Tribological Properties of 2D Materials and Composites—A Review of Recent Advances

Abstract

1. Introduction

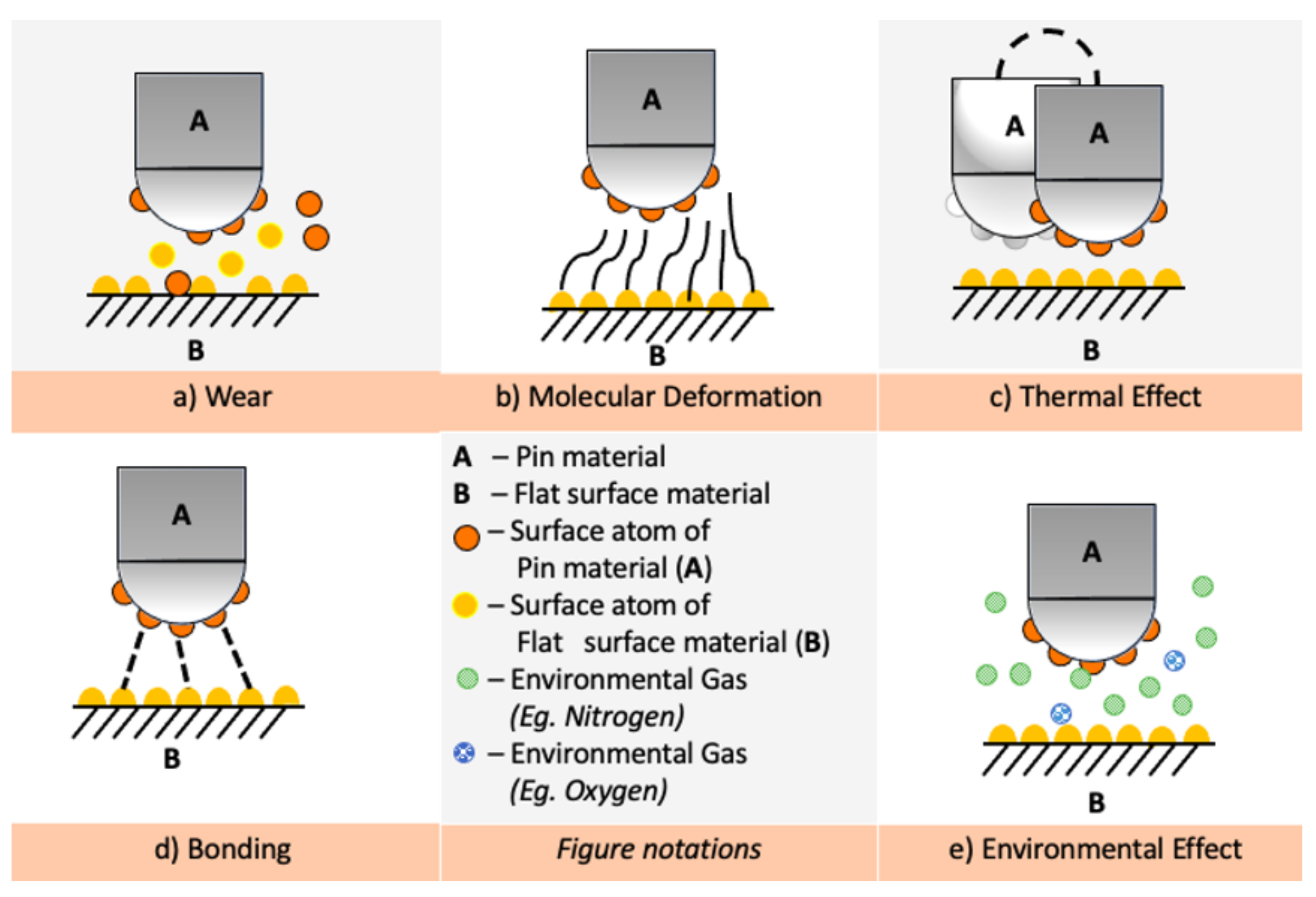

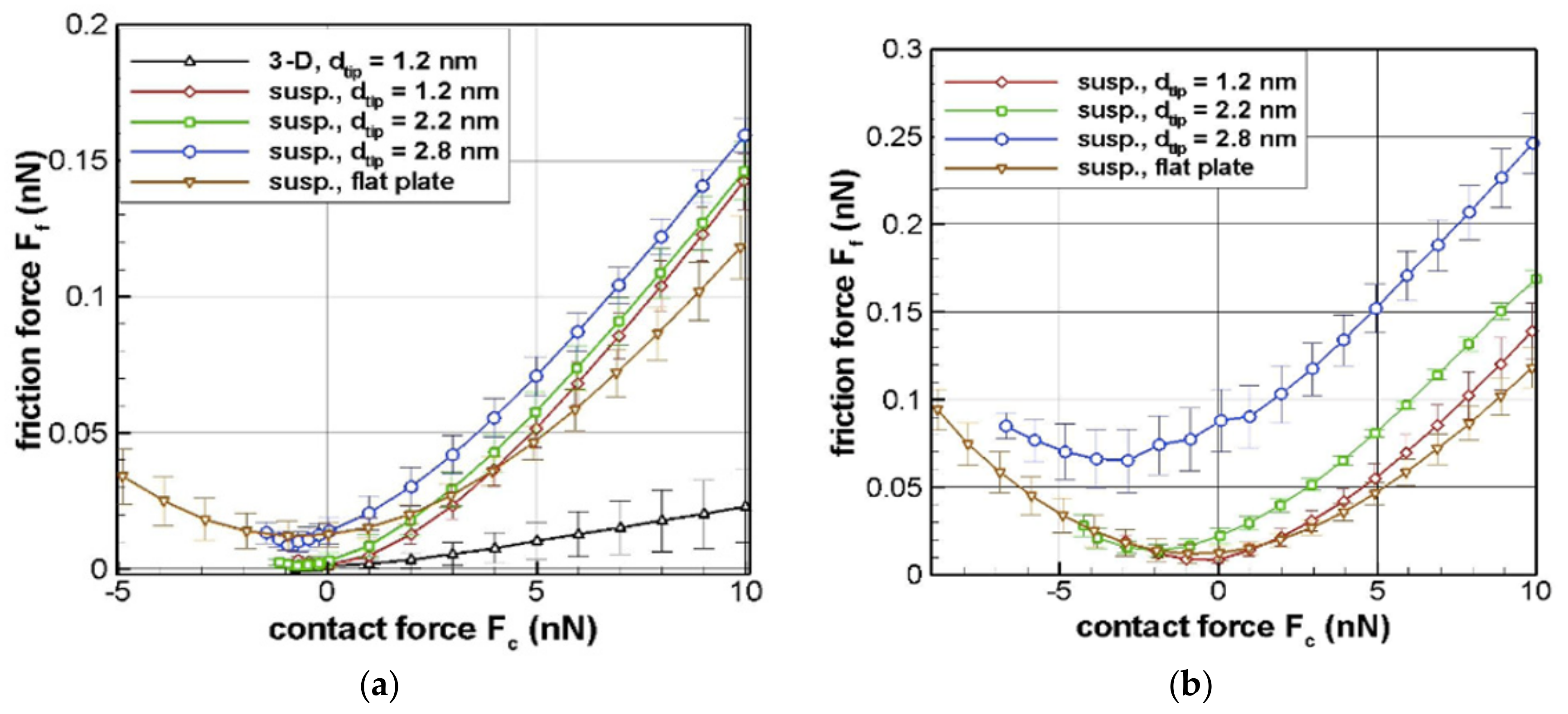

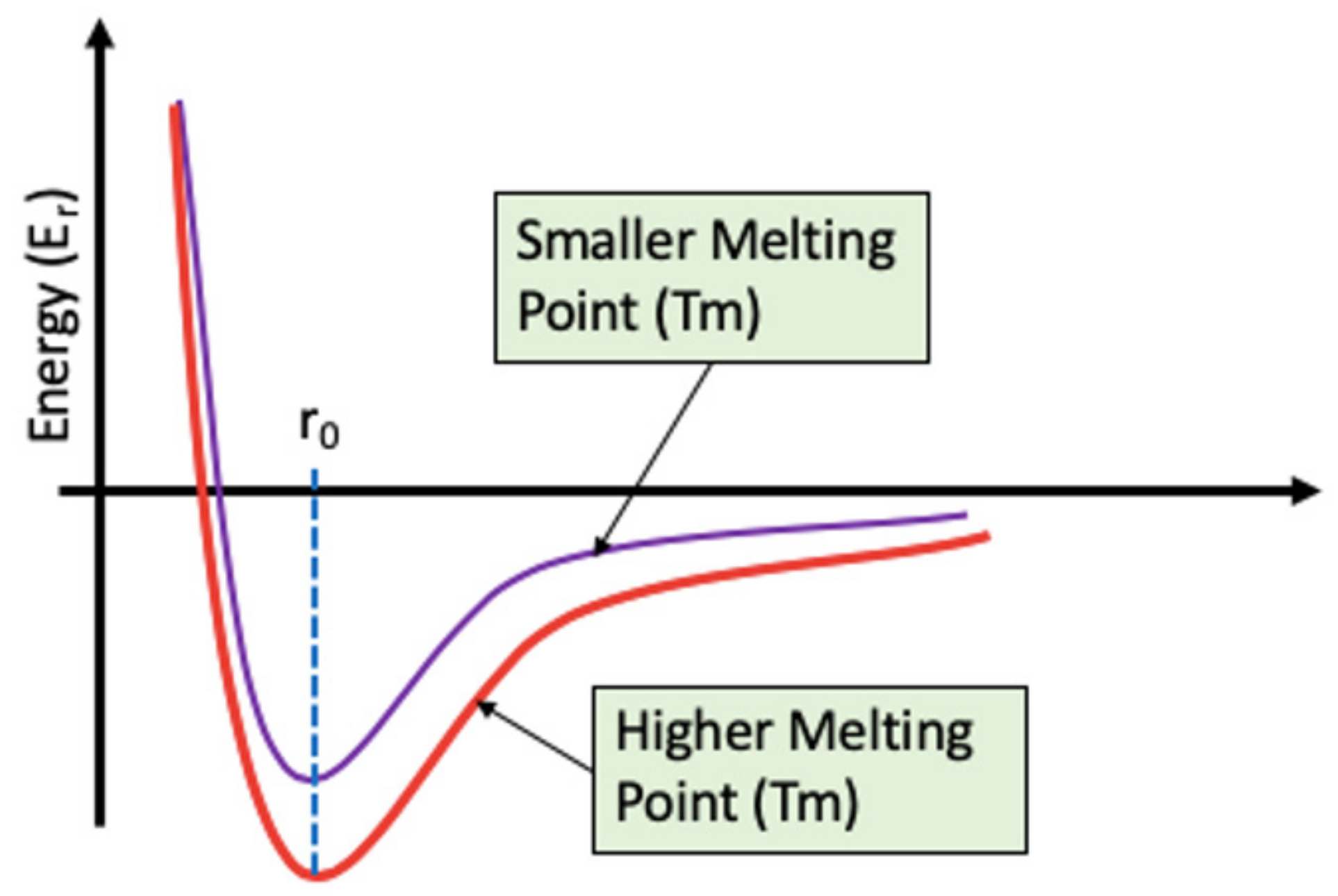

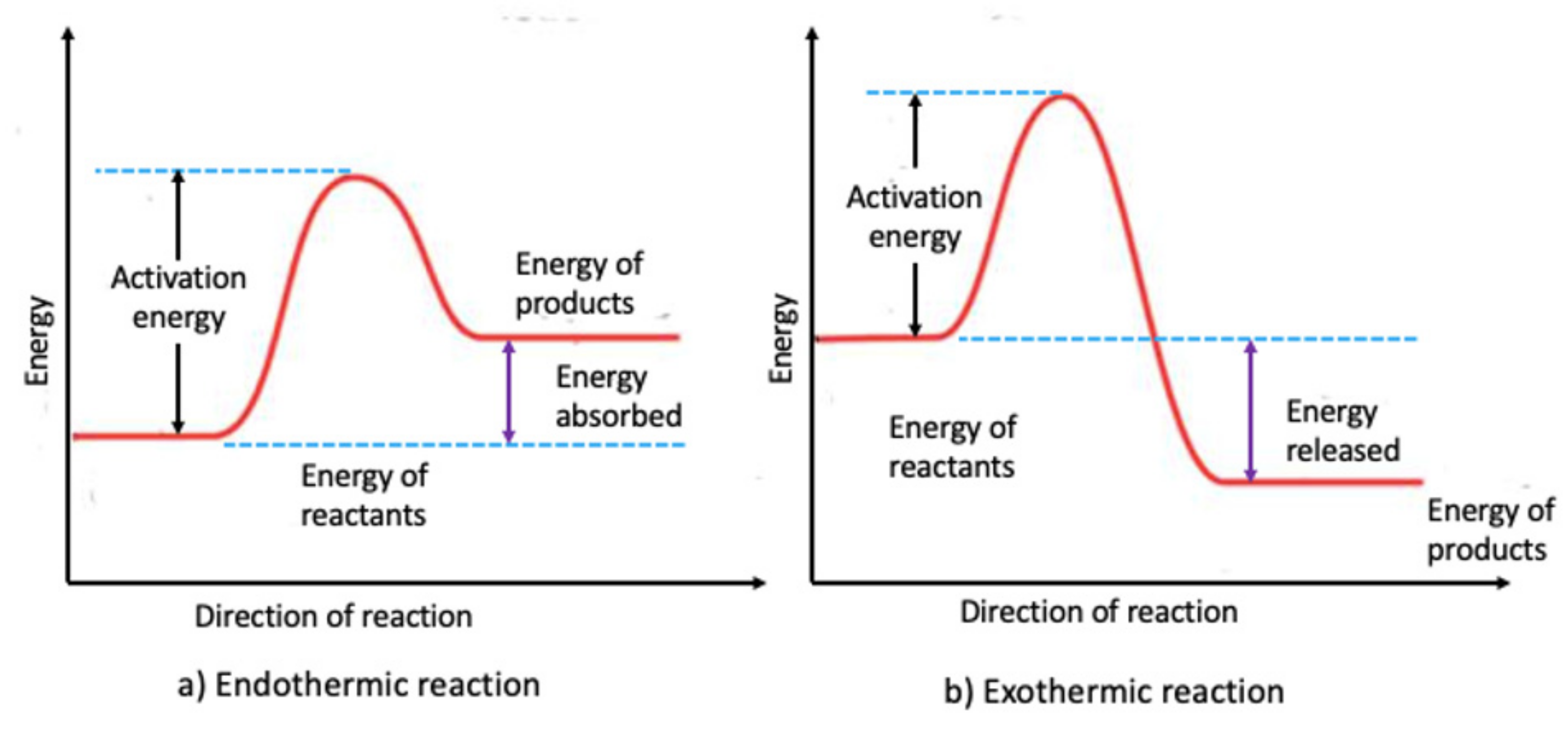

2. Mechanisms of Frictional Energy Dissipation on an Atomic Scale

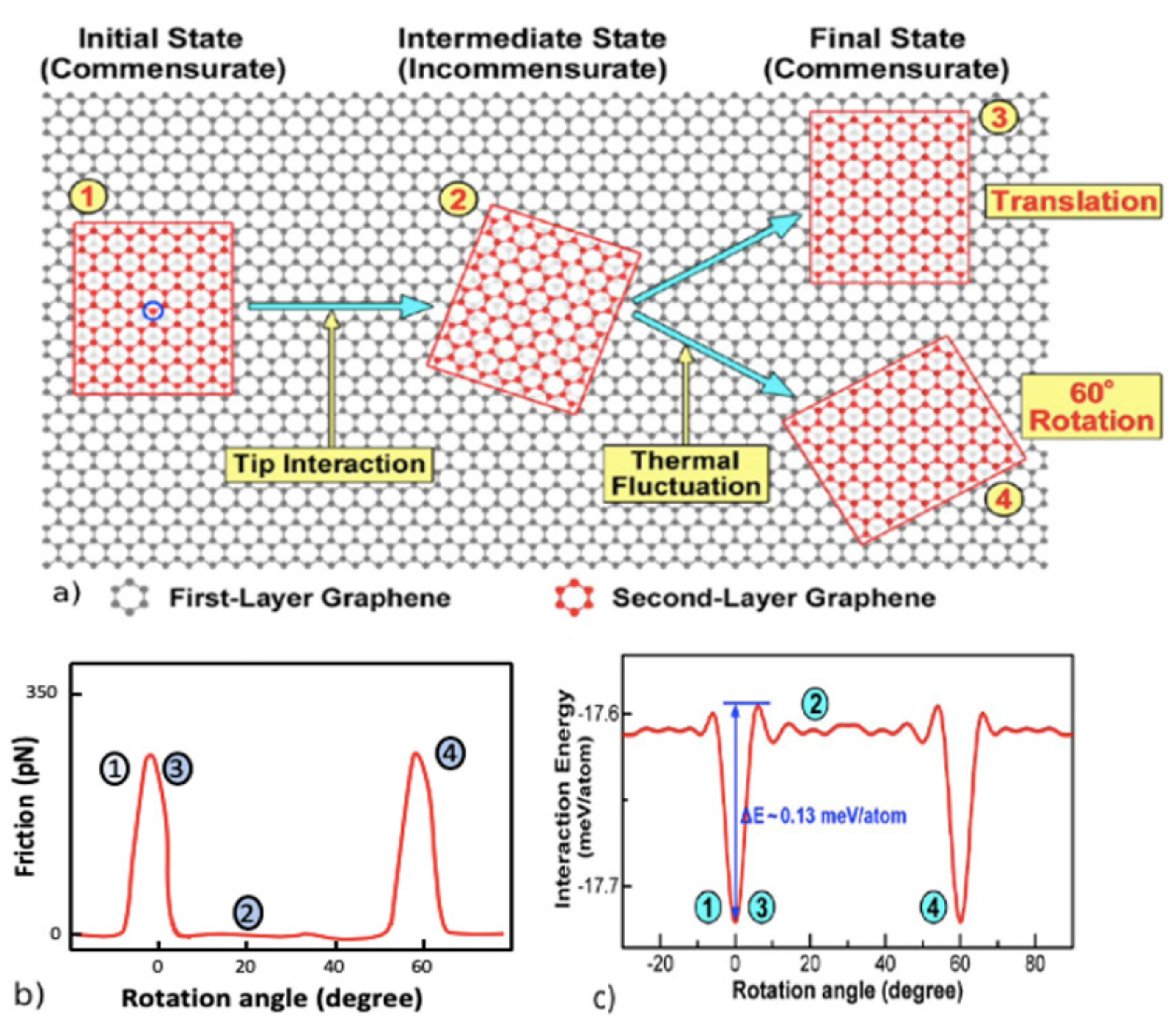

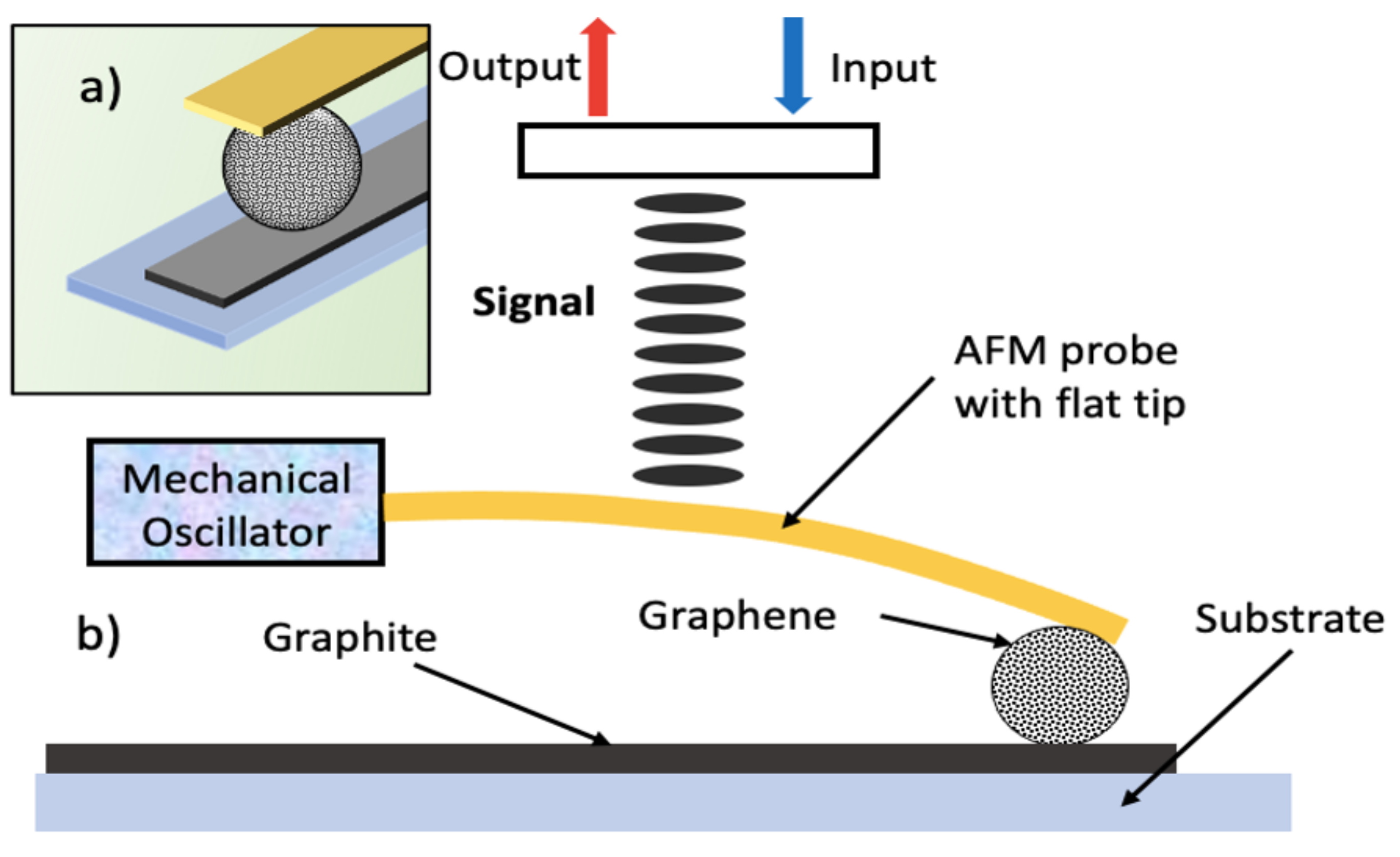

3. Graphite and Graphene

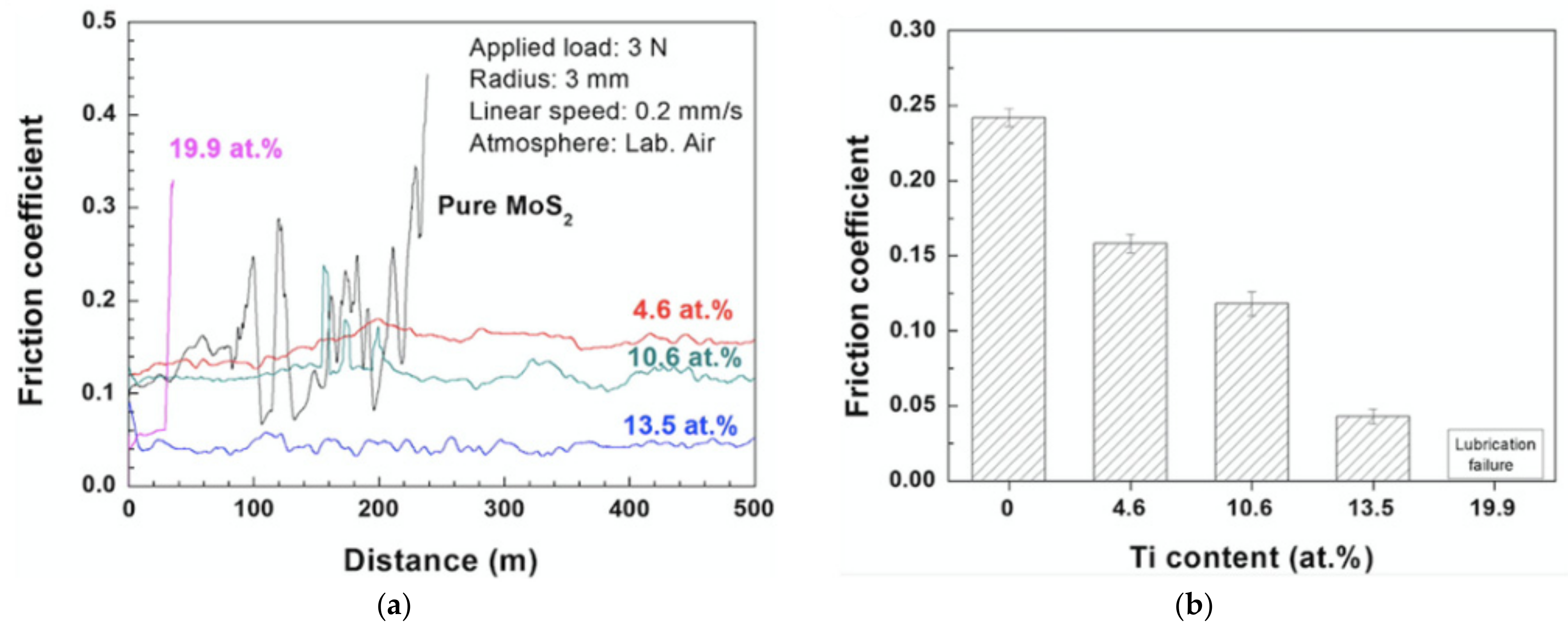

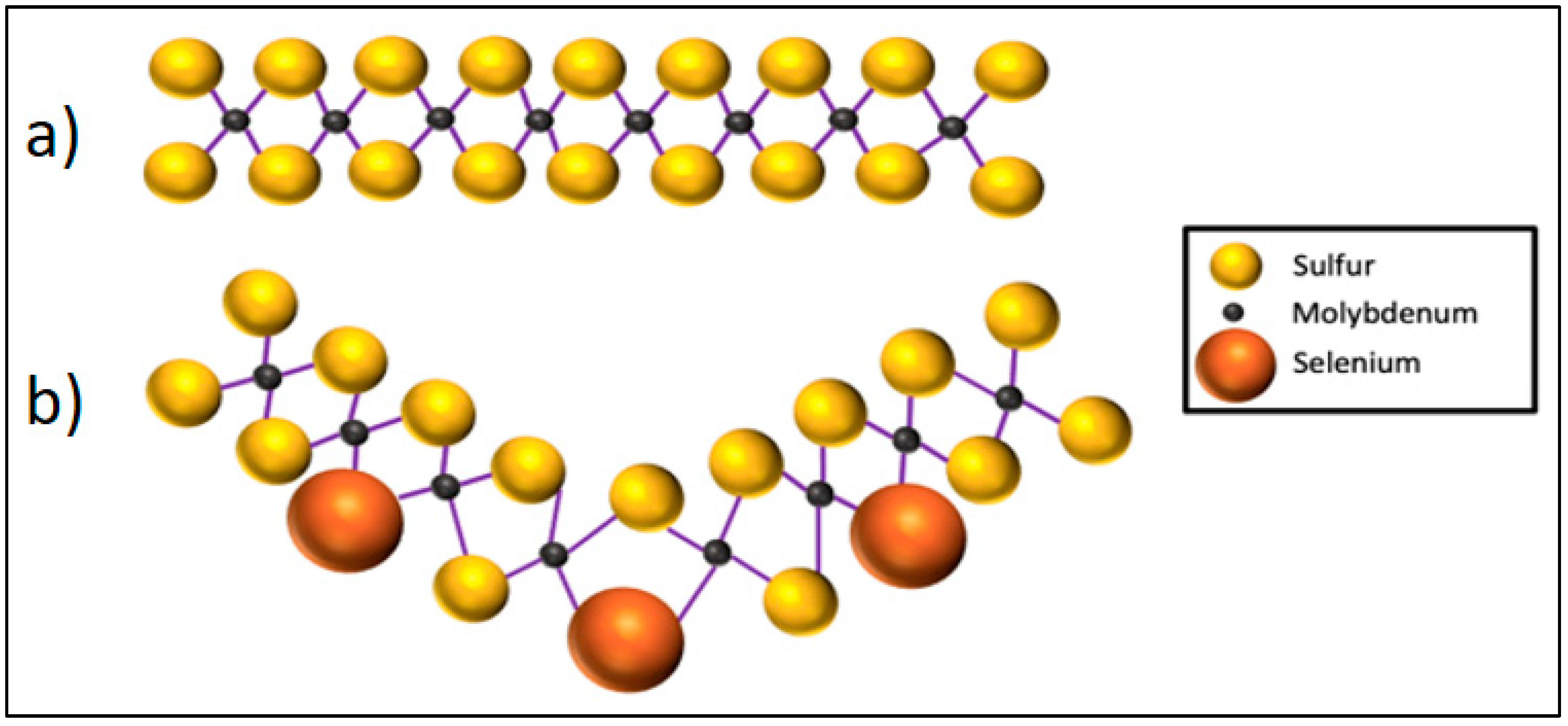

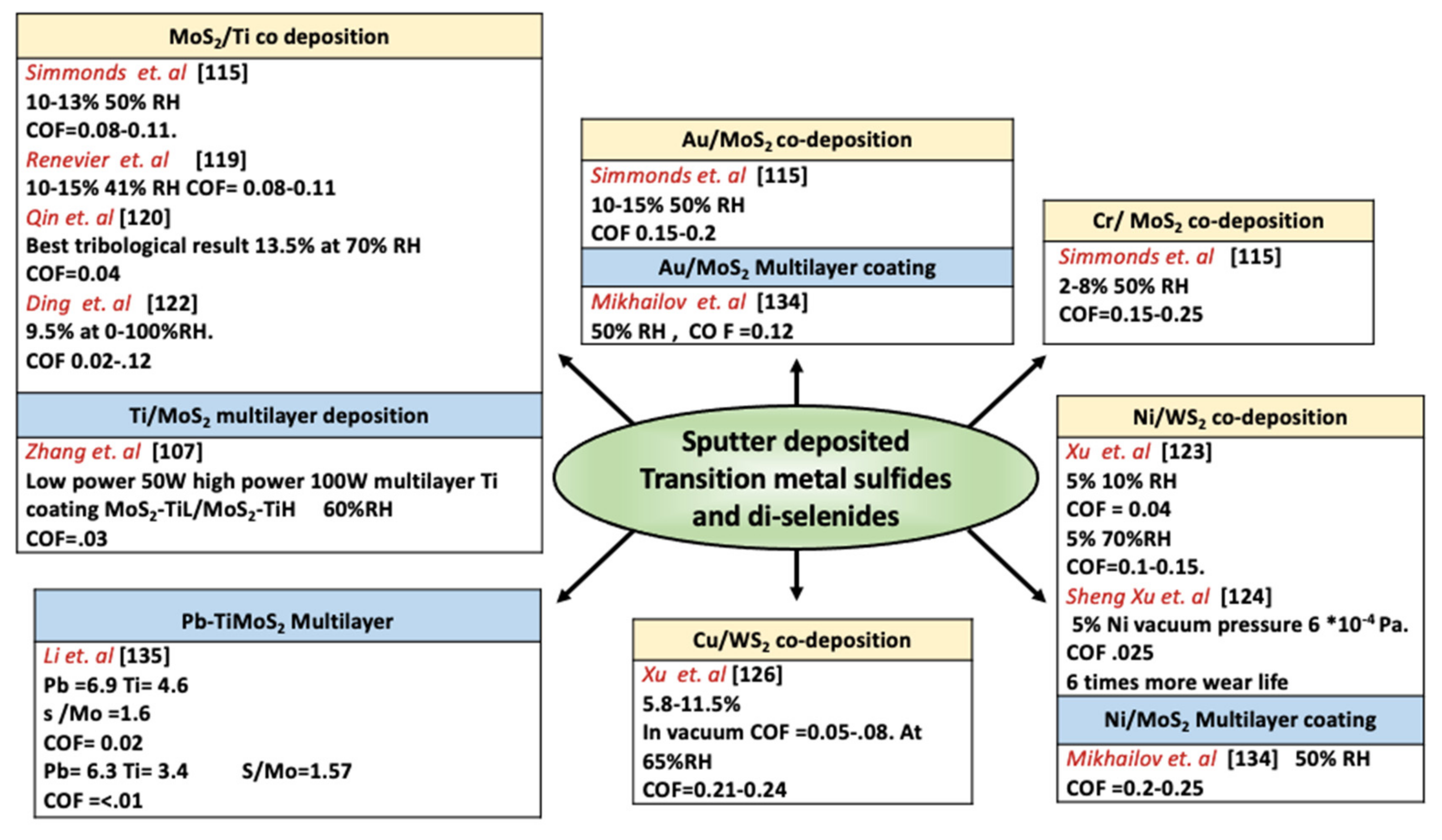

4. Transition Metal Sulfides and Di-Selenides

5. Phosphorus with Layered Structures (Black Phosphorous)

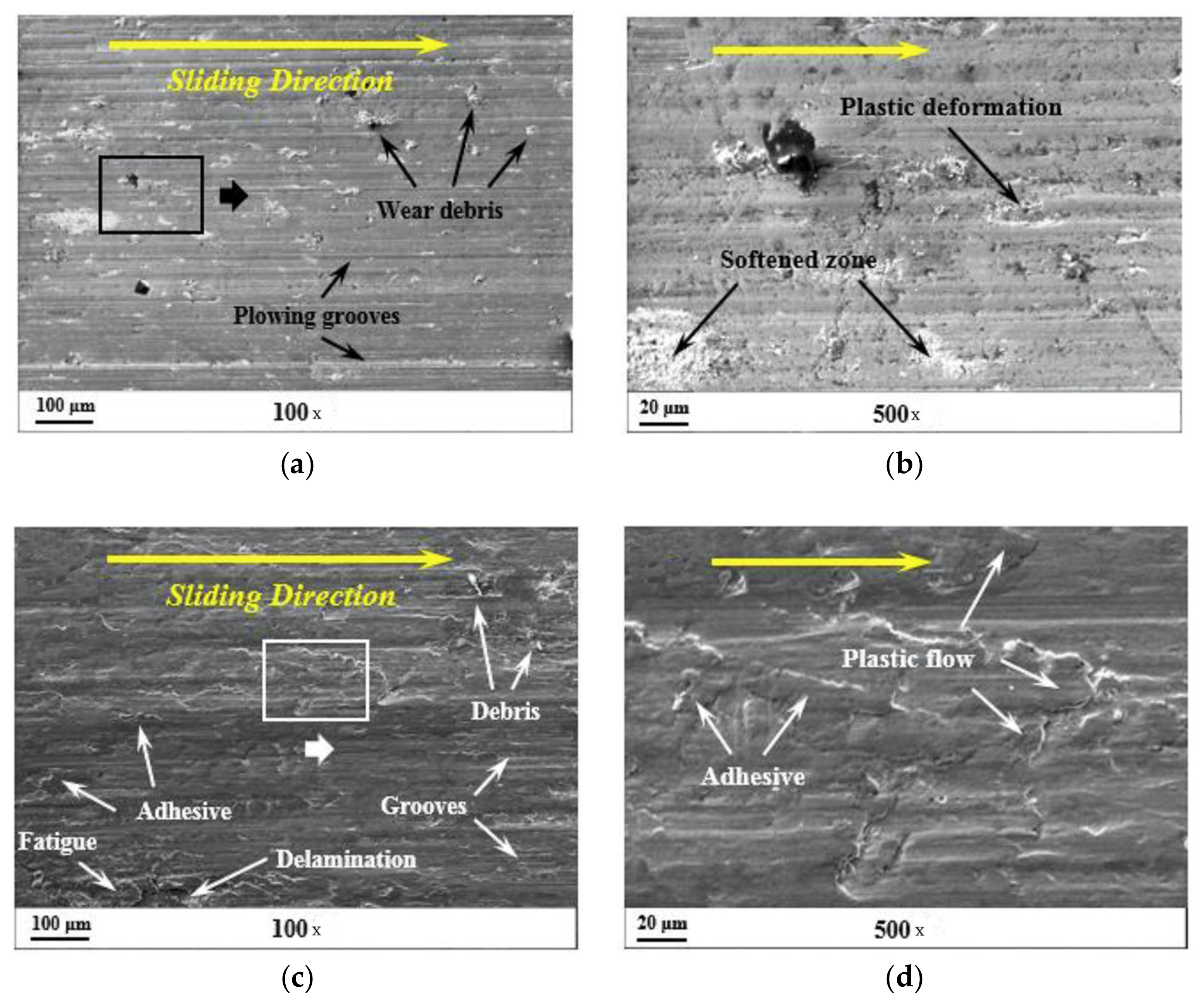

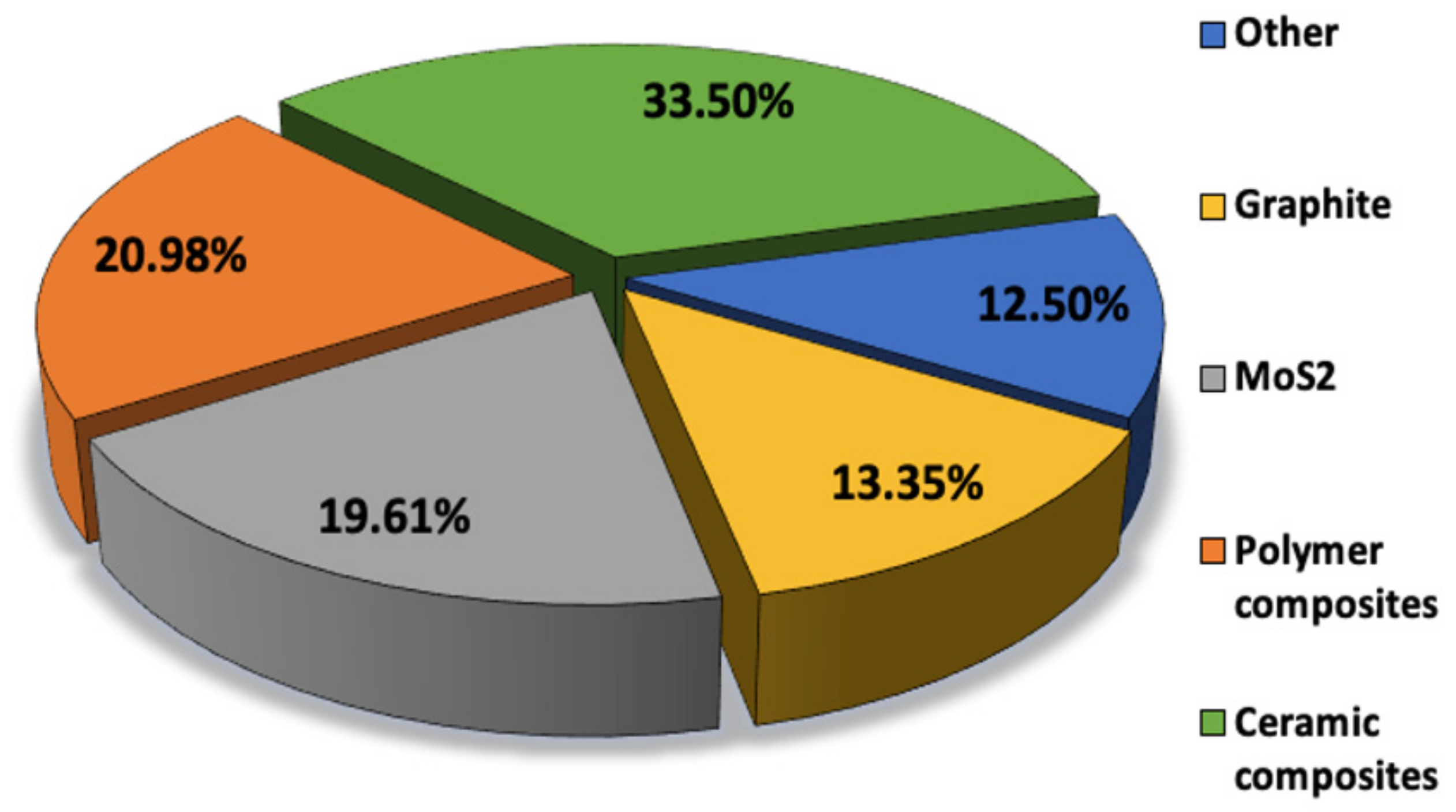

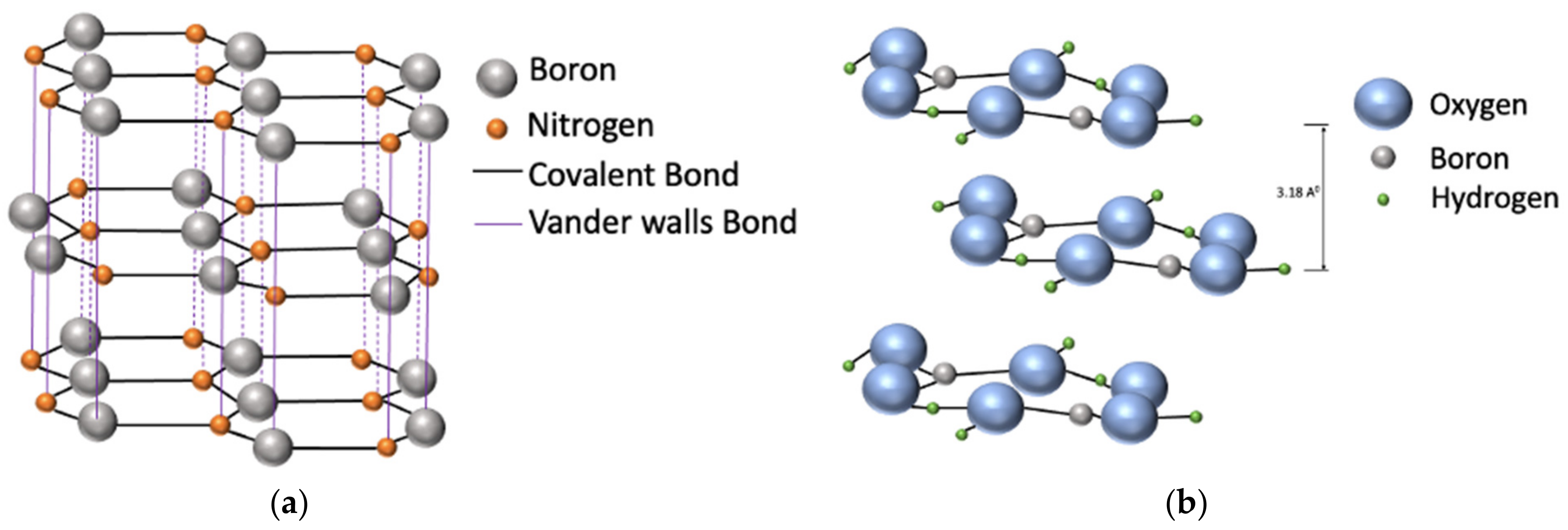

6. Ceramics in Tribology Research

7. Metals, Ceramic, and Polymer-Based Matrix Composites

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Holmberg, K.; Siilasto, R.; Laitinen, R.T.; Andersson, P.; Jäsberg, A. Global energy consumption due to friction in paper machines. Tribol. Int. 2013, 62, 58–77. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Nylund, N.O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Global impact of friction on energy consumption, economy and environment. FME Trans. 2015, 43, 181–185. [Google Scholar]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribo. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Dowson, D. History of Tribology, 2nd ed.; Longman: London, NY, USA, 1979. [Google Scholar]

- Tichy, J.A.; Meyer, D.M. Review of solid mechanics in tribology. Int. J. Solids Struct. 2000, 37, 391–400. [Google Scholar] [CrossRef]

- Bermúdez, M.D.; Jiménez, A.E.; Sanes, J.; Carrión, F.J. Ionic liquids as advanced lubricant fluids. Molecules 2009, 14, 2888–2908. [Google Scholar] [CrossRef] [PubMed]

