Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCP Composites Produced by Powder Metallurgy

Abstract

1. Introduction

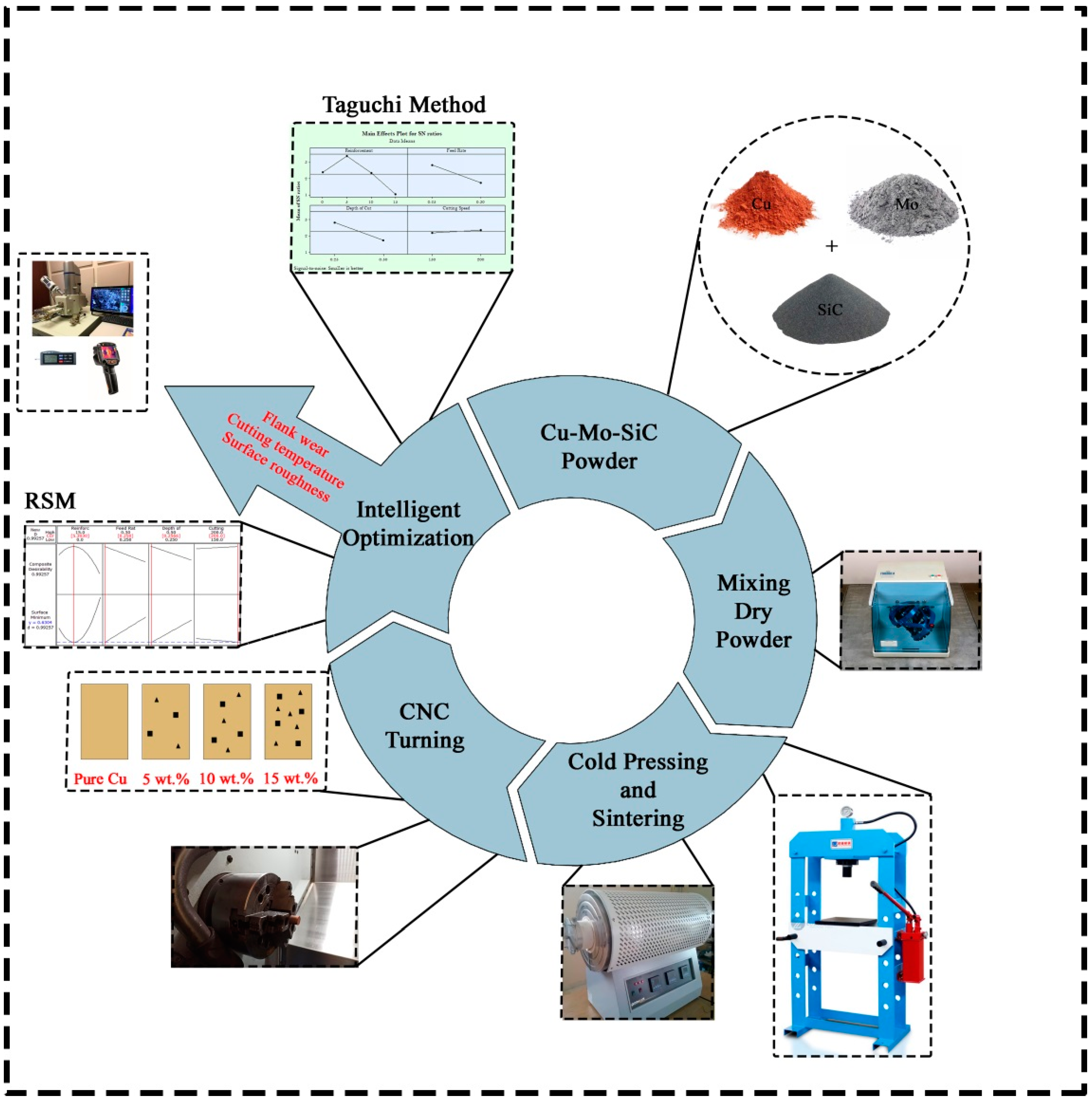

2. Materials and Methods

2.1. Composite Materials Production Process

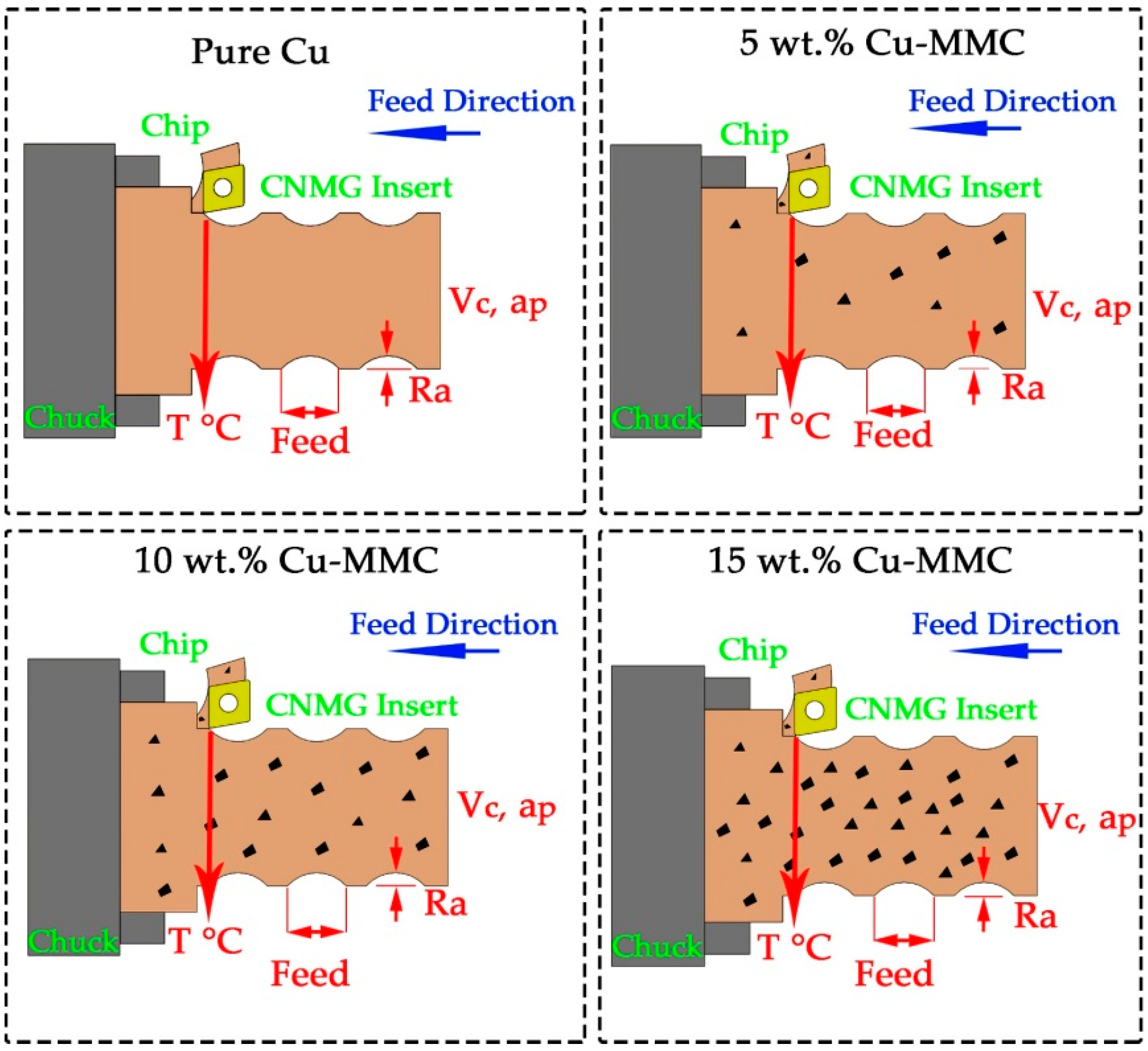

2.2. Experimental Procedure

2.3. Taguchi Based Design of Experiment and Parameter Optimization

2.4. Parameter Optimization with Response Surface Methodology (RSM)

2.5. Analysis of Variance (ANOVA)

3. Results and Discussion

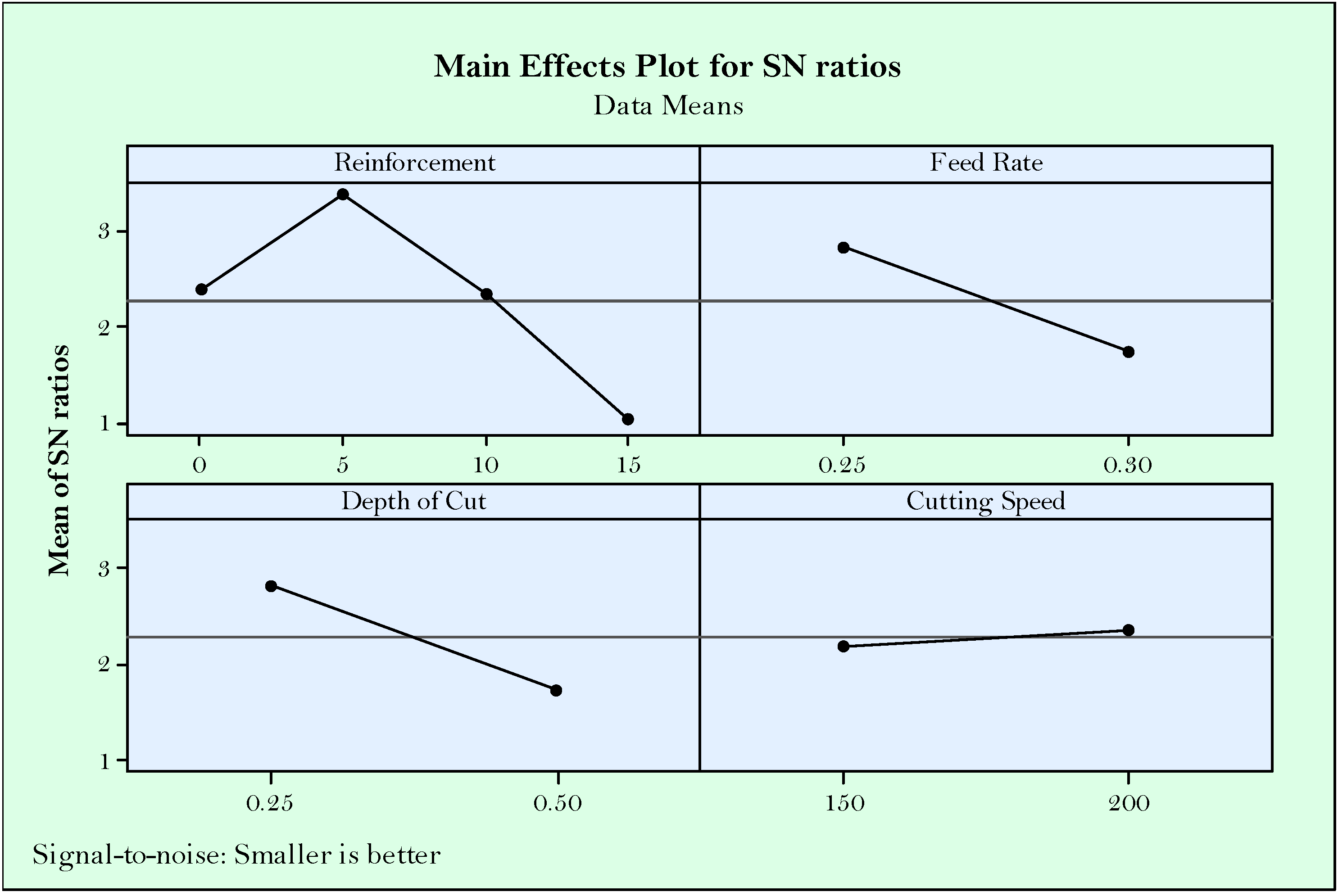

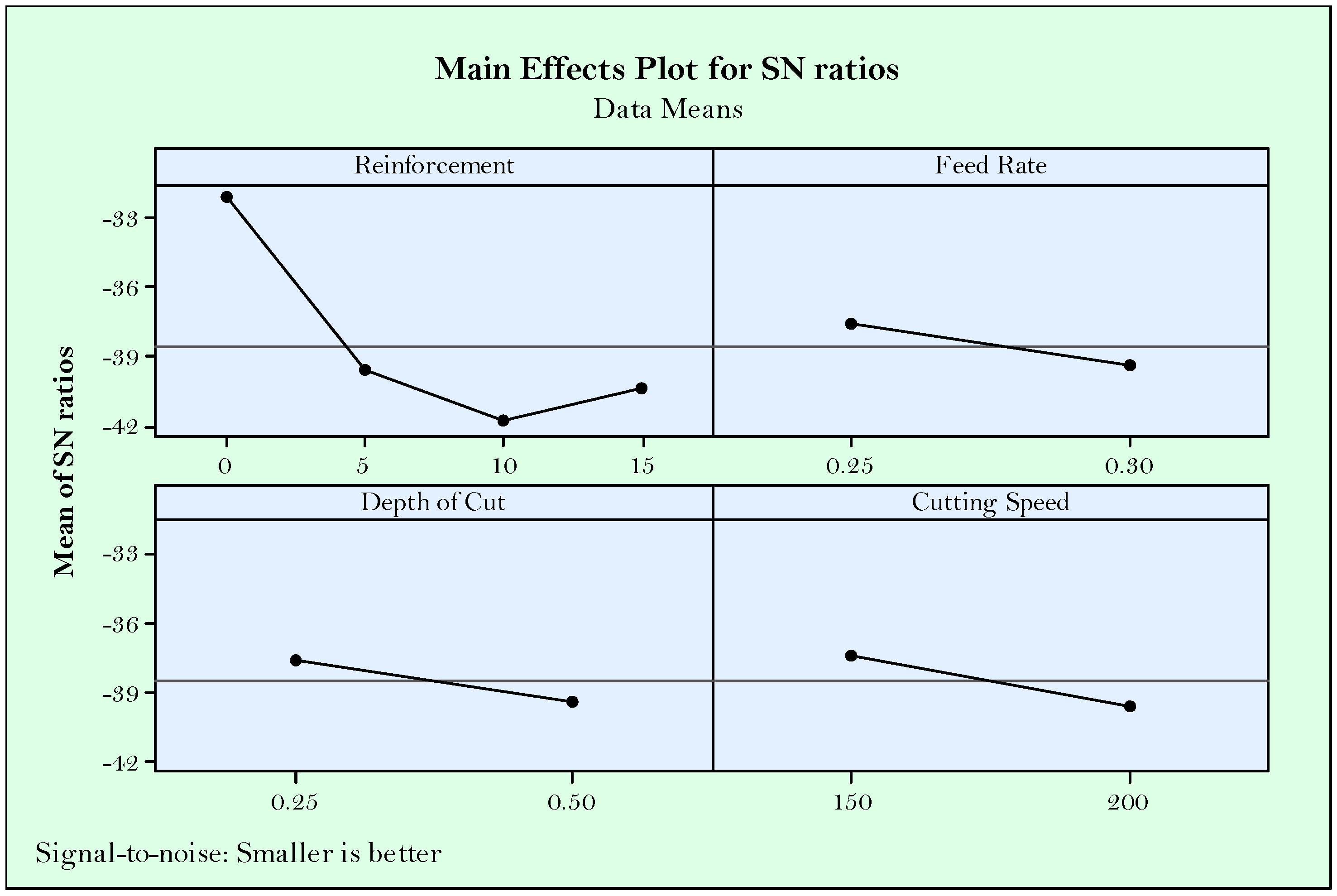

3.1. Surface Roughness Analysis and Parameter Optimization

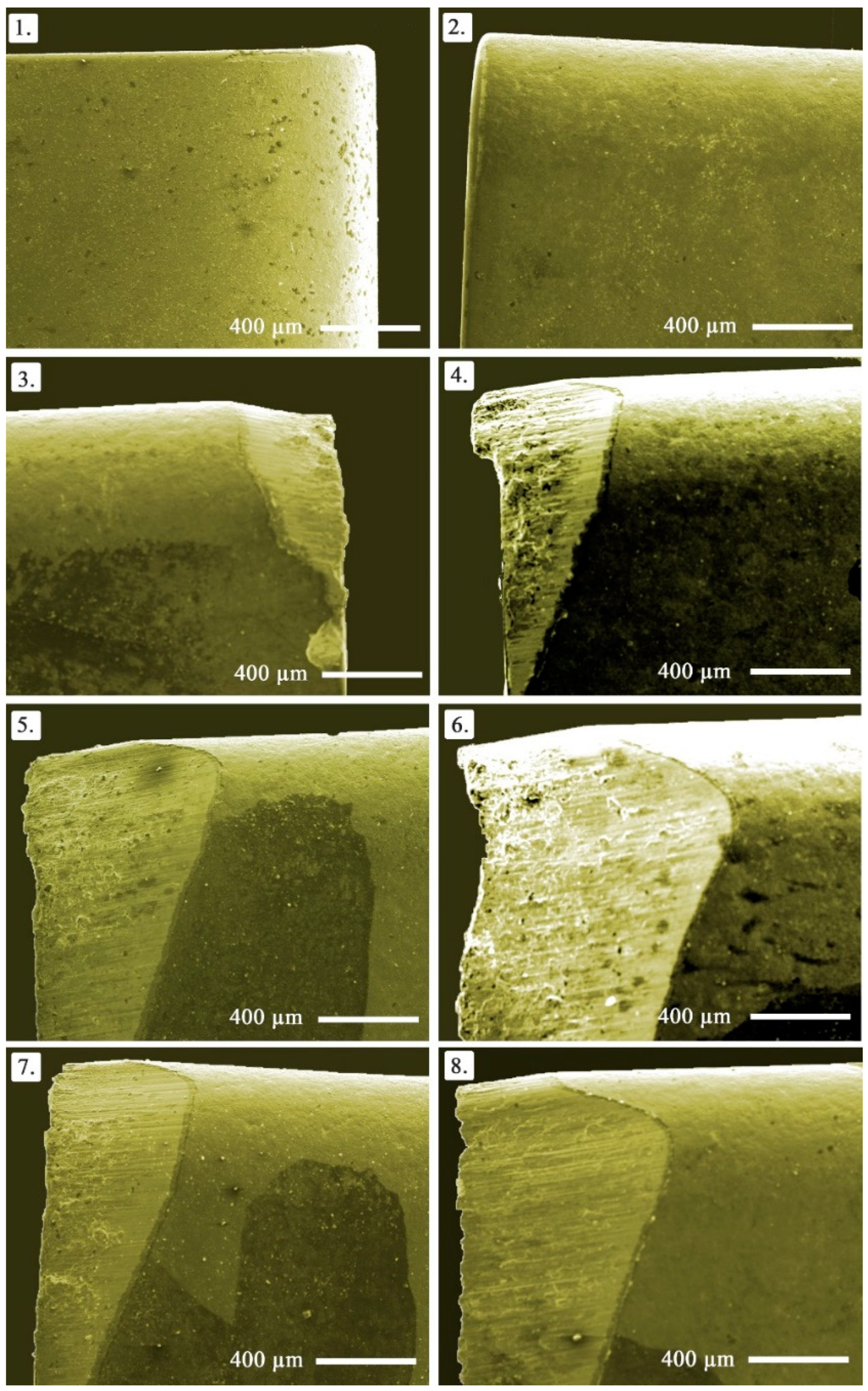

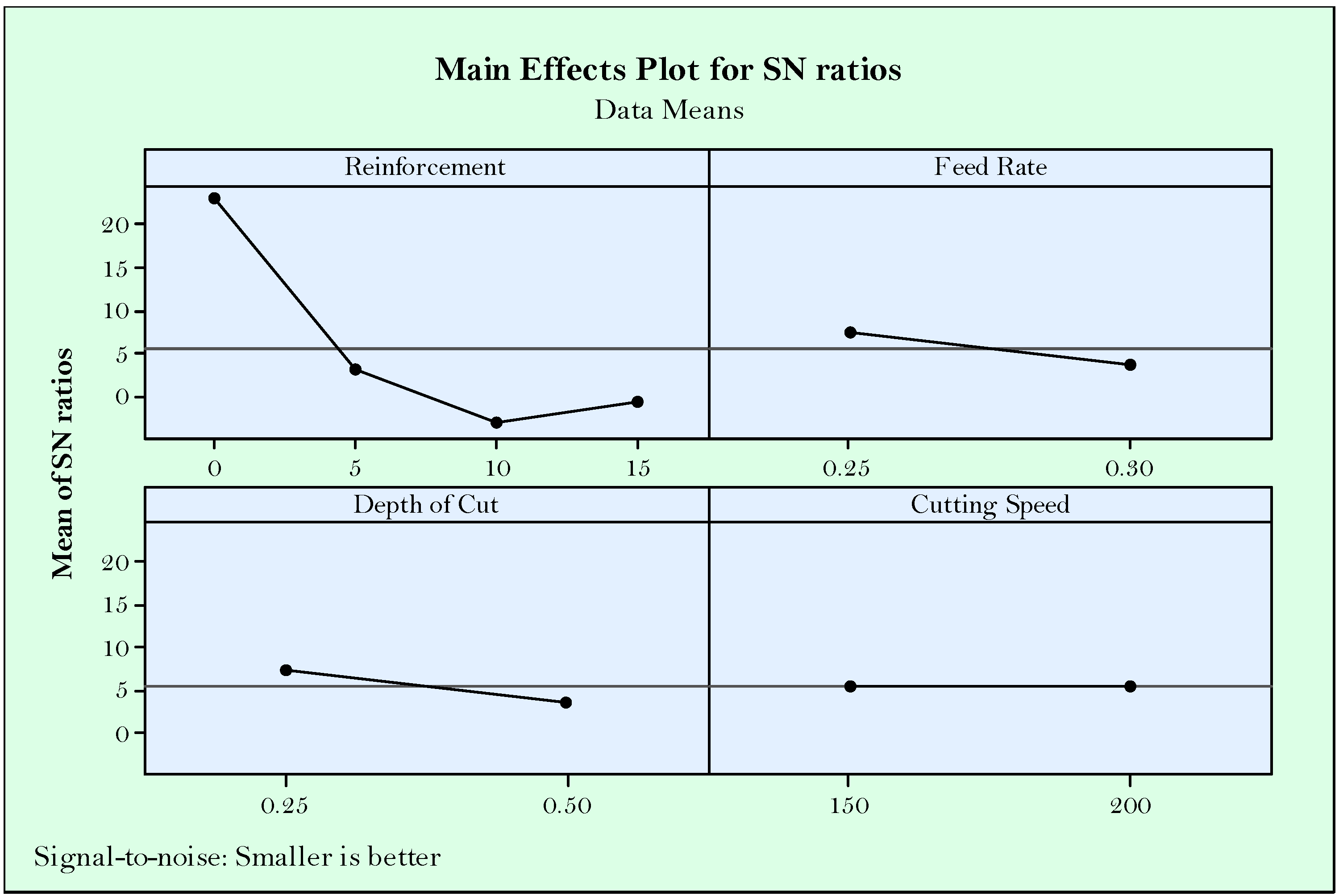

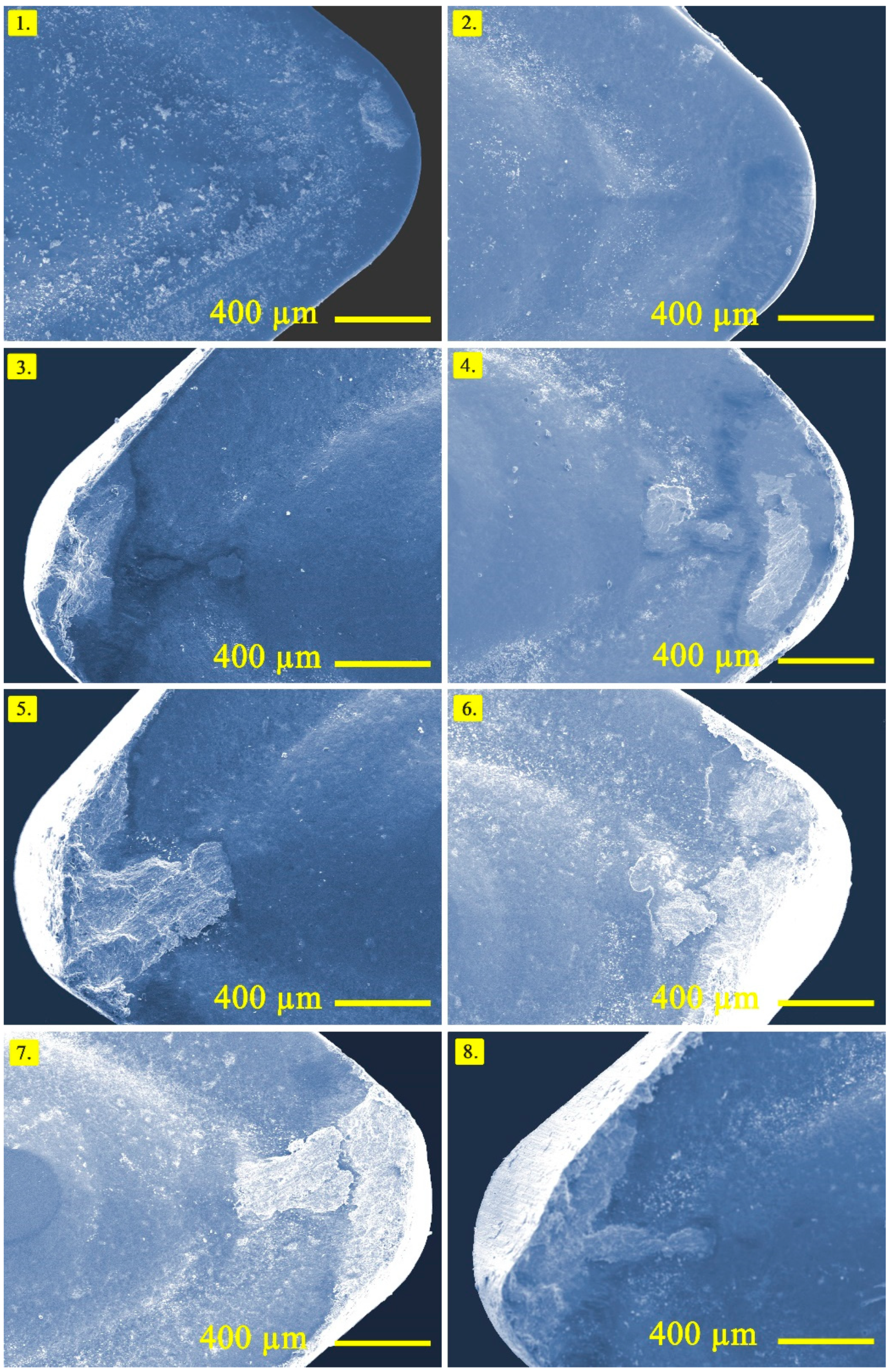

3.2. Tool Wear Analysis and Parameter Optimization

3.3. Cutting Temperature Analysis and Parameter Optimization

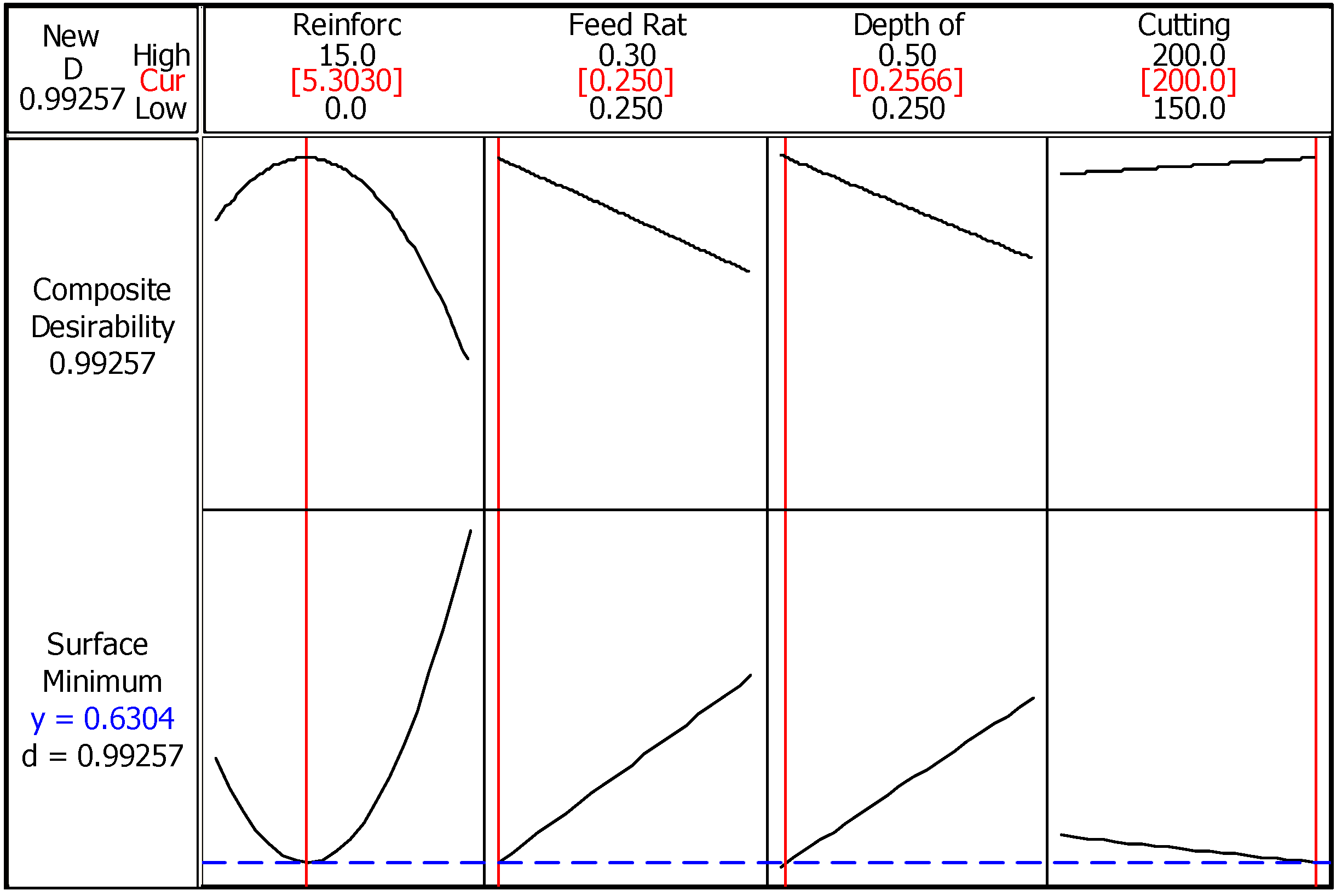

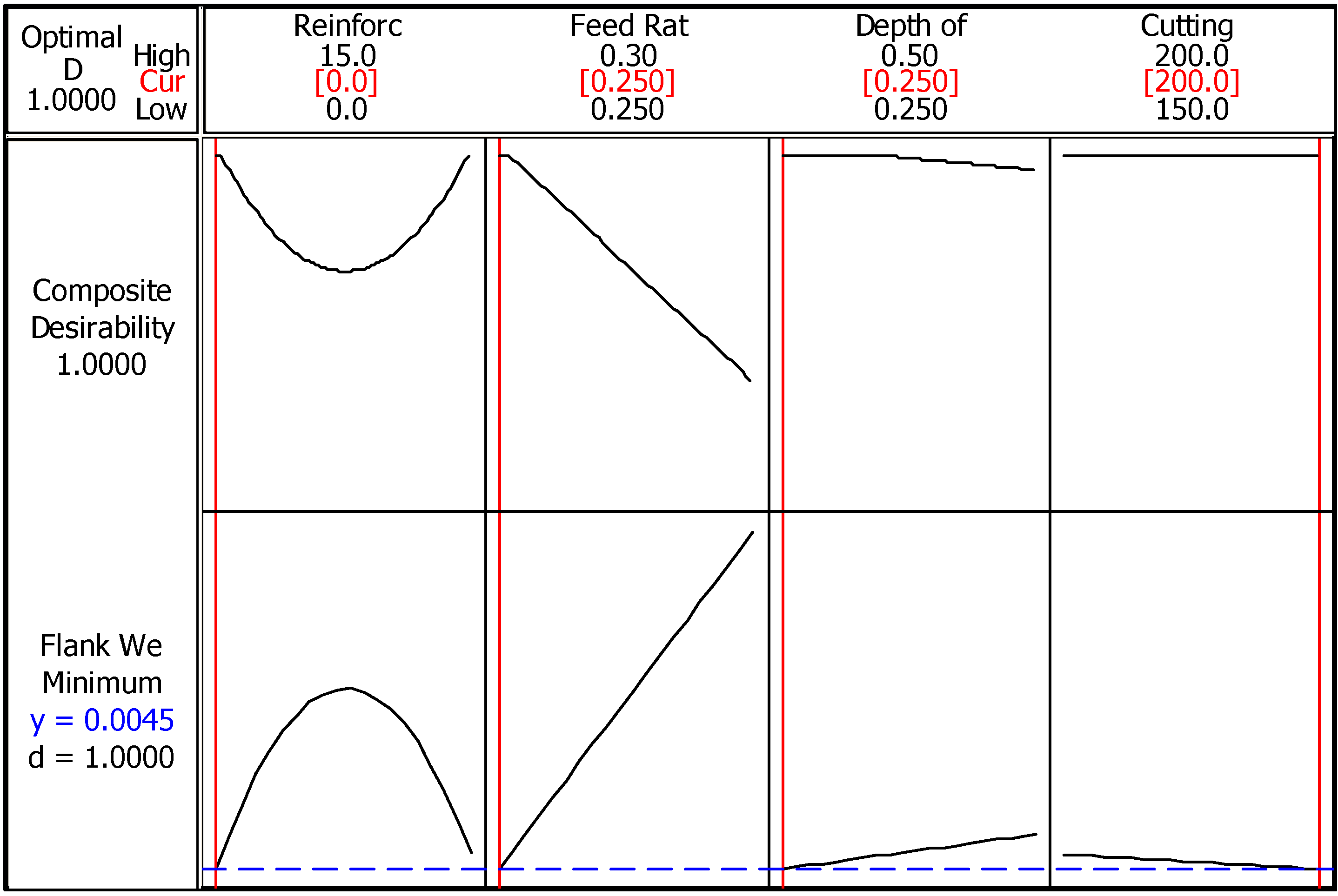

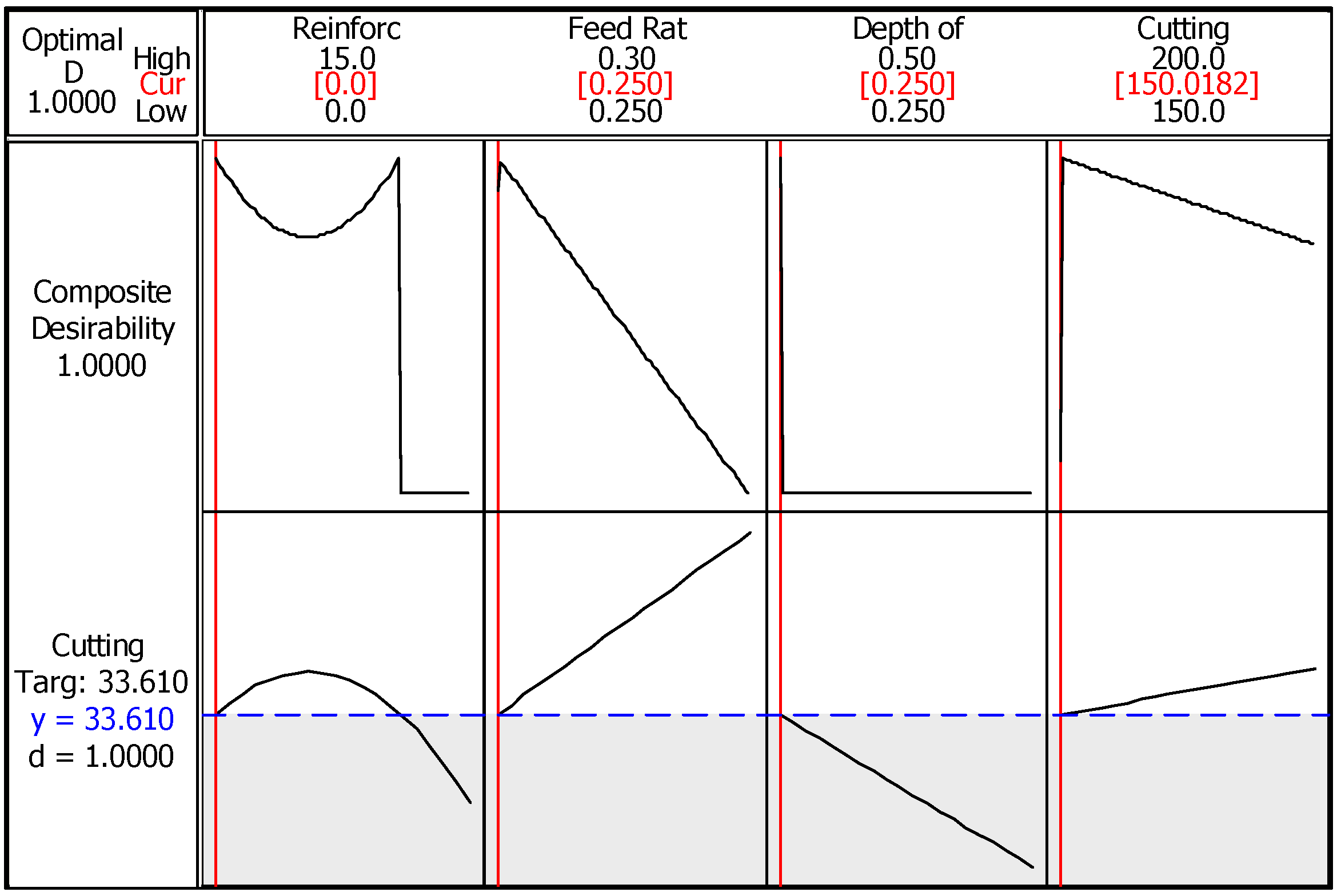

