A Review of Research on Mechanical Properties and Durability of Concrete Mixed with Wastewater from Ready-Mixed Concrete Plant

Abstract

:1. Introduction

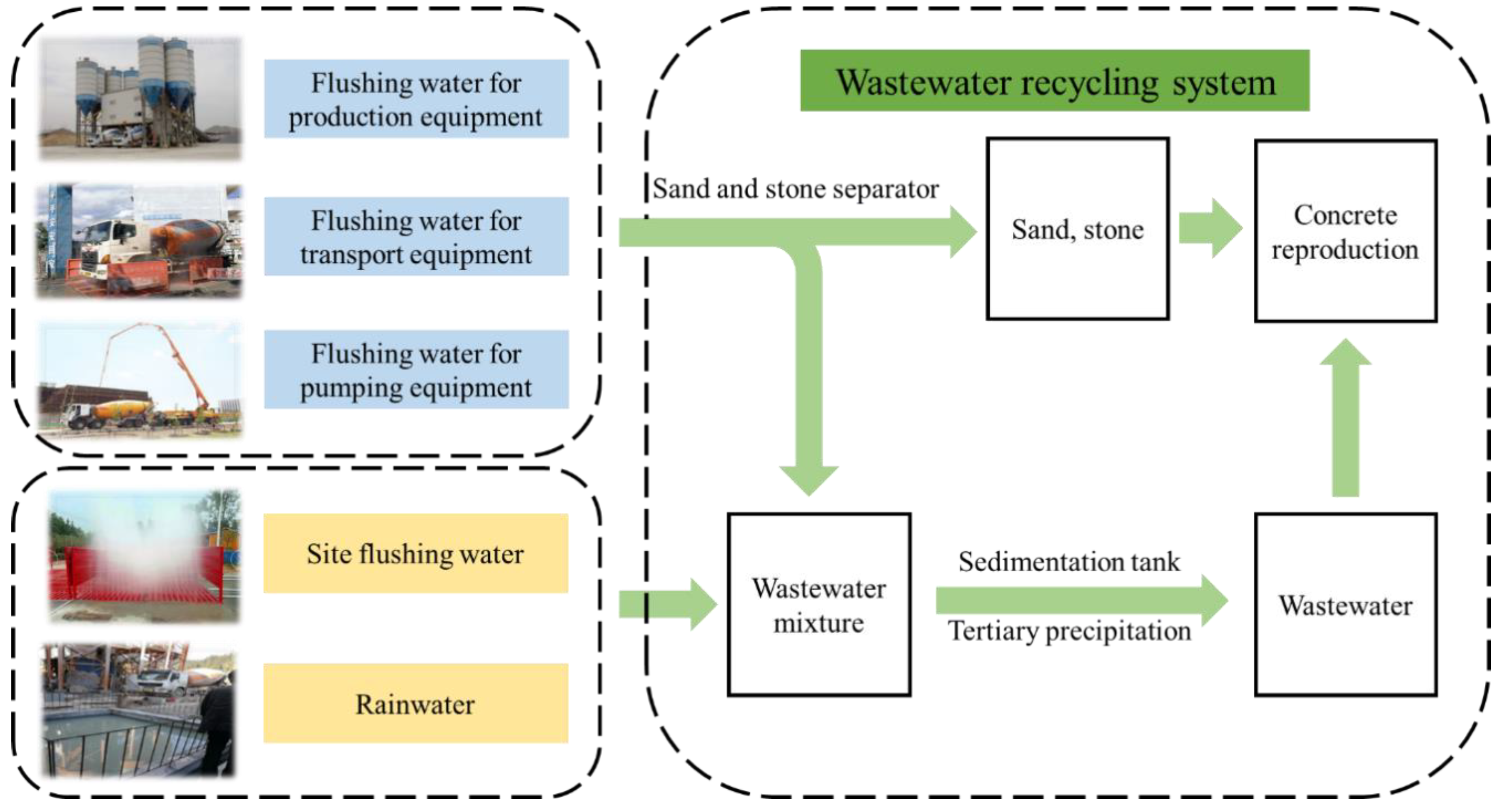

2. Wastewater Properties

3. Influence of Solid Content in Mixed Water on the Performance of Concrete

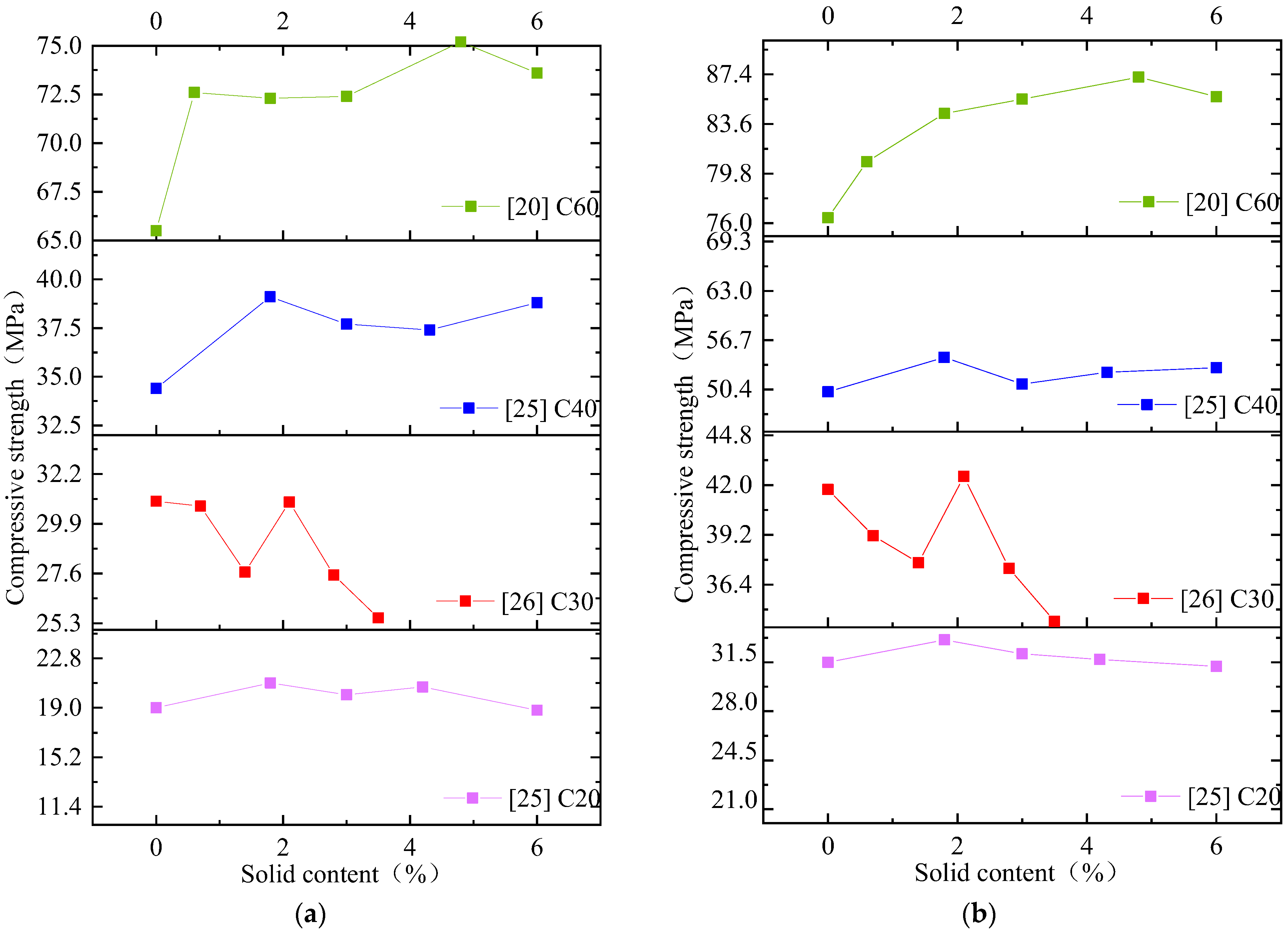

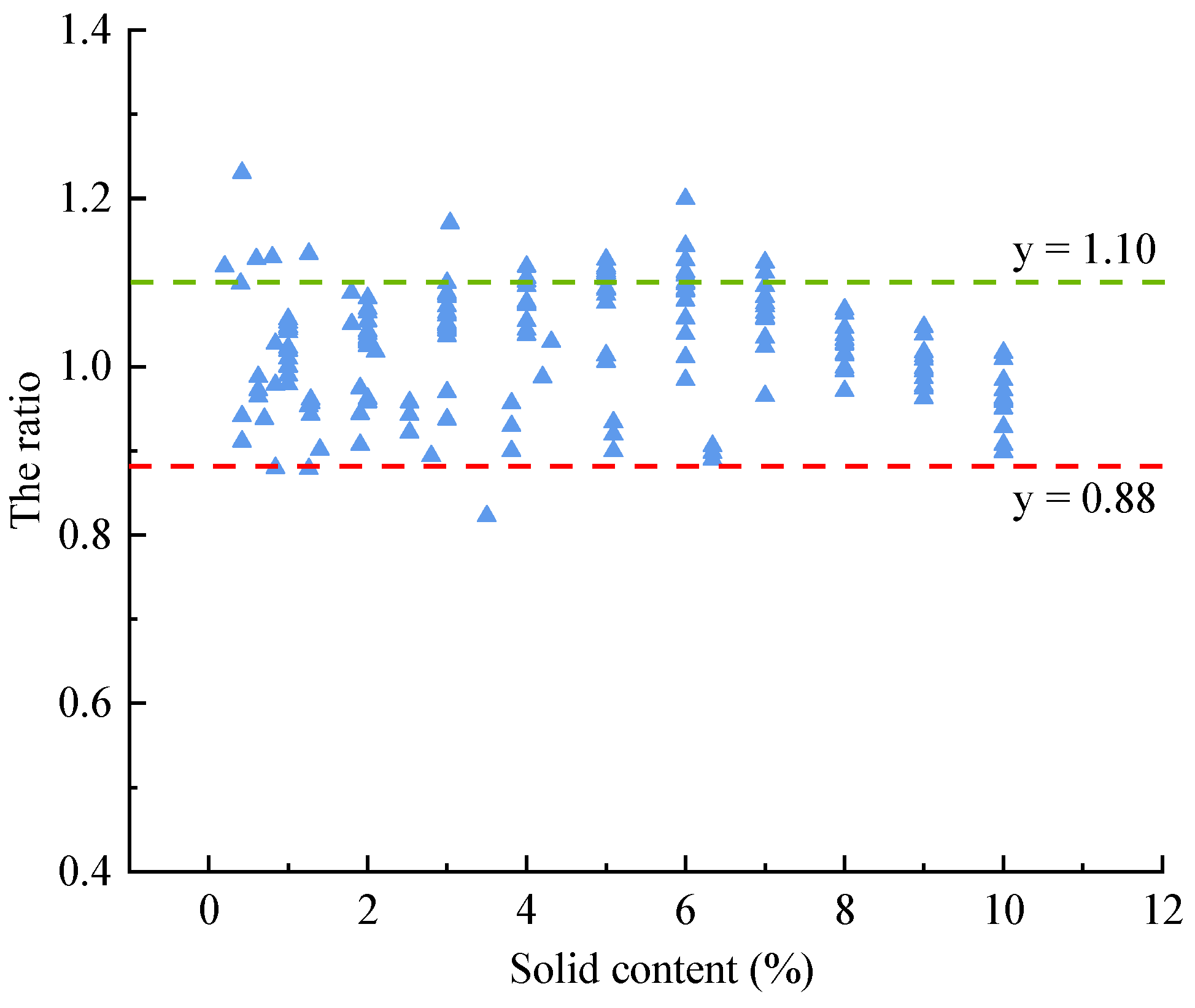

4. Influence of Solid Content in Mixed Water on the Compressive Strength of Concrete

5. Effect of Wastewater on the Durability of Concrete

