Sorption and Micro-Scale Strength Properties of Coals Susceptible to Outburst Caused by Changes in Degree of Coalification

Abstract

1. Introduction

2. Properties Examined in the Study

2.1. Degree of Coalification

2.2. Sorption Capacity

2.3. Effective Diffusion Coefficient

2.4. Coal Microhardness

3. Materials and Methods

3.1. Area of Study

3.2. Coal Samples

3.3. Characteristics of Coals

3.4. Measurement of Coalification Degree

3.5. Sorption Studies

- —methane absorbed at pressure p, cm3CH4/Mg (STP: 25 °C and 0.1 MPa; daf).

- —methane equilibrium pressure, bar.

- T—temperature, °C.

- —maximum sorption capacity at p approaching ∞, cm3CH4/Mg (STP, daf).

- —Langmuir pressure, MPa.

- —relative quantity of absorbed gas, -.

- —quantity of gas absorbed at the time of , cm3CH4/g.

- —total quantity of gas absorbed in coal under measurement conditions, cm3CH4/g.

- —equivalent grain radius for a sample with a specific grain class,

- —effective diffusion coefficient, cm2/s.

- —is the time, s.

