Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy

Abstract

1. Introduction

| Material | Tool Details | Input Parameters | Analyzed Outputs | Refs |

|---|---|---|---|---|

| Al6061 drilling | Uncoated HSS Helix angle: 45° Point angle: 100°, 110°, 118° Drill diameter: 8, 10, and 12 mm | Feed rate: 0.3, 0.5, 0.6 (mm/rev) Spindle speed: 600, 800, 1000 (rpm) | SR, BH, BT, CIRC | [19,21] |

| AI6061 drilling | TiN-HSS Point angle: 118° Drill diameter: 8 mm | Feed rate: 0.04, 0.08 (mm/rev) Spindle speed: 1000, 1500, 2000 (rpm) | CF, TW, BH, BT, CIRC, CHF | [13] |

| Al6061/20%SiCp composite drilling | Tipped carbide Point angle: 90°, 118°, 135° Drill diameter: 10 mm | Feed rate: 0.12, 0.16, 0.20 (mm/rev) Spindle speed: 900, 1120, 1330 (rpm) | CF, SR | [20] |

| Al6061/B4C composite milling | Uncoated carbide inserts Cutting diameter: 40 mm | Feed rate: 0.08, 0.1, 12, 0.16 (mm/tooth) Milling speed: 220, 285, 370, 480 (mm/min) | SR, PO | [16] |

| Al6061-T6 drilling | Uncoated HSS Drill diameter: 11.7 mm | Feed rate: 0.2, 0.3, 0.4 (mm/rev) Cutting speed: 60, 75, 100 (rpm) | HS, CIRC, SR | [26] |

| Al6061/SiC/B4C/t lc composite drilling | Uncoated HSS Drill diameter: 6, 7, 8 mm | Feed rate: 15, 25, 35 (mm/min) Cutting speed: 750, 1000, 1250 (rpm) | CF, SR, CIRC | [15] |

| Al2124/20 % B4C end milling | Uncoated carbide | Feed rate: 0.1, 0.2, 0.3 (mm/rev) Cutting speed: 50, 100, 150 (rpm) | SR | [14] |

| Al6061 and Al6061-SiC drilling | Uncoated carbide Point angle: 96°, 118°, 140° Drill diameter: 10 mm | Feed rate: 0.1, 0.15, 0.2 (mm/rev) Cutting speed: 40, 60, 80 (rpm) | BH, BT | [25] |

| Al6061-T6 turning | - | Feed rate: 0.2, 0.1, 0.05, 0.01 (mm/rev) Spindle speed: 1000 (rpm) | SR (rendering) | [35] |

