The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

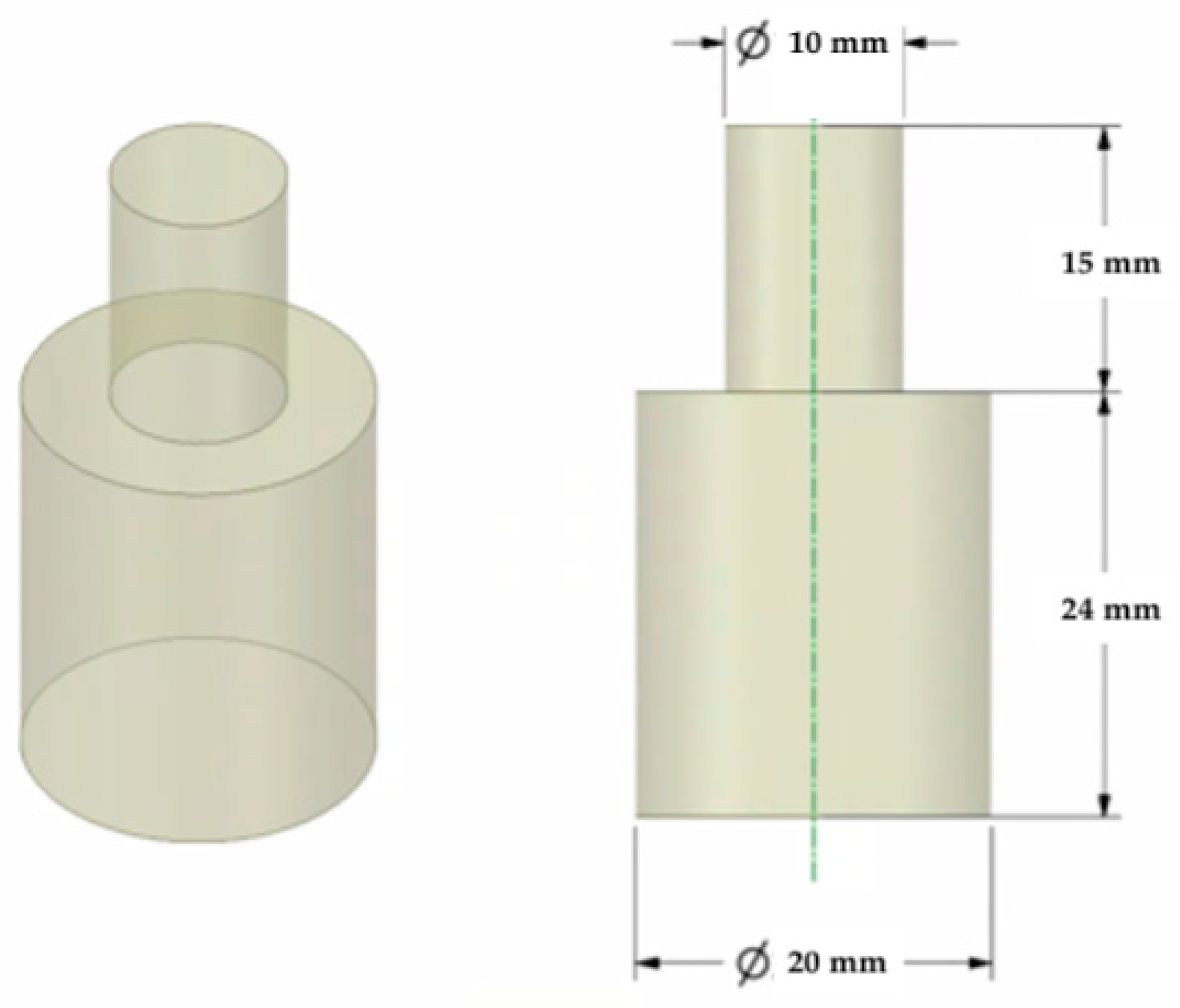

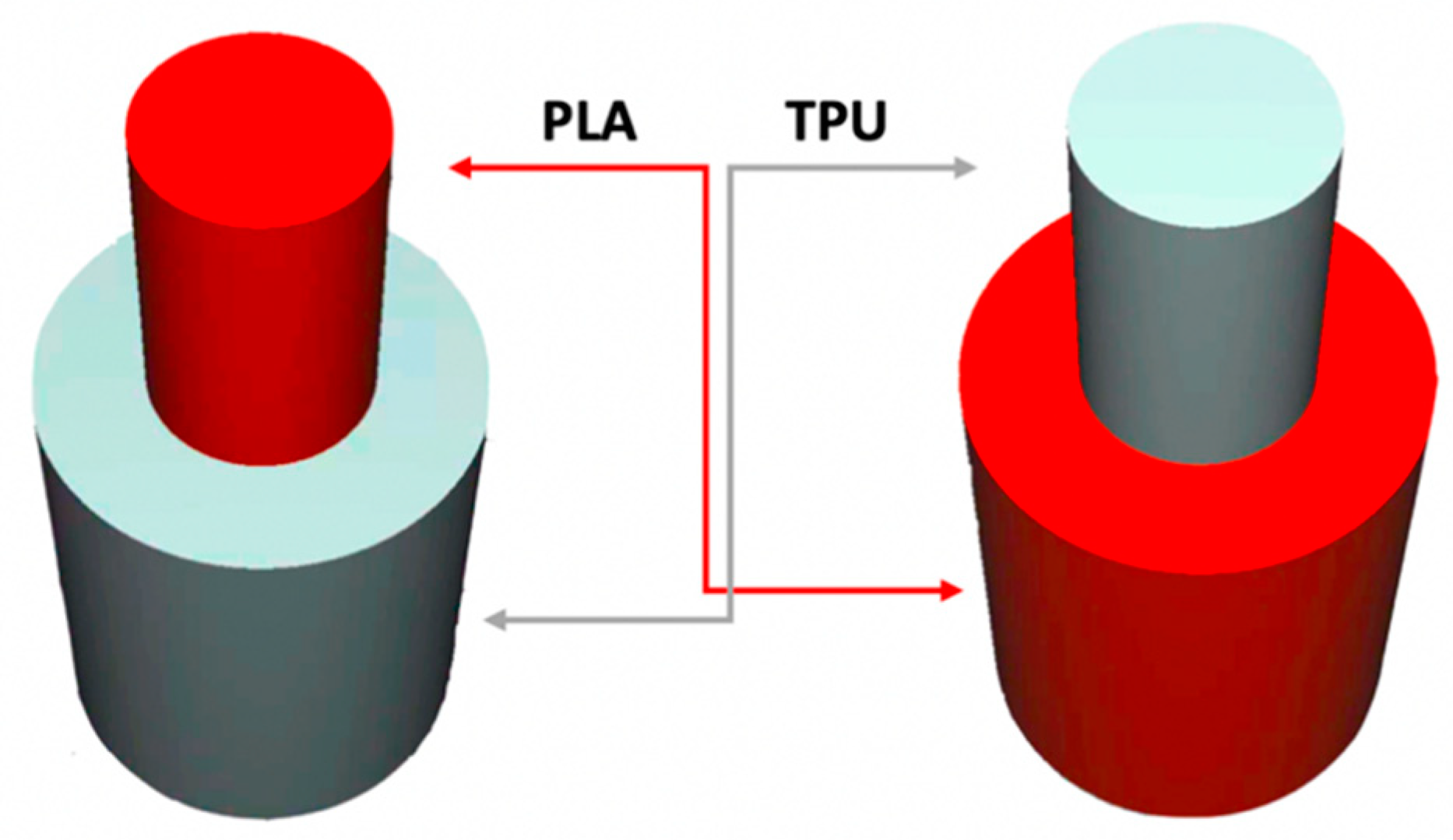

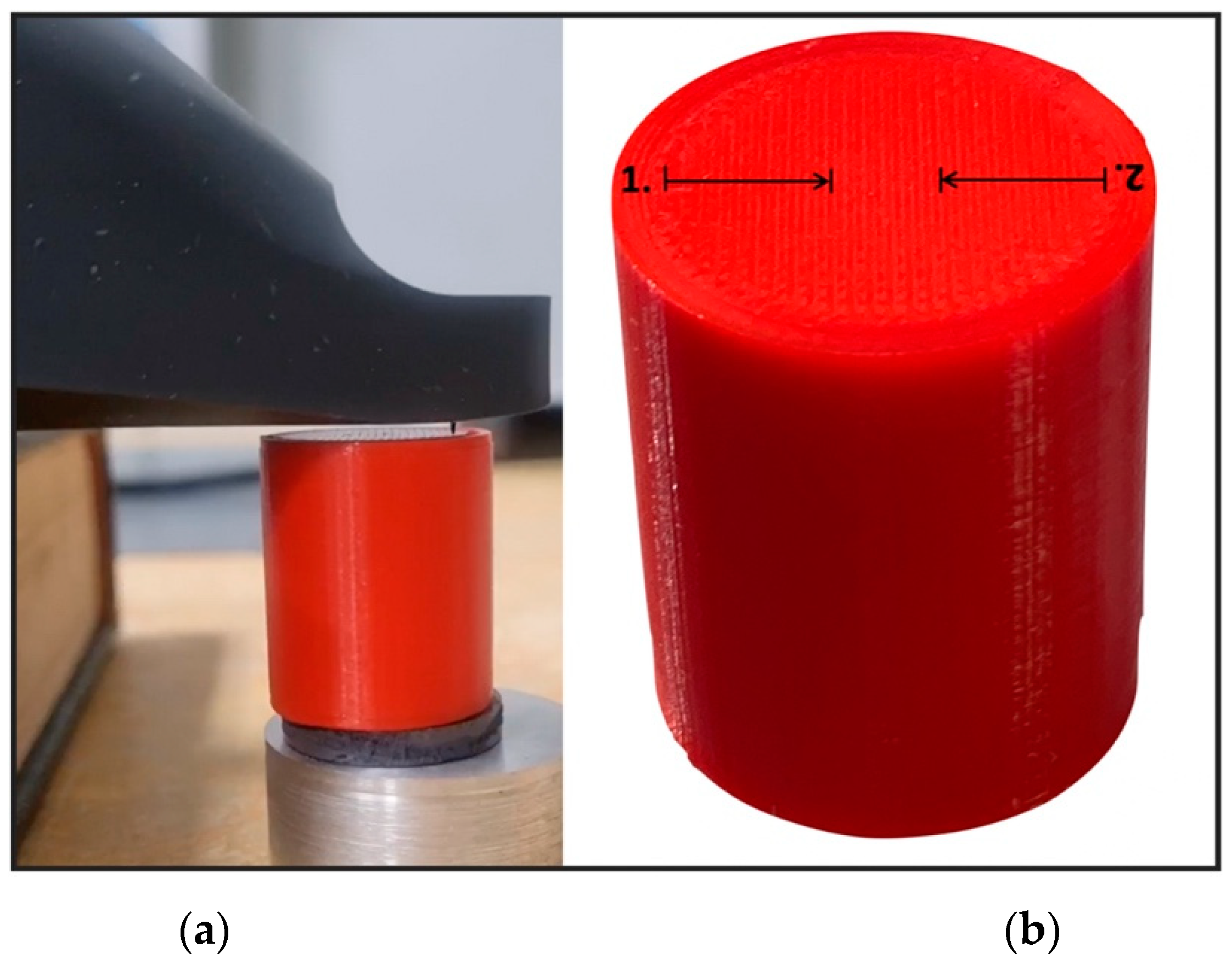

2.2. Samples

