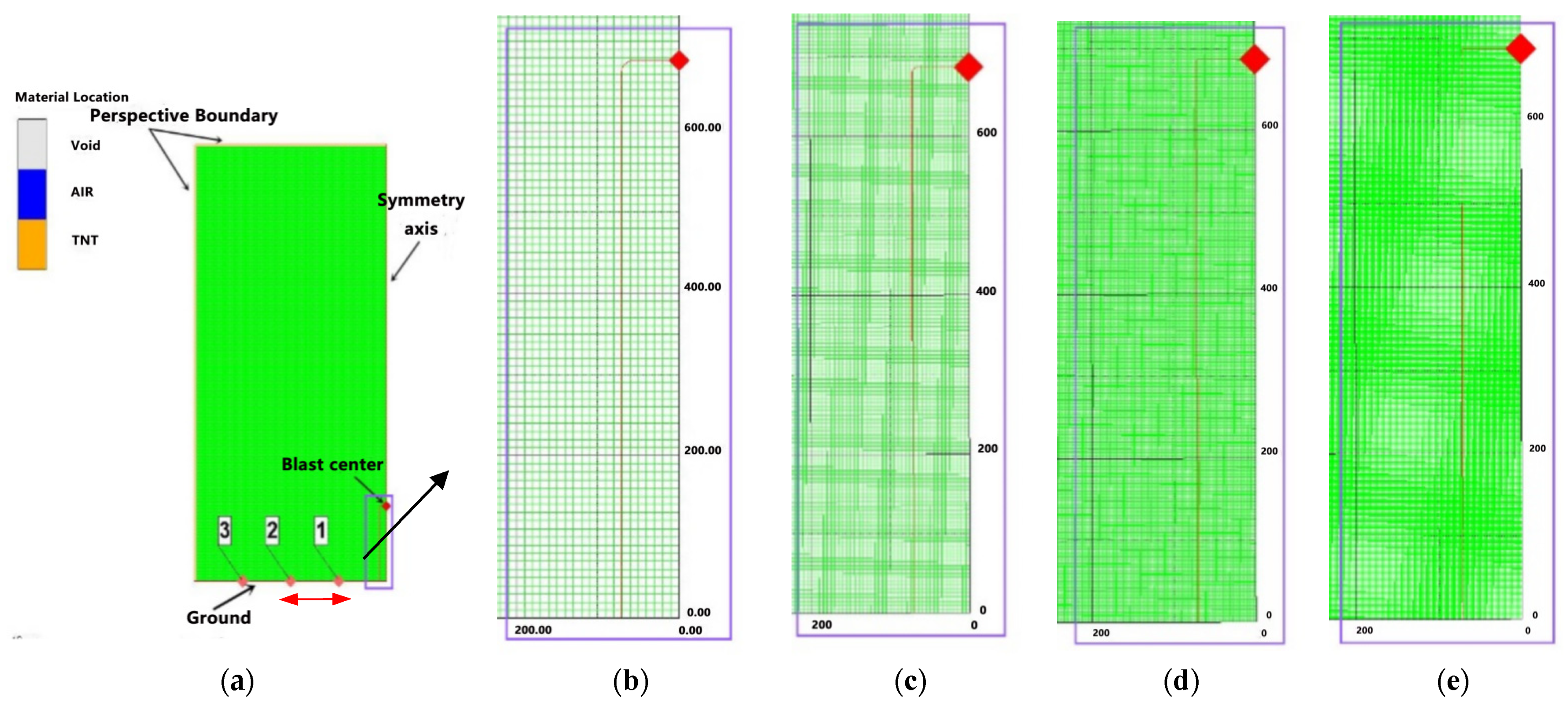

4.1.1. Finite Element Model

The test object was a single entrance/exit protective sealing door ZCFM1220(5) of civil air resistance level 5, and a size of 1.4 × 2.08 m. The door was composed of a skeleton, internal and external panels, a lock head, a reducer, a screw or sleeve combined drive device, a sealing beam, filling blocks, and sealing strips. The door material was ordinary carbon steel Q235A, and the door skeleton profile was HW100 section steel. The skeleton was surrounded by a complete circle of H-beam. The transverse arrangement length of the main beam was 1200 mm (equal to the net width of the door opening). The secondary beam was segmented and fixed with the main beam and the side frame and the panel by 4.8 grade M10 × 1.5 high strength bolts, and the panel was made of 8 mm thick ordinary hot-rolled steel plate. There were 4 Φ40 lock heads distributed on the inner surface of the door, made of 45# steel, one set on the left and one set on the right, which were driven by the reducer and the combination of screw and sleeve through the connecting plate. The sealing beam at the threshold was composed of L50 × 32 angles with adhesive strips inside. The driving mechanism was similar to that of the lock head, and the extrusion force in the direction of the door sash was reversely borne by three convex handles fixed on the inner surface of the door sash. The sealing joints at the corners on both sides were arranged on the door frame, and the trapezoidal frame was filled with sealing blocks. The Ω rubber strip was set on the circumference of the inner surface of the door (except the bottom). The pressure strip plate was an ordinary 8 mm thick steel plate, and the pressure bolt was an ordinary bolt M6 × 1, tapped through the panel and profile flange with a spacing of 250 mm. The door frame adopted an L125 equilateral angle, split design, and the corner end was connected with an L160 equilateral angle, bolt sub, and positioning pin assembly, and the screw anchor bolts were used to replace the welded anchor hooks. Compared with the common protective door, the structure and connection mode of each component of the test door is more complex.

To facilitate the analysis, the components and connection modes of the test door were simplified in the finite element modeling. Specifically, the dynamic responses of the main stressed components were considered, including the skeleton, panels, and screw or sleeve combined drive device, while the reducer, sealing strips, and sealing beams were ignored. The connection mode of using high-strength bolts between the main beam and the secondary beam or the skeleton was simplified to a consolidation connection at the components. The connection mode of using high-strength bolts between the skeleton and the panels was simplified to a consolidation connection at the bolts. The circular bolt hole with threads was simplified as a square hole.