- Peterson, M.B.; Murray, S.F.; Florek, J.J. Consideration of lubricants for temperatures above 1000 F. ASLE Trans. 1959, 2, 225–234. [Google Scholar] [CrossRef]

- Spalvins, T. A review of recent advances in solid film lubrication. J. Vac. Sci. Technol. A 1987, 5, 212–219. [Google Scholar] [CrossRef]

- Miyoshi, K. Solid Lubricants and Coatings for Extreme Environments: State-of-the-Art Survey. NASA/TM 2007, 214668, 1–16. [Google Scholar]

- Shah, F.U.; Glavatskih, S.; Antzutkin, O.N. Boron in tribology: From borates to ionic liquids. Tribol. Lett. 2013, 51, 281–301. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mat. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Mannix, A.J.; Kiraly, B.; Hersam, M.C.; Guisinger, N.P. Synthesis and chemistry of elemental 2D materials. Nat. Rev. Chem. 2017, 1.2, 1–14. [Google Scholar] [CrossRef]

- Guo, S.; Dong, S. Graphene nanosheet: Synthesis, molecular engineering, thin film, hybrids, and energy and analytical applications. Chem. Soc. Rev. 2011, 40, 2644–2672. [Google Scholar] [CrossRef]

- Winer, W.O. Molybdenum disulfide as a lubricant: A review of the fundamental knowledge. Wear 1967, 10, 422–452. [Google Scholar] [CrossRef]

- Mbamara, U.S.; Olofinjana, B.; Ajayi, O.O.; Lorenzo-Martin, C.; Obiajunwa, E.I.; Ajayi, E.O.B. Friction and wear behavior of nitrogen-doped ZnO thin films deposited via MOCVD under dry contact. Eng. Sci. Technol. Int. J. 2016, 19, 956–963. [Google Scholar] [CrossRef][Green Version]

- Saito, T.; Honda, F. Chemical contribution to friction behavior of sintered hexagonal boron nitride in water. Wear 2000, 237, 253–260. [Google Scholar] [CrossRef]

- Zhan, H.; Guo, D.; Xie, G.X. Two-dimensional layered materials: From mechanical and coupling properties towards applications in electronics. Nanoscale 2019, 11, 13181–13212. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, F.; Yu, M.; Zhuang, X.; Feng, X. Two-dimensional materials for miniaturized energy storage devices: From individual devices to smart integrated systems. Chem. Soc. Rev. 2018, 47, 7426–7451. [Google Scholar] [CrossRef] [PubMed]

