Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties

Abstract

1. Introduction

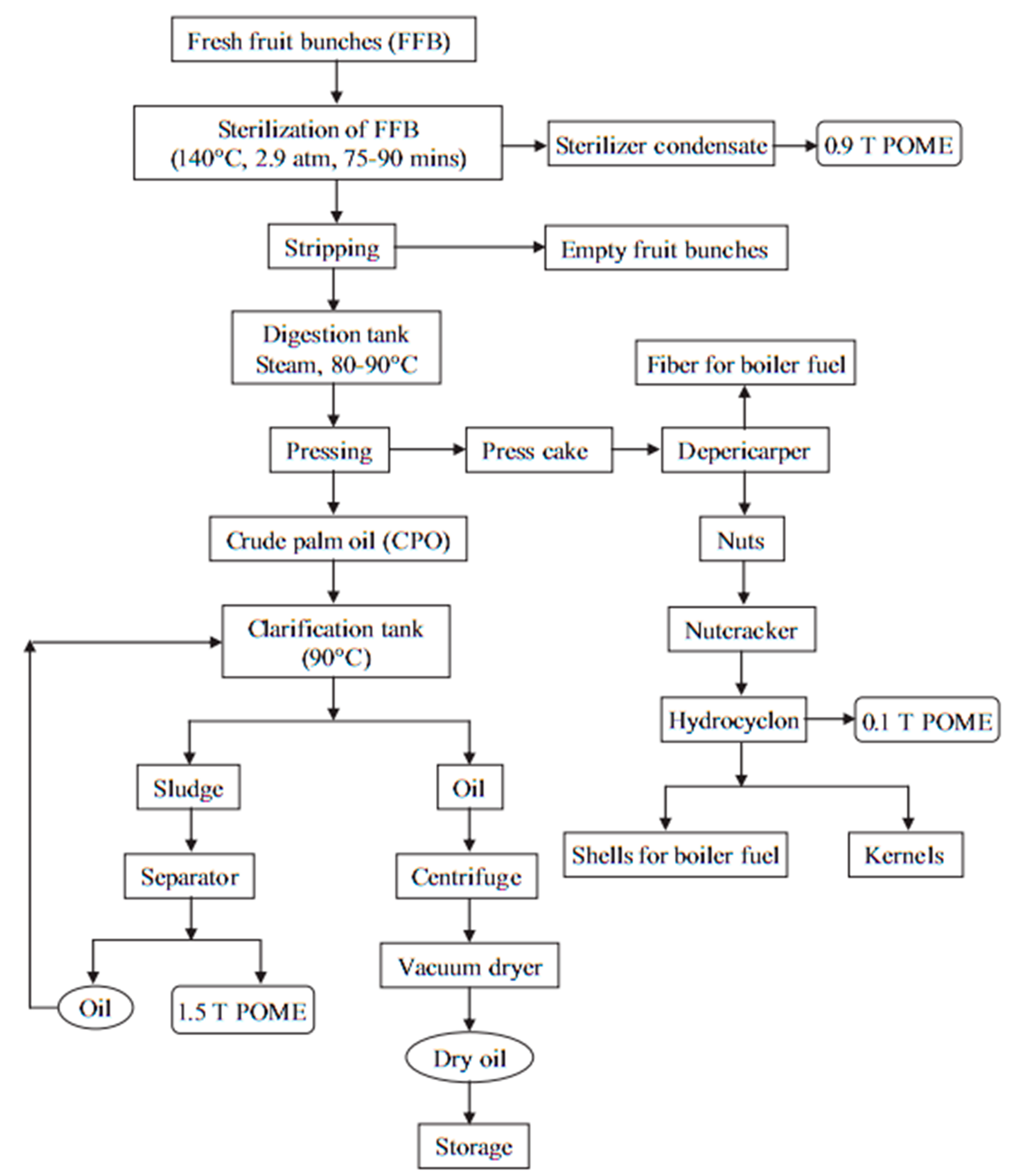

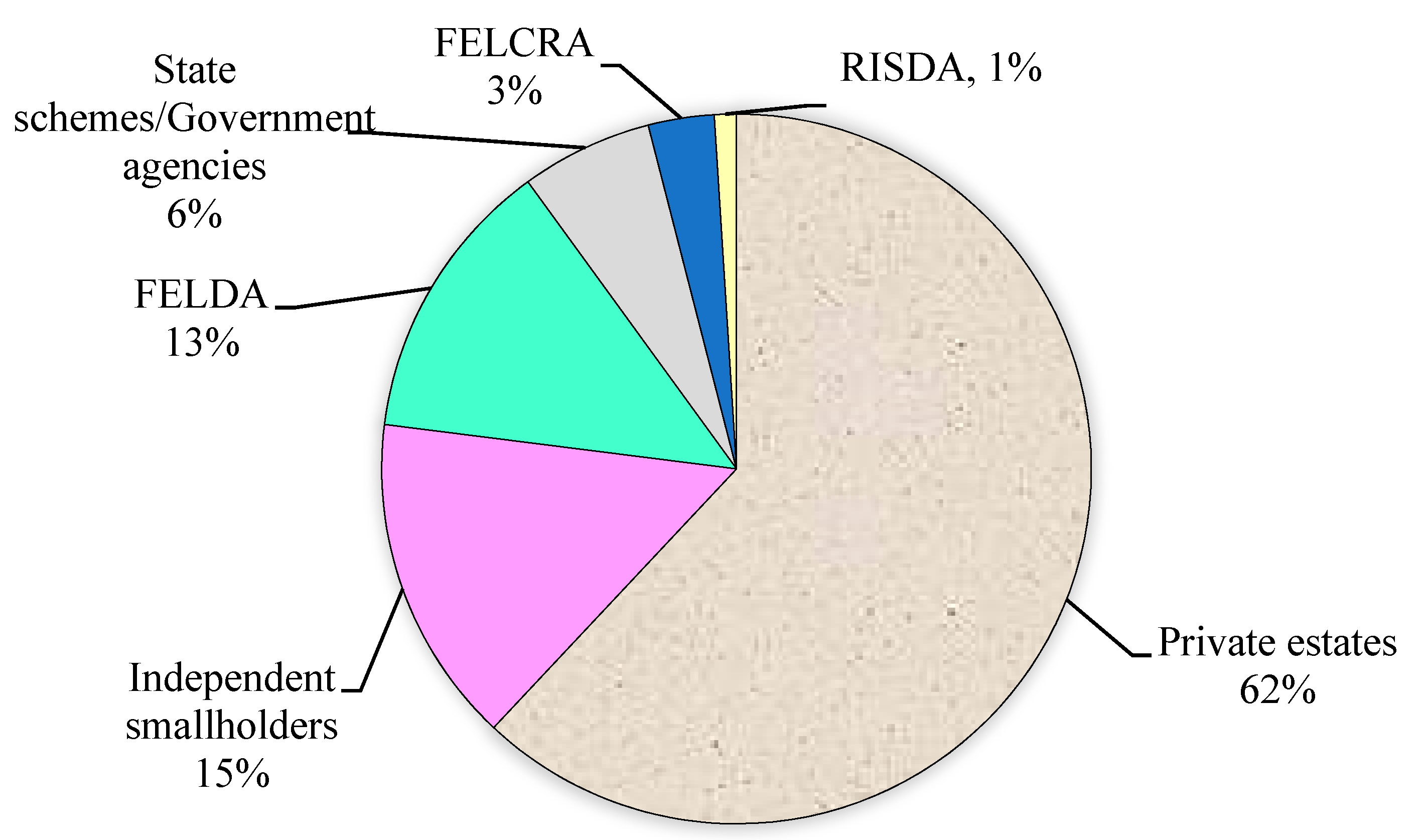

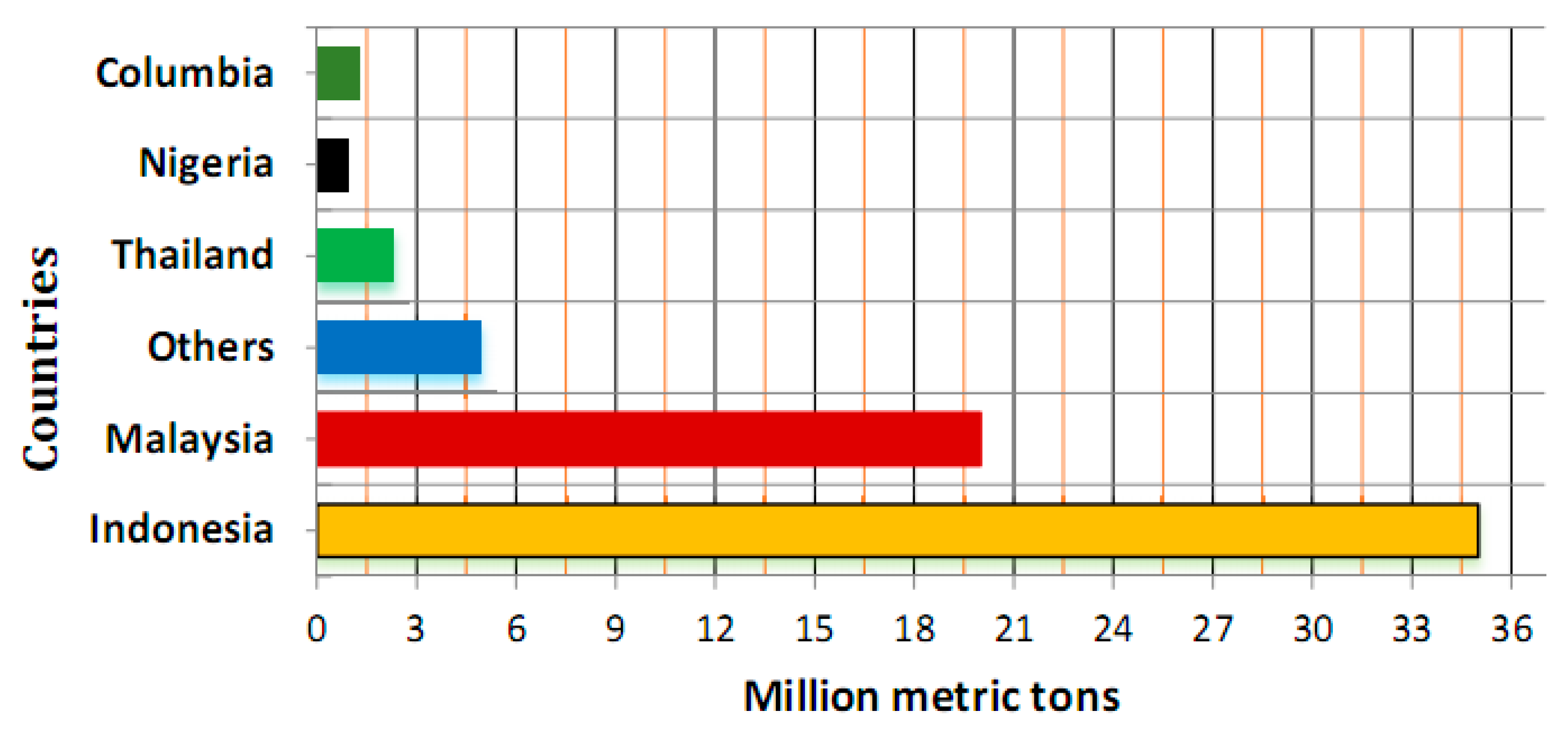

2. POFA Source and the Possibility of Its Application in Construction

3. Clean Production of POFA

4. Chemical Composition

5. Physical Properties

5.1. Density and Specific Gravity

5.2. Color

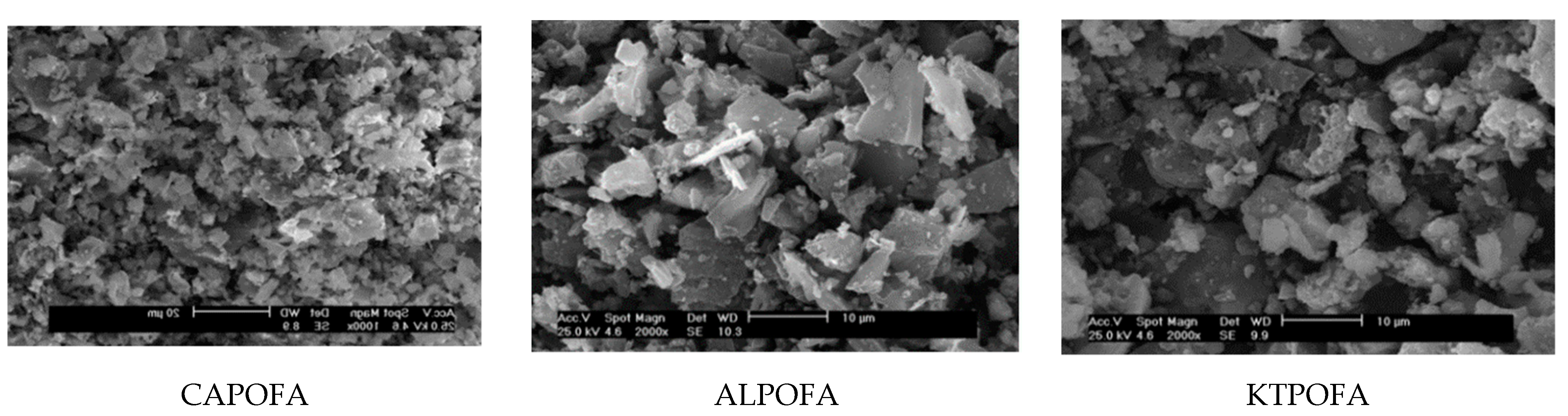