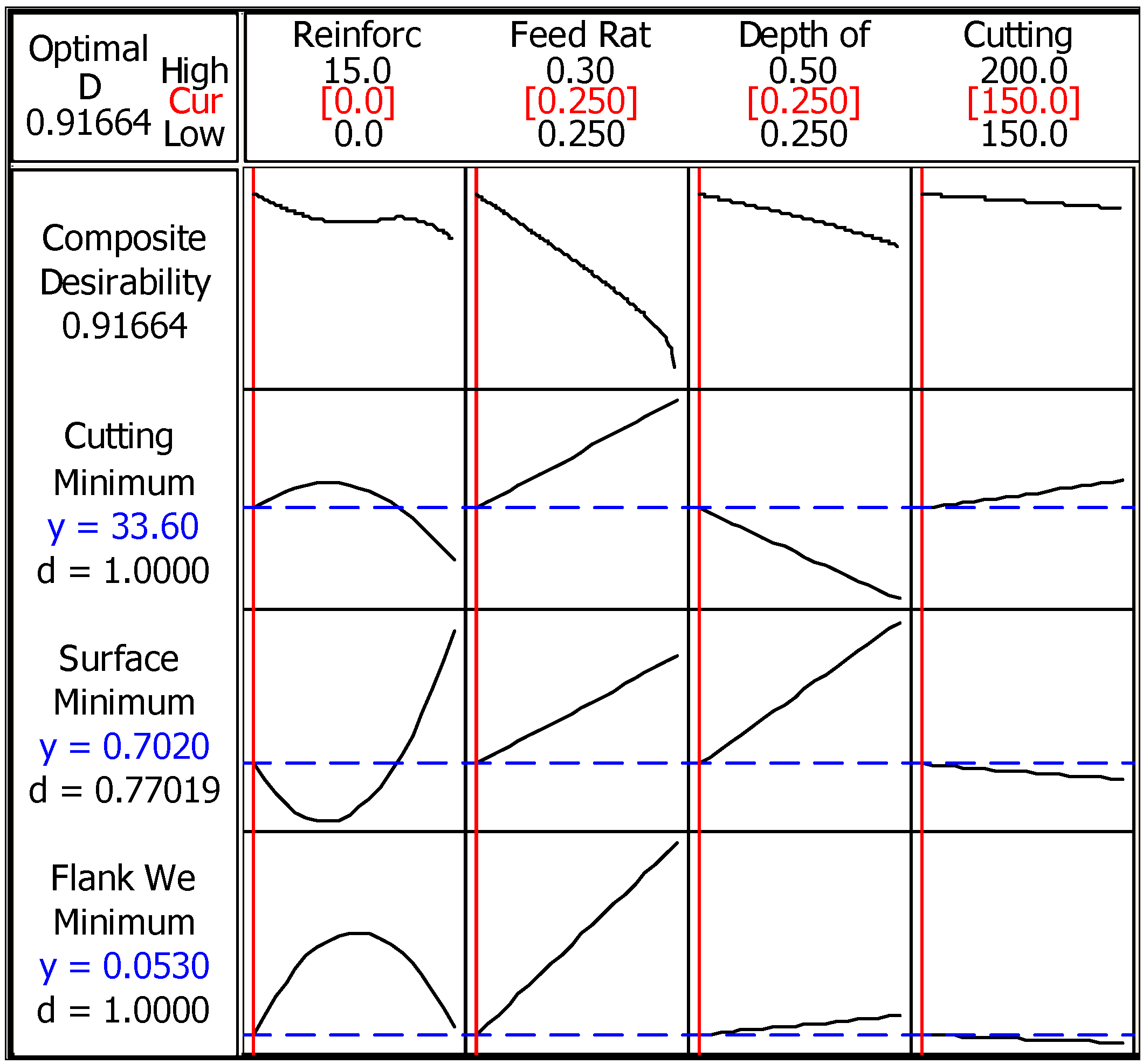

3.4. Multiple Optimizations of Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Mia, M.; Jamil, M.; Singla, A.K.; Bansal, A.; Pimenov, D.Y.; Kuntoğlu, M. Tribological Performance Based Machinability Investigations in Cryogenic Cooling Assisted Turning of α-β Titanium Alloy. Tribol. Int. 2021, 160, 107032. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Düzcükoğlu, H.; Şahin, Ö.S.; Ekrem, M. The effects of harsh aging environments on the properties of neat and MWCNT reinforced epoxy resins. Constr. Build. Mater. 2021, 272, 121929. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; Khan, A.M.; Dhar, N.R. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Singh, G.; Pimenov, D.Y.; Sarikaya, M.; Sharma, V.S. Hybrid cooling-lubrication strategies to improve surface topography and tool wear in sustainable turning of Al 7075-T6 alloy. Int. J. Adv. Manuf. Technol. 2019, 101, 55–69. [Google Scholar] [CrossRef]