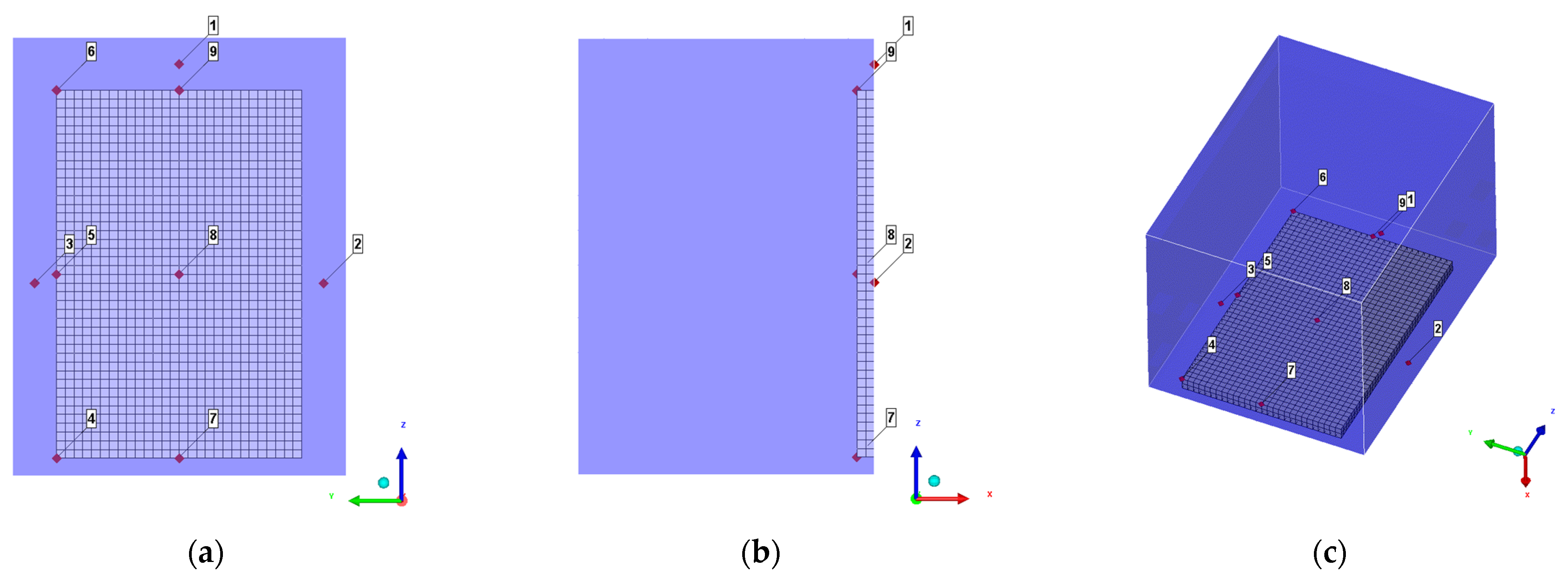

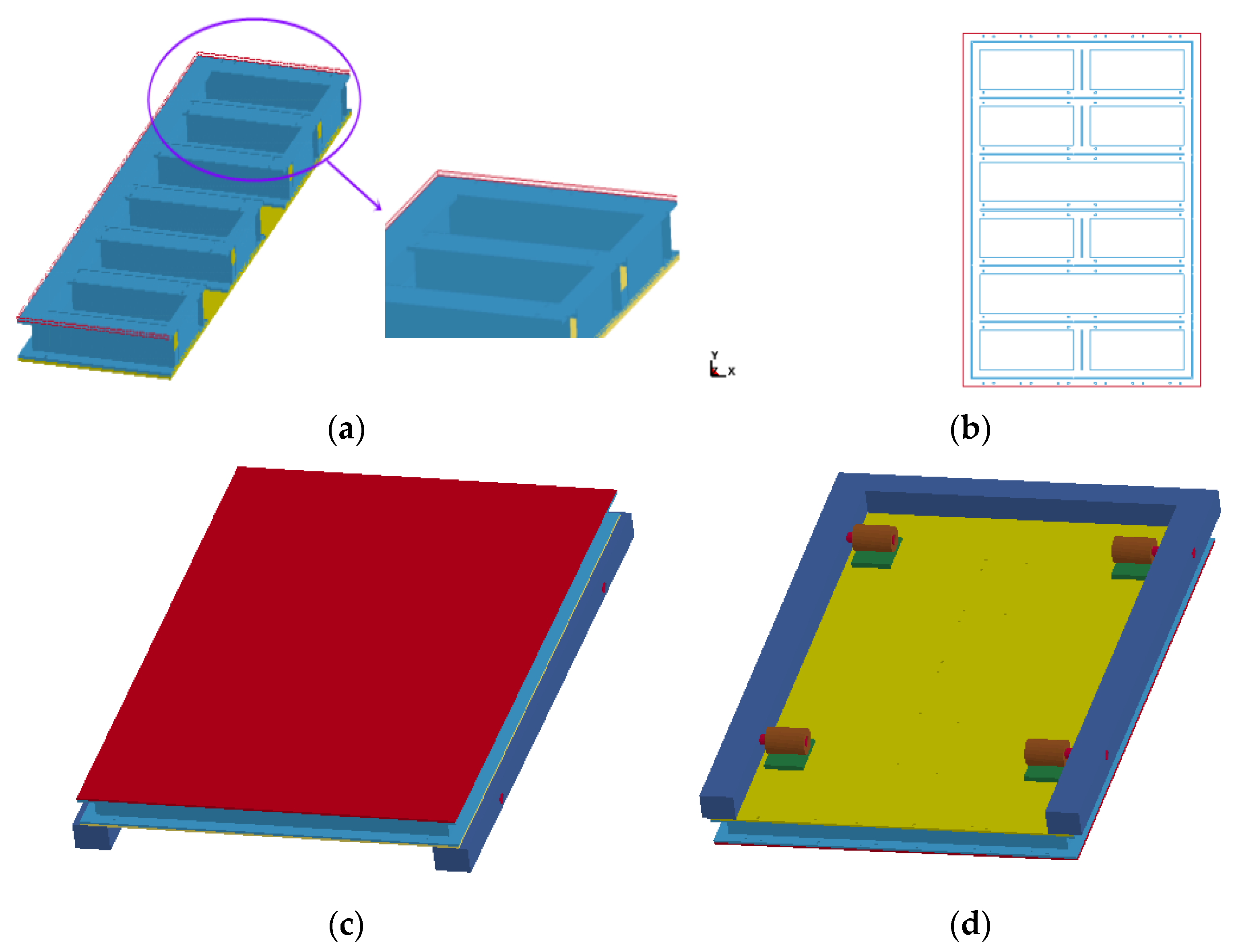

A finite element model of the steel structure protective door was established according to the aforementioned method, with the dimensions of all the parts the same as the actual sizes, as shown in

Figure 14.

Figure 14a shows the finite element model of half of the skeleton. The coordinate origin overlapped with the vertex at the lower left corner of the inner panel of the protective door. The square hole in

Figure 14b is the consolidation area between the skeleton and the inner and outer panels. The side length of the hole was 10 mm, and the other parts were set for automatic surface-to-surface contact.

Figure 14c,d show the finite element models of the door and the doorframe, respectively. Four rectangular steel gasket plates, each with a thickness of 2 cm, had fixed connections with the inner panel. The four sleeves also had fixed connections with their gasket panels. The four screws and their corresponding sleeves had automatic surface-to-surface contact. The screws and their corresponding holes in the doorframe also had automatic surface-to-surface contact, as did the connection between the door and the doorframe. This type of contact is defined by the keyword “*CONTACT_AUTOMATIC_SURFACE_TO_SURFACE” [

