Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices

Abstract

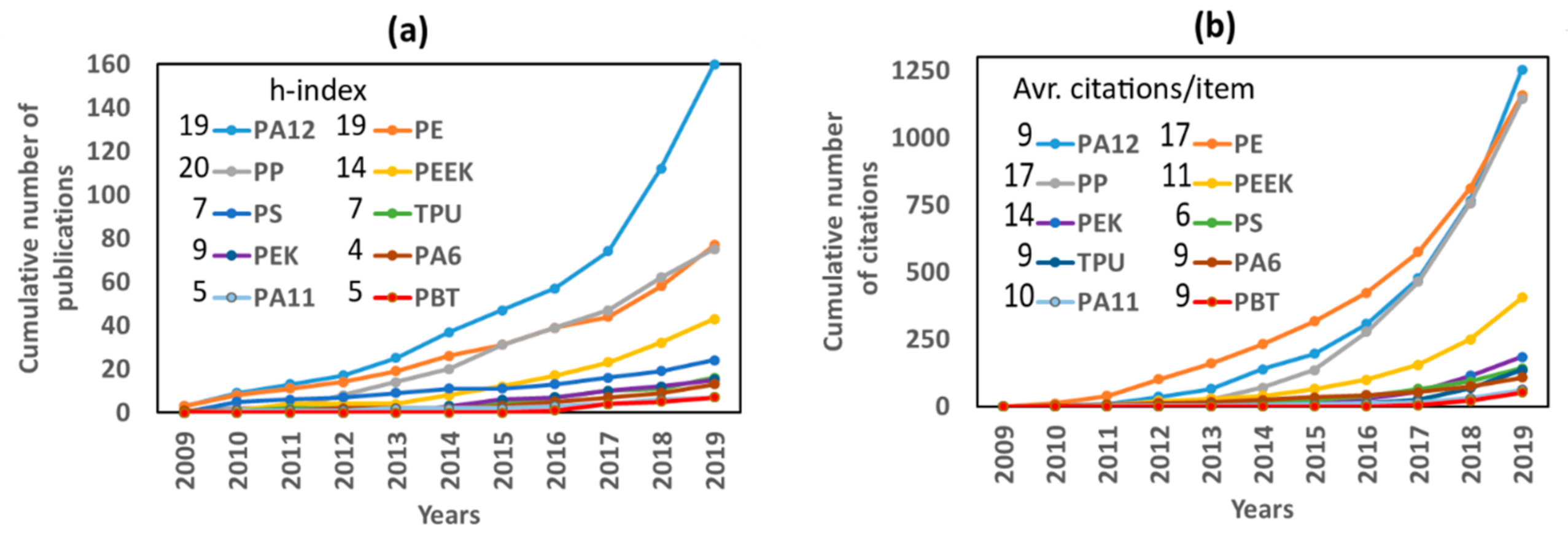

1. Introduction

2. Approach and Bibliometric Method

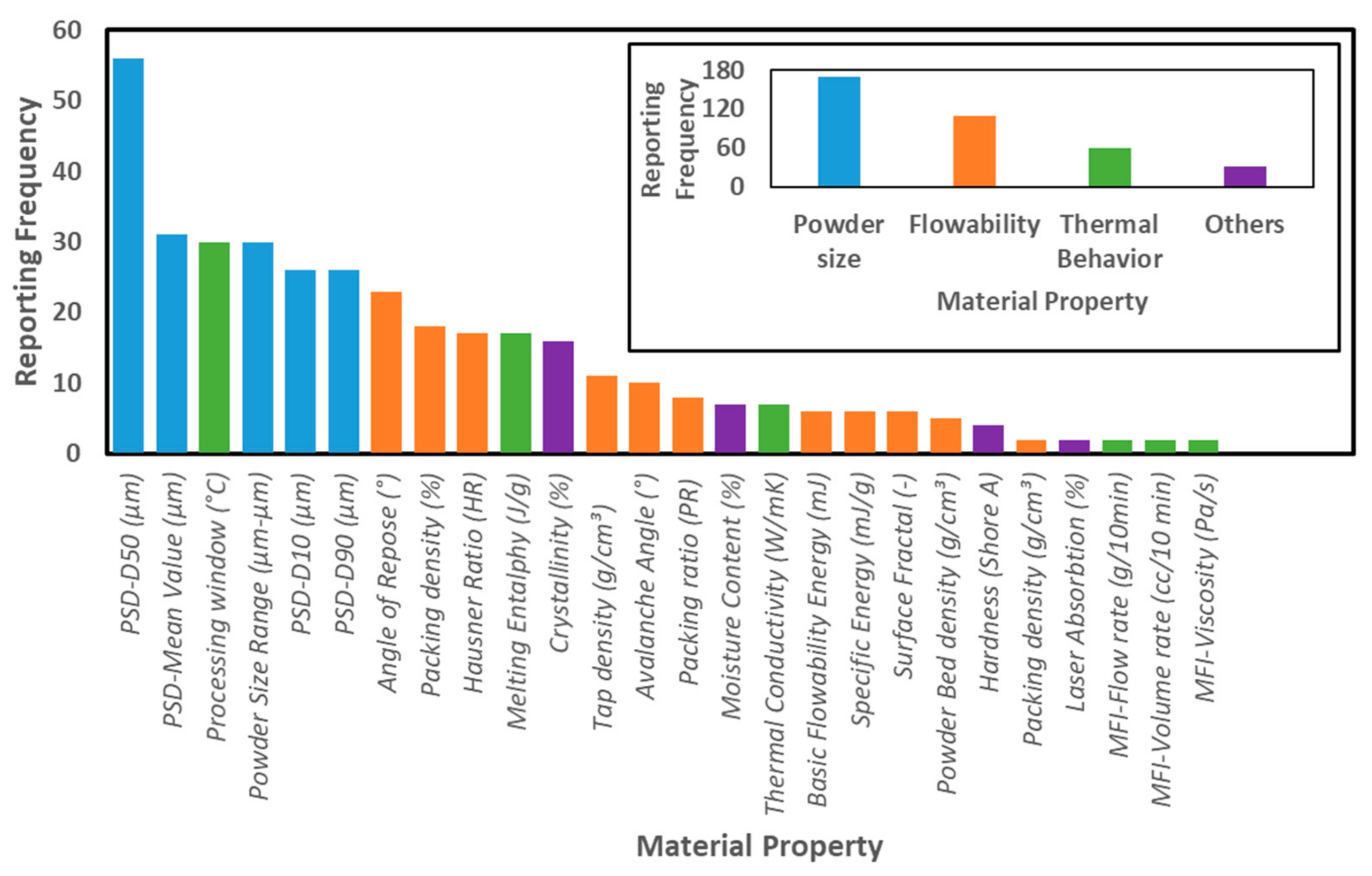

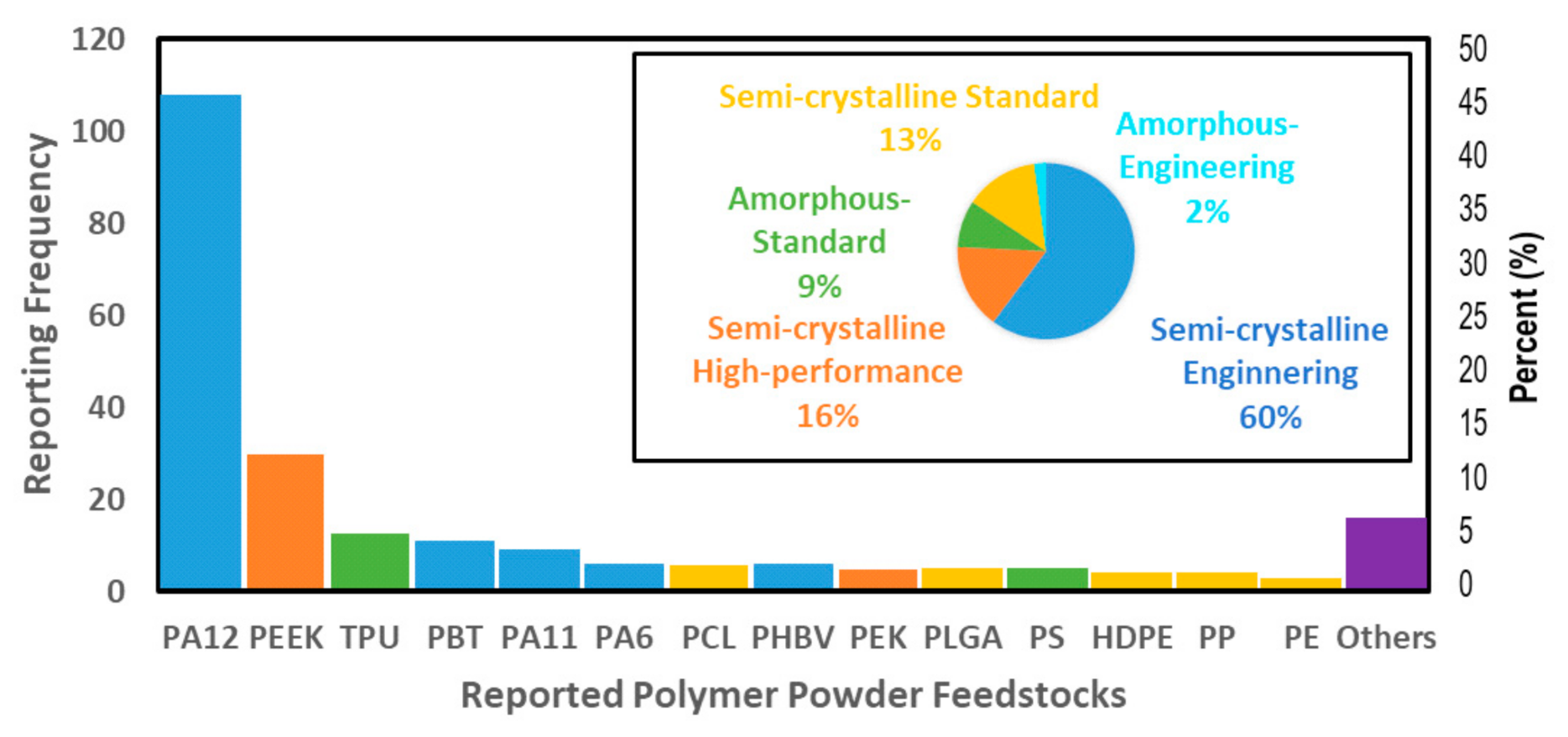

3. Material Properties of Polymer Powder Feedstocks

3.1. General Properties and Material Type

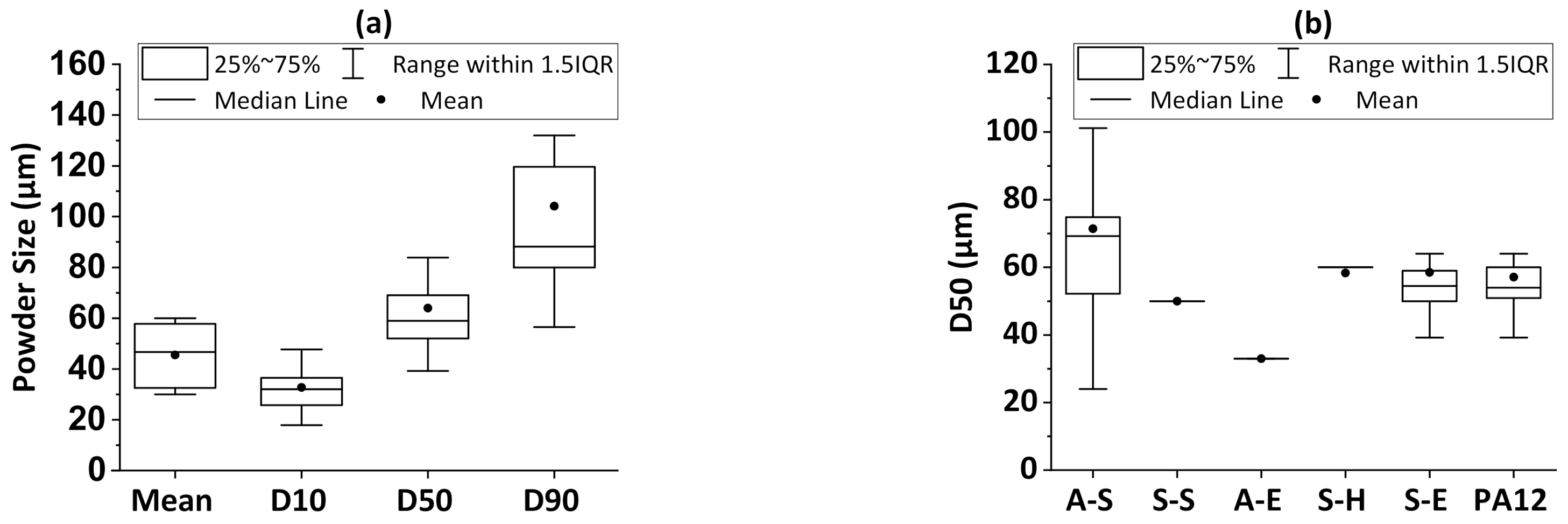

3.2. Powder Size

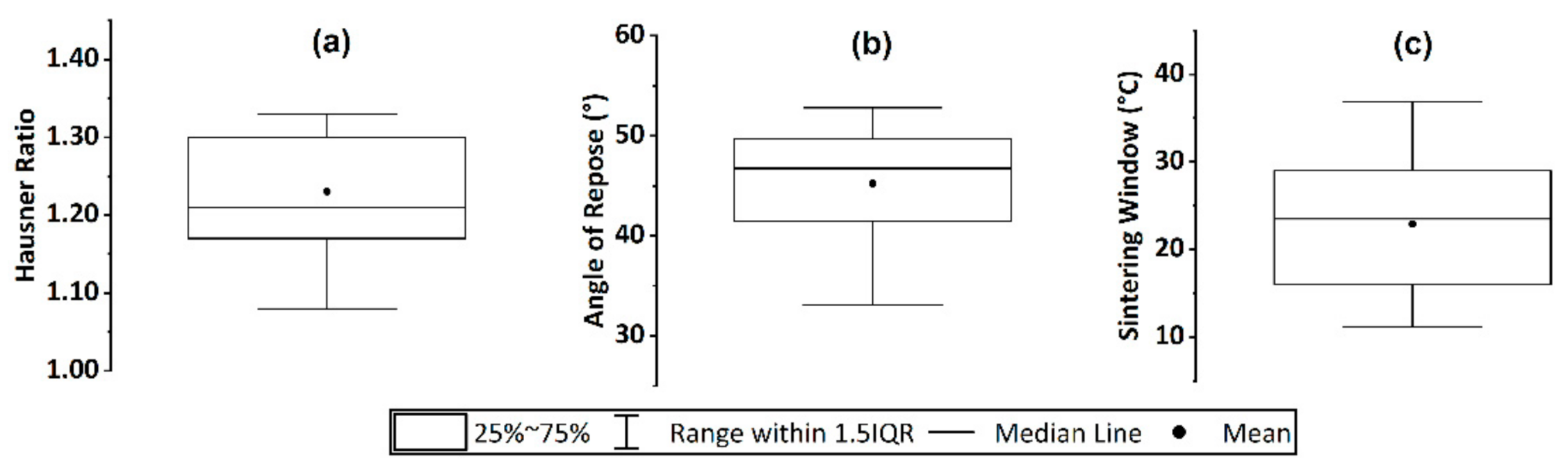

3.3. Flowability and Processing Window

3.4. Additives

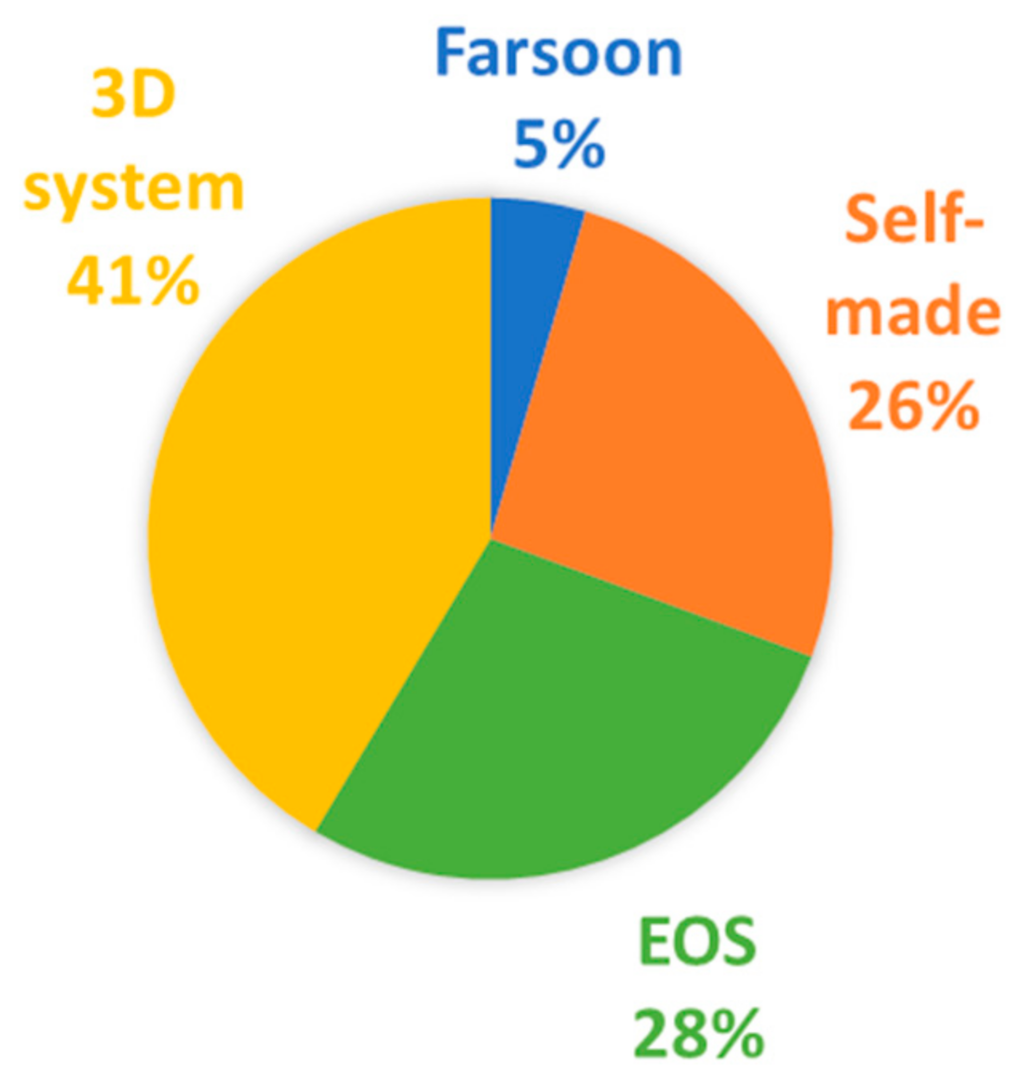

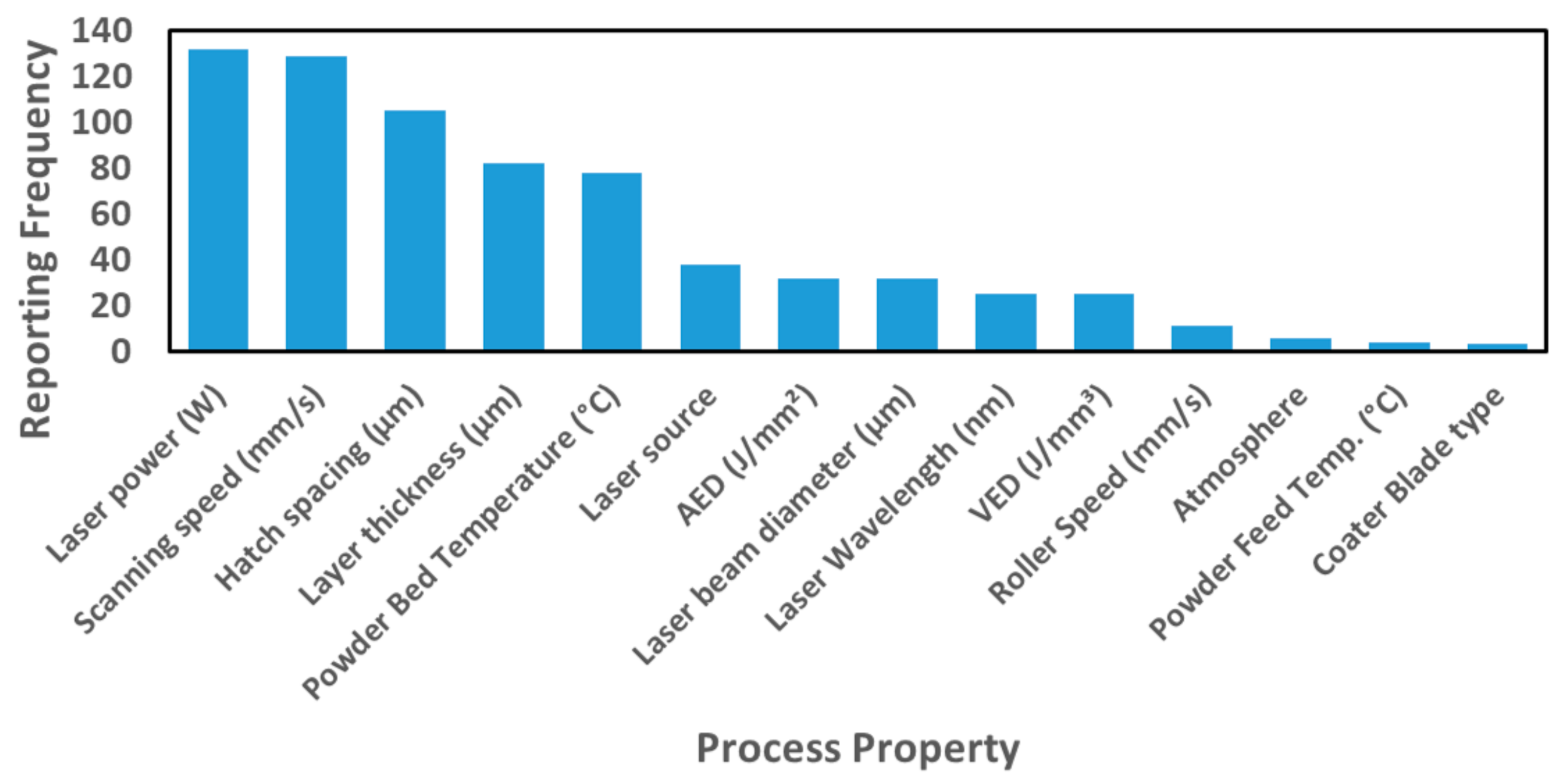

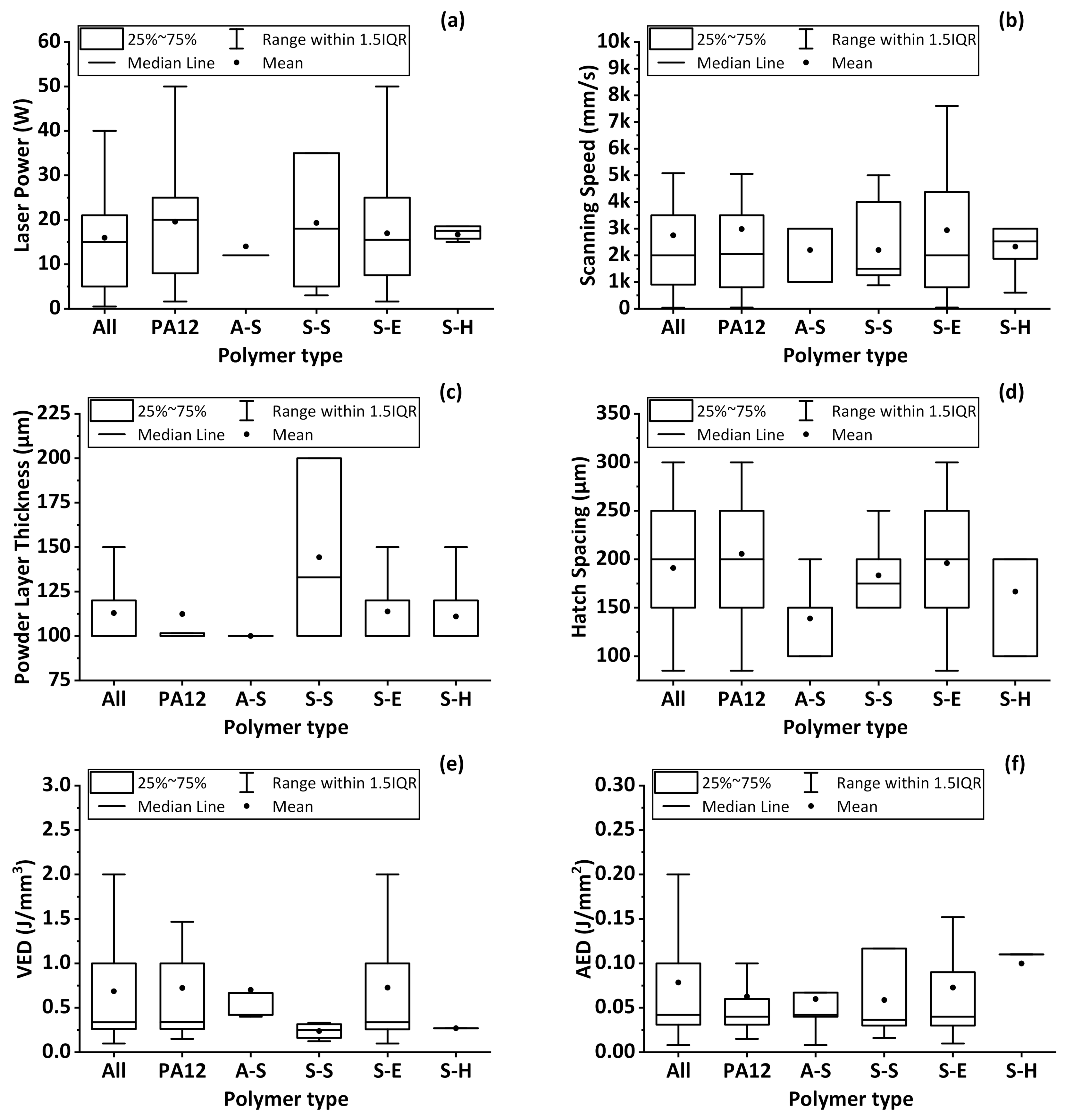

4. L-PBF Machine and Process Parameters

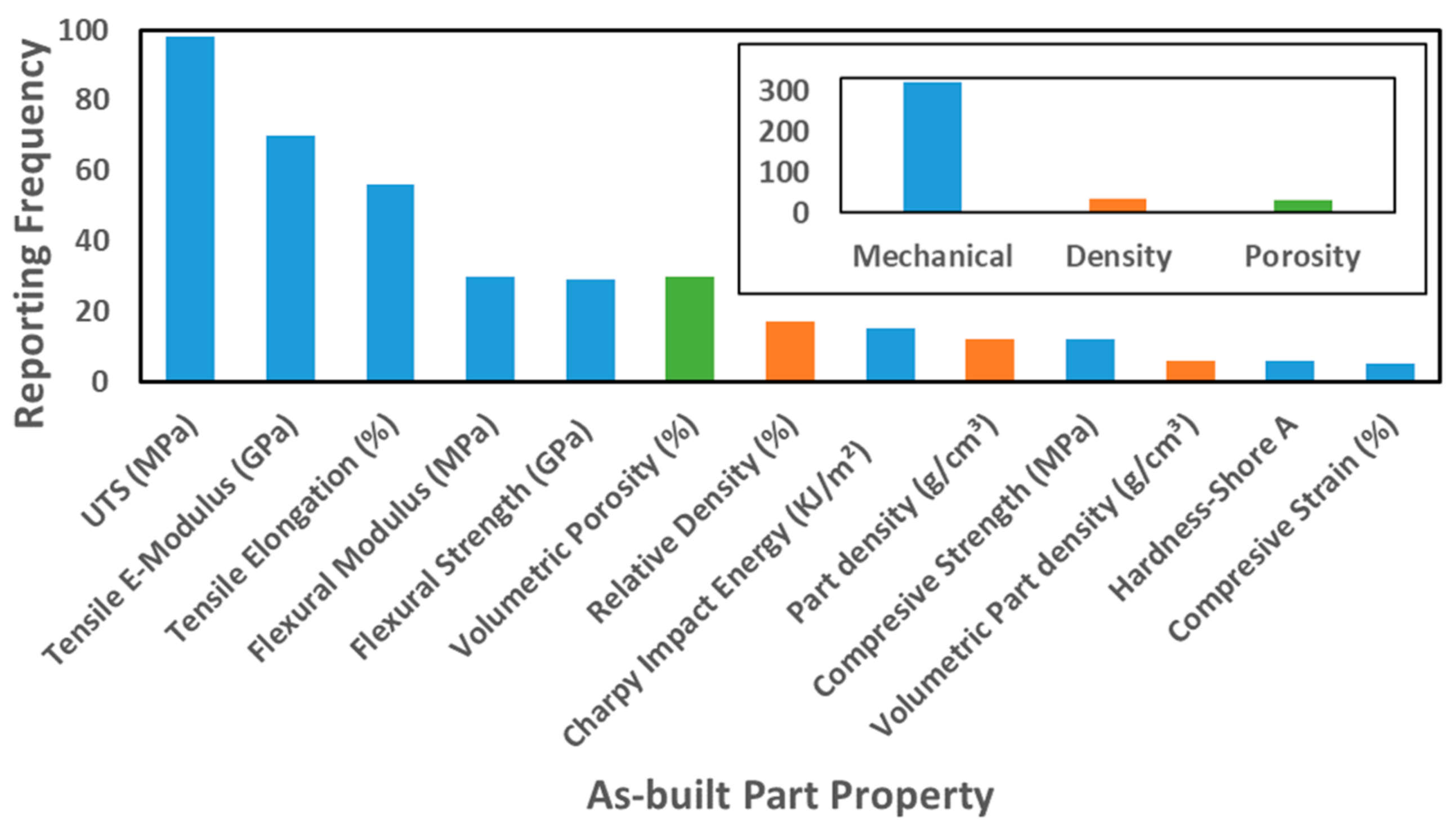

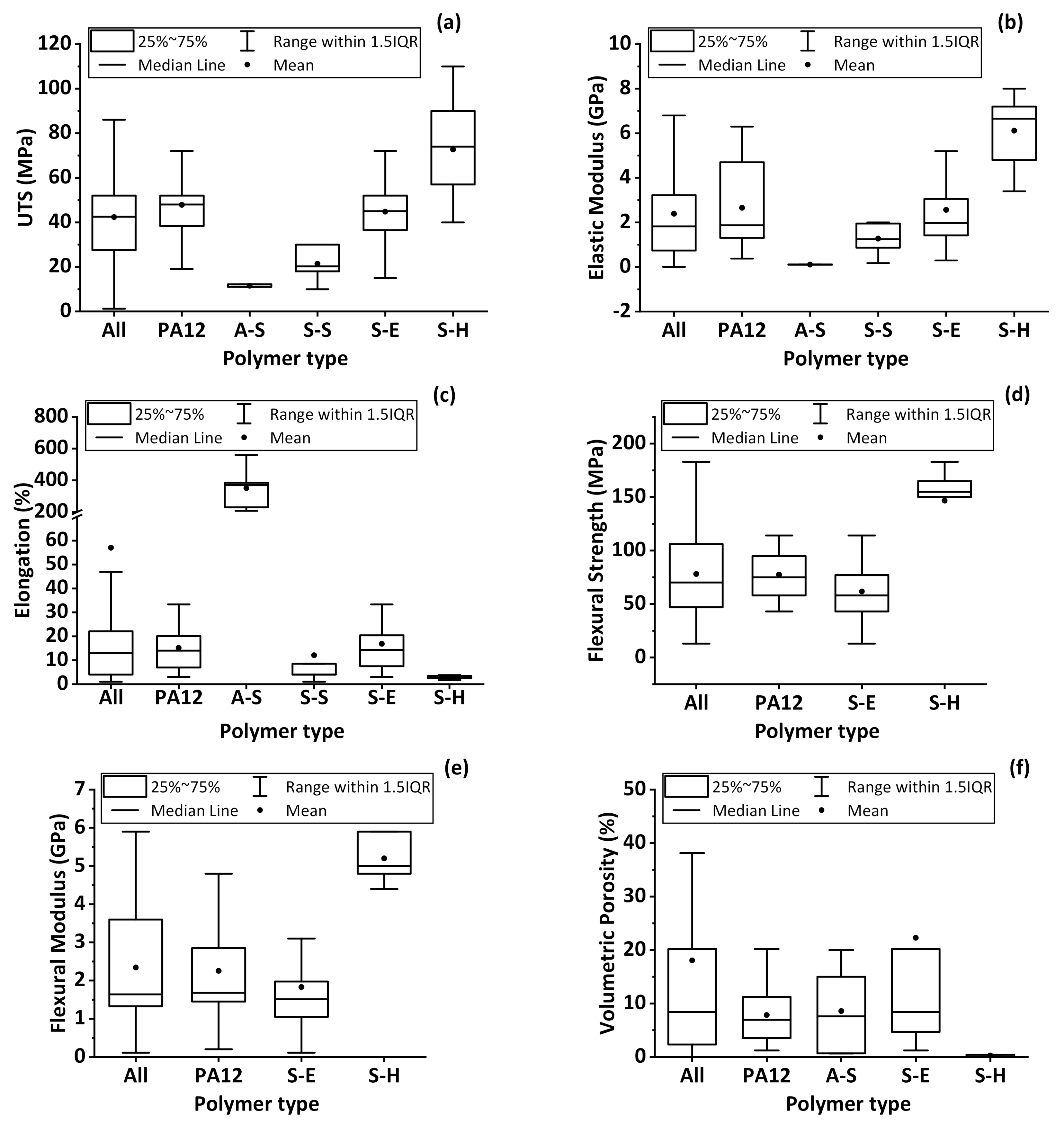

5. As-Built Part Properties of Polymer Powder Feedstocks

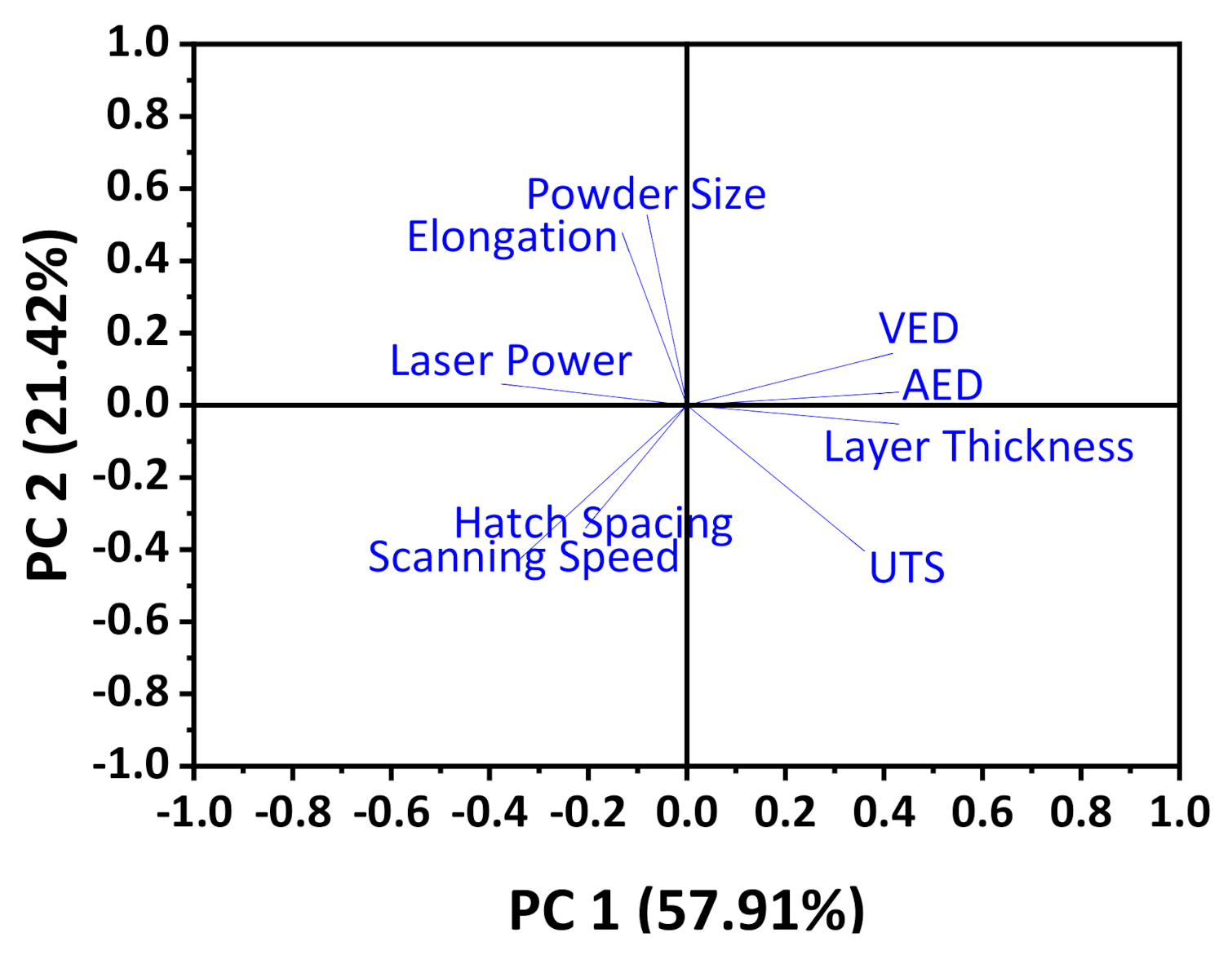

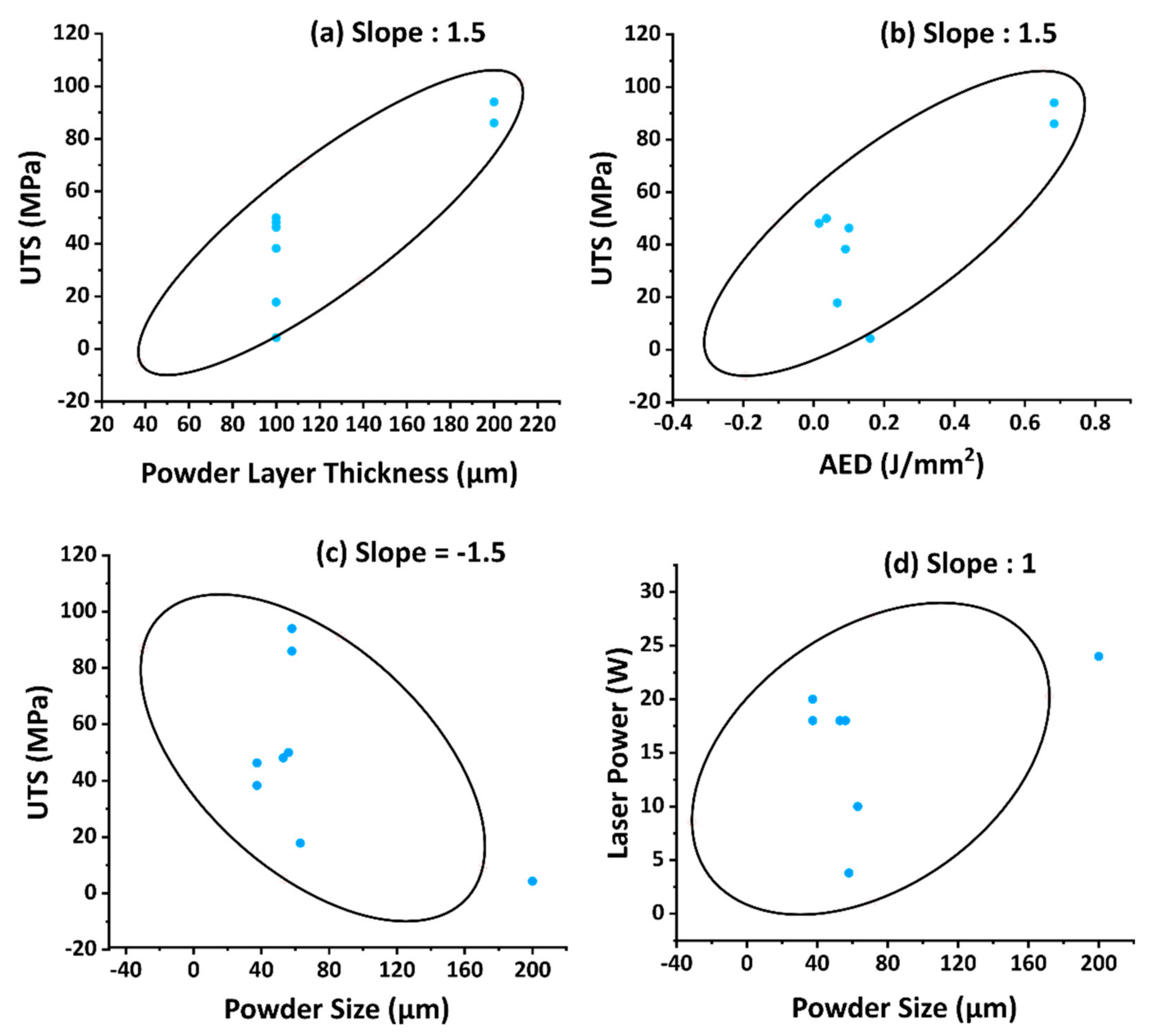

6. Quantification of Cross-Correlations by Principle Component Analysis of the Most Reported Material, Process, and as-Built Part Properties