5.1. Chloride Ion Penetration Resistance

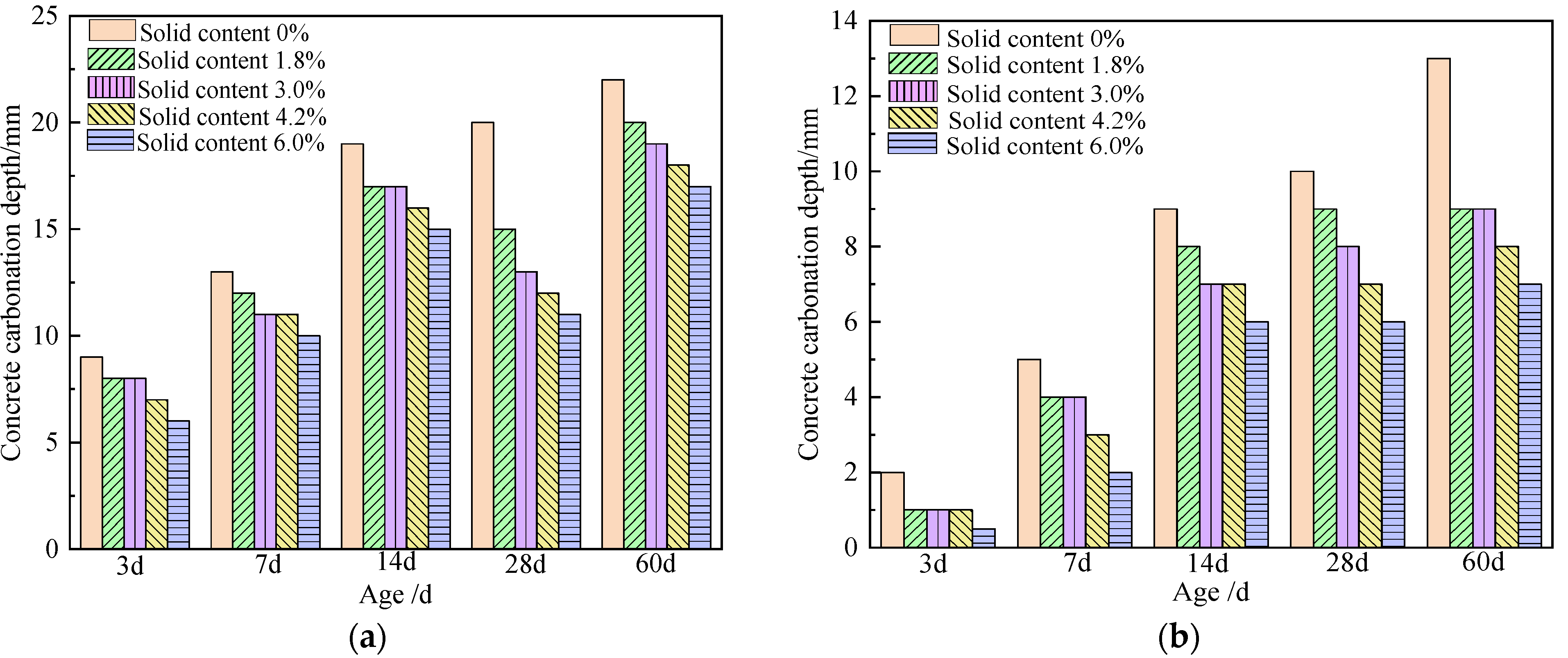

5.2. Carbonization Resistance

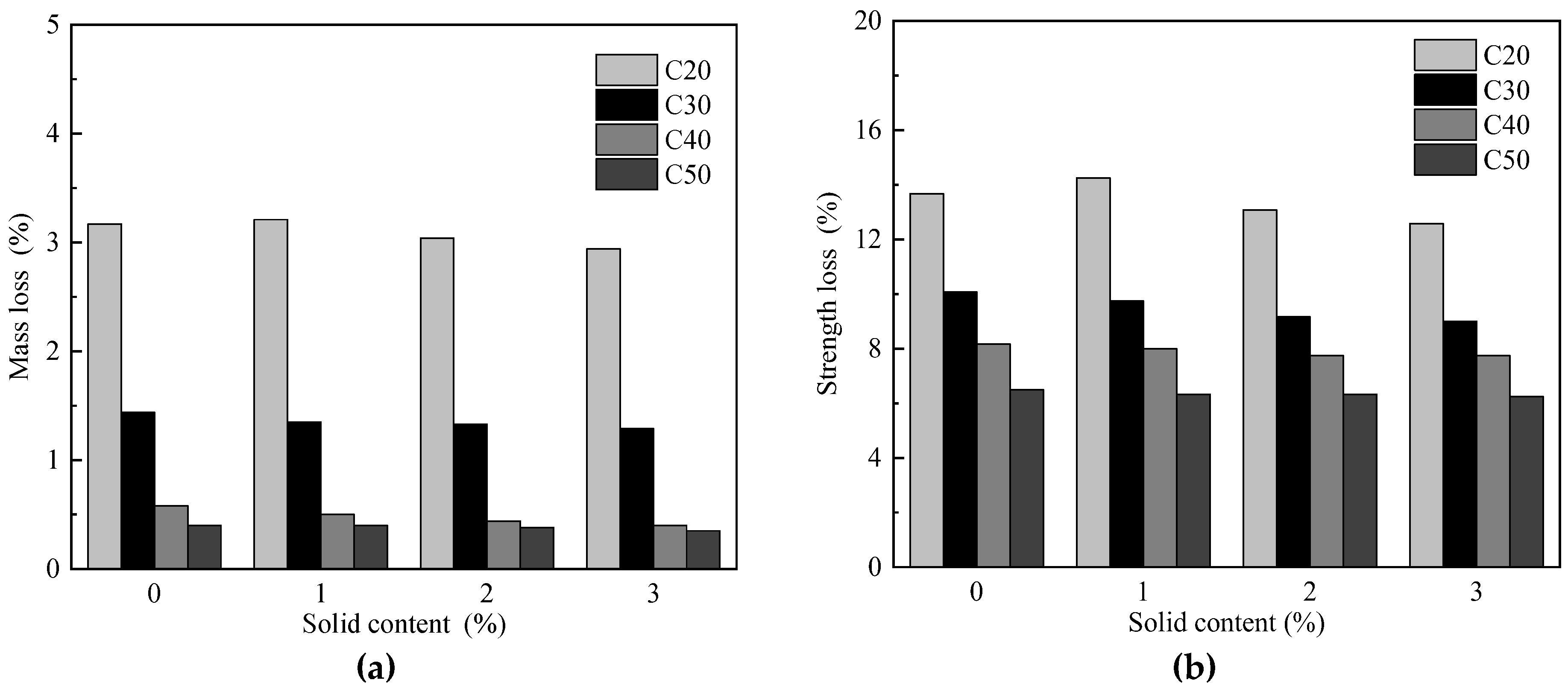

5.3. Frost Resistance

5.4. Sulfate Corrosion Resistance

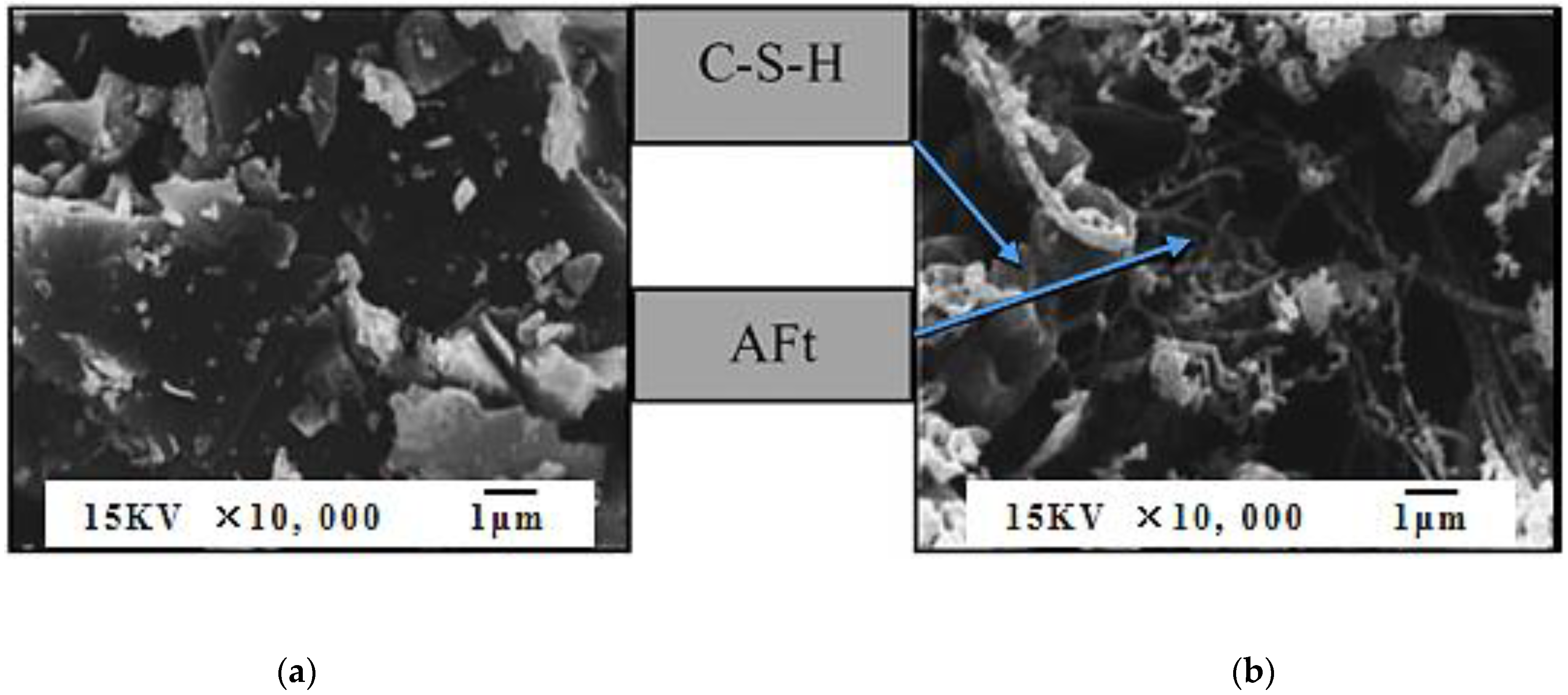

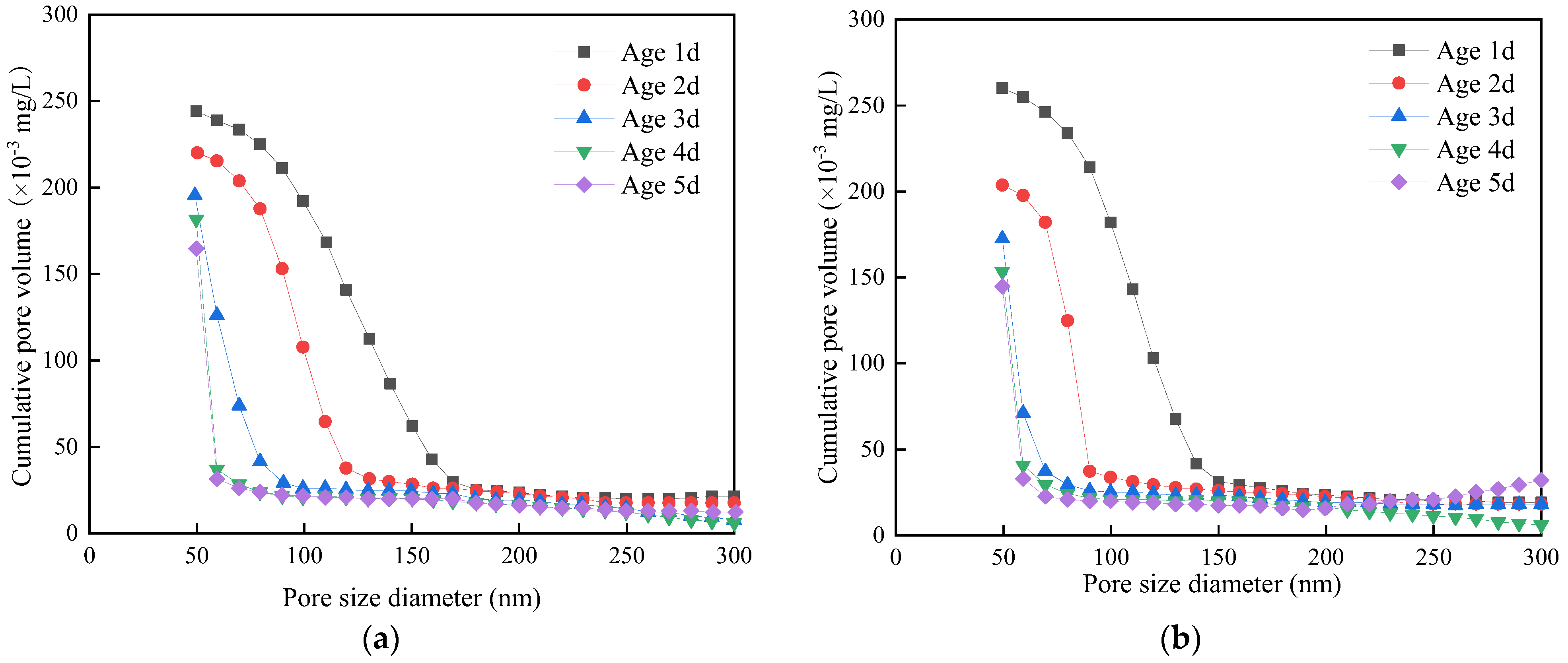

6. Effect of Solid Content on the Microscopic Properties of Concrete

7. Conclusions and Prospects

- (1)

- The main components of wastewater in different regions are roughly the same, i.e., main cement hydration products and fine sands and gravel particles, however the solid content of wastewater is quite different. Therefore, if wastewater is recycled, the solid content of wastewater from the ready-mixed concrete plant should be detected simultaneously, and the solid content of wastewater should be adjusted as needed before use.

- (2)

- Concrete is prepared by replacing tap water with wastewater in a certain proportion. When the solid content of the mixed water is less than or equal to 6%, the change of concrete slump is within 30 mm. When the solid content in the mixed water is at the optimal solid content, the fluidity and compressive strength of the concrete change little compared to the concrete prepared from tap water, and the optimal solid content in the mixed water of wastewater is generally less than or equal to 5%.

- (3)

- The filling effect of wastewater particles can enhance the concrete durability to a certain extent. Currently, there are a few studies on the frost resistance and sulfate corrosion resistance of wastewater concrete. The influence of the solid content of wastewater on the frost resistance and sulfate resistance of concrete with different water-binder ratios is unclear, and as such, research on these aspects should be strengthened.

- (4)

- The storage time of wastewater greatly influences on the properties of wastewater particles, which leads to different effects of wastewater on various concrete properties. At present, there are limited studies on the influence of wastewater storage time on various properties of concrete. Further research should be carried out on the influence of wastewater storage time on concrete.

