Effect of Graded-Indium-Content Superlattice on the Optical and Structural Properties of Yellow-Emitting InGaN/GaN Quantum Wells

Abstract

1. Introduction

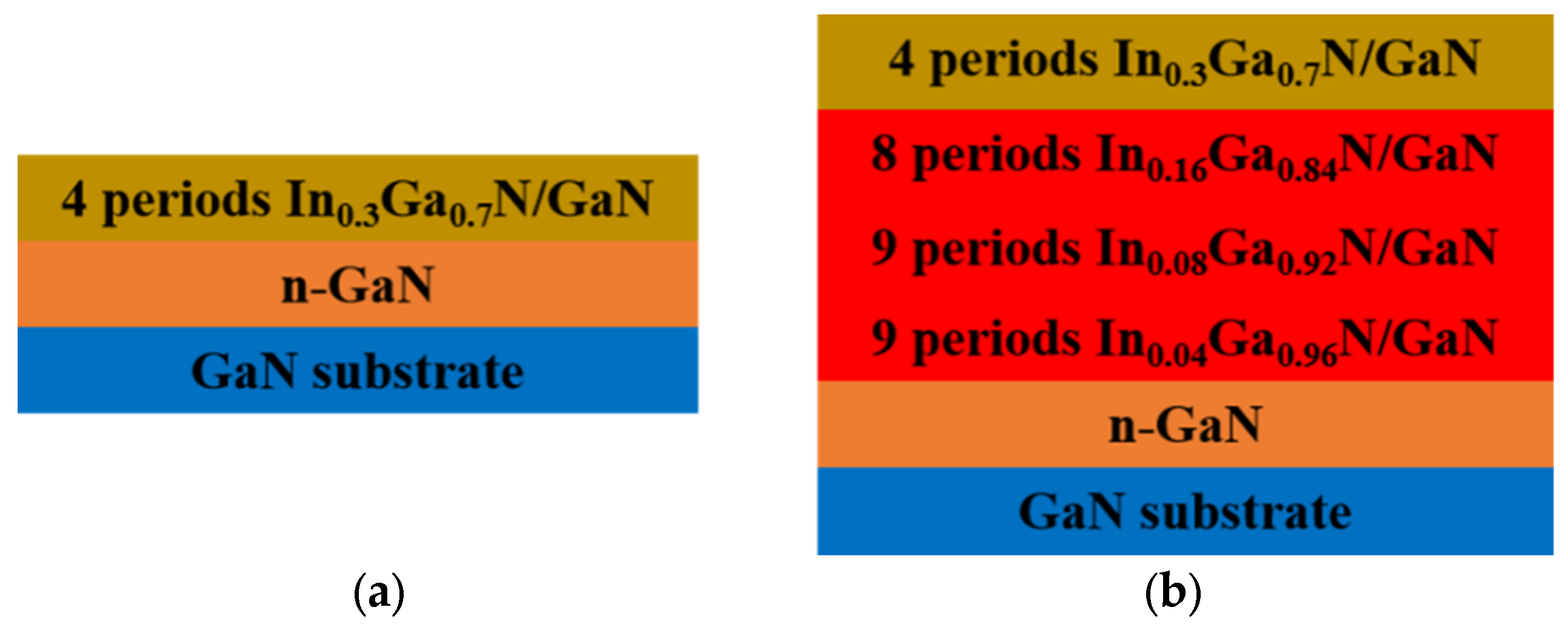

2. Experimental

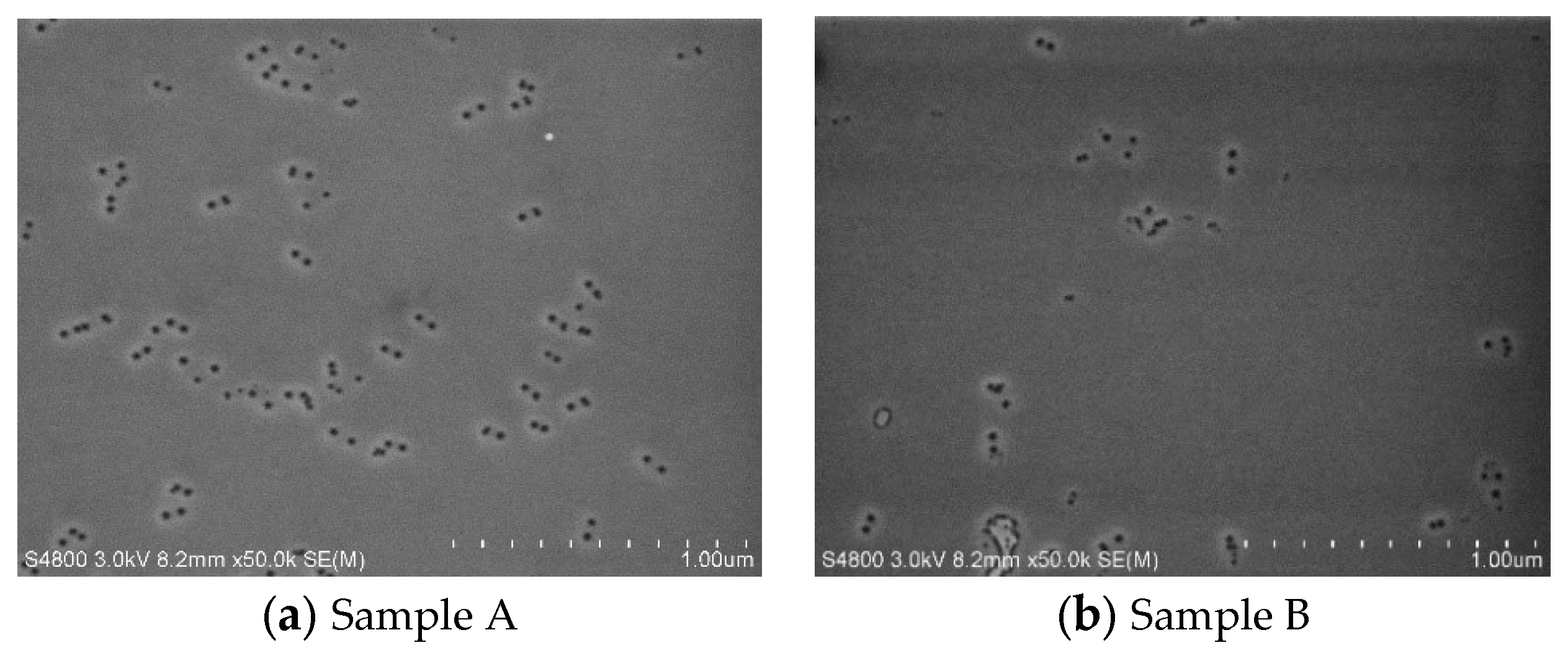

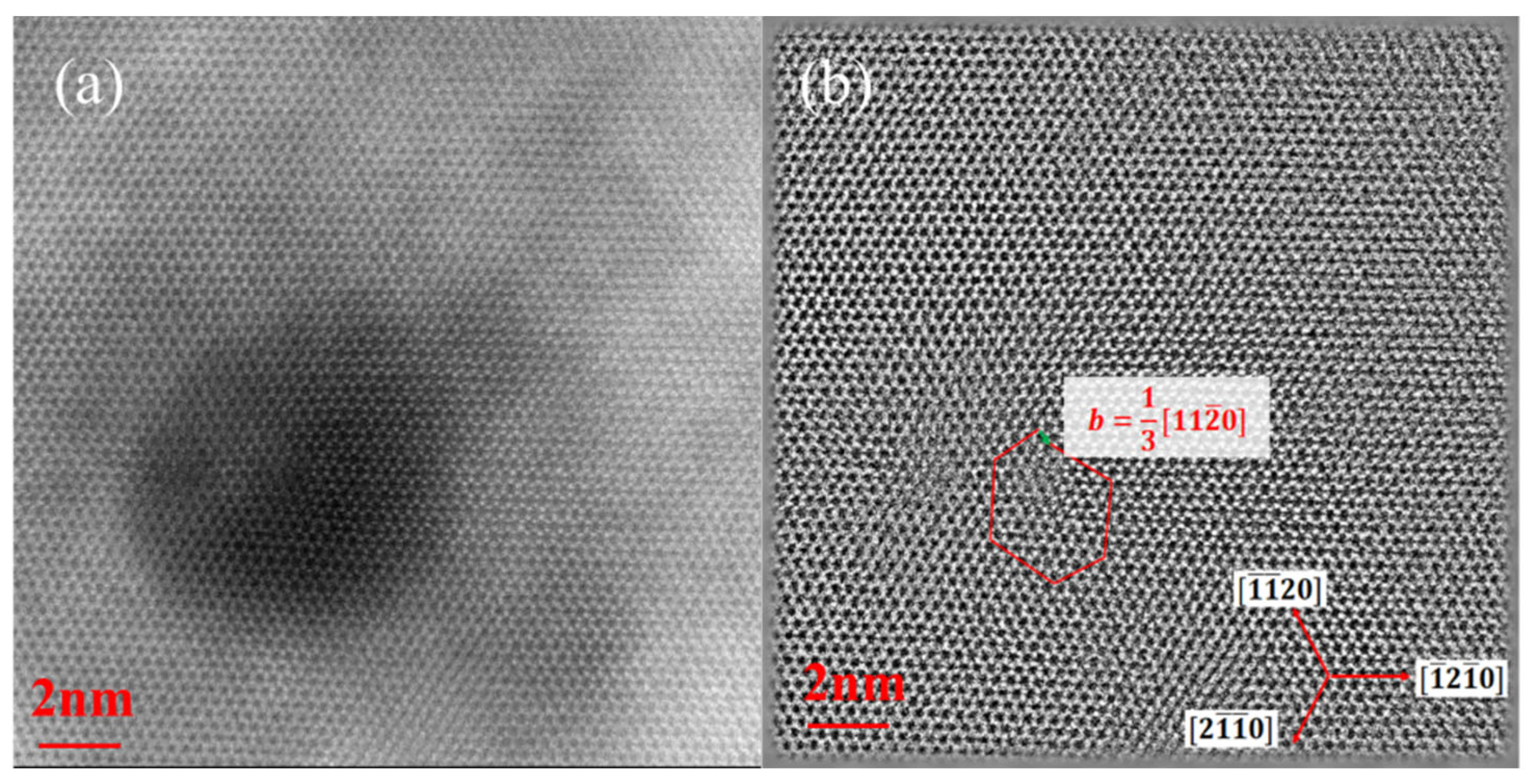

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nakamura, S.; Senoh, M.; Nagahama, S.-I.; Iwasa, N.; Matsushita, T.; Mukai, T. Blue InGaN-based laser diodes with an emission wavelength of 450 nm. Appl. Phys. Lett. 2000, 76, 22–24. [Google Scholar] [CrossRef]

- Zhong, Z.; Lu, S.; Li, J.; Lin, W.; Huang, K.; Li, S.; Cai, D.; Kang, J. Design and fabrication of high power InGaN blue laser diode over 8 W. Opt. Laser Technol. 2021, 139, 106985. [Google Scholar] [CrossRef]

- Nakamura, S.; Mukai, T.; Senoh, M. Candela-class high-brightness InGaN/AlGaN double-heterostructure blue-light-emitting diodes. Appl. Phys. Lett. 1994, 64, 1687–1689. [Google Scholar] [CrossRef]

- Liu, J.P.; Zhang, L.Q.; Li, D.Y.; Zhou, K.; Cheng, Y.; Zhou, W.; Tian, A.Q.; Ikeda, M.S.; Zhang, S.M.; Yang, H. GaN-Based Blue Laser Diodes With 2.2 W of Light Output Power Under Continuous-Wave Operation. IEEE Photonics Technol. Lett. 2017, 29, 2203–2206. [Google Scholar] [CrossRef]

