Characterization of Graphite Oxide and Reduced Graphene Oxide Obtained from Different Graphite Precursors and Oxidized by Different Methods Using Raman Spectroscopy Statistical Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. The Selection of Graphite for the Preparation of Graphite Oxide and Reduced Graphene Oxide

2.2. Methods of Characterization for the Obtained GO and rGO

2.3. Data Analysis—Chemometric Approach

3. Results

4. Discussion

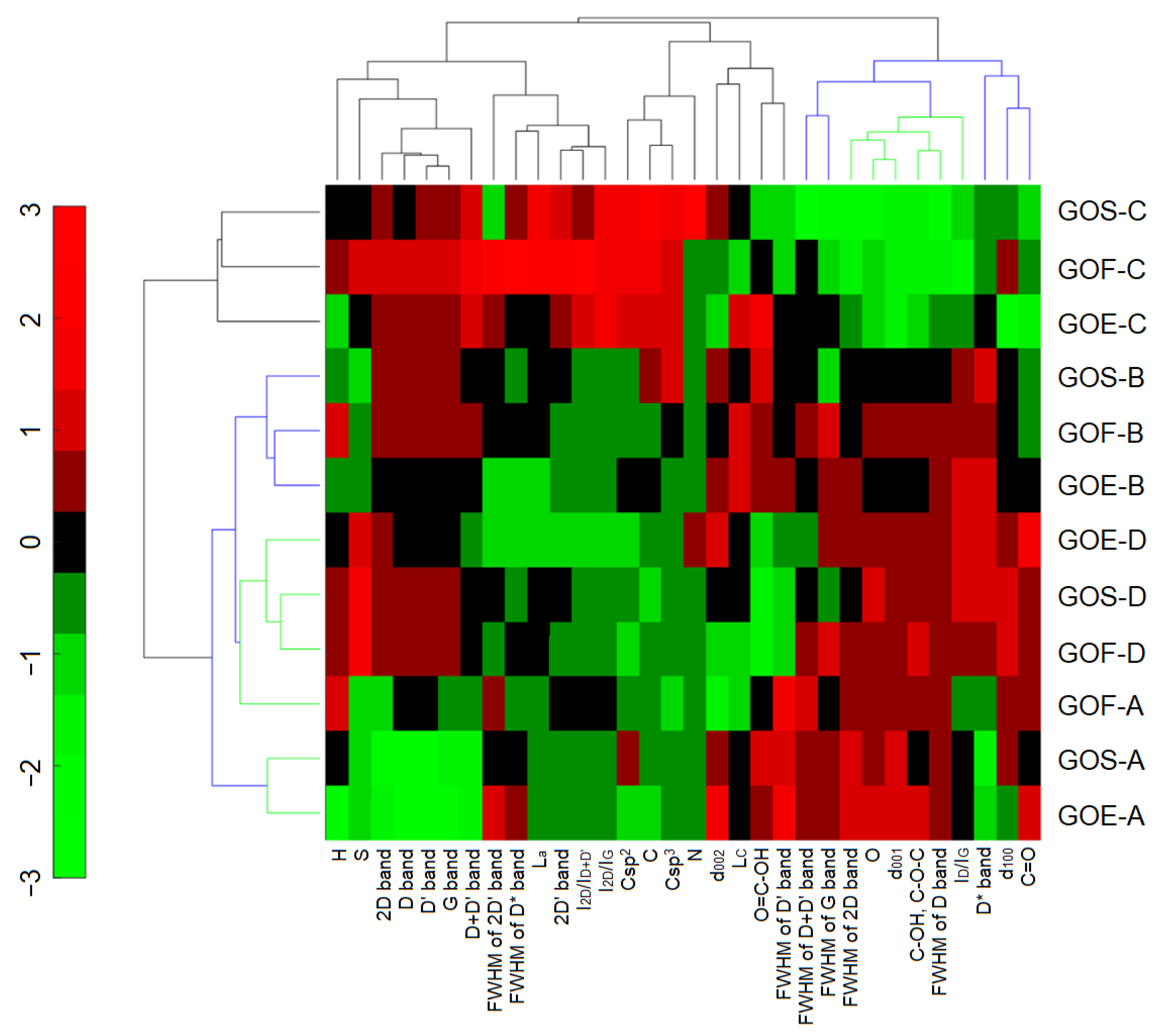

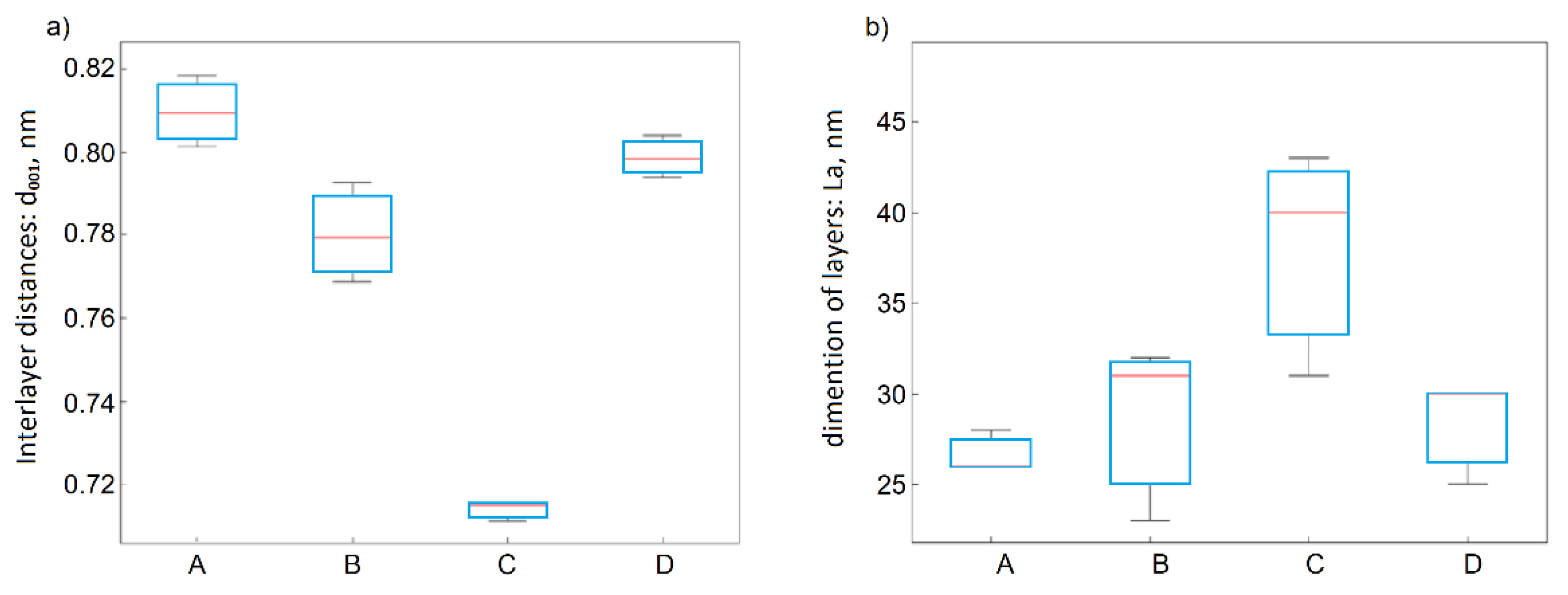

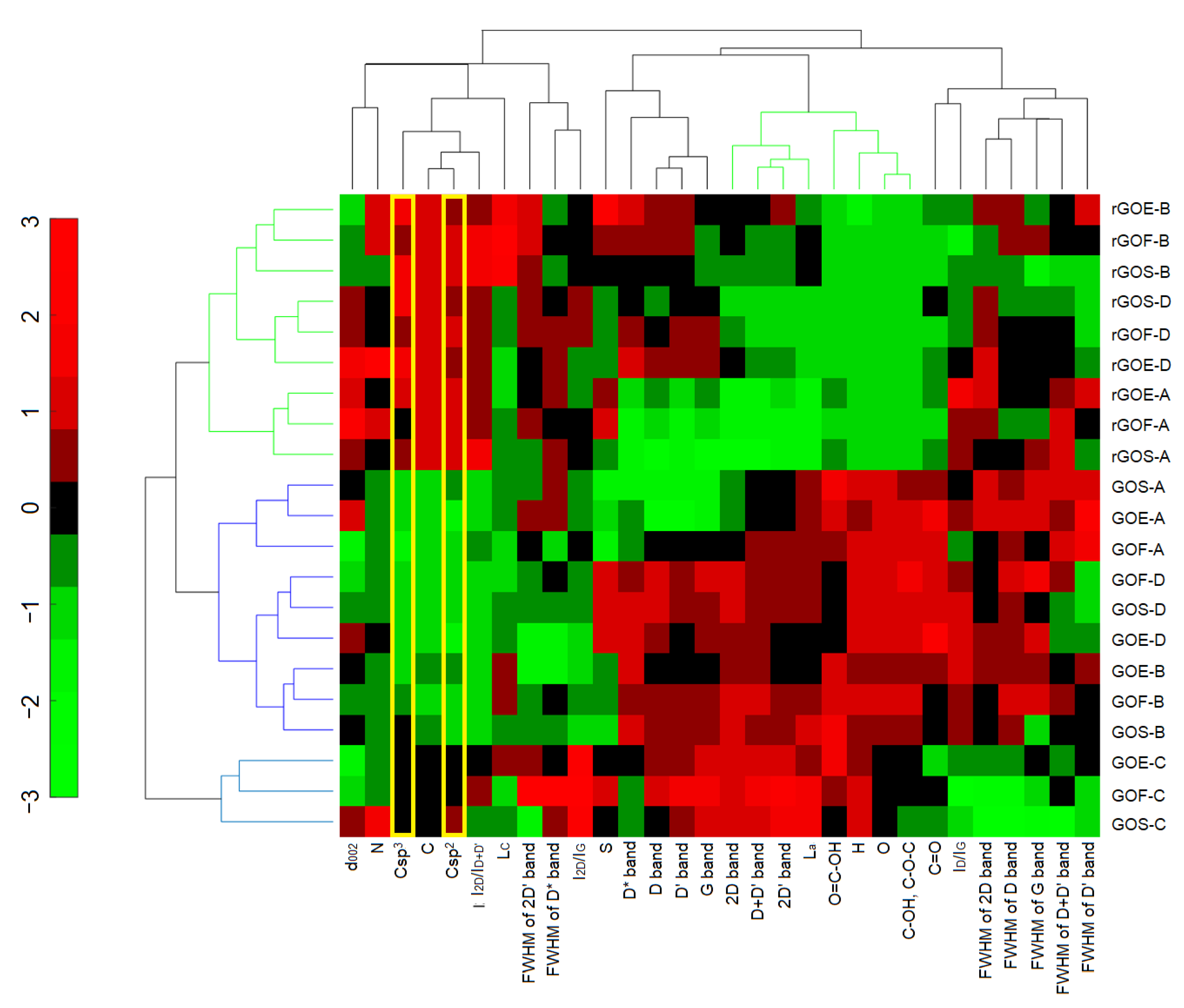

- Based on the HCA method, it was determined that the graphite oxides with high and homogeneous oxygen contents, interlayer distances d001, and epoxy and hydroxyl group contents were obtained using methods A and D;