2. Materials and Methods

2.1. Workpiece Material

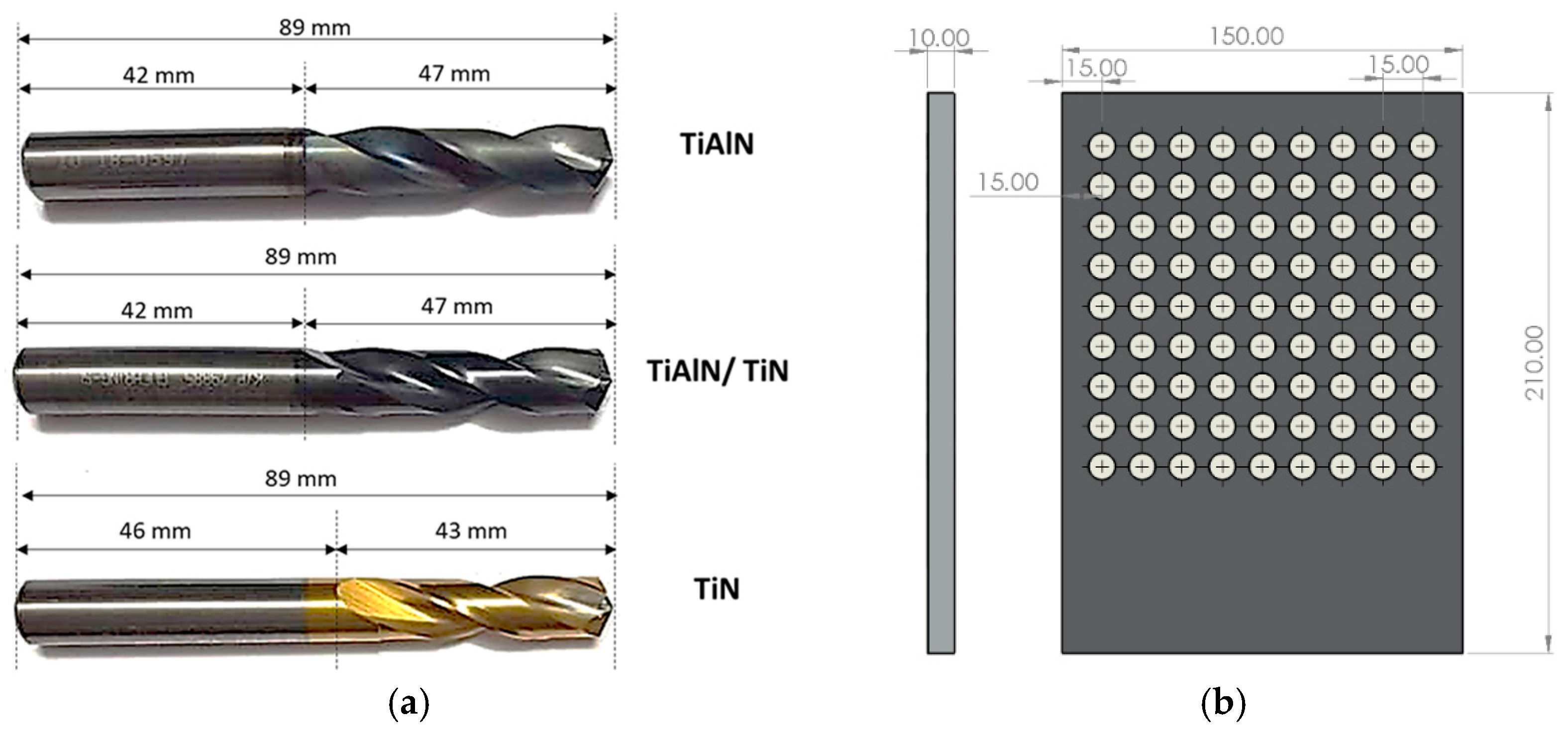

2.2. Cutting Tools

2.3. Experimental Procedure

2.4. Measurement of Surface Roughness

2.5. Measurement of Hole Form and Dimensional Tolerances

2.6. Scanning Electron Microscopy

3. Results and Discussion

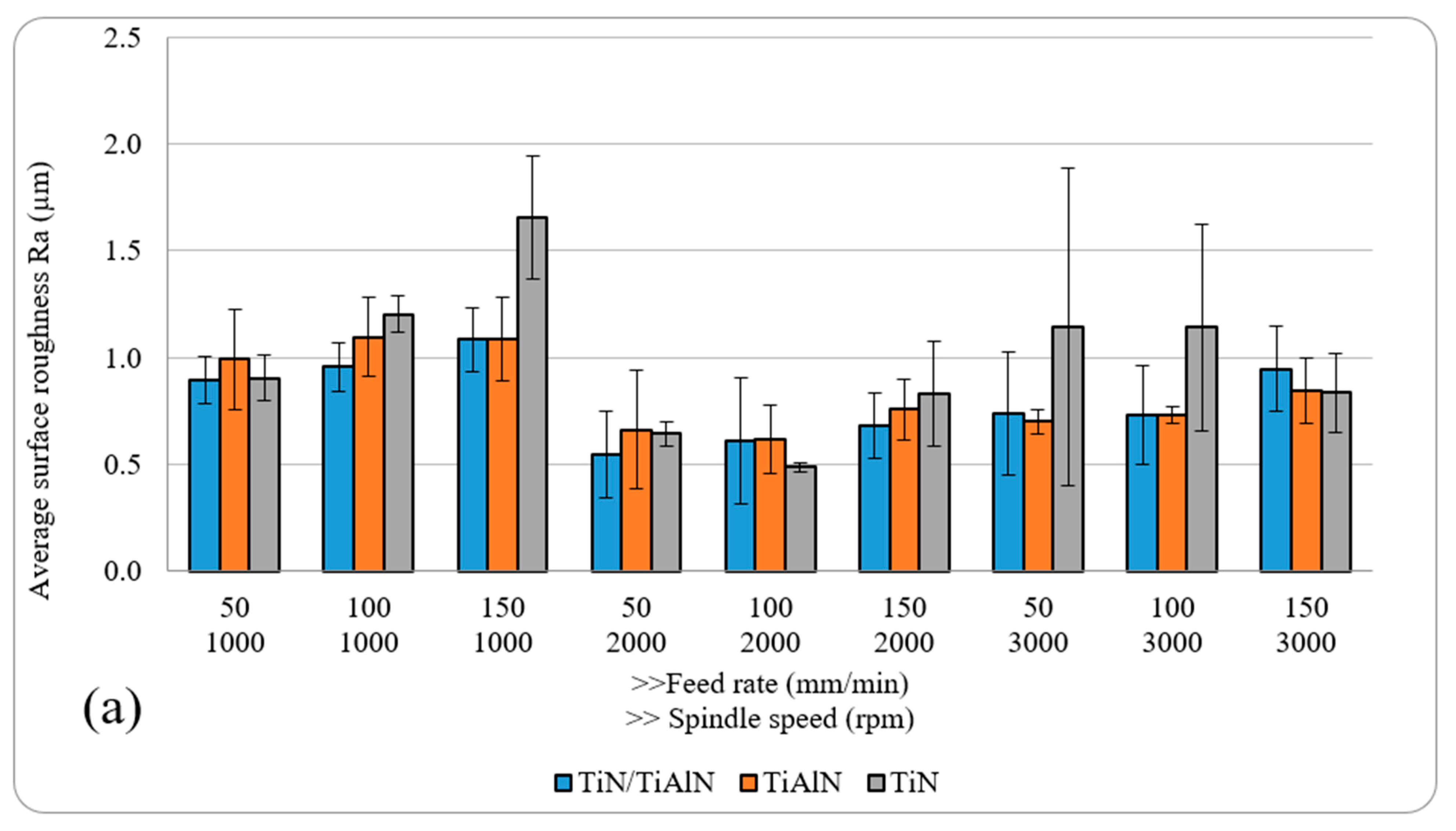

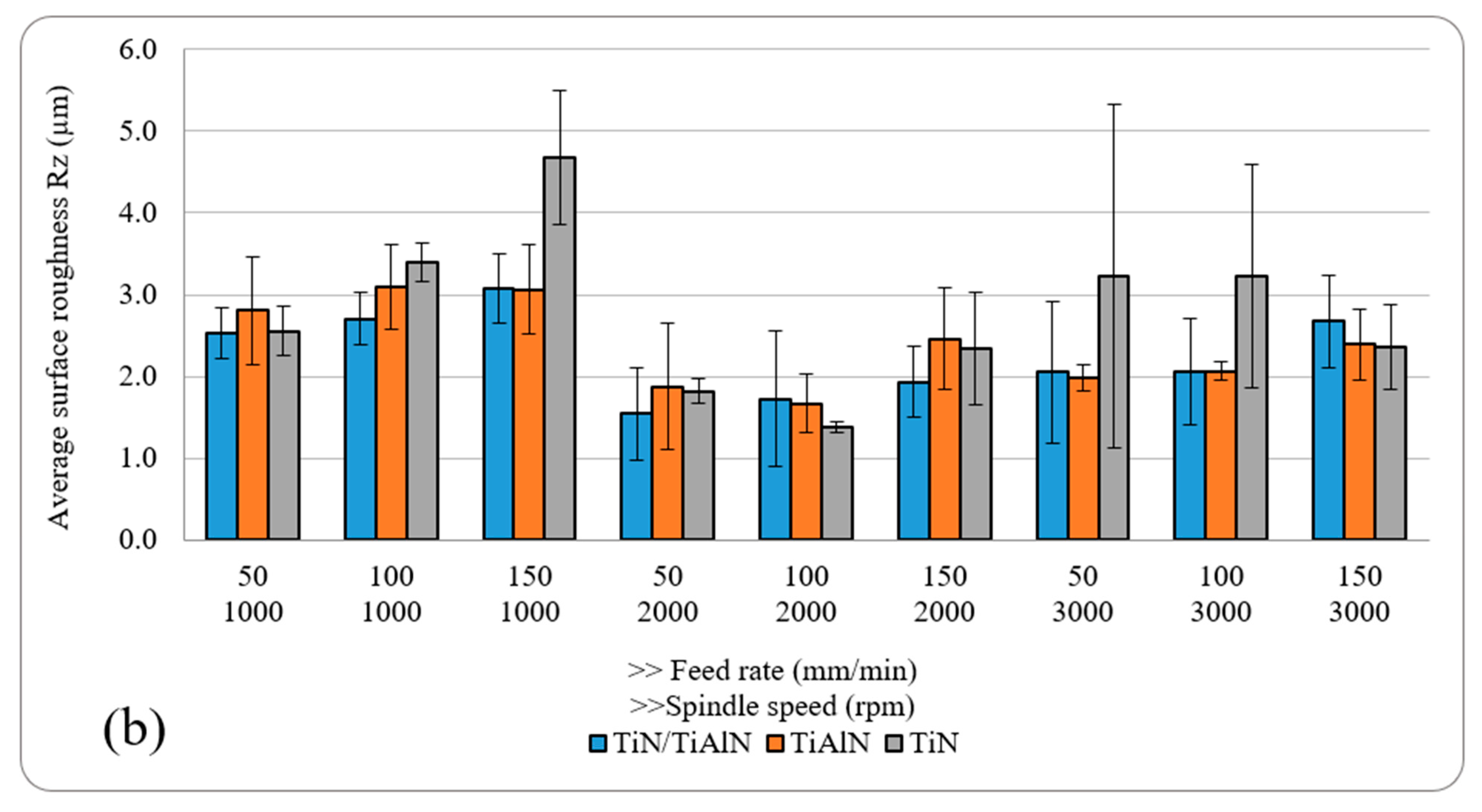

3.1. Analysis of Surface-Roughness Metrics

3.2. Effects of Cutting Parameters and Tool Coatings on Hole Size

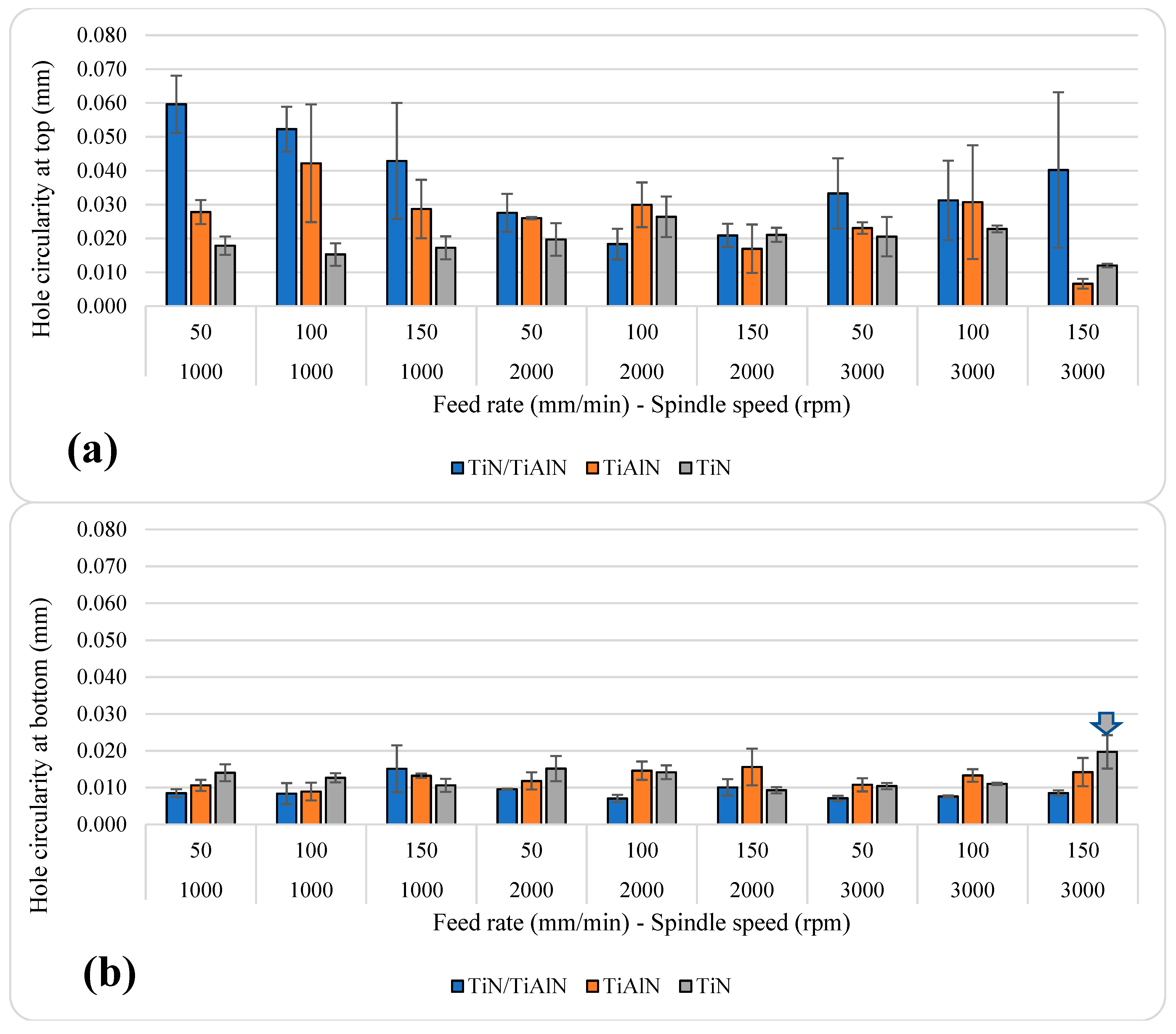

3.3. Effects of Cutting Parameters and Tool Coatings on Circularity Error

