Investigations on the Effect of Layers’ Thickness and Orientations in the Machining of Additively Manufactured Stainless Steel 316L

Abstract

1. Introduction

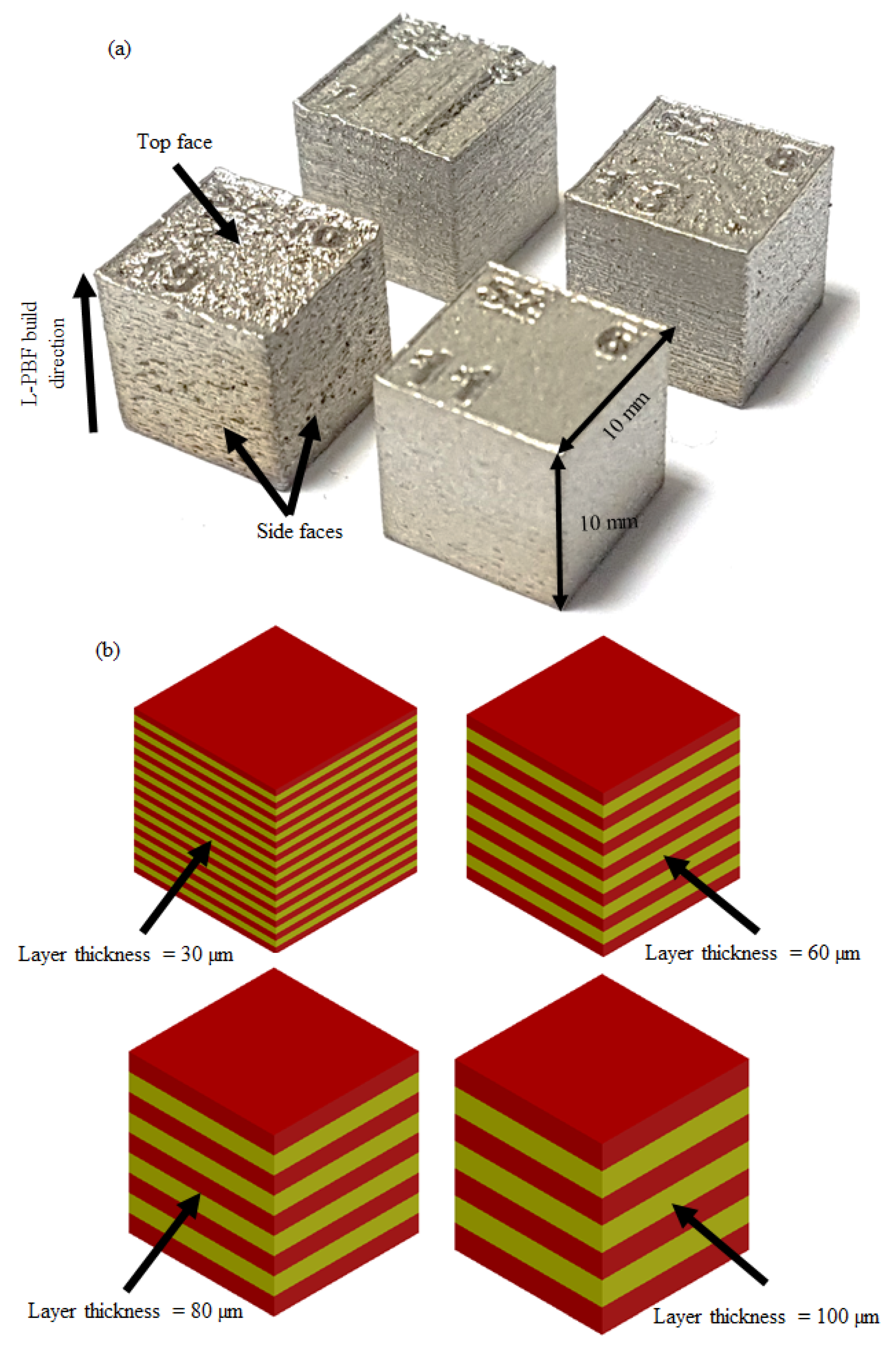

2. Experimental Work

3. Results and Discussions

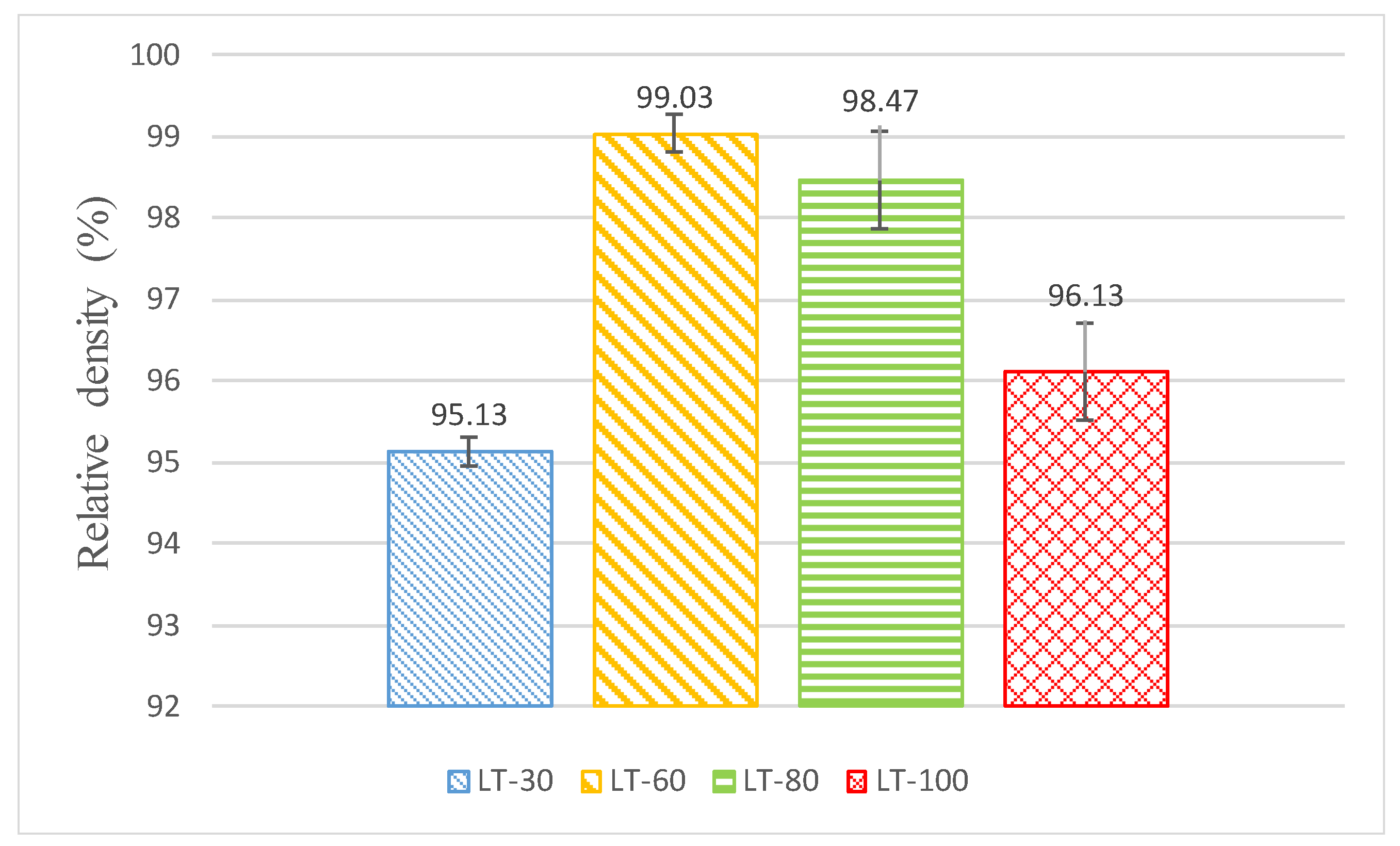

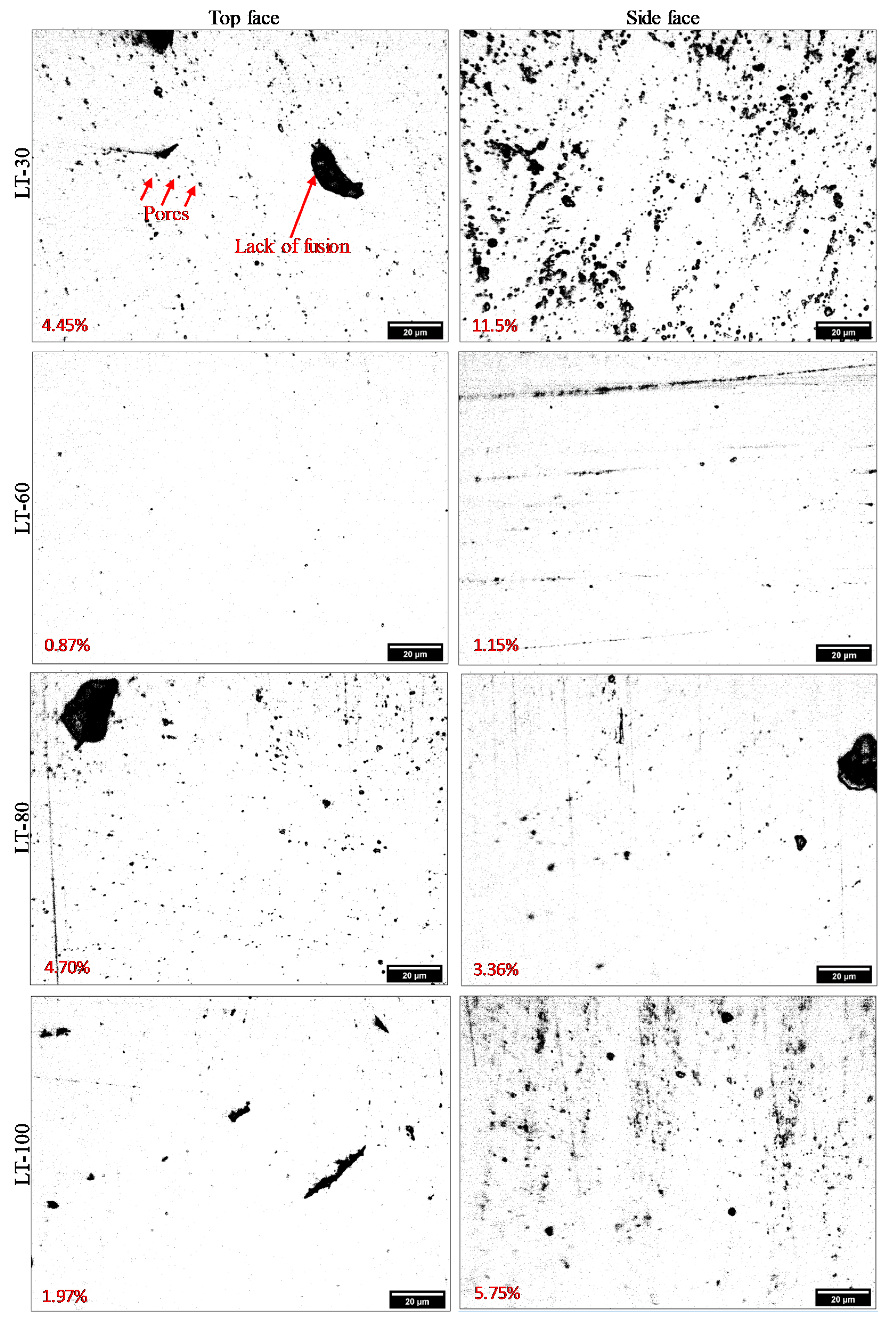

