Temperature-Dependent Photoluminescence of ZnO Thin Films Grown on Off-Axis SiC Substrates by APMOCVD

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

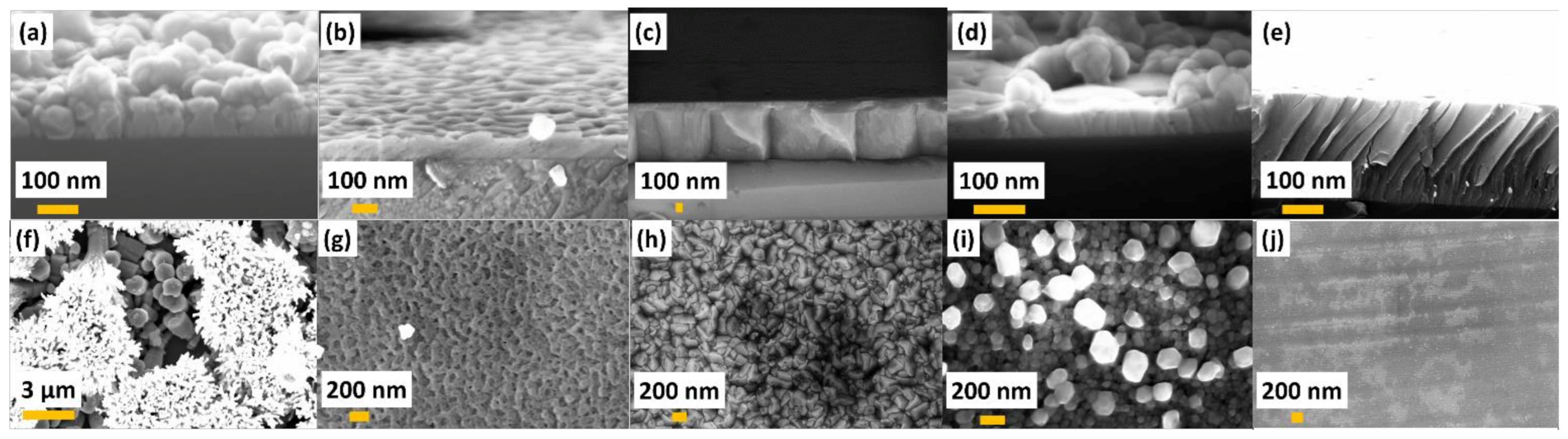

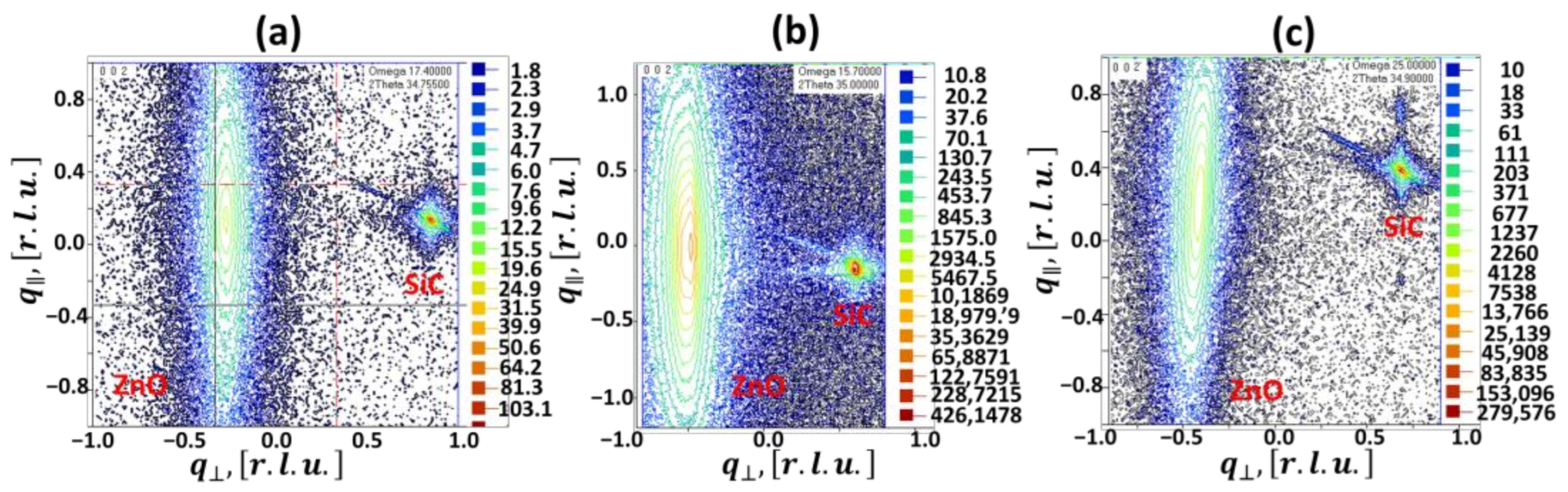