3.4. Effect of Cutting Parameters and Tool Coatings on Hole Cylindricity and Perpendicularity

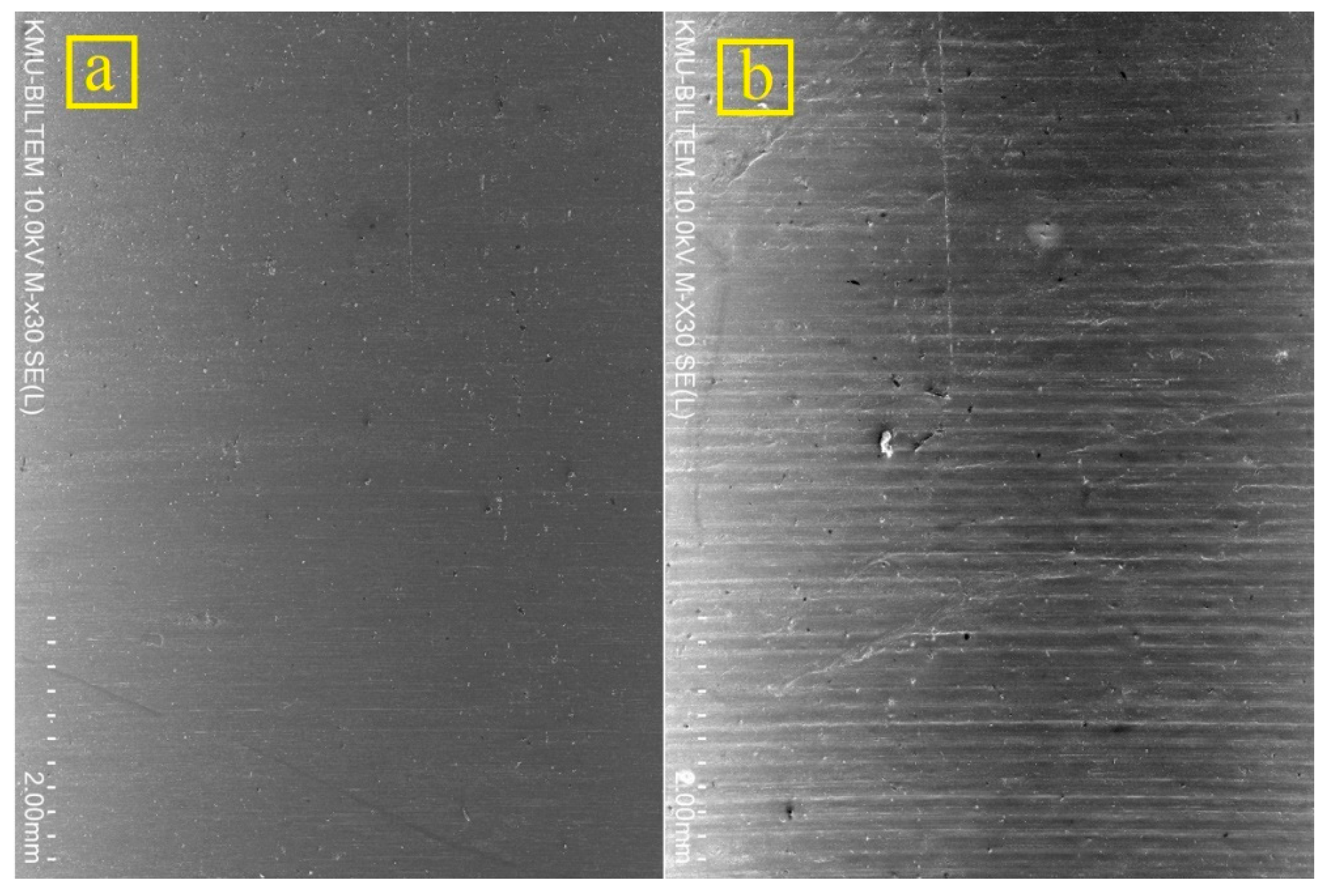

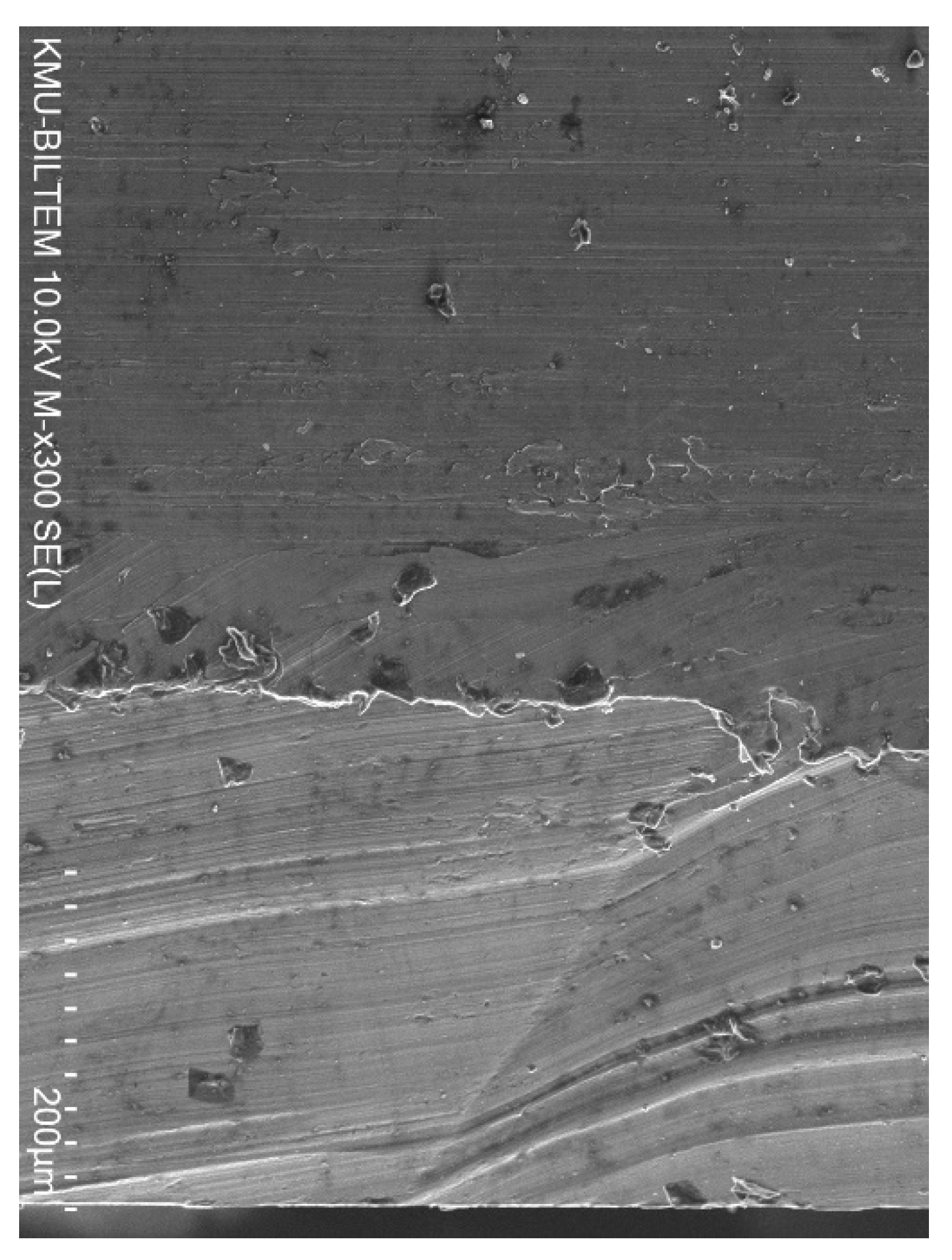

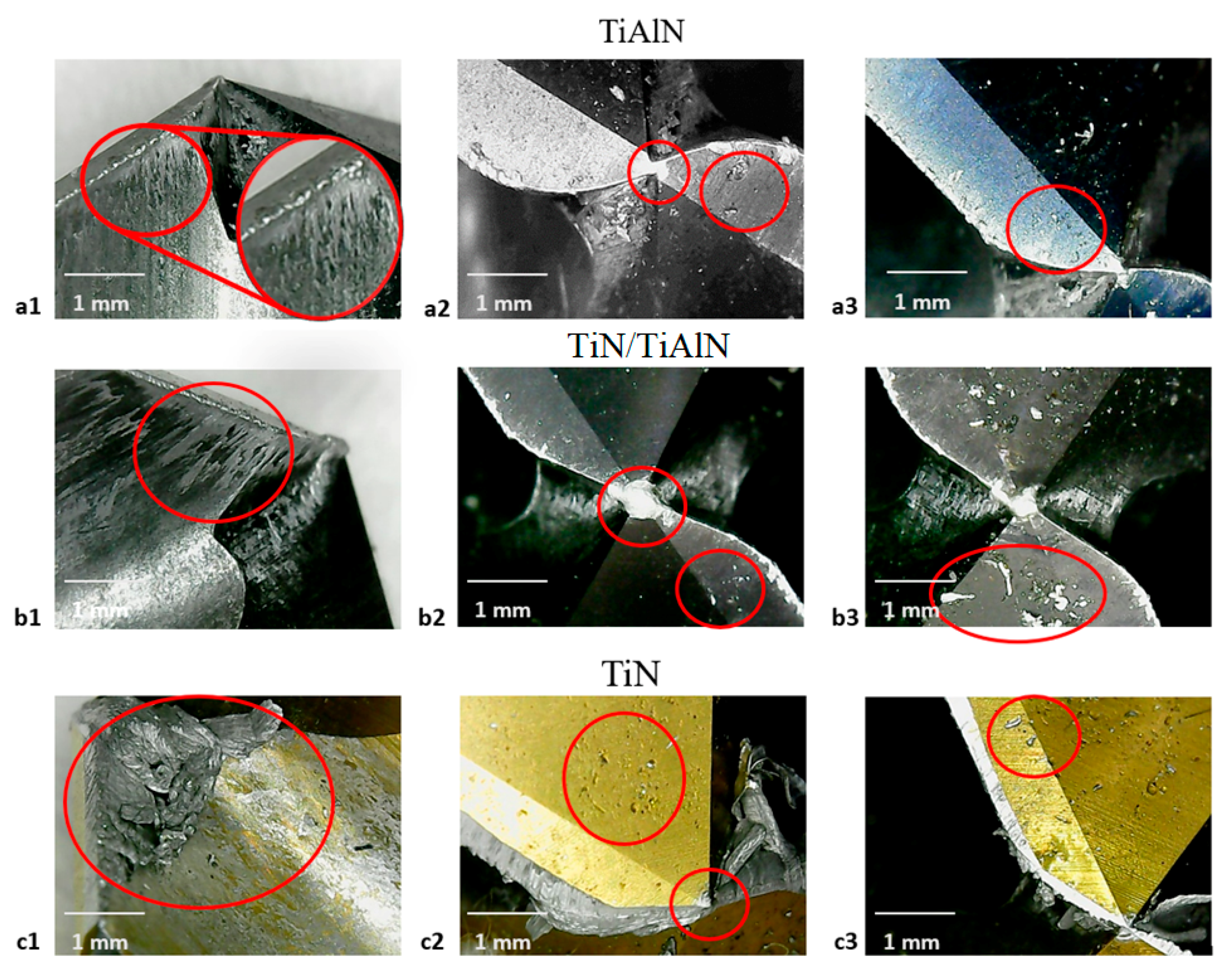

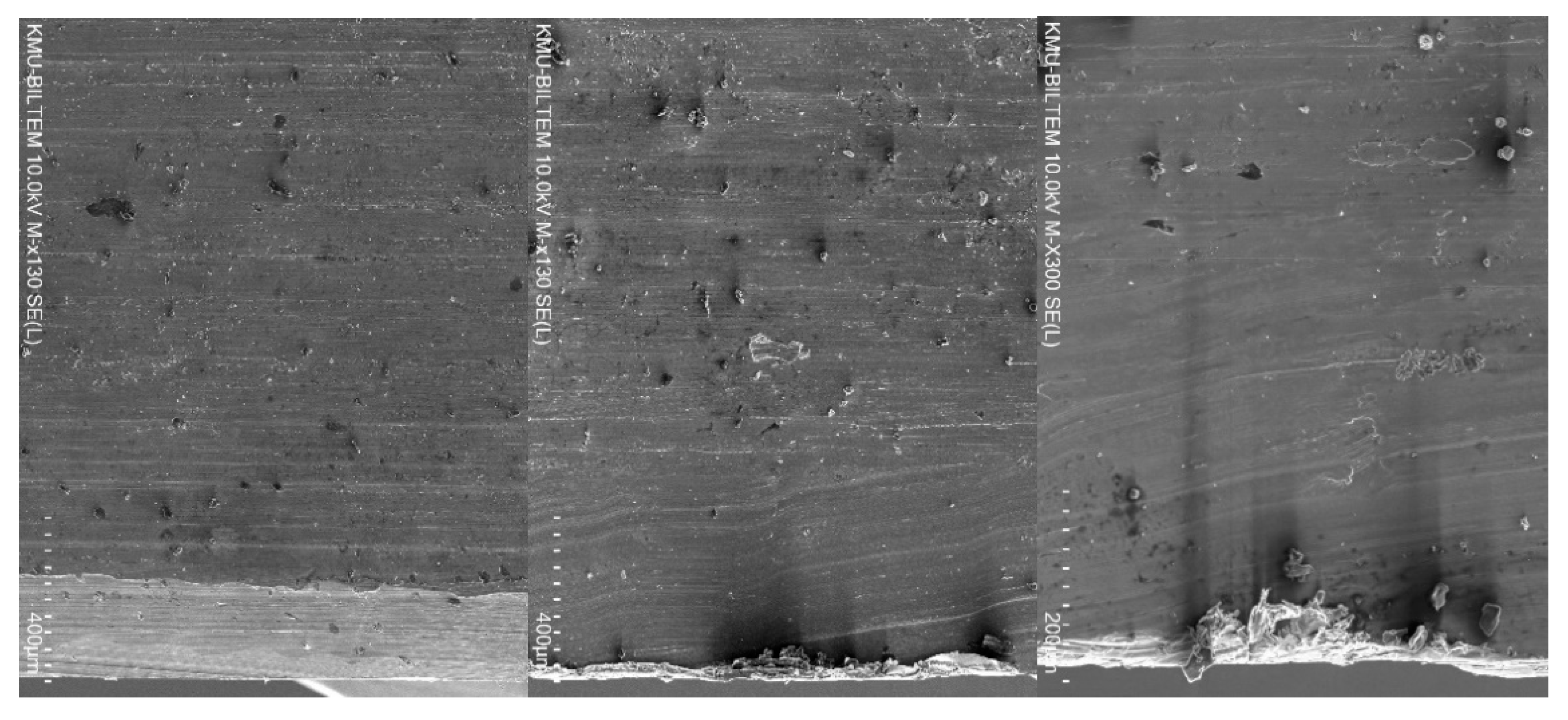

3.5. Cutting-Tool Examination

4. Conclusions

- The surface-roughness metrics Ra and Rz in most holes did not exceed 1 µm and 3 µm, respectively. Holes drilled using TiN-coated tools had the highest surface roughness. This was mainly attributed to the lower oxidation temperature and hardness of TiN coating and its high affinity to react with aluminum during the drilling process, as evident in the microscopic images.

- Hole size and circularity at the top were better than those at the bottom regardless of the tool coating or cutting parameters used. TiN/TiAlN-coated tools produced the worst hole size and circularity at the top, especially at low and medium spindle speeds, followed by holes drilled using TiN and TiAlN coatings.

- Under all cutting conditions, the holes produced were always oversized (between 15 and 80 µm). Similarly, hole circularity at the top and bottom ranged between 7 and 60 µm.

- TiN/TiAlN-coated tools produced the worst hole cylindricity, followed by the TiAlN and TiN tools. Hole cylindricity was the worst in TiN/TiAlN-coated tools, especially at low and medium spindle speeds. Holes drilled using TiN-coated tools gave the lowest hole cylindricity among the three coatings.

- TiN coatied tools were more suitable for drilling Al6061 alloy at low cutting parameters, while TiN/TiAlN- and TiAlN-coated tools were more suitable when machining at higher cutting parameters, where the thermal performance of the tool coating became more critical to the quality of machined holes.