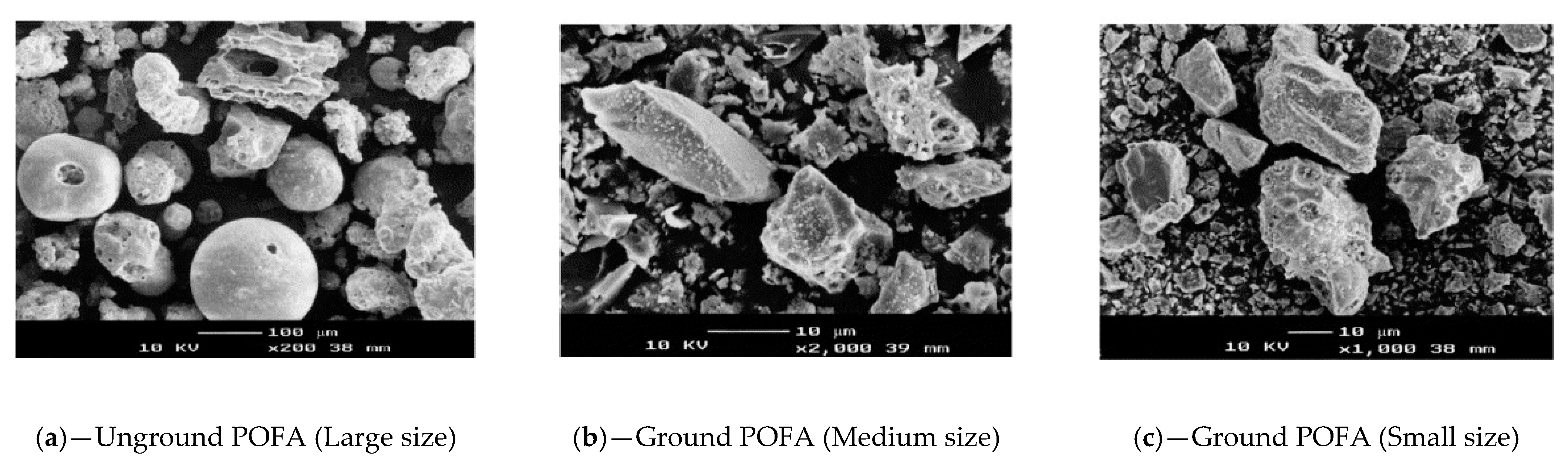

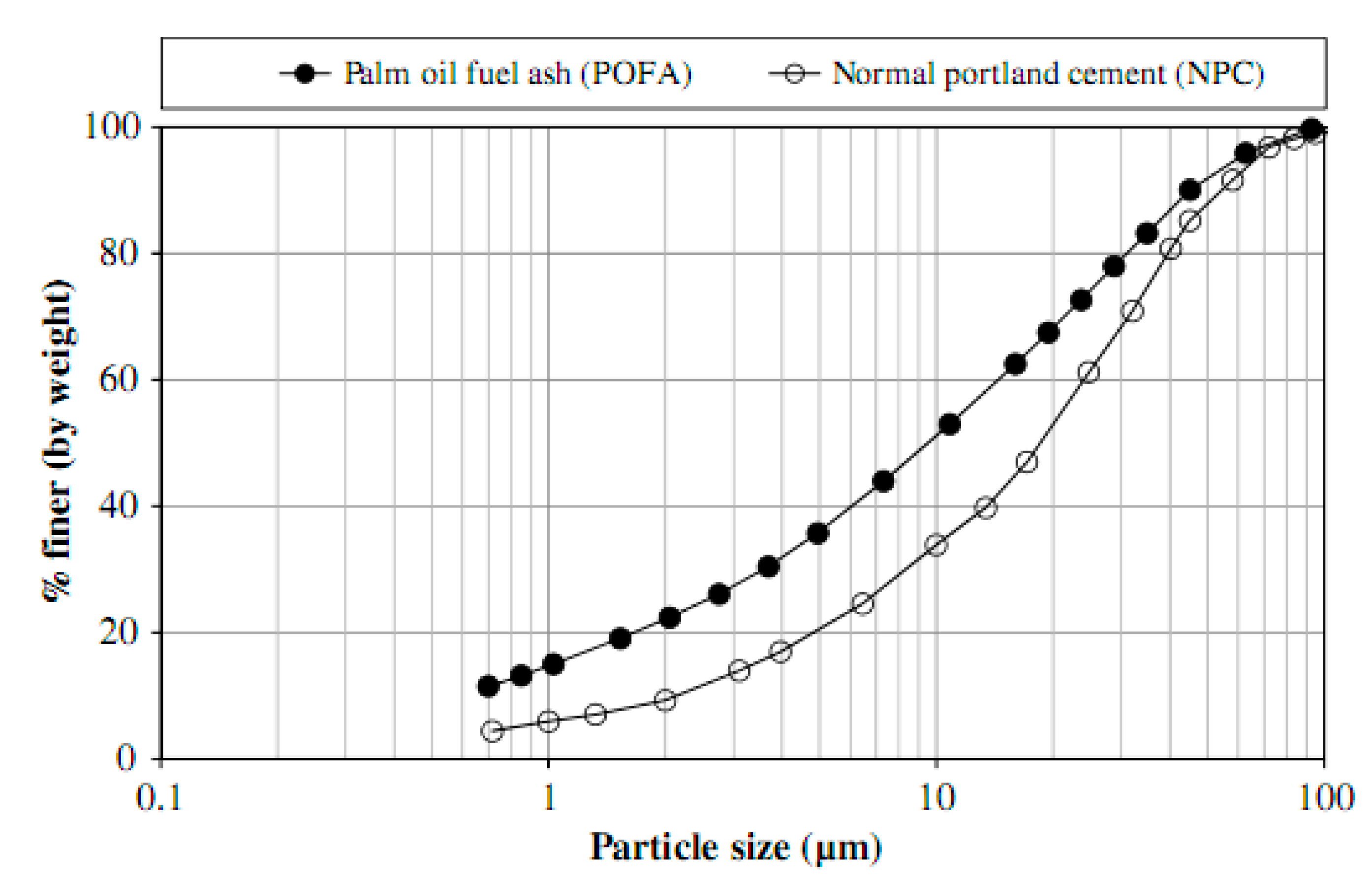

5.3. Particle Size and Shape

- Dground POFA = 0.35 µm

- DOPC = 0.2 µm

- Dunground POFA = 0.07 µm

- Cu = (DOPC/Dground POFA) = 2.86

- Cc = (Dunground POFA)2/(Dground POFA × DOPC) = 0.35

- Cu (uniformity coefficient) is more than 2, and Cc (coefficient of gradation) is limited to 0.30 and 1. Therefore, M-sand is quite rated and is within zone C BS882:1992 [93].

