Active Thermography in Diagnostics of Timber Elements Covered with Polychrome

Abstract

1. Introduction

2. Materials and Methods

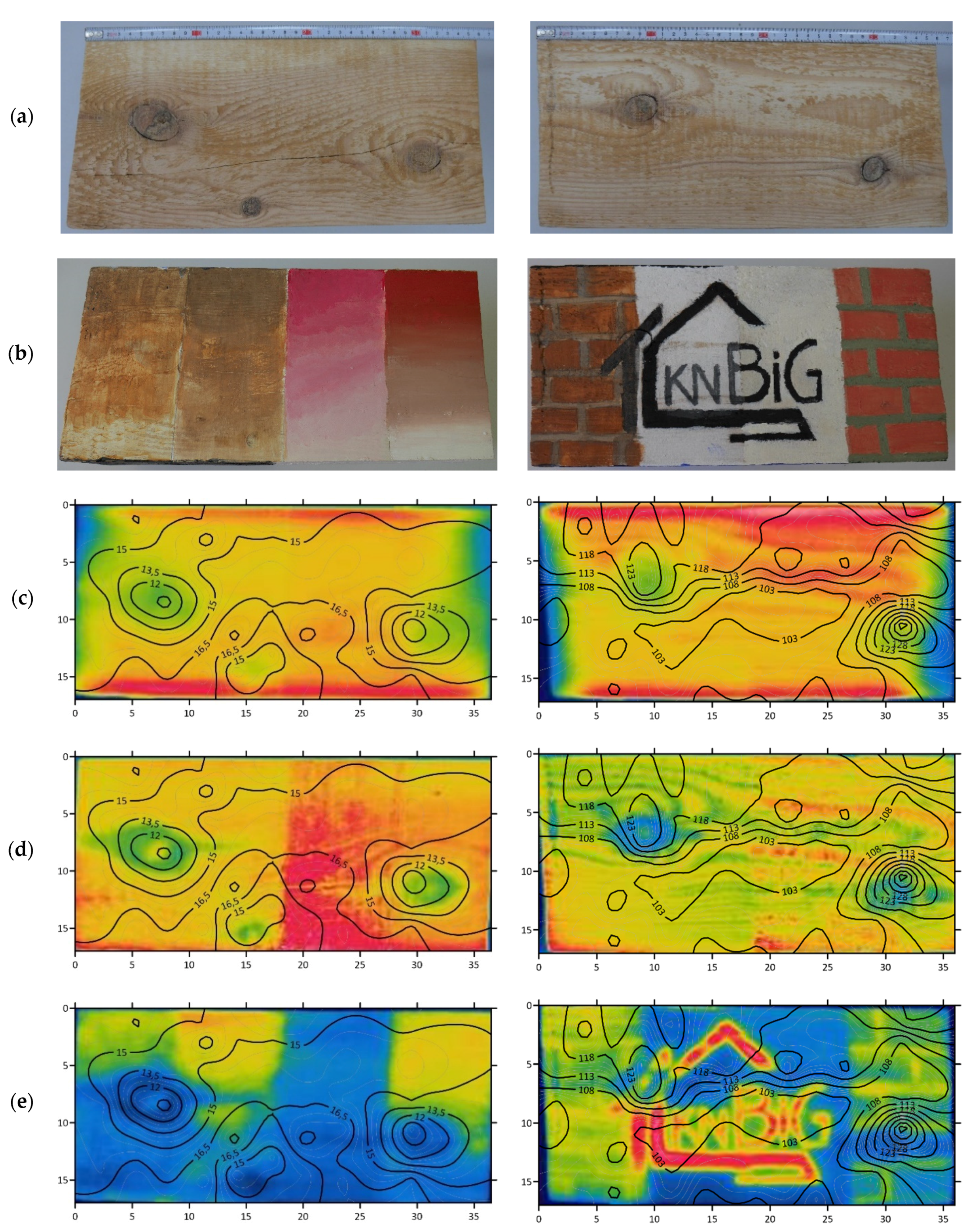

2.1. Materials and Test Elements

2.2. Test Plan