- The ANOVA results showed that both the cutting parameters and the cutting-tool coatings had an impact on hole size, circularity, cylindricity, and perpendicularity. The contribution of the cutting-tool coating was more significant at the hole entry than at the exit. The spindle speed had a major effect on hole perpendicularity compared to feed rate and type of tool coating.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmidt, A.; Siebeck, S.; Götze, U.; Wagner, G.; Nestler, D. Particle-Reinforced Aluminum Matrix Composites (AMCs)—Selected Results of an Integrated Technology, User, and Market Analysis and Forecast. Metals 2018, 8, 143. [Google Scholar] [CrossRef]

- Davis, J.R. Corrosion of Aluminum and Aluminum Alloys; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Joseph, R.; Davis, J. Aluminium and Aluminium Alloys. Asm Int. Mater. 1993, 4. [Google Scholar]

- Kermanidis, A.T. Aircraft Aluminum Alloys: Applications and Future Trends. In Revolutionizing Aircraft Materials and Processes; Springer: Berlin, Germany, 2020; pp. 21–55. [Google Scholar]

- Gupta, M.K.; Mia, M.; Singh, G.; Pimenov, D.Y.; Sarikaya, M.; Sharma, V.S. Hybrid cooling-lubrication strategies to improve surface topography and tool wear in sustainable turning of Al 7075-T6 alloy. Int. J. Adv. Manuf. Technol. 2019, 101, 55–69. [Google Scholar] [CrossRef]

- Siwawut, S.; Saikaew, C.; Wisitsoraat, A.; Surinphong, S. Cutting performances and wear characteristics of WC inserts coated with TiAlSiN and CrTiAlSiN by filtered cathodic arc in dry face milling of cast iron. Int. J. Adv. Manuf. Technol. 2018, 97, 3883–3892. [Google Scholar] [CrossRef]

- Myasnikov, Y.I.; Pimenov, D.Y. Fast drilling of small-diameter holes by core flat drills. Russ. Eng. Res. 2016, 36, 1044–1047. [Google Scholar] [CrossRef]

- Myasnikov, Y.I.; Pimenov, D.Y. High-speed drilling of small-diameter holes by core flat drills. Russ. Eng. Res. 2016, 36, 879–882. [Google Scholar] [CrossRef]

- Pan, J.; Ni, J.; He, L.; Cui, Z.; Feng, K. Influence of micro-structured milling cutter on the milling load and surface roughness of 6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 110, 3201–3208. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2020, 62, 179–201. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Ikumapayi, O.M.; Okonkwo, U.C.; Salawu, E.Y.; Afolalu, S.A.; Dirisu, J.O.; Nwoke, O.N.; Ajayi, O.O. Experimental and mathematical modeling for prediction of tool wear on the machining of aluminium 6061 alloy by high speed steel tools. Open Eng. 2017, 7, 461–469. [Google Scholar] [CrossRef]

- Giasin, K.; Gorey, G.; Byrne, C.; Sinke, J.; Brousseau, E. Effect of machining parameters and cutting tool coating on hole quality in dry drilling of fibre metal laminates. Compos. Struct. 2019, 212, 159–174. [Google Scholar] [CrossRef]

- Uddin, M.; Basak, A.; Pramanik, A.; Singh, S.; Krolczyk, G.M.; Prakash, C. Evaluating Hole Quality in Drilling of Al 6061 Alloys. Materials 2018, 11, 2443. [Google Scholar] [CrossRef] [PubMed]

- Boswell, B.; Islam, M.N.; Davies, I.J.; Pramanik, A. Effect of machining parameters on the surface finish of a metal matrix composite under dry cutting conditions. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2017, 231, 913–923. [Google Scholar] [CrossRef]

- Kumar, C.R.; JaiGanesh, V.; Malarvannan, R.R.R. Optimization of drilling parameters in hybrid (Al6061/SiC/B 4 C/talc) composites by grey relational analysis. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–10. [Google Scholar]

- Karabulut, Ş.; Karakoç, H.; Çıtak, R. Influence of B4C particle reinforcement on mechanical and machining properties of Al6061/B4C composites. Compos. Part. B Eng. 2016, 101, 87–98. [Google Scholar] [CrossRef]

- Motorcu, A.R.; Kuş, A.; Durgun, İ. The evaluation of the effects of control factors on surface roughness in the drilling of Waspaloy superalloy. Measurement 2014, 58, 394–408. [Google Scholar] [CrossRef]

- Choudhary, R.; Singh, G. Effect of machining parametrs on metal removal rate during electric discharge drilling of Al 6061 with hollow Cu electrode. Int. J. Des. Manuf. Technol. 2017, 11, 34–38. [Google Scholar]

- Sreenivasulu, R.; Rao, C. Application of grey relational analysis for surface roughness and roundness error in drilling of Al 6061 alloy. Int. J. Lean Think. 2012, 3, 67–78. [Google Scholar]

- Ravikumar, H.; Arun, P.; Thileepan, S. Analysis in Drilling of Al6061/20% SiCp Composites Using Grey Taguchi Based TOPSIS (GT-TOPSIS). Int. J. Chem.Tech. Res. (IJCRGG) 2015, 8, 292–303. [Google Scholar]

- Sreenivasulu, R. Optimization of burr size, surface roughness and circularity deviation during drilling of Al 6061 using Taguchi design method and artificial neural network. Indep. J. Manag. Prod. 2015, 6, 93–108. [Google Scholar] [CrossRef][Green Version]

- Narahari, P.; Pai, B.C.; Pillai, R.M. Some aspects of machining cast Al-SiCp composites with conventional high speed steel and tungsten carbide tools. J. Mater. Eng. Perform. 1999, 8, 538–542. [Google Scholar] [CrossRef]

- Faverjon, P.; Rech, J.; Leroy, R. Influence of Minimum Quantity Lubrication on Friction Coefficient and Work-Material Adhesion During Machining of Cast Aluminum With Various Cutting Tool Substrates Made of Polycrystalline Diamond, High Speed Steel, and Carbides. J. Tribol. 2013, 135, 8. [Google Scholar] [CrossRef]

- Roy, P.; Sarangi, S.K.; Ghosh, A.; Chattopadhyay, A.K. Machinability study of pure aluminium and Al–12% Si alloys against uncoated and coated carbide inserts. Int. J. Refract. Met. Hard Mater. 2009, 27, 535–544. [Google Scholar] [CrossRef]

- Thakre, A.A.; Soni, S. Modeling of burr size in drilling of aluminum silicon carbide composites using response surface methodology. Eng. Sci. Technol. Int. J. 2016, 19, 1199–1205. [Google Scholar] [CrossRef]

- Islam, M.N.; Boswell, B. Effect of cooling methods on hole quality in drilling of aluminium 6061-6T. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bali, Indonesia, 19–20 March 2016; p. 012022. [Google Scholar]

- Ranjan, J.; Patra, K.; Szalay, T.; Mia, M.; Gupta, M.K.; Song, Q.; Krolczyk, G.; Chudy, R.; Pashnyov, V.A.; Pimenov, D.Y. Artificial Intelligence-Based Hole Quality Prediction in Micro-Drilling Using Multiple Sensors. Sensors 2020, 20, 885. [Google Scholar] [CrossRef] [PubMed]

- Myasnikov, Y.I.; Pimenov, D.Y. Optimizing the high-speed drilling of small-diameter holes by core flat drills. Russ. Eng. Res. 2016, 36, 788–790. [Google Scholar] [CrossRef]