- Narukawa, Y.; Ichikawa, M.; Sanga, D.; Sano, M.; Mukai, T. White light emitting diodes with super-high luminous efficacy. J. Phys. D Appl. Phys. 2010, 43, 354002. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, N.; Iwasa, N.; Nagahama, S.I. High-brightness InGaN blue, green and yellow light-emitting-diodes eith quantum-well structures. Jpn. J. Appl. Phys. Part 2 Lett. Express Lett. 1995, 34, L797–L799. [Google Scholar] [CrossRef]

- O’Donnell, K.P.; Auf der Maur, M.; Di Carlo, A.; Lorenz, K.; The Sorbet Consortium. It’s not easy being green: Strategies for all-nitrides, all-colour solid state lighting. Phys. Status Solidi RRL 2012, 6, 49–52. [Google Scholar] [CrossRef]

- Krames, M.R.; Shchekin, O.B.; Mueller-Mach, R.; Mueller, G.O.; Zhou, L.; Harbers, G.; Craford, M.G. Status and future of high-power light-emitting diodes for solid-state lighting. J. Disp. Technol. 2007, 3, 160–175. [Google Scholar] [CrossRef]

- Langer, T.; Kruse, A.; Ketzer, F.A.; Schwiegel, A.; Hoffmann, L.; Jönen, H.; Bremers, H.; Rossow, U.; Hangleiter, A. Origin of the “green gap”: Increasing nonradiative recombination in indium-rich GaInN/GaN quantum well structures. Phys. Status Solidi C 2011, 8, 2170–2172. [Google Scholar] [CrossRef]

- Avramescu, A.; Lermer, T.; Müller, J.; Eichler, C.; Bruederl, G.; Sabathil, M.; Lutgen, S.; Strauss, U. True Green Laser Diodes at 524 nm with 50 mW Continuous Wave Output Power onc-Plane GaN. Appl. Phys. Express 2010, 3, 061003. [Google Scholar] [CrossRef]

- Chichibu, S.; Azuhata, T.; Sota, T.; Nakamura, S. Spontaneous emission of localized excitons in InGaN single and multiquantum well structures. Appl. Phys. Lett. 1996, 69, 4188–4190. [Google Scholar] [CrossRef]

- Bernardini, F.; Fiorentini, V.; Vanderbilt, D. Spontaneous polarization and piezoelectric constants of III-V nitrides. Phys. Rev. B 1997, 56, 10024–10027. [Google Scholar] [CrossRef]

- Enya, Y.; Yoshizumi, Y.; Kyono, T.; Akita, K.; Ueno, M.; Adachi, M.; Sumitomo, T.; Tokuyama, S.; Ikegami, T.; Katayama, K.; et al. 531 nm Green Lasing of InGaN Based Laser Diodes on Semi-Polar {20\bar21} Free-Standing GaN Substrates. Appl. Phys. Express 2009, 2, 082101. [Google Scholar] [CrossRef]

- Yoshizumi, Y.; Adachi, M.; Enya, Y.; Kyono, T.; Tokuyama, S.; Sumitomo, T.; Akita, K.; Ikegami, T.; Ueno, M.; Katayama, K.; et al. Continuous-Wave Operation of 520 nm Green InGaN-Based Laser Diodes on Semi-Polar {20\bar21} GaN Substrates. Appl. Phys. Express 2009, 2, 092101. [Google Scholar] [CrossRef]

- Takagi, S.; Enya, Y.; Kyono, T.; Adachi, M.; Yoshizumi, Y.; Sumitomo, T.; Yamanaka, Y.; Kumano, T.; Tokuyama, S.; Sumiyoshi, K.; et al. High-Power (over 100 mW) Green Laser Diodes on Semipolar {20-21} GaN Substrates Operating at Wavelengths beyond 530 nm. Appl. Phys. Express 2012, 5, 082102. [Google Scholar] [CrossRef]