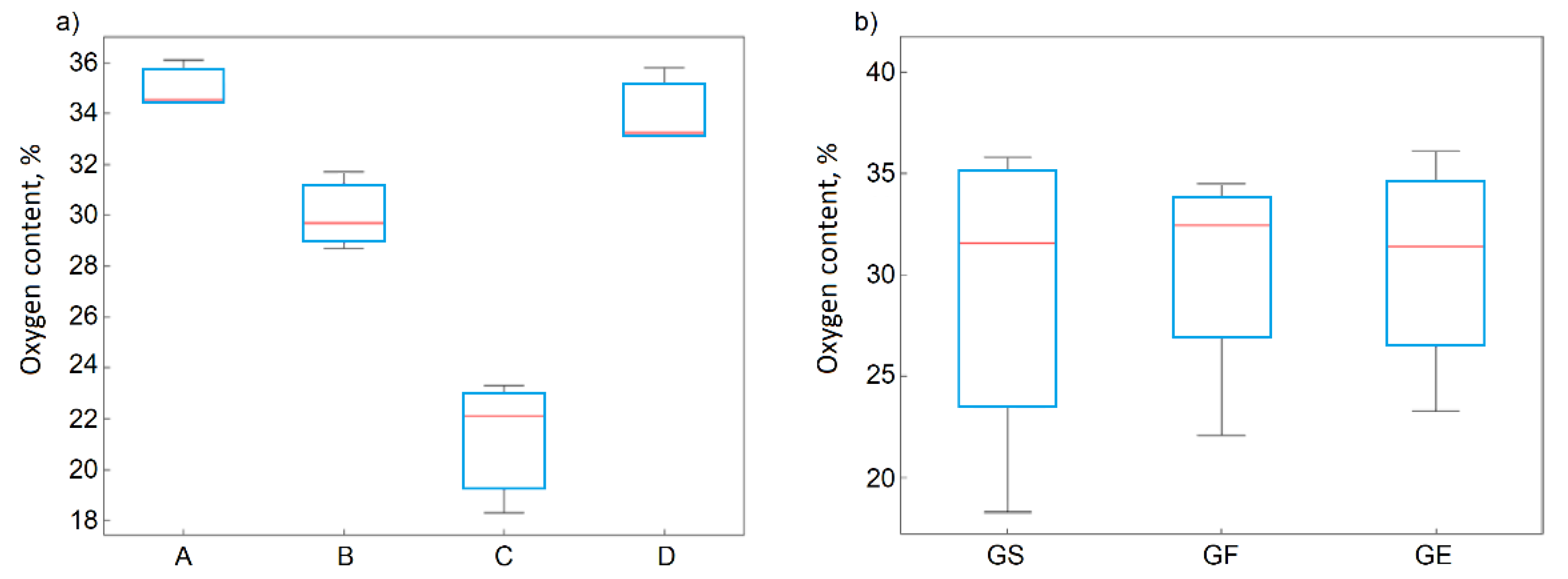

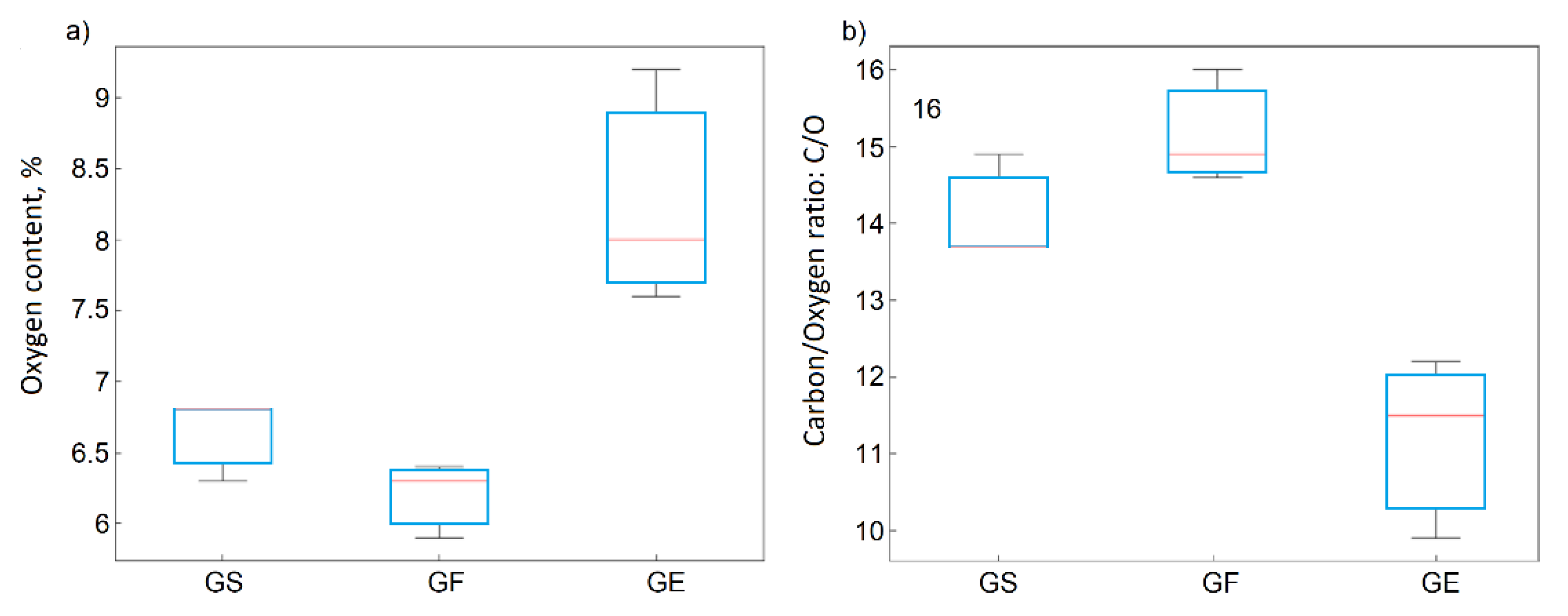

- Statistical analysis confirmed that the oxygen content in the graphite oxides was influenced by the oxidation method, while the graphite precursor had no significant influence on this;