- Furlan, K.P.; De Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Chen, Z.; He, X.; Xiao, C.; Kim, S. Effect of Humidity on Friction and Wear—A Critical Review. Lubricants 2018, 6, 74. [Google Scholar] [CrossRef]

- Zang, X.; Zhou, Q.; Chang, J.; Liu, Y.; Lin, L. Graphene and carbon nanotube (CNT) in MEMS/NEMS applications. Microelectron. Eng. 2015, 132, 192–206. [Google Scholar] [CrossRef]

- Pu, J.; Mo, Y.; Wan, S.; Wang, L. Fabrication of novel graphene–fullerene hybrid lubricating films based on self-assembly for MEMS applications. Chem. Commun. 2014, 50, 469–471. [Google Scholar] [CrossRef] [PubMed]

- Adams, J.B.; Hector, L.G.; Siegel, D.J.; Yu, H.; Zhong, J. Adhesion, lubrication and wear on the atomic scale. Surf. Interf. Analy. 2001, 31, 619–626. [Google Scholar] [CrossRef]

- Bhushan, B.; Israelachvili, J.N.; Landman, U. Nanotribology: Friction, wear and lubrication at the atomic scale. Nature 1995, 374, 607–616. [Google Scholar] [CrossRef]

- Bhushan, B. Nanotribology and nanomechanics. Wear 2005, 259, 1507–1531. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Approaches for Achieving Superlubricity in Two-Dimensional Materials. ACS Nano. 2018, 12, 2122–2137. [Google Scholar] [CrossRef]

- Hutchings, I.; Shipway, P. Tribology: Friction and Wear of Engineering Materials, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Aquaro, D.; Fontani, E. Erosion of ductile and brittle materials. Meccanica 2001, 36, 651–661. [Google Scholar] [CrossRef]

- Rice, J.R. Fracture mechanics. Appl. Mech. Rev. 1985, 38, 1271–1275. [Google Scholar] [CrossRef]

- Qiu, B.; Xing, S.; Dong, Q. Green preparation and dry sliding wear properties of a macro-ZTA/fe composite produced by a two-step method. Metals 2019, 9, 986. [Google Scholar] [CrossRef]