- Sizov, D.; Bhat, R.; Heberle, A.; Visovsky, N.; Zah, C.-E. True-green (11-22) plane optically pumped laser with cleaved m-plane facets. Appl. Phys. Lett. 2011, 99, 041117. [Google Scholar] [CrossRef]

- Zhang, J.; Xiong, C.; Liu, J.; Quan, Z.; Wang, L.; Jiang, F. High brightness InGaN-based yellow light-emitting diodes with strain modulation layers grown on Si substrate. Appl. Phys. A 2014, 114, 1049–1053. [Google Scholar] [CrossRef]

- Saito, S.; Hashimoto, R.; Hwang, J.; Nunoue, S. InGaN Light-Emitting Diodes onc-Face Sapphire Substrates in Green Gap Spectral Range. Appl. Phys. Express 2013, 6, 111004. [Google Scholar] [CrossRef]

- Shioda, T.; Yoshida, H.; Tachibana, K.; Sugiyama, N.; Nunoue, S. Enhanced light output power of green LEDs employing AlGaN interlayer in InGaN/GaN MQW structure on sapphire (0001) substrate. Phys. Status Solidi A 2012, 209, 473–476. [Google Scholar] [CrossRef]

- Koleske, D.D.; Fischer, A.J.; Bryant, B.N.; Kotula, P.G.; Wierer, J.J. On the increased efficiency in InGaN-based multiple quantum wells emitting at 530–590 nm with AlGaN interlayers. J. Cryst. Growth 2015, 415, 57–64. [Google Scholar] [CrossRef]

- Al Muyeed, S.A.; Sun, W.; Wei, X.; Song, R.; Koleske, D.D.; Tansu, N.; Wierer, J.J. Strain compensation in InGaN-based multiple quantum wells using AlGaN interlayers. Aip Adv. 2017, 7, 105312. [Google Scholar] [CrossRef]

- Akasaka, T.; Gotoh, H.; Saito, T.; Makimoto, T. High luminescent efficiency of InGaN multiple quantum wells grown on InGaN underlying layers. Appl. Phys. Lett. 2004, 85, 3089–3091. [Google Scholar] [CrossRef]

- Armstrong, A.M.; Bryant, B.N.; Crawford, M.H.; Koleske, D.D.; Lee, S.R.; Wierer, J.J. Defect-reduction mechanism for improving radiative efficiency in InGaN/GaN light-emitting diodes using InGaN underlayers. J. Appl. Phys. 2015, 117, 134501. [Google Scholar] [CrossRef]

- Haller, C.; Carlin, J.F.; Jacopin, G.; Martin, D.; Butté, R.; Grandjean, N. Burying non-radiative defects in InGaN underlayer to increase InGaN/GaN quantum well efficiency. Appl. Phys. Lett. 2017, 111, 262101. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, J.; Xu, L.; Ding, J.; Wang, G.; Wu, X.; Wang, X.; Mo, C.; Quan, Z.; Guo, X.; et al. Efficient InGaN-based yellow-light-emitting diodes. Photonics Res. 2019, 7, 144–148. [Google Scholar] [CrossRef]

- Jiang, X.G.; Zheng, C.D.; Mo, C.L.; Wang, X.L.; Zhang, J.L.; Quan, Z.J.; Liu, J.L.; Jiang, F.Y. Study on the performance of InGaN-based green LED by designing different preparing layers. Opt. Mater. 2019, 89, 505–511. [Google Scholar] [CrossRef]

- Qi, W.J.; Zhang, J.L.; Mo, C.L.; Wang, X.L.; Wu, X.M.; Quan, Z.J.; Wang, G.X.; Pan, S.; Fang, F.; Liu, J.L.; et al. Effects of thickness ratio of InGaN to GaN in superlattice strain relief layer on the optoelectrical properties of InGaN-based green LEDs grown on Si substrates. J. Appl. Phys. 2017, 122, 7. [Google Scholar] [CrossRef]