3.1. Laser-Powder Bed Fusion of SS 316L

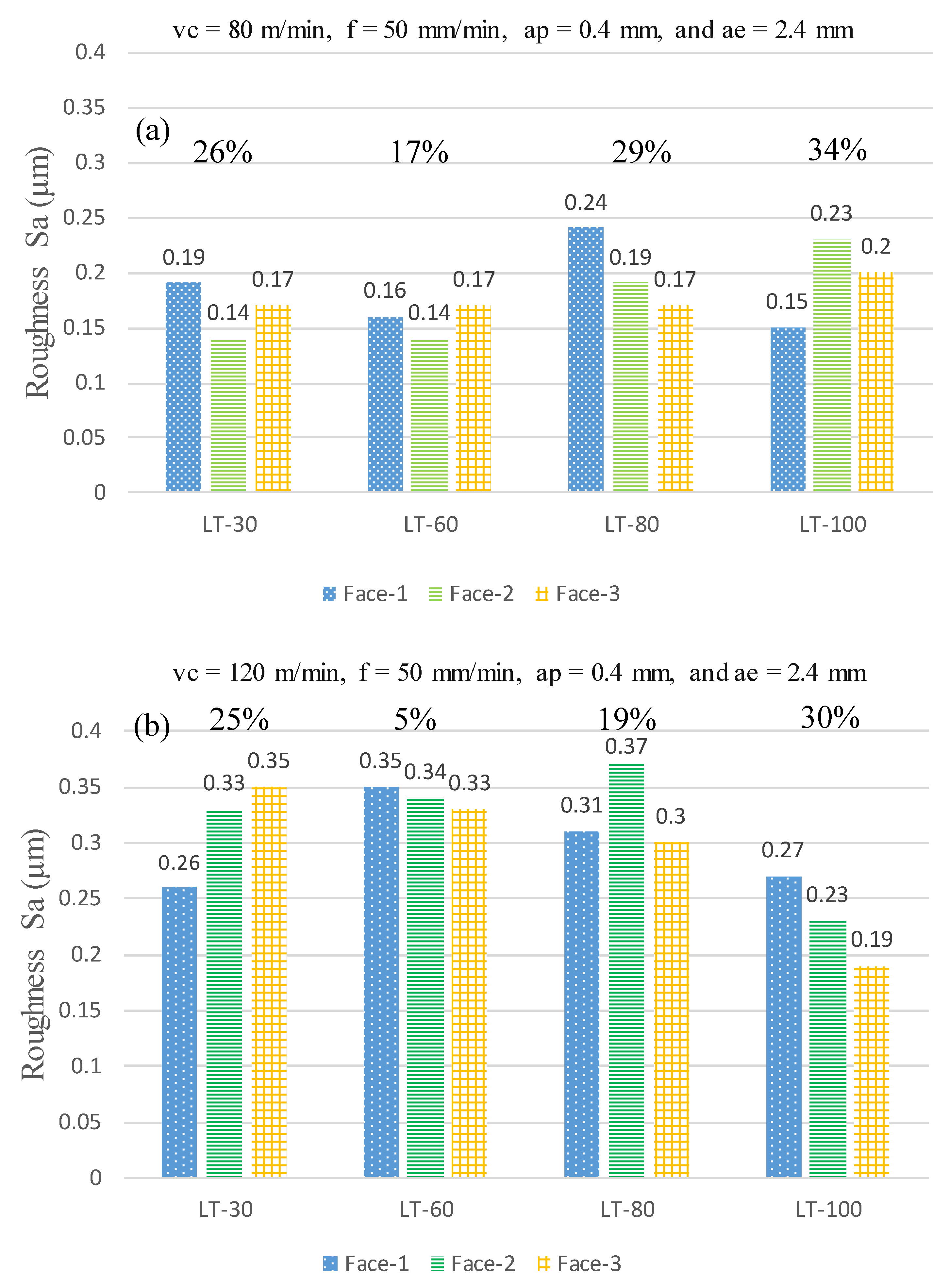

3.2. Surface Roughness

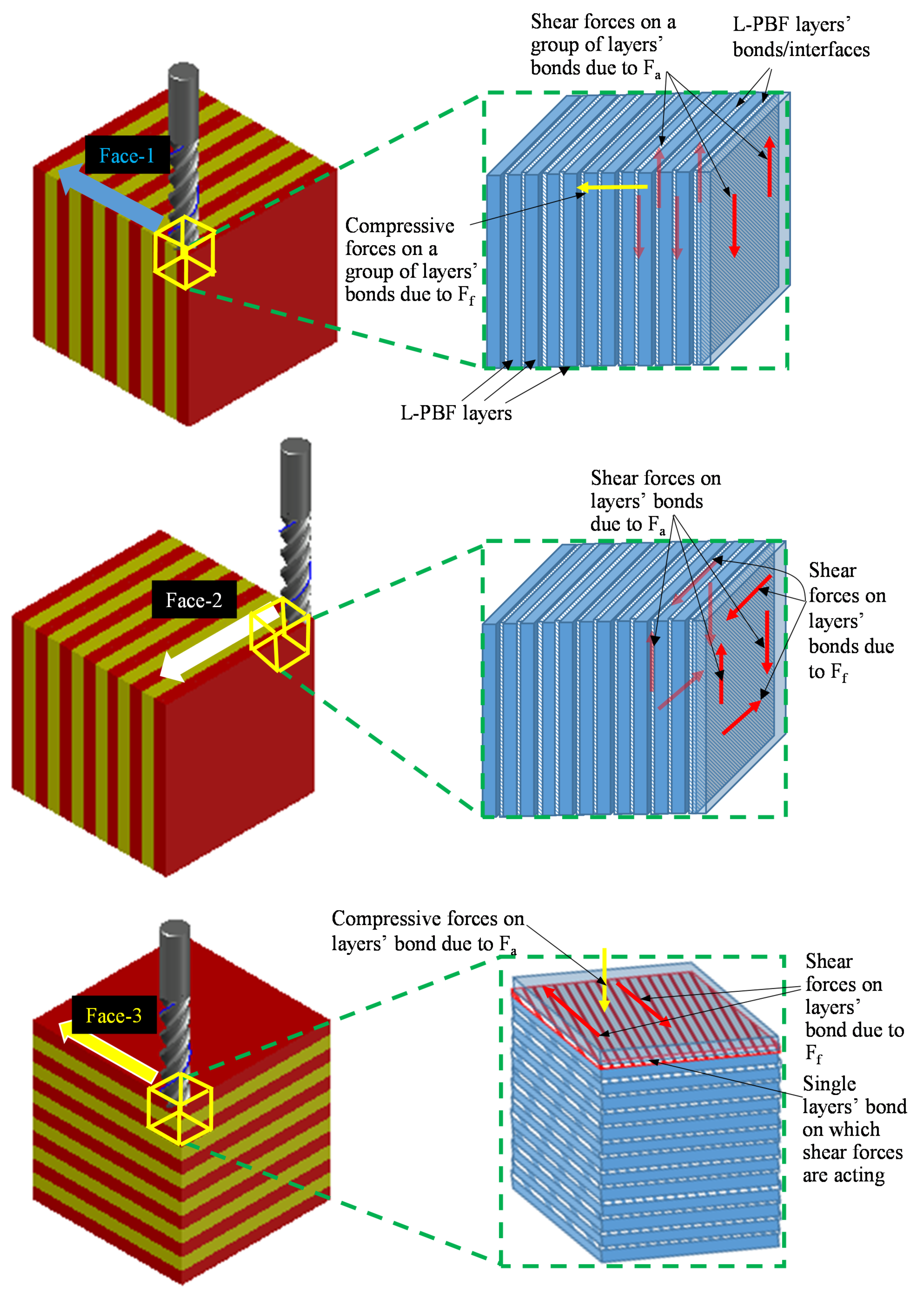

3.3. Cutting Force