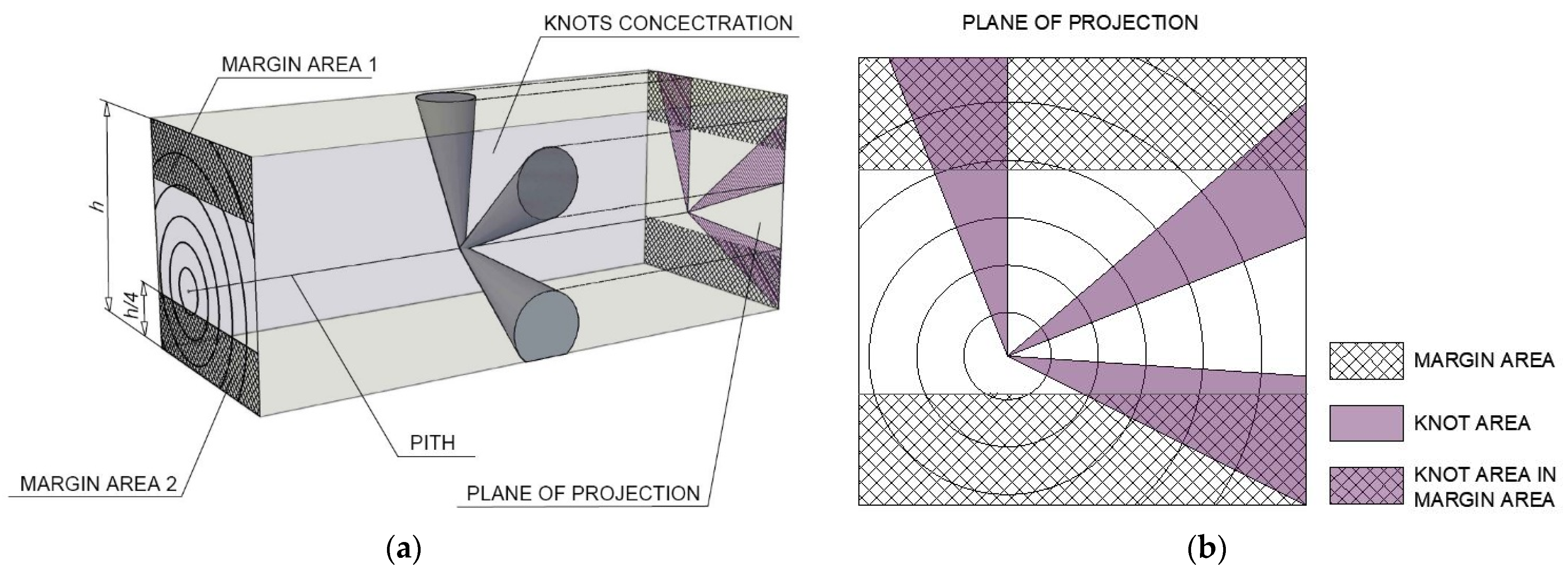

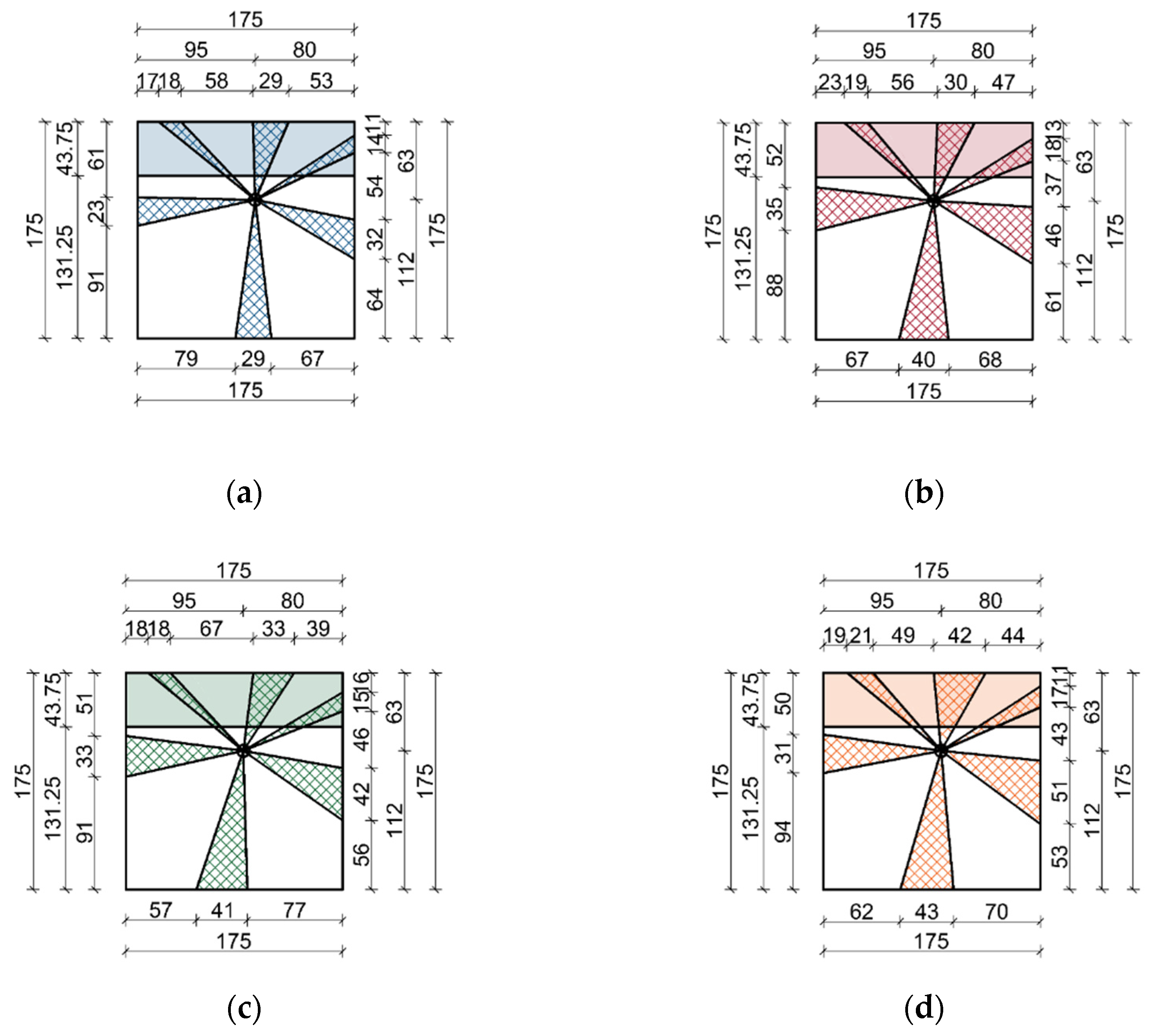

2.2.1. KAR Determination

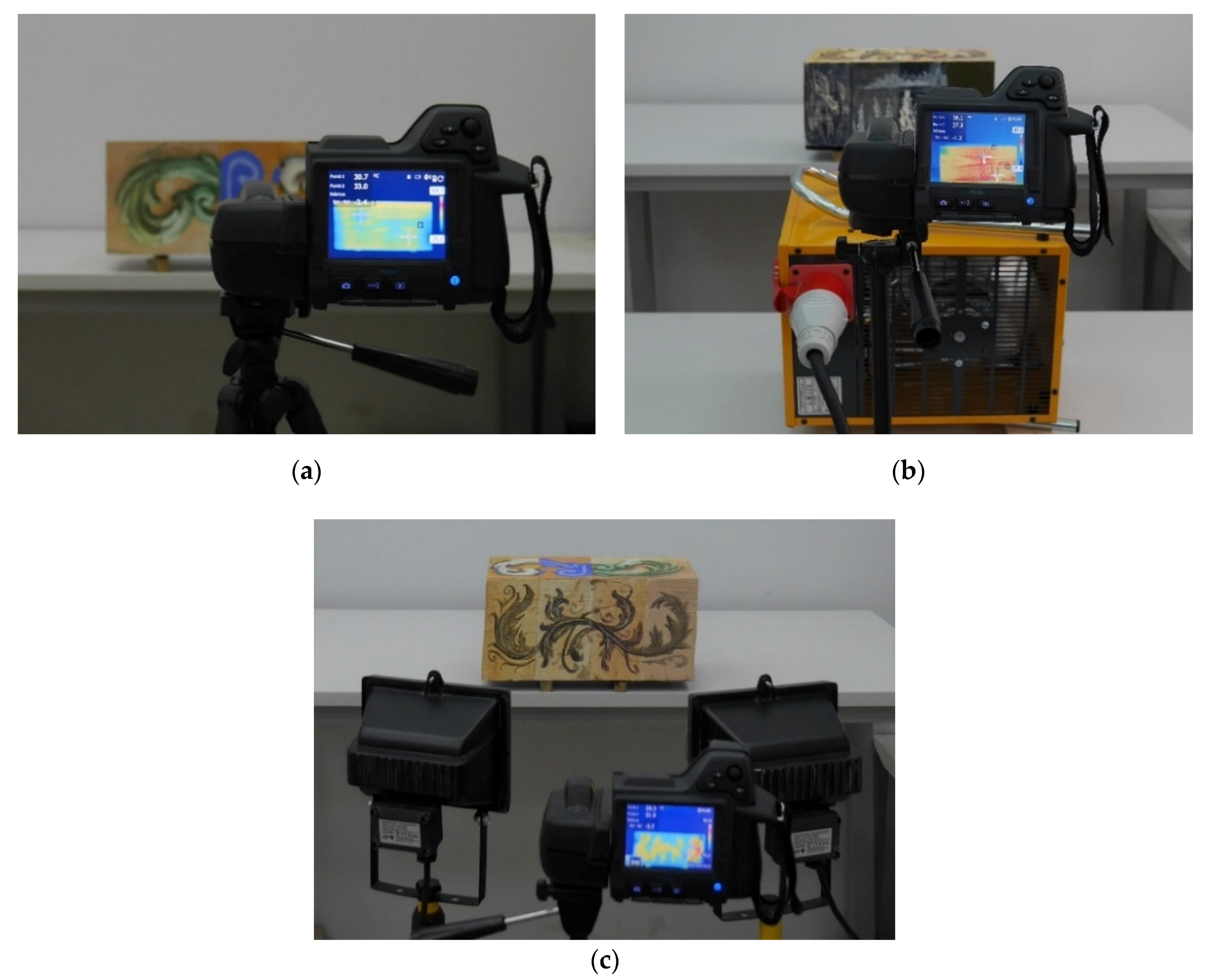

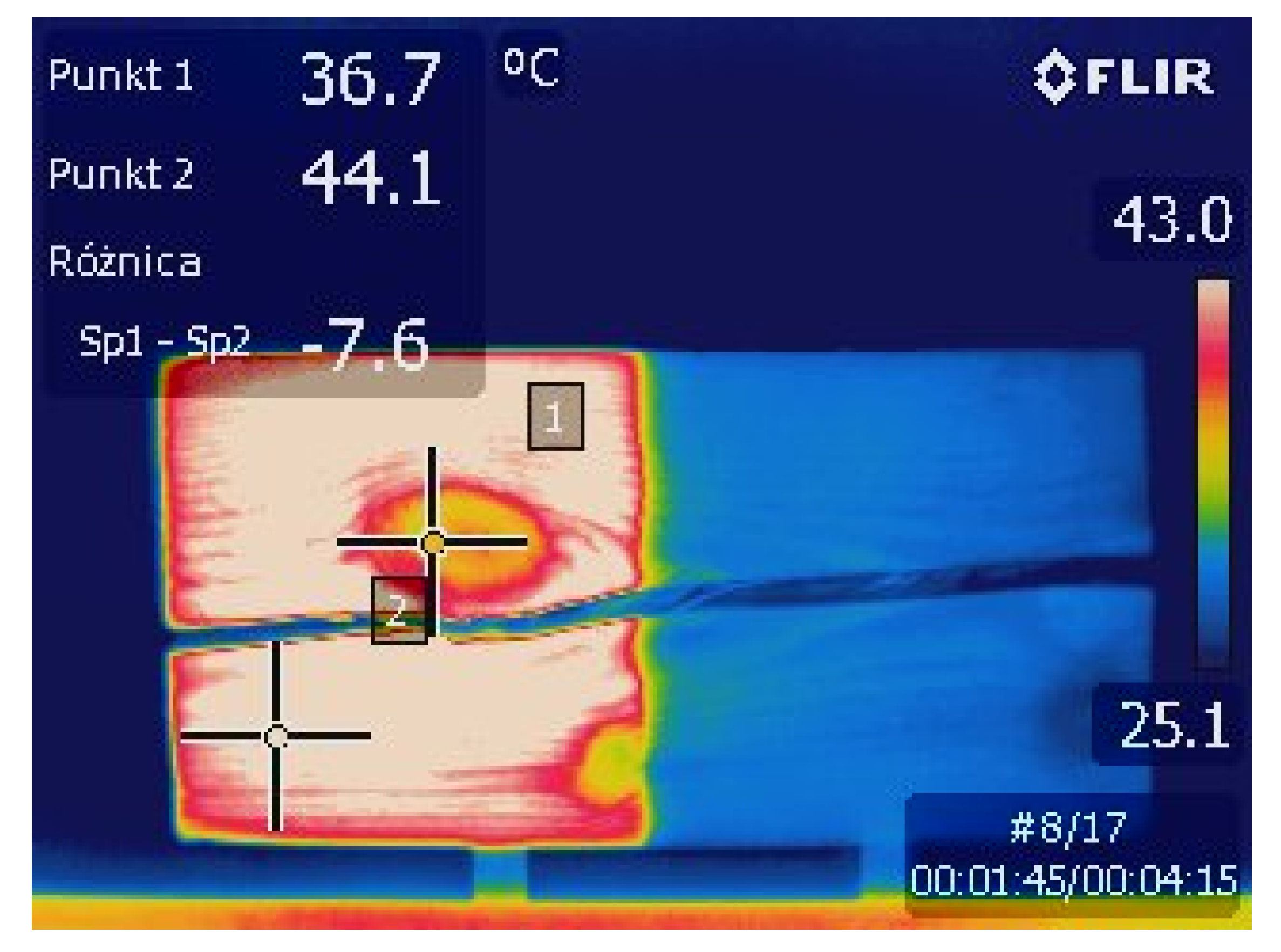

2.2.2. Active Thermography

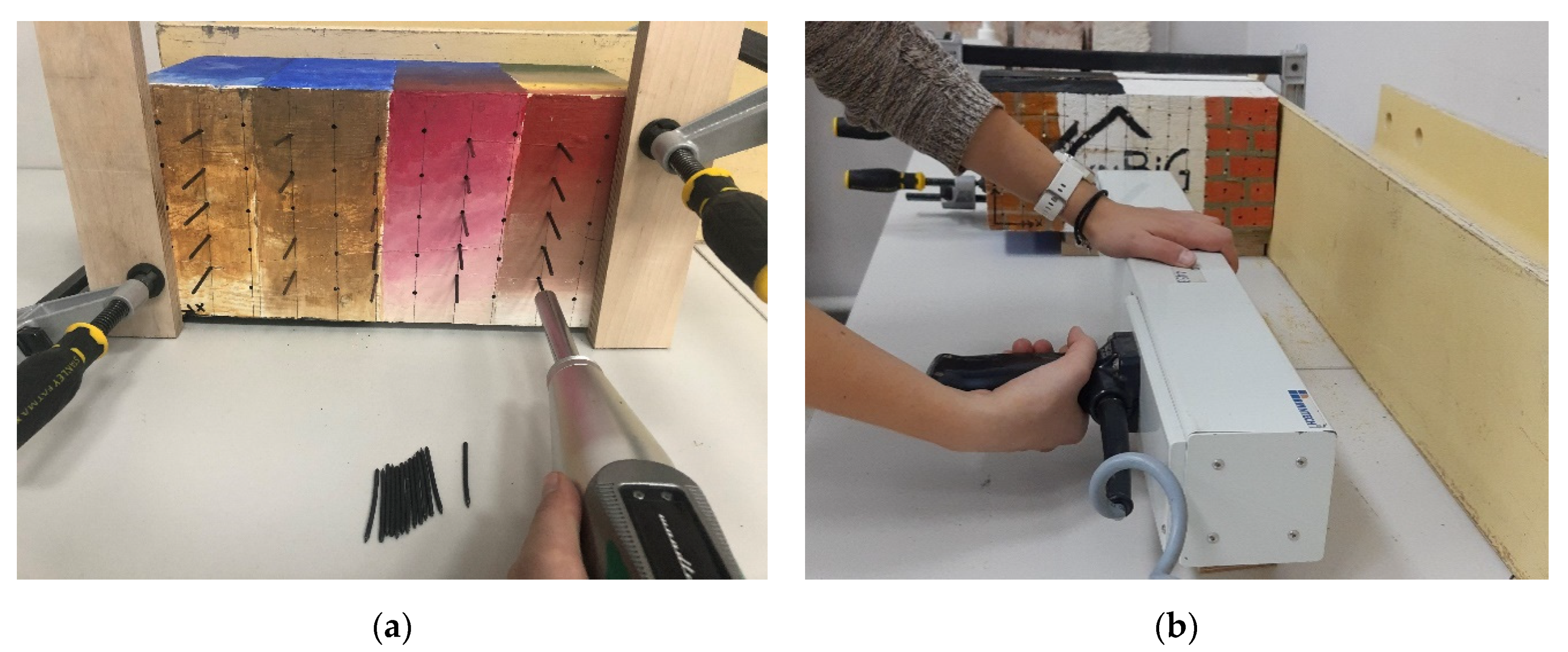