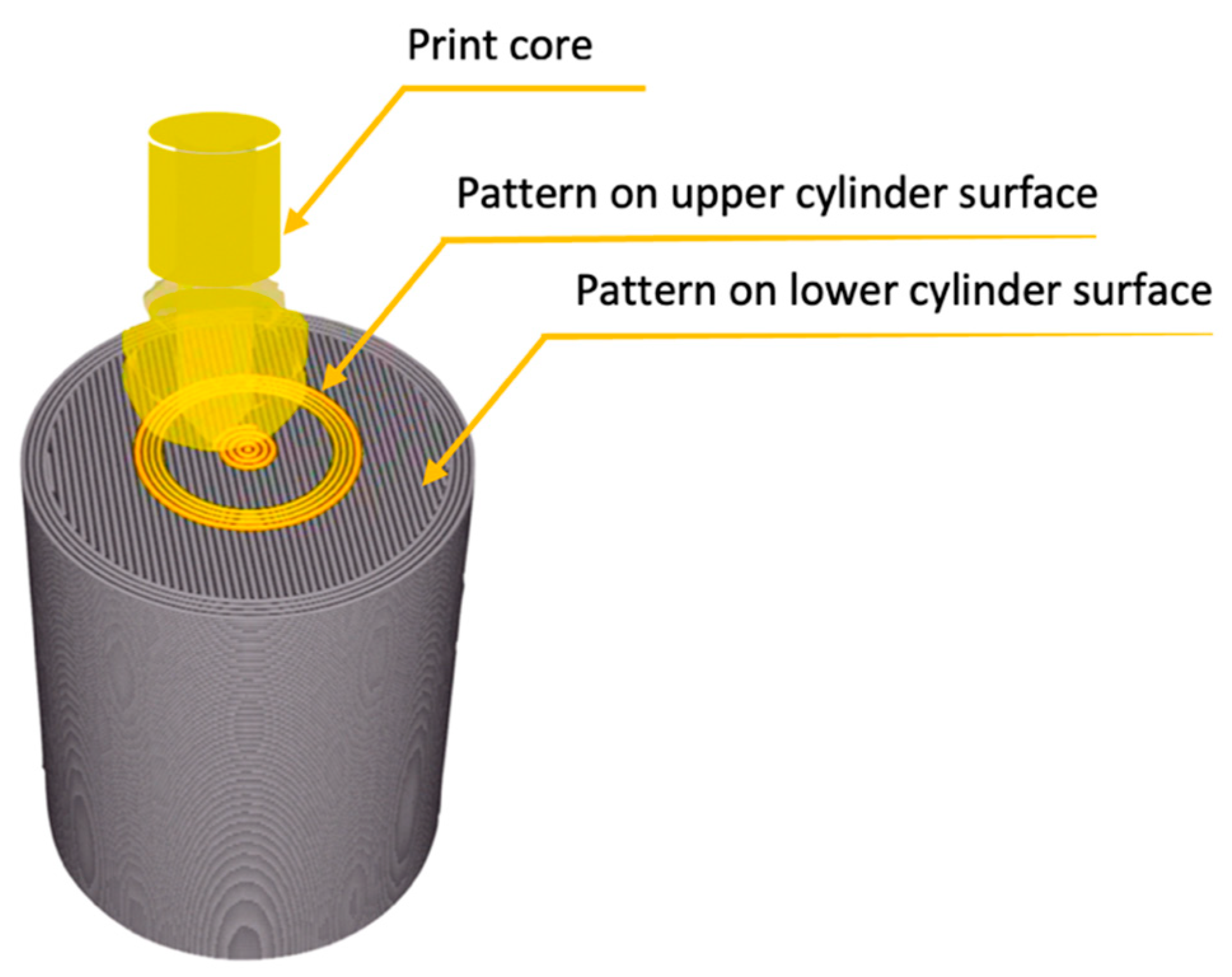

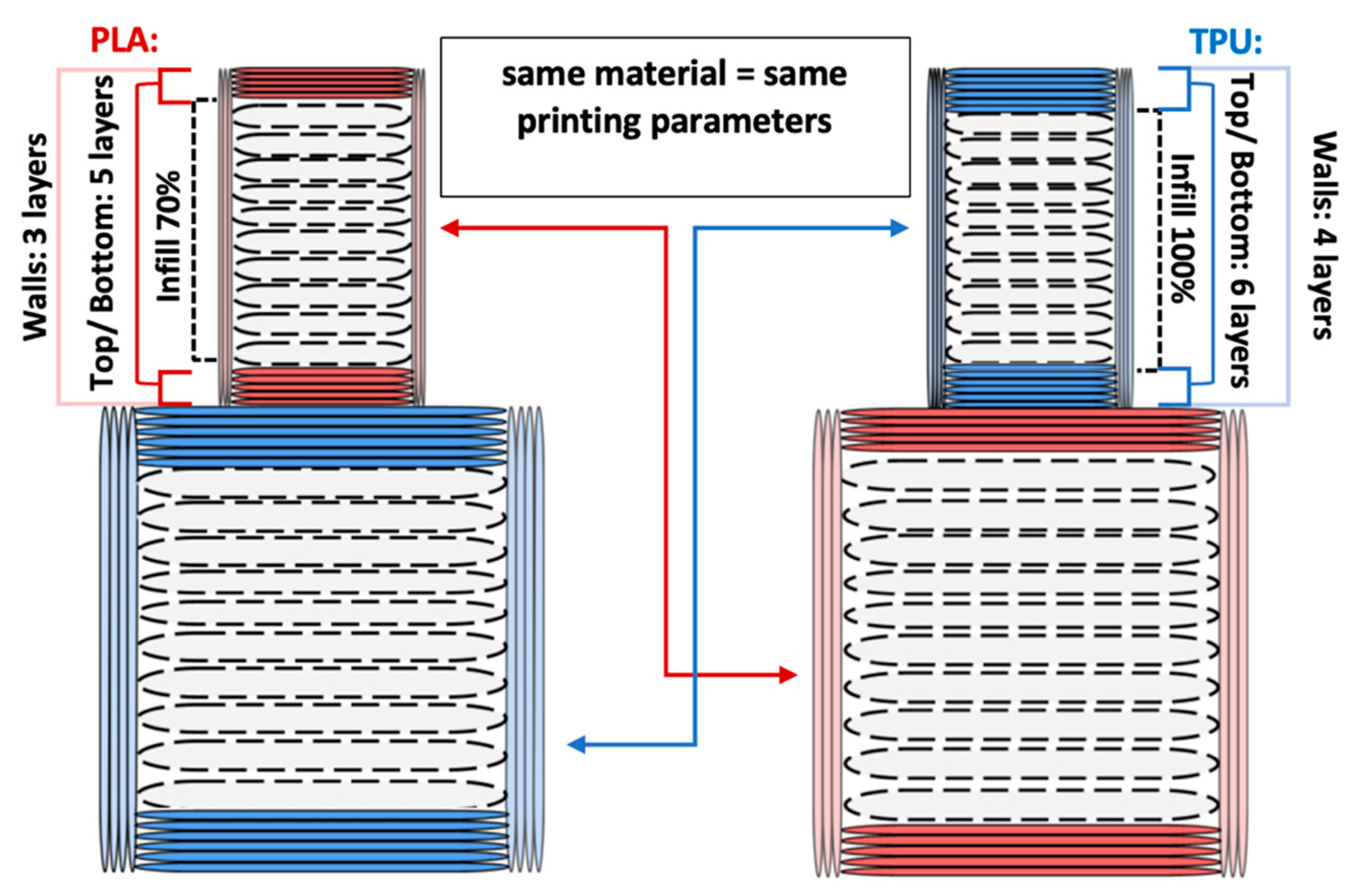

2.3. Printing Parameters

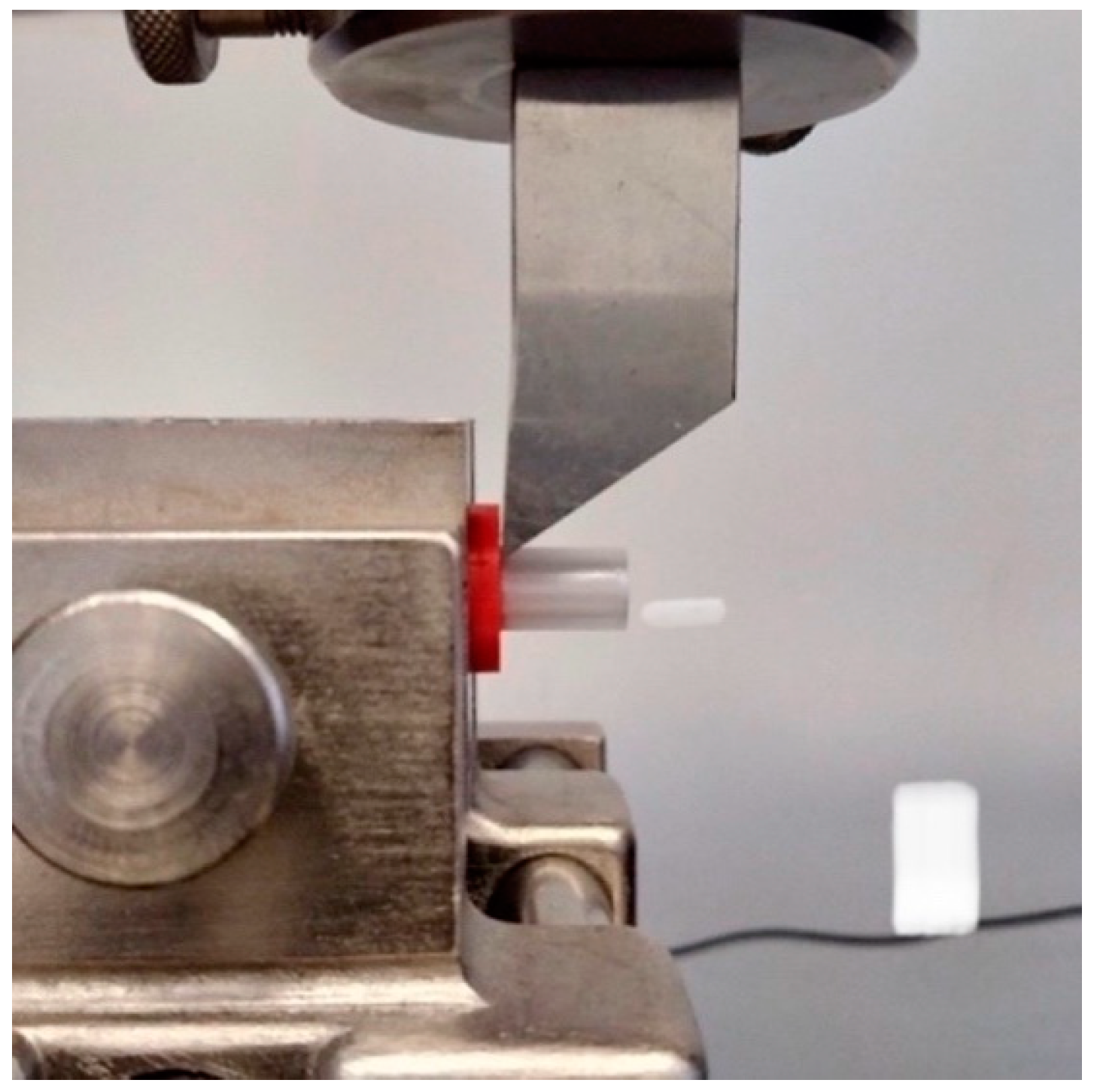

2.4. Adhesion

2.5. Roughness

3. Results