3.4. Micro-Hardness

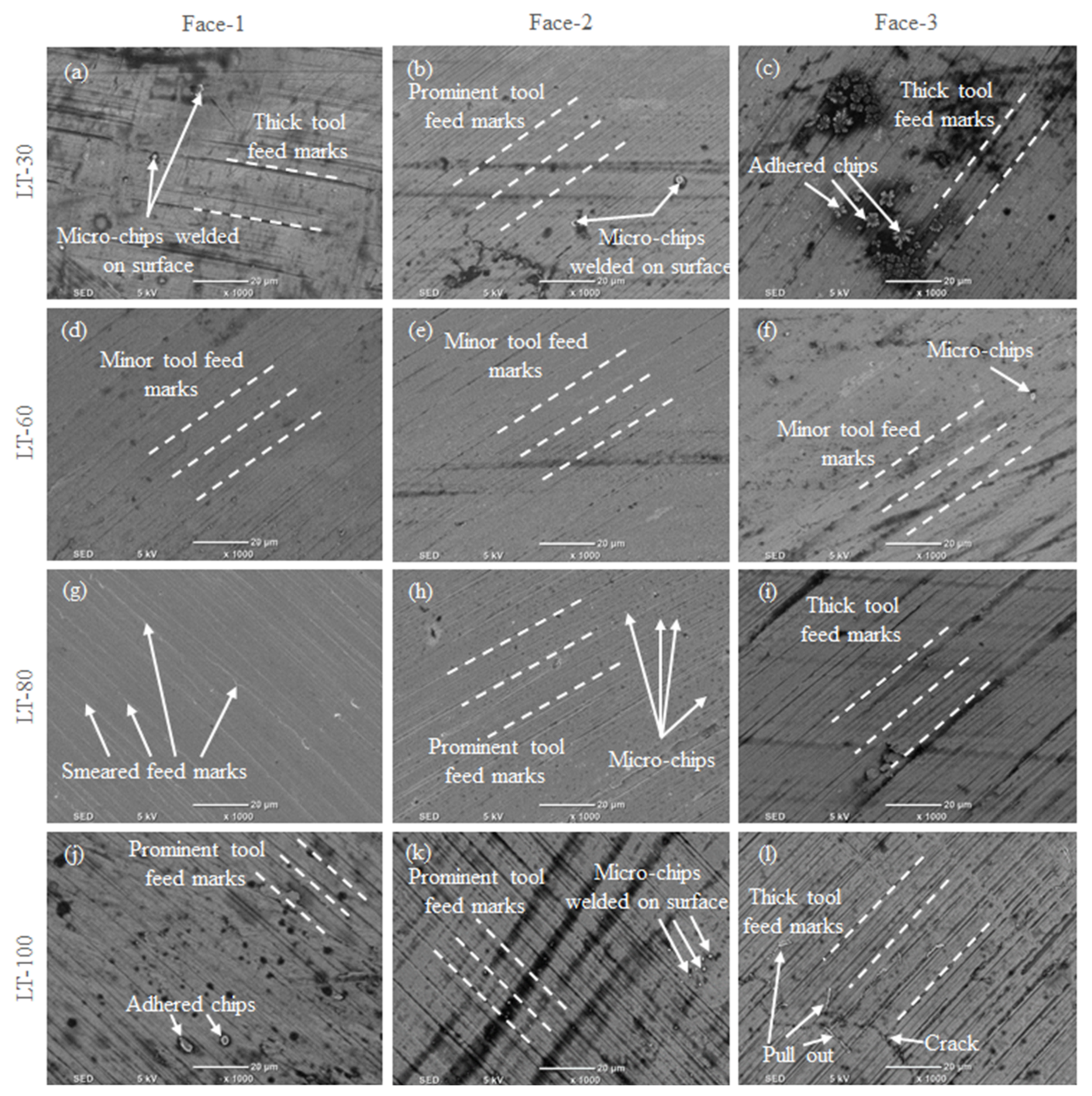

3.5. Surface Morphology

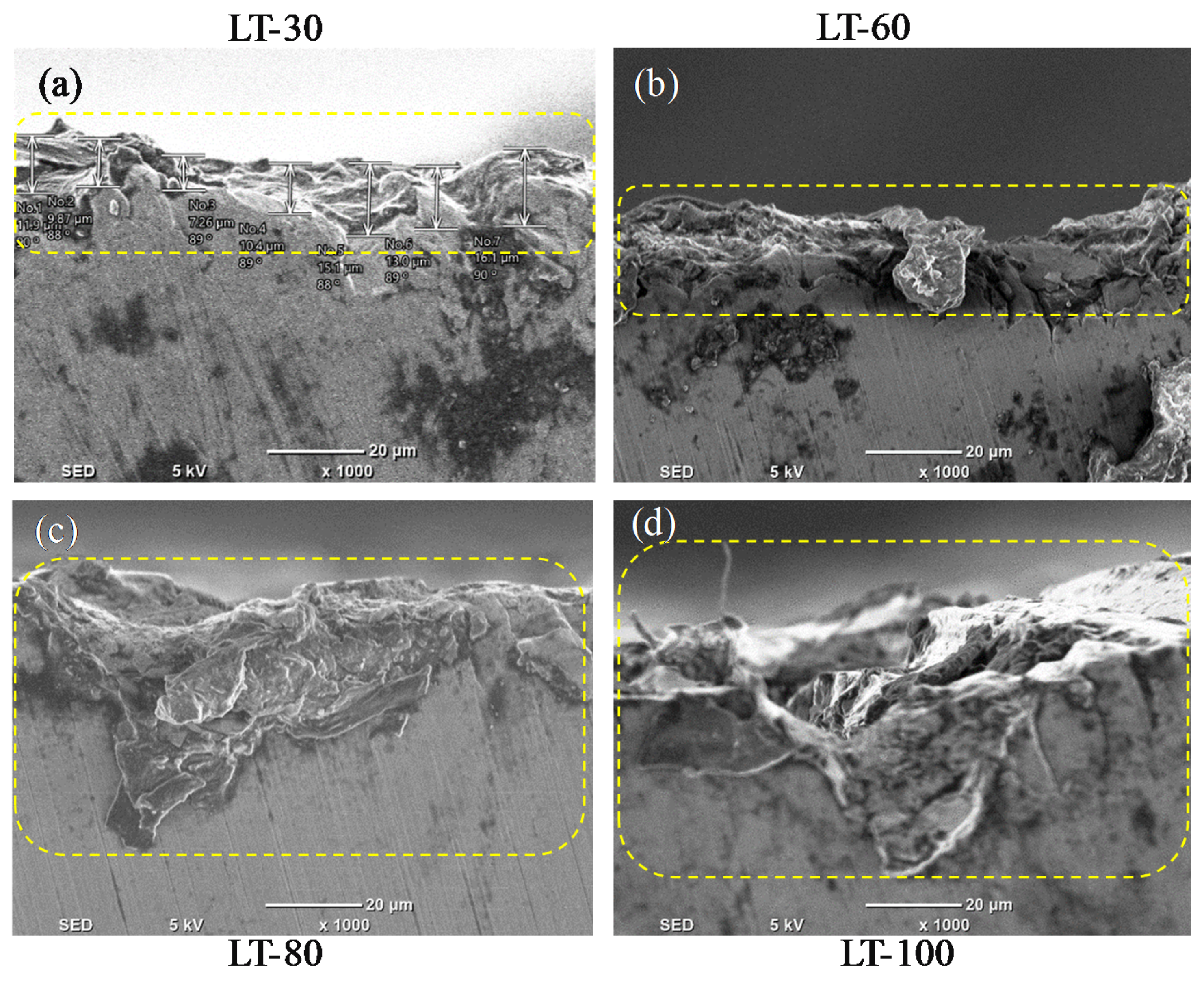

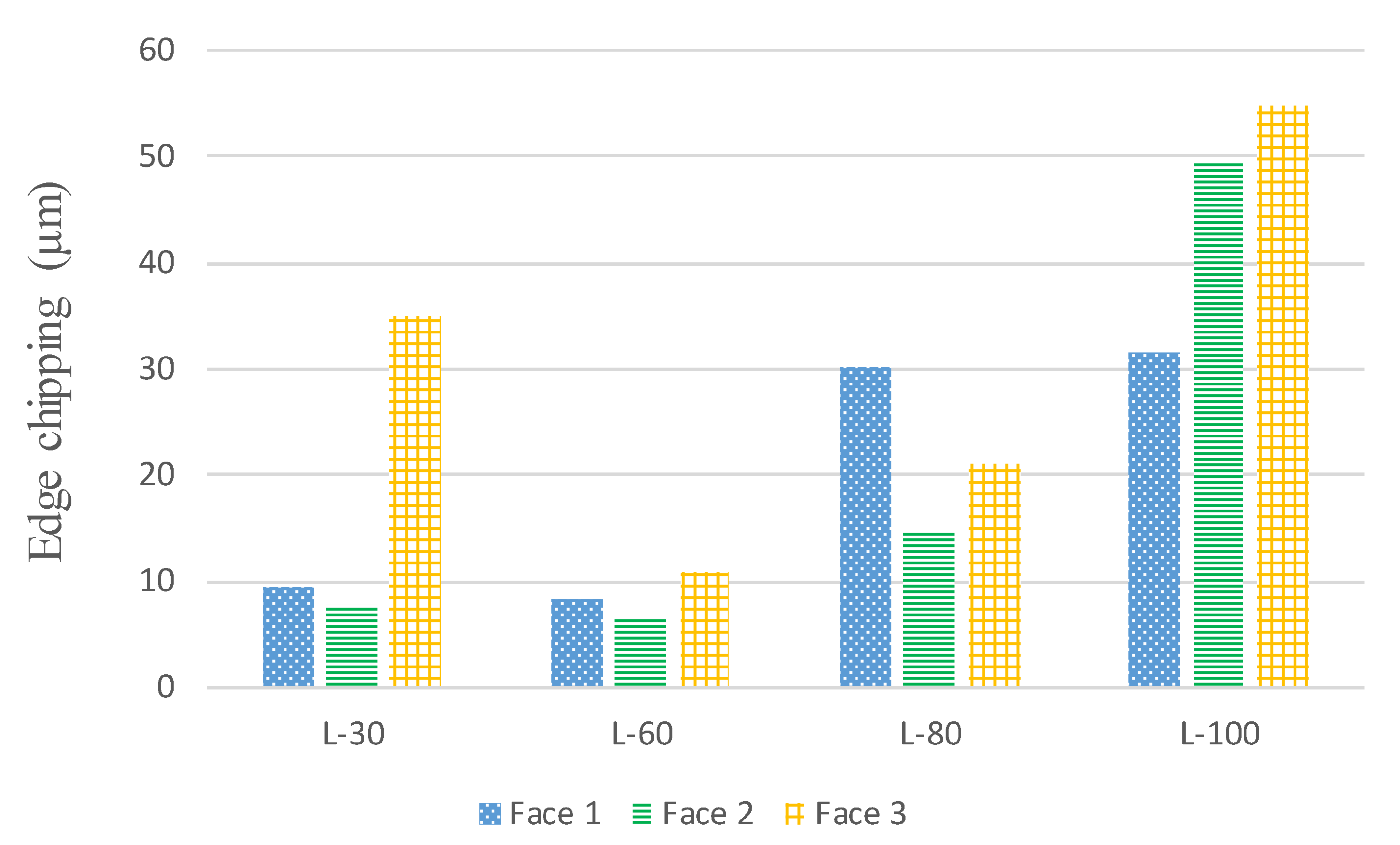

3.6. Edge Chipping

4. Conclusions

- SS 316L L-PBF parts revealed high surface roughness values on the top and side faces despite using the different layer thickness (LTs).