2.2.3. Semi-Destructive Tests

3. Results

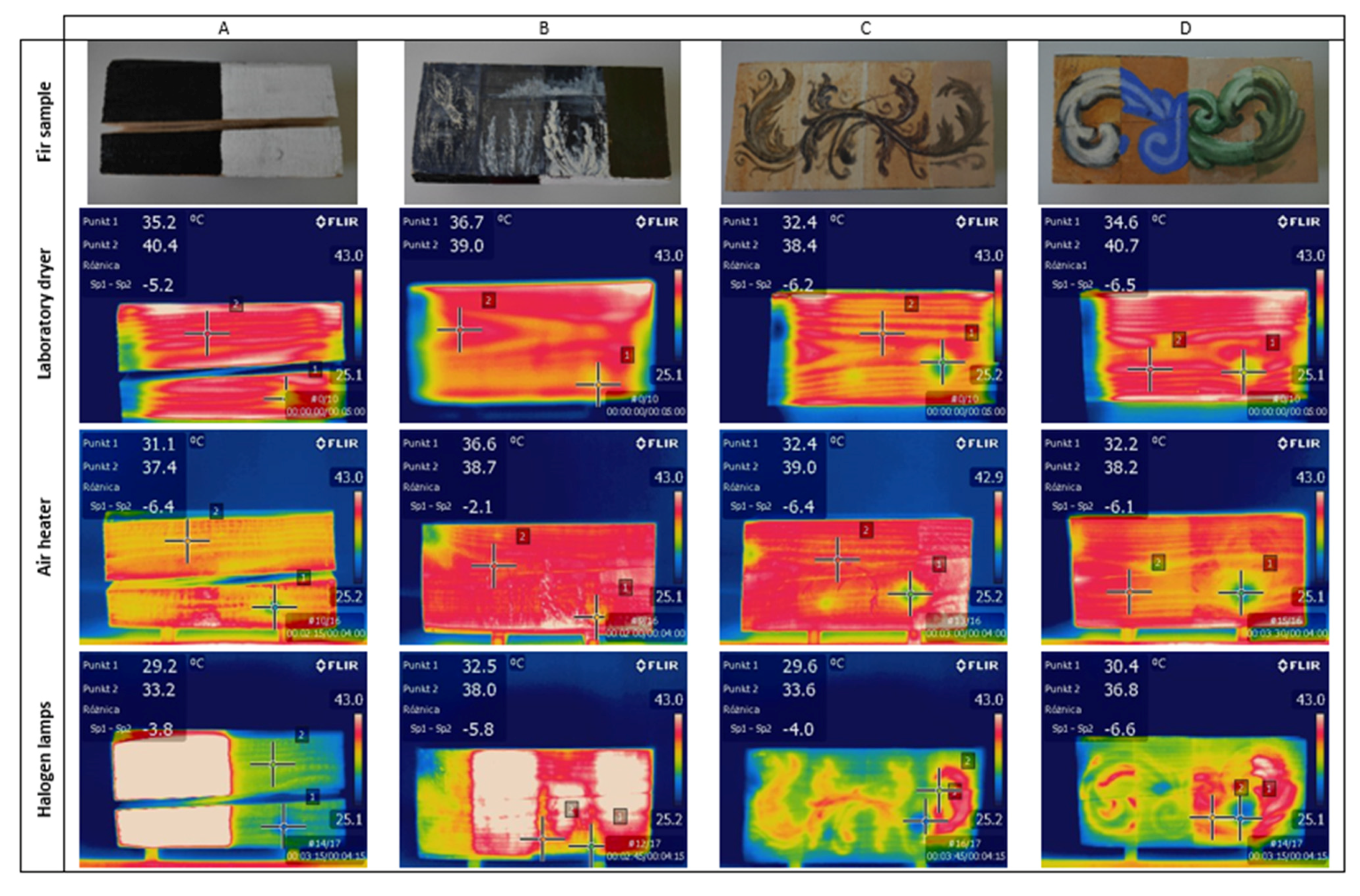

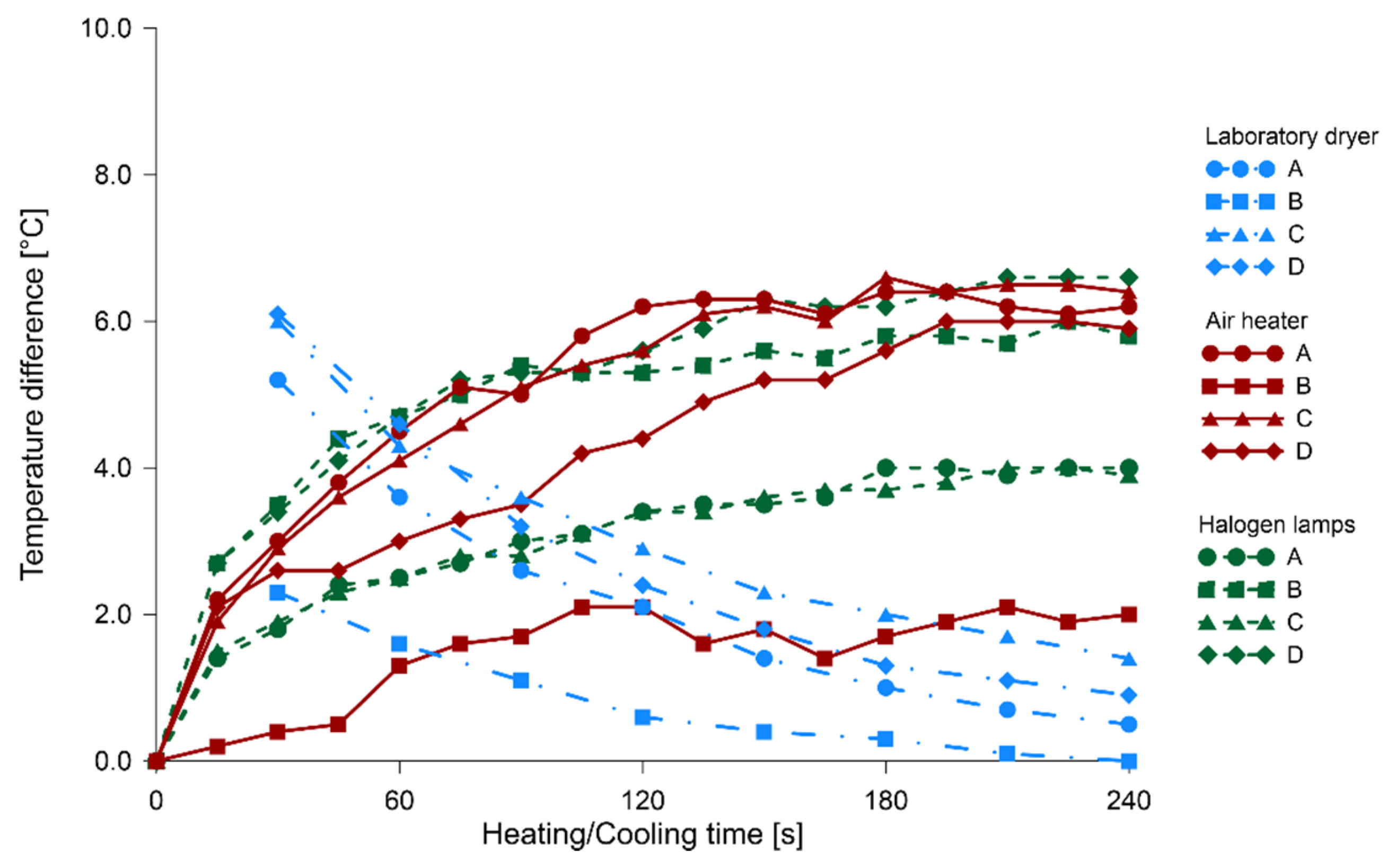

3.1. Active Thermography

3.2. Knot Area Ratio

3.3. Semi-Destructive Test

4. Discussion

5. Conclusions

- Defects of timber are exposed in the thermal images due to the decreased temperature in relation to solid wood. In the whole scope of research, for thermal images taken during the sample heating after 90 s, the difference between knots and solid wood was approximately 4 °C; for images taken during the sample cooling after 30 s, the difference between knots and solid wood was approximately 5 °C, which allowed us to determine the approximate position of knots within the element.