3.1. Morphology and Crystal Structure of ZnO Films Grown on SiC Substrates with Different Off-Cut Angles

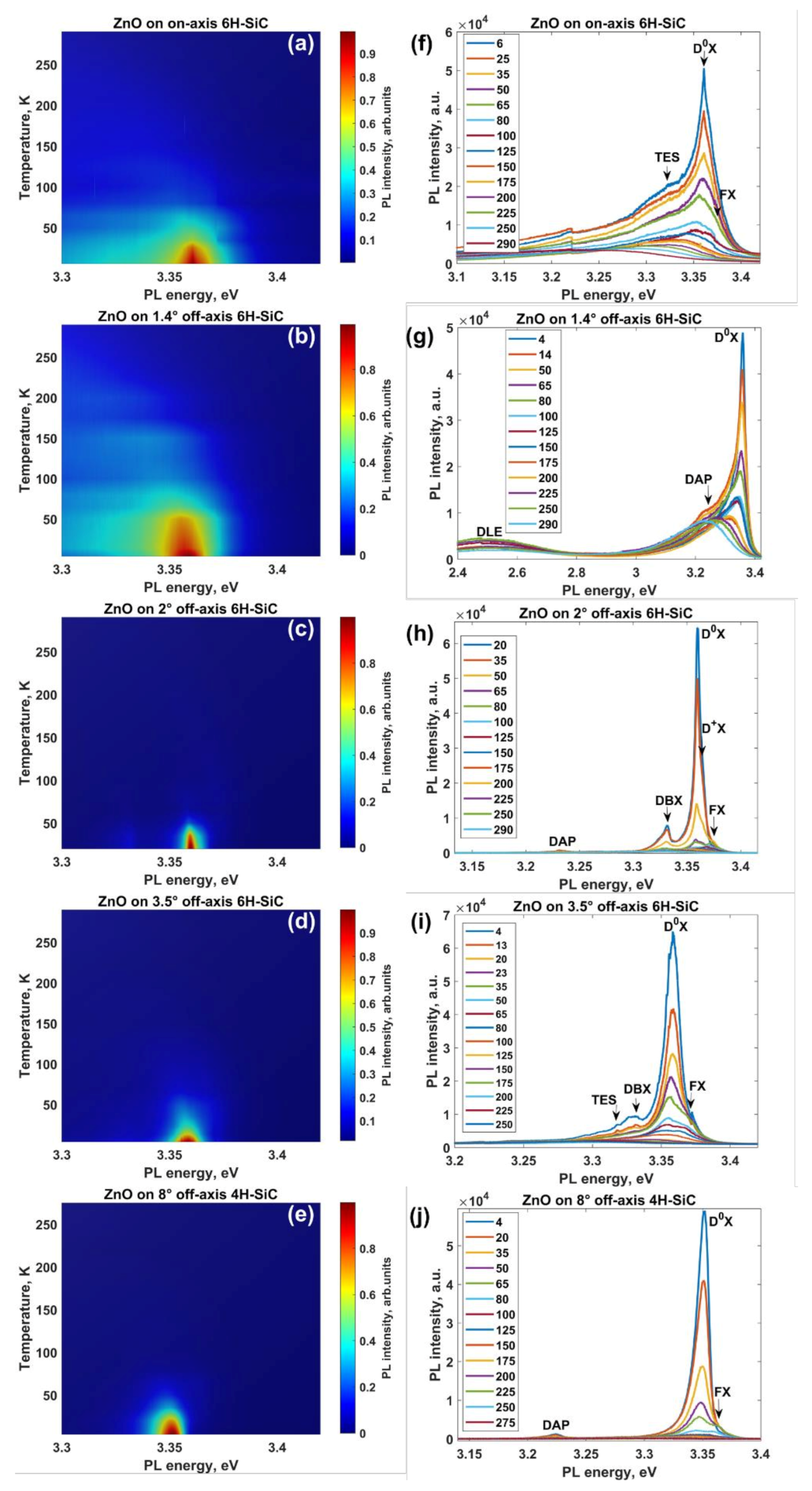

3.2. Photoluminescence of ZnO Films Grown on SiC Substrates with Different Off-Cut Angles