- (5)

- At present, there are few researches on the influence of wastewater on the microstructure of concrete. However, the changes of macroscopic mechanical properties of concrete are the external manifestation of the changes of microstructure. Therefore, we should strengthen the research in this area to provide reference for evaluating the changes of macroscopic mechanical properties of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bu, C.; Liu, L.; Lu, X.; Zhu, D.; Sun, Y.; Yu, L.; Ouyang, Y.; Cao, X.; Wei, Q. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef]

- Kelechi, S.E.; Adamu, M.; Mohammed, A.; Ibrahim, Y.E.; Obianyo, I.I. Durability Performance of Self-Compacting Concrete Containing Crumb Rubber, Fly Ash and Calcium Carbide Waste. Materials 2022, 15, 488. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef] [PubMed]

- Qu, R.Z. Study on the Influence of Waste Paste on the Performance of Ready-Mixed Concrete; Harbin Institute of Technology: Harbin, China, 2016. (In Chinese) [Google Scholar]

- Klus, L.; Václavík, V.; Dvorský, T.; Svoboda, J.; Papesch, R. The properties of waste water from a concrete plant. IOP Conf. Ser. Earth Environ. Sci. 2017, 92, 12028. [Google Scholar] [CrossRef]

- Kou, S.-C.; Zhan, B.-J.; Poon, C.S. Feasibility study of using recycled fresh concrete waste as coarse aggregates in concrete. Constr. Build. Mater. 2012, 28, 549–556. [Google Scholar] [CrossRef]

- Kou, S.-C.; Zhan, B.-J.; Poon, C.-S. Properties of partition wall blocks prepared with fresh concrete wastes. Constr. Build. Mater. 2012, 36, 566–571. [Google Scholar] [CrossRef]

- Chen, Z.H.; Guo, Y.Q.; Lai, G.X.; Fang, Y.H.; Zhang, X.F. Exploring the ball milling time of wastewater paste and its influence on the performance of concrete mixture. New Build. Mater. 2019, 46, 162–165. (In Chinese) [Google Scholar]

- Chang, H.M. Experimental study on separation and reuse technology of waste concrete mixture. Concrete 2007, 7, 69–70. (In Chinese) [Google Scholar]

- Asadollahfardi, G.; Asadi, M.; Jafari, H.; Moradi, A.; Asadollahfardi, R. Experimental and statistical studies of using washwater from ready-mix concrete trucks and a batching plant in the production of fresh concrete. Constr. Build. Mater. 2015, 98, 305–314. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.X.; Li, Q.; Wang, J.; Ling, Y. Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders—A review. J. Clean. Prod. 2020, 258, 120896. [Google Scholar] [CrossRef]

- Ma, X.W.; Liu, C. Utilization status of wastewater from concrete mixing station in concrete. Concrete 2017, 7, 102–107. (In Chinese) [Google Scholar]

- Aldossary, M.H.A.; Ahmad, S.; Bahraq, A.A. Effect of total dissolved solids-contaminated water on the properties of concrete. J. Build. Eng. 2020, 32, 101496. [Google Scholar] [CrossRef]

- Huang, H.C.; Yan, S.C.; Wu, Z.H.; Zhou, Y.Z.; Ni, K.S. Study on recycling method of mixing plant wastewater. Concrete 2020, 11, 157–160. (In Chinese) [Google Scholar]

- Yang, X.H.; Ji, X.K.; Wang, M.Y.; Wei, Q.D. Performance analysis and utilization of waste water and paste from concrete mixing plant. Concrete 2015, 5, 109–112. (In Chinese) [Google Scholar]

- Xiang, J.Y.; Li, X.; Jiang, Z.; Leng, Z.; Yuan, J.T. Preparation and engineering application of C20~C60 concrete with waste water from ready-mixed plant. Concr. Cem. Prod. 2018, 11, 97–100. (In Chinese) [Google Scholar]

- Mariane, A.; Pierre-yves, M.; Philippe, T. Utilization of sludge from ready-mixed concrete plants as a substitute for limestone fillers. Constr. Build. Mater. 2016, 112, 790–799. [Google Scholar] [CrossRef]

- Lu, D.Y. Research on Wastewater Treatment Technology and Recycling of Concrete Mixing Plant. Master’s Thesis, Southwest University of Science and Technology, Mianyang, China, 2020. (In Chinese). [Google Scholar]

- Chen, J.L. Recycling of waste mud water in concrete mixing plant. Concrete 2014, 9, 130–141. (In Chinese) [Google Scholar]

- Zhou, X.Q. Study on Recycling of High Concentration Wastewater from Mixing Plant. Master’s Thesis, Guangzhou University, Guangzhou, China, 2018. (In Chinese). [Google Scholar]

- Chatveera, B.; Lertwattanaruk, P.; Makul, N. Effect of sludge water from ready-mixed concrete plant on properties and durability of concrete. Cem. Concr. Compos. 2006, 28, 441–450. [Google Scholar] [CrossRef]

- Sandrolini, F.; Franzoni, E. Waste wash water recycling in ready-mixed concrete plants. Cem. Concr. Res. 2001, 31, 485–489. [Google Scholar] [CrossRef]

- Tsimas, S.; Zervaki, M. Reuse of waste water from ready-mixed concrete plants. Manag. Environ. Qual. Int. J. 2011, 22, 7–17. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, K.F.; Liu, K.; Zhao, S.R.; Wang, N. Experimental study on the influence of wastewater reuse in concrete mixing plant on C10~C60 concrete performance. New Build. Mater. 2015, 42, 12–14, 47. (In Chinese) [Google Scholar]

- Li, X.L. Study on the Influence of Mixing Plant Wastewater on the Performance of Pumped Concrete with Different Strength Grades. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2015. (In Chinese). [Google Scholar]

- Ouyang, M.X.; Li, Y.P.; Zhang, K.F.; Meng, G.; Wu, X. Preparation of C20~C40 concrete with wastewater from mixing plant. Concrete 2013, 11, 124–125, 129. (In Chinese) [Google Scholar]