- The contribution of knots in the piece of wood is one of the basic features determining its strength. Therefore, the possibility of determining the knot area ratio in polychromed historical buildings is an important and ongoing concern. The conducted research indicated that it is possible to estimate the knot area ratio by using active thermography; however, it is likely to be affected by an error. The limitation of this determination method is the necessity to access the element from four sides and the relatively subjective measurement of the knot diameter on the thermal image.

- The comparisons of semi-destructive and thermographic tests showed a great potential of using active thermography to determine the zones for NDT and SDT tests of polychromed timber elements. The use of active thermography prior to performing such tests prevents misinterpretations associated with unintentional measurements in the area of natural defects of wood (such as knots) and may also reduce the number of measurement areas necessary to properly assess the technical condition and thus the extent of damage caused by the examinations.

- The paper describes three methods of energy supply to the samples and their influence on the values of the estimation of the KAR and the possibility of determining the locations for further SDTs. In terms of practical applications in historic buildings, halogen lamps would be the most convenient; however, the results of those (KAR values and correlation with the SDTs) were rather insufficient. The supply of heat through convection would be more troublesome due to the availability of equipment and power source. In principle, without dismantling the element, it is rather not possible to use free convection (laboratory dryer), for which the most obvious wood grain and defect location is obtained regardless of the type of paint coating. Therefore, it seems that, in terms of conservation practice, the most suitable solution would be to use an air heater, for which, despite the influence of the type of paint coating on the thermal image, it was possible to determine the location of possible defects or the value of knot area ratio.

- The further research in the field of active thermography for the detection of natural defects in polychrome decorated timber should be focused on the application of post-processing methods such as Eulerian video magnification for air heating [57,58] and quantitative evaluation, using noise-related parameters. However, using energy sources that are hazardous to polychromes should be avoided, especially devices that emit excessively high UV radiation (e.g., Xenon flash lamps), sources generating elevated temperatures (higher than 45 °C) and techniques that require direct contact between the source and the examined object. It would also be beneficial to develop an algorithm for determining the KAR and proper locations for semi-destructive testing in the case of elements which could not be tested perpendicularly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Caniato, M.; Bettarello, F.; Fausti, P.; Ferluga, A.; Marsich, L.; Schmid, C. Impact sound of timber floors in sustainable buildings. Build. Environ. 2017, 120, 110–122. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, Q.; Han, Y.; Lau, D. Piezoelectric materials for sustainable building structures: Fundamentals and applications. Renew. Sustain. Energy Rev. 2019, 101, 14–25. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Marsono, A.K.B.; Khaleghi, S.J. Sustainability choice of different hybrid timber structure for low medium cost single-story residential building: Environmental, economic and social assessment. J. Build. Eng. 2018, 20, 235–247. [Google Scholar] [CrossRef]

- Kasal, B. In-situ assessment of structural timber: State-of-the-art, challenges and future directions. Adv. Mater. Res. 2010, 133–134, 43–52. [Google Scholar] [CrossRef]

- Riggio, M.; D’Ayala, D.; Parisi, M.A.; Tardini, C. Assessment of heritage timber structures: Review of standards, guidelines and procedures. J. Cult. Herit. 2018, 31, 220–235. [Google Scholar] [CrossRef]

- Perria, E.; Sieder, M. Six-Steps Process of Structural Assessment of Heritage Timber Structures: Definition Based on the State of the Art. Buildings 2020, 10, 109. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 17121: Conservation of Cultural Heritage—Historic timber Structures—Guidelines for the on-Site Assessment of Load-Bearing Timber Structures; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- Piazza, M.; Riggio, M. Visual strength-grading and NDT of timber in traditional structures. J. Build. Apprais. 2008, 3, 267–296. [Google Scholar] [CrossRef]

- Dackermann, U.; Crews, K.; Kasal, B.; Li, J.; Riggio, M.; Rinn, F.; Tannert, T. In situ assessment of structural timber using stress-wave measurments. Mater. Struct. 2014, 47, 787–803. [Google Scholar] [CrossRef]

- Riggio, M.; Anthony, R.W.; Augelli, F.; Kasal, B.; Lechner, T.; Muller, W.; Tannert, T. In situ assessment of structural timber using semi-destructive techniques. Mater. Struct. 2014, 47, 767–785. [Google Scholar] [CrossRef]

- Jaskowska-Lemańska, J.; Wałach, D. Impact of the Direction of Non-destructive Test with Respect to the Annual Growth Rings of Pine Wood. Procedia Eng. 2016, 161, 925–930. [Google Scholar]

- Cruz, H.; Yeomans, D.; Tsakanika, E.; Macchioni, N.; Jorissen, A.; Touza, M.; Mannucci, M.; Lourenço, P.B. Guidelines for on-site assessment of historic timber structures. Int. J. Archit. Herit. 2015, 9, 277–289. [Google Scholar] [CrossRef]

- Jurek, M. Application of active thermography in steel element surface testing (in Polish). J. Civ. Eng. Environ. Archit. 2017, 64, 65–75. [Google Scholar]

- Vollmer, M.; Möllmann, K.-P. Infrared Thermal Imaging: Fundamentals, Research and Applications; WILEY-VCH: Weinheim, Germany, 2010; ISBN 9783527403820. [Google Scholar]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A.; Christou, P.; Kalogirou, S.A. Infrared thermography (IRT) applications for building diagnostics: A review. Appl. Energy 2014, 134, 531–549. [Google Scholar] [CrossRef]