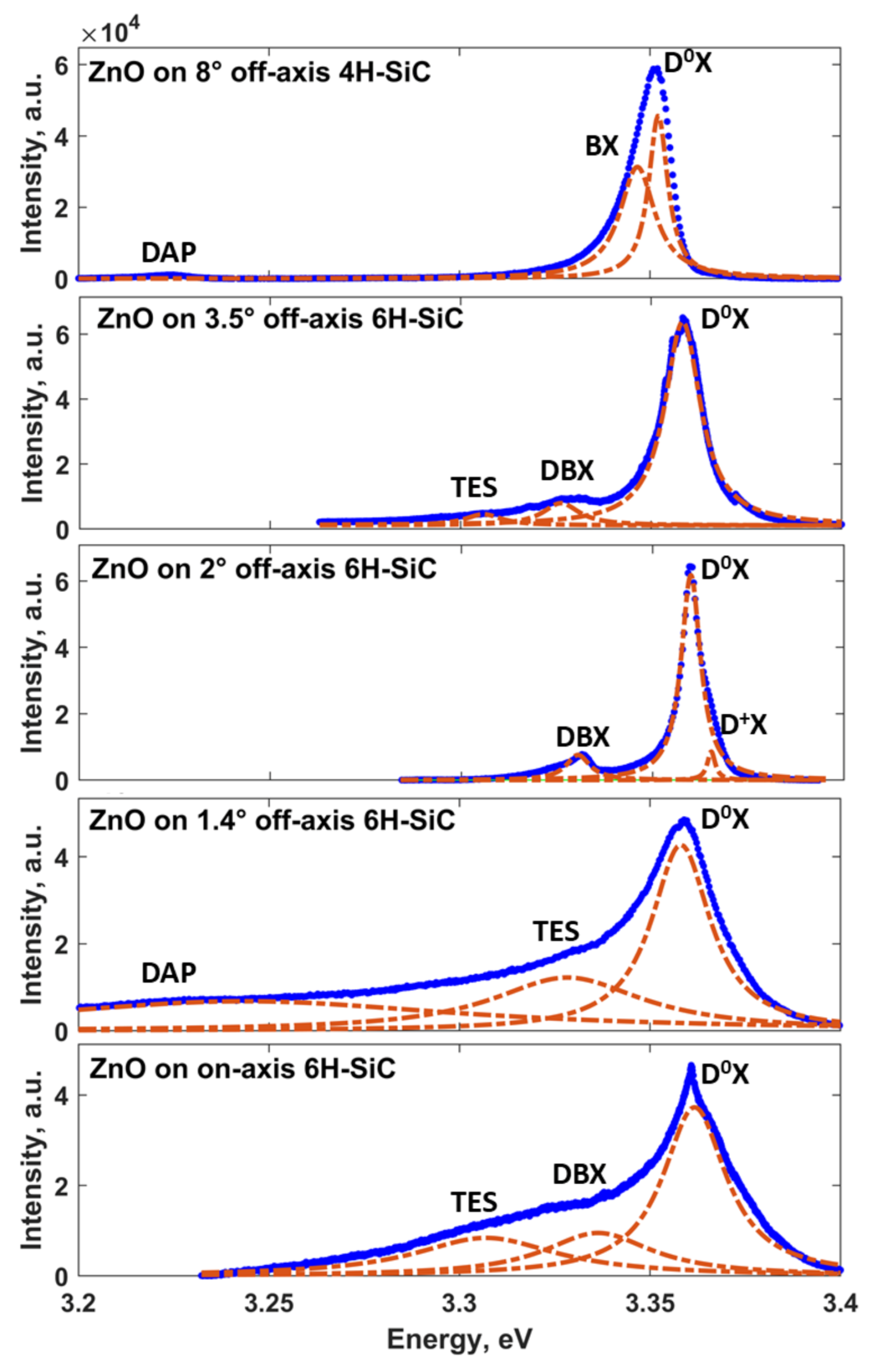

3.2.1. Off-Cut Angle Effect on the Low-Temperature PL

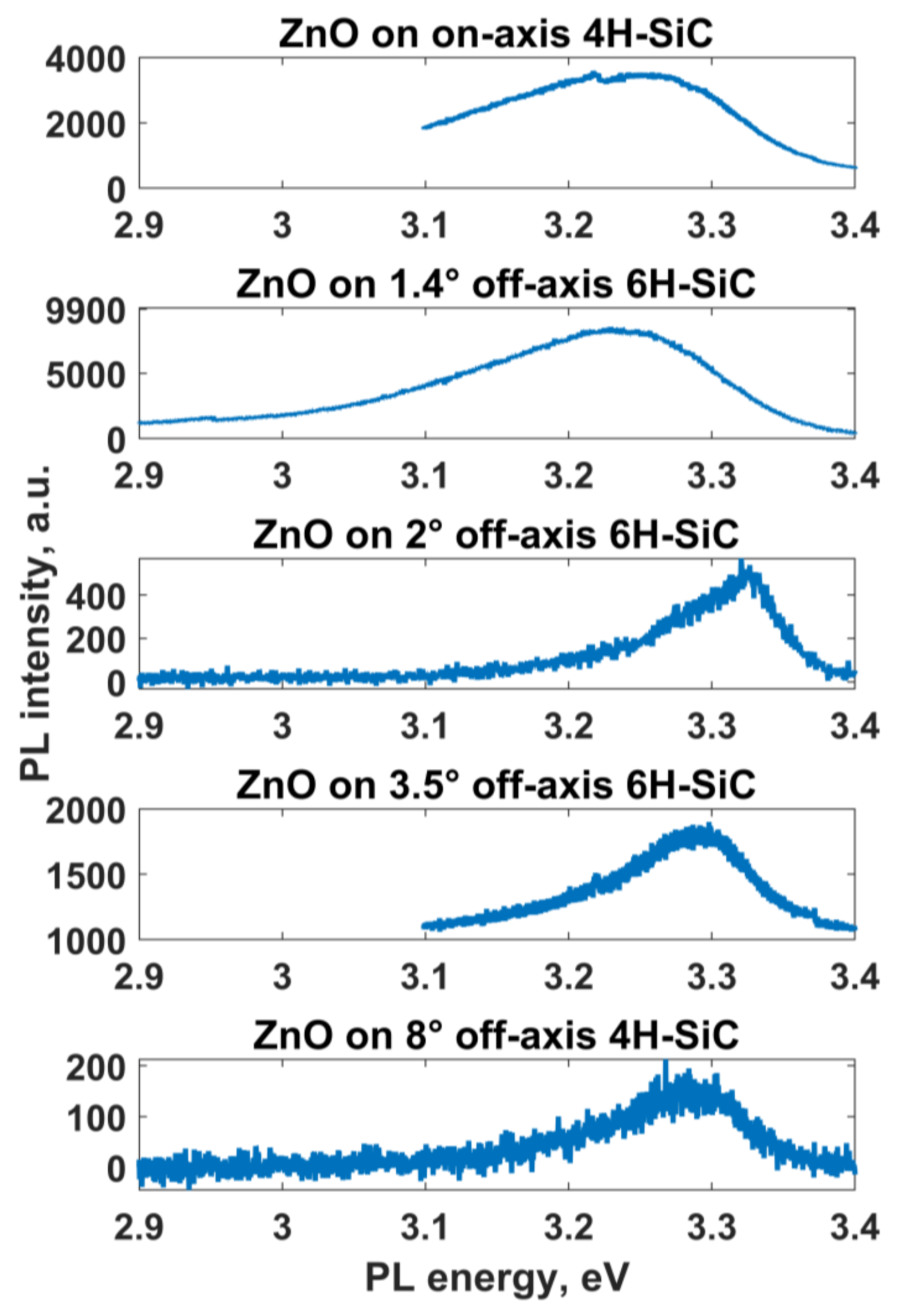

3.2.2. Off-Cut Angle Effect on the Room-Temperature PL

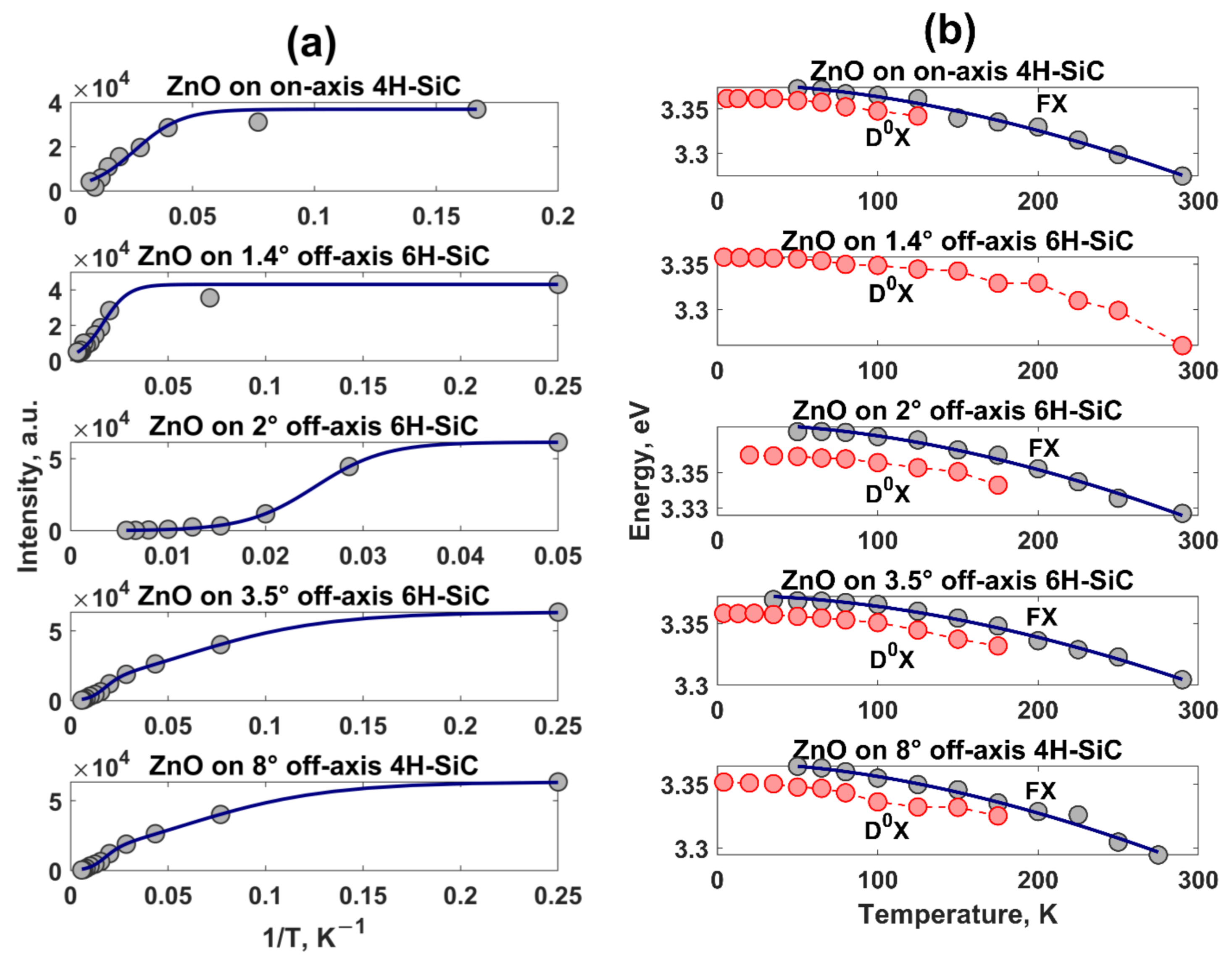

3.2.3. Temperature Dependences of PL Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.J.; Shi, Z.F.; Shan, C.X.; Shen, D.Z. ZnO nanostructures and lasers. Nanoscale Semicond. Lasers 2019, 75–108. [Google Scholar] [CrossRef]

