Comparison of Transmission Measurement Methods of Elastic Waves in Phononic Band Gap Materials

Abstract

1. Introduction

2. Materials and Methods

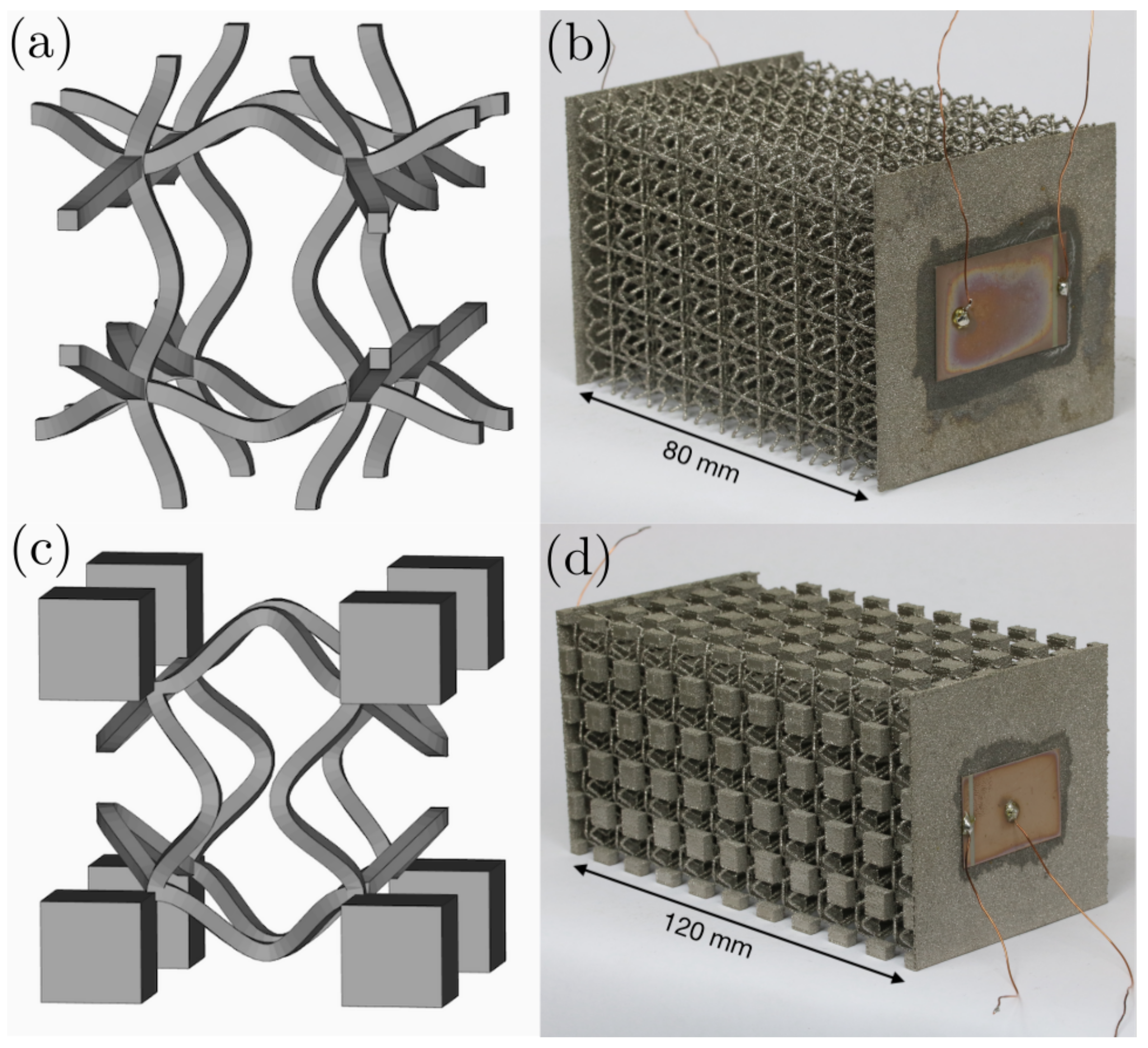

2.1. Phononic Band Gap Material

2.1.1. Sample Manufacturing and Preparation

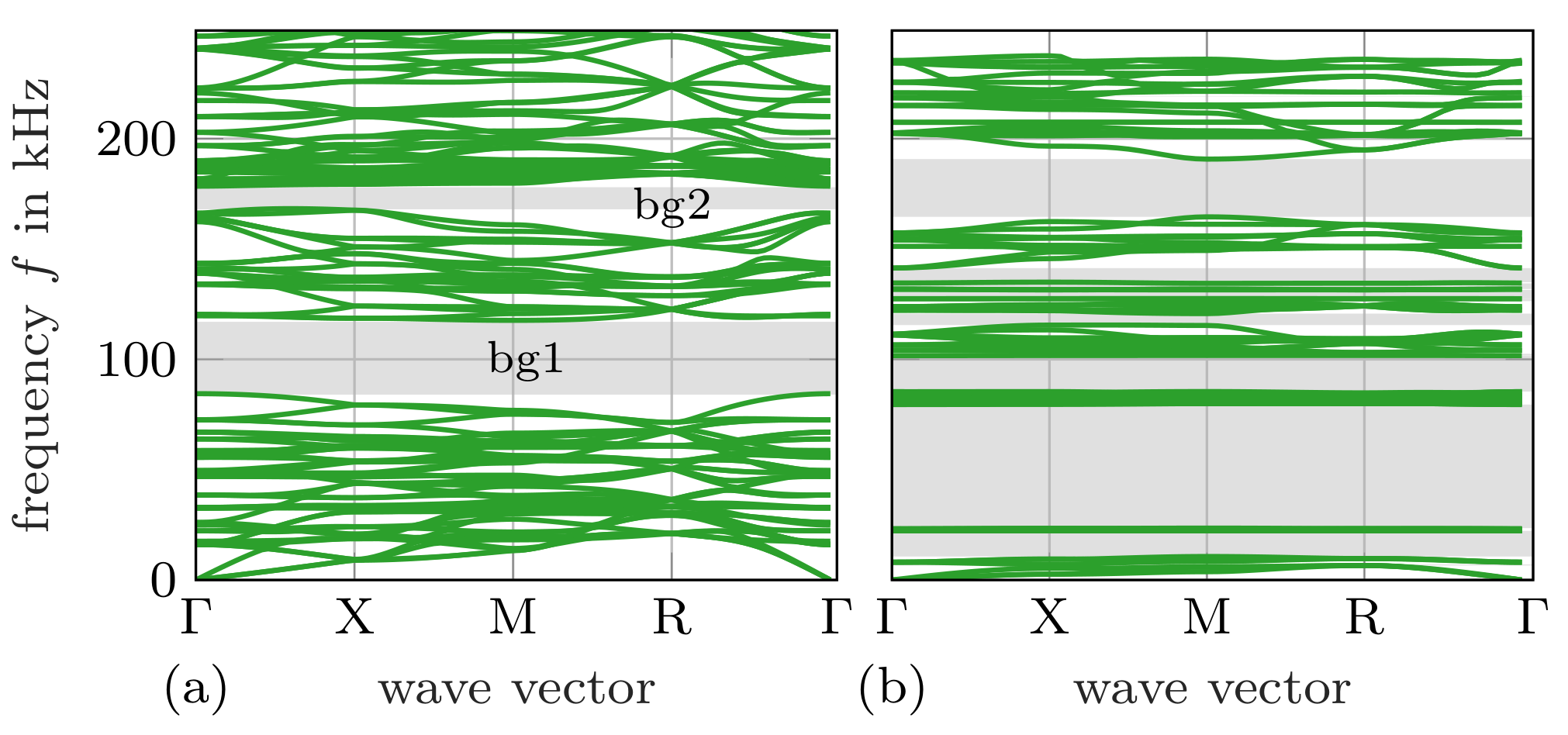

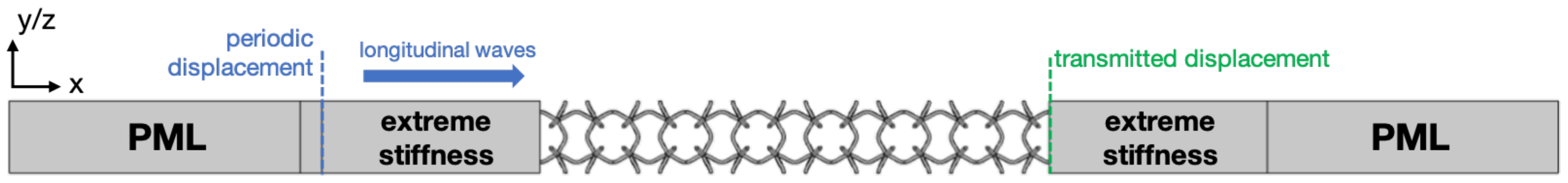

2.1.2. Numerical Evaluation

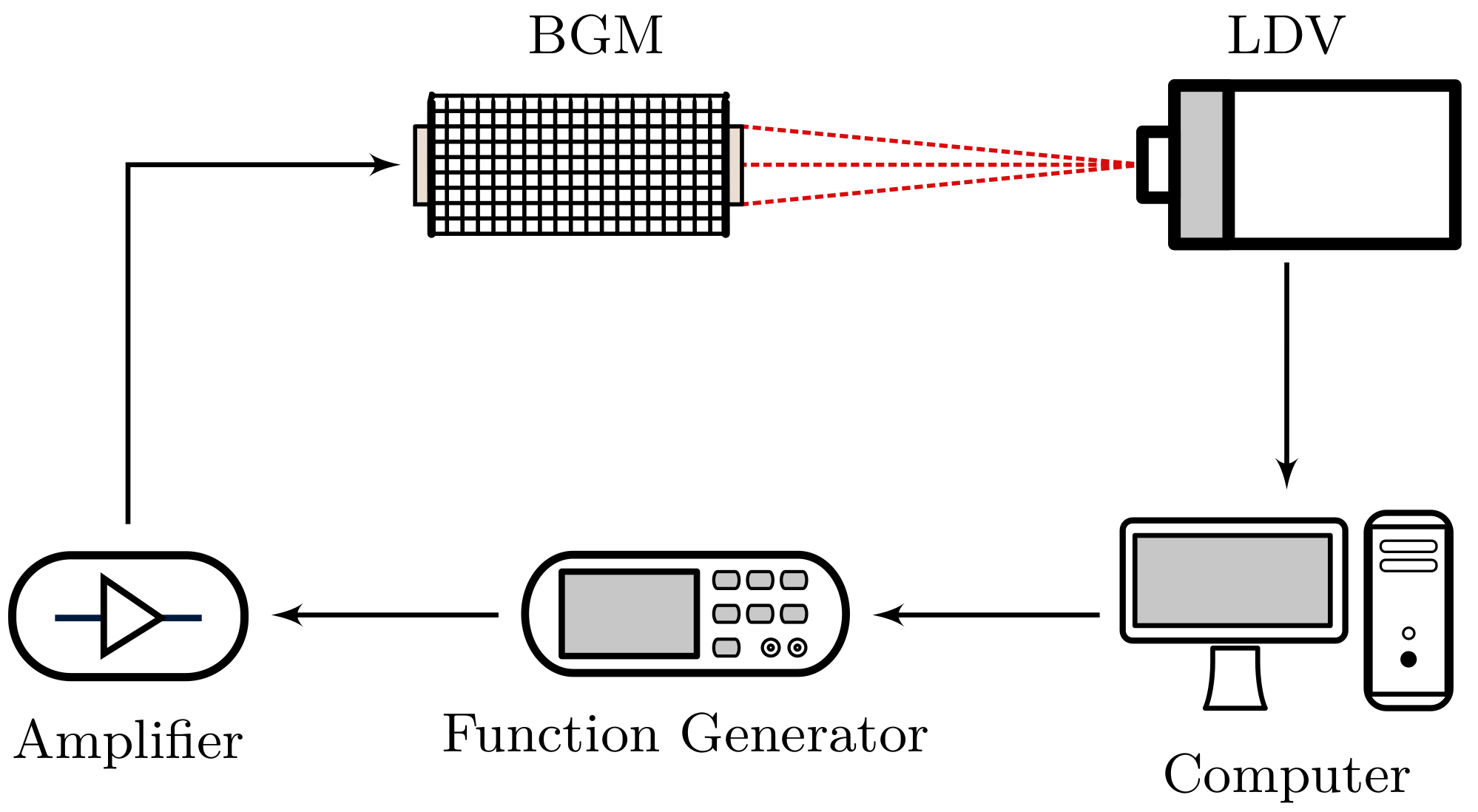

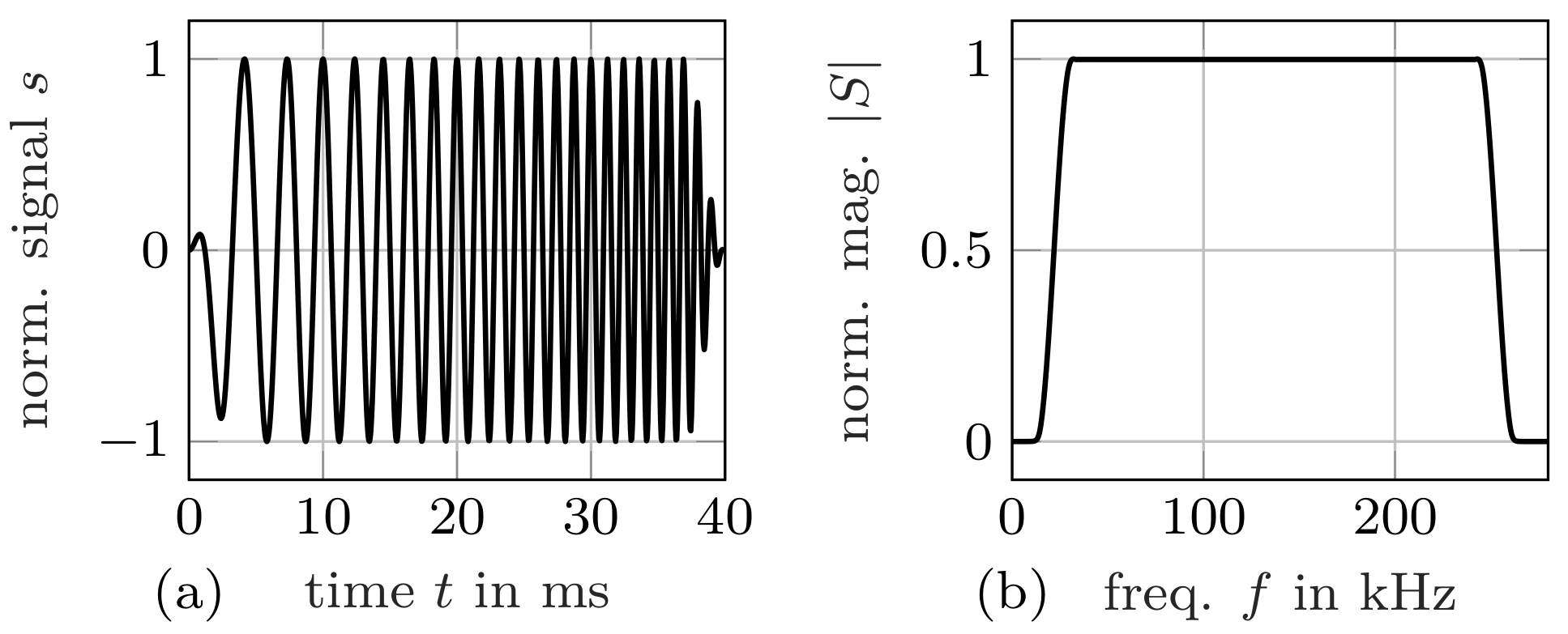