5.4. Fineness

5.5. Heat of Hydration

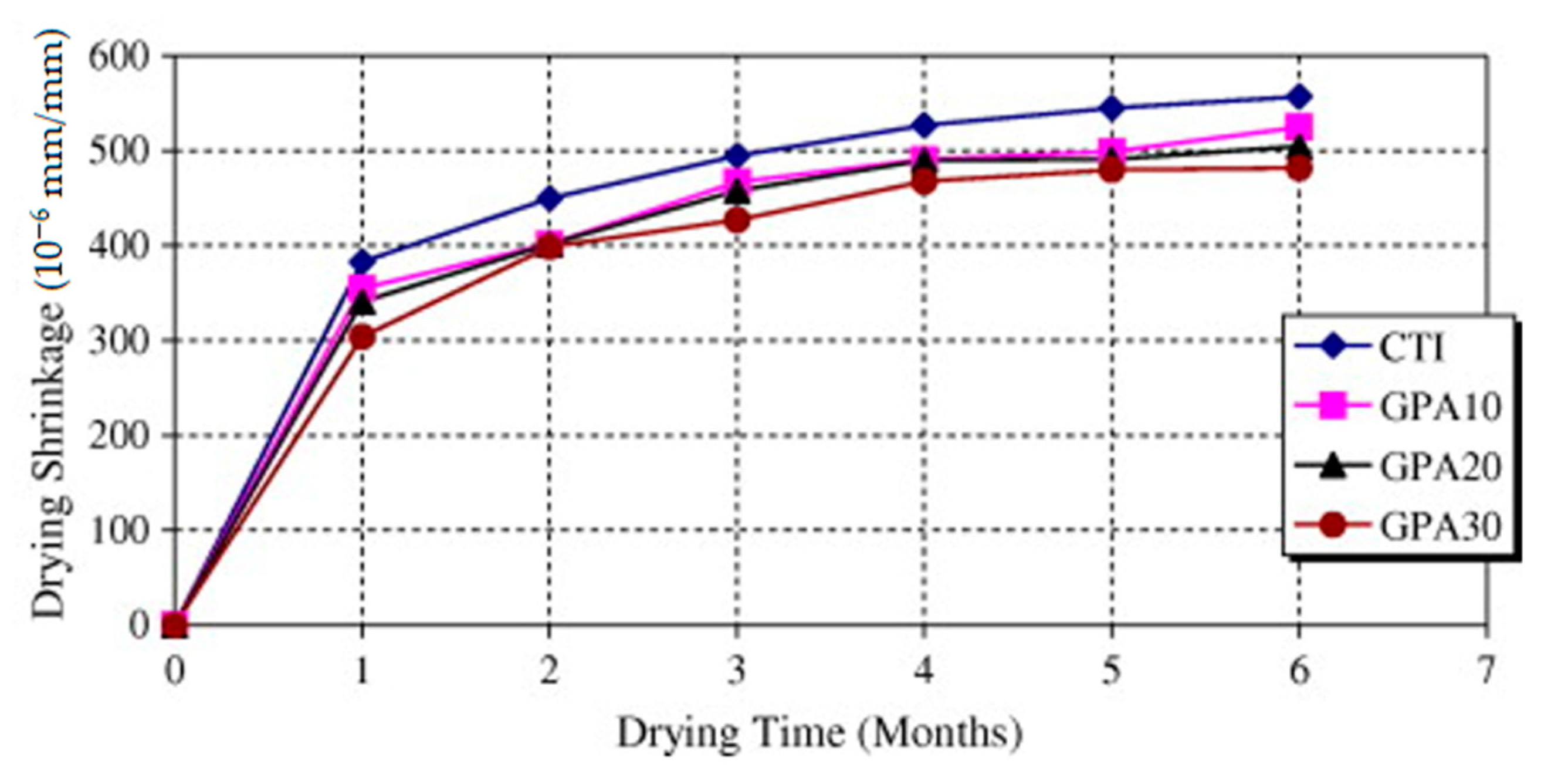

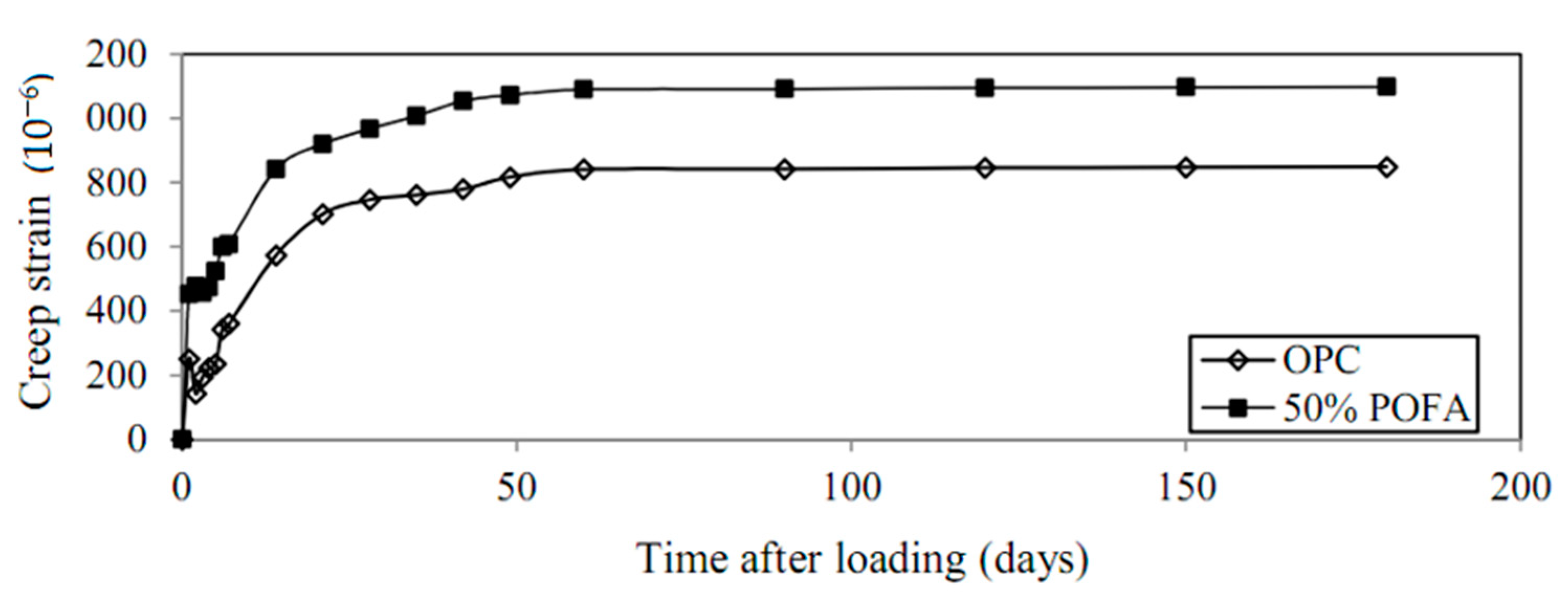

5.6. Drying Shrinkage

5.7. Porosity

6. Fresh Properties

6.1. Workability

6.2. Setting Time

6.3. Segregation and Bleeding

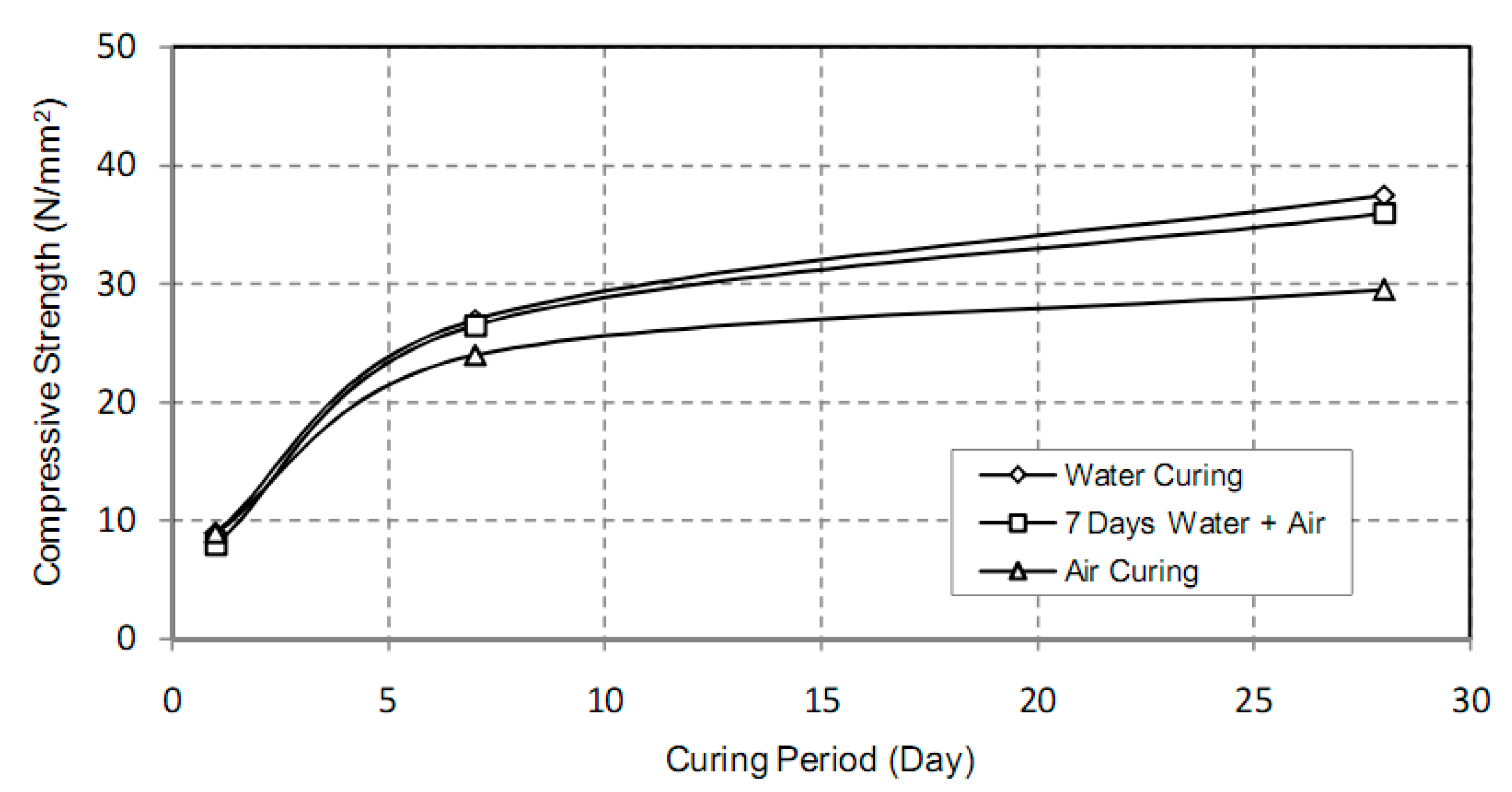

7. Curing Regimes of POFA

7.1. Water Curing

7.2. Air Curing

8. Mechanical Properties

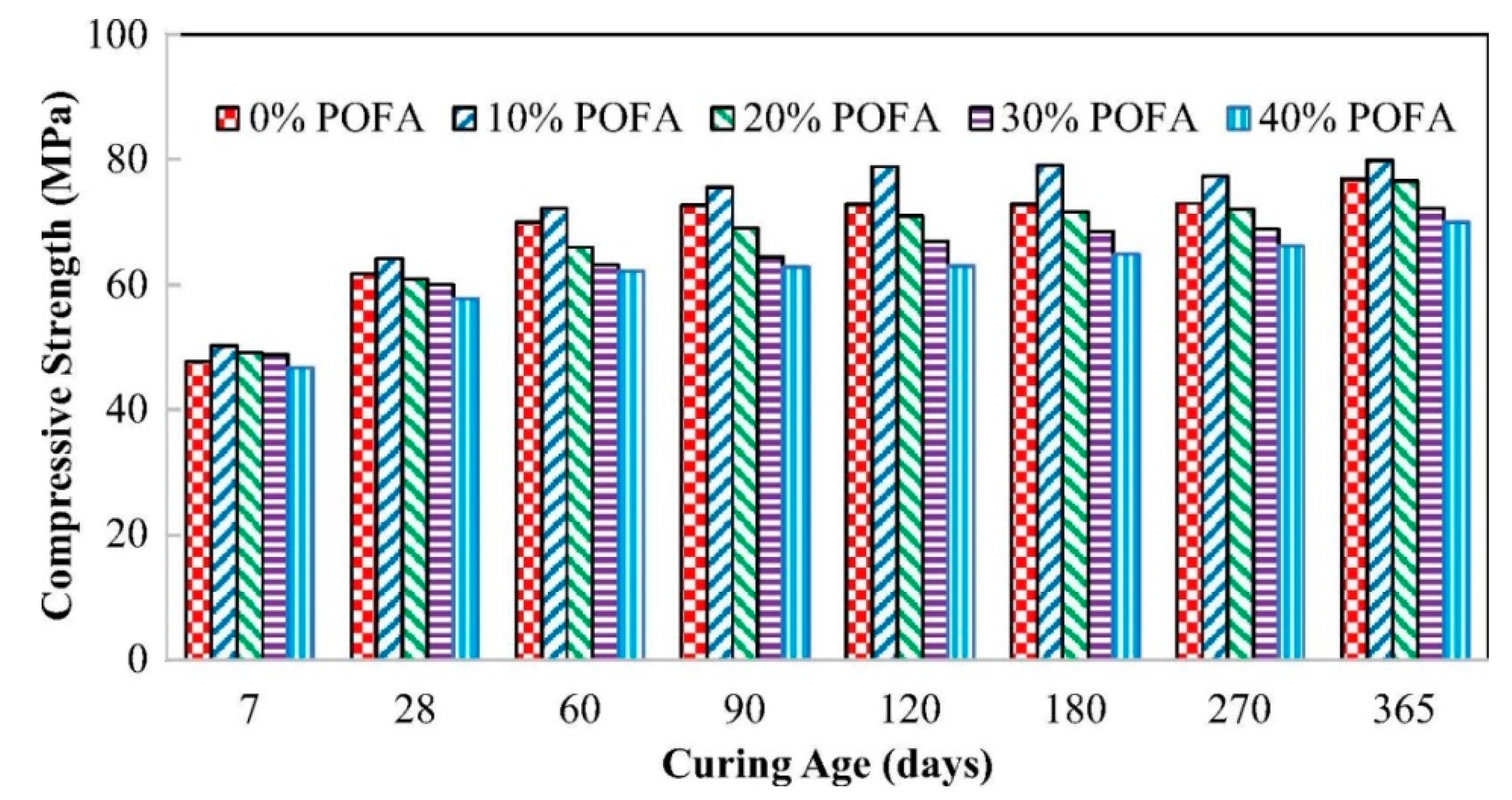

8.1. Compressive Strength

8.2. Splitting Tensile Strength

8.3. Flexural Strength

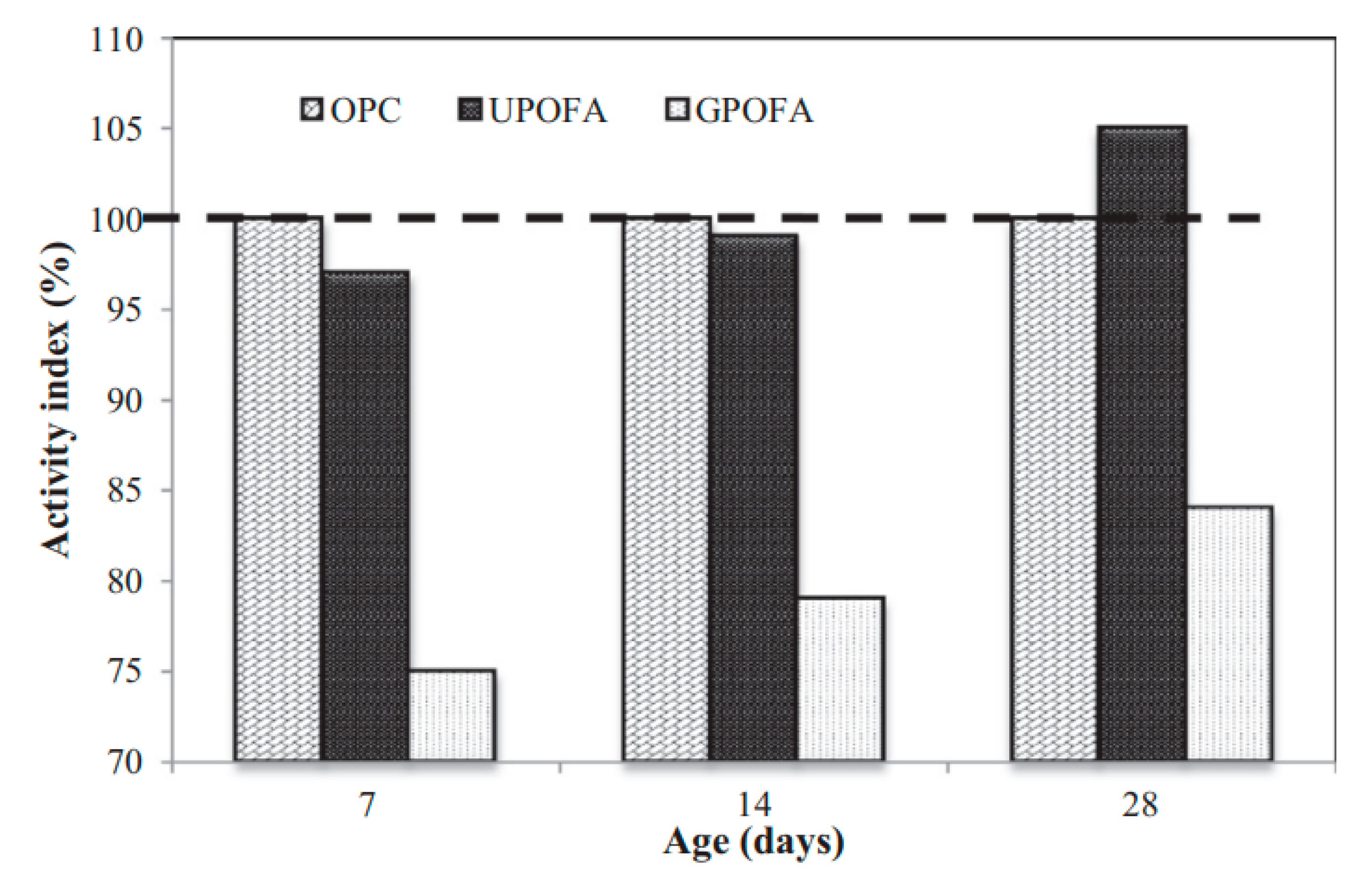

8.4. Strength Activity Index

8.5. Pozzolanic Activity

8.6. Modulus of Elasticity

9. Application

10. Conclusions

- To investigate the influences of POFA on the slump loss and plastic shrinkage as well as the air content of concrete and examine the influences of POFA on the rheological characteristics, such as plastic viscosity and yield stress of concrete.

- To examine the impress of POFA on the bond, tensile, fatigue, impact, shear, and flexural strengths of concrete; and to study the feasibility of POFA concrete in resisting aggressive environment.

- To study the influences of POFA on the autogenous, creep, water absorption, and shrinkage.

- To investigate the characteristic of high fineness POFA in order to improve the microstructure that results in a highly impermeable matrix, and to prove the potential use of POFA materials in the making of ultra-high-strength and SCC concretes, to expand the strength of POFA in a hardened state using fibers.

- To further survey the possible applications of POFA in building green structures and future maintainable cities with a decreased carbon footprint.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AIR | Acoustic insulation resistance |

| AE | Aggressive environment |

| ASR | Alkali-silica reaction |

| CNP | Calcined natural pozzolan |

| CAPOFA | Calcium salt palm oil fuel ash |

| DS | Drying shrinkage |

| EDX | Energy dispersive X-ray |

| FELCRA | Federal land consolidation and rehabilitation authority |

| FELDA | Federal land development authority |

| FA | Fly ash |

| GFC | Foamed concrete |

| GGBS | Ground granulated blast-furnace slag |

| HoH | Heat of hydration |

| ISAT | Initial surface absorption test |

| LAAM | Los Angeles abrasion machine |

| MIP | Mercury intrusion Porosimetry |

| Mt | Million tons |

| MTPOFA | Modified treated-POFA |

| MoE | Modulus of elasticity |

| NWC | Normal weight concrete |

| OPC | Ordinary Portland cement |

| PO | Palm oil |

| POC | Palm oil clinker |

| POFA | Palm-oil-fuel-ash |

| PCR | Partial cement replacement |

| PSA | Particle size analyzer |

| PCE | Polycarboxylate ether |

| PA | Pozzolanic activity |

| PFA | Pulverized fuel ash |

| RCPT | Rapid chloride penetration test |

| RoCA | Rate of capillary absorption |

| R | Raw |

| RC | Reinforced concrete |

| RISDA | Rubber industry smallholders development authority |

| SEM | Scanning electron microscopy |

| SL | Slump loss |

| SG | Specific gravity |

| STS | Splitting tensile strength |

| SAI | Strength activity index |

| SP | Superplasticizer |

| VSI | Visual stability index |

References

- Celik, K.; Meral, C.; Petek Gursel, A.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of recycled aggregate on fly ash geopolymer concrete properties. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Embong, R.; Kusbiantoro, A.; Shafiq, N.; Nuruddin, M.F. Strength and microstructural properties of fly ash based geopolymer concrete containing high-calcium and water-absorptive aggregate. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Lakshmi, R.; Nagan, S. Utilization of waste e plastic particles in cementitious mixtures. J. Struct. Eng. 2011, 38, 26–35. [Google Scholar]

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Sci. Iran. 2012. [Google Scholar] [CrossRef]

- Dhakal, S. Urban energy use and carbon emissions from cities in China and policy implications. Energy Policy 2009. [Google Scholar] [CrossRef]

- Ye, G.; Huang, H.; Van Tuan, N. Rice husk ash. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; Springer: Berlin/Heidelberg, Germany, 2018; pp. 283–302. [Google Scholar]