- Rahman, F. Zinc oxide light-emitting diodes: A review. Opt. Eng. 2019, 58, 010901. [Google Scholar] [CrossRef]

- Tan, S.T.; Zhao, J.L.; Sun, X.W. Light-emitting diodes based on n-ZnO/n-Si(GaAs) isotype heterojunctions. In Handbook of Zinc Oxide and Related Materials: Volume Two, Devices and Nano-Engineering; Feng, Z.C., Ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 219–236. [Google Scholar]

- Vanmaekelbergh, D.; Van Vugt, L.K. ZnO nanowire lasers. Nanoscale 2011, 3, 2783–2800. [Google Scholar] [CrossRef]

- Phillips, J.; Bowen, W.; Cagin, E.; Wang, W. Electronic and optoelectronic devices based on semiconducting zinc oxide. In Comprehensive Semiconductor Science and Technology; Pallab, B., Roberto, F., Hiroshi, K., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2011; pp. 101–127. [Google Scholar]

- Djurišić, A.B.; Ng, A.M.C.; Chen, X.Y. ZnO nanostructures for optoelectronics: Material properties and device applications. Prog. Quantum Electron. 2010, 34, 191–259. [Google Scholar] [CrossRef]

- Klingshirn, C. ZnO: From basics towards applications. Phys. Status Solidi B 2007, 244, 3027–3073. [Google Scholar] [CrossRef]

- Coleman, V.A.; Jagadish, C. Basic Properties and Applications of ZnO. In Zinc Oxide Bulk, Thin Films and Nanostructures; Elsevier Science: Amsterdam, The Netherlands, 2006; pp. 1–20. [Google Scholar] [CrossRef]

- Bakin, A.; El-Shaer, A.; Mofor, A.C.; Al-Suleiman, M.; Schlenker, E.; Waag, A. ZnMgO-ZnO quantum wells embedded in ZnO nanopillars: Towards realisation of nano-LEDs. Phys. Status Solidi C 2007, 4, 158–161. [Google Scholar] [CrossRef]

- Shtepliuk, I.; Khranovskyy, V.; Yakimova, R. Effect of Zn-Cd interdiffusion on the band structure and spontaneous emission of ZnO/Zn1-xCdxO/ZnO quantum wells. Superlattices Microstruct. 2015, 85, 438–444. [Google Scholar] [CrossRef][Green Version]

- Shtepliuk, I.; Khranovskyy, V.; Yakimova, R. Effect of c-axis inclination angle on the properties of ZnO/Zn1-xCdxO/ZnO quantum wells. Thin Solid Films 2016, 603, 139–148. [Google Scholar] [CrossRef][Green Version]

- Shtepliuk, I.; Khranovskyy, V.; Yakimova, R. Theoretical study of O- and Zn-face polarity effect on the optical properties of the conventional and staggered ZnO/Zn1−xCdxO/ZnO quantum wells. Thin Solid Films 2015, 594, 323–327. [Google Scholar] [CrossRef]

- Lopez-Ponce, M.; Nakamura, A.; Suzuki, M.; Temmyo, J.; Agouram, S.; Martínez-Tomás, M.C.; Muñoz-Sanjosé, V.; Lefebvre, P.; Ulloa, J.M.; Muñoz, E. VIS-UV ZnCdO/ZnO multiple quantum well nanowires and the quantification of Cd diffusion. Nanotechnology 2014, 25, 255202. [Google Scholar] [CrossRef]

- Sartel, C.; Sallet, V.; Lusson, A.; Haneche, N.; Laroche, J.M.; Galtier, P. Homoepitaxy of ZnO on bulk and thin film substrates by low temperature metal organic chemical vapor deposition using tert-butanol. J. Vac. Sci. Technol. B 2009, 27, 1615. [Google Scholar] [CrossRef]

- Cho, M.W.; Harada, C.; Suzuki, H.; Minegishi, T.; Yao, T.; Ko, H.; Maed, K.; Nikura, I. Issues in ZnO homoepitaxy. Superlattices Microstruct. 2005, 38, 349–363. [Google Scholar] [CrossRef]

- Wenisch, H.; Kirchner, V.; Hong, S.K.; Chen, Y.F.; Ko, H.J.; Yao, T. Evaluation of ZnO substrates for homoepitaxy. J. Cryst. Growth 2001, 227–228, 944–949. [Google Scholar] [CrossRef]

- Wei, X.H.; Li, Y.R.; Jie, W.J.; Tang, J.L.; Zeng, H.Z.; Huang, W.; Zhang, Y.; Zhu, J. Heteroepitaxial growth of ZnO on perovskite surfaces. J. Phys. D Appl. Phys. 2007, 40, 7502. [Google Scholar] [CrossRef]

- Khranovskyy, V.; Shtepliuk, I.; Vines, L.; Yakimova, R. Complementary study of the photoluminescence and electrical properties of ZnO films grown on 4H-SiC substrates. J. Lumin. 2017, 181, 374–381. [Google Scholar] [CrossRef][Green Version]