- Scarpa, F.; Adhikari, S.; Chowdhury, R. The transverse elasticity of bilayer graphene. Phys. Lett. A 2010, 374, 2053–2057. [Google Scholar] [CrossRef]

- Smolyanitsky, A.; Killgore, J.P. Anomalous friction in suspended graphene. Available online: https://arxiv.org/abs/1207.5173 (accessed on 16 March 2021).

- Zhang, L.; Tanaka, H. Towards a deeper understanding of wear and friction on the atomic scale–A molecular dynamics analysis. Wear 1997, 211, 44–53. [Google Scholar] [CrossRef]

- Riedo, E.; Gnecco, E.; Bennewitz, R.; Meyer, E.; Brune, H. Interaction Potential and Hopping Dynamics Governing Sliding Friction. Phys. Rev. Lett. 2003, 91, 084502. [Google Scholar] [CrossRef]

- Krylov, S.Y.; Frenken, J.W.M. The physics of atomic-scale friction: Basic considerations and open questions. Phys. Status Solidi B 2014, 251, 711–736. [Google Scholar] [CrossRef]

- Smolyanitsky, A. Effects of thermal rippling on the frictional properties of free-standing graphene. RSC Adv. 2015, 5, 29179–29184. [Google Scholar] [CrossRef][Green Version]

- Padmavathi, D.A. Potential Energy Curves & Material Properties. Mat. Sci. Appl. 2011, 2, 97–104. [Google Scholar]

- Li, J.; Luo, J. Superlow Friction of Graphite Induced by the Self-Assembly of Sodium Dodecyl Sulfate Molecular Layers. Langmuir 2017, 33, 12596–12601. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Smolyanitsky, A.; Li, Q.; Feng, X.Q.; Cannara, R.J. Adhesion-dependent negative friction coefficient on chemically modified graphite at the nanoscale. Nat. Mater. 2012, 11, 1032–1037. [Google Scholar] [CrossRef] [PubMed]

- Truong-Son, N. Gibbs Free Energy. Why Are Equilibrium Constants for a Chemical Reaction Temperature Dependent? 17 March. Available online: socrat-ic.org/questions/gibbs-free-energy-why-are-equilibrium-constants-for-a-chemical-reaction-temperat (accessed on 17 March 2021).