- Regarding the surface roughness after machining, in the case of the layer thicknesses 30, 80 and 100 μm, variation ranges from 19% to 34%. Meanwhile, in the case of the layer thickness 60 μm a uniform surface roughness was produced for all the Faces/part orientations with variation ranging from 5% to 17%.

- For cutting forces, in the case of the layer thickness of 30 μm, the differences are almost 12%, 34%, 56% for Fa, Ff and Fr, respectively. Meanwhile, for LT 80 μm, the variations among Fa, Ff and Fr are almost 25%, 28% and 51%, respectively. In addition, for the layer thickness 100 μm the differences are almost 23%, 33% and 48% for Fa, Ff and Fr, respectively. Nevertheless, for the layer thickness of 60 μm, the differences are found to be the lowest at 11%, 25% and 28% for Fa, Ff and Fr, respectively.

- After machining of the L-PBF parts produced with LT 60 μm, the micro-hardness differences among all the Faces were reduced to an insignificant of 1.7%. On the contrary, the micro-hardness variations of 8.3%, 14.7%, 6.5% were observed after milling across different faces for LTs 30, 80 and 100 μm, respectively.

- For LTs 30, 80 and 100 μm, the machined L-PBF parts showed varying surface morphology for different Faces with indications of welded micro to macro-sized chips and fluctuating minor to thick tool feed marks. In contrast, only minor tool feed marks and some micro-redeposited chips were observed after milling of the LT 60 μm parts for any Faces/part orientations.

- The side edge chipping is found to be high for the two-layer thicknesses 80 and 100 μm. Meanwhile, the layer thickness of 30 and 60 μm present low side edge chipping.

- Overall, the results indicate that the L-PBF parts produced with LT 60 μm present better machinability in terms of improved surface finish and surface integrity. In addition, the Face-1 orientation must be preferred while finishing the L-PBF parts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Rosa, F.; Manzoni, S.; Casati, R. Damping behavior of 316L lattice structures produced by Selective Laser Melting. Mater. Des. 2018, 160, 1010–1018. [Google Scholar] [CrossRef]

- Muthukumaran, V.; Selladurai, V.; Nandhakumar, S.; Senthilkumar, M. Experimental investigation on corrosion and hardness of ion implanted AISI 316L stainless steel. Mater. Des. 2010, 31, 2813–2817. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Osakada, K.; Shiomi, M. Flexible manufacturing of metallic products by selective laser melting of powder. Int. J. Mach. Tools Manuf. 2006, 46, 1188–1193. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L.; Sewell, N. Effect of selective laser melting layout on the quality of stainless steel parts. Rapid Prototyp. J. 2012, 18, 241–249. [Google Scholar] [CrossRef]

- Wong, M.; Owen, I.; Sutcliffe, C.; Puri, A. Convective heat transfer and pressure losses across novel heat sinks fabricated by Selective Laser Melting. Int. J. Heat Mass Transf. 2009, 52, 281–288. [Google Scholar] [CrossRef]

- Mathisen, M.B. In-Situ Tensile Testing Combined with EBSD Analysis of Ti-6Al-4V Samples from Components Fabricated by Additive Layer Manufacture. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2012. [Google Scholar]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. J. Mater. Process. Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Alrbaey, K.; Wimpenny, D.; Tosi, R.; Manning, W.; Moroz, A. On Optimization of Surface Roughness of Selective Laser Melted Stainless Steel Parts: A Statistical Study. J. Mater. Eng. Perform. 2014, 23, 2139–2148. [Google Scholar] [CrossRef]

- Abele, E.; Kniepkamp, M. Analysis and optimisation of vertical surface roughness in micro selective laser melting. Surf. Topogr. Metrol. Prop. 2015, 3, 034007. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- Mohammadi, M.; Asgari, H. Achieving low surface roughness AlSi10Mg_200C parts using direct metal laser sintering. Addit. Manuf. 2018, 20, 23–32. [Google Scholar] [CrossRef]

- Tebaldo, V.; Faga, M.G. Influence of the heat treatment on the microstructure and machinability of titanium aluminides produced by electron beam melting. J. Mater. Process. Technol. 2017, 244, 289–303. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.-P. Microstructural investigation of Selective Laser Melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Delgado, J.; Ciurana, J.; Rodríguez, C.A. Influence of process parameters on part quality and mechanical properties for DMLS and SLM with iron-based materials. Int. J. Adv. Manuf. Technol. 2012, 60, 601–610. [Google Scholar] [CrossRef]

- Ali, U.; Esmaeilizadeh, R.; Ahmed, F.; Sarker, D.; Muhammad, W.; Keshavarzkermani, A.; Mahmoodkhani, Y.; Marzbanrad, E.; Toyserkani, E. Identification and characterization of spatter particles and their effect on surface roughness, density and mechanical response of 17-4 PH stainless steel laser powder-bed fusion parts. Mater. Sci. Eng. A 2019, 756, 98–107. [Google Scholar] [CrossRef]

- Gupta, M.K.; Singla, A.K.; Ji, H.; Song, Q.; Liu, Z.; Cai, W.; Mia, M.; Khanna, N.; Krolczyk, G.M. Impact of layer rotation on micro-structure, grain size, surface integrity and mechanical behaviour of SLM Al-Si-10Mg alloy. J. Mater. Res. Technol. 2020, 9, 9506–9522. [Google Scholar] [CrossRef]