- Sun, D.; Lemoine, P.; Keys, D.; Doyle, P.; Malinov, S.; Zhao, Q.; Qin, X.; Jin, Y. Hole-making processes and their impacts on the microstructure and fatigue response of aircraft alloys. Int. J. Adv. Manuf. Technol. 2018, 94, 1719–1726. [Google Scholar] [CrossRef]

- Gu, W.; Xu, H.; Liu, J.; Yue, Z. Effect of drilling process on fatigue life of open holes. Tsinghua Sci. Technol. 2009, 14, 54–57. [Google Scholar] [CrossRef]

- Blau, P.; Martin, R.; Riester, L. A Comparison of Several Surface Finish Measurement Methods as Applied to Ground Ceramic and Metal Surfaces; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1996. [Google Scholar]

- Kivak, T.; Habali, K.; Şeker, U. The effect of cutting paramaters on the hole quality and tool wear during the drilling of Inconel 718. Gazi Univ. J. Sci. 2012, 25, 533–540. [Google Scholar]

- Sheth, S.; George, P. Experimental investigation, prediction and optimization of cylindricity and perpendicularity during drilling of WCB material using grey relational analysis. Precis. Eng. 2016, 45, 33–43. [Google Scholar] [CrossRef]

- Giasin, K. The effect of drilling parameters, cooling technology, and fiber orientation on hole perpendicularity error in fiber metal laminates. Int. J. Adv. Manuf. Technol. 2018, 97, 4081–4099. [Google Scholar] [CrossRef]

- Bartkowiak, T.; Brown, C.A. Multiscale 3D curvature analysis of processed surface textures of aluminum alloy 6061 T6. Materials 2019, 12, 257. [Google Scholar] [CrossRef] [PubMed]

- Pitchayyapillai, G.; Seenikannan, P.; Balasundar, P.; Narayanasamy, P. Effect of nano-silver on microstructure, mechanical and tribological properties of cast 6061 aluminum alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 2137–2145. [Google Scholar] [CrossRef]

- Bang, H.; Bang, H.; Jeon, G.; Oh, I.; Ro, C. Gas tungsten arc welding assisted hybrid friction stir welding of dissimilar materials Al6061-T6 aluminum alloy and STS304 stainless steel. Mater. Des. 2012, 37, 48–55. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. An experimental study on drilling of unidirectional GLARE fibre metal laminates. Compos. Struct. 2015, 133, 794–808. [Google Scholar] [CrossRef]

- Giasin, K.; Hodzic, A.; Phadnis, V.; Ayvar-Soberanis, S. Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: Experimental and finite element study. Int. J. Adv. Manuf. Technol. 2016, 87, 2041–2061. [Google Scholar] [CrossRef]

- Islam, M.; Boswell, B. Effect of cooling methods on cutting temperature, cutting force and hole quality in drilling of three ferrous alloys. In Proceedings of the International Conference on Mechanical and Manufacturing Engineering (ICME2018), Johor, Malaysia, 16–17 July 2018; p. 012068. [Google Scholar]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining–Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Erzincanlı, F. Influence of Different Cooling Methods on Tool Life, Wear Mechanisms and Surface Roughness in the Milling of Nickel-Based Waspaloy with WC Tools. Arab. J. Sci. Eng. 2019, 44, 7979–7995. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Machinability of Al2024, Al6061, and Al5083 alloys using multi-hole simultaneous drilling approach. J. Mater. Res. Technol. 2020, 9, 10991–11002. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Bagci, E. Evaluation of drilled hole quality in Al 2024 alloy. Int. J. Adv. Manuf. Technol. 2008, 37, 1051–1060. [Google Scholar] [CrossRef]

- Bresseler, B.; El-Wardany, T.; Elbestawi, M. Material side flow in high speed finish boring of case hardened steel. In Proceedings of the 1st French and German Conference on High Speed Machining, Metz, France, June 1997; pp. 196–206. [Google Scholar]

- Kishawy, H.; Elbestawi, M.A. Effects of process parameters on material side flow during hard turning. Int. J. Mach. Tools Manuf. 1999, 39, 1017–1030. [Google Scholar] [CrossRef]

- Whitehouse, D.J. Handbook of Surface and Nanometrology; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Giasin, K. Machining Fibre Metal Laminates and Al2024-T3 Aluminium Alloy. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2017. [Google Scholar]

- Coromant, S. Machining carbon fibre materials. In Sandvik Coromant User’s Guide-Composite Solutions; Sandvik: Stockholm, Sweden, 2010. [Google Scholar]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Kurt, M.; Bagci, E.; Kaynak, Y. Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int. J. Adv. Manuf. Technol. 2009, 40, 458–469. [Google Scholar] [CrossRef]

- Shareef, I.; Natarajan, M.; Ajayi, O.O. Dry machinability of aluminum alloys. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; pp. 831–832. [Google Scholar]

- Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D. Burr Formation and Hole Quality when Drilling Titanium and Aluminium Alloys. Procedia CIRP 2015, 37, 230–235. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Papazoglou, E.-L.; Karmiris-Obratański, P. Experimental study on the influence of machining conditions on the quality of electrical discharge machined surfaces of aluminum alloy Al5052. Machines 2020, 8, 12. [Google Scholar] [CrossRef]

- GD&T. GD&T: Perpendicularity. Available online: https://www.gdandtbasics.com/perpendicularity/ (accessed on 25 January 2021).

- Giasin, K.; Hawxwell, J.; Sinke, J.; Dhakal, H.; Köklü, U.; Brousseau, E. The effect of cutting tool coating on the form and dimensional errors of machined holes in GLARE® fibre metal laminates. Int. J. Adv. Manuf. Technol. 2020, 1–16. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; French, T.; Phadnis, V. 3D Finite Element Modelling of Cutting Forces in Drilling Fibre Metal Laminates and Experimental Hole Quality Analysis. Appl. Compos. Mater. 2016, 24, 1–25. [Google Scholar]

- AlSi, I. Effect of cutting parameters on the drilling of AlSi7 metallic foams. Mater. Tehnol. 2017, 51, 19–24. [Google Scholar]

- Hayajneh, M.T. Hole quality in deep hole drilLING. Mater. Manuf. Process. 2001, 16, 147–164. [Google Scholar] [CrossRef]

- Zitoune, R.; Krishnaraj, V.; Collombet, F. Study of drilling of composite material and aluminium stack. Compos. Struct. 2010, 92, 1246–1255. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S. An Investigation of burrs, chip formation, hole size, circularity and delamination during drilling operation of GLARE using ANOVA. Compos. Struct. 2017, 159, 745–760. [Google Scholar] [CrossRef]

- Govindaraju, N.; Shakeel, A.L.; Pradeepkumar, M. Experimental investigations on cryogenic cooling in drilling of aluminium alloy. In Applied Mechanics and Materials; Trans Tech Publications Ltd: Stafa-Zurich, Switzerland, 2014; pp. 316–320. [Google Scholar]