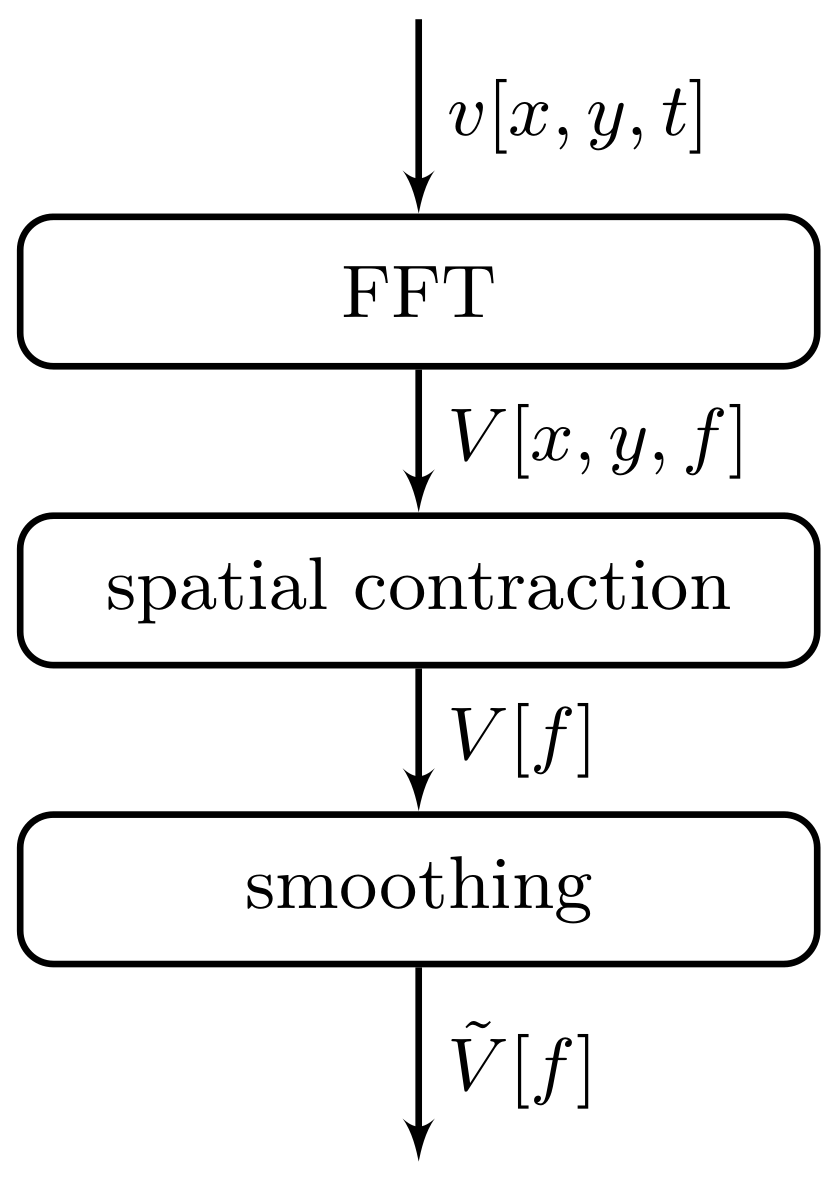

2.2. Measurement Setup and Evaluation

2.2.1. Piezoelectric Transducers

2.2.2. Laser Doppler Vibrometry

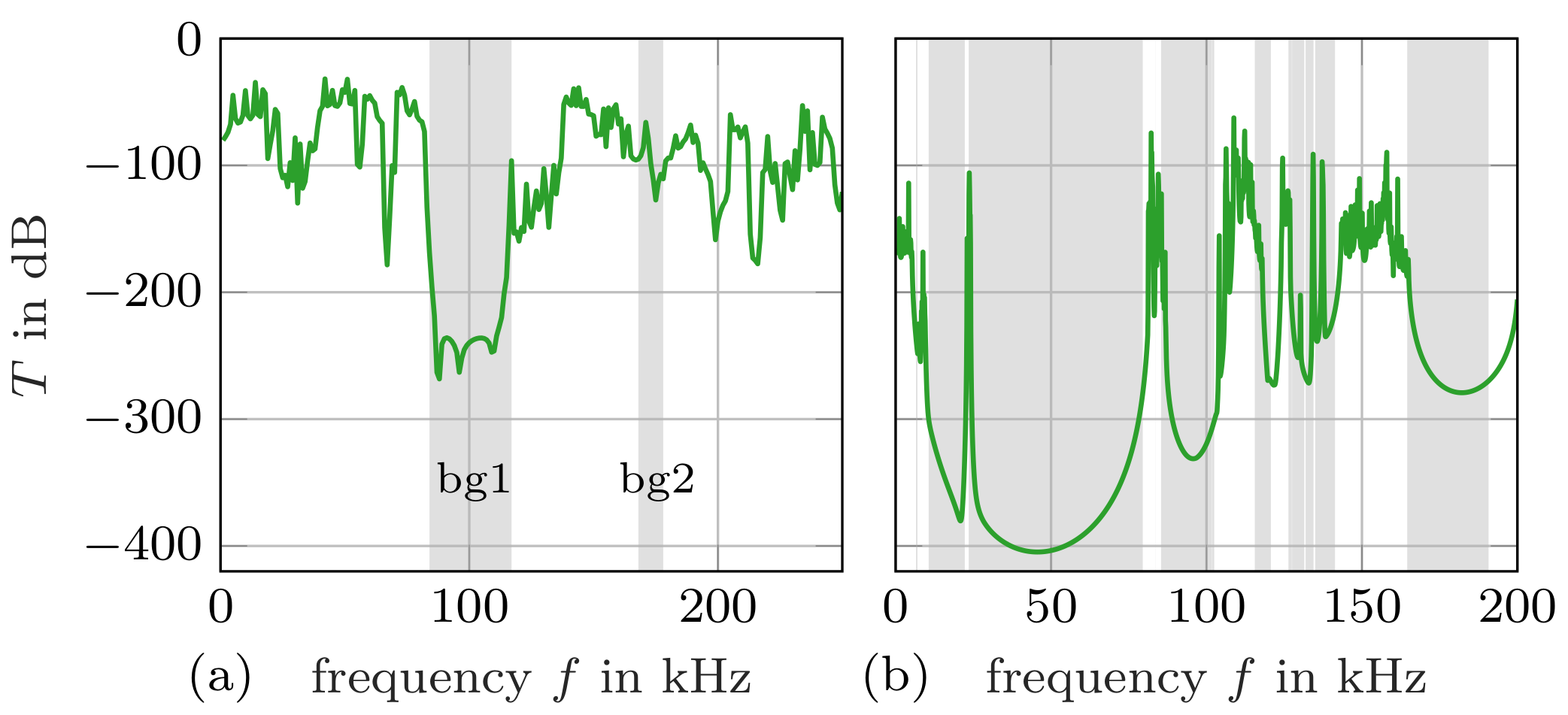

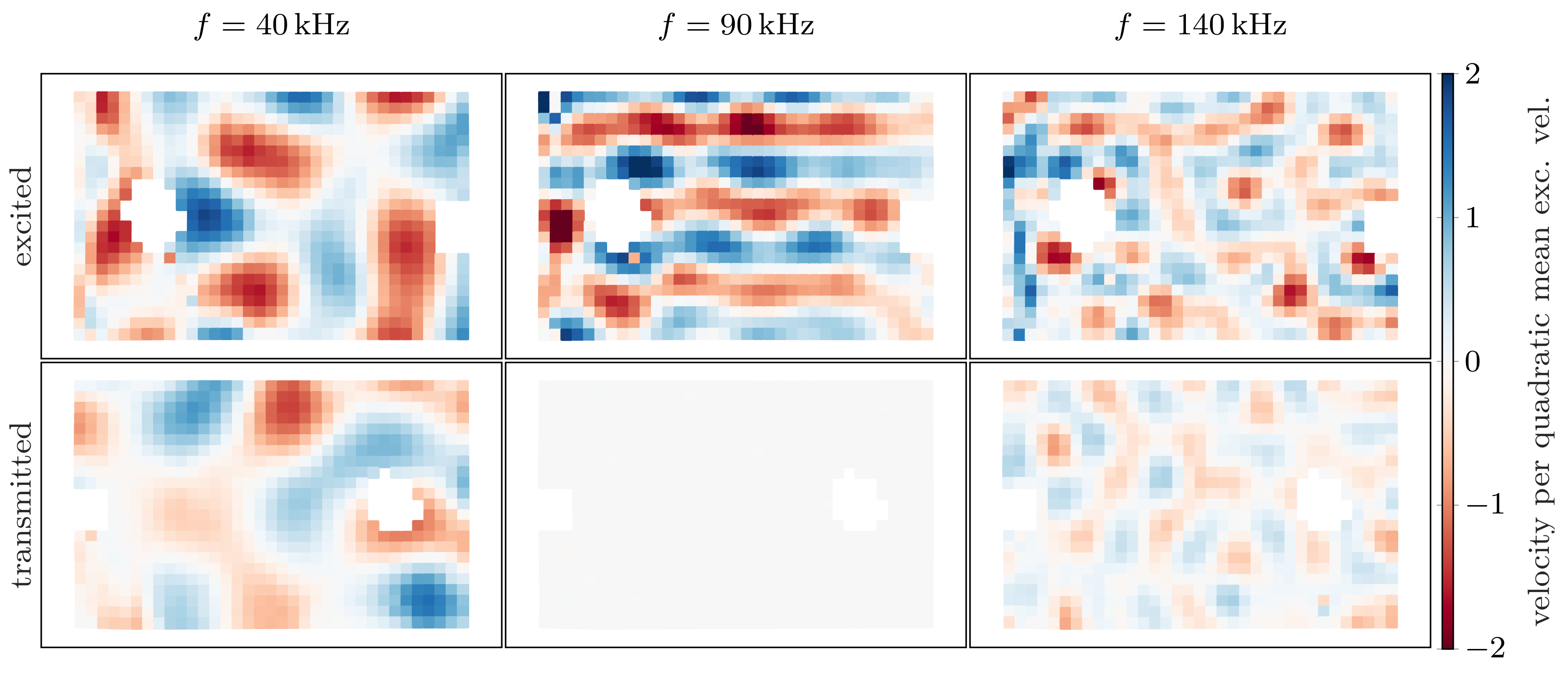

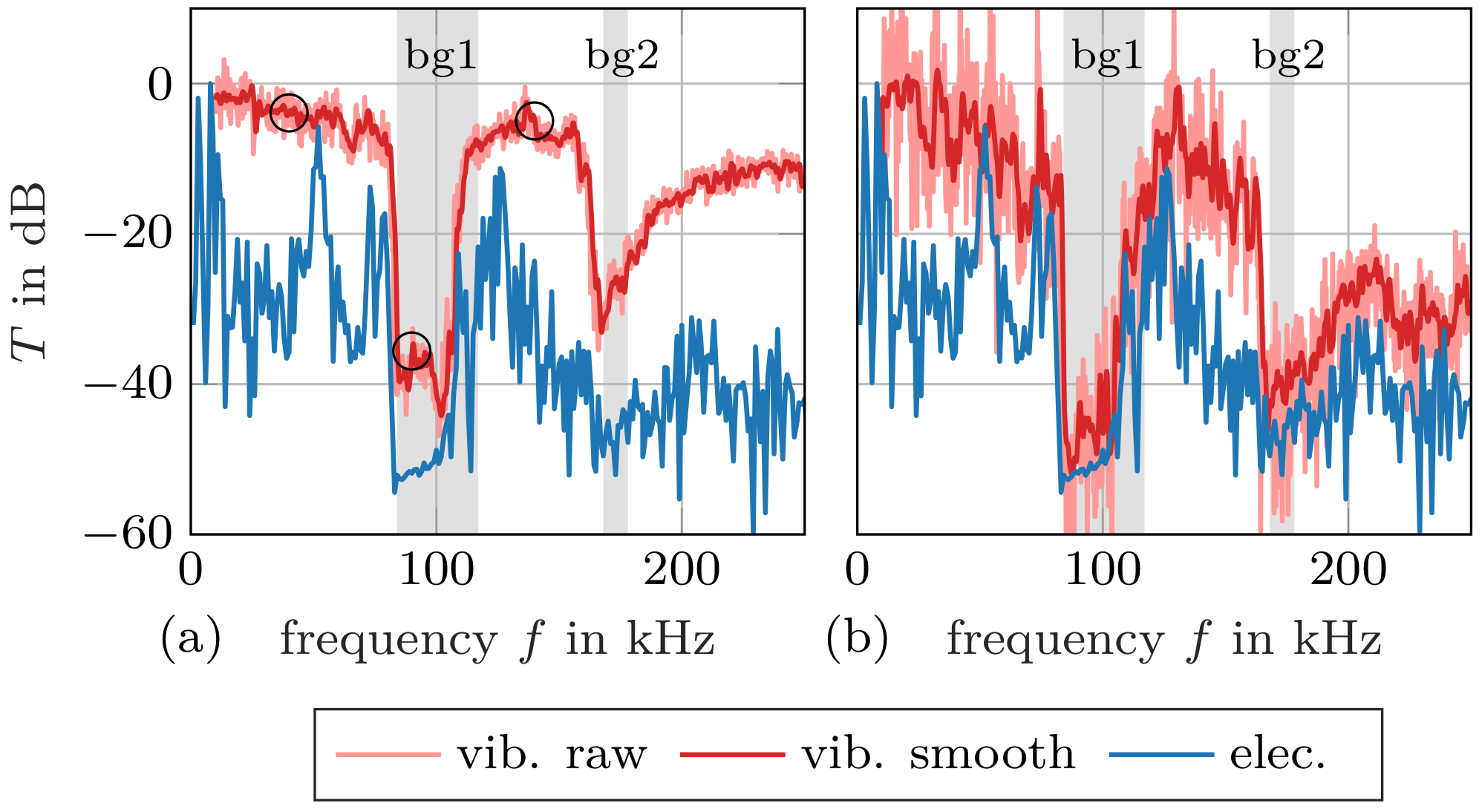

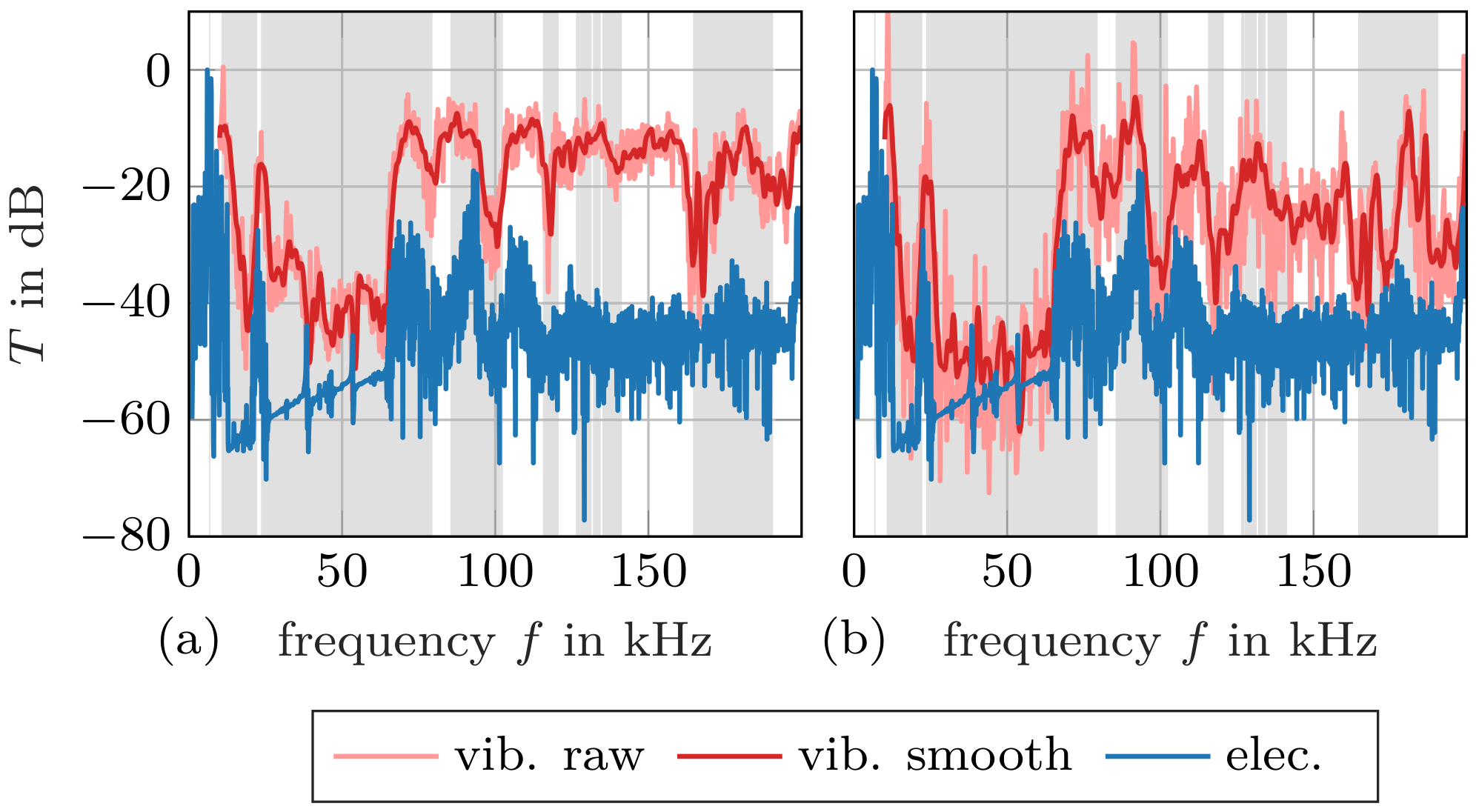

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PBG | phononic band gap |

| LDV | laser Doppler vibrometry |

| CT | computed tomography |

| PML | perfectly matched layer |

References