- Davidovits, P.J. 30 years of successes and failures in geopolymer applications. Market trends and potential breakthroughs. Geopolymer 2002 Conf. 2002. [Google Scholar] [CrossRef]

- Albitar, M.; Mohamed Ali, M.S.; Visintin, P.; Drechsler, M. Effect of granulated lead smelter slag on strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2015. [Google Scholar] [CrossRef]

- Sumathi, S.; Chai, S.P.; Mohamed, A.R. Utilization of oil palm as a source of renewable energy in Malaysia. Renew. Sustain. Energy Rev. 2008. [Google Scholar] [CrossRef]

- Thomas, B.S.; Kumar, S.; Arel, H.S. Sustainable concrete containing palm oil fuel ash as a supplementary cementitious material—A review. Renew. Sustain. Energy Rev. 2017. [Google Scholar] [CrossRef]

- Awalludin, M.F.; Sulaiman, O.; Hashim, R.; Nadhari, W.N.A.W. An overview of the oil palm industry in Malaysia and its waste utilization through thermochemical conversion, specifically via liquefaction. Renew. Sustain. Energy Rev. 2015. [Google Scholar] [CrossRef]

- Gatto, M.; Wollni, M.; Qaim, M. Oil palm boom and land-use dynamics in Indonesia: The role of policies and socioeconomic factors. Land Use Policy 2015. [Google Scholar] [CrossRef]

- Abutaha, F.; Abdul Razak, H.; Kanadasan, J. Effect of palm oil clinker (POC) aggregates on fresh and hardened properties of concrete. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Al-Mulali, M.Z.; Awang, H.; Abdul Khalil, H.P.S.; Aljoumaily, Z.S. The incorporation of oil palm ash in concrete as a means of recycling: A review. Cem. Concr. Compos. 2015. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Utilization of high-volume treated palm oil fuel ash to produce sustainable self-compacting concrete. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Isaia, G.C.; Gastaldini, A.L.G.; Moraes, R. Physical and pozzolanic action of mineral additions on the mechanical strength of high-performance concrete. Cem. Concr. Compos. 2003. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Hussin, M.W. The effectiveness of palm oil fuel ash in preventing expansion due to alkali-silica reaction. Cem. Concr. Compos. 1997. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk-bark ash. Constr. Build. Mater. 2007. [Google Scholar] [CrossRef]

- Astm Standard specification for coal fly ash and raw or calcined natural pozzolan for use. Annu. B. ASTM Stand. 2010. [CrossRef]

- Jaturapitakkul, C.; Kiattikomol, K.; Tangchirapat, W.; Saeting, T. Evaluation of the sulfate resistance of concrete containing palm oil fuel ash. Constr. Build. Mater. 2007. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Muhit, B.A.A.; Jumaat, M.Z.B. Utilization of oil palm kernel shell as lightweight aggregate in concrete—A review. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014. [Google Scholar] [CrossRef]

- Aldahdooh, M.A.A.; Muhamad Bunnori, N.; Megat Johari, M.A. Development of green ultra-high performance fiber reinforced concrete containing ultrafine palm oil fuel ash. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious geopolymer concrete using recycled aggregates. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Abdullah, A.Z.; Salamatinia, B.; Mootabadi, H.; Bhatia, S. Current status and policies on biodiesel industry in Malaysia as the world’s leading producer of palm oil. Energy Policy 2009. [Google Scholar] [CrossRef]

- Tambichik, M.A.; Mohamad, N.; Samad, A.A.A.; Bosro, M.Z.M.; Iman, M.A. Utilization of construction and agricultural waste in Malaysia for development of green concrete: A review. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Langkawi, Malaysia, 4–5 December 2017. [Google Scholar] [CrossRef]

- Bamaga, S.O.; Hussin, M.W.; Ismail, M.A. Palm Oil Fuel Ash: Promising supplementary cementing materials. KSCE J. Civ. Eng. 2013. [Google Scholar] [CrossRef]

- Hwang, J.P.; Shim, H.B.; Lim, S.; Ann, K.Y. Enhancing the durability properties of concrete containing recycled aggregate by the use of pozzolanic materials. KSCE J. Civ. Eng. 2013. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of waste ash from palm oil industry in concrete. Waste Manag. 2007. [Google Scholar] [CrossRef]