- Seo, S.H.; Kang, H.C. Growth of ZnO/sapphire heteroepitaxial thin films by radio-frequency sputtering with a raw powder target. Thin Solid Films 2010, 518, 5164–5168. [Google Scholar] [CrossRef]

- Hamada, T.; Ito, A.; Nagao, N.; Suzuki, N.; Fujii, E.; Tsujimura, A. Direct Heteroepitaxial Growth of ZnO over GaN Crystal in Aqueous Solution. Jpn. J. Appl. Phys. 2013, 52, 04CH04. [Google Scholar] [CrossRef]

- Khranovskyy, V.; Yakimova, R. Heteroepitaxy of ZnO on SiC as a route toward nanoscale p-n junction. In Handbook of Zinc Oxide and Related Materials: Volume Two, Devices and Nano-Engineering; Feng, Z.C., Ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 83–131. [Google Scholar]

- Goela, J.; Brese, N.; Burns, L.; Pickering, M. High-Thermal-Conductivity SiC and Applications. In High Thermal Conductivity Materials; Shindé, S.L., Goela, J.S., Eds.; Springer: New York, NY, USA, 2006; pp. 167–198. [Google Scholar] [CrossRef]

- Decremps, F.; Zhang, J.; Liebermann, R.C. New phase boundary and high-pressure thermoelasticity of ZnO. Europhys. Lett. 2000, 51, 268. [Google Scholar] [CrossRef]

- Suzuki, A.; Okumura, H.; Kimoto, T.; Fuyuki, T.; Fukuda, K.; Nishizawa, S.-I. Thermal Expansion Coefficients of 6H Silicon Carbide. Mater. Sci. Forum 2008, 600–603, 517–520. [Google Scholar] [CrossRef]

- Wei, R.; Song, S.; Yang, K.; Cui, Y.; Peng, Y.; Chen, X.; Hu, X.; Xu, X. Thermal conductivity of 4H-SiC single crystals. J. Appl. Phys. 2013, 113, 053503. [Google Scholar] [CrossRef]

- Khranovskyy, V.; Tsiaoussis, I.; Yazdi, G.R.; Hultman, L.; Yakimova, R. Heteroepitaxial ZnO nanohexagons on p-type SiC. J. Cryst. Growth 2010, 312, 327–332. [Google Scholar] [CrossRef]

- Xie, M.H.; Zheng, L.X.; Cheung, S.H.; Ng, Y.F.; Wu, H.; Tong, S.Y.; Ohtani, N. Reduction of threading defects in GaN grown on vicinal SiC (0001) by molecular-beam epitaxy. Appl. Phys. Lett. 2000, 77, 1105–1107. [Google Scholar] [CrossRef]

- Chen, W.; Capano, M.A. Growth and characterization of epilayers on substrates with different off-cut angles. J. Appl. Phys. 2005, 98, 114907. [Google Scholar] [CrossRef]

- Jantawongrit, P.; Sanorpim, S.; Yaguchi, H.; Orihara, M.; Limsuwan, P. Influence of off-cut angle of (0001) 4H-SiC on the crystal quality of InN grown by RF-MBE. Procedia Eng. 2012, 32, 882–887. [Google Scholar] [CrossRef]

- Xie, M.H.; Seutter, S.M.; Zhu, W.K.; Zheng, L.X.; Wu, H.; Tong, S.Y. Anisotropic Step-Flow Growth and Island Growth of GaN(0001) by Molecular Beam Epitaxy. Phys. Rev. Lett. 1999, 82, 2749–2752. [Google Scholar] [CrossRef]

- Li, Z.; Gao, W. ZnO thin films with DC and RF reactive sputtering. Mater. Lett. 2004, 58, 1363–1370. [Google Scholar] [CrossRef]

- Khomyak, V.V.; Slyotov, M.M.; Shtepliuk, I.I.; Lashkarev, G.V.; Slyotov, O.M.; Marianchuk, P.D.; Kosolovskiy, V.V. Annealing effect on the near-band edge emission of ZnO. J. Phys. Chem. Solids 2013, 74, 291–297. [Google Scholar] [CrossRef]

- Wang, S.P.; Shan, C.X.; Yao, B.; Li, B.H.; Zhang, J.Y.; Zhao, D.X.; Shen, D.Z.; Fan, X.W. Electrical and optical properties of ZnO films grown by molecular beam epitaxy. Appl. Surf. Sci. 2009, 255, 4913–4915. [Google Scholar] [CrossRef]

- Matsubara, K.; Fons, P.; Iwata, K.; Yamada, A.; Sakurai, K.; Tampo, H.; Niki, S. ZnO transparent conducting films deposited by pulsed laser deposition for solar cell applications. Thin Solid Films 2003, 431–432, 369–372. [Google Scholar] [CrossRef]

- Fang, L.; Li, H.; Ma, X.; Song, Q.; Chen, R. Optical properties of ultrathin ZnO films fabricated by atomic layer deposition. Appl. Surf. Sci. 2020, 527, 146818. [Google Scholar] [CrossRef]

- Cruickshank, A.C.; Tay, S.E.R.; Illy, B.N.; Da Campo, R.; Schumann, S.; Jones, T.S.; Heutz, S.; McLachlan, M.A.; McComb, D.W.; Jason Riley, D.; et al. Electrodeposition of ZnO Nanostructures on Molecular Thin Films. Chem. Mater. 2011, 23, 3863–3870. [Google Scholar] [CrossRef]