- Kadir, A.A.; Shahidan, S.; Yee, L.H.; Hassan, M.I.H.; Abdullah, M.M.A.B. The effect on slurry water as a fresh water replacement in concrete properties. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012041. [Google Scholar] [CrossRef] [Green Version]

- Chatveera, B.; Lertwattanaruk, P. Use of ready-mixed concrete plant sludge water in concrete containing an additive or admixture. J. Environ. Manag. 2009, 90, 1901–1908. [Google Scholar] [CrossRef]

- Su, N.; Miao, B.; Liu, F.-S. Effect of wash water and underground water on properties of concrete. Cem. Concr. Res. 2002, 32, 777–782. [Google Scholar] [CrossRef]

- Zhang, K.F.; Yao, Y.; Zhao, S.R.; Liu, K.; Wang, X.G.; Liu, X.Y. Experimental study on wastewater from mixing station as concrete mixing water. Concrete 2015, 2, 101–103. (In Chinese) [Google Scholar]

- Zhang, P.; Li, Q.F.; Wang, J.; Shi, Y.; Ling, Y. Effect of PVA fiber on durability of cementitious composite containing nano-SiO2. Nanotechnol. Rev. 2019, 8, 116–127. [Google Scholar] [CrossRef]

- He, T.S.; Li, X.L.; Wang, F.H.; Zhu, W.H.; Bai, F.J. Influence of waste water from mixing station on the strength of C80 high-strength concrete prepared with different admixtures. Silic. Bull. 2011, 30, 384–388. (In Chinese) [Google Scholar]

| Sources | Region | Test Substance | Main Components |

|---|---|---|---|

| [4] | Harbin, China | Cement paste mixed with wastewater | Ca(OH)2, AFt |

| [16] | Hunan, China | Drying wastewater sedimentation | Ca(OH)2, SiO2, CaCO3, CaSO4·2H2O |

| [17] | France | Sediment in wastewater sedimentation tank | SiO2, CaCO3, aggregates formed by Ca(OH)2 and/or C-S-H gel, C2S, C3S and CaSO4•2H2O |

| [18] | Sichuan, China | Wastewater | Ca(OH)2, AFt, C2S, C3S and CaSO4•2H2O |

| [19] | Tianjin, China | Fresh wastewater generated within 24 h | Containing Na-hydrated calcium sulfoaluminate (monosulfur type), containing Cl-hydrated calcium aluminateand and unhydrated C2S, C3S minerals, CaCO3 containing magnesium |

| Store wastewater for more than 30 days | CaCO3, SiO2, AFt | ||

| [20] | Guangzhou, China | Wastewater | CaCO3, C-S-H, Ca(OH)2 and a small amount of mud powder |

| [21] | Thailand | Drying wastewater powder | Al2O3, Fe2O3, MgO, K2O, Na2O, SO3, and free CaO |

| [22] | Italy | Wastewater evaporation residue | CaCO3, SiO2 |

| [23] | Greece | Wastewater sedimentation | CaO, Ca(OH)2, CaCO3, SiO2 |

| Concrete Strength Grade | Data Sources | Solid Content (%) | Slump Change Range(mm) |

|---|---|---|---|

| C20 | [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | −20 ~ +20 |

| [25] | 0, 1.8, 3.0, 4.2, 6.0 | −25 ~ −5 | |

| C30 | [4] | 0, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0 | 0 ~ +20 |

| [16] | −20 ~ −5 | ||

| [18] | 0, 3.0, 6.0 | −10 ~ 0 | |

| [19] | 0, 2.0, 5.0 | −20 ~ −10 | |

| [20] | 0, 0.6, 1.8, 3.0, 4.8 | −26 ~ +7 | |

| 0, 0.8, 2.4, 4.0, 6.4 | −26 ~ +6 | ||

| 0, 1.0, 3.0, 5.0 | −28 ~ −6 | ||

| 0, 1.2, 3.6, 6.0 | −30 ~ −13 | ||

| [24] | 0, 0.2, 0.4, 0.6, 0.8 | −26 ~ −10 | |

| [26] | 0, 0.7, 1.4, 2.1, 2.8, 3.5 | −10 ~ +10 | |

| C40 | [19] | 0, 2.0, 5.0 | −30 ~ −20 |

| [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | −20 ~ −10 | |

| [25] | 0, 1.8, 3.0, 4.2, 6.0 | −30 ~ −5 | |

| C50 | [18] | 0, 3.0, 6.0 | −10 ~ 0 |

| [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | −10 ~ +10 | |

| C60 | [4] | 0, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0 | 0 ~ +20 |

| [20] | 0, 0.6, 1.8, 3.0, 4.8 | −40 ~ −10 | |

| 0, 0.8, 2.4, 4.0 | −44 ~ −5 | ||

| [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | −30 ~ 0 |

| Data Sources | Solid Content (%) | w/c | Slump Change Range (mm) |

|---|---|---|---|

| [21] | 0, 0.63, 1.27, 1.90, 2.54, 3.80, 5.07 | 0.5 | −2 ~ −22 |

| 0.6 | −2 ~ −30 | ||

| 0.7 | −2 ~ −31 | ||

| [22] | 0, 0.82, 1.14, 2.56, 3.40, 3.99 | 0.57 | −10 ~ −25 |

| [23] | 0, 0.13, 0.15 | 0.85 | −10 ~ +90 |

| [27] | 0.45 | +7 ~ +16 | |

| [28] | 5.64 | 0.7 | −10 ~ +5 |

| 0.5 | −5 ~ +5 |

| Concrete Strength Grade | Data Sources | Solid Content (%) | The Ratio (%) | Optimum Solid Content (%) | |