- Aqilah, D.N.; Sayuti, A.K.M.; Farazila, Y.; Suleiman, D.Y.; Amirah, M.A.N.; Izzati, W.B.W.N. Effects of Process Parameters on the Surface Roughness of Stainless Steel 316L Parts Produced by Selective Laser Melting. J. Test. Evaluation 2018, 46, 1673–1683. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of Layer Thickness in Selective Laser Melting on Microstructure of Al/5 wt.%Fe2O3Powder Consolidated Parts. Sci. World J. 2014, 2014, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Savalani, M.M.; Pizarro, J.M. Effect of preheat and layer thickness on selective laser melting (SLM) of magnesium. Rapid Prototyp. J. 2016, 22, 115–122. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Gao, M.; Zeng, X. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Chen, C.; Wu, Q.; Chen, X.; Lu, J. Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V. Materials 2016, 9, 975. [Google Scholar] [CrossRef] [PubMed]

- Sufiiarov, V.; Popovich, A.; Borisov, E.; Polozov, I.; Masaylo, D.; Orlov, A. The Effect of Layer Thickness at Selective Laser Melting. Procedia Eng. 2017, 174, 126–134. [Google Scholar] [CrossRef]

- Shi, W.; Wang, P.; Liu, Y.; Hou, Y.; Han, G. Properties of 316L formed by a 400 W power laser Selective Laser Melting with 250 μm layer thickness. Powder Technol. 2020, 360, 151–164. [Google Scholar] [CrossRef]

- Nguyen, Q.; Luu, D.; Nai, S.; Zhu, Z.; Chen, Z.; Wei, J. The role of powder layer thickness on the quality of SLM printed parts. Arch. Civ. Mech. Eng. 2018, 18, 948–955. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Abbas, A.T.; Gupta, M.K.; Erdakov, I.N.; Soliman, M.S.; El Rayes, M.M. Investigations of surface quality and energy consumption associated with costs and material removal rate during face milling of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 2020, 107, 3511–3525. [Google Scholar] [CrossRef]

- Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Mikolajczyk, T.; Soliman, M.S.; El Rayes, M.M. Optimization of cutting conditions using artificial neural networks and the Edgeworth-Pareto method for CNC face-milling operations on high-strength grade-H steel. Int. J. Adv. Manuf. Technol. 2019, 105, 2151–2165. [Google Scholar] [CrossRef]

- Mikołajczyk, T.; Latos, H.; Pimenov, D.Y.; Paczkowski, T.; Gupta, M.K.; Krolczyk, G. Influence of the main cutting edge angle value on minimum uncut chip thickness during turning of C45 steel. J. Manuf. Process. 2020, 57, 354–362. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Lebon, N.; Tapie, L.; Vennat, E.; Mawussi, B. Influence of CAD/CAM tool and material on tool wear and roughness of dental prostheses after milling. J. Prosthet. Dent. 2015, 114, 236–247. [Google Scholar] [CrossRef] [PubMed]

- Kaynak, Y.; Kitay, O. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2019, 26, 84–93. [Google Scholar] [CrossRef]

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.; Goyal, D.K. Selective laser melting of Ti6Al4V alloy: Process parameters, defects and post-treatments. J. Manuf. Process. 2021, 64, 161–187. [Google Scholar] [CrossRef]

- Struzikiewicz, G.; Zębala, W.; Matras, A.; Machno, M.; Ślusarczyk, Ł.; Hichert, S.; Laufer, F. Turning Research of Additive Laser Molten Stainless Steel 316L Obtained by 3D Printing. Materials 2019, 12, 182. [Google Scholar] [CrossRef]

- Matras, A. Research and Optimization of Surface Roughness in Milling of SLM Semi-Finished Parts Manufactured by Using the Different Laser Scanning Speed. Materials 2019, 13, 9. [Google Scholar] [CrossRef]

- Marimuthu, S.; Triantaphyllou, A.; Antar, M.; Wimpenny, D.; Morton, H.; Beard, M. Laser polishing of selective laser melted components. Int. J. Mach. Tools Manuf. 2015, 95, 97–104. [Google Scholar] [CrossRef]

- Balan, A.; Chidambaram, K.; Kumar, A.; Krishnaswamy, H.; Pimenov, D.; Giasin, K.; Nadolny, K. Effect of Cryogenic Grinding on Fatigue Life of Additively Manufactured Maraging Steel. Materials 2021, 14, 1245. [Google Scholar] [CrossRef]

- Dabwan, A.; Anwar, S.; Al-samhan, A. Effects of Milling Process Parameters on Cutting Forces and Surface Roughness when Finishing Ti6al4v Produced by Electron Beam Melting. Int. J. Mech. Mater. Eng. 2020, 14, 324–328. [Google Scholar]

- Kaynak, Y.; Tascioglu, E. Finish machining-induced surface roughness, microhardness and XRD analysis of selective laser melted Inconel 718 alloy. Procedia CIRP 2018, 71, 500–504. [Google Scholar] [CrossRef]

- Anwar, S.; Ahmed, N.; Abdo, B.M.; Pervaiz, S.; Chowdhury, M.A.K.; AlAhmari, A.M. Electron beam melting of gamma titanium aluminide and investigating the effect of EBM layer orientation on milling performance. Int. J. Adv. Manuf. Technol. 2018, 96, 3093–3107. [Google Scholar] [CrossRef]

- Dabwan, A.; Anwar, S.; Al-Samhan, A.M.; Nasr, M.M. On the Effect of Electron Beam Melted Ti6Al4V Part Orientations during Milling. Metals 2020, 10, 1172. [Google Scholar] [CrossRef]

- AlFaify, A.; Hughes, J.; Ridgway, K. Controlling the porosity of 316L stainless steel parts manufactured via the powder bed fusion process. Rapid Prototyp. J. 2019, 25, 162–175. [Google Scholar] [CrossRef]

- Hajnys, J.; Pagáč, M.; Měsíček, J.; Petru, J.; Król, M. Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials 2020, 13, 1659. [Google Scholar] [CrossRef] [PubMed]

- Khleif, A.A. Effect of Cutting Parameters on Wear and Surface Roughness of Stainless Steel (316L) Using Milling Process. Al-Nahrain Univ. Coll. Eng. J. 2016, 91, 286–292. [Google Scholar]

- Yasir, M.; Ginta, T.L.; Ariwahjoedi, B.; Alkali, A.U.; Danish, M. Effect of cutting speed and feed rate on surface roughness of AISI 316l SS using end-milling. ARPN J. Eng. Appl. Sci. 2016, 11, 2496–2500. [Google Scholar]