- Veselago, V.G. The electrodynamics of substances with simultaneously negative values of ϵ and μ. Sov. Phys. Uspekhi 1968, 10, 509–514. [Google Scholar] [CrossRef]

- Sigalas, M.M.; Economou, E.N. Elastic and acoustic wave band structure. J. Sound Vib. 1992, 158, 377–382. [Google Scholar] [CrossRef]

- Kadic, M.; Milton, G.W.; van Hecke, M.; Wegener, M. 3D metamaterials. Nat. Rev. Phys. 2019, 1, 198–210. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. Perspective of additive manufacturing for metamaterials development. Smart Mater. Struct. 2019, 28, 093001. [Google Scholar] [CrossRef]

- Askari, M.; Hutchins, D.A.; Thomas, P.J.; Astolfi, L.; Watson, R.L.; Abdi, M.; Ricci, M.; Laureti, S.; Nie, L.; Freear, S.; et al. Additive manufacturing of metamaterials: A review. Addit. Manuf. 2020, 36, 101562. [Google Scholar] [CrossRef]

- Hussein, M.I.; Leamy, M.J.; Ruzzene, M. Dynamics of Phononic Materials and Structures: Historical Origins, Recent Progress, and Future Outlook. Appl. Mech. Rev. 2014, 66, 040802. [Google Scholar] [CrossRef]

- Ma, G.; Sheng, P. Acoustic metamaterials: From local resonances to broad horizons. Sci. Adv. 2016, 2, e1501595. [Google Scholar] [CrossRef] [PubMed]

- Ge, H.; Yang, M.; Ma, C.; Lu, M.H.; Chen, Y.F.; Fang, N.; Sheng, P. Breaking the barriers: Advances in acoustic functional materials. Natl. Sci. Rev. 2017, 5, 159–182. [Google Scholar] [CrossRef]