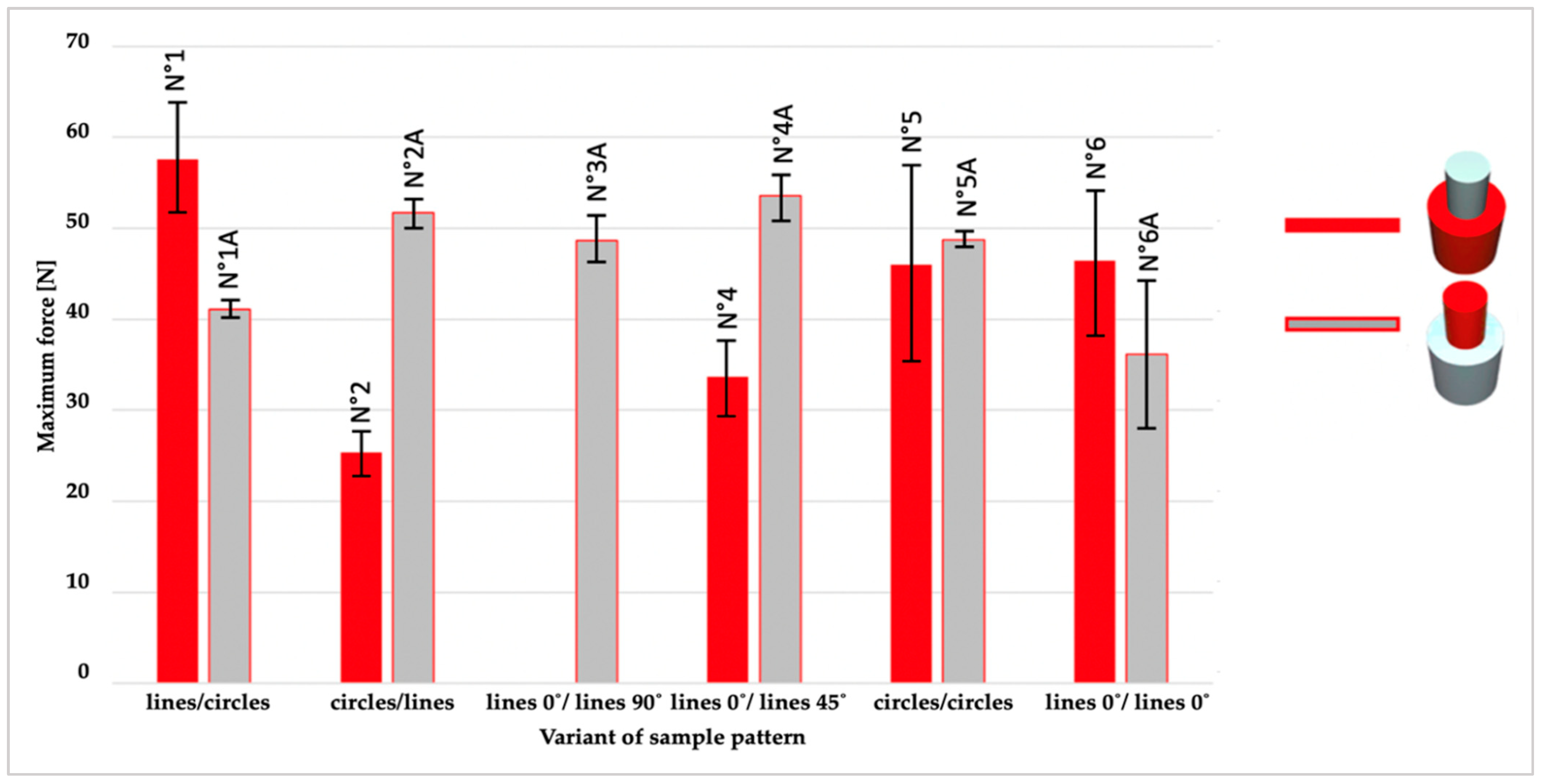

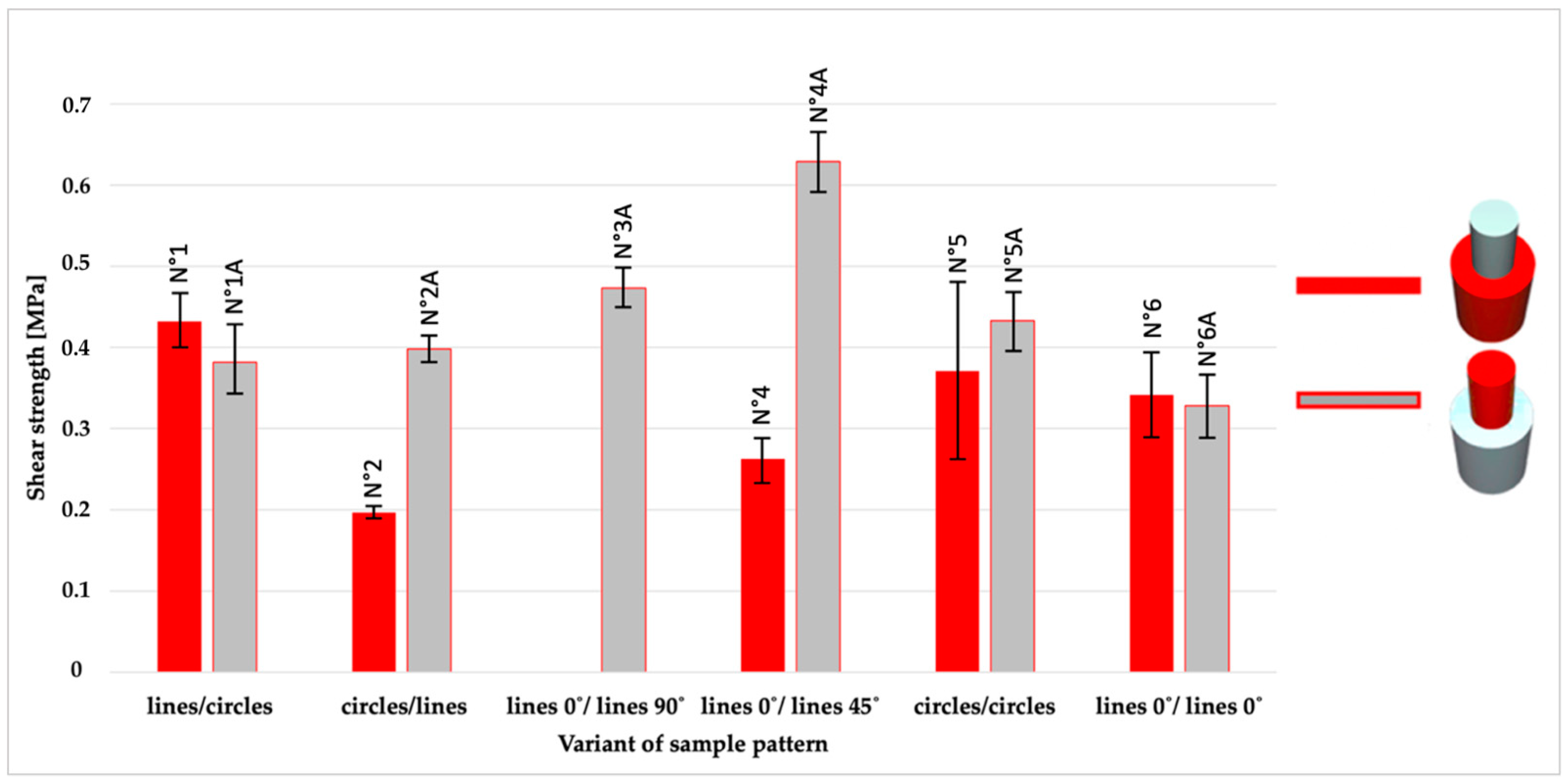

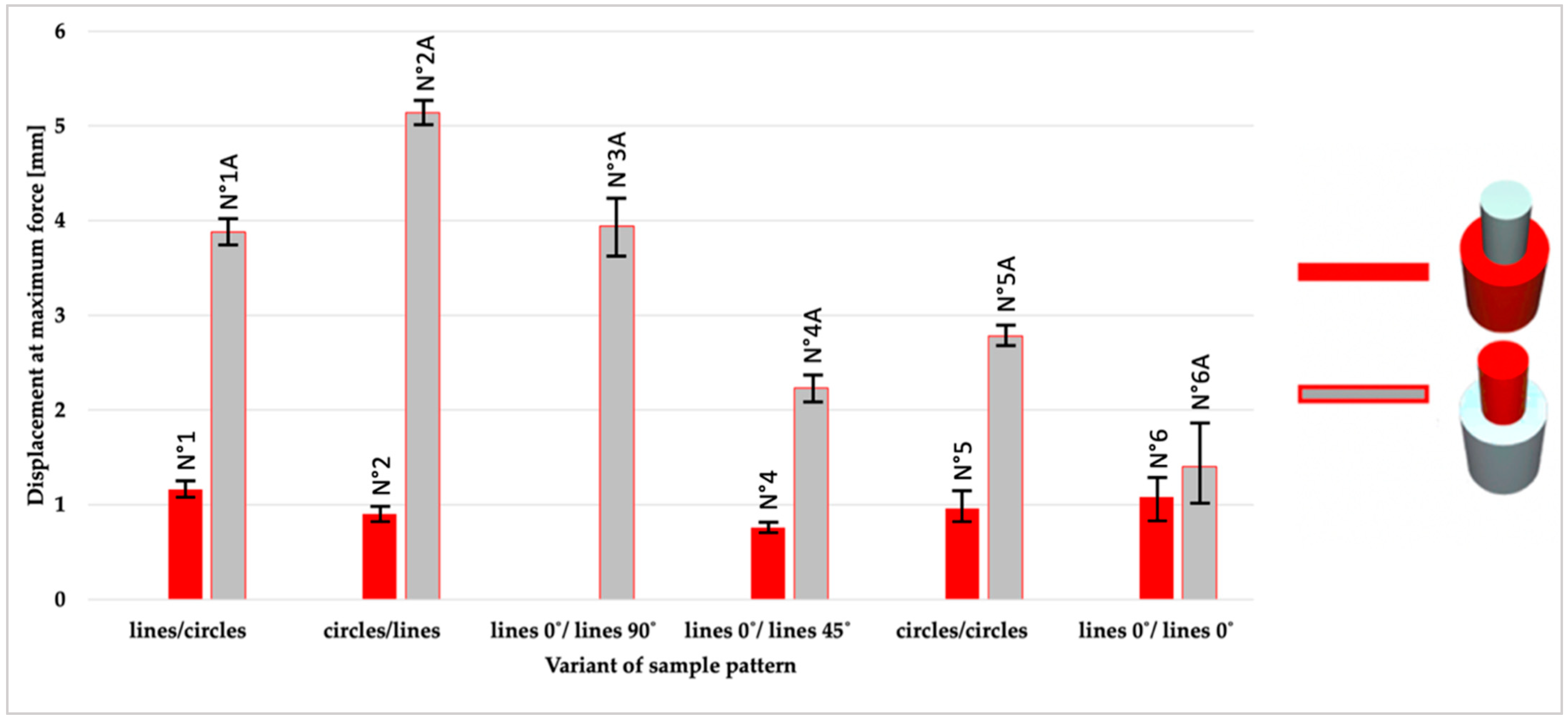

3.1. Adhesion

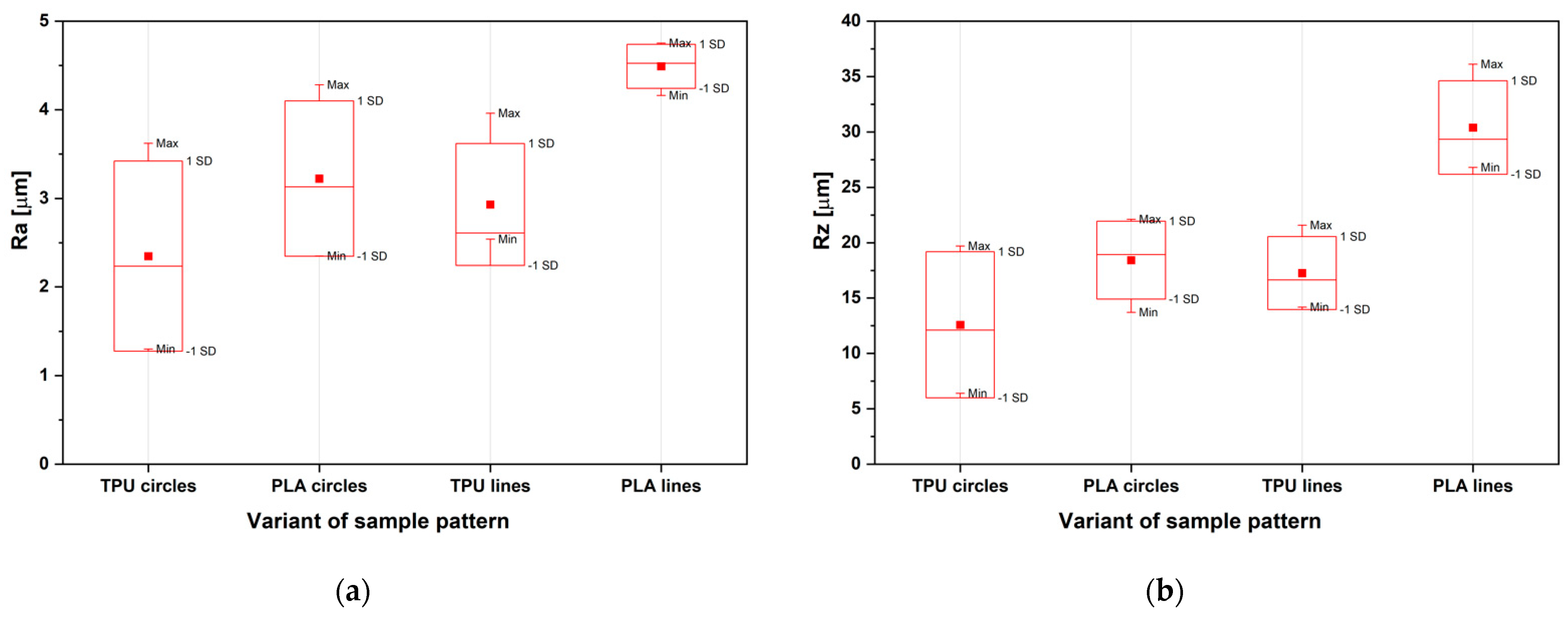

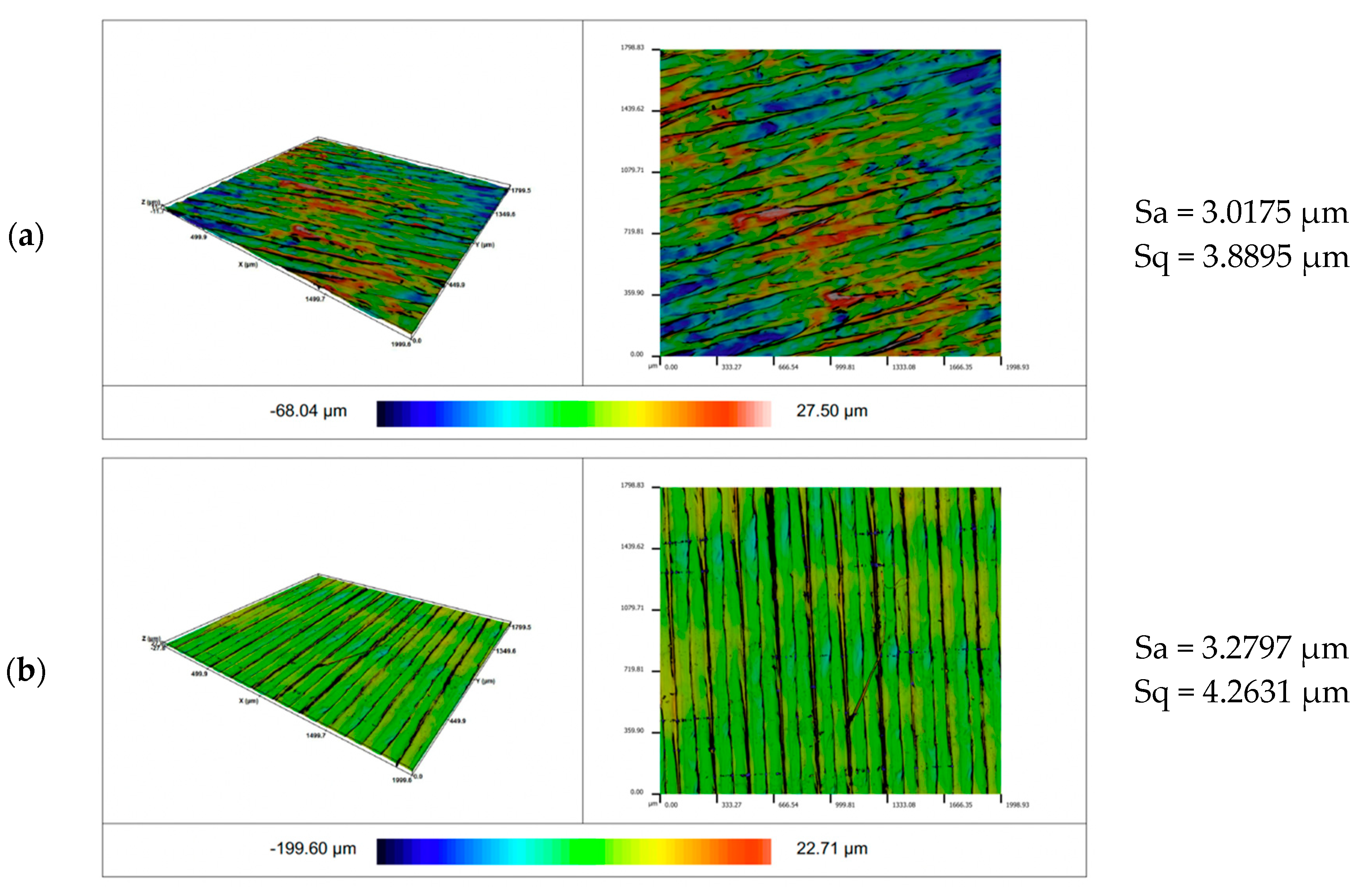

