modified Asphalt. Polym. Mater. Sci. Eng. 2015, 31, 52–56. [Google Scholar]

- Ilyin, S.O.; Strelets, L.A. Basic Fundamentals of Petroleum Rheology and Their Application for the Investigation of Crude Oils of Different Natures. Energy Fuels 2018, 32, 268–278. [Google Scholar] [CrossRef]

| Test Indicators | Unit | Technical Requirements | Test Result |

|---|---|---|---|

| Penetration 25 °C, 100 g, 5 s | 0.1 mm | 60~70 | 68 |

| Softening point | °C | ≥47 | 48.5 |

| Ductility 10 °C, 5 cm/min | cm | ≥20 | 51 |

| Residual material loss after RTFOT * | % | ≤±0.8 | 0.1 |

| Penetration ratio of residue after RTFOT * (25 °C) | % | ≥61 | 70.0 |

| Test Indicators | Test Result |

|---|---|

| Exterior | Brown–yellow liquid |

| Odor | Odor of tung oil |

| Transparency (24 h/20 °C) | A small amount of precipitation |

| Relative density (20 °C) | 0.9360–0.9395 |

| Refractive index (20 °C) | 1.5170–1.5220 |

| Iodine number | 163–173 |

| Saponification number | 190–195 |

| Drying time | 3–7 days in summer, 3–20 days in winter |

| Acid value (mgKOH/g) | <7 |

| Moisture and volatile matter content | <0.20% |

| Impurity | <0.20% |

| β-tung oil test (3.3 °C–4.4 °C for 24 h) | No crystallization |

| PCB-NMF percentage (%) | 0 | 10 | 20 | 30 | 40 |

| SPD (°C) | 0 | 0.8 | 1.4 | 1.9 | 2.4 |

| Item | Result | Requirement | |

|---|---|---|---|

| Matrix asphalt | Dynamic cut 64 °C, G*/sinδ, kPa | 1.07 | ≥1.0 |

| Dynamic cut 70 °C, G*/sinδ, kPa | 0.50 | ||

| 30% NMF powder modified asphalt | Dynamic cut 70 °C, G*/sinδ, kPa | 1.08 | |

| Dynamic cut 76 °C, G*/sinδ, kPa | 0.58 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Sun, Y.; Fang, S.; Huang, Y.; Yu, H.; Ye, J. Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material. Materials 2022, 15, 4172. https://doi.org/10.3390/ma15124172

Li S, Sun Y, Fang S, Huang Y, Yu H, Ye J. Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material. Materials. 2022; 15(12):4172. https://doi.org/10.3390/ma15124172

Chicago/Turabian StyleLi, Sheng, Yu Sun, Shuo Fang, You Huang, Huanan Yu, and Ji Ye. 2022. "Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material" Materials 15, no. 12: 4172. https://doi.org/10.3390/ma15124172

APA StyleLi, S., Sun, Y., Fang, S., Huang, Y., Yu, H., & Ye, J. (2022). Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material. Materials, 15(12), 4172. https://doi.org/10.3390/ma15124172