- Johnson Alengaram, U.; Al Muhit, B.A.; bin Jumaat, M.Z.; Jing, M.L.Y. A comparison of the thermal conductivity of oil palm shell foamed concrete with conventional materials. Mater. Des. 2013. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015. [Google Scholar] [CrossRef]

- Topark-Ngarm, P.; Chindaprasirt, P.; Sata, V. Setting time, strength, and bond of high-calcium fly ash geopolymer concrete. J. Mater. Civ. Eng. 2014. [Google Scholar] [CrossRef]

- Zain, M.F.M.; Islam, M.N.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Hatanaka, S.; Cao, T. High-strength geopolymer using fine high-calcium fly ash. J. Mater. Civ. Eng. 2010. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Taebuanhuad, S. Resistance to acid and sulfate solutions of microwave-assisted high calcium fly ash geopolymer. Mater. Struct. Constr. 2013. [Google Scholar] [CrossRef]

- Tay, J. Ash from oil-palm waste as a concrete material. J. Mater. Civ. Eng. 1990. [Google Scholar] [CrossRef]

- Kroehong, W.; Sinsiri, T.; Jaturapitakkul, C. Effect of palm oil fuel ash fineness on packing effect and pozzolanic reaction of blended cement paste. Procedia Eng. 2011. [Google Scholar] [CrossRef]

- Posi, P.; Teerachanwit, C.; Tanutong, C.; Limkamoltip, S.; Lertnimoolchai, S.; Sata, V.; Chindaprasirt, P. Lightweight geopolymer concrete containing aggregate from recycle lightweight block. Mater. Des. 2013. [Google Scholar] [CrossRef]

- Ahmed, Y.; Yaakob, Z.; Akhtar, P.; Sopian, K. Production of biogas and performance evaluation of existing treatment processes in palm oil mill effluent (POME). Renew. Sustain. Energy Rev. 2015. [Google Scholar] [CrossRef]

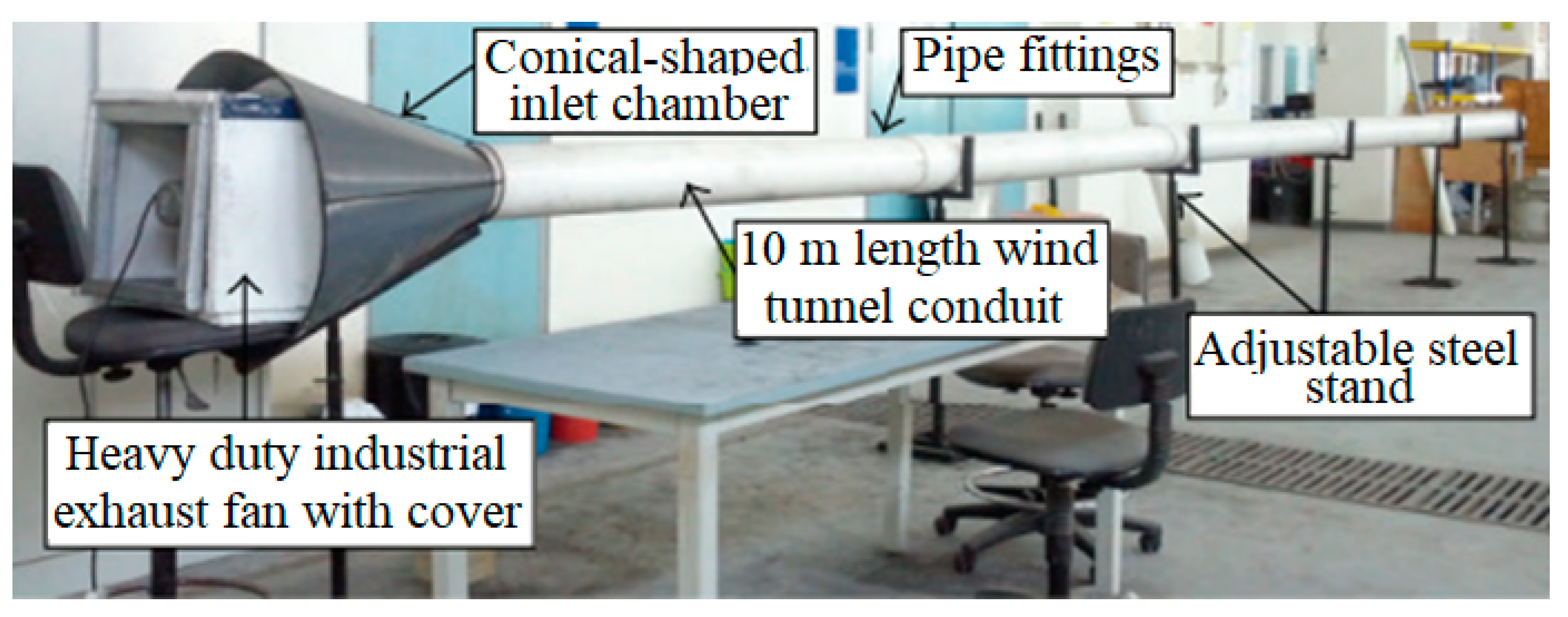

- Ahmadi, R.; Zainudin, N.; Ismail, I.; Mannan, M.A.; Abidin, A.S.Z. Micro Fine Sized Palm Oil Fuel Ash Produced Using a Wind Tunnel Production System. Adv. Mater. Sci. Eng. 2016. [Google Scholar] [CrossRef]

- Narong, L.C.; Sia, C.K.; Yee, S.K.; Ong, P.; Zainudin, A.; Nor, N.H.M.; Kasim, N.A. Optimization of the EMI shielding effectiveness of fine and ultrafine POFA powder mix with OPC powder using flower pollination algorithm. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Johor, Malaysia, 18–19 December 2017. [Google Scholar] [CrossRef]

- Berijani, S.; Assadi, Y.; Anbia, M.; Milani Hosseini, M.R.; Aghaee, E. Dispersive liquid-liquid microextraction combined with gas chromatography-flame photometric detection. Very simple, rapid and sensitive method for the determination of organophosphorus pesticides in water. J. Chromatogr. A 2006. [Google Scholar] [CrossRef]

- ASTM C 114-18. Standard test methods for chemical analysis of hydraulic cement. Annu. B. ASTM Stand. 2018. [Google Scholar] [CrossRef]

- Day, K.; Aldred, J.; Hudson, B. Properties of concrete. In Concrete Mix Design, Quality Control and Specification, 4th ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. A new approach for the classification of coal fly ashes based on their origin, composition, properties, and behaviour. Fuel 2007. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Khamklai, S.; Jaturapitakkul, C. Use of ground palm oil fuel ash to improve strength, sulfate resistance, and water permeability of concrete containing high amount of recycled concrete aggregates. Mater. Des. 2012. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.; Kamarudin, H.; Bnhussain, M.; Nizar, I.K.; Mastura, W.I.W. Mechanism and Chemical Reaction of Fly Ash Geopolymer Cement—A Review. J. Chem. Inf. Model. 2013. [Google Scholar] [CrossRef]

- Ranjbar, N.; Behnia, A.; Alsubari, B.; Moradi Birgani, P.; Jumaat, M.Z. Durability and mechanical properties of self-compacting concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Ibrahim, Z.; Jumaat, M.Z. Heat-treated palm oil fuel ash as an effective supplementary cementitious material originating from agriculture waste. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Ibrahim, Z.; Alnahhal, M.F.; Jumaat, M.Z. Properties of eco-friendly self-compacting concrete containing modified treated palm oil fuel ash. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

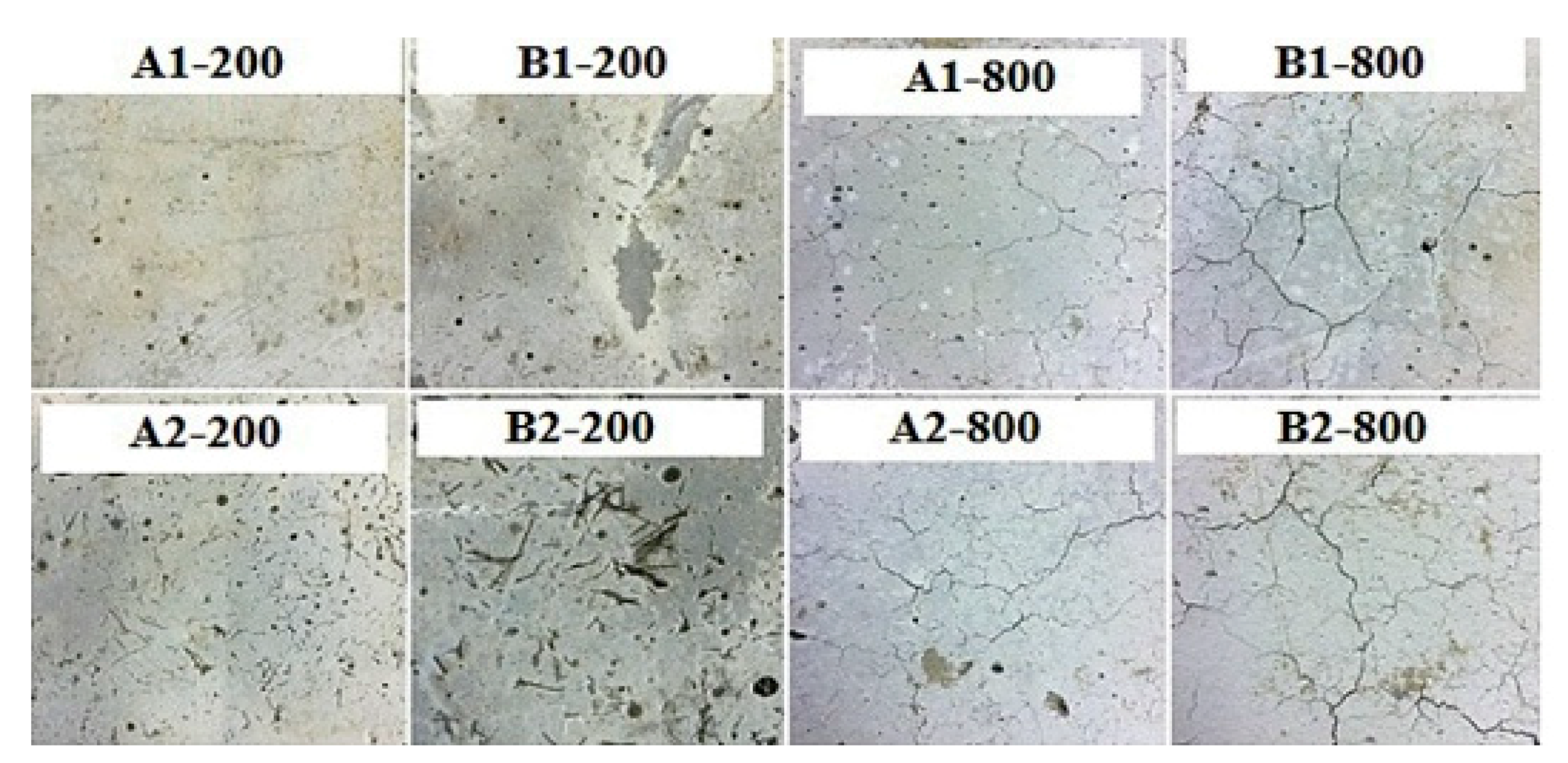

- Awal, A.S.M.A.; Shehu, I.A.; Ismail, M. Effect of cooling regime on the residual performance of high-volume palm oil fuel ash concrete exposed to high temperatures. Constr. Build. Mater. 2015. [Google Scholar] [CrossRef]