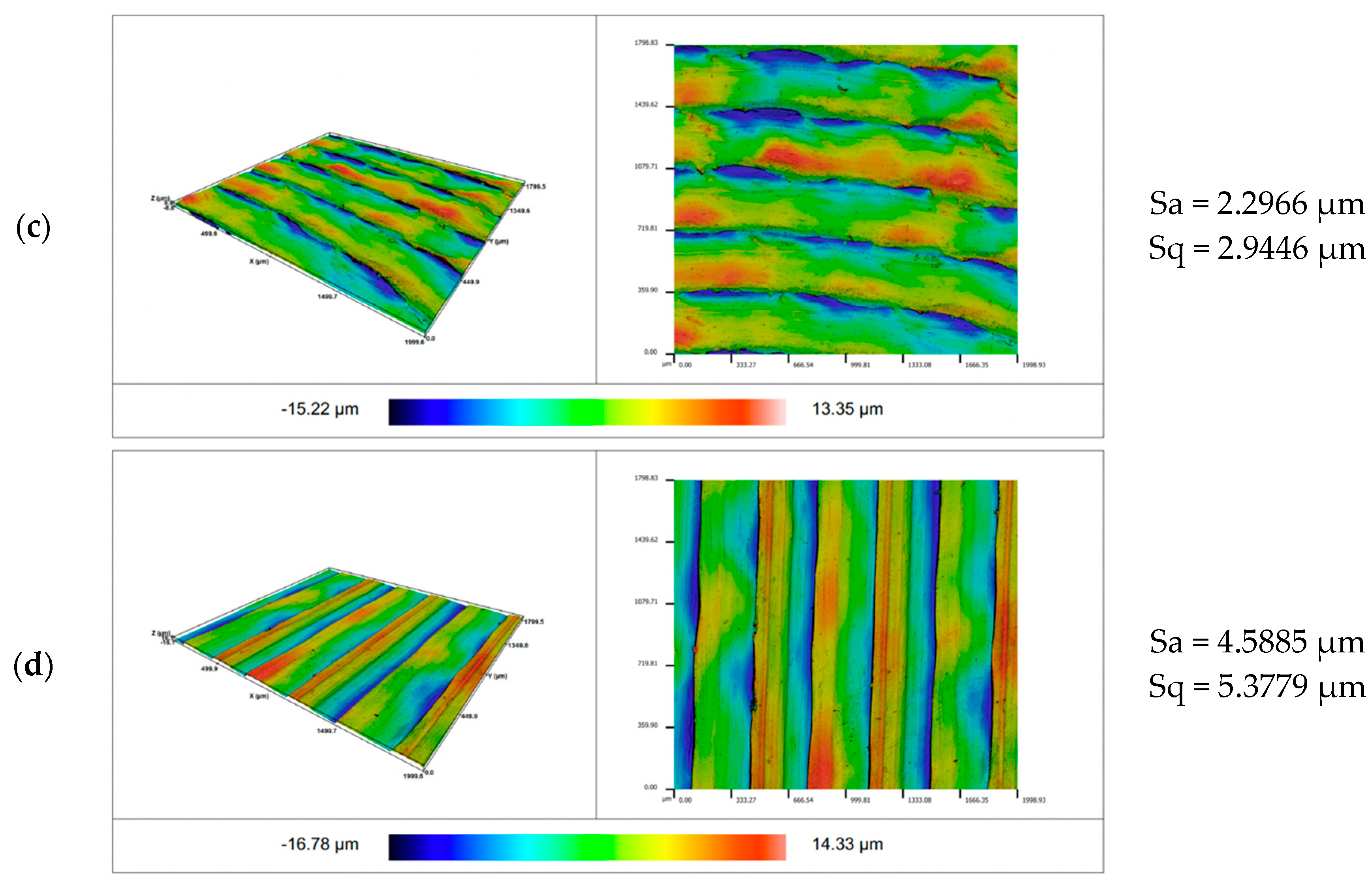

3.2. Roughness

3.3. Roughness and Adhesion Summarised

4. Discussion

- No5A: TPU with a Concentric pattern—PLA with Concentric pattern

- No4A: TPU with a Lines 0° pattern—PLA with Lines 45° pattern

- No5: PLA with a Concentric pattern—TPU with Concentric pattern

- No1: PLA with a Line pattern—TPU with Concentric pattern

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Chen, J.; Shang, E.; Chen, Y. Process based modeling of energy consumption for multi-material FDM 3D printing. Chin. J. Mech. Eng. 2020, 20. [Google Scholar] [CrossRef]