- Aslan, A.; Güneş, A.; Salur, E.; Şahin, Ö.S.; Karadağ, H.B.; Akdemir, A. Mechanical properties and microstructure of composites produced by recycling metal chips. Int. J. Miner. Metall. Mater. 2018, 25, 1070–1079. [Google Scholar] [CrossRef]

- Salur, E.; Acarer, M.; Şavkliyildiz, İ. Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing. Mater. Today Commun. 2021, 27, 102202. [Google Scholar] [CrossRef]

- Şahin, Ö.S.; Güneş, A.; Aslan, A.; Salur, E.; Karadağ, H.B.; Akdemir, A. Low-velocity impact behavior of porous metal matrix composites produced by recycling of bronze and iron chips. Iran. J. Sci. Technol. Trans. Mech. Eng. 2019, 43, 53–60. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Gupta, M.K.; Mia, M.; Królczyk, G.; Khanna, N. Synthesis, characterization, corrosion resistance and in-vitro bioactivity behavior of biodegradable Mg–Zn–Mn–(Si–HA) composite for orthopaedic applications. Materials 2018, 11, 1602. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Güneş, A.; Şahin, Ö.S.; Karadağ, H.B.; Akdemir, A. The Effect of Ultrasonic Cleaning Upon Mechanical Properties of Metal Matrix Composites. Trans. Indian Inst. Met. 2021, 74, 107–118. [Google Scholar] [CrossRef]

- Ismail, S.O.; Sarfraz, S.; Niamat, M.; Mia, M.; Gupta, M.K.; Pimenov, D.Y.; Shehab, E. Comprehensive study on tool wear during machining of fiber-reinforced polymeric composites. In Machining and Machinability of Fiber Reinforced Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2021; pp. 129–147. [Google Scholar]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos. Part B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Vinod, A.; Gowda, T.Y.; Vijay, R.; Sanjay, M.; Gupta, M.K.; Jamil, M.; Kushvaha, V.; Siengchin, S. Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: A sustainable and green material for cleaner production. J. Clean. Prod. 2021, 294, 126337. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K.; Prakash, S. Grey-fuzzy algorithm to optimise machining parameters in drilling of hybrid metal matrix composites. Compos. Part B Eng. 2013, 50, 297–308. [Google Scholar] [CrossRef]