- Fouad, O.A.; Ismail, A.A.; Zaki, Z.I.; Mohamed, R.M. Zinc oxide thin films prepared by thermal evaporation deposition and its photocatalytic activity. Appl. Catal. B Environ. 2006, 62, 144–149. [Google Scholar] [CrossRef]

- Xiao, Q.; Huang, S.; Zhang, J.; Xiao, C.; Tan, X. Sonochemical synthesis of ZnO nanosheet. J. Alloy. Compd. 2008, 459, L18–L22. [Google Scholar] [CrossRef]

- Hasanpoor, M.; Aliofkhazraei, M.; Delavari, H. Microwave-assisted Synthesis of Zinc Oxide Nanoparticles. Procedia Mater. Sci. 2015, 11, 320–325. [Google Scholar] [CrossRef]

- Yu, J.; Huang, B.; Qin, X.; Zhang, X.; Wang, Z.; Liu, H. Hydrothermal synthesis and characterization of ZnO films with different nanostructures. Appl. Surf. Sci. 2011, 257, 5563–5565. [Google Scholar] [CrossRef]

- Znaidi, L. Sol–gel-deposited ZnO thin films: A review. Mater. Sci. Eng. B 2010, 174, 18–30. [Google Scholar] [CrossRef]

- Sbrockey, N.M.; Ganesan, S. ZnO thin films by MOCVD. III Vs Rev. 2004, 17, 23–25. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Pei, Y.; Wang, G. Study on the uniformity of ZnO films grown by MOCVD. Ceram. Int. 2019, 45, 13971–13978. [Google Scholar] [CrossRef]

- Koleske, D.D.; Wickenden, A.E.; Henry, R.L.; Twigg, M.E.; Culbertson, J.C.; Gorman, R.J. Enhanced GaN decomposition in H2 near atmospheric pressures. Appl. Phys. Lett. 1998, 73, 2018. [Google Scholar] [CrossRef]

- Einfeldt, S.; Bottcher, T.; Figge, S.; Hommel, D. Thermally induced stress in GaN layers with regard to film coalescence. J. Cryst. Growth 2001, 230, 357. [Google Scholar] [CrossRef]

- Dai, J.; Liu, H.; Fang, W.; Wang, L.; Pu, Y.; Chen, Y.; Jian, F. Atmospheric pressure MOCVD growth of high-quality ZnO films on GaN/Al2O3 templates. J. Cryst. Growth 2005, 283, 93–99. [Google Scholar] [CrossRef]

- Park, C.H.; Cheong, B.-H.; Lee, K.-H.; Chang, K.J. Structural and electronic properties of cubic, 2H, 4H, and 6H SiC. Phys. Rev. B 1994, 49, 4485. [Google Scholar] [CrossRef]

- Ashrafia, A.; Aminuzzaman, M. ZnO epitaxy on SiC (000) substrate: Comparison with ZnO/SiC (0001) heterostructure. Appl. Surf. Sci. 2011, 257, 6191–6196. [Google Scholar] [CrossRef]

- Taube, A.; Sochacki, M.; Kwietniewski, N.; Werbowy, A.; Gierałtowska, S.; Wachnicki, Ł.; Godlewski, M.; Szmidt, J. Electrical properties of isotype and anisotype ZnO/4H-SiC heterojunction diodes. Appl. Phys. Lett. 2017, 110, 143509. [Google Scholar] [CrossRef]

- Khranovskyy, V.; Yakimova, R. Morphology engineering of ZnO nanostructures. Phys. B Condens. Matter 2012, 407, 1533. [Google Scholar] [CrossRef]

- Shtepliuk, I.; Khranovskyy, V.; Gogova, D.; Danilson, M.; Krunks, M.; Ivanov, I.G.; Yakimova, R. Excitonic emission in heavily Ga-doped zinc oxide films grown on GaN. J. Lumin. 2020, 223, 117265. [Google Scholar] [CrossRef]

- Syväjärvi, M.; Yakimova, R.; Janzén, E. Step-bunching in SiC epitaxy: Anisotropy and influence of growth temperature. J. Cryst. Growth 2002, 236, 297–304. [Google Scholar] [CrossRef]

- Tabuchi, Y.; Ashida, K.; Sonoda, M.; Kaneko, T.; Ohtani, N.; Katsuno, M.; Sato, S.; Tsuge, H.; Fujimoto, T. Wide (0001) terrace formation due to step bunching on a vicinal 4H-SiC (0001) epitaxial layer surface. J. Appl. Phys. 2017, 122, 075702. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Hu, S.-Y.; Feng, Z.-C.; Yang, C.-S.; Huang, C.-C. Temperature-dependent excitonic luminescence in ZnO thin film grown by metal organic chemical vapor deposition. Jpn. J. Appl. Phys. 2009, 48, 112302. [Google Scholar] [CrossRef]

- Tang, K.; Gu, S.; Ye, J.; Huang, S.; Gu, R.; Zhang, R.; Zheng, Y. Temperature-dependent photoluminescence of ZnO films codoped with tellurium and nitrogen. J. Appl. Phys. 2012, 112, 103534. [Google Scholar] [CrossRef]