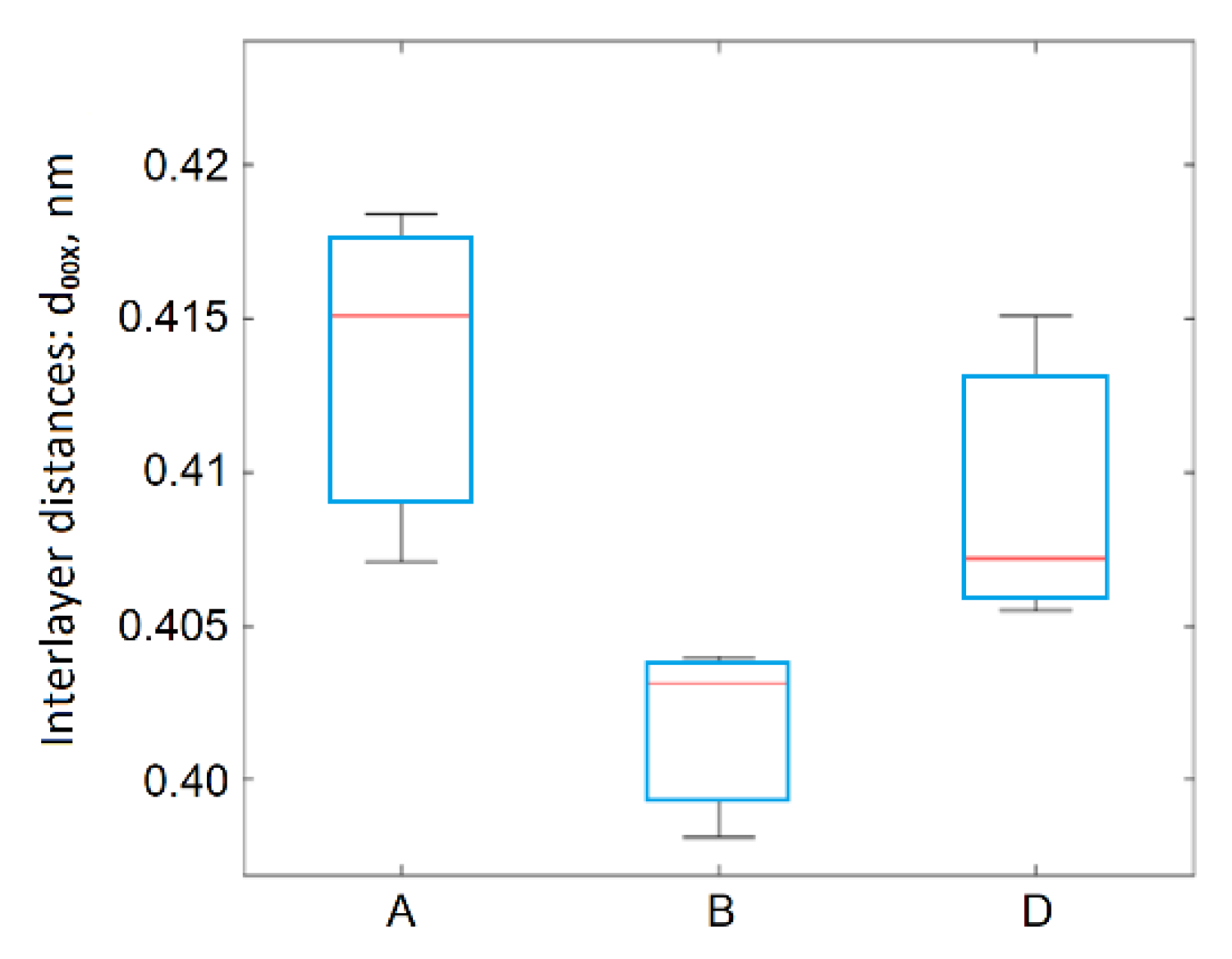

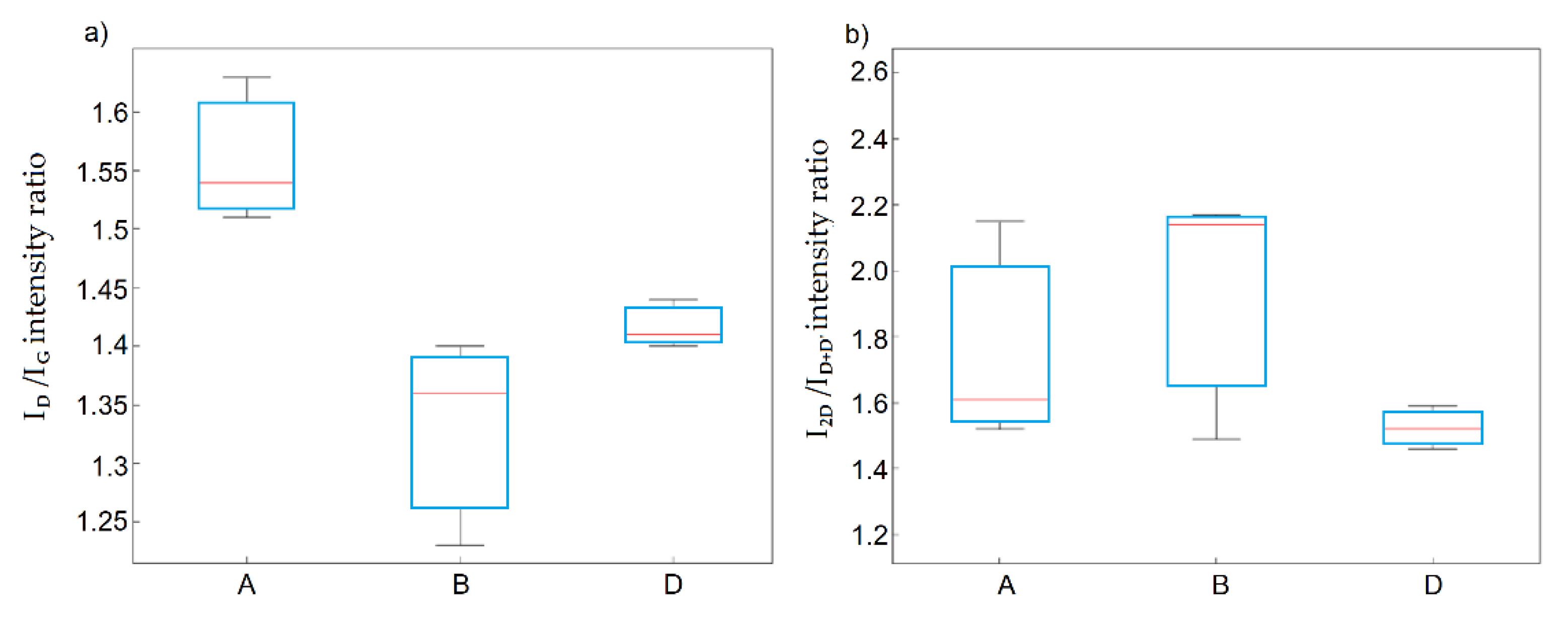

- The ANOVA confirmed that the GOs obtained using method A contained the greatest interlayer distances d001 and the smallest dimensions for the La graphite layers;