- Manu, B.R.; Jayatissa, A.H. Effect of Humidity on Friction of Molybdenum Disulfide Films Produced by Thermal Evaporation on Titanium Substrates. Chem. Sci. Int. J. 2020, 29, 25–33. [Google Scholar] [CrossRef]

- Gallagher, P.; Lee, M.; Taniguchi, T.; Goldhaber-Gordon, D. Switchable friction enabled by nanoscale self-assembly on graphene. Nat. Commun. 2016, 7, 10745. [Google Scholar] [CrossRef]

- Manu, B.R.; Schroeder, A.M.; Jayatissa, A.H. Characterization of the Effect of Moisture on Tribology of Titanium Rubbed Against Different Pin Materials. Chem. Sci. Int. J. 2020, 29, 1–10. [Google Scholar] [CrossRef]

- Manimunda, P.; Al-Azizi, A.; Kim, S.H.; Chromik, R.R. Shear-Induced Structural Changes and Origin of Ultralow Friction of Hydrogenated Diamond-like Carbon (DLC) in Dry Environment. ACS Appl. Mater. Interf. 2017, 9, 16704–16714. [Google Scholar] [CrossRef] [PubMed]

- Heimberg, J.A.; Wahl, K.J.; Singer, I.L.; Erdemir, A. Superlow friction behavior of diamond-like carbon coatings: Time and speed effects. Appl. Phys. Lett. 2001, 78, 2449–2451. [Google Scholar] [CrossRef]

- Kurahashi, Y.; Tanaka, H.; Terayama, M.; Sugimura, J. Effects of environmental gas and trace water on the friction of DLC sliding with metals. Micromachines 2017, 8, 217. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Tribology of Diamond-Like Carbon Films: Fundamentals and Applications, 1st ed.; Springer Sci. Bus: New York, NY, USA, 2008. [Google Scholar]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Role of humidity in reducing sliding friction of multilayered graphene. Carbon 2015, 87, 374–384. [Google Scholar] [CrossRef]

- Ohmae, N. Humidity effects on tribology of advanced carbon materials. Tribol. Int. 2006, 39, 1497–1502. [Google Scholar] [CrossRef]

- Arif, T.; Colas, G.; Filleter, T. Effect of Humidity and Water Intercalation on the Tribological Behavior of Graphene and Graphene Oxide. ACS Appl. Mater. Interf. 2018, 10, 22537–22544. [Google Scholar] [CrossRef]

- Theiler, G.; Gradt, T.; Österle, W.; Brückner, A.; Weihnacht, V. Friction and endurance of MoS2/ta-C coatings produced by Laser Arc deposition. Wear 2013, 297, 791–801. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Shi, Z.; Shum, P.; Wasy, A.; Zhou, Z.; Li, L.K.Y. Tribological performance of few layer graphene on textured M2 steel surfaces. Surf. Coat. Technol. 2016, 296, 164–170. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Penkov, O.; Kim, H.J.; Kim, H.J.; Kim, D.E. Tribology of graphene: A review. Int. J. Precis. Eng. Manuf. 2014, 15, 577–585. [Google Scholar] [CrossRef]

- Ko, J.H.; Kwon, S.; Park, B.H.; Park, J.Y. Nanotribological properties of fluorinated, hydrogenated, and oxidized graphenes. Tribol. Lett. 2013, 50, 137–144. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Extraordinary Macroscale Wear Resistance of One Atom Thick Graphene Layer. Adv. Funct. Mater. 2014, 24, 6640–6646. [Google Scholar] [CrossRef]

- Kwon, S.; Ko, J.H.; Jeon, K.J.; Kim, Y.H.; Park, J.Y. Enhanced nanoscale friction on fluorinated graphene. Nano Lett. 2012, 12, 6043–6048. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Kim, J.H.; Ahn, J.H.; Lee, H.J. Chemical vapor deposition-grown graphene: The thinnest solid lubricant. ACS Nano. 2011, 5, 5107–5114. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.F.; Ma, T.B.; Hu, Y.Z.; Wang, H. Atomic-scale friction in graphene oxide: An interfacial interaction perspective from first-principles calculations. Phys. Rev. B 2012, 86, 1–9. [Google Scholar] [CrossRef]

- Wang, J.; Song, Y.; Sun, Q.; Jia, Y. Theoretical study of superlow friction between two single-side hydrogenated graphene sheets. Tribol. Lett. 2012, 48, 255–261. [Google Scholar] [CrossRef]

- Lin, T.W.; Modafe, A.; Shapiro, B.; Ghodssi, R. Characterization of dynamic friction in MEMS-based microball bearings. IEEE Trans. Instrum. Meas. 2004, 53, 839–846. [Google Scholar] [CrossRef]

- Ghalichechian, N.; Modafe, A.; Beyaz, M.; Waits, C.M.; Ghodssi, R. Design and Fabrication of a Rotary Electrostatic Micromotor Supported on Microball Bearings. Sixth Int. Work. Micro Nanotechnol. Power Gener. Energy Convers. Appl. 2006, 6, 227–230. [Google Scholar]

- Liang, T.; Sawyer, W.G.; Perry, S.S.; Sinnott, S.B.; Phillpot, S.R. First-principles determination of static potential energy surfaces for atomic friction in MoS2 and MoO3. Phys. Rev. B 2008, 77, 1–6. [Google Scholar] [CrossRef]

- Cahangirov, S.; Ataca, C.; Topsakal, M.; Sahin, H.; Ciraci, S. Frictional figures of merit for single layered nanostructures. Phys. Rev. Lett. 2012, 108, 1–5. [Google Scholar] [CrossRef]

- Miura, K.; Sasaki, N.; Kamiya, S. Friction mechanisms of graphite from a single-atomic tip to a large-area flake tip. Phys. Rev. B 2004, 69, 1–9. [Google Scholar] [CrossRef]

- Dienwiebel, M.; Verhoeven, G.S.; Pradeep, N.; Frenken, J.W.M.; Heimberg, J.A.; Zandbergen, H.W. Superlubricity of graphite. Phys. Rev. Lett. 2004, 92, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Ishigami, M.; Chen, J.H.; Cullen, W.G.; Fuhrer, M.S.; Williams, E.D. Atomic structure of graphene on SiO2. Nano Lett. 2007, 7, 1643–1648. [Google Scholar] [CrossRef]

- Feng, X.; Kwon, S.; Park, J.Y.; Salmeron, M. Superlubric sliding of graphene nanoflakes on graphene. ACS Nano. 2013, 7, 1718–1724. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.W.; Wang, H.P.; Hu, Y.Z.; Luo, J. Robust microscale superlubricity under high contact pressure enabled by graphene-coated microsphere. Nat. Commun. 2017, 8, 1–8. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Macroscale superlubricity enabled by graphene nanoscroll formation. Science 2015, 348, 1118–1122. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Li, Q.; Berger, H.; Carpick, R.W.; Hone, J. Frictional characteristics of atomically thin sheets. Science 2010, 328, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Paolicelli, G.; Tripathi, M.; Corradini, V.; Candini, A.; Valeri, S. Nanoscale frictional behavior of graphene on SiO2 and Ni(111) substrates. Nanotechnology 2015, 26, 055703. [Google Scholar] [CrossRef]

- Ye, Z.; Tang, C.; Dong, Y.; Martini, A. Role of wrinkle height in friction variation with number of graphene layers. J. Appl. Phys. 2012, 112, 116102. [Google Scholar] [CrossRef]

- Mohammadi, H.; Müser, M.H. Friction of wrinkles. Phys. Rev. Lett. 2010, 105, 224301. [Google Scholar] [CrossRef] [PubMed]

- Banhart, F.; Kotakoski, J.; Krasheninnikov, A.V. Structural defects in graphene. ACS Nano. 2011, 5, 26–41. [Google Scholar] [CrossRef] [PubMed]

- López-Polín, G.; Gómez-Herrero, J.; Gómez-Navarro, C. Confining crack propagation in defective graphene. Nano Lett. 2015, 15, 2050–2054. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, H. Toughening graphene with topological defects: A perspective. J. Appl. Mech. 2015, 82, 051001. [Google Scholar] [CrossRef]

- Sun, X.Y.; Wu, R.; Xia, R.; Chu, X.H.; Xu, Y.J. Effects of Stone-Wales and vacancy defects in atomic-scale friction on defective graphite. Appl. Phys. Lett. 2014, 104, 183109. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Chemical functionalization of graphene and its applications. Prog. Mat. Sci. 2012, 57, 1061–1105. [Google Scholar] [CrossRef]

- Georgakilas, V.; Otyepka, M.; Bourlinos, A.B.; Zboril, R.; Kim, K.S. Functionalization of graphene: Covalent and non-covalent approaches, derivatives and applications. Chem. Rev. 2012, 112, 6156–6214. [Google Scholar] [CrossRef] [PubMed]

- Müller, T.; Lohrmann, M.; Kässer, T.; Marti, O.; Mlynek, J.; Krausch, G. Frictional force between a sharp asperity and a surface step. Phys. Rev. Lett. 1997, 79, 5066–5069. [Google Scholar] [CrossRef]

- Hunley, D.P.; Flynn, T.J.; Dodson, T.; Sundararajan, A.; Boland, M.J.; Strachan, D.R. Friction, adhesion, and elasticity of graphene edges. Phys. Rev. B 2013, 87, 035417. [Google Scholar] [CrossRef]

- Egberts, P.; Ye, Z.; Liu, X.Z.; Dong, Y.; Martini, A.; Carpick, R.W. Environmental dependence of atomic-scale friction at graphite surface steps. Phys. Rev. B 2013, 88, 035409. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, X.Z.; Egberts, P.; Ye, Z.; Carpick, R.W.; Martini, A. Correlation between probe shape and atomic friction peaks at graphite step edges. Tribol. Lett. 2013, 50, 49–57. [Google Scholar] [CrossRef]

- Li, Q.; Liu, X.Z.; Kim, S.P.; Shenoy, V.B.; Sheehan, P.E.; Robinson, J.T. Fluorination of graphene enhances friction due to increased corrugation. Nano Lett. 2014, 14, 5212–5217. [Google Scholar] [CrossRef]

- Roberts, E.W. Thin solid lubricant films in space. Tribol. Int. 1990, 23, 95–104. [Google Scholar] [CrossRef]

- Lewis, J.H.; McDaniel, R.H. A Test of Molybdenum Disulfide Lubricants in Radiation and Vacuum Environments. J. Lubr. Technol. 1969, 91, 390–395. [Google Scholar] [CrossRef]

- Gradt, T.; Schneider, T. Tribological performance of MoS2 coatings in various environments. Lubricants 2016, 4, 32. [Google Scholar] [CrossRef]

- Roberts, E.W. Ultralow friction films of MoS2 for space applications. Thin Solid Films. 1989, 181, 461–473. [Google Scholar] [CrossRef]

- Bergmann, E.; Melet, G.; Müller, C.; Simon-Vermot, A. Friction properties of sputtered dichalcogenide layers. Tribol. Int. 1981, 14, 329–332. [Google Scholar] [CrossRef]

- Sliney, H.E. High Temperature Solid Lubricants –When and Where to Use Them. NASA/TM 1973, X-68201. [Google Scholar]

- Brainard, W.A. The thermal stability and friction of the disulfides, diselenides, and ditellurides of molybdenum and tungsten in vaccum (10-9 to 10-6 TORR). NASA/TN 1968, D-5141. [Google Scholar]

- Gould, S.G.; Roberts, E.W. In-vacuo torque performance of dry-lubricated ball bearings and cryogenic temperatures. NASA/N89 1989, 23914. [Google Scholar]

- Yukhno, T.P.; Vvedensky, Y.V.; Sentyurikhina, L.N. Low temperature investigations on frictional behaviour and wear resistance of solid lubricant coatings. Tribol. Int. 2001, 34, 293–298. [Google Scholar] [CrossRef]

- Hilton, M.R.; Fleischauer, P.D. Applications of solid lubricant films in spacecraft. Surf. Coat. Technol. 1992, 54, 435–441. [Google Scholar] [CrossRef]

- Miyake, S.; Komiya, M.; Shindo, T. Boundary lubrication properties of nanoperiod solid lubricant multilayer films composed of diamond-like carbon and gold layers. Tribol. Lett. 2012, 46, 1–9. [Google Scholar] [CrossRef]