- Zangeneh-Nejad, F.; Fleury, R. Active times for acoustic metamaterials. Rev. Phys. 2019, 4, 100031. [Google Scholar] [CrossRef]

- Shan, S.; Kang, S.H.; Wang, P.; Qu, C.; Shian, S.; Chen, E.R.; Bertoldi, K. Harnessing Multiple Folding Mechanisms in Soft Periodic Structures for Tunable Control of Elastic Waves. Adv. Funct. Mater. 2014, 24, 4935–4942. [Google Scholar] [CrossRef]

- Ba’ba’a, H.A.; Attarzadeh, M.A.; Nouh, M. Experimental Evaluation of Structural Intensity in Two-Dimensional Plate-Type Locally Resonant Elastic Metamaterials. J. Appl. Mech. 2018, 85. [Google Scholar] [CrossRef]

- Chen, Y.; Li, T.; Scarpa, F.; Wang, L. Lattice Metamaterials with Mechanically Tunable Poisson’s Ratio for Vibration Control. Phys. Rev. Appl. 2017, 7. [Google Scholar] [CrossRef]

- McGee, O.; Jiang, H.; Qian, F.; Jia, Z.; Wang, L.; Meng, H.; Chronopoulos, D.; Chen, Y.; Zuo, L. 3D printed architected hollow sphere foams with low-frequency phononic band gaps. Addit. Manuf. 2019, 30, 100842. [Google Scholar] [CrossRef]