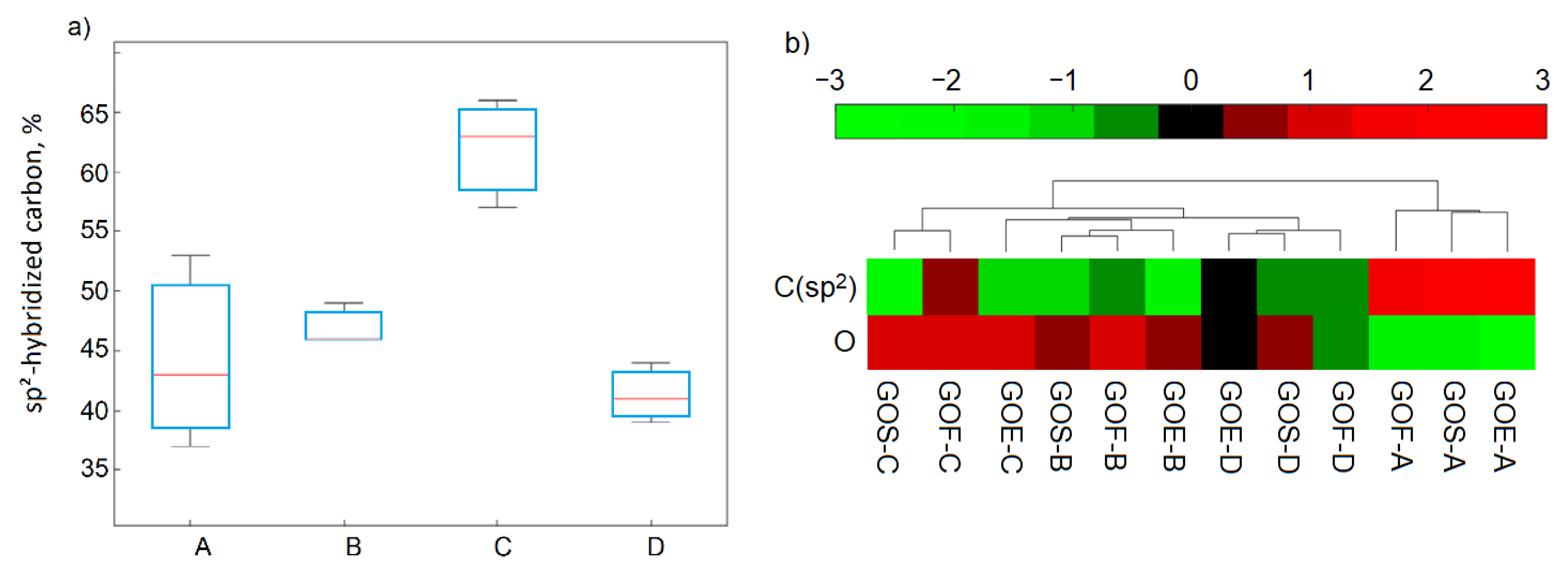

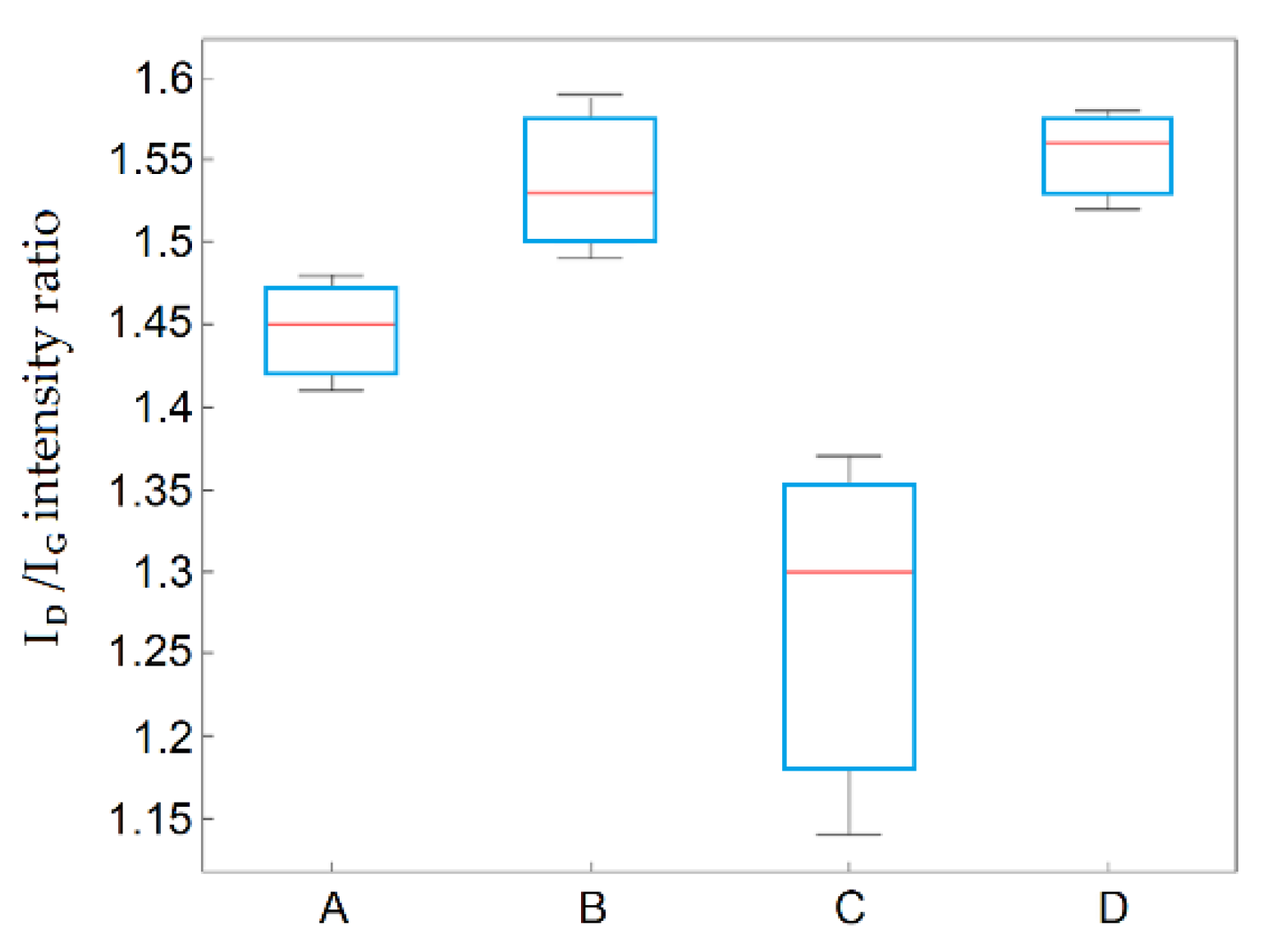

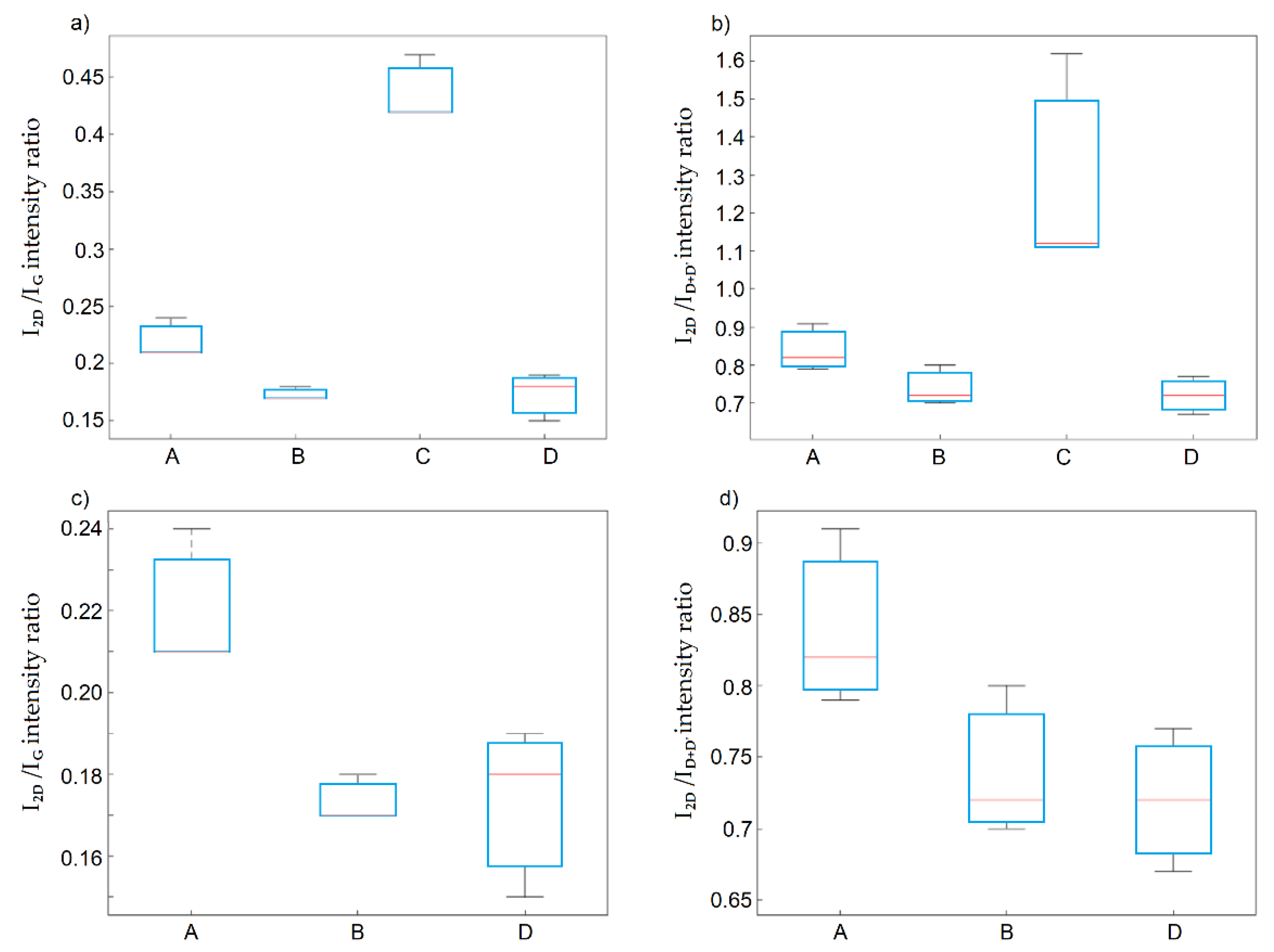

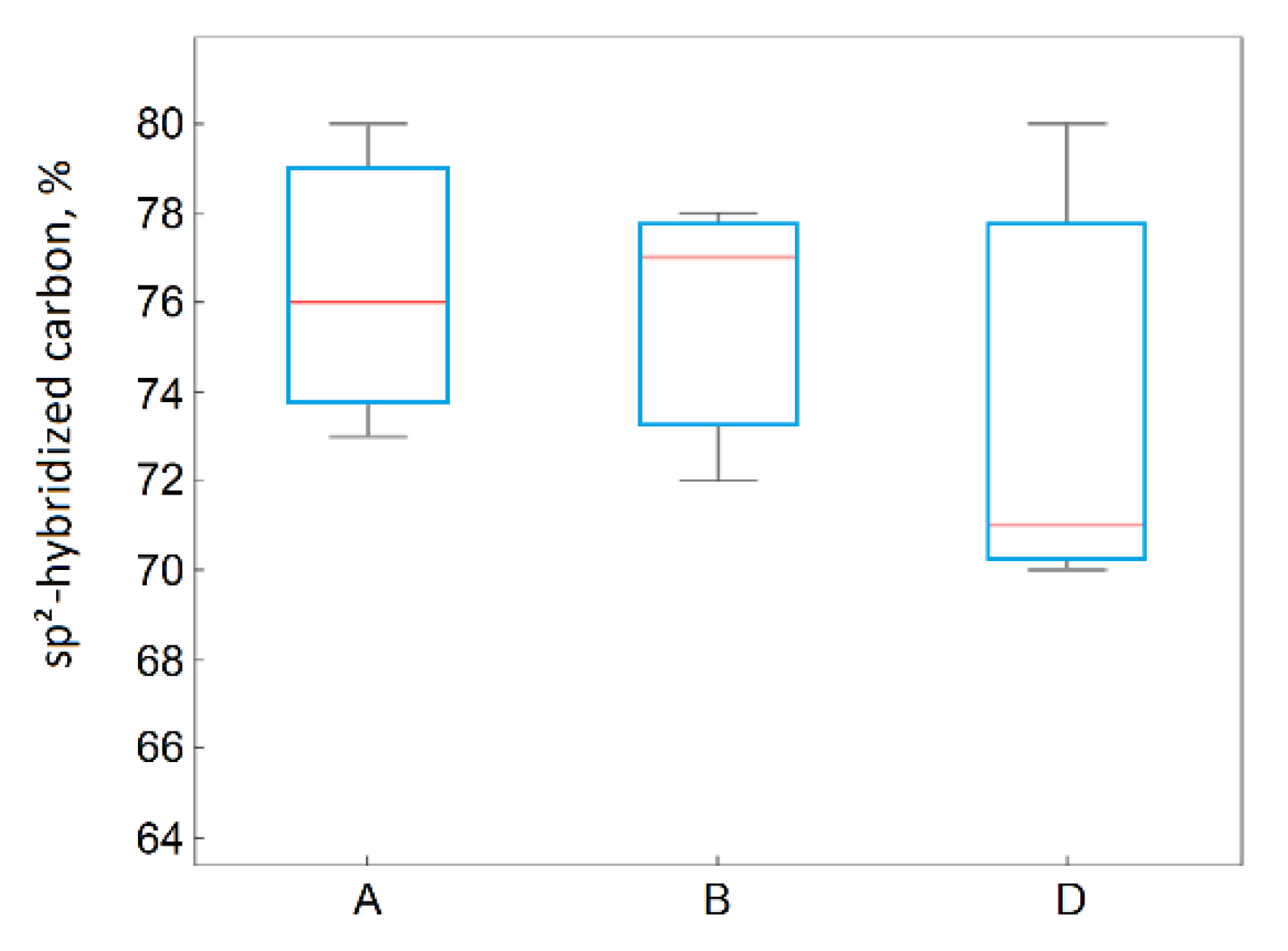

- The ANOVA method showed the statistical significance of the influence of the graphite oxidation