- Milovanović, B.; Pečur, I.B. Review of Active IR Thermography for Detection and Characterization of Defects in Reinforced Concrete. J. Imaging 2016, 2, 11. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Burleigh, D.D. Review of pulsed thermal NDT: Physical principles, theory and data processing. NDT E Int. 2015, 73, 28–52. [Google Scholar] [CrossRef]

- Chatterjee, K.; Tuli, S.; Pickering, S.G.; Almond, D.P. A comparison of the pulsed, lock-in and frequency modulated thermography nondestructive evaluation techniques. NDT E Int. 2011, 44, 655–667. [Google Scholar] [CrossRef]

- Zalewski, L.; Lassue, S.; Rousse, D.; Boukhalfa, K. Experimental and numerical characterization of thermal bridges in prefabricated building walls. Energy Convers. Manag. 2010, 51, 2869–2877. [Google Scholar] [CrossRef]

- Lucchi, E. Applications of the infrared thermography in the energy audit of buildings: A review. Renew. Sustain. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- Kabouri, A.; Khabbazi, A.; Youlal, H. Applied multiresolution analysis to infrared images for defects detection in materials. NDT E Int. 2017, 92, 38–49. [Google Scholar] [CrossRef]

- López, G.; Basterra, L.A.; Acuña, L. Infrared thermography for wood density estimation. Infrared Phys. Technol. 2018, 89, 242–246. [Google Scholar] [CrossRef]

- Milovanović, B.; Banjad Pečur, I.; Štirmer, N. The methodology for defect quantification in concrete using IR thermography. J. Civ. Eng. Manag. 2017, 23, 573–582. [Google Scholar] [CrossRef][Green Version]

- Barreira, E.; de Freitas, V.P. Evaluation of building materials using infrared thermography. Constr. Build. Mater. 2007, 21, 218–224. [Google Scholar] [CrossRef]

- Wong, C.W. Applications of Non-destructive Tests for Diagnosis of Heritage Buildings: Case Studies from Singapore and Malaysia. Built Herit. 2019, 3, 14–25. [Google Scholar] [CrossRef]

- Vidal, D.; Pitarma, R. Infrared thermography applied to tree health assessment: A review. Agriculture 2019, 9, 156. [Google Scholar] [CrossRef]

- Rodriáguez-Liñán, C.; Morales-Conde, M.J.; Rubio-de Hita, P.; Pérez-Gálvez, F. Analysis of the influence of density on infrared thermography and of the scope of this technique in the detection of internal defects in wood. Mater. Constr. 2012, 62, 99–113. [Google Scholar]

- Aoyagi, M.; Hiraguri, T.; Ueno, T. Nondestructive detection of cracks near the surface of wooden boards by dynamic heat dissipation. Wood Sci. Technol. 2014, 48, 773–786. [Google Scholar] [CrossRef]

- Chulkov, A.O.; Sfarra, S.; Saeed, N.; Peeters, J.; Ibarra-Castanedo, C.; Gargiulo, G.; Steenackers, G.; Maldague, X.P.V.; Omar, M.A.; Vavilov, V. Evaluating quality of marquetries by applying active IR thermography and advanced signal processing. J. Therm. Anal. Calorim. 2020, 1, 1–14. [Google Scholar] [CrossRef]

- Madruga, F.J.; Sfarra, S.; Real, E.; Gargiulo, G.; Conde, O.M.; López-Higuera, J.M. Complementary Use of Active Infrared Thermography and Optical Coherent Tomography in Non-destructive Testing Inspection of Ancient Marquetries. J. Nondestruct. Eval. 2020, 39, 1–8. [Google Scholar] [CrossRef]

- Pitarma, R.; Crisóstomo, J.; Pereira, L. Detection of wood damages using infrared thermography. Procedia Comput. Sci. 2019, 155, 480–486. [Google Scholar] [CrossRef]

- Chulkov, A.O.; Pradere, C.; Puiggali, J.R.; Batsale, J.C.; Vavilov, V.P. Estimating the humidity of wood by terahertz infrared thermography. Russ. J. Nondestruct. Test. 2016, 52, 753–757. [Google Scholar] [CrossRef]

- López, G.; Basterra, L.A.; Acuña, L.; Casado, M. Determination of the emissivity of wood for inspection by infrared thermography. J. Nondestruct. Eval. 2013, 32, 172–176. [Google Scholar] [CrossRef]

- Sfarra, S.; Ibarra-Castanedo, C.; Ambrosini, D.; Paoletti, D.; Bendada, A.; Maldague, X. Discovering the defects in paintings using non-destructive testing (NDT) techniques and passing through measurements of deformation. J. Nondestruct. Eval. 2014, 33, 358–383. [Google Scholar] [CrossRef]

- Arnold, R.; McKay, H. Environmental Guidelines for Paintings; Notes 10/4; Canadian Conservation Institute (CCI): Ottawa, ON, Canada, 2017. [Google Scholar]

- Conn, D. Protection from Light Damage; NEDCC Preservation Leaflets; Northeast Document Conservation Center: Andover, MA, USA, 2012. [Google Scholar]

- Michalski, S. Damage to museum objects by visible radiation (Light) and ultraviolet radiation (UV). In Lighting in Museums, Galleries and Historic Houses; Museums Association, UKIC, and Group of Designers and Interpreters for Museums: London, UK, 1987. [Google Scholar]

- Michalski, S. Preventive Conservation and Risks. Agent of Deterioration: Light, Ultraviolet and Infrared. Available online: https://www.canada.ca/en/conservation-institute/services/agents-deterioration/light.html#sources5 (accessed on 22 January 2021).

- Michalski, S. Preventive Conservation and Risks. Agent of Deterioration: Incorrect Temperature. Available online: https://www.canada.ca/en/conservation-institute/services/agents-deterioration/temperature.html#source5 (accessed on 22 January 2021).