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Campbell, I.; Diegel, O.; Kowen, J.; Wohlers, T. Wohlers Report. 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2019. [Google Scholar]

- Kusoglu, I.M.; Gökce, B.; Barcikowski, S. Research trends in laser powder bed fusion of Al alloys within the last decade. Addit. Manuf. 2020, 36, 101489. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ligon, S.M.; Samuel, C.; Liska, R.; Stampfl, J.; Gurr, M.; Malhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- EOS 3D Printing Materials, Plastics for Additive Manufacturing, SLS Materials and Processes. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic/sls-polymer-materials (accessed on 26 February 2021).

- Eshkalak, S.K.; Ghomi, E.R.; Dai, Y.; Choudhury, D.; Ramakrishna, S. The role of three-dimensional printing in healthcare and medicine. Mater. Des. 2020, 194, 1–15. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive Manufacturing: Polymers Applicable for Laser Sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- ISO/ASTM 52910:2018—Additive Manufacturing—Design—Requirements, Guidelines and Recommendations. Available online: https://www.iso.org/standard/67289.html (accessed on 14 February 2020).

- Duan, B.; Wang, M.; Zhou, W.Y.; Cheung, W.L.; Li, Z.Y.; Lu, W.W. Three-dimensional nanocomposite scaffolds fabricated via selective laser sintering for bone tissue engineering. Acta Biomater. 2010, 6, 4495–4505. [Google Scholar] [CrossRef]

- Duan, B.; Wang, M. Customized Ca–P/PHBV nanocomposite scaffolds for bone tissue engineering: Design, fabrication, surface modification and sustained release of growth factor. J. R. Soc. Interface 2010, 7, S615–S629. [Google Scholar] [CrossRef]

- Goodridge, R.; Shofner, M.; Hague, R.; McClelland, M.; Schlea, M.; Johnson, R.; Tuck, C. Processing of a Polyamide-12/carbon nanofibre composite by laser sintering. Polym. Test. 2011, 30, 94–100. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; Moens, D.; Boonen, R.; Kruth, J.