method on the degree of oxidation of GO. Method C, characterized by having the mildest oxidation conditions, resulted in GO samples with the least disturbed structure, and thus with the largest share of bonds with sp2 hybridization.

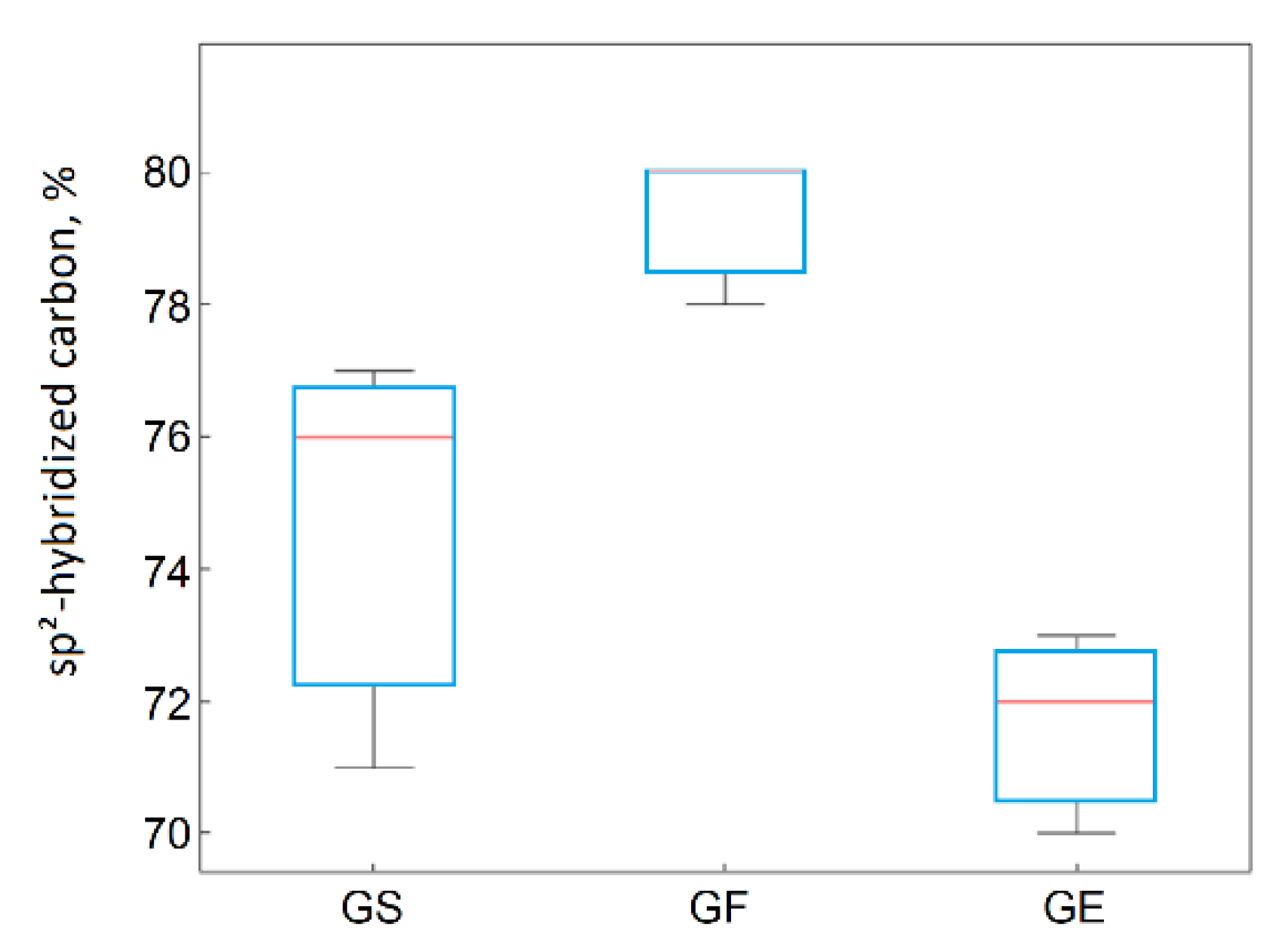

- The used cluster analysis showed the most important variables, which characterize the degree of oxidation. It was confirmed with a high probability that an increase in the C(sp2) share in rGO indicates a partial reconstruction of the graphite structure;