16]. Both the static and dynamic friction coefficients were set to 0.3. Default values were used for other contact parameters. Each element in the finite element model was modeled by the SOLID164 hexahedral constant stress element with a Lagrangian grid. To ensure regular meshing of the cell grid, different grid partition methods were used for the components with different shapes. The “mapped” grid partition method was adopted for the skeleton, panels, and gasket plate with an element size of 5 mm. There were 334,036 elements in the skeleton, 232,960 elements in the inner and outer panels, and 8640 elements in the gasket plate. The “sweep” grid partition method was adopted for the cylindrical screws, sleeves, and doorframe, with an element size of 10 mm. There were 3596 elements in the screws, 7920 elements in the sleeves, and 69,360 elements in the doorframe.

Because there was no evident deformation or damage to the doorframe during the test, the impact of deformation on the analysis results can be ignored. The doorframe wall was simplified to a rigid body. The three translational and three rotational degrees of freedom were constrained for the doorframe wall to ensure that the doorframe did not move or rotate during the deformation process of the door.

Figure 14.

Finite element calculation model of protective door: (a) 1/2 finite element model of skeleton; (b) Connection mode between skeleton and panel; (c) Finite element model of protective door and door frame (front); (d) Finite element model of protective door and door frame (back).

Figure 14.

Finite element calculation model of protective door: (a) 1/2 finite element model of skeleton; (b) Connection mode between skeleton and panel; (c) Finite element model of protective door and door frame (front); (d) Finite element model of protective door and door frame (back).

4.1.2. Steel

The material of the skeleton, panels, and gasket plate of the door was Q235 steel. The material of the screws and sleeves was No. 45 steel. The keyword “*MAT_PLASTIC_KINEMATIC” in LS-DYNA was used to describe the mechanical properties of the steel material under the shock wave load. This material model was a hybrid model of isotropic hardening and follow-up hardening with the effect of the strain rate [

17]. The Cowper–Symonds equation [

18] was used to calculate the strain rate effect of steel. The dynamic yield strength is calculated as follows:

where

σy is the dynamic yield stress,

σ0 is the initial yield stress,

is the strain rate,

C and

P are strain rate parameters,

is the effective plastic strain,

β is the hardening parameter, and

Ep is the plastic hardening modulus. The values of

C and

P are related to the steel type.

Table 6 shows the strain rate data of different types of steel. The

C and

P values used in this paper were 40.4 s

−1 and 5, respectively.