-P.; Sas, P. On the difference in material structure and fatigue properties of nylon specimens produced by injection molding and selective laser sintering. Polym. Test. 2013, 32, 972–981. [Google Scholar] [CrossRef]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Processing and characterization of a carbon black-filled electrically conductive Nylon-12 nanocomposite produced by selective laser sintering. Mater. Sci. Eng. A 2010, 527, 2637–2642. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Xu, L.; Shi, Y. Preparation, characterization and processing of carbon fibre/polyamide-12 composites for selective laser sintering. Compos. Sci. Technol. 2011, 71, 1834–1841. [Google Scholar] [CrossRef]

- Zhao, M.; Wudy, K.; Drummer, D. Crystallization kinetics of polyamide 12 during selective laser sintering. Polymers 2018, 168, 1–14. [Google Scholar]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Mechanical and microstructural properties of Nylon-12/carbon black composites: Selective laser sintering versus melt compounding and injection molding. Compos. Sci. Technol. 2011, 71, 506–510. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; van den Eynde, M.; Kruth, J.P.; Goderis, B.; van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Ziegelmeier, S.; Christou, P.; Wöllecke, F.; Tuck, C.; Goodridge, R.; Hague, R.; Krampe, E.; Wintermantel, E. An experimental study into the effects of bulk and flow behaviour oflaser sintering polymer powders on resulting part properties. J. Mater. Process. Technol. 2015, 215, 239–250. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Paggi, R.A.; Lago, A.; Beal, V.E. Microstructural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering. Polym. Test. 2011, 30, 611–615. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.; Song, M.; Okamoto, M. Influence of carbon nanotubes on the rheology and dynamic mechanical properties of polyamide-12 for laser sintering. Polym. Test. 2014, 36, 95–100. [Google Scholar] [CrossRef]

- Schmidt, J.; Sachs, M.; Blümel, C.; Winzer, B.; Toni, F.; Wirth, K.-E.; Peukert, W. A Novel Process Chain for the Production of Spherical SLS Polymer Powders with Good Flowability. Procedia Eng. 2015, 102, 550–556. [Google Scholar] [CrossRef]