- Voumard, P.; Savan, A.; Pflüger, E. Advances in solid lubrication with MoS2 multilayered coatings. Lubr. Sci. 2001, 13, 135–145. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppea, N.C.; Basturk, S.; Hild, R. Synthesis, characterization, and tribological evaluation of HPPMS (Cr1 – xAlx)N + MoSy coatings. Surf. Coat. Technol. 2016, 308, 383–393. [Google Scholar] [CrossRef]

- Prasad, S.V.; McDevitt, N.T.; Zabinski, J.S. Tribology of tungsten disulfide films in humid environments: The role of a tailored metal-matrix composite substrate. Wear 1999, 230, 24–34. [Google Scholar] [CrossRef]

- Tagawa, M.; Yokota, K.; Matsumoto, K.; Fontaine, J.; Martin, J.-M. Space environmental effects on MoS2 and diamond-like carbon lubricating films: Atomic oxygen-induced erosion and its effect on tribological properties. Surf. Coat. Technol. 2007, 202, 1003–1010. [Google Scholar] [CrossRef]

- Gustavsson, F. Triboactive Component Coatings: Tribological Testing and Microanalysis of Low-Friction Tribofilms. PhD Diss. Acta Universitatis Upsaliensis, Uppsala, Sweden, 2013. [Google Scholar]

- Curry, J.F.; Argibay, N.; Babuska, T.; Nation, B.; Martini, A.; Strandwitz, N.C.; Krick, B.A. Highly Oriented MoS2 Coatings: Tribology and Environmental Stability. Tribol. Lett. 2016, 64, 1–9. [Google Scholar] [CrossRef]

- Lince, J.R.; Loewenthal, S.H.; Clark, C.S. Tribological and chemical effects of long-term humid air exposure on sputter-deposited nanocomposite MoS2 coatings. Wear 2019, 432, 202935. [Google Scholar] [CrossRef]

- Fleischauer, P.D.; Lince, J.R. Comparison of oxidation and oxygen substitution in MoS2 solid film lubricants. Tribol. Int. 1999, 32, 627–636. [Google Scholar] [CrossRef]

- Prasad, S.V.; Zabinski, J.S. Tribology of tungsten disulphide (WS2): Characterization of wear-induced transfer films. J. Mater. Sci. Lett. 1993, 12, 1413–1415. [Google Scholar] [CrossRef]

- Lauwerens, W.; Wang, J.; Navratil, J.; Wieers, E.; D’haen, J.; Stals, L.M.; Bruynseraede, Y. Humidity resistant MoS(x) films prepared by pulsed magnetron sputtering. Surf. Coat. Technol. 2000, 131, 216–221. [Google Scholar] [CrossRef]

- Fayeulle, S.; Ehni, P.D.; Singer, I.L. Analysis of transfer films formed on steel and Co-WC during sliding against MoS2-coated steel in argon. Surf. Coat. Technol. 1990, 41, 93–101. [Google Scholar] [CrossRef]

- Dimigen, H.; Hübsch, H.; Willich, P.; Reichelt, K. Stoichiometry and friction properties of sputtered MoSx layers. Thin Solid Films. 1985, 129, 79–91. [Google Scholar] [CrossRef]

- Spalvins, T. Tribological properties of sputtered MoS2 films in relation to film morphology. Thin Solid Films. 1980, 73, 291–297. [Google Scholar] [CrossRef]

- Ding, X.Z.; Zeng, X.T. Structural, mechanical and tribological properties of CrAlN coatings deposited by reactive unbalanced magnetron sputtering. Surf. Coat. Technol. 2005, 200, 1372–1376. [Google Scholar] [CrossRef]

- Fox, V.; Hampshire, J.; Teer, D. MoS2/metal composite coatings deposited by closed-field unbalanced magnetron sputtering: Tribological properties and industrial uses. Surf. Coat. Technol. 1999, 112, 118–122. [Google Scholar] [CrossRef]

- Simmonds, M.C.; Savan, A.; Pflüger, E.; Van Swygenhoven, H. Mechanical and tribological performance of MoS2 co-sputtered composites. Surf. Coat. Technol. 2000, 126, 15–24. [Google Scholar] [CrossRef]

- Ahmed, O.; Cioc, S.; Cioc, C.; Jayatissa, A.H. Tribological Properties of Multilayer TiN and MoS2 Thin Films. Colloid Surf. Sci. 2017, 2, 137–142. [Google Scholar]

- Stoyanov, P.; Strauss, H.W.; Chromik, R.R. Scaling effects between micro–and macro-tribology for a Ti-MoS2 coating. Wear 2012, 274, 149–161. [Google Scholar] [CrossRef]

- Rigato, V.; Maggioni, G.; Boscarino, D.; Fox, V.C.; Santini, C. A study of the structural and mechanical properties of Ti-MoS2 coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Tech. 1999, 116, 176–183. [Google Scholar] [CrossRef]

- Renevier, N.M.; Hamphire, J.; Fox, V.C.; Witts, J.; Allen, T.; Teer, D.G. Advantages of using self-lubricating, hard, wear-resistant MoS2-based coatings. Surf. Coat. Technol. 2001, 142, 67–77. [Google Scholar] [CrossRef]

- Qin, X.; Ke, P.; Wang, A.; Kim, K.H. Microstructure, mechanical and tribological behaviors of MoS2-Ti composite coatings deposited by a hybrid HIPIMS method. Surf. Coat. Technol. 2013, 228, 275–281. [Google Scholar] [CrossRef]

- Arslan, E.; Bülbül, F.; Alsaran, A.; Celik, A.; Efeoglu, I. The effect of deposition parameters and Ti content on structural and wear properties of MoS2Ti coatings. Wear 2005, 259, 814–819. [Google Scholar] [CrossRef]

- Ding, X.Z.; Zeng, X.T.; He, X.Y.; Chen, Z. Tribological properties of Cr–and Ti-doped MoS2 composite coatings under different humidity atmosphere. Surf. Coat. Technol. 2010, 205, 224–231. [Google Scholar] [CrossRef]

- Xu, S.; Gao, X.; Hu, M.; Sun, J.; Jiang, D.; Zhou, F.; Liu, W.; Weng, L. Nanostructured WS2 -Ni composite films for improved oxidation, resistance and tribological performance. Appl. Surf. Sci. 2014, 288, 15–25. [Google Scholar] [CrossRef]

- Xu, S.S.; Weng, L.J.; Liu, Y.Z.; Kang, K.H.; Kim, C.L.; Kim, D.E. Microstructure evolution and enhanced vacuum tribological performance of Ni-doped WS2 composite coating. Surf. Coat. Technol. 2017, 325, 81–88. [Google Scholar] [CrossRef]

- An, V.; Irtegov, Y. Tribological properties of nanolamellar MoS2 doped with copper nanoparticles. J. Nanomater. 2014, 2014, 731073. [Google Scholar] [CrossRef]

- Xu, S.; Weng, L.J.; Liu, Y.Z.; Kang, K.H.; Kim, D.E. Microstructure evolution and enhanced tribological properties of cu-doped WS2 films. Tribol. Lett. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Song, W.; Xia, Z.; Pei, Y.; Ze, W.; Jun, Z.; Xing, A. Influence of negative bias voltage on the mechanical and tribological properties of MoS2/Zr composite films. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 412–416. [Google Scholar] [CrossRef]

- Hu, J.J.; Zabinski, J.S.; Bultman, J.E.; Sanders, J.H.; Voevodin, A.A. Structure characterization of pulsed laser deposited MoSx-WSey composite films of tribological interests. Tribol. Lett. 2006, 24, 127–135. [Google Scholar] [CrossRef]

- Hilton, M.R.; Bauer, R.; Didziulis, S.V.; Dugger, M.T.; Keem, J.M.; Scholhamer, J. Structural and tribological studies of MoS2 solid lubricant films having tailored metal-multilayer nanostructures. Surf. Coat. Technol. 1992, 53, 13–23. [Google Scholar] [CrossRef]

- Spalvins, T. Frictional and morphological properties of AuMoS2 films sputtered from a compact target. Thin Solid Films. 1984, 118, 375–384. [Google Scholar] [CrossRef]

- Wu, Y.; Li, H.; Ji, L.; Ye, Y.; Chen, J.; Zhou, H. Preparation and properties of MoS2/a-C films for space tribology. J. Phys. D. Appl. Phys. 2013, 46, 425301. [Google Scholar] [CrossRef]

- Nautiyal, H.; Kumari, S.; Khatri, O.P.; Tyagi, R. Copper matrix composites reinforced by rGO-MoS2 hybrid: Strengthening effect to enhancement of tribological properties. Compos. Part B Eng. 2019, 173, 106931. [Google Scholar] [CrossRef]

- Watanabe, S.; Noshiro, J.; Miyake, S. Tribological characteristics of WS2/MoS2 solid lubricating multilayer films. Surf. Coat. Technol. 2004, 183, 347–351. [Google Scholar] [CrossRef]

- Mikhailov, S.; Savan, A.; Hauert, R.; Swygenhoven, H.V. Morphology and tribological properties of metal (oxide)-MoS2 nanostructured multilayer coatings. Surf. Coat. Technol. 1998, 105, 175–183. [Google Scholar] [CrossRef]

- Li, H.; Xie, M.; Zhang, G.; Zhu, M.; Wang, L. Structure and tribological behaviour of Pb-Ti/MoS2 nanoscaled multilayer films deposited by magnetron sputtering method. Appl. Surf. Sci. 2018, 435, 48–54. [Google Scholar] [CrossRef]

- Renevier, N.M.; Fox, V.C.; Teer, D.G.; Hampshire, J. Coating characteristics and tribological properties of sputter-deposited MoS2/metal composite coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Technol. 2000, 127, 24–37. [Google Scholar] [CrossRef]

- Savan, A.; Pflüger, E.; Goller, R.; Gissler, W. Use of nanoscaled multilayer and compound films to realize a soft lubrication phase within a hard, wear-resistant matrix. Surf. Coat. Technol. 2000, 126, 159–165. [Google Scholar] [CrossRef]

- Miyake, S.; Shindo, T.; Saito, Y. Low friction wear resistant electroconductive gold and silver nanoperiod multilayer solid lubricant films. Tribol. Mater. Surfaces Interfaces 2011, 5, 114–120. [Google Scholar] [CrossRef]

- Miyake, S.; Shindo, T.; Miyake, M. Deposition and Tribology of Electroconductive and Wear-Resistant Nanocomposite Solid Lubricant Films Composed of Carbon and Silver or Gold. Tribol. Lett. 2016, 61, 1–9. [Google Scholar] [CrossRef]

- Kubart, T.; Polcar, T.; Kopecký, L.; Novák, R.; Nováková, D. Temperature dependence of tribological properties of MoS2 and MoSe2 coatings. Surf. Coat. Technol. 2005, 193, 230–233. [Google Scholar] [CrossRef]

- Polcar, T.; Evaristo, M.; Colaço, R.; Silviu Sandu, C.; Cavaleiro, A. Nanoscale triboactivity: The response of Mo-Se-C coatings to sliding. Acta Mater. 2008, 56, 5101–5111. [Google Scholar] [CrossRef]

- Maharana, H.S.; Basu, A.; Mondal, K. Structural and tribological correlation of electrodeposited solid lubricating Ni-WSe2 composite coating. Surf. Coat. Technol. 2018, 349, 328–339. [Google Scholar] [CrossRef]

- Domínguez-Meister, S.; Rojas, T.C.; Brizuela, M.; Sánchez-López, J.C. Solid lubricant behavior of MoS2 and WSe2-based nanocomposite coatings. Sci. Technol. Adv. Mater. 2017, 18, 122–133. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Somers, A.E.; Biddulph, S.M.; Howlett, P.C.; Sun, J.; MacFarlane, D.R.; Forsyth, M. A comparison of phosphorus and fluorine containing IL lubricants for steel on aluminium. Phys. Chem. Chem. Phys. 2012, 14, 8224–8231. [Google Scholar] [CrossRef]

- Ye, C.; Liu, W.; Chen, Y.; Yu, L. Room-temperature ionic liquids: A novel versatile lubricant. Chem. Commun. 2001, 21, 2244–2245. [Google Scholar] [CrossRef]

- Liu, W.; Ye, C.; Gong, Q.; Wang, H.; Wang, P. Tribological performance of room-temperature ionic liquids as lubricant. Tribol. Letts. 2002, 13, 81–85. [Google Scholar] [CrossRef]

- Koskilinna, J.O.; Linnolahti, M.; Pakkanen, T.A. Friction coefficient for hexagonal boron nitride surfaces from ab initio calculations. Tribol. Lett. 2006, 24, 37–41. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Li, C.; Zhao, G.; Wang, X. A high-performance multifunctional lubricant additive for water-glycol hydraulic fluid. Tribol. Lett. 2011, 43, 235–245. [Google Scholar] [CrossRef]