- Gowda, B.M.U.; Ravindra, H.V.; Jain, S.P.; Raj, M.N.; Prakesh, G.V.N.; Ugrasen, G. Comparative Study of Surface Roughness and Cylindricity of Aluminium Silicon Nitride Material Using MRA GMDH & Pattern Recognition Technique in Drilling. Procedia Mater. Sci. 2014, 6, 1770–1779. [Google Scholar]

- Herghelegiu, E.; Radu, M.C.; Schnakovszky, C.; Tampu, C.N. Considerations on material thickness influence on the AWJ processing quality of an aluminium alloy. In Proceedings of the MATEC Web of Conferences, Brasov, Romania, 3–4 November 2016; p. 03007. [Google Scholar]

| Properties | Metric | Element | Percentage |

|---|---|---|---|

| Density (g/cc) | 2.7 | Aluminum (Al) | 98 |

| Ultimate Tensile Strength (MPa) | 310 | Chromium (Cr) | 0.04–0.35 |

| Tensile Yield Strength (MPa) | 276 | Copper (Cu) | 0.15–0.4 |

| Modulus of Elasticity (GPa) | 68.9 | Iron (Fe) | 0.7 |

| Bearing Yield Strength (MPa) | 386 | Magnesium (Mg) | 0.8–1.2 |

| Poisson’s Ratio | 0.33 | Manganese (Mn) | 0.15 |

| Fatigue Strength (MPa) | 96.5 | Silicon (Si) | 0.4–0.8 |

| Fracture Toughness (MPa-m½) | 29 | Titanium (Ti) | 0.15 |

| Machinability (%) | 50 | Zinc (Zn) | 0.25 |

| Shear Modulus (GPa) | 26 | ||

| Specific Heat Capacity (J/g-°C) | 0.896 | ||

| Melting Point (°C) | 582–652 | ||

| Hardness (HV) | 107 |

| Description | Tool A | Tool B | Tool C |

|---|---|---|---|

| Tool material | Solid carbide | Micrograin carbide | Solid carbide |

| Drill diameter (mm) | 10 | 10 | 10 |

| Helix angle (°) | 30 | 30 | 30 |

| Point angle (°) | 140 | 140 | 140 |

| Tolerance | M7 | M7 | M7 |

| Coating | Firex coating (TiN/TiAlN) | TiAlN | TiN |

| Flute length | 47 | 47 | 43 |

| Overall length | 89 | 89 | 89 |

| Color | Red violet | Black violet | Gold |

| Coating thickness (μm) | 1.5–5 | 1.5–4 | 1.5–3 |

| Layer structure | Multilayer | Monolayer | Monolayer |

| Nano hardness (HV 0.05) | 3000–3300 | 3300 | 2400 |

| Friction coefficient | 0.5 | 0.5–0.55 | 0.4–0.5 |

| Oxidation resistance (°C) | 930 | 700–800 | 593 |

| Manufacturer | GUHRING (Germany) | OSG (Japan) | GUHRING (Germany) |

| Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Spindle speed (rpm) | 1000 | 2000 | 3000 |

| Feed rate (mm/min) | 50 | 100 | 150 |

| Coating | TiN/TiAlN | TiAlN | TiN |

| Parameter | Ra | Rz | HST | HSB | HCT | HCB | HC | HP |

|---|---|---|---|---|---|---|---|---|

| Model | 50.79% | 50.48% | 91.91% | 86.34% | 64.50% | 60.94% | 73.62% | 97.00% |

| Blocks | 0.34% | 0.42% | 0.32% | 1.80% | 0.70% | 1.27% | 0.83% | 0.09% |

| Linear | 36.81% | 35.95% | 42.73% | 23.94% | 36.88% | 26.04% | 41.30% | 66.75% |

| Spindle speed | 27.47% | 26.02% | 16.89% | 3.75% | 10.35% | 0.43% | 4.14% | 50.61% |

| Feed rate | 4.11% | 4.88% | 1.95% | 3.39% | 4.06% | 6.08% | 2.75% | 1.68% |

| Coating | 5.23% | 5.05% | 23.90% | 16.80% | 22.48% | 19.53% | 34.41% | 14.46% |

| 2-Way Interactions | 6.03% | 6.35% | 35.11% | 47.32% | 21.73% | 15.64% | 20.04% | 19.93% |

| Spindle speed*Feed rate | 3.00% | 3.13% | 13.63% | 11.80% | 0.15% | 5.89% | 6.84% | 0.66% |

| Spindle speed*Coating | 2.76% | 3.13% | 19.24% | 26.99% | 16.71% | 6.63% | 4.17% | 10.79% |

| Feed rate*Coating | 0.27% | 0.09% | 2.24% | 8.52% | 4.87% | 3.11% | 9.04% | 8.48% |

| 3-Way Interactions | 7.61% | 7.76% | 13.74% | 13.27% | 5.19% | 18.00% | 11.45% | 10.23% |

| Spindle speed*Feed rate*Coating | 7.61% | 7.76% | 13.74% | 13.27% | 5.19% | 18.00% | 11.45% | 10.23% |

| Error | 49.21% | 49.52% | 8.09% | 13.66% | 35.50% | 39.06% | 26.38% | 3.00% |

| Total | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% |

| Coating | Top (µm) | Bottom (µm) |

|---|---|---|

| TiN/TiAlN | 24.23–79.9 | 20.6–48.13 |

| TiAlN | 17.83–34.87 | 19.87–29.17 |

| TiN | 25.13–51.53 | 15.47–32.7 |

| Coating | Top (µm) | Bottom (µm) |

|---|---|---|

| TiN/TiAlN | 18.33–59.63 | 7.03–15.13 |

| TiAlN | 6.63–42.2 | 8.93–15.6 |

| TiN | 12–26.4 | 9.3–19.7 |

| Coating | Cylindricity (µm) | Perpendicularity (µm) |

|---|---|---|

| TiN/TiAlN | 33.27–78.10 | 53.23–76.03 |

| TiAlN | 20.17–74.17 | 48–84.77 |

| TiN | 22.77–44.67 | 66.57–84.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Tameemi, H.A.; Al-Dulaimi, T.; Awe, M.O.; Sharma, S.; Pimenov, D.Y.; Koklu, U.; Giasin, K. Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy. Materials 2021, 14, 1783. https://doi.org/10.3390/ma14071783

Al-Tameemi HA, Al-Dulaimi T, Awe MO, Sharma S, Pimenov DY, Koklu U, Giasin K. Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy. Materials. 2021; 14(7):1783. https://doi.org/10.3390/ma14071783

Chicago/Turabian StyleAl-Tameemi, Hamza A., Thamir Al-Dulaimi, Michael Oluwatobiloba Awe, Shubham Sharma, Danil Yurievich Pimenov, Ugur Koklu, and Khaled Giasin. 2021. "Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy" Materials 14, no. 7: 1783. https://doi.org/10.3390/ma14071783

APA StyleAl-Tameemi, H. A., Al-Dulaimi, T., Awe, M. O., Sharma, S., Pimenov, D. Y., Koklu, U., & Giasin, K. (2021). Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy. Materials, 14(7), 1783. https://doi.org/10.3390/ma14071783