- Hupfeld, T.; Laumer, T.; Stichel, T.; Schuffenhauer, T.; Heberle, J.; Schmidt, M.; Barcikowski, S.; Gökce, B. A new approach to coat PA12 powders with laser-generated nanoparticles for selective laser sintering. Procedia CIRP 2018, 74, 244–248. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Pande, S.; Bobade, S.M.; Kumar, S. A Targeted Functional Value Based Nanoclay/PA12 Composite Material Development for Selective Laser Sintering Process. Procedia Manuf. 2018, 21, 630–637. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.M.; Song, M. Improving the Mechanical Properties of Laser-Sintered Polyamide 12 through Incorporation of Carbon Nanotubes. Polym. Eng. Sci. 2013, 53, 1937–1946. [Google Scholar] [CrossRef]

- Chunze, S.; Yusheng, Y.; Jinsong, L.; Jinhui, A. Nanosilica/Nylon-12 composite powder for Selective Laser Sintering. J. Reinf. Plast. Compos. 2009, 28, 2889–2901. [Google Scholar] [CrossRef]

- Kim, H.C.; Hahn, H.T.; Yang, Y.S. Synthesis of PA12/functionalized GNP nanocomposite powders for the selective laser sintering process. J. Compos. Mater. 2012, 47, 501–509. [Google Scholar] [CrossRef]

- Jing, W.; Hui, C.; Qiong, W.; Hongbo, L.; Zhanjun, L. Surface modification of carbon fibers and the selective laser sintering of modified carbon fiber/nylon 12 composite powder. Mater. Des. 2017, 116, 253–260. [Google Scholar] [CrossRef]

- Yuan, S.; Zheng, Y.; Chua, C.K.; Yan, Q.; Zhou, K. Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering. Compos. Part. A Appl. Sci. Manuf. 2018, 105, 203–213. [Google Scholar] [CrossRef]

- Jain, P.K.; Pandey, P.M.; Rao, P. Selective laser sintering of clay-reinforced polyamide. Polym. Compos. 2009, 31, 732–743. [Google Scholar] [CrossRef]

- Wudy, K.; Lanzl, L.; Drummer, D. Selective laser sintering of filled polymer systems: Bulk properties and laser beam material interection. Phys. Procedia 2016, 83, 991–1002. [Google Scholar] [CrossRef]

- Wegner, A.; Witt, G. Adjustment of isotropic part properties in laser sintering based on adapted double laser exposure strategies. Opt. Laser Technol. 2019, 109, 381–388. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; Eynde, M.V.D.; Strobbe, D.; Kruth, J.-P.; Goderis, B.; Van Puyvelde, P. Analysis of the material properties involved in laser sintering of thermoplastic polyurethane. Addit. Manuf. 2017, 15, 12–19. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Vandeputte, T.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of Powder Size and Shape on the SLS Processability and Mechanical Properties of a TPU Elastomer. Phys. Procedia 2016, 83, 971–980. [Google Scholar] [CrossRef]

- Wahap, M.S.; Dalgamo, K.W.; Cochrane, R.F.; Hassan, S. Development of Polymer Nanocomposites for Rapid Prototyping Process. Proc. World Congr. Eng. 2009, 2, 1–6. [Google Scholar]

- Drummer, D.; Drexler, M.; Wudy, K. Impact of Heating Rate During Exposure of Laser Molten Parts on the Processing Window of PA12 Powder. Phys. Procedia 2014, 56, 184–192. [Google Scholar] [CrossRef]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Microstructure, thermomechanical properties, and electrical conductivity of carbon black-filled nylon-12 nanocomposites prepared by selective laser sintering. Polym. Eng. Sci. 2011, 52, 12–20. [Google Scholar] [CrossRef]

- Flodberg, G.; Pettersson, H.; Yang, L. Pore analysis and mechanical performance of selective laser sintered objects. Addit. Manuf. 2018, 24, 307–315. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D. Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Addit. Manuf. 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Eynde, M.V.D.; Verbelen, L.; Van Puyvelde, P. Assessing polymer powder flow for the application of laser sintering. Powder Technol. 2015, 286, 151–155. [Google Scholar] [CrossRef]

- Pavan, M.; Craeghs, T.; Verhelst, R.; Ducatteeuw, O.; Kruth, J.P.; Dewulf, W. CT-based quality control of Laser Sintering of Polymers. Case Stud. Nondestruct. Test. Eval. 2016, 6, 62–68. [Google Scholar] [CrossRef]

- Dechet, M.A.; Goblirsch, A.; Romeis, S.; Zhao, M.; Lanyi, F.J.; Kaschta, J.; Schubert, D.W.; Drummer, D.; Peukert, W.; Schmidt, J. Production of polyamide 11 microparticles for Additive Manufacturing by liquid-liquid phase separation and precipitation. Chem. Eng. Sci. 2019, 197, 11–25. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef]

- Shen, F.; Yuan, S.; Chua, C.K.; Zhou, K. Development of process efficiency maps for selective laser sintering of polymeric composite powders: Modeling and experimental testing. J. Mater. Process. Technol. 2018, 254, 52–59. [Google Scholar] [CrossRef]

- Wegner, A.; Oehler, M.; Ünlü, T. Development of a new polybutylene terephthalate material for laser sintering process. Procedia CIRP 2018, 74, 254–258. [Google Scholar] [CrossRef]

- Yan, M.; Tian, X.; Peng, G.; Li, D.; Zhang, X. High temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos. Sci. Technol. 2018, 165, 140–147. [Google Scholar] [CrossRef]

- Salazar, A.; Rico, A.; Rodriguez, J.; Escudero, J.S.; Seltzer, R.; Cutillas, F.M.D.L.E. Fatigue crack growth of SLS polyamide 12: Effect of reinforcement and temperature. Compos. Part B Eng. 2014, 59, 285–292. [Google Scholar] [CrossRef]

- Lindberg, A.; Alfthan, J.; Pettersson, H.; Flodberg, G.; Yang, L. Mechanical performance of polymer powder bed fused objects—FEM simulation and verification. Addit. Manuf. 2018, 24, 577–586. [Google Scholar] [CrossRef]

- Berretta, S.; Ghita, O.; Evans, K. Morphology of polymeric powders in Laser Sintering (LS): From Polyamide to new PEEK powders. Eur. Polym. J. 2014, 59, 218–229. [Google Scholar] [CrossRef]

- Wegner, A. New Polymer Materials for the Laser Sintering Process: Polypropylene and Others. Phys. Procedia 2016, 83, 1003–1012. [Google Scholar] [CrossRef]

- Drummer, D.; Medina-Hernández, M.; Drexler, M.; Wudy, K. Polymer Powder Production for Laser Melting Through Immiscible Blends. Procedia Eng. 2015, 102, 1918–1925. [Google Scholar] [CrossRef]

- Franco, A.; Lanzetta, M.; Romoli, L. Experimental analysis of selective laser sintering of polyamide powders: An energy perspective. J. Clean. Prod. 2010, 18, 1722–1730. [Google Scholar] [CrossRef]

- Laumer, T.; Stichel, T.; Nagulin, K.; Schmidt, M. Optical analysis of polymer powder materials for Se-lective Laser Sintering. Polym. Test. 2016, 56, 207–213. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- Peyre, P.; Rouchausse, Y.; Defauchy, D.; Régnier, G. Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 2015, 225, 326–336. [Google Scholar] [CrossRef]

- Greiner, S.; Wudy, K.; Wörz, A.; Drummer, D. Thermographic investigation of laser-induced temperature fields in selective laser beam melting of polymers. Opt. Laser Technol. 2019, 109, 569–576. [Google Scholar] [CrossRef]

- Greiner, S.; Wudy, K.; Lanzl, L.; Drummer, D. Selective laser sintering of polymer blends: Bulk properties and process behavior. Polym. Test. 2017, 64, 136–144. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Scherbakov, V. Selective Laser Sintering of Biopolymers with Micro and Nano Ceramic Additives for Medicine. Phys. Procedia 2012, 39, 491–499. [Google Scholar] [CrossRef]

- Drexler, M.; Lexow, M.; Drummer, D. Selective Laser Melting of Polymer Powder—Part Mechanics as Function of Exposure Speed. Phys. Procedia 2015, 78, 328–336. [Google Scholar] [CrossRef]

- Tian, X.; Peng, G.; Yan, M.; He, S.; Yao, R. Process prediction of selective laser sintering based on heat transfer analysis for polyamide composite powders. Int. J. Heat Mass Transf. 2018, 120, 379–386. [Google Scholar] [CrossRef]

- Mokrane, A.; Boutaous, M.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. CR Mecanique 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

- Bourell, D.L.; Watt, T.J.; Leigh, D.K.; Fulcher, B. Performance Limitations in Polymer Laser Sintering. Phys. Procedia 2014, 56, 147–156. [Google Scholar] [CrossRef]

- Drummer, D.; Wudy, K.; Kühnlein, F.; Drexler, M. Polymer blends for Selective Laser Sintering: Material and process requirements. Phys. Procedia 2012, 39, 509–517. [Google Scholar] [CrossRef]

- Wang, Y.; Rouholamin, D.; Davies, R.; Ghita, O.R. Powder characteristics, microstructure and properties of graphite platelet reinforced Poly Ether Ether Ketone composites in High Temperature Laser Sinter-ing (HT-LS). Mater. Des. 2015, 88, 1310–1320. [Google Scholar] [CrossRef]

- Berretta, S.; Evans, K.E.; Ghita, O.R. Predicting processing parameters in high temperature laser sintering (HT-LS) from powder properties. Mater. Des. 2016, 105, 301–314. [Google Scholar] [CrossRef]