- Tao, X.; Liu, J.; Zhang, J.; Mo, C.; Xu, L.; Ding, J.; Wang, G.; Wang, X.; Wu, X.; Quan, Z.; et al. Performance enhancement of yellow InGaN-based multiple-quantum-well light-emitting diodes grown on Si substrates by optimizing the InGaN/GaN superlattice interlayer. Opt. Mater. Express 2018, 8, 1221–1230. [Google Scholar] [CrossRef]

- Zhou, R.; Ikeda, M.; Zhang, F.; Liu, J.; Zhang, S.; Tian, A.; Wen, P.; Li, D.; Zhang, L.; Yang, H. Steady-state recombination lifetimes in polar InGaN/GaN quantum wells by time-resolved photoluminescence. Jpn. J. Appl. Phys. 2019, 58, SCCB07. [Google Scholar] [CrossRef]

- Zhou, R.; Ikeda, M.; Zhang, F.; Liu, J.; Zhang, S.; Tian, A.; Wen, P.; Li, D.; Zhang, L.; Yang, H. Total-InGaN-thickness dependent Shockley-Read-Hall recombination lifetime in InGaN quantum wells. J. Appl. Phys. 2020, 127, 013103. [Google Scholar] [CrossRef]

- Haller, C.; Carlin, J.F.; Jacopin, G.; Liu, W.; Martin, D.; Butté, R.; Grandjean, N. GaN surface as the source of non-radiative defects in InGaN/GaN quantum wells. Appl. Phys. Lett. 2018, 113, 111106. [Google Scholar] [CrossRef]

- Armstrong, A.; Henry, T.A.; Koleske, D.D.; Crawford, M.H.; Lee, S.R. Quantitative and depth-resolved deep level defect distributions in InGaN/GaN light emitting diodes. Opt. Express 2012, 20, A812–A821. [Google Scholar] [CrossRef] [PubMed]

- Haller, C.; Carlin, J.-F.; Mosca, M.; Rossell, M.D.; Erni, R.; Grandjean, N. InAlN underlayer for near ultraviolet InGaN based light emitting diodes. Appl. Phys. Express 2019, 12, 034002. [Google Scholar] [CrossRef]

| Scheme | Tset(°C) | Growth Rate (nm/s) |

|---|---|---|

| QW | 830 | 0.033 |

| QB | 1005 | 0.063 |

| GSL (16% InGaN) | 903 | 0.022 |

| GSL (8% InGaN) | 903 | 0.02 |

| GSL (4% InGaN) | 903 | 0.018 |

| GSL (GaN) | 903 | 0.017 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, J.; Su, X.; Huang, S.; Tian, A.; Zhou, W.; Jiang, L.; Ikeda, M.; Yang, H. Effect of Graded-Indium-Content Superlattice on the Optical and Structural Properties of Yellow-Emitting InGaN/GaN Quantum Wells. Materials 2021, 14, 1877. https://doi.org/10.3390/ma14081877

Li X, Liu J, Su X, Huang S, Tian A, Zhou W, Jiang L, Ikeda M, Yang H. Effect of Graded-Indium-Content Superlattice on the Optical and Structural Properties of Yellow-Emitting InGaN/GaN Quantum Wells. Materials. 2021; 14(8):1877. https://doi.org/10.3390/ma14081877

Chicago/Turabian StyleLi, Xuan, Jianping Liu, Xujun Su, Siyi Huang, Aiqin Tian, Wei Zhou, Lingrong Jiang, Masao Ikeda, and Hui Yang. 2021. "Effect of Graded-Indium-Content Superlattice on the Optical and Structural Properties of Yellow-Emitting InGaN/GaN Quantum Wells" Materials 14, no. 8: 1877. https://doi.org/10.3390/ma14081877

APA StyleLi, X., Liu, J., Su, X., Huang, S., Tian, A., Zhou, W., Jiang, L., Ikeda, M., & Yang, H. (2021). Effect of Graded-Indium-Content Superlattice on the Optical and Structural Properties of Yellow-Emitting InGaN/GaN Quantum Wells. Materials, 14(8), 1877. https://doi.org/10.3390/ma14081877