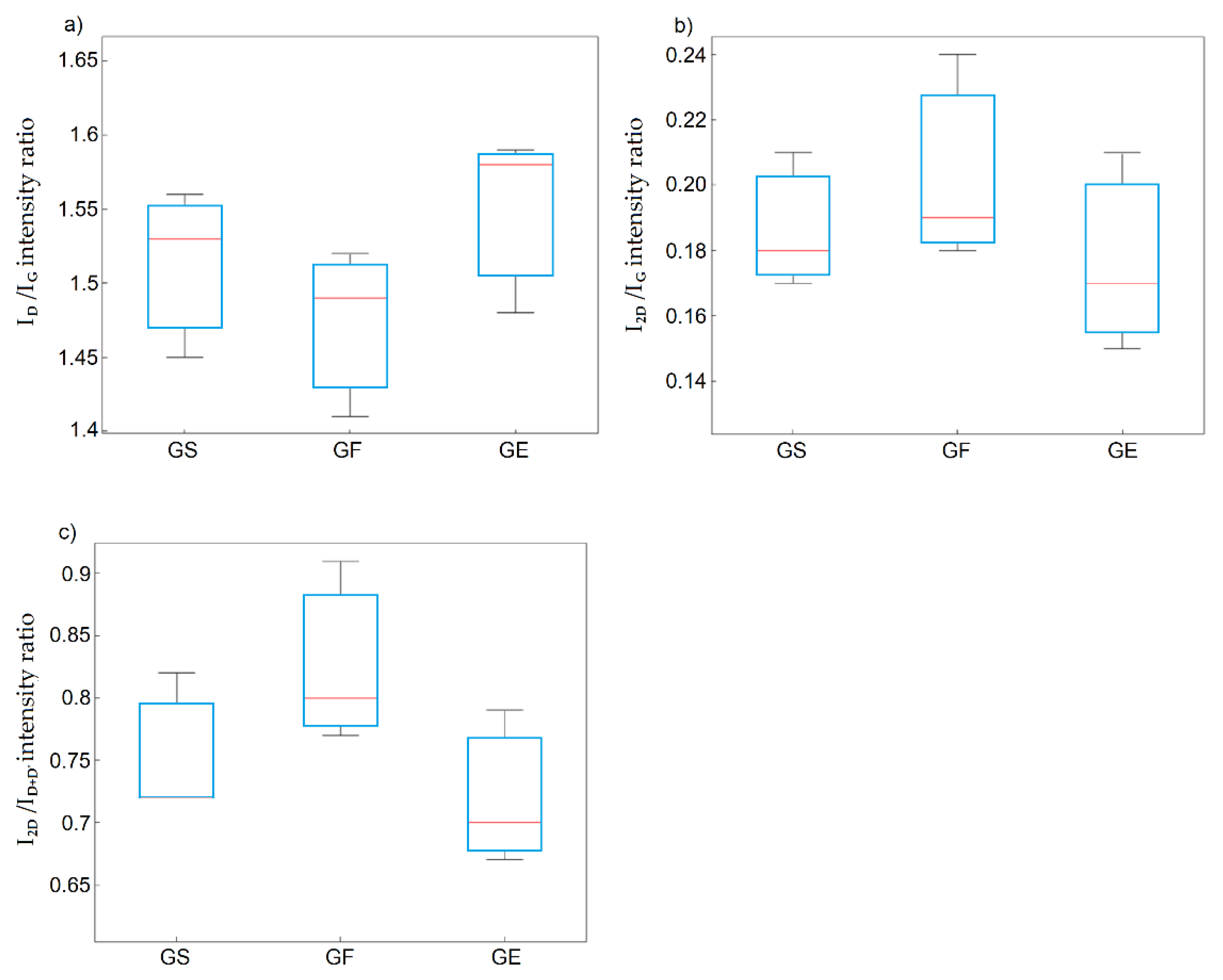

- The statistical analysis showed the influence of the precursors (GS, GF) on the properties of the obtained reduced graphene oxides (the ANOVA analysis confirmed that the type of precursor influences the oxygen content and degree of reduction after thermal exfoliation–reduction). It is worth mentioning that there is also an influence on the ID/IG ratio and number of structure defects;

- Moreover, the used ANOVA analysis showed statistically significant differences between the tested oxidation methods and the interlayer distance values d00X;

- The largest specific surfaces for rGO were obtained using method D. This type of reduced graphene oxide will be better suited for further technological processes for graphene production;

- On the other hand, rGO particles characterized by a higher degree of oxidation seem to be more appropriate for applications in gas sensors (especially in hydrogen sensors working in air atmosphere).

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Deal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Inagaki, M.; Kim, Y.A.; Endo, M. Graphene: Preparation and structural perfection. J. Mater. Chem. 2011, 21, 3280–3294. [Google Scholar] [CrossRef]

- Brodie, B.C. Sur le poids atomique du graphite (On the atomic weight of graphite). Ann. Chim. Phys. 1960, 59, 466–472. [Google Scholar]

- Staudenmaier, L. Verfahren zur darstellung der graphitsäure. Ber. Dtsch. Chem. Ges. 1898, 31, 1481–1487. [Google Scholar] [CrossRef]

- Hofmann, U.; Holst, R. Über die Säurenatur und die Methylierung von Graphitoxyd. Ber. Dtsch. Chem. Ges. 1939, 72, 754–771. [Google Scholar] [CrossRef]

- Hummers, W.S. Preparation of graphitic acid. U.S. Patent No. 2,798,878, 9 July 1954. [Google Scholar]

- Dimiev, A.M.; Eigler, S. Graphene Oxide: Fundamentals and Applications, 1st ed.; John Wiley & Sons: Chichester, West Sussex, UK, 2016; pp. 1–439. [Google Scholar]

- Chua, C.K.; Pumera, M. Chemical reduction of graphene oxide: A synthetic chemistry viewpoint. Chem. Soc. Rev. 2014, 43, 291–312. [Google Scholar] [CrossRef] [PubMed]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved synthesis of graphene oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Fugetsu, B. Mass production of graphene oxide from expanded graphite. Mater. Lett. 2013, 109, 207–210. [Google Scholar] [CrossRef]

- Botas, C.; Alvarez, P.; Blanco, C.; Santamarıa, R.; Granda, M.; Ares, P.; Rodriguez-Reinoso, F.; Menendez, R. The effect of the parent graphite on the structure of graphene oxide. Carbon 2012, 50, 275–282. [Google Scholar] [CrossRef]

- Shao, G.; Lu, Y.; Wu, F.; Yang, C.; Zeng, F.; Wu, Q. Graphene oxide: The mechanisms of oxidation and exfoliation. J. Mater. Sci. 2012, 47, 4400–4409. [Google Scholar] [CrossRef]

- Luo, D.; Zhang, G.; Liu, J.; Sun, X. Evaluation criteria for reduced graphene oxide. J. Phys. Chem. 2011, 115, 11327–11335. [Google Scholar] [CrossRef]

- Muzyka, R.; Drewniak, S.; Pustelny, T.; Chrubasik, M.; Gryglewicz, G. Characterization of graphite oxide and reduced graphene oxide obtained from different graphite precursors and oxidised by different methods using Raman spectroscopy. Materials 2018, 7, 1050. [Google Scholar]

- McAllister, M.J.; Li, J.L.; Adamson, D.H.; Schniepp, H.C.; Abdala, A.A.; Liu, J.; Herrera-Alonso, M.; Milius, D.L.; Car, R.; Prud’homme, R.K.; et al. Single sheet functionalised graphene by oxidation and thermal expansion of graphite. Chem. Mater. 2007, 19, 4396–4404. [Google Scholar] [CrossRef]

- Zhang, C.; Lv, W.; Xie, X.; Tang, D.; Liu, C.; Yang, Q.-H. Towards low temperature thermal exfoliation of graphite oxide for graphene production. Carbon 2013, 62, 1–24. [Google Scholar] [CrossRef]