- Qi, F.; Chen, N.; Wang, Q. Preparation of PA11/BaTiO3 nanocomposite powders with improved processability, dielectric and piezoelectric properties for use in selective laser sintering. Mater. Des. 2017, 131, 135–143. [Google Scholar] [CrossRef]

- Wang, G.; Wang, P.; Zhen, Z.; Zhang, W.; Ji, J. Preparation of PA12 microspheres with tunable morphology and size for use in SLS processing. Mater. Des. 2015, 87, 656–662. [Google Scholar] [CrossRef]

- Wudy, K.; Greiner, S.; Zhao, M.; Drummer, D. Selective laser beam melting of polymers: In situ and offline measurements for process adapted thermal characterization. Procedia CIRP 2018, 74, 238–243. [Google Scholar] [CrossRef]

- Vasquez, M.; Haworth, B.; Hopkinson, N. Methods for quantifying the stable sintering region in laser sintered polyamide-12. Polym. Eng. Sci. 2013, 53, 1230–1240. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the processability, recyclability and crystalline structure of selective laser sintered Polyamide 6 in comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- Lanzl, L.; Wudy, K.; Drexler, M.; Drummer, D. Laser-High-Speed-DSC: Process-oriented thermal analysis of PA12 in Selective Laser Sinering. Phys. Procedia 2016, 83, 981–990. [Google Scholar] [CrossRef]

- Schmid, M.; Kleijnen, R.; Vetterli, M.; Wegener, K. Influence of the Origin of Polyamide 12 Powder on the Laser Sintering Process and Laser Sintered Parts. Appl. Sci. 2017, 7, 462. [Google Scholar] [CrossRef]

- Eosoly, S.; Vrana, N.E.; Lohfeld, S.; Hindie, M.; Looney, L. Interaction of cell culture with composition effects on the mechanical properties of polycaprolactone-hydroxyapatite scaffolds fabricated via selective laser sintering (SLS). Mater. Sci. Eng. C 2012, 32, 2250–2257. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Leite, J.L.; Vieira, L.; Pires, A.T.N.; Roesler, C. Mechanical properties of PA6/PA12 blend specimens prepared by selective laser sintering. Polym. Test. 2012, 31, 411–416. [Google Scholar] [CrossRef]

- Beitz, S.; Uerlich, R.; Bokelmann, T.; Diener, A.; Vietor, T.; Kwade, A. Influence of Powder Deposition on Powder Bed and Specimen Properties. Materials 2019, 12, 297. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Berretta, S.; Evans, K.; Smith, K.; Ghita, O. A primary study into graphene/polyether ether ketone (PEEK) nanocomposite for laser sintering. Appl. Surf. Sci. 2018, 428, 1018–1028. [Google Scholar] [CrossRef]

- Blümel, C.; Sachs, M.; Laumer, T.; Winzer, B.; Schmidt, J.; Schmidt, M.; Peukert, W.; Wirth, K.-E. In-creasing flowability and bulk density of PE-HD powders by a dry particle coating process and impact on LBM processes. Rapid Prototyp. J. 2015, 6, 697–704. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.-P.; Vleugels, J. Additive manufacturing of zirconia parts by indirect selective laser sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Kruth, J.-P.; Vleugels, J. Additive manufacturing of alumina parts by indirect selective laser sintering and post processing. J. Mater. Process. Technol. 2013, 213, 1484–1494. [Google Scholar] [CrossRef]

- Xia, Y.; Zhou, P.; Cheng, X.; Xie, Y.; Liang, C.; Li, C.; Xu, S. Selective laser sintering fabrication of nano-hydroxyapatite/poly-ε-caprolactone scaffolds for bone tissue engineering applications. Int. J. Nanomed. 2013, 8, 4197–4213. [Google Scholar]

- Duan, B.; Cheung, W.L.; Wang, M. Optimized fabrication of Ca–P/PHBV nanocomposite scaffolds via selective laser sintering for bone tissue engineering. Biofabrication 2011, 3, 015001. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Boury, S.; Neirinck, B.; Kruth, J.-P.; Vleugels, J. Preparation and indirect selective laser sintering of alumina/PA microspheres. Ceram. Int. 2012, 38, 1241–1247. [Google Scholar] [CrossRef]

- Dupin, S.; Lame, O.; Barrès, C.; Charmeau, J.-Y. Microstructural origin of physical and mechanical properties of polyamide 12 processed by laser sintering. Eur. Polym. J. 2012, 48, 1611–1621. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ash-croft, I.A.; Hague, R.J.M. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Beal, V.E.; Paggi, R.A.; Salmoria, G.V.; Lago, A. Statistical evaluation of laser energy density effect on mechanical properties of polyamide parts manufactured by selective laser sintering. J. Appl. Polym. Sci. 2009, 113, 2910–2919. [Google Scholar] [CrossRef]

- Jain, P.K.; Pandey, P.M.; Rao, P.V.M. Effect of delay time on part strength in selective laser sintering. Int. J. Adv. Manuf. Technol. 2009, 43, 117–126. [Google Scholar] [CrossRef]

- Bai, J.; Yuan, S.; Shen, F.; Zhang, B.; Chua, C.K.; Zhou, K.; Wei, J. Toughening of polyamide 11 with carbon nanotubes for additive manufacturing. Virtual Phys. Prototyp. 2017, 12, 1–6. [Google Scholar] [CrossRef]

- Türk, D.-A.; Brenni, F.; Zogg, M.; Meboldt, M. Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing. Mater. Des. 2017, 118, 256–265. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Klauss, P.; Paggi, R.A.; Kanis, L.A.; Lago, A. Structure and mechanical properties of cellulose based scaffolds fabricated by selective laser sintering. Polym. Test. 2009, 28, 648–652. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; De Coninck, F.; Moens, D.; Boonen, R.; Sas, P. Microstructural characterization of SLS-PA12 specimens under dynamic tension/compression excitation. Polym. Test. 2010, 29, 319–326. [Google Scholar] [CrossRef]

- Vasquez, M.; Haworth, B.; Hopkinson, N. Optimum sintering region for laser sintered nylon-12. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2011, 225, 2240–2248. [Google Scholar] [CrossRef]

- Kenzari, S.; Bonina, D.; Dubois, J.; Fournée, V. Quasicrystal–polymer composites for selective laser sintering technology. Mater. Des. 2012, 35, 691–695. [Google Scholar] [CrossRef]

- Vesenjak, M.; Krstulovi-Opara, L.; Ren, Z.; Domazet, Z. Cell shape effect evaluation of polyamide cel-lular structures. Polym. Test. 2010, 29, 991–994. [Google Scholar] [CrossRef]

- Ghita, O.; James, E.; Trimble, R.; Evans, K.E. Physico-chemical behaviour of Poly (Ether Ketone) (PEK) in High Temperature Laser Sintering (HT-LS). J. Mater. Process. Technol. 2014, 214, 969–978. [Google Scholar] [CrossRef]

- Duan, B.; Wang, M. Encapsulation and release of biomolecules from Ca-P/PHBV nanocomposite microspheres and three-dimensional scaffolds fabricated by selective laser sintering. Polym. Degrad. Stab. 2010, 95, 1655–1664. [Google Scholar] [CrossRef]

- Lindner, M.; Hoeges, S.; Meiners, W.; Wissenbach, K.; Smeets, R.; Telle, R.; Poprawe, R.; Fischer, H. Manufacturing of individual biodegradable bone substitute implants using selective laser melting tech-nique. J. Biomed. Mater. Res. A 2011, 97, 466–471. [Google Scholar] [CrossRef]

- Van Bael, S.; Desmet, T.; Chai, Y.C.; Pyka, G.; Dubruel, P.; Kruth, J.-P.; Schrooten, J. In vitro cell-biological performance and structural characterization of selective laser sintered and plasma surface functionalized polycaprolactone scaffolds for bone regeneration. Mater. Sci. Eng. C 2013, 33, 3404–3412. [Google Scholar] [CrossRef]

- Cooke, W.; Tomlinson, R.A.; Burguete, R.; Johns, D.; Vanard, G. Anisotropy, homogeneity and ageing in an SLS polymer. Rapid Prototyp. J. 2011, 17, 269–279. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Yuan, S.; Zhou, K.; Chua, C.K.; Wei, J. Thermal Influence of CNT on the Polyamide 12 Nanocomposite for Selective Laser Sintering. Molecules 2015, 20, 19041–19050. [Google Scholar] [CrossRef]

- Savalani, M.M.; Hao, L.; Dickens, P.M.; Zhang, Y.; Tanner, K.E. The effects and interactions of fabrication parameters on the properties of selective laser sintered hydroxyapatite polyamide composite bio-materials. Rapid Prototyp. J. 2012, 18, 16–27. [Google Scholar] [CrossRef]

- Griessbach, S.; Lach, R.; Grellmann, W. Structure–property correlations of laser sintered nylon 12 for dynamic dye testing of plastic parts. Polym. Test. 2010, 29, 1026–1030. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, B.; Song, J.; Bi, G.; Wang, P.; Wie, J. The effect of processing conditions on the mechanical properties of polyethylene produced by selective laser sintering. Polym. Test. 2016, 52, 89–93. [Google Scholar] [CrossRef]

- Qi, F.; Chen, N.; Wang, Q. Dielectric and piezoelectric properties in selective laser sintered polyamide11/BaTiO3/CNT ternary nanocomposites. Mater. Des. 2018, 143, 72–80. [Google Scholar] [CrossRef]