- Chen, B.; Bi, Q.; Yang, J.; Xia, Y.; Hao, J. Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites. Tribol. Int. 2008, 41, 1145–1152. [Google Scholar] [CrossRef]

- Tocci, G.; Joly, L.; Michaelides, A. Friction of water on graphene and hexagonal boron nitride from Ab initio methods: Very different slippage despite very similar interface structures. Nano Lett. 2014, 14, 6872–6877. [Google Scholar] [CrossRef]

- Mahathanabodee, S.; Palathai, T.; Raadnui, S.; Tongsri, R.; Sombatsompop, N. Effects of hexagonal boron nitride and sintering temperature on mechanical and tribological properties of SS316L/h-BN composites. Mater. Des. 2013, 46, 588–597. [Google Scholar] [CrossRef]

- Du, M.; Bi, J.Q.; Wang, W.L.; Sun, X.L.; Long, N.N. Influence of sintering temperature on microstructure and properties of SiO2 ceramic incorporated with boron nitride nanotubes. Mater. Sci. Eng. A 2012, 543, 271–276. [Google Scholar] [CrossRef]

- Mahathanabodee, S.; Palathai, T.; Raadnui, S.; Tongsri, R.; Sombatsompop, N. Effect of h-BN content on the sintering of SS316L/h-BN Composites. Adv. Mater. Res. 2011, 410, 216–219. [Google Scholar] [CrossRef]

- Avril, L.; Courant, B.; Hantzpergue, J.J. Tribological performance of α-Fe(Cr)-Fe2B-FeB and α-Fe(Cr)-h-BN coatings obtained by laser melting. Wear 2006, 260, 351–360. [Google Scholar] [CrossRef]

- Miyake, S.; Wang, M. Deposition and Tribology of Carbon and Boron Nitride Nanoperiod Multilayer Hard and Solid Lubricating Films. New Tribol. Ways 2011, 1, 71–88. [Google Scholar]

- Mahathanabodee, S.; Palathai, T.; Raadnui, S.; Tongsri, R.; Sombatsompop, N. Dry sliding wear behavior of SS316L composites containing h-BN and MoS2 solid lubricants. Wear 2014, 316, 37–48. [Google Scholar] [CrossRef]

- Miyake, S.; Hashizume, T.; Kurosaka, W.; Sakurai, M.; Wang, M. Deposition and tribology of carbon and boron nitride nanoperiod multilayer solid lubricating films. Surf. Coat. Technol. 2007, 202, 1023–1028. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Fu, Q.; Qiang, X. Tribological behaviors of SiC/h-BN composite coating at elevated temperatures. Tribol. Int. 2012, 56, 58–65. [Google Scholar]

- Tyagi, R.; Xiong, D.; Li, J. Effect of load and sliding speed on friction and wear behavior of silver/h-BN containing Ni-base P/M composites. Wear 2011, 270, 423–430. [Google Scholar] [CrossRef]

- Tyagi, R.; Xiong, D.S.; Li, J.L.; Dai, J. High-temperature friction and wear of Ag/h-BN-containing Ni-based composites against steel. Tribol. Lett. 2010, 40, 181–186. [Google Scholar] [CrossRef]

- Deshmukh, P.; Lovell, M.; Sawyer, W.G.; Mobley, A. On the friction and wear performance of boric acid lubricant combinations in extended duration operations. Wear 2006, 260, 1295–1304. [Google Scholar] [CrossRef]

- Lovell, M.R.; Kabir, M.A.; Menezes, P.L.; Higgs, C.F. Influence of boric acid additive size on green lubricant performance. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4851–4868. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.A.; Higgs, C.F.; Lovell, M.R. A pin-on-disk experimental study on a green particulate-fluid lubricant. J. Tribol. 2008, 130, 041801. [Google Scholar] [CrossRef]

- Uzoma, P.C.; Hu, H.; Khadem, M.; Penkov, O.V. Tribology of 2D Nanomaterials: A Review. Coatings 2020, 10, 897. [Google Scholar] [CrossRef]

- Liu, H.; Du, Y.; Deng, Y.; Ye, P.D. Semiconducting black phosphorus: Synthesis, transport properties and electronic applications. Chem. Soc. Rev. 2015, 44, 2732–2743. [Google Scholar] [CrossRef]

- Guo, P.; Qi, S.; Chen, L.; Gou, C.; Lin, B.; Lu, Z.; Zhang, G. Black Phosphorus–Graphene Oxide Hybrid Nanomaterials toward Advanced Lubricating Properties under Water. Adv. Mater. Interf. 2019, 6, 1901174. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.; Luo, J. Black phosphorus as a new lubricant. Friction 2018, 6, 116–142. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, W.; Xie, G.; Luo, J. Self-Lubricating PTFE-Based Composites with Black Phosphorus Nanosheets. Tribol. Lett. 2018, 66, 1–11. [Google Scholar] [CrossRef]

- Peng, S.; Guo, Y.; Xie, G.; Luo, J. Tribological behavior of polytetrafluoroethylene coating reinforced with black phosphorus nanoparticles. Appl. Surf. Sci. 2018, 441, 670–677. [Google Scholar] [CrossRef]

- Erdemir, A.; Fenske, G.R.; Erck, R.A.; Nichols, F.A.; Busch, D.E. Tribological properties of boric acid and boric-acid-forming surfaces. Part II. Mechanisms of formation and self-lubrication of boric acid films on boron–and boric oxide-containing surfaces. Lubr. Eng. 1991, 47, 179–184. [Google Scholar]

- Jayatissa, A.H.; Ahmed, O.; Manu, B.R.; Schroeder, A.M. Tribological Behaviour of Sputter Coated ZnO Thin Films. Prog. Mater. Sci. 2021, 3, 1–13. [Google Scholar]

- Wang, Y.; Liua, Z. Tribological properties of high temperature self-lubrication metal ceramics with an interpenetrating network. Wear 2008, 265, 1720–1726. [Google Scholar] [CrossRef]

- Prasad, S.V.; Zabinski, J.S. Tribological behavior of nanocrystalline zinc oxide films. Wear 1997, 203, 498–506. [Google Scholar] [CrossRef]

- Jayatissa, A.H.; Manu, B.R. Tribological Properties at the Interface of the Aluminum and Aluminum Oxide. J. Multidisciplinary Eng. Sci. St. (JMESS) 2019, 5, 2595–2599. [Google Scholar]

- Karch, J.; Birringer, R.; Gleiter, H. Ceramics ductile at low temperature. Nature 1987, 330, 556–558. [Google Scholar] [CrossRef]

- Gardos, M.N. The effect of anion vacancies on the tribological properties of rutile (Ti02-x). Tribol. Trans. 1988, 31, 427–436. [Google Scholar] [CrossRef]

- Goto, S.; Fujimura, N.; Nishihara, T.; Ito, T. Heteroepitaxy of zinc oxide thin films, considering non-epitaxial preferential orientation. J. Cryst. Growth. 1991, 115, 816–820. [Google Scholar] [CrossRef]

- Goto, M.; Kasahara, A.; Tosa, M. Low-friction coatings of zinc oxide synthesized by optimization of crystal preferred orientation. Tribol. Lett. 2011, 43, 155–162. [Google Scholar] [CrossRef]

- Venkatraman, R.; Bravman, J.C. Separation of film thickness and grain boundary strengthening effects in Al thin films on Si. J. Mater. Res. 1992, 7, 2040–2048. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Yukimura, K.; Ding, C.X.; Zhang, P.Y. Tribological properties of nanostructured and conventional WC-Co coatings deposited by plasma spraying. Thin Solid Films. 2001, 388, 277–282. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Noor Ahmed, R.; Mujeebu, M.A.; Abdullah, M.Z. Fabrication and study on tribological characteristics of cast copper-TiO2-boric acid hybrid composites. Mater. Des. 2009, 30, 1632–1637. [Google Scholar] [CrossRef]

- Prasad, S.V.; Asthana, R. Aluminum metal-matrix composites for automotive applications: Tribological considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Li, D.X.; You, Y.L.; Deng, X.; Li, W.J.; Xie, Y. Tribological properties of solid lubricants filled glass fiber reinforced polyamide 6 composites. Mater. Des. 2013, 46, 809–815. [Google Scholar] [CrossRef]

- You, Y.L.; Li, D.X.; Si, G.J.; Deng, X. Investigation of the influence of solid lubricants on the tribological properties of polyamide 6 nanocomposites. Wear 2014, 311, 57–64. [Google Scholar] [CrossRef]

- Moser, J.; Lévy, F.; Bussy, F. Composition and growth mode of MoSx sputtered films. J. Vac. Sci. Tech. A Vac. Surf. Film. 1994, 12, 494–500. [Google Scholar] [CrossRef][Green Version]

- Veiga, C.; Davim, J.P.; Loureiro, A.J.R. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mat. Sci. 2012, 32, 133–148. [Google Scholar]

- Engler, O.; Hirsch, J. Texture control by thermomechanical processing of AA6xxx Al-Mg-Si sheet alloys for automotive applications –a review. Mater. Sci. Eng. A. 2002, 336, 249–262. [Google Scholar] [CrossRef]

- Merie, V.V.; Cândea, V.C.; Bîrleanu, C.; Pǎşcuţǎ, P.; Popa, C.O. The influence of titanium dioxide on the tribological characteristics of a Fe-based friction composite material. J. Compos. Mater. 2014, 48, 235–243. [Google Scholar] [CrossRef]

- Quazi, M.M.; Ishak, M.; Arslan, A.; Fazal, M.A.; Yusof, F.; Sazzad, B.S.; Nasir Bashir, M.; Jamshaid, M. Mechanical and tribological performance of a hybrid MMC coating deposited on Al-17Si piston alloy by laser composite surfacing technique. RSC Adv. 2018, 8, 6858–6869. [Google Scholar] [CrossRef]

- Dorri Moghadam, A.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene–A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Menezes, P.L.; Rohatgi, P.K.; Omrani, E. Self-Lubricating Composites; Springer Sci. Bus: Berlin, Germany, 2018. [Google Scholar]

- Popescu, I.N.; Ghiţǎ, C.; Bratu, V.; Palacios Navarro, G. Tribological behavior and statistical experimental design of sintered iron-copper based composites. Appl. Surf. Sci. 2013, 285, 72–85. [Google Scholar] [CrossRef]

- Shu-xian, C.; Yi, F.; Shu, L.; Yu-juan, X. Influences of MoS2 contents on sintering process and properties of Cu-MoS2 composites. J. Mat. Sci. Eng. 2008, 2, 7–12. [Google Scholar]

- Kato, H.; Takama, M.; Iwai, Y.; Washida, K.; Sasaki, Y. Wear and mechanical properties of sintered copper-tin composites containing graphite or molybdenum disulfide. Wear 2003, 255, 573–578. [Google Scholar] [CrossRef]

- Watanabe, Y. High-speed sliding characteristics of Cu-Sn-based composite materials containing lamellar solid lubricants by contact resistance studies. Wear 2008, 264, 624–631. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Fushchich, O.I.; Danyluk, S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 2012, 290, 106–123. [Google Scholar] [CrossRef]

- Chandrasekaran, M.; Singh, P. Sintered iron-copper-tin-lead antifriction materials –effect of temperature. Mater. Sci. Eng. A. 2000, 292, 26–33. [Google Scholar] [CrossRef]

- Teisanu, C.; Gheorghe, S. Development of new PM iron-based materials for self-lubricating bearings. Adv. Tribol. 2011, 2011, 1–11. [Google Scholar] [CrossRef]

- Dhanasekaran, S.; Gnanamoorthy, R. Abrasive wear behavior of sintered steels prepared with MoS2 addition. Wear 2007, 262, 617–623. [Google Scholar] [CrossRef]

- Dhanasekaran, S.; Gnanamoorthy, R. Microstructure, strength and tribological behavior of Fe-C-Cu-Ni sintered steels prepared with MoS2 addition. J. Mater. Sci. 2007, 42, 4659–4666. [Google Scholar] [CrossRef]

- Xue, M. High temperature oxidation and wear behavior of powder metallurgically developed Ni-Cr-W-Al-Ti-MoS2 composite. Indian J. Eng. Mater. Sci. 2009, 16, 111–115. [Google Scholar]

- Li, J.L.; Xiong, D.S.; Huo, M.F. Friction and wear properties of Ni-Cr-W-Al-Ti-MoS2 at elevated temperatures and self-consumption phenomena. Wear 2008, 265, 566–575. [Google Scholar] [CrossRef]

- Shia, X.; Zhaia, W.; Wang, M.; Xu, Z.; Yao, J.; Song, S.; Wang, Y. Synergetic lubricating effect of MoS2 and Ti3SiC2 on tribological properties of NiAl matrix self-lubricating composites over a wide temperature range. Mater. Des. 2014, 55, 93–103. [Google Scholar] [CrossRef]