- Botas, C.; Perez-Mas, A.M.; Alvarez, P.; Santamaria, R.; Granda, M.; Blanco, C.; Menendez, R. Optimization of the size and yield of graphene oxide sheets in the exfoliation step. Carbon 2013, 63, 576–578. [Google Scholar] [CrossRef]

- Deemer, E.M.; Paul, P.K.; Manciu, F.S.; Botez, C.E.; Hodges, D.R.; Landis, Z.; Akter, T.; Castro, E.; Chianelli, R.R. Consequence of oxidation method on graphene oxide produced with different size graphite precursors. Mater. Sci. Eng. B 2017, 224, 150–157. [Google Scholar] [CrossRef]

- Muzyka, R. Influence of Graphitic Precursor on the Composition, Morphology and Structure of Thermally Reduced Graphene Oxides. Ph.D. Thesis, Wroclaw University of Science and Technology, Wroclaw, Poland, 1–28 February 2018. [Google Scholar]

- Botas, C.; Alvarez, P.; Blanco, C.; Santamaria, R.; Granda, M.; Gutierrez, M.D.; Rodriguez-Reinoso, F.; Menendez, R. Critical temperatures in the synthesis of graphene-like materials by thermal exfoliation-reduction of graphite oxide. Carbon 2013, 52, 476–485. [Google Scholar] [CrossRef]

- Schniepp, H.C.; Li, J.L.; McAllister, M.J.; Sai, H.; Herrera-Alonso, M.; Adamson, D.H.; Prud’homme, R.K.; Car, R.; Saville, D.A.; Aksay, I.A. Functionalized single graphene sheets derived from splitting graphite oxide. J. Phys. Chem. B 2006, 110, 8535–8539. [Google Scholar] [CrossRef]

- Drewniak, S.E.; Pustelny, T.P.; Muzyka, R.; Plis, A. Studies of physicochemical properties of graphite oxide and thermally exfoliated/reduced graphene oxide. Polish J. Chem. Technol. 2015, 17, 109–114. [Google Scholar] [CrossRef]

- Drewniak, S.; Muzyka, R.; Drewniak, Ł. The structure of thermally reduced graphene oxide. Photonics Lett. Poland 2020, 12, 52–54. [Google Scholar] [CrossRef]

- Drewniak, S.; Muzyka, R.; Stolarczyk, A.; Pustelny, T.; Kotyczka-Moranska, M.; Setkiewicz, M. Studies of reduced graphene oxide and graphite oxide in the aspect of their possible application in gas sensors. Sensors 2016, 16, 103. [Google Scholar] [CrossRef]

- Davies, M.P.; De Biasi, V.; Perrett, D. Approaches to the rational design of molecularly imprinted polymers. Anal. Chim. Acta 2004, 504, 7–14. [Google Scholar] [CrossRef]

- Navarro-Villoslada, F.; San Vicente, B.; Moreno-Bondi, M.C. Application of multivariate analysis to the screening of molecularly imprinted polymers for bisphenol A. Anal. Chim. Acta 2004, 504, 149–162. [Google Scholar] [CrossRef]

- Potyrailo, R.A. Polymeric sensor materials: Toward an alliance of combinatorial and rational design tools? Angew. Chem. Int. Ed. Engl. 2006, 45, 702–723. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Mirsky, V.M. Combinatorial Methods for Chemical and Biological Sensors, 1st ed.; Springer: New York, NY, USA, 2009. [Google Scholar]

- Steinke, J.; Sherrington, D.C.; Dukin, I.R. Imprinting of synthetic polymers using molecular templates. Adv. Polym. Sci. 1995, 123, 81–125. [Google Scholar]

- Abollino, O.; Aceto, M.; Malandrino, M.; Mentasti, E.; Sarzanini, E.; Barberis, R. Distribution and mobility of metals in contaminated sites. Chemometric investigation of pollutant profiles. Environ. Pollut. 2002, 119, 177–193. [Google Scholar] [CrossRef]

- Abollino, O.; Aceto, M.; Malandrino, M.; Mentasti, E.; Sarzanini, C.; Petrella, F. Heavy metals in agricultural soils from Piedmont, Italy. Distribution, speciation and chemometric data treatment. Chemosphere 2002, 49, 545–557. [Google Scholar] [CrossRef]

- Sajdak, M.; Stelmach, S.; Kotyczka-Morańska, M.; Plis, A. Application of chemometric methods to evaluate the origin of solid fuels subjected to thermal conversion. J. Anal. Appl. Pyrolysis 2015, 113, 65–72. [Google Scholar] [CrossRef]

- Pérez, G.; Valiente, M. Determination of pollution trends in an abandoned mining site by application of a multivariate statistical analysis to heavy metals fractionation using SM&T–SES. J. Environ. Monitor. 2005, 7, 29–36. [Google Scholar]

| Oxidation Method | Material | Ratio C/O | [Ref.] |

|---|---|---|---|

| Brodie | natural graphite (Ceylon) | 3.5 | [3] |

| Staudenmaier | natural graphite | 2.9 | [4] |

| Hofmann | natural graphite | 3.3 | [5] |

| Hummers (various) | natural graphite with variable grain sizes smaller than 60 and at 60–90 µm | (16.0–2.0) | [6] |

| Hummers–Offemann | natural graphite | 3.0 | [7,8] |

| Symbol | Base Acid | Oxidizing Mixture (Reagents) | Time |

|---|---|---|---|

| Method A | H2SO4 (20 mL) | HNO3 (15 mL), KMnO4 (3 g) | 24 h |

| Method B | H2SO4 (30 mL) | NaNO3 (3 g), KMnO4 (3 g) | 2 h |

| Method C | H2SO4 (22.5 mL) | NaNO3 (0.5 g), KMnO4 (3 g) | 0.5 h |

| Method D | H2SO4 (45 mL), H3PO4 (5 mL), | KMnO4 (5 g), KNO3 (1.5 g) | 5 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muzyka, R.; Drewniak, S.; Pustelny, T.; Sajdak, M.; Drewniak, Ł. Characterization of Graphite Oxide and Reduced Graphene Oxide Obtained from Different Graphite Precursors and Oxidized by Different Methods Using Raman Spectroscopy Statistical Analysis. Materials 2021, 14, 769. https://doi.org/10.3390/ma14040769

Muzyka R, Drewniak S, Pustelny T, Sajdak M, Drewniak Ł. Characterization of Graphite Oxide and Reduced Graphene Oxide Obtained from Different Graphite Precursors and Oxidized by Different Methods Using Raman Spectroscopy Statistical Analysis. Materials. 2021; 14(4):769. https://doi.org/10.3390/ma14040769

Chicago/Turabian StyleMuzyka, Roksana, Sabina Drewniak, Tadeusz Pustelny, Marcin Sajdak, and Łukasz Drewniak. 2021. "Characterization of Graphite Oxide and Reduced Graphene Oxide Obtained from Different Graphite Precursors and Oxidized by Different Methods Using Raman Spectroscopy Statistical Analysis" Materials 14, no. 4: 769. https://doi.org/10.3390/ma14040769

APA StyleMuzyka, R., Drewniak, S., Pustelny, T., Sajdak, M., & Drewniak, Ł. (2021). Characterization of Graphite Oxide and Reduced Graphene Oxide Obtained from Different Graphite Precursors and Oxidized by Different Methods Using Raman Spectroscopy Statistical Analysis. Materials, 14(4), 769. https://doi.org/10.3390/ma14040769