- Megat Johari, M.A.; Zeyad, A.M.; Muhamad Bunnori, N.; Ariffin, K.S. Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel ash. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Altwair, N.M.; Azmi, M.; Johari, M.; Fuad, S.; Hashim, S. Strength Activity Index and Microstructural Characteristics of Treated Palm Oil Fuel Ash. Int. J. Civ. Environ. Eng. 2011, 11, 5. [Google Scholar]

- Awal, A.S.M.A.; Nguong, S.K. A Short-Term Investigation On High Volume Palm Oil Fuel Ash (POFA) Concrete. In Proceedings of the 35th Conference on Our World in Concrete & Structures, Singapore, 25–27 August 2010. [Google Scholar]

- Chandara, C.; Mohd Azizli, K.A.; Ahmad, Z.A.; Saiyid Hashim, S.F.; Sakai, E. Heat of hydration of blended cement containing treated ground palm oil fuel ash. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Safiuddin, M.; Jumaat, M.Z. Fresh properties of self-consolidating concrete incorporating palm oil fuel ash as a supplementary cementing material. Chiang Mai J. Sci. 2011, 38, 389–404. [Google Scholar]

- Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Development of self-consolidating high strength concrete incorporating treated palm oil fuel ash. Materials 2015, 2154. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C. Strength, drying shrinkage, and water permeability of concrete incorporating ground palm oil fuel ash. Cem. Concr. Compos. 2010. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Rattanashotinunt, C. Compressive strength and heat evolution of concretes containing palm oil fuel ash. J. Mater. Civ. Eng. 2010. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Shehu, I.A. Evaluation of heat of hydration of concrete containing high volume palm oil fuel ash. Fuel 2013. [Google Scholar] [CrossRef]

- Lim, S.K.; Tan, C.S.; Lim, O.Y.; Lee, Y.L. Fresh and hardened properties of lightweight foamed concrete with palm oil fuel ash as filler. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Comparison of mechanical and bond properties of oil palm kernel shell concrete with normal weight concrete. Int. J. Phys. Sci. 2010, 5, 1231–1239. [Google Scholar]

- Salami, B.A.; Megat Johari, M.A.; Ahmad, Z.A.; Maslehuddin, M. Durability performance of palm oil fuel ash-based engineered alkaline-activated Cementitious Composite (POFA-EACC) mortar in sulfate environment. Constr. Build. Mater. 2017. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Megat Johari, M.A.; Tayeh, B.A.; Yusuf, M.O. Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- Abdul Awal, A.S.M.; Warid Hussin, M. Effect of palm oil fuel ash in controlling heat of hydration of concrete. Procedia Eng. 2011, 14, 2650–2657. [Google Scholar] [CrossRef]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.H.; Thomas, M.D.A. Alkali-silica reaction: Current understanding of the reaction mechanisms and the knowledge gaps. Cem. Concr. Res. 2015. [Google Scholar] [CrossRef]

- Wongpa, J.; Kiattikomol, K.; Jaturapitakkul, C.; Chindaprasirt, P. Compressive strength, modulus of elasticity, and water permeability of inorganic polymer concrete. Mater. Des. 2010. [Google Scholar] [CrossRef]

- Khankhaje, E.; Hussin, M.W.; Mirza, J.; Rafieizonooz, M.; Salim, M.R.; Siong, H.C.; Warid, M.N.M. On blended cement and geopolymer concretes containing palm oil fuel ash. Mater. Des. 2016. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of palm oil fuel ash in high-strength concrete. J. Mater. Civ. Eng. 2004. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson Education Ltd.: Harlow, UK, 2010. [Google Scholar] [CrossRef]

- ASTM Standard C567 Standard Test Method for Determining Density of Structural Lightweight Concrete. ASTM Int. 2004. [CrossRef]

- Mohammed, B.S.; Al-Ganad, M.A.; Abdullahi, M. Analytical and experimental studies on composite slabs utilising palm oil clinker concrete. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Mohammadhosseini, H. Green concrete production incorporating waste carpet fiber and palm oil fuel ash. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H. A review on energy scenario and sustainable energy in Malaysia. Renew. Sustain. Energy Rev. 2011. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Hamid, R.; Taha, M.R. Fire resistance of high-volume fly ash mortars with nanosilica addition. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Hussin, M.W.; Muthusamy, K.; Zakaria, F. Effect of mixing constituent toward engineering properties of POFA cement-based aerated concrete. J. Mater. Civ. Eng. 2010. [Google Scholar] [CrossRef]

- Abdullah, N.; Sulaim, F. The oil palm wastes in Malaysia. In Biomass Now—Sustainable Growth and Use; IntechOpen: London, UK, 2013. [Google Scholar] [CrossRef]

- Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z.; Islam, A.; Santhi, H.; Sharmin, A. Engineering properties and fracture behaviour of high volume palm oil fuel ash based fibre reinforced geopolymer concrete. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Jumaat, M.Z.; Johnson Alengaram, U.; Mahmud, H. Shear strength of oil palm shell foamed concrete beams. Mater. Des. 2009. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011. [Google Scholar] [CrossRef]

- Kanadasan, J.; Abdul Razak, H. Engineering and sustainability performance of self-compacting palm oil mill incinerated waste concrete. J. Clean. Prod. 2015. [Google Scholar] [CrossRef]

- ASTM C127. Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Ganeshan, A.; Venkataraman, S. Self consolidating geopolymer concrete as an aid to green technologies—Review on present status. Asian J. Res. Soc. Sci. Humanit. 2017. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Mechanical and fresh properties of sustainable oil palm shell lightweight concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M. Microstructure and residual properties of green concrete composites incorporating waste carpet fibers and palm oil fuel ash at elevated temperatures. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- Noorvand, H.; Ali, A.A.A.; Demirboga, R.; Noorvand, H.; Farzadnia, N. Physical and chemical characteristics of unground palm oil fuel ash cement mortars with nanosilica. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Castel, A. Bond between steel reinforcement and geopolymer concrete. In Handbook of Low Carbon Concrete; Butterworth-Heinemann Elsevier Ltd.: Oxford, UK, 2016; ISBN 9780128045404. [Google Scholar] [CrossRef]

- BS 882:1992. Specification for Aggregates from Natural Sources for Concrete; 8821992; British Standards Institution: London, UK, 1992. [Google Scholar]

- Safiuddin, M.; Salam, M.A.; Jumaat, M.Z. Key Fresh Properties of Self-Consolidating High-Strength POFA Concrete. J. Mater. Civ. Eng. 2013. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Peris-Mora, E. Comparisons among magnetic and non-magnetic fly ash fractions: Strength development of cement-fly ash mortars. Waste Manag. 1996. [Google Scholar] [CrossRef]

- Ranganath, R.V.; Bhattacharjee, B.; Krishnamoorthy, S. Influence of size fraction of ponded ash on its pozzolanic activity. Cem. Concr. Res. 1998. [Google Scholar] [CrossRef]

- Swamy, R.N. The alkali-silica reaction in concrete. Cem. Concr. Compos. 2003. [Google Scholar] [CrossRef]

- Hussin, M.W.; Ismail, M.A.; Budiea, A.; Muthusamy, K. Durability of high strength concrete containing palm oil fuel ash of different fineness. Malaysian J. Civ. Eng. 2009, 21, 180–194. [Google Scholar]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of bagasse ash as a pozzolanic material in concrete. Constr. Build. Mater. 2009. [Google Scholar] [CrossRef]

- Hope, B.B.; Page, J.A.; Ip, A.K.C. Corrosion rates of steel in concrete. Cem. Concr. Res. 1986. [Google Scholar] [CrossRef]

- ASTM C186- 05. Standard test method for heat of hydration of hydraulic cement. Chem. Anal. 2005. [Google Scholar] [CrossRef]

- Ibragimov, R.; Fediuk, R. Improving the early strength of concrete: Effect of mechanochemical activation of the cementitious suspension and using of various superplasticizers. Constr. Build. Mater. 2019. [Google Scholar] [CrossRef]

- ASTM C157. StandardTest Method for Length Change of Hardened Hydraulic-Cement Mortarand Concrete; C157/C157M—08; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Luo, W.; Zhou, W. Effects of adding nano-TiO2 on compressive strength, drying shrinkage, carbonation and microstructure of fluidized bed fly ash based geopolymer paste. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- ASTM C29/C29M–97. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar] [CrossRef]

- Khalid, N.H.A.; Hussin, M.W.; Mirza, J.; Ariffin, N.F.; Ismail, M.A.; Lee, H.S.; Mohamed, A.; Jaya, R.P. Palm oil fuel ash as potential green micro-filler in polymer concrete. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Lesovik, V.S.; Liseitsev, Y.L.; Timokhin, R.A.; Bituyev, A.V.; Zaiakhanov, M.Y.; Mochalov, A.V. Composite binders for concretes with improved shock resistance. Mag. Civ. Eng. 2019. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Shehu, I.A. Deformation characteristics of concrete containing high volume palm oil fuel ash. Appl. Mech. Mater. 2014, 534, 9–15. [Google Scholar] [CrossRef]

- Satpute Manesh, B.; Madhukar, R.W.; Subhash, V.P. Effect of duration and temperature of curing on compressive strength of geopolymer concrete. Int. J. Eng. Innov. Technol. 2012, 1, 152–155. [Google Scholar]

- Thokchom, S.; Ghosh, P.; Ghosh, S. Effect of water absorption, porosity and sorptivity on durability of geopolymer mortars. J. Eng. Appl. Sci. 2009, 4, 28–32. [Google Scholar]

- Segui, P.; Aubert, J.E.; Husson, B.; Measson, M. Characterization of wastepaper sludge ash for its valorization as a component of hydraulic binders. Appl. Clay Sci. 2012, 57, 79–85. [Google Scholar] [CrossRef]

- Yusuf, M.O.; Megat Johari, M.A.; Ahmad, Z.A.; Maslehuddin, M. Evolution of alkaline activated ground blast furnace slag-ultrafine palm oil fuel ash based concrete. Mater. Des. 2014. [Google Scholar] [CrossRef]

- Eldagal, O.E.A. Study on the Behaviour of High-Strength Palm Oil Fuel Ash (POFA) Concrete. Master′s Thesis, Universiti Teknologi, Skudai, Malaysia, 2008. [Google Scholar]

- ASTM C143/C143M Standard Test Method for Slump of Hydraulic-Cement Concrete. Astm C143 2015. [CrossRef]

- ASTM C1611M Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM Int. 2014. [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour. Conserv. Recycl. 2013. [Google Scholar] [CrossRef]

- ASTM International C 150/C150M—Standard Specification for Portland Cement. Annu. B. ASTM Stand. 2017. [CrossRef]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C. Fabrication of a non-cement binder using slag, palm oil fuel ash and rice husk ash with sodium hydroxide. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.B.; Hamid, N.A.A. Lightweight concrete made from crushed oil palm shell: Tensile strength and effect of initial curing on compressive strength. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- British Standards Institution BSI. Testing Concrete (Part 108)—Method for Making Test Cubes from Fresh Concrete; 1881Part 1081983; British Standards Institution: London, UK, 1983. [Google Scholar]

- Liu, M.Y.J.; Chua, C.P.; Alengaram, U.J.; Jumaat, M.Z. Utilization of palm oil fuel ash as binder in lightweight oil palm shell geopolymer concrete. Adv. Mater. Sci. Eng. 2014, 2014, 610274. [Google Scholar] [CrossRef]

- Kou, S.C.; Xing, F. The effect of recycled glass powder and reject fly ash on the mechanical properties of fibre-reinforced ultrahigh performance concrete. Adv. Mater. Sci. Eng. 2012. [Google Scholar] [CrossRef]

- ASTM C39. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; C39/C39M –17b; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Uy, B.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016. [Google Scholar] [CrossRef]