- D’Alessandro, L.; Zega, V.; Ardito, R.; Corigliano, A. 3D auxetic single material periodic structure with ultra-wide tunable bandgap. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef] [PubMed]

- D’Alessandro, L.; Ardito, R.; Braghin, F.; Corigliano, A. Low frequency 3D ultra-wide vibration attenuation via elastic metamaterial. Sci. Rep. 2019, 9, 8039. [Google Scholar] [CrossRef]

- Oh, J.H.; Kwon, Y.E.; Lee, H.J.; Kim, Y.Y. Elastic metamaterials for independent realization of negativity in density and stiffness. Sci. Rep. 2016, 6, 23630. [Google Scholar] [CrossRef]

- Lee, H.; Oh, J.H.; Seung, H.M.; Cho, S.H.; Kim, Y.Y. Extreme stiffness hyperbolic elastic metamaterial for total transmission subwavelength imaging. Sci. Rep. 2016, 6, 24026. [Google Scholar] [CrossRef] [PubMed]

- Trainiti, G.; Rimoli, J.J.; Ruzzene, M. Optical evaluation of the wave filtering properties of graded undulated lattices. J. Appl. Phys. 2018, 123, 091706. [Google Scholar] [CrossRef]

- Warmuth, F.; Wormser, M.; Körner, C. Single phase 3D phononic band gap material. Sci. Rep. 2017, 7, 3843. [Google Scholar] [CrossRef] [PubMed]

- Olsson, R.H., III; El-Kady, I. Microfabricated phononic crystal devices and applications. Meas. Sci. Technol. 2009, 20, 012002. [Google Scholar] [CrossRef]

- Bilal, O.R.; Ballagi, D.; Daraio, C. Architected Lattices for Simultaneous Broadband Attenuation of Airborne Sound and Mechanical Vibrations in All Directions. Phys. Rev. Appl. 2018, 10, 054060. [Google Scholar] [CrossRef]

- Lucklum, F.; Vellekoop, M.J. Realization of Complex 3-D Phononic Crystals With Wide Complete Acoustic Band Gaps. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2016, 63, 796–797. [Google Scholar] [CrossRef]

- Rupitsch, S.J. Piezoelectric Sensors and Actuators-Fundamentals and Applications, 1st ed.; Topics in Mining, Metallurgy and Materials Engineering; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Elmadih, W.; Chronopoulos, D.; Syam, W.P.; Maskery, I.; Meng, H.; Leach, R.K. Three-dimensional resonating metamaterials for low-frequency vibration attenuation. Sci. Rep. 2019, 9, 11503. [Google Scholar] [CrossRef]

- Wormser, M.; Wein, F.; Stingl, M.; Körner, C. Design and Additive Manufacturing of 3D Phononic Band Gap Structures Based on Gradient Based Optimization. Materials 2017, 10, 1125. [Google Scholar] [CrossRef]

- Wormser, M.; Warmuth, F.; Körner, C. Evolution of full phononic band gaps in periodic cellular structures. Appl. Phys. A 2017, 123, 661. [Google Scholar] [CrossRef]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef]

- Warmuth, F.; Körner, C. Phononic Band Gaps in 2D Quadratic and 3D Cubic Cellular Structures. Materials 2015, 8, 8327–8337. [Google Scholar] [CrossRef]

- Suard, M.; Martin, G.; Lhuissier, P.; Dendievel, R.; Vignat, F.; Blandin, J.J.; Villeneuve, F. Mechanical equivalent diameter of single struts for the stiffness prediction of lattice structures produced by Electron Beam Melting. Addit. Manuf. 2015, 8, 124–131. [Google Scholar] [CrossRef]

- Setyawan, W.; Curtarolo, S. High-throughput electronic band structure calculations: Challenges and tools. Comput. Mater. Sci. 2010, 49, 299–312. [Google Scholar] [CrossRef]

- Kiefer, D.A.; Fink, M.; Rupitsch, S.J. Simultaneous Ultrasonic Measurement of Thickness and Speed of Sound in Elastic Plates Using Coded Excitation Signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2017, 64, 1744–1757. [Google Scholar] [CrossRef]

- Lanza di Scalea, F.; Matt, H.; Bartoli, I. The response of rectangular piezoelectric sensors to Rayleigh and Lamb ultrasonic waves. J. Acoust. Soc. Am. 2007, 121, 175–187. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wormser, M.; Kiefer, D.A.; Rupitsch, S.J.; Körner, C. Comparison of Transmission Measurement Methods of Elastic Waves in Phononic Band Gap Materials. Materials 2021, 14, 1133. https://doi.org/10.3390/ma14051133

Wormser M, Kiefer DA, Rupitsch SJ, Körner C. Comparison of Transmission Measurement Methods of Elastic Waves in Phononic Band Gap Materials. Materials. 2021; 14(5):1133. https://doi.org/10.3390/ma14051133

Chicago/Turabian StyleWormser, Maximilian, Daniel A. Kiefer, Stefan J. Rupitsch, and Carolin Körner. 2021. "Comparison of Transmission Measurement Methods of Elastic Waves in Phononic Band Gap Materials" Materials 14, no. 5: 1133. https://doi.org/10.3390/ma14051133

APA StyleWormser, M., Kiefer, D. A., Rupitsch, S. J., & Körner, C. (2021). Comparison of Transmission Measurement Methods of Elastic Waves in Phononic Band Gap Materials. Materials, 14(5), 1133. https://doi.org/10.3390/ma14051133