- Uzun, M.; Munis, M.M.; Usca, U. Different ratios CrC particle-reinforced Cu matrix composite materials and investigation of wear performance. J. Eng. Res. Appl. 2018, 8, 1–7. [Google Scholar]

- Uzun, M.; Usca, U.A. Effect of Cr particulate reinforcements in different ratios on wear performance and mechanical properties of Cu matrix composites. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 197. [Google Scholar] [CrossRef]

- Sap, E. Microstructure and Mechanical Effects of Co–Ti Powder Particles on Cu Matrix Composites. Russ. J. Non Ferr. Met. 2021, 62, 107–118. [Google Scholar]

- Halil, K.; İsmail, O.; Sibel, D.; Ramazan, Ç. Wear and mechanical properties of Al6061/SiC/B4C hybrid composites produced with powder metallurgy. J. Mater. Res. Technol. 2019, 8, 5348–5361. [Google Scholar] [CrossRef]

- Gode, C. Mechanical properties of hot pressed SiCp and B4Cp/Alumix 123 composites alloyed with minor Zr. Compos. Part B Eng. 2013, 54, 34–40. [Google Scholar] [CrossRef]

- Vijay, R.; Lenin Singaravelu, D.; Filip, P. Influence of molybdenum disulfide particle size on friction and wear characteristics of non-asbestos-based copper-free brake friction composites. Surf. Rev. Lett. 2020, 27, 1950085. [Google Scholar] [CrossRef]

- Razavykia, A.; Farahany, S.; Yusof, N.M. Evaluation of cutting force and surface roughness in the dry turning of Al–Mg2Si in-situ metal matrix composite inoculated with bismuth using DOE approach. Measurement 2015, 76, 170–182. [Google Scholar] [CrossRef]

- Barzani, M.M.; Farahany, S.; Songmene, V. Machinability characteristics, thermal and mechanical properties of Al-Mg2Si in-situ composite with bismuth. Measurement 2017, 110, 263–274. [Google Scholar] [CrossRef]

- Laghari, R.A.; Li, J.; Xie, Z.; Wang, S.-Q. Modeling and Optimization of Tool Wear and Surface Roughness in Turning of Al/SiCp Using Response Surface Methodology. 3D Res. 2018, 9, 46. [Google Scholar] [CrossRef]