- Saffuan, W.A.; Muthusamy, K.; Salleh, N.A.M.; Nordin, N. Properties of concrete containing ground palm oil fuel ash as fine aggregate replacement. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Lyon, France, 21–23 September 2017. [Google Scholar]

- Muthusamy, K.; Mirza, J.; Zamri, N.A.; Hussin, M.W.; Abdul Majeed, A.P.P.; Kusbiantoro, A.; Albshir Budiea, A.M. Properties of high strength palm oil clinker lightweight concrete containing palm oil fuel ash in tropical climate. Constr. Build. Mater. 2019. [Google Scholar] [CrossRef]

- Sharfuddin Ahmed, M.; Kayali, O.; Anderson, W. Chloride penetration in binary and ternary blended cement concretes as measured by two different rapid methods. Cem. Concr. Compos. 2008. [Google Scholar] [CrossRef]

- Salam, A.; Jumaat, M.Z. Utilization Of Palm Oil Fuel Ash In Concrete Construction Essay. Mater. Sci. Forum 2016, 5. [Google Scholar] [CrossRef]

- ASTM C496 Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM Int. 2006. [CrossRef]

- Druta, C. Tensile Strength and Bonding Characteristics of Self-Compacting Concrete. Master’s Thesis, Louisiana State University and Agricultural and Mechanical College, Baton Rouge, LA, USA, 2003. [Google Scholar]

- Mazaheripour, H.; Ghanbarpour, S.; Mirmoradi, S.H.; Hosseinpour, I. The effect of polypropylene fibers on the properties of fresh and hardened lightweight self-compacting concrete. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- ASTM C78. Standard Test Method for Flexural Strength of Concrete Using Simple Beam with; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Altwair, N.M.; Megat Johari, M.A.; Saiyid Hashim, S.F. Flexural performance of green engineered cementitious composites containing high volume of palm oil fuel ash. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Kiattikomol, K.; Jaturapitakkul, C.; Songpiriyakij, S.; Chutubtim, S. A study of ground coarse fly ashes with different finenesses from various sources as pozzolanic materials. Cem. Concr. Compos. 2001. [Google Scholar] [CrossRef]

- Lim, N.H.A.S.; Ismail, M.A.; Lee, H.S.; Hussin, M.W.; Sam, A.R.M.; Samadi, M. The effects of high volume nano palm oil fuel ash on microstructure properties and hydration temperature of mortar. Constr. Build. Mater. 2015, 93, 29–34. [Google Scholar] [CrossRef]

- ASTM 311-04. Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete; Annu. B. ASTM Stand; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM C 469-02. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar] [CrossRef]

- Anuradha, R.; Bala Thirumal, R.; Naveen John, P. Optimization of Molarity on Workable Self-Compacting Geopolymer Concrete and Strength Study on SCGC by Replacing Flyash with Silica fume and GGBFS. Int. J. Adv. Struct. Geotech. Eng. 2014, 3. [Google Scholar]

- Kovler, K.; Roussel, N. Properties of fresh and hardened concrete. Cem. Concr. Res. 2011. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S.; Sirivivatnanon, V. Resistance to chloride penetration of blended Portland cement mortar containing palm oil fuel ash, rice husk ash and fly ash. Constr. Build. Mater. 2008. [Google Scholar] [CrossRef]

- Mosaberpanah, M.A.; Mugahed Amran, Y.H.; Akoush, A. Performance investigation of palm kernel shell ash in high strength concrete. Comput. Concr. 2020, 26, 577–585. [Google Scholar] [CrossRef]

- Karayannis, V.G.; Moustakas, K.G.; Baklavaridis, A.N.; Domopoulou, A.E. Sustainable ash-based geopolymers. Chem. Eng. Trans. 2018. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and applications of foamed concrete: A review. Constr. Build. Mater. 2015. [Google Scholar] [CrossRef]

- Tiwari, V.; Shukla, A.; Bose, A. Acoustic properties of cenosphere reinforced cement and asphalt concrete. Appl. Acoust. 2004. [Google Scholar] [CrossRef]

| Ref. | Chemical Composition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | MgO | Na2O | K2O | P2O5 | SO3 | LOI | SiO2 + Al2O3 + Fe2O3 | |

| [51] | 64.17 | 5.8 | 4.87 | 0.18 | 8.25 | - | 0.72 | - | 74.23 |

| [16,52,53] | 66.24 | 5.21 | 4.83 | 0.16 | 6.7 | - | 0.53 | 4.41 | 73.69 |

| [54] | 62.6 | 5.7 | 3.52 | - | 9.05 | - | 1.16 | 6.25 | 75.37 |

| [55] | 51.18 | 6.93 | 4.02 | 0.06 | 5.52 | 4.10 | 0.36 | 21.60 | 59.20 |

| [49] | 55.50 | 12.40 | 4.60 | 0.00 | 0.00 | - | 2.30 | 7.90 | 70.30 |

| - | 65.01 | 8.19 | 4.58 | 0.07 | 6.48 | 4.69 | 0.33 | 2.53 | 75.10 |

| [16] | 59.0 | 11.00 | 3.50 | - | - | - | - | 10.10 | 67.50 |

| - | 63.2 | 10.10 | 0.60 | - | 5.80 | - | 0.20 | 13.50 | 70.70 |

| [56] | 66.91 | 5.56 | 3.13 | 0.19 | 5.20 | 3.72 | 0.33 | 2.30 | 79.10 |

| [57] | 59.62 | 4.92 | 4.52 | 0.76 | 7.52 | 3.58 | 1.28 | 8.25 | 67.20 |

| [58] | 53.50 | 8.30 | 4.10 | 1.30 | 6.50 | 2.40 | - | 18.00 | 56.50 |

| [59] | 79.30 | 2.79 | 1.21 | - | 3.23 | 2.32 | 0.45 | - | 89.50 |

| [60] | 65.30 | 6.42 | 3.08 | 0.36 | 5.72 | - | 0.47 | 10.05 | 69.80 |

| 43.60 | 8.40 | 4.80 | 0.39 | 3.50 | - | 2.80 | 18.00 | 59.70 | |

| [61] | 61.85 | 5.09 | 2.79 | 0.10 | 5.09 | 3.32 | 0.28 | 9.88 | 72.90 |

| - | 67.09 | 5.58 | 3.06 | 0.11 | 5.45 | 3.62 | 0.32 | 2.20 | 79.10 |

| [62] | 65.30 | 6.40 | 3.00 | 0.30 | 5.70 | _ | 0.40 | 10.00 | 69.70 |

| [63] | 42.50 | 11.00 | 7.10 | 7.00 | 0.40 | 5.70 | 2.20 | 20.90 | 45.80 |

| [30] | 58.30 | 6.72 | 3.69 | - | 8.40 | - | 0.96 | 7.34 | 74.80 |

| - | 49.20 | 7.50 | 3.93 | 0.90 | 5.30 | 6.41 | 1.73 | 13.85 | 60.40 |

| [16] | 65.30 | 6.40 | 3.00 | 0.30 | 5.70 | - | 0.40 | 10.00 | 69.70 |

| [64] | 63.60 | 7.60 | 3.90 | 0.10 | 6.90 | - | 0.20 | 9.60 | 66.60 |

| - | 53.82 | 4.24 | 3.19 | 0.10 | 4.47 | 3.01 | 2.25 | 10.49 | 64.00 |

| [11,15] | 64.50 | 7.80 | 3.70 | 0.20 | 6.60 | - | 0.10 | 9.40 | 67.70 |

| 62.80 | 7.70 | 3.60 | 0.10 | 6.50 | - | 0.30 | 9.70 | 66.30 | |

| 63.60 | 7.60 | 3.90 | 0.10 | 6.90 | - | 0.20 | 9.60 | 66.50 | |

| Property | OPC | Ground POFA | Treated POFA |

|---|---|---|---|

| Maximum size (mm) | - | - | - |

| Median particle size, d50 (µm) | 10–20 | 7.2–10.1 | 54.3–183 |

| Water absorption (%) | - | - | - |

| Color | Grey | Dark grey | Grey |

| Passed on in a sieve No. 325, with 45 µm, (%) | 92 | 96 | 100 |

| Surface area, (m2/g) | – | 104 | – |

| Relative density | 3.16 | 2.04 | 2.20 |

| Soundness, (mm) | 0.45–1 | 1 | 0.5–2.6 |

| Strength activity index (%) | - | 78.6–115 | - |

| Specific Gravity | Blain Fineness (m2/kg) | Retained on 45 µm Sieve (%) | Strength Activity Index (%) 7, 28 days | Median Particle Size d50 µm | Ref. |

|---|---|---|---|---|---|

| 2.42 | 493 | 10.50 | -, 112 | - | [65] |

| 2.2 | - | 9.0 | - | - | [66,67] |

| 2.56 | - | - | - | 1.10 | |

| 2.42 | - | - | 98 | 10.89 | [68] |

| 2.56 | - | - | - | 1.068 | |

| 2.15 | - | - | - | 17.1 | [51,64] |

| 1.81 | - | - | - | 10 | |

| 2.59 | - | - | - | 2.06 | [69] |

| 2.53 | - | 1.70 | 105, 109 | 10.70 | [49] |

| 2.42 | 435 | - | - | 15.76 | [55] |

| 2.50 | 1694 | - | - | 2.45 | |

| 2.50 | 1438 | - | - | 2.99 | |

| 2.56 | 1775 | - | - | 2.06 | |

| 2.36 | 670 | - | - | 15.60 | [40] |

| 2.48 | 1490 | - | - | 2.10 | |

| 2.42 | 493 | 4.98 | 79, 93 | 14.58 | [57] |

| 2.78 | 670 | 10.60 | - | - | [59] |

| 2.39 | 1228 | 4.30 | - | 12.30 | [60] |

| 2.22 | 719 | 13.70 | - | 13.00 | |

| 2.05 | 660 | 34.80 | - | 30.80 | |

| 2.22 | 520 | - | - | [70] | |

| 2.42 | 540 | - | - | 22.52 | [61] |

| 2.56 | 450 | - | - | 22.53 | |

| 2.36 | 234 | - | - | 15.60 | [40] |

| 2.48 | 1800 | - | - | 2.10 | |

| 2.50 | - | 1.20 | - | 9.20 | [63] |

| 2.25 | 1180 | 1.00–3.00 | - | 7.20 | [33,71] |

| 1.97 | - | 41.20 | - | 62.50 | [72] |

| 2.17 | - | 17.10 | 90, 90 | 19.90 | |

| 2.33 | - | 1.50 | 89, 95 | 10.10 | |

| 1.95 | - | 70.00 | - | 55.00 | [73] |

| 2.15 | 750 | 15.00 | - | 20.00 | |

| 2.25 | 1180 | 3.00 | - | 7.20 | |

| 2.43 | - | 1.00 | - | 8.00 | [20] |

| 1.97 | - | 41.20 | - | 62.50 | [74] |

| 2.33 | 1244 | 1.50 | - | 10.10 | |

| 3.14–3.28 | 314–358 | - | - | 10–20 | OPC |

| - | - | 34 (max) | 75 (min) | - | ASTM C618-12a |

| Ref. | Percentage of RePlacement of POFA, % | Initial Temperature (°C) | Peak Temperature Rise, (°C) | Maximum Temperature (°C) | Time Since Mixing to Peak Temperature (h) |