- Grguras, D.; Kern, M.; Pusavec, F. Cutting performance of solid ceramic and carbide end milling tools in machining of nickel based alloy Inconel 718 and stainless steel 316L. Adv. Prod. Eng. Manag. 2019, 14, 27–38. [Google Scholar] [CrossRef]

- Wade, S.; Javed, M.; Palombo, E.; McArthur, S.; Stoddart, P. On the need for more realistic experimental conditions in laboratory-based microbiologically influenced corrosion testing. Int. Biodeterior. Biodegradation 2017, 121, 97–106. [Google Scholar] [CrossRef]

- Heinl, M.; Greiner, S.; Wudy, K.; Pobel, C.; Rasch, M.; Huber, F.; Papke, T.; Merklein, M.; Schmidt, M.; Körner, C.; et al. Measuring procedures for surface evaluation of additively manufactured powder bed-based polymer and metal parts. Meas. Sci. Technol. 2020, 31, 095202. [Google Scholar] [CrossRef]

- Kruth, J.P.; Deckers, J.; Yasa, E.; Wauthlé, R. Assessing influencing factors of residual stresses in SLM using a novel analysis method. In Proceedings of the 16th Intenrational Symposium on Electromachining ISEM, Shanghai, China, 19–23 April 2010. [Google Scholar]

- Liu, B.; Wildman, R.; Tuck, C.; Ashcroft, I.; Hague, R. Investigation the Effect of Particle Size Distribution on Processing Parameters Optimisation in Selective Laser Melting Process; Additive Manufacturing Research Group, Loughborough University: Loughborough, UK, 2011; pp. 227–238. [Google Scholar]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of metal powder layers in laser powder bed fusion processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Bin Anwar, A.; Pham, Q.-C. Study of the spatter distribution on the powder bed during selective laser melting. Addit. Manuf. 2018, 22, 86–97. [Google Scholar] [CrossRef]

- Shrestha, R.; Simsiriwong, J.; Shamsaei, N.; Thompson, S.M.; Bian, L. Effect of Build Orientation on the Fatigue Behavior of Stainless. In Proceedings of the 2016 Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Mindt, H.W.; Megahed, M.; Lavery, N.P.; Holmes, M.A.; Brown, S.G.R. Powder Bed Layer Characteristics: The Overseen First-Order Process Input. Met. Mater. Trans. A 2016, 47, 3811–3822. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Gusarov, A.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Heat transfer modelling and stability analysis of selective laser melting. Appl. Surf. Sci. 2007, 254, 975–979. [Google Scholar] [CrossRef]

- Anwar, S.; Ahmed, N.; Pervaiz, S.; Ahmad, S.; Mohammad, A.; Saleh, M. On the turning of electron beam melted gamma-TiAl with coated and uncoated tools: A machinability analysis. J. Mater. Process. Technol. 2020, 282, 116664. [Google Scholar] [CrossRef]

- Nasr, M.M.; Anwar, S.; Al-Samhan, A.M.; Abdo, H.S.; Dabwan, A. On the machining analysis of graphene nanoplatelets reinforced Ti6Al4V matrix nanocomposites. J. Manuf. Process. 2020, 61, 574–589. [Google Scholar] [CrossRef]

- Wang, F.Z.; Zhao, J.; Li, A.H.; Zhao, J.B. Cutting Forces and Surface Roughness in High-Speed End Milling of Ti6Al4V. Key Eng. Mater. 2013, 589–590, 76–81. [Google Scholar] [CrossRef]

| Element | Wt. (%) |

|---|---|

| Cr | 17.50–18.00 |

| Ni | 12.50–13.00 |

| Mo | 2.25–2.50 |

| Mn | ≤2.00 |

| Si | ≤0.75 |

| Cu | ≤0.50 |

| N | ≤0.10 |

| O | ≤0.10 |

| P | ≤0.025 |

| C | ≤0.030 |

| L-PBF Parameters | Unit | Values |

|---|---|---|

| Point distance | μm | 70 |

| Laser power | W | 200 |

| Hatching distance | μm | 120 |

| Energy density | J/mm3 | 50 |

| Layer thickness | μm | 30, 60, 80, 100 |

| Parameters | Symbol | Value |

|---|---|---|

| Cutting speed | vc | 80, 120 m/min |

| Feed rate | f | 50 mm/min |

| Depth of cut | ap | 0.4 mm |

| Radial depth of cut | ae | 2.4 mm |

| Layer thickness | LT | 30, 60, 80, 100 μm |

| Tool feed direction | TFD | Face-1, Face-2, Face-3 |

| LT-30 | LT-60 | LT-80 | LT-100 | |

|---|---|---|---|---|

| Top side | 12.37 | 6.05 | 9.63 | 23.09 |

| Side face | 11.58 | 7.54 | 8.28 | 9.41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dabwan, A.; Anwar, S.; Al-Samhan, A.M.; AlFaify, A.; Nasr, M.M. Investigations on the Effect of Layers’ Thickness and Orientations in the Machining of Additively Manufactured Stainless Steel 316L. Materials 2021, 14, 1797. https://doi.org/10.3390/ma14071797

Dabwan A, Anwar S, Al-Samhan AM, AlFaify A, Nasr MM. Investigations on the Effect of Layers’ Thickness and Orientations in the Machining of Additively Manufactured Stainless Steel 316L. Materials. 2021; 14(7):1797. https://doi.org/10.3390/ma14071797

Chicago/Turabian StyleDabwan, Abdulmajeed, Saqib Anwar, Ali M. Al-Samhan, Abdullah AlFaify, and Mustafa M. Nasr. 2021. "Investigations on the Effect of Layers’ Thickness and Orientations in the Machining of Additively Manufactured Stainless Steel 316L" Materials 14, no. 7: 1797. https://doi.org/10.3390/ma14071797

APA StyleDabwan, A., Anwar, S., Al-Samhan, A. M., AlFaify, A., & Nasr, M. M. (2021). Investigations on the Effect of Layers’ Thickness and Orientations in the Machining of Additively Manufactured Stainless Steel 316L. Materials, 14(7), 1797. https://doi.org/10.3390/ma14071797