|---|---|---|---|---|---|

| 7 Days | 28 Days | ||||

| C20 | [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | 103.8 ~ 112.1 | 94.5 ~ 106.1 | 0.8 |

| [25] | 0, 1.8, 3.0, 4.2, 6.0 | 98.9 ~ 110.0 | 100.0 ~ 105.0 | 1.8 | |

| C30 | [4] | 0, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0 | 124.4 ~ 147.4 | 111.0 ~ 116.0 | 6.5 |

| [9] | 1.5 | 97.1 | 103.8 | ||

| [15] | 0, 0.42, 0.84, 1.26 | 93.5 ~ 100.1 | 88.3 ~ 91.1 | ||

| [18] | 0, 3.0, 6.0, 9.0, 12.0, 15.0 | 109.9 ~ 154.0 | 109.9 ~ 147.2 | 15 | |

| [19] | 0, 2.0, 5.0, 10.0 | 100.0 ~ 107.3 | 93.2 ~ 102.1 | 2.0 ~ 5.0 | |

| [20] | 0, 0.6, 1.8, 3.0, 4.8, 6.0 | 98.6 ~ 105.1 | 97.7 ~ 104.2 | 3.0 | |

| 0, 0.8, 2.4, 4.0, 6.4, 8.0 | 97.6 ~ 109.3 | 98.7 ~ 107.3 | 2.4 | ||

| 0, 1.0, 3.0, 5.0, 8.0, 10.0 | 93.9 ~ 104.6 | 96.7 ~ 100.6 | 3.0 | ||

| 0, 1.2, 3.6, 6.0, 9.6, 12 | 91.1 ~ 98.6 | 94.5 ~ 97.4 | 3.6 | ||

| [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | 95.8 ~ 113.5 | 90.4 ~ 108.9 | 0.2 | |

| [25] | 0, 1.8, 3.0, 4.2, 6.0 | 108.7 ~ 113.6 | 102.0 ~ 108.7 | 1.8 | |

| [26] | 0, 0.7, 1.4, 2.1, 2.8, 3.5 | 82.5 ~ 100.0 | 82.8 ~ 102.6 | 2.10 | |

| C60 | [4] | 0, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0 | 109.4 ~ 113.5 | 109.1 ~ 112.8 | 5.0 |

| [15] | 0, 0.42, 0.84, 1.26 | 99.8 ~ 107.0 | 94.1 ~ 97.8 | 0.84 | |

| [20] | 0, 0.6, 1.8, 3.0, 4.8, 6.0 | - | 110.5 ~ 114.8 | 4.8 | |

| 0, 0.8, 2.4, 4.0, 6.4, 8.0 | - | 109.1 ~ 113.5 | 4.0 | ||

| [24] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | 95.3 ~ 107.8 | 97.9 ~ 114.5 | 0.8 | |

| [30] | 0, 0.2, 0.4, 0.6, 0.8, 1.0 | 95.5 ~ 106.9 | 95.5 ~ 113.0 | 0.8 | |

| Data Sources | Solid Content (%) | w/c | The Ratio (%) | |

|---|---|---|---|---|

| 7 Days | 28 Days | |||

| [21] | 0, 0.63, 1.27, 1.90, 2.54, 3.80, 5.07, 6.34 | 0.5 | 90.0 ~ 95.0 | 88.9 ~97.2 |

| 0.6 | 88.9 ~ 95.2 | 89.8 ~ 96.4 | ||

| 0.7 | 88.7 ~ 96.1 | 90.5 ~ 99.8 | ||

| [22] | 0, 0.82, 1.14, 2.56, 3.40, 3.99 | 0.57 | 100.0 ~ 103.0 | 95.9 ~ 100.1 |

| [23] | 0, 0.13, 0.15 | 0.85 | 96.0 ~ 106.7 | 94.9 ~ 106.2 |

| [27] | 0.45 | 80.9 ~ 97.5 | 89.3 ~ 100.5 | |

| [28] | 5.64 | 0.7 | 77.0 ~ 84.7 | 76.6 ~ 86.2 |

| 0.5 | 85.1 ~ 91.9 | 87.6 ~ 93.5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, X.; Xi, J.; Guan, J.; Liu, L.; Shangguan, L.; Xu, Z. A Review of Research on Mechanical Properties and Durability of Concrete Mixed with Wastewater from Ready-Mixed Concrete Plant. Materials 2022, 15, 1386. https://doi.org/10.3390/ma15041386

Yao X, Xi J, Guan J, Liu L, Shangguan L, Xu Z. A Review of Research on Mechanical Properties and Durability of Concrete Mixed with Wastewater from Ready-Mixed Concrete Plant. Materials. 2022; 15(4):1386. https://doi.org/10.3390/ma15041386

Chicago/Turabian StyleYao, Xianhua, Junyi Xi, Junfeng Guan, Lijun Liu, Linjian Shangguan, and Zhaowen Xu. 2022. "A Review of Research on Mechanical Properties and Durability of Concrete Mixed with Wastewater from Ready-Mixed Concrete Plant" Materials 15, no. 4: 1386. https://doi.org/10.3390/ma15041386

APA StyleYao, X., Xi, J., Guan, J., Liu, L., Shangguan, L., & Xu, Z. (2022). A Review of Research on Mechanical Properties and Durability of Concrete Mixed with Wastewater from Ready-Mixed Concrete Plant. Materials, 15(4), 1386. https://doi.org/10.3390/ma15041386