- Liu, H.; Zong, W. Prediction model of tool wear volume in precision turning of ceramic particle reinforced aluminum matrix composites. Int. J. Adv. Manuf. Technol. 2019, 100, 2689–2700. [Google Scholar] [CrossRef]

- Lin, K.; Wang, W.; Jiang, R.; Xiong, Y. Effect of tool nose radius and tool wear on residual stresses distribution while turning in situ TiB 2/7050 Al metal matrix composites. Int. J. Adv. Manuf. Technol. 2019, 100, 143–151. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Nataraj, M.; Palanisamy, D. Machinability analysis and application of response surface approach on CNC turning of LM6/SiCp composites. Mater. Manuf. Process. 2019, 34, 1389–1400. [Google Scholar]

- Kumar, A.; Mahapatra, M.; Jha, P. Effect of machining parameters on cutting force and surface roughness of in situ Al–4.5% Cu/TiC metal matrix composites. Measurement 2014, 48, 325–332. [Google Scholar] [CrossRef]

- Barzani, M.M.; Sarhan, A.A.; Farahany, S.; Ramesh, S.; Maher, I. Investigating the Machinability of Al–Si–Cu cast alloy containing bismuth and antimony using coated carbide insert. Measurement 2015, 62, 170–178. [Google Scholar] [CrossRef]

- Kumar, R.; Chauhan, S. Study on surface roughness measurement for turning of Al 7075/10/SiCp and Al 7075 hybrid composites by using response surface methodology (RSM) and artificial neural networking (ANN). Measurement 2015, 65, 166–180. [Google Scholar] [CrossRef]

- Kumar, N.S.; Shankar, G.S.; Basavarajappa, S.; Suresh, R. Some studies on mechanical and machining characteristics of Al2219/n-B4C/MoS2 nano-hybrid metal matrix composites. Measurement 2017, 107, 1–11. [Google Scholar] [CrossRef]

- Pugazhenthi, A.; Kanagaraj, G.; Dinaharan, I.; Selvam, J.D.R. Turning characteristics of in situ formed TiB2 ceramic particulate reinforced AA7075 aluminum matrix composites using polycrystalline diamond cutting tool. Measurement 2018, 121, 39–46. [Google Scholar] [CrossRef]

- Bai, W.; Roy, A.; Sun, R.; Silberschmidt, V.V. Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning. J. Mater. Process. Technol. 2019, 268, 149–161. [Google Scholar] [CrossRef]

- Shoba, C.; Ramanaiah, N.; Rao, D.N. Effect of reinforcement on the cutting forces while machining metal matrix composites—An experimental approach. Eng. Sci. Technol. Int. J. 2015, 18, 658–663. [Google Scholar] [CrossRef]

- Laghari, R.A.; Li, J.; Mia, M. Effects of turning parameters and parametric optimization of the cutting forces in machining SiCp/Al 45 wt% composite. Metals 2020, 10, 840. [Google Scholar] [CrossRef]

- Niknam, S.A.; Kamalizadeh, S.; Asgari, A.; Balazinski, M. Turning titanium metal matrix composites (Ti-MMCs) with carbide and CBN inserts. Int. J. Adv. Manuf. Technol. 2018, 97, 253–265. [Google Scholar] [CrossRef]

- Josyula, S.K.; Narala, S.K.R. Performance enhancement of cryogenic machining and its effect on tool wear during turning of Al-Ticp composites. Mach. Sci. Technol. 2018, 22, 225–248. [Google Scholar] [CrossRef]

- Nataraj, M.; Balasubramanian, K. Parametric optimization of CNC turning process for hybrid metal matrix composite. Int. J. Adv. Manuf. Technol. 2017, 93, 215–224. [Google Scholar] [CrossRef]

- Şap, E.; Usca, U.A.; Gupta, M.K.; Kuntoğlu, M. Tool wear and machinability investigations in dry turning of Cu/Mo-SiC p hybrid composites. Int. J. Adv. Manuf. Technol. 2021, 1–18. [Google Scholar] [CrossRef]

- Abbas, A.T.; Gupta, M.K.; Soliman, M.S.; Mia, M.; Hegab, H.; Luqman, M.; Pimenov, D.Y. Sustainability assessment associated with surface roughness and power consumption characteristics in nanofluid MQL-assisted turning of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1311–1327. [Google Scholar] [CrossRef]

- Kumar, P.; Chauhan, S.R.; Pruncu, C.I.; Gupta, M.K.; Pimenov, D.Y.; Mia, M.; Gill, H.S. Influence of different grades of CBN inserts on cutting force and surface roughness of AISI H13 die tool steel during hard turning operation. Materials 2019, 12, 177. [Google Scholar] [CrossRef]

- Meral, G.; Sarıkaya, M.; Mia, M.; Dilipak, H.; Şeker, U.; Gupta, M.K. Multi-objective optimization of surface roughness, thrust force, and torque produced by novel drill geometries using Taguchi-based GRA. Int. J. Adv. Manuf. Technol. 2019, 101, 1595–1610. [Google Scholar] [CrossRef]

- Mia, M.; Rifat, A.; Tanvir, M.F.; Gupta, M.K.; Hossain, M.J.; Goswami, A. Multi-objective optimization of chip-tool interaction parameters using Grey-Taguchi method in MQL-assisted turning. Measurement 2018, 129, 156–166. [Google Scholar] [CrossRef]

- Nouioua, M.; Yallese, M.A.; Khettabi, R.; Belhadi, S.; Bouhalais, M.L.; Girardin, F. Investigation of the performance of the MQL, dry, and wet turning by response surface methodology (RSM) and artificial neural network (ANN). Int. J. Adv. Manuf. Technol. 2017, 93, 2485–2504. [Google Scholar] [CrossRef]

- Parida, A.K.; Maity, K. Modeling of machining parameters affecting flank wear and surface roughness in hot turning of Monel-400 using response surface methodology (RSM). Measurement 2019, 137, 375–381. [Google Scholar] [CrossRef]

- Costa, N.R.; Lourenço, J.; Pereira, Z.L. Desirability function approach: A review and performance evaluation in adverse conditions. Chemom. Intell. Lab. Syst. 2011, 107, 234–244. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Sağlam, H.; Pimenov, D.Y.; Giasin, K.; Mikolajczyk, T. Optimization and Analysis of Surface Roughness, Flank Wear and 5 Different Sensorial Data via Tool Condition Monitoring System in Turning of AISI 5140. Sensors 2020, 20, 4377. [Google Scholar] [CrossRef]

- Mia, M.; Khan, M.A.; Dhar, N.R. Study of surface roughness and cutting forces using ANN, RSM, and ANOVA in turning of Ti-6Al-4V under cryogenic jets applied at flank and rake faces of coated WC tool. Int. J. Adv. Manuf. Technol. 2017, 93, 975–991. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Gunes, A.; Sahin, O.; Karadag, H.; Akdemir, A. The mechanical properties of composite materials recycled from waste metallic chips under different pressures. Int. J. Environ. Sci. Technol. 2019, 16, 5259–5266. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of Signal Behaviors for Sensor Fusion with Tool Condition Monitoring System in Turning. Measurement 2020, 173, 108582. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of progressive tool wear for determining of optimized machining parameters in turning. Measurement 2019, 140, 427–436. [Google Scholar] [CrossRef]

- Aslan, A. Optimization and Analysis of Process Parameters for Flank Wear, Cutting Forces and Vibration in Turning of AISI 5140: A Comprehensive Study. Measurement 2020, 163, 107959. [Google Scholar] [CrossRef]

- Khanna, N.; Airao, J.; Gupta, M.K.; Song, Q.; Liu, Z.; Mia, M.; Maruda, R.; Krolczyk, G. Optimization of Power Consumption Associated with Surface Roughness in Ultrasonic Assisted Turning of Nimonic-90 Using Hybrid Particle Swarm-Simplex Method. Materials 2019, 12, 3418. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Giasin, K.; Mikolajczyk, T.; Sharma, S. Modeling of cutting parameters and tool geometry for multi-criteria optimization of surface roughness and vibration via response surface methodology in turning of AISI 5140 steel. Materials 2020, 13, 4242. [Google Scholar] [CrossRef] [PubMed]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2020, 21, 108. [Google Scholar] [CrossRef] [PubMed]