- Meyer, B.K.; Alves, H.; Hofmann, D.M.; Kriegseis, W.D.; Bertram, F.F.; Christen, J.; Hoffmann, A.; Straßburg, M.; Dworzak, M.; Haboeck, U.; et al. Bound exciton and donor–acceptor pair recombinations in ZnO. Phys. Status Solidi B 2004, 241, 231–260. [Google Scholar] [CrossRef]

- Wagner, M.R.; Callsen, G.; Reparaz, J.S.; Schulze, J.-H.; Kirste, R.; Cobet, M.; Ostapenko, I.A.; Rodt, S.; Nenstiel, C.; Kaiser, M.; et al. Bound excitons in ZnO: Structural defect complexes versus shallow impurity centers. Phys. Rev. B 2011, 84, 035313. [Google Scholar] [CrossRef]

- Vidya, R.; Ravindran, P.; Fjellvag, H.; Svensson, B.G.; Monakhov, E.; Ganchenkova, M.; Nieminen, R.M. Energetics of intrinsic defects and their complexes in ZnO investigated by density functional calculation. Phys. Rev. B 2011, 83, 045206. [Google Scholar] [CrossRef]

- Elkar, T.; Mzabi, N.; Hassine, M.B.; Gemeiner, P.; Dkhil, B.; Guermazi, S.; Guermazi, H. Structural and optical investigation of (V, Al) doped and co-doped ZnO nanopowders: Tailored visible luminescence for white light emitting diodes. Superlattices Microstruct. 2018, 122, 349–361. [Google Scholar] [CrossRef]

- Ye, Z.; Wang, T.; Wu, S.; Ji, X.; Zhang, Q. Na-doped ZnO nanorods fabricated by chemical vapor deposition and their optoelectrical properties. J. Alloy. Compd. 2017, 690, 189–194. [Google Scholar] [CrossRef]

- Mohanta, S.K.; Tripathy, S.; Soh, C.B.; Kim, D.C.; Kong, B.H.; Cho, H.K. Emission characteristics of ZnO nanorods on nanosilicon-on-insulator: Competition between exciton–phonon coupling and surface resonance effect. J. Phys. D Appl. Phys. 2010, 43, 145404. [Google Scholar] [CrossRef]

- He, H.P.; Wang, Z.; Duan, H.F.; Ye, Z.Z. Band tail-induced photoluminescence broadening in heavily In-doped n-type ZnO nanowires. Phys. Chem. Chem. Phys. 2015, 17, 17552–17556. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.; Huo, K.; Qian, G.; Fu, J.; Chu, P.K. Temperature dependent photoluminescence from ZnO nanowires and nanosheets on brass substrate. Appl. Phys. Lett. 2008, 93, 203117. [Google Scholar] [CrossRef]

- Hong, W.K.; Jo, G.; Choe, M.; Lee, T.; Sohn, J.I.; Welland, M.E. Influence of surface structure on the phonon-assisted emission process in the ZnO nanowires grown on homoepitaxial films. Appl. Phys. Lett. 2009, 94, 043103. [Google Scholar] [CrossRef]

- Varshni, Y.P. Temperature dependence of the energy gap in semiconductors. Physica 1967, 34, 149. [Google Scholar] [CrossRef]

- Ye, H.B.; Kong, J.F.; Shen, W.Z.; Zhao, J.L.; Li, X.M. Temperature-dependent photoluminescence of undoped, N-doped and N-In codoped ZnO thin films. J. Phys. D Appl. Phys. 2007, 40, 5588–5591. [Google Scholar] [CrossRef]

- Fonoberov, V.A.; Alim, K.A.; Balandin, A.A.; Xiu, F.; Liu, J. Photoluminescence investigation of the carrier recombination processes in ZnO quantum dots and nanocrystals. Phys. Rev. B 2006, 73, 165317. [Google Scholar] [CrossRef]

- Hutson, A.R. Electronic properties of ZnO. J. Phys. Chem. Solids 1959, 467–472. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shtepliuk, I.; Khranovskyy, V.; Ievtushenko, A.; Yakimova, R. Temperature-Dependent Photoluminescence of ZnO Thin Films Grown on Off-Axis SiC Substrates by APMOCVD. Materials 2021, 14, 1035. https://doi.org/10.3390/ma14041035

Shtepliuk I, Khranovskyy V, Ievtushenko A, Yakimova R. Temperature-Dependent Photoluminescence of ZnO Thin Films Grown on Off-Axis SiC Substrates by APMOCVD. Materials. 2021; 14(4):1035. https://doi.org/10.3390/ma14041035

Chicago/Turabian StyleShtepliuk, Ivan, Volodymyr Khranovskyy, Arsenii Ievtushenko, and Rositsa Yakimova. 2021. "Temperature-Dependent Photoluminescence of ZnO Thin Films Grown on Off-Axis SiC Substrates by APMOCVD" Materials 14, no. 4: 1035. https://doi.org/10.3390/ma14041035

APA StyleShtepliuk, I., Khranovskyy, V., Ievtushenko, A., & Yakimova, R. (2021). Temperature-Dependent Photoluminescence of ZnO Thin Films Grown on Off-Axis SiC Substrates by APMOCVD. Materials, 14(4), 1035. https://doi.org/10.3390/ma14041035