|---|---|---|---|---|---|

| [2] | 0 | 27.2 | 57.3 | - | 18 |

| 50 | 27.1 | 46.8 | 24 | ||

| 60 | 27.8 | 44.2 | 24 | ||

| 70 | 26.9 | 41.5 | 32 | ||

| [110] | 0 | 31.0 | 36.7 | - | 20 |

| 30 | 31.1 | 35.4 | 28 | ||

| [32] | 0 | 30.7 | 30.3 | 61.0 | 12 |

| 10 | 30.4 | 30.0 | 60.4 | 14 | |

| 20 | 30.4 | 27.3 | 57.7 | 15 | |

| 30 | 30.6 | 24.3 | 54.9 | 16 | |

| [40] | 0 | 26.0 | 47.0 | 73.0 | 12 |

| 10 | 27.0 | 46.0 | 73.0 | 13 | |

| 20 | 28.0 | 44.0 | 72.0 | 14 | |

| 30 | 28.0 | 40.0 | 68.0 | 15 |

| Percentage of Replacement of POFA,% | Ground-POFA | Unground-POFA | Ref. | ||

|---|---|---|---|---|---|

| Slump, mm | Compacting Factor, % | Slump, mm | Compacting Factor, % | ||

| 0 | 200 | 0.970 | 150 | 0.975 | [114] |

| 10 | 200 | - | 150 | 0.970 | |

| 20 | 180 | 0.950 | 140 | 0.965 | [23] |

| 30 | 185 | 0.930 | 130 | 0.960 | |

| 40 | 0 | - | 130 | 0.955 | [39] |

| 50 | 0 | - | 120 | 0.950 | |

| Materials | OPC Concrete | Percentage of Replacement of POFA, % | ||

|---|---|---|---|---|

| 60% | 50% | 70% | ||

| POFA (kg/m3) | - | 256 | 213 | 299 |

| OPC (kg/m3) | 427 | 171 | 214 | 128 |

| Fine aggregate (kg/m3) | 787 | 787 | 787 | 787 |

| Coarse aggregate (kg/m3) | 961 | 961 | 961 | 961 |

| Slump (mm) | 160 | 110 | 140 | 80 |

| Water (kg/m3) | 205 | 205 | 205 | 205 |

| Slump (mm) | ||||

|---|---|---|---|---|

| Time (Min) | HSC | HSC20 | HSC40 | HSC60 |

| 7 | 190 | 210 | 225 | 230 |

| 30 | 150 | 190 | 210 | 205 |

| 60 | 135 | 175 | 195 | 190 |

| 90 | 125 | 155 | 160 | 180 |

| Percentage of Replacement of POFA, % | Early Setting Time, Min | Final Setting Time, Min | ||

|---|---|---|---|---|

| Ground POFA | Unground POFA | Ground POFA | Unground POFA | |

| 0 | 250 | 125 | 390 | 195 |

| 10 | 255 | 130 | 395 | 225 |

| 20 | 275 | 130 | 420 | 240 |

| 30 | 290 | 140 | 445 | 250 |

| 40 | 310 | 150 | 460 | 270 |

| 50 | - | 160 | - | 280 |

| Mix. No. | W/B | Percentage of Replacement of POFA, % | Ability of Filling | Ability of Passing | Resistance of Segregation | |||

|---|---|---|---|---|---|---|---|---|

| T50 cm Spread Time (s) | V-Funnel Flow Time (s) | Slump Flow (mm) | J-Ring Flow (mm) | Segre. Factor (%) | Segre. Index (%) | |||

| 1 | 0.5 | 0 | 1.10 | 1.50 | 655 | 655 | 25.2 | 23.2 |

| 2 | 5 | 1.13 | 1.89 | 655 | 645 | 23.8 | 22.0 | |

| 3 | 10 | 1.43 | 2.37 | 650 | 630 | 15.7 | 15.7 | |

| 4 | 15 | 1.81 | 2.66 | 630 | 610 | 10.9 | 11.3 | |

| 5 | 0.6 | 0 | 0.57 | 1.35 | 650 | 635 | 19.1 | 21.3 |

| 6 | 5 | 0.58 | 1.64 | 640 | 635 | 16.1 | 20.2 | |

| 7 | 10 | 0.88 | 1.99 | 610 | 600 | 12.7 | 14.7 | |

| 8 | 15 | 0.97 | 2.52 | 600 | 585 | 10.8 | 10.2 | |

| Properties | Oil Palm Shells |

|---|---|

| Specific gravity | 1.17–1.37 |

| Bulk density (uncompacted) (kg/m3) | 510–550 |

| Void ratio (compacted) (%) | 57 |

| Void ratio (uncompacted) (%) | 63 |

| Absorption of water at 24 h (%) | 21–33 |

| Flakiness index (%) | 65 |

| Value of aggregate crushing (%) | 5–10 |

| Thermal conductivity (W/mc) | 0.19 |

| LOI (%) | 98–100 |

| Value of aggregate impact (%) | 4–8 |

| Thickness of shell (mm) | 2–8 |

| Los Angeles abrasion value (%) | 3–5 |

| Percentage of Replacement of POFA, % | w/b Ratio | SP (%) | Slump (mm) | Compressive Strength (MPa) 28 d | Final Setting Time (Min) | Initial Setting Time (Min) | Ref. |

|---|---|---|---|---|---|---|---|

| 0 | 0.28 | 2.3 | 160 | 48.0 | - | - | [22] |

| 25 | 2.3 | 57.5 | |||||

| 0 | 2.0 | 46.0 | |||||

| 50 | 0.48 | - | 41.0 | - | - | [65] | |

| 60 | 2.0 | 115 | 36.0 | ||||

| 70 | 2.0 | 90 | 28.0 | ||||

| 0 | 2.0 | 80 | 75.0 | ||||

| 10 | - | - | 79.3 | ||||

| 20 | 0.35 | - | - | 77.3 | - | - | [40] |

| 30 | 72.8 | ||||||

| 40 | 66.5 | ||||||

| 0 | 0.27 | 2.2 | 190 | 91.4 | 285 | 140 | [55] |

| 20 | 2.2 | 210 | 98.3 | 385 | 230 | ||

| 40 | 2.2 | 225 | 104.2 | 460 | 270 | ||

| 60 | 2.2 | 230 | 98.1 | 555 | 350 | ||

| 0 | 0.35 | 0.40 0.75 | - | 75.0 | - | - | [40] |

| 10 | 80.2 | ||||||

| 20 | 77.3 | ||||||

| 30 | 72.8 | ||||||

| 40 | 66.5 | ||||||

| 0 | 68.9 | ||||||

| 10 | 76.5 | ||||||

| 20 | 0.35 | 0.80 | 210 | 58.3 | - | - | [16,74] |

| 30 | 0.83 | 48.3 | |||||

| 40 | 1.0 | 43.3 | |||||

| 0 | 7.6 | 65.0 | |||||

| 10 | 0.30 | 7.5 | 210 | 67.5 | - | - | |

| 20 | 9.0 | 220 | 67.0 | ||||

| 30 | 0.40 | 18.5 | 220 | 65.5 | - | - | [57] |

| 0 | 1.0 | 60 | - | ||||

| 50 | 1.0 | 45 | 39.5 | ||||

| 0 | 0.32 | 1.16 | 245 | 58.5 | - | - | [16] |

| 10 | 1.24 | 250 | 59.5 | ||||

| 20 | 1.56 | 240 | 60.9 | ||||

| 30 | 2.11 | 250 | 58.8 | ||||

| 0 | 0.67 | - | - | 42.8 | 180 | 114 | [65] |

| 10 | 42.0 | 180 | 120 | ||||

| 20 | 40.6 | 195 | 124 | ||||

| 30 | 38.7 | 210 | 130 | ||||

| 40 | 33.8 | 210 | 133 | ||||

| 0 | 0.28 | 1.41 | 200 | 85.0 | - | - | [23,96] |

| 10 | 1.52 | 200 | 81.0 | ||||

| 20 | 2.11 | 185 | 86.0 | ||||

| 30 | 3.02 | 185 | 80.0 | ||||

| 0 | 0.71 | - | 75 | 26.1 | 390 | 250 | [20] |

| 20 | 0.73 | 65 | 23.9 | ||||

| 40 | 0.74 | 70 | 20.7 | ||||

| 55 | 0.75 | 90 | 18.1 | ||||

| 0 | 0.70 | - | 65 | 31.9 | 395 | 265 | [32] |

| 10 | 55 | 31.9 | 420 | 275 | |||

| 20 | 60 | 31.6 | 445 | 290 | |||

| 30 | 60 | 30.1 | 460 | 310 | |||

| 40 | 60 | 27.5 | |||||

| 0 | 0.60 | - | 150 | 35.5 | 195 | 125 | [39] |

| 10 | 150 | 35.5 | 225 | 130 | |||

| 20 | 140 | 29.5 | 240 | 130 | |||

| 30 | 130 | 25.5 | 250 | 140 | |||

| 40 | 130 | 20.2 | 270 | 150 | |||

| 50 | 120 | 17.8 | 280 | 160 |

| Percentage of Replacement of POFA, % | Applications | Ref. |

|---|---|---|

| POFA filler POFA ash POFA binder | To upsurge the concrete strength | [16,43,53,78,89] |

| To use as an effective polymer concrete filler | [107] | |

| To reduce the total temperature rise | [66] | |

| To improve surface resistance and water permeability of concrete | [49] | |

| To construct roads, ground in the plantations and mills | [12,16,30,82] | |

| To produce unfired green bricks | [57,139,144] | |

| In produce foamed concrete | [24,25,66,145] | |

| To produce aerated concrete | [73,81,139] | |

| To produce lightweight FC for non-structural building material | [24,25,33,66] | |

| To construct footbridge and low-cost house | [1,14,70] | |

| 0% and 20% | The 20% POFA in concrete attained in the reduction of DS. | [26,90] |

| 0%, 5%, 7.5%, 10%, 12.5%, 15% and 17.5% | The 12.5% of POFA substituted on OPC displays the enhancement in strength. | [8,146] |

| 0%, 10%, 30% and 50% 0% and 70% | The 10% of POFA illustrates the greater strength than reference at the age of 3 months. | [39,64,143] |

| 0%, 50%, 60% and 70% | The strength of concrete encompassing a high POFA content explains the lesser strength. The high content of POFA reduced workability but improved with the use of a super-plasticizer. | [57] |

| 0%, 5%, 10% and 15% | Workability indicates a significant decrease with the addition of a high volume of POFA. The 15% POFA substitution demonstrates a higher strength similar to normal concrete samples. | [30,64,120,126] |

| 0%, 50%, 60% and 70% | The abilities of passing and filling are superior to reference. 70% of OPC substitution was recommended to make durable concrete. | [51,52,53,61] |

| 0%, 10%, 15% and 20% | The increments of the content of POFA contribute to a reduction in initial hardened properties, but the SCC strength comprising POFA was equivalent. | [51,64] |

| 0%, 30% and 60% | The replacement of POFA, shows weak concrete workability with an acceptable limit. Higher content of POFA substitution presents a reduction in strength. | [66,67] |

| 10%, 20%, 30%, 40% and 50% | The 20% inclusion of POFA into FC exhibits the suitable strength of FC for non-structural concrete applications. | [24,25,66] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amran, M.; Murali, G.; Fediuk, R.; Vatin, N.; Vasilev, Y.; Abdelgader, H. Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties. Materials 2021, 14, 332. https://doi.org/10.3390/ma14020332

Amran M, Murali G, Fediuk R, Vatin N, Vasilev Y, Abdelgader H. Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties. Materials. 2021; 14(2):332. https://doi.org/10.3390/ma14020332

Chicago/Turabian StyleAmran, Mugahed, Gunasekaran Murali, Roman Fediuk, Nikolai Vatin, Yuriy Vasilev, and Hakim Abdelgader. 2021. "Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties" Materials 14, no. 2: 332. https://doi.org/10.3390/ma14020332

APA StyleAmran, M., Murali, G., Fediuk, R., Vatin, N., Vasilev, Y., & Abdelgader, H. (2021). Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties. Materials, 14(2), 332. https://doi.org/10.3390/ma14020332