- Shia, X.; Zhaia, W.; Wang, M.; Xu, Z.; Yao, J.; Song, S.; Wang, Y. Tribological behaviors of NiAl based self-lubricating composites containing different solid lubricants at elevated temperatures. Wear 2014, 310, 1–11. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, D.S. Tribological properties of nickel-based self-lubricating composite at elevated temperature and counter face material selection. Wear 2008, 265, 533–539. [Google Scholar] [CrossRef]

- Volochko, A.T.; Rumyantseva, I.N. Thermal stability of aluminum composite materials containing sulfides of copper, molybdenum, and zinc. Sov. Powder Metall. Met. Ceram. 1992, 31, 446–448. [Google Scholar] [CrossRef]

- Xu, Z.; Shi, X.; Zhang, Q.; Zhai, W.; Li, X.; Yao, J.; Chen, L.; Zhu, Q.; Xiaov, Y. Effect of sliding speed and applied load on dry sliding tribological performance of TiAl matrix Self-Lubricating composites. Tribol. Lett. 2014, 55, 393–404. [Google Scholar] [CrossRef]

- Li, S.; Feng, Y.; Yang, X.; Chen, S.; Wang, J. Structure and formation mechanism of surface film of Ag-MoS2 composite during electrical sliding Wear. Mater. Eng. 2009, 38, 1881–1885. [Google Scholar]

- Chen, F.; Feng, Y.; Shao, H.; Zhang, X.; Chen, J.; Chen, N. Friction and wear behaviors of Ag/MoS2/G composite in different atmospheres and at different temperatures. Tribol. Lett. 2012, 47, 139–148. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Wang, Y.M.; Zhou, Y.; Murakami, T.; Sasaki, S. Microstructure and tribological properties of ZrO2(Y2O3) matrix composites doped with different solid lubricants from room temperature to 800 °C. Wear 2009, 267, 1353–1360. [Google Scholar] [CrossRef]

- Jin, Y.; Kato, K.; Umehara, N. Tribological properties of self-lubricating CMC/Al2O3 pairs at high temperature in air. Tribol. Lett. 1998, 4, 243–250. [Google Scholar] [CrossRef]

- Jianxin, D.; Tongkun, C.; Zeliang, D.; Jianhua, L.; Junlong, S.; Jinlong, Z. Tribological behaviors of hot-pressed Al2O3/TiC ceramic composites with the additions of CaF2 solid lubricants. J. Eur. Ceram. Soc. 2006, 26, 1317–1323. [Google Scholar] [CrossRef]

- De Mello, J.D.B.; Binder, C.; Binder, R.; Klein, A.N. Effect of precursor content and sintering temperature on the scuffing resistance of sintered self-lubricating steel. Wear 2011, 271, 1862–1867. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Li, J.; Cao, H.; He, L. Effect of sintering process on the microstructures and properties of in situ TiB2-TiC reinforced steel matrix composites produced by spark plasma sintering. J. Mater. Process. Technol. 2010, 210, 91–95. [Google Scholar] [CrossRef]

- Friedrich, K.; Lu, Z.; Hager, A.M. Recent advances in polymer composites’ tribology. Wear 1995, 190, 139–144. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 53, 5–25. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene-based polymer composites. Prog. Polymer Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Wang, H.; Chang, L.; Yang, X.; Yuan, L.; Ye, L.; Harris, A.T.; Minett, A.I.; Trimby, P.; Friedrich, K. Anisotropy in tribological performances of long aligned carbon nanotubes/polymer composites. Carbon 2014, 67, 38–47. [Google Scholar] [CrossRef]

- Gardos, M.N. Self-lubricating composites for extreme environment applications. Tribol. Int. 1982, 15, 273–283. [Google Scholar] [CrossRef]

- Bijwe, J.; Logani, C.M.; Tewari, U.S. Influence of fillers and fiber reinforcement on abrasive wear resistance of some polymeric composites. Wear 1990, 138, 77–92. [Google Scholar] [CrossRef]

- Davim, J.P. Ecotribology, 1st ed.; Springer Sci. Bus: Cham, Switzerland, 2016. [Google Scholar]

- Tang, H.; Cao, K.; Wu, Q.; Li, C.; Yang, X.; Xuehua, Y. Synthesis and tribological properties of copper matrix solid self-lubricant composites reinforced with NbSe2 nanoparticles. Cryst. Res. Technol. 2011, 46, 195–200. [Google Scholar] [CrossRef]

- Zhang, F.X.; Chu, Y.Q.; Li, C.S. Fabrication and tribological properties of copper matrix solid self-lubricant composites reinforced with Ni/NbSe2 composites. Materials 2019, 12, 1854. [Google Scholar] [CrossRef]

- Sundararajan, S.; Rajadurai, J.S.; Antony Vasanthakumar, C. Impact of solid self-lubricant and hard ceramic reinforcements on tribological characteristics of microwave-sintered Cu hybrid composites processed by solid-state mixing technique. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 523–542. [Google Scholar] [CrossRef]

- Prabhu, T.R. Effects of solid lubricants, load, and sliding speed on the tribological behavior of silica reinforced composites using design of experiments. Mater. Des. 2015, 77, 149–160. [Google Scholar] [CrossRef]

- Zhen, J.; Zhu, S.; Cheng, J.; Li, M.; Lu, Y.; Qia, Z.; Yang, J. Influence of graphite content on the dry sliding behavior of nickel alloy matrix solid lubricant composites. Tribol. Int. 2017, 114, 322–328. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, K.; Yao, C.; Nie, P.; Huang, J.; Li, Z. Microstructure and tribological properties of laser cladded self-lubricating nickel-base composite coatings containing nano-Cu and h-BN solid lubricants. Surf. Coat. Technol. 2019, 359, 485–494. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, J.; Jia, J.; Hu, W.; Gong, C. Tribological properties of solid lubricants (graphite, MoS2) for Ni based materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 012030. [Google Scholar] [CrossRef]

- Yang Huang, X.; Wang, J.; Zhang, H.; Ren, J.; Zan, Q.; Gong, Q.; Wu, B. WC-Ni-Cr-based self-lubricating composites fabricated by pulsed electric current sintering with addition of WS2 solid lubricant. Int. J. Refract. Met. Hard Mater. 2017, 66, 158–162. [Google Scholar] [CrossRef]

- Kotkowiak, M.; Piasecki, A.; Kulka, M. The influence of solid lubricant on tribological properties of sintered Ni–20%CaF2 composite material. Ceram. Int. 2019, 45, 17103–17113. [Google Scholar] [CrossRef]

- Gupta, A.; Mohan, S.; Anand, A.; Haq, M.I.U.; Raina, A.; Kumar, R.; Singh, R.A.; Jayalakshmi, S.; Kamal, M. Tribological behavior of Fe-C-Ni self-lubricating composites with WS2 solid lubricant. Mater. Res. Express 2019, 6, 126507. [Google Scholar] [CrossRef]

- Zalaznik, M.; Kalin, M.; Novak, S.; Jakša, G. Effect of the type, size and concentration of solid lubricants on the tribological properties of the polymer PEEK. Wear 2016, 364, 31–39. [Google Scholar] [CrossRef]

- Cura, M.E.; Kim, S.H.; Muukkonen, T.; Varjus, S.; Vaajoki, A.; Soderberg, O.; Suhonen, T.; Kanerva, U.; Lee, S.W.; Hannnula, S.P. Microstructure and tribological properties of pulsed electric current sintered alumina-zirconia nanocomposites with different solid lubricants. Ceram. Int. 2013, 39, 2093–2105. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H. M50 Matrix Sintered with Nanoscale Solid Lubricants Shows Enhanced Self-lubricating Properties Under Dry Sliding at Different Temperatures. Tribol. Lett. 2019, 67, 1–16. [Google Scholar] [CrossRef]

- Li, T.; Tao, J.; Cong, P.; Liu, X. Study on the tribological characteristics of solid lubricants embedded tin-bronze bearings. J. Appl. Polym. Sci. 2001, 80, 2394–2399. [Google Scholar] [CrossRef]

- Mushtaq, S.; Wani, M.F.; Nadeem, M.; Najar, K.A.; Mursaleen, M. A study on friction and wear characteristics of Fe–Cu–Sn alloy with MoS2 as solid lubricant under dry conditions. Sadhana 2019, 44, 1–7. [Google Scholar] [CrossRef]

| Bonding Type | Substance | Binding Energy (Kcal/mol) | Melting Temperature (°C) |

|---|---|---|---|

| Ionic | NaCl | 153 | 801 |

| MgO | 239 | 1000 | |

| Si | 108 | 1410 | |

| Covalent | C | 170 | >3550 |

| Hg | 16 | −39 | |

| Al | 77 | 660 | |

| Metallic | Fe | 97 | 1538 |

| W | 203 | 3410 | |

| Van der Waals | Ar | 1.8 | −189 |

| Cl2 | 7.4 | −101 |

| Humidity |

|

| Nitrogen |

|

| Oxygen |

|

| Hydrogen |

|

| Temperature |

|

| Vacuum |

|

| Material | Temperature Range (°C) | Temperature of Thermal Stability (°C) | Friction Coefficient |

|---|---|---|---|

| MoS2 | −184–400 | 350 | 0.05–0.25 |

| WS2 | −184–454 | 425 | 0.05–0.25 |

| Graphite | −184–650 | 500 | 0.1–0.3 |

| h-BN Boric Acid Black Phosphorous | −184–538 20–80 | 700 170 | 0.1–0.2 0.05–0.07 0.2–0.33 |

| Publication | Matrix | Lubricant | Parameters | Important Findings |

|---|---|---|---|---|

| Chen et al., 2008 [150] | Copper |

|

|

|

| Tang et al., 2011 [224] | Copper | NbSe2 nanofiber |

|

|

| Zhang et al., 2019 [225] | Copper | Ni/NbSe2 |

|

|

| Sundararajan et al. 2016 [226] | Cu-X SiC wt.% (X = 0, 5, 10, and 15 wt.%) | Gr at 5 and 10 wt.% |

|

|

| Prabhu et al., 2015 [227] | Cu-20 vol.% silica | 10 vol.% of MoS2 or graphite or h-BN |

|

|

| Zhen et al. 2017 [228] | Nickel | Ag = 12.5 wt.% Baf2/CaF2 = 5 wt.%, Graphite = 0, 0.5, 1, 2 wt.% |

|

|

| Zhao et al. 2019 [229] | Nickel | h-BN=1.25 wt.% nano-Carbon = 5 wt.% |

|

|

| Chen et al. 2018 [230] | Ni Cr 80–20 wt.% | MoS2 Graphite |

|

|

| Huang et al., 2017 [231] | WC-Ni-Cr88 wt.% WC, 11 wt.% Ni and 1 wt.% Cr | WS2= 5 wt.% |

|

|

| Kulka et al. 2019 [232] | Ni | CaF2 20% |

|

|

| Gupta et al., 2019 [233] | Fe-0.3C-2Ni based composites | WS2 (3, 5, 7 and 9 wt.%) |

| |

| Zalaznik et al., 2016 [234] | PEEK | micro and nano MoS2, WS2 |

|

|

| Cura et al., 2013 [235] | Al2O3 – 15 wt.% ZrO2 (AZ) | 3 wt.% of CaF2, BaF2, MoS2, WS2, h-BN, or graphite |

|

|

| Ali et al. 2019 [236] | M50 steel | TiO2 10 wt.% TiO2/G powder (10 wt.% TiO2+5 wt.% G) |

|

|

| Tao et al. 2001 [237] | Tin-bronze | Graphite, MoS2 or PTFE |

|

|

| Mushtaq et al.2018 [238] | Fe–Cu 5 wt.%–Sn3 wt.% | MoS2 (0-3 wt.%) |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manu, B.R.; Gupta, A.; Jayatissa, A.H. Tribological Properties of 2D Materials and Composites—A Review of Recent Advances. Materials 2021, 14, 1630. https://doi.org/10.3390/ma14071630

Manu BR, Gupta A, Jayatissa AH. Tribological Properties of 2D Materials and Composites—A Review of Recent Advances. Materials. 2021; 14(7):1630. https://doi.org/10.3390/ma14071630

Chicago/Turabian StyleManu, Bodhi R., Anju Gupta, and Ahalapitiya H. Jayatissa. 2021. "Tribological Properties of 2D Materials and Composites—A Review of Recent Advances" Materials 14, no. 7: 1630. https://doi.org/10.3390/ma14071630

APA StyleManu, B. R., Gupta, A., & Jayatissa, A. H. (2021). Tribological Properties of 2D Materials and Composites—A Review of Recent Advances. Materials, 14(7), 1630. https://doi.org/10.3390/ma14071630