- Schmidt, J.; Sachs, M.; Fanselow, S.; Zhao, M.; Romeis, S.; Drummer, D.; Wirth, K.-E.; Peukert, W. Optimized polybutylenetere phthalate powders for selective laser beam melting. Chem. Eng. Sci. 2016, 156, 1–10. [Google Scholar] [CrossRef]

- Shuai, C.; Yang, B.; Peng, S.; Li, Z. Development of composite porous scaffolds based on poly(lactide-co-glycolide)/nano-hydroxyapatite via selective laser sintering. Int. J. Adv. Manuf. Technol. 2013, 69, 51–57. [Google Scholar] [CrossRef]

- Franco, A.; Romoli, L. Characterization of laser energy consumption in sintering of polymer based powders. J. Mater. Process. Technol. 2012, 212, 917–926. [Google Scholar] [CrossRef]

- Goodridge, R.; Hague, R.; Tuck, C. Effect of long-term ageing on the tensile properties of a polyamide 12 laser sintering material. Polym. Test. 2010, 29, 483–493. [Google Scholar] [CrossRef]

- Yang, J.; Shi, Y.; Yan, C. Selective laser sintering of polyamide 12/potassium titanium whisker composites. J. Appl. Polym. Sci. 2010, 117, 2196–2204. [Google Scholar] [CrossRef]

- Majewski, C.; Hopkinson, N. Effect of section thickness and build orientation on tensile properties and material characteristics of laser sintered nylon-12 parts. Rapid Prototyp. J. 2011, 17, 176–180. [Google Scholar] [CrossRef]

- Meyer, K.; Zimmermann, I. Effect of glidants in binary powder mixtures. Powder Technol. 2004, 139, 40–54. [Google Scholar] [CrossRef]

- Hupfeld, T.; Sommereyns, A.; Schuffenhauer, T.; Zhuravlev, E.; Krebs, M.; Gann, S.; Keßler, O.; Schmidt, M.; Gökce, B.; Barcikowski, S. How colloidal surface additivation of polyamide 12 powders with well-dispersed silver nanoparticles influences the crystallization already at low 0.01 vol%. Addit. Manuf. 2020, 36, 101419. [Google Scholar] [CrossRef]

- Hupfeld, T.; Salamon, S.; Landers, J.; Sommereyns, A.; Doñate-Buendía, C.; Schmidt, J.; Wende, H.; Schmidt, M.; Barcikowski, S.; Gökce, B. 3D printing of magnetic parts by laser powder bed fusion of iron oxide nanoparticle functionalized polyamide powders. J. Mater. Chem. C 2020, C 8, 12204–12217. [Google Scholar] [CrossRef]

- Hupfeld, T.; Sommereyns, A.; Riahi, F.; Doñate-Buendía, C.; Gann, S.; Schmidt, M.; Gökce, B.; Barcikowski, S. Analysis of the nanoparticle dispersion and its effect on the crystalline microstructure in carbon-additivated PA12 feedstock material for laser powder bed fusion. Materials 2020, 13, 3312. [Google Scholar] [CrossRef] [PubMed]

- Hupfeld, T.; Wegner, A.; Blanke, M.; Doñate-Buendía, C.; Sharov, V.; Nieskens, S.; Piechotta, M.; Giese, M.; Barcikowski, S.; Gökce, B. Plasmonic seasoning: Giving color to desktop laser 3D printed polymers by highly dispersed nanoparticles. Adv. Opt. Mater. 2020, 8, 2070060. [Google Scholar] [CrossRef]

- Moylan, S.; Brown, C.; Slotwinski, J. Recommended Protocol for Round-Robin Studies in Additive Manufacturing. J. Test. Eval. 2016, 44, 1009–1018. [Google Scholar] [CrossRef] [PubMed]

- Brown, C.U.; Jacob, G.; Stoudt, M.; Moylan, S.; Slotwinski, J.; Donmez, A. Interlaboratory Study for Nickel Alloy 625 Made by Laser Powder Bed Fusion to Quantify Mechanical Property Variability. J. Mater. Eng. Perform. 2016, 25, 3390–3397. [Google Scholar] [CrossRef] [PubMed]

- Ahuja, B.; Schaub, A.; Junker, D.; Tenner, F.; Plettke, R.; Merklein, M.; Schmidt, M.; Karg, M. A Round Robin Study for Laser Beam Melting in Metal Powder Bed. S. Afr. J. Ind. Eng. 2016, 27, 30–42. [Google Scholar] [CrossRef]

- Bourell, D.; Coholich, J.; Chalancon, A.; Bhat, A. Evaluation of energy density measures and validation for powder bed fusion of polyamide. CIRP Ann. Manuf. Technol. 2017, 66, 210–220. [Google Scholar] [CrossRef]

- Jansson, A.; Pejryd, L. Characterisation of carbon fibre-reinforced polyamide manufactured by selective laser sintering. Addit. Manuf. 2016, 9, 7–13. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2126–2142. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Davies, R.; Liu, Y.; Yi, N.; Qiang, D.; Zhu, Y.; Ghita, O. Laser sintering of graphene nano-platelets encapsulated polyamide powders. Addit. Manuf. 2020, 35, 101363. [Google Scholar]

- Sommereyns, A.; Hupfeld, T.; Gann, S.; Wang, T.; Wu, C.; Zhuravlev, E.; Lüddecke, A.; Baumann, S.; Rudloff, J.; Lang, M.; et al. Influence of sub-monolayer quantities of carbon nanoparticles on the melting and crystallization behavior of polyamide 12 powders for additive manufacturing. Mater. Des. 2021, 201. [Google Scholar] [CrossRef]

- Sanguansat, P. (Ed.) Principal Component Analysis—Engineering Applications; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0182-6. [Google Scholar]

- Naik, G.R. (Ed.) Advances in Principal Component Analysis—Research and Development; Springer: Singapore, 2018. [Google Scholar]

| Powder Size | VED | AED | Laser Power | Scanning Speed | Layer Thickness | Hatch Spacing | UTS | Elongation | |

|---|---|---|---|---|---|---|---|---|---|

| Powder Size | 1 | 0.09922 | −0.03446 | 0.39481 | −0.23362 | −0.14307 | 0.02324 | −0.54097 | 0.28128 |

| VED | 0.09922 | 1 | 0.98235 | −0.72197 | −0.84689 | 0.94208 | −0.49303 | 0.67412 | −0.26240 |

| AED | −0.03446 | 0.98235 | 1 | −0.81100 | −0.78176 | 0.98819 | −0.38709 | 0.78199 | −0.30151 |

| Laser Power | 0.39481 | −0.72197 | −0.81100 | 1 | 0.63875 | −0.86263 | 0.22207 | −0.74786 | −0.02901 |

| Scanning Speed | −0.23362 | −0.84689 | −0.78176 | 0.63875 | 1 | −0.70787 | 0.71575 | −0.31273 | −0.17942 |

| Layer Thickness | −0.14307 | 0.94208 | 0.98819 | −0.86263 | −0.70787 | 1 | −0.29013 | 0.84981 | −0.32563 |

| Hatch Spacing | 0.02324 | −0.49303 | −0.38709 | 0.22207 | 0.71575 | −0.29013 | 1 | −0.10027 | −0.00206 |

| UTS | −0.54097 | 0.67412 | 0.78199 | −0.74786 | −0.31273 | 0.84981 | −0.10027 | 1 | −0.61968 |

| Elongation | 0.28128 | −0.26240 | −0.30151 | −0.02901 | −0.17942 | −0.32563 | −0.00206 | −0.61968 | 1 |

| Ref. | Polymer Type | Additives | D50 (μm) | VED (J/mm³) | AED (J/mm²) | Laser Power (W) | Scanning Speed (mm/s) | Layer Thickness (µm) | Hatch Spacing (µm) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [71] | aged PA12 | 53 | 0.15 | 0.02 | 18 | 4000 | 100 | 300 | 48 | 47 | |

| [70] | PA12 | 56 | 0.36 | 0.04 | 18 | 2500 | 100 | 200 | 50 | 18 | |

| [35] | TPU | 63 | 0.67 | 0.07 | 10 | 1000 | 100 | 150 | 18 | 559 | |

| [27] | PA12 | 37 | 0.90 | 0.09 | 18 | 2000 | 100 | 100 | 38 | 21 | |

| [27] | PA12 | silica | 37 | 1.00 | 0.1 | 20 | 2000 | 100 | 100 | 46 | 20 |

| [35] | TPU | 200 | 1.60 | 0.16 | 24 | 1000 | 100 | 150 | 4 | 208 | |

| [21] | PA12 | 58 | 3.41 | 0.68 | 4 | 45 | 200 | 125 | 86 | 11 | |

| [21] | PA12 | MWCNT | 58 | 3.41 | 0.68 | 4 | 45 | 200 | 125 | 94 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusoglu, I.M.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. https://doi.org/10.3390/ma14051169

Kusoglu IM, Doñate-Buendía C, Barcikowski S, Gökce B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials. 2021; 14(5):1169. https://doi.org/10.3390/ma14051169

Chicago/Turabian StyleKusoglu, Ihsan Murat, Carlos Doñate-Buendía, Stephan Barcikowski, and Bilal Gökce. 2021. "Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices" Materials 14, no. 5: 1169. https://doi.org/10.3390/ma14051169

APA StyleKusoglu, I. M., Doñate-Buendía, C., Barcikowski, S., & Gökce, B. (2021). Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials, 14(5), 1169. https://doi.org/10.3390/ma14051169