- Yadav, D.; Chhabra, D.; Garg, R.K.; Ahlawat, A.; Phogat, A. Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Mater. Today Proc. 2020, 9, 1583–1591. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D printed polymers: An experimental-modelling methodology for the prediction of mechanical properties. Mater. Des. 2020, 188, 108414. [Google Scholar] [CrossRef]

- Citarella, R.; Giannella, V. Additive Manufacturing in Industry. Appl. Sci. 2021, 11, 840. [Google Scholar] [CrossRef]

- Budzik, G.; Woźniak, J.; Paszkiewicz, A.; Przeszłowski, Ł.; Dziubek, T.; Dębski, M. Methodology for the Quality Control Process of Additive Manufacturing Products Made of Polymer Materials. Materials 2021, 14, 2202. [Google Scholar] [CrossRef]

- Kusoglu, I.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Haghsefat, K.; Eng, M.; Tingting, L. FDM 3D Printing Technology and Its Fundemental Properties. In Proceedings of the International Conference on Innovation and Research in Engineering Sciences, Tbilisi, Georgia, 30 June 2020. [Google Scholar]

- Bergonzi, L.; Vettori, M.; Stefanini, L.; D’Alcamo, L. Different infill geometry influence on mechanical properties of FDM produced PLA. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 49th AIAS Conference (AIAS 2020), Genova, Italy, 2–5 September 2020; IOP Publishing: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Bagheri, A.; Domínguez-Fernández, A.; Casado-López, R. Influence of infill and nozzle diameter on porosity of FDM printed parts with rectilinear grid pattern. Procedia Manuf. 2019, 41, 288–295. [Google Scholar] [CrossRef]

- Yahamed, A.; Ikonomov, P.; Fleming, P.D.; Pekarovicova, A.; Gustafson, P.; Alden, A.Q.; Alrafeek, S. Mechanical properties of 3D printed polymers. J. Print Media Technol. Res. 2016, 5, 273–289. [Google Scholar]

- Taczała, J.; Czepułkowska, W.; Konieczny, B.; Sokołowski, J.; Kozakiewicz, M.; Szymor, P. Comparison of 3D printing MJP and FDM technology in dentistry. Arch. Mater. Sci. Eng. 2020, 1, 32–40. [Google Scholar] [CrossRef]

- Lüchtenborg, J.; Burkhardt, F.; Nold, J.; Rothlauf, S.; Wesemann, C.; Pieralli, S.; Wemken, G.; Witkowski, S.; Spies, B. Implementation of Fused Filament Fabrication in Dentistry. Appl. Sci. 2021, 11, 6444. [Google Scholar] [CrossRef]

- Jeon, B.; Han, J.W.; Lee, K.S.; Cha, S.W. Improvement of the Mechanical Properties of Biodegradable Polymers Using a Microcellular Foaming Process and Natural By-Products. Polym. Technol. Eng. 2012, 51, 401–406. [Google Scholar] [CrossRef]

- Tao, Y.; Shao, J.; Li, P.; Shi, S.Q. Application of a thermoplastic polyurethane/polylactic acid composite filament for 3D-printed personalized orthosis. Mater. Teh. 2019, 53, 71–76. [Google Scholar] [CrossRef]

- Mamiński, M.; Novák, I.; Mičušík, M.; Małolepszy, A.; Toczyłowska-Mamińska, R. Discharge Plasma Treatment as an Efficient Tool for Improved Poly(lactide) Adhesive–Wood Interactions. Materials 2021, 14, 3672. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Kang, B.-K.; Kim, H.-D.; Yoo, H.-J.; Kim, J.-S.; Huh, J.-H.; Jung, Y.-J.; Lee, D.-J. Effect of hot pressing/melt mixing on the properties of thermoplastic polyurethane. Macromol. Res. 2009, 17, 616–622. [Google Scholar] [CrossRef]

- Tabuani, D.; Bellucci, F.; Terenzi, A.; Camino, G. Flame retarded Thermoplastic Polyurethane (TPU) for cable jacketing application. Polym. Degrad. Stab. 2012, 97, 2594–2601. [Google Scholar] [CrossRef]

- Mrówka, M.; Szymiczek, M.; Machoczek, T.; Pawlyta, M. Influence of the Halloysite Nanotube (HNT) Addition on Selected Mechanical and Biological Properties of Thermoplastic Polyurethane. Materials 2021, 14, 3625. [Google Scholar] [CrossRef]

- He, X.; Zhou, J.; Jin, L.; Long, X.; Wu, H.; Xu, L.; Gong, Y.; Zhou, W. Improved Dielectric Properties of Thermoplastic Polyurethane Elastomer Filled with Core–Shell Structured PDA@TiC Particles. Materials 2020, 13, 3341. [Google Scholar] [CrossRef]

- Lee, H.; Eom, R.-I.; Lee, Y. Evaluation of the Mechanical Properties of Porous Thermoplastic Polyurethane Obtained by 3D Printing for Protective Gear. Adv. Mater. Sci. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Sambruno, A.; Bañon, F.; Salguero, J.; Simonet, B.; Batista, M. Kerf Taper Defect Minimization Based on Abrasive Waterjet Machining of Low Thickness Thermoplastic Carbon Fiber Composites C/TPU. Materials 2019, 12, 4192. [Google Scholar] [CrossRef]

- Ji, X.; Gao, F.; Geng, Z.; Li, D. Fabrication of thermoplastic polyurethane/polylactide shape-memory blends with tunable optical and mechanical properties via a bilayer structure design. Polym. Test. 2021, 97, 107135. [Google Scholar] [CrossRef]

- Lis-Bartos, A.; Smieszek, A.; Frańczyk, K.; Marycz, K. Fabrication, Characterization, and Cytotoxicity of Thermoplastic Polyurethane/Poly(lactic acid) Material Using Human Adipose Derived Mesenchymal Stromal Stem Cells (hASCs). Polymers 2018, 10, 1073. [Google Scholar] [CrossRef]

- Hu, Q.; Suihong, L.; Yan, G.; Zhicheng, S. Topological Structure Design and Fabrication of Biocompatible PLA/TPU/ADM Mesh with Appropriate Elasticity for Hernia Repair. Macromol. Biosci. 2021, 21, 2000423. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, L.; Heng, P.; Xiao, J.; Lv, J.; Zhang, Q.; Hickey, M.E.; Tu, Q.; Wang, J. Lecithin doped electrospun poly(lactic acid)-thermoplastic polyurethane fibers for hepatocyte viability improvement. Colloids Surf. B Biointerfaces 2018, 175, 264–271. [Google Scholar] [CrossRef]

- Han, Y.; Kim, J. A Study on the Mechanical Properties of Knit Fabric Using 3D Printing—Focused on PLA, TPU Filament. J. Fash. Bus. 2018, 22, 93–105. [Google Scholar] [CrossRef]

- Lopes, L.; Silva, A.; Carneiro, O. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Schwartz, J.J.; Boydston, A.J. Multimaterial actinic spatial control 3D and 4D printing. Nat. Commun. 2019, 10, 791. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Tatineni, J.; Cadd, B.; Peart, G.; Gibson, I. Advanced auricular prosthesis development by 3D modelling and multi-material printing. In Proceedings of the International Conference on Design and Technology (DesTech 2016), Geelong, Australia, 5–8 December 2016; Volume 7. Available online: https://dro.deakin.edu.au/eserv/DU:30091544/gibson-advancedauricular-2017.pdf (accessed on 8 September 2021).