- Feller, R.; Wilt, M. Evaluation of Cellulose Ethers for Conservation; The Getty Conservation Institute: Los Angeles, CA, USA, 1990; Volume 3, ISBN 0-89236-099-2. [Google Scholar]

- Kuckova, S.; Sandu, I.C.A.; Crhova, M.; Hynek, R.; Fogas, I.; Schafer, S. Protein identification and localization using mass spectrometry and staining tests in cross-sections of polychrome samples. J. Cult. Herit. 2013, 14, 31–37. [Google Scholar] [CrossRef]

- Ghezzi, L.; Duce, C.; Bernazzani, L.; Bramanti, E.; Colombini, M.P.; Tiné, M.R.; Bonaduce, I. Interactions between inorganic pigments and rabbit skin glue in reference paint reconstructions. J. Therm. Anal. Calorim. 2015, 122, 315–322. [Google Scholar] [CrossRef]

- Polski Komitet Normalizacyjny. PN-D-94021:2013-10: Tarcica konstrukcyjna Iglasta Sortowana Metodami Wytrzymałościowymi (Construction Timber Graded by Strength Methods); Polski Komitet Normalizacyjny: Warsaw, Poland, 2013. [Google Scholar]

- British Standards Institution. BS 4978:2017 Visual Strength Grading of Softwood. Specification; British Standards Institution: London, UK, 2017. [Google Scholar]

- Deutsches Institut für Normung. DIN 4074-1:2012 Strength Grading of Wood—Part 1: Coniferous Sawn Timber; Deutsches Institut für Normung: Berlin, Germany, 2012. [Google Scholar]

- Sikora, K.; Krzosek, S. Timber grading within the European Union—Irish and Polish example. Ann. Warsaw Univ. Life Sci. SGGW. For. Wood Technol. 2014, 86, 204–209. [Google Scholar]

- Ibarra-castanedo, C.; Maldague, X.P.V. Handbook of Technical Diagnostics; Springer: Berlin, Germany, 2013; ISBN 9783642258503. [Google Scholar]

- Electronic Temperature Instruments Emissivity Table. Available online: https://thermometer.co.uk/img/documents/emissivity_table.pdf (accessed on 15 January 2020).

- Nowak, T.; Jasieńko, J.; Hamrol-Bielecka, K. In situ assessment of structural timber using the resistance drilling method—Evaluation of usefulness. Constr. Build. Mater. 2016, 102, 403–415. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 338:2016-06: Structural Timber. Strength Classes; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Saporiti-Machado, J. Predicting the density of structural timber members in service. The combine use of wood cores and drill resistance data. Mater. Construcción 2014, 64, e029. [Google Scholar] [CrossRef]

- Cown, D.J. Comparison of the Pilodyn and torsiometer methods for the rapid assessment of wood density in living trees. N. Zeal. J. For. Sci. 1978, 8, 384–391. [Google Scholar]

- Avdelidis, N.P.; Moropoulou, A. Emissivity considerations in building thermography. Energy Build. 2003, 35, 663–667. [Google Scholar] [CrossRef]

- Hiraoka, N. Method, Apparatus and Program Product for Searching Knots in Wood. U.S. Patent 7,778,458, 17 August 2010. [Google Scholar]

- Hill, M.; Faupel, B. A Robotized Non-destructive Quality Device for the Inspection of Glue Joints by Active Thermography. J. Nondestruct. Eval. 2020, 39, 1–10. [Google Scholar] [CrossRef]

- Wu, H.Y.; Rubinstein, M.; Shih, E.; Guttag, J.; Durand, F.; Freeman, W. Eulerian video magnification for revealing subtle changes in the world. ACM Trans. Graph. 2012, 31. [Google Scholar] [CrossRef]

- Qiu, Q. Automated defect detection in FRP-bonded structures by Eulerian video magnification and adaptive background mixture model. Autom. Constr. 2020, 116, 103244. [Google Scholar] [CrossRef]

| Surface | A | B | C | D |

|---|---|---|---|---|

| Primer | None | Construction Putty | Glue–Chalk Plaster | None |

| Paint coating | Alkyd paint | Protein binder with pigment | ||

| Klucel with pigment | ||||

| Acrylic paint | ||||

| Oil paint | ||||

| Wood Species | Type of Test | Total KAR | Margin KAR | Grading Strength Class | Strength Class |

|---|---|---|---|---|---|

| Fir | Macroscopic | 0.11 | 0.12 | KW | C22 |

| Laboratory dryer | 0.19 | 0.18 | KW | C22 | |

| Air heater | 0.16 | 0.13 | KW | C22 | |

| Halogen lamps | 0.17 | 0.15 | KW | C22 | |

| Pine | Macroscopic | 0.19 | 0.23 | KW | C35 |

| Laboratory dryer | 0.26 | 0.25 | KS | C24 | |

| Air heater | 0.25 | 0.25 | KW | C35 | |

| Halogen lamps | 0.28 | 0.31 | KG | C20 | |

| Spruce | Macroscopic | 0.17 | 0.35 | KS | C24 |

| Laboratory dryer | 0.25 | 0.48 | KS | C24 | |

| Air heater | 0.19 | 0.41 | KS | C24 | |

| Halogen lamps | 0.21 | 0.38 | KS | C24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kucharska, M.; Jaskowska-Lemańska, J. Active Thermography in Diagnostics of Timber Elements Covered with Polychrome. Materials 2021, 14, 1134. https://doi.org/10.3390/ma14051134

Kucharska M, Jaskowska-Lemańska J. Active Thermography in Diagnostics of Timber Elements Covered with Polychrome. Materials. 2021; 14(5):1134. https://doi.org/10.3390/ma14051134

Chicago/Turabian StyleKucharska, Milena, and Justyna Jaskowska-Lemańska. 2021. "Active Thermography in Diagnostics of Timber Elements Covered with Polychrome" Materials 14, no. 5: 1134. https://doi.org/10.3390/ma14051134

APA StyleKucharska, M., & Jaskowska-Lemańska, J. (2021). Active Thermography in Diagnostics of Timber Elements Covered with Polychrome. Materials, 14(5), 1134. https://doi.org/10.3390/ma14051134