- Siddhpura, A.; Paurobally, R. A review of flank wear prediction methods for tool condition monitoring in a turning process. Int. J. Adv. Manuf. Technol. 2013, 65, 371–393. [Google Scholar] [CrossRef]

- Özbek, O.; Saruhan, H. The effect of vibration and cutting zone temperature on surface roughness and tool wear in eco-friendly MQL turning of AISI D2. J. Mater. Res. Technol. 2020, 9, 2762–2772. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Raykar, S.J. Thermal modeling of tool temperature distribution during high pressure coolant assisted turning of Inconel 718. Materials 2019, 12, 408. [Google Scholar] [CrossRef] [PubMed]

- Davim, J.P. Machining of Metal Matrix Composites; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Iuliano, L.; Settineri, L.; Gatto, A. High-speed turning experiments on metal matrix composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1501–1509. [Google Scholar] [CrossRef]

| Ref. | Reinf. Ratios | Main/ Additive Materials | Investigated Response Parameters | The Effect of Increased Reinforcement | The Effect of Other Parameters |

|---|---|---|---|---|---|

| [20] | 0.4% | Al-Mg2Si/Bismuth | Surface Roughness, Cutting Force, Chip Formation, Tool Wear | Lower cutting force, surface roughness, chip length, and built-up-edge tendency | Feed rate and cutting speed are effective on surface roughness |

| [21] | 0.4% | Al-Mg2Si/Bismuth | Surface Roughness, Cutting Force, Chip Formation, Tool Wear | Improved cutting force, surface roughness, chip breakability, less built up edge tendency | Feed rate and cutting speed are effective on surface roughness |

| [26] | 5-7-10% | Al-4.5%Cu/TiC | Cutting Force, Surface Roughness, Built Up Edge Formation, Chip Formation | Discontinuous and short chips, less built up edge, poor surface roughness | Increasing feed rate, depth of cut, and decreasing cutting speed have negative impact on surface roughness |

| [27] | 1% Bi- 0.5% Sb | Al–11.3Si–2Cu | Cutting Force, Surface Roughness, Chip Formation | Bi containing has positive, Sb containing has negative effect on surface roughness | Increasing feed rate enhances surface roughness |

| [28] | 10% SiC- 7% SiC and 3% graphite | Al7075 | Surface roughness | Graphite particles improve surface roughness | Feed rate provides primary contribution |

| [29] | 2% n-B4C- 2% MoS2 | Al2219 | Cutting Force, Surface Roughness | Particle inclusion had negative effect on surface roughness | High cutting speed and low feed rate produce better surface roughness |

| [30] | 0-12% TiB2 | AA7075 | Cutting Force, Surface Roughness, Built Up Edge Formation, Chip Formation | The reinforcement decreases surface roughness | If cutting speed increases, built up edge decreases, surface roughness increases |

| Experiment Number | Reinforcement Ratio RR (%wt.) | Feed Rate f (mm/rev) | Depth of Cut aP (mm) | Cutting Speed vC (m/min) |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 2 | 1 | 1 | 2 |

| 4 | 2 | 2 | 2 | 1 |

| 5 | 3 | 1 | 2 | 1 |

| 6 | 3 | 2 | 1 | 2 |

| 7 | 4 | 1 | 2 | 2 |

| 8 | 4 | 2 | 1 | 1 |

| Experiment Number | Reinforcement (%wt.) | Feed Rate (mm/rev) | Depth of Cut (mm) | Cutting Speed (m/min) | Surface Roughness (µm) | Flank Wear (mm) | Cutting Temperature (°C) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 0.25 | 0.25 | 150 | 0.702 | 0.053 | 33.6 |

| 2 | 0 | 0.3 | 0.5 | 200 | 0.824 | 0.097 | 48.9 |

| 3 | 5 | 0.25 | 0.25 | 200 | 0.628 | 0.541 | 81.1 |

| 4 | 5 | 0.3 | 0.5 | 150 | 0.735 | 0.943 | 113.5 |

| 5 | 10 | 0.25 | 0.5 | 150 | 0.744 | 1.245 | 93.1 |

| 6 | 10 | 0.3 | 0.25 | 200 | 0.785 | 1.699 | 163 |

| 7 | 15 | 0.25 | 0.5 | 200 | 0.832 | 0.955 | 131.1 |

| 8 | 15 | 0.3 | 0.25 | 150 | 0.95 | 1.245 | 84.5 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | Percent Contribution (%) |

|---|---|---|---|---|---|---|

| Reinforcement | 3 | 5.51437 | 1.83812 | 29.06 | 0.135 | 67.36 |

| Feed te | 1 | 2.39400 | 2.39400 | 37.85 | 0.103 | 29.23 |

| Depth of cut | 1 | 0.16257 | 0.16257 | 2.57 | 0.355 | 1.98 |

| Cutting speed | 1 | 0.05459 | 0.05459 | 0.86 | 0.523 | 0.66 |

| Residual error | 1 | 0.06325 | 0.06325 | - | - | 0.77 |

| Total | 7 | 8.18877 | - | - | - | 100 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | Percent Contribution (%) |

|---|---|---|---|---|---|---|

| Reinforcement | 3 | 849.475 | 283.158 | 3,233,584.61 | 0.000 | 96.39 |

| Feed rate | 1 | 28.426 | 28.426 | 324,614.34 | 0.001 | 3.22 |

| Depth of cut | 1 | 3.216 | 3.216 | 36,727.61 | 0.003 | 0.36 |

| Cutting speed | 1 | 0.084 | 0.084 | 961.68 | 0.021 | 0.03 |

| Residual error | 1 | 0.000 | 0.000 | - | - | 0 |

| Total | 7 | 881.202 | - | - | - | 100 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | Percent Contribution (%) |

|---|---|---|---|---|---|---|

| Reinforcement | 3 | 112.572 | 37.524 | 4.32 | 0.337 | 79.69 |

| Feed rate | 1 | 6.532 | 6.532 | 0.75 | 0.545 | 4.62 |

| Depth of cut | 1 | 3.288 | 3.288 | 0.38 | 0.649 | 2.32 |

| Cutting speed | 1 | 10.169 | 10.169 | 1.17 | 0.475 | 7.21 |

| Residual error | 1 | 8.694 | 8.694 | - | - | 6.16 |

| Total | 7 | 141.256 | - | - | - | 100 |

| Parameter | Goal | Lower | Target | Upper | Weight | Import |

|---|---|---|---|---|---|---|

| Cutting Temperature | Minimum | 33.6 | 33.6 | 131.100 | 1 | 1 |

| Surface Roughness | Minimum | 0.628 | 0.628 | 0.95 | 1 | 1 |

| Flank Wear | Minimum | 0.053 | 0.053 | 1.699 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şap, E.; Usca, Ü.A.; Gupta, M.K.; Kuntoğlu, M.; Sarıkaya, M.; Pimenov, D.Y.; Mia, M. Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCP Composites Produced by Powder Metallurgy. Materials 2021, 14, 1921. https://doi.org/10.3390/ma14081921

Şap E, Usca ÜA, Gupta MK, Kuntoğlu M, Sarıkaya M, Pimenov DY, Mia M. Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCP Composites Produced by Powder Metallurgy. Materials. 2021; 14(8):1921. https://doi.org/10.3390/ma14081921

Chicago/Turabian StyleŞap, Emine, Üsame Ali Usca, Munish Kumar Gupta, Mustafa Kuntoğlu, Murat Sarıkaya, Danil Yurievich Pimenov, and Mozammel Mia. 2021. "Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCP Composites Produced by Powder Metallurgy" Materials 14, no. 8: 1921. https://doi.org/10.3390/ma14081921

APA StyleŞap, E., Usca, Ü. A., Gupta, M. K., Kuntoğlu, M., Sarıkaya, M., Pimenov, D. Y., & Mia, M. (2021). Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCP Composites Produced by Powder Metallurgy. Materials, 14(8), 1921. https://doi.org/10.3390/ma14081921