- Yin, J.; Li, M.; Dai, G.; Zhou, H.; Ma, L.; Zheng, Y. 3D Printed Multi-material Medical Phantoms for Needle-tissue Interaction Modelling of Heterogeneous Structures. J. Bionic Eng. 2021, 18, 346–360. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The influence of slicing parameters on the multi-material adhesion mechanisms of FDM printed parts: An exploratory study. Virtual Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Rahmati, S.; Vahabli, E. Evaluation of analytical modeling for improvement of surface roughness of FDM test part using measurement results. Int. J. Adv. Manuf. Technol. 2015, 79, 823–829. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. On Surface Finish and Dimensional Accuracy of FDM Parts after Cold Vapor Treatment. Mater. Manuf. Process. 2016, 31, 522–529. [Google Scholar] [CrossRef]

- Ahn, D.; Kweon, J.-H.; Kwon, S.; Song, J.; Lee, S. Representation of surface roughness in fused deposition modeling. J. Mater. Process. Technol. 2009, 209, 5593–5600. [Google Scholar] [CrossRef]

- Bouzouita, A.; Notta-Cuvier, D.; Raquez, J.-M.; Lauro, F.; Dubois, P. Poly(lactic acid)-Based Materials for Automotive Applications. In Industrial Applications of Poly(lactic acid). Advances in Polymer Science; Di Lorenzo, M., Androsch, R., Eds.; Springer: Cham, Switzerland, 2017; Volume 282. [Google Scholar] [CrossRef]

- Bouzouita, A. Elaboration of Polylactide-Based Materials for Automotive Application: Study of Structure-Process-Properties Interactions Amani Bouzouita. Ph.D. Thesis, Université de Valenciennes et du Hainaut-Cambresis, Valenciennes, France, Université de Mons, Mons, Belgium, 2016. [Google Scholar]

- Fort, T.; Bruns, K.; Bichel, A.; Miller, J.; Vanstrom, J.R.; Koziel, J.A. Puncture and Cut Resistant Glove Testing; TSM 416 Technology Capstone Projects. 31; Iowa State University Digital Repository: Ames, IA, USA, 2018. [Google Scholar] [CrossRef]

- Higher Dimension Materials, Inc. Cut, Abrasion and/or Puncture Resistant Knitted Gloves. U.S. Patent 20170055608, 2 March 2017.

- Chari, S.; Haines, T.; Varghese, P.; Economidis, A. Are non-slip socks really ’non-slip’? An analysis of slip resistance. BMC Geriatr. 2009, 9, 39. [Google Scholar] [CrossRef] [PubMed]

- Filamentum, Flexfill TPU 98A, TDS. Available online: http://www.fillamentumautomotive.com/wp-content/uploads/2020/10/Technical-Data-Sheet_Flexfill-TPU-98A_26082019.pdf (accessed on 16 August 2021).

- Ultimaker PLA, TDS. Available online: https://support.ultimaker.com/hc/en-us/articles/360011962720 (accessed on 16 August 2021).

- Taczała, J.; Rak, K.; Sawicki, J.; Krasowski, M. Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification. Materials 2021, 14, 3927. [Google Scholar] [CrossRef]

- Surface Texture from Ra to Rz. Available online: https://www.mmsonline.com/columns/surface-texture-from-ra-to-rz (accessed on 16 August 2021).

| Mechanical Properties | Material | Typical Value | Test Method |

|---|---|---|---|

| Hardness | PLA | 83 (Shore D) | Durometer |

| Tensile modulus | PLA | 2.346 MPa | ISO 527 (1 mm/min) |

| Elongation at break | PLA | 5.2% | ISO 527 (50 mm/min) |

| Hardness | TPU | 60 (Shore D) | ISO 7619–1 |

| Tensile strength | TPU | 53.7 MPa | DIN 53504 (200 mm/min) |

| Elongation at break | TPU | 318% | DIN 53504 (200 mm/min) |

| Print Setting | Extruder 1: PLA | Extruder 2: TPU |

|---|---|---|

| Layer Height | 0.2 mm | 0.2 mm |

| Top/Bottom Line Width | 0.35 mm | 0.35 mm |

| Wall Line Court | 3 | 4 |

| Top/Bottom Layers | 5 | 6 |

| Infill Density | 70% | 100% |

| Infill Pattern | Triangles | Grid |

| Printing Temperature | 200 °C | 210 °C |

| Print Speed | 70 mm/s | 30 mm/s |

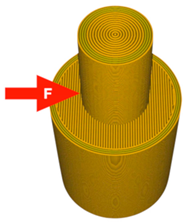

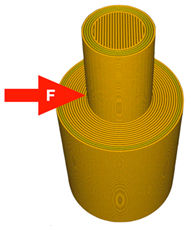

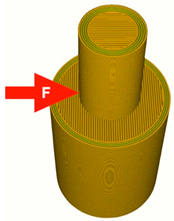

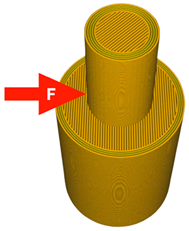

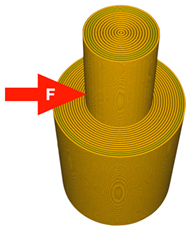

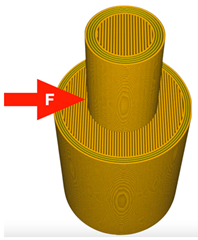

| A 3D Model with A Visible Pattern | Pattern Configuration | Material Configuration/N° | |

|---|---|---|---|

| Bottom: PLA Top: TPU | Bottom: TPU Top: PLA | ||

| Bottom part: Lines Top part: Concentric |  N°−1 |  N°−1A |

| Bottom part: Concentric Top part: Lines |  N°−2 |  N°−2A |

| Bottom part: Lines (Line direction: 0°) Top part: Lines (Line direction: 90°) | Failure N°−3 |  N°−3A |

| Bottom part: Lines (Line direction: 0°) Top part: Lines (Line direction: 45°) |  N°−4 |  N°−4A |

| Bottom part: Concentric Top part: Concentric |  N°−5 |  N°−5A |

| Bottom part: Lines 0° Top part: Lines 0° |  N°−6 |  N°−6A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brancewicz-Steinmetz, E.; Sawicki, J.; Byczkowska, P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials 2021, 14, 6464. https://doi.org/10.3390/ma14216464

Brancewicz-Steinmetz E, Sawicki J, Byczkowska P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials. 2021; 14(21):6464. https://doi.org/10.3390/ma14216464

Chicago/Turabian StyleBrancewicz-Steinmetz, Emila, Jacek Sawicki, and Paulina Byczkowska. 2021. "The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU)" Materials 14, no. 21: 6464. https://doi.org/10.3390/ma14216464

APA StyleBrancewicz-Steinmetz, E., Sawicki, J., & Byczkowska, P. (2021). The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials, 14(21), 6464. https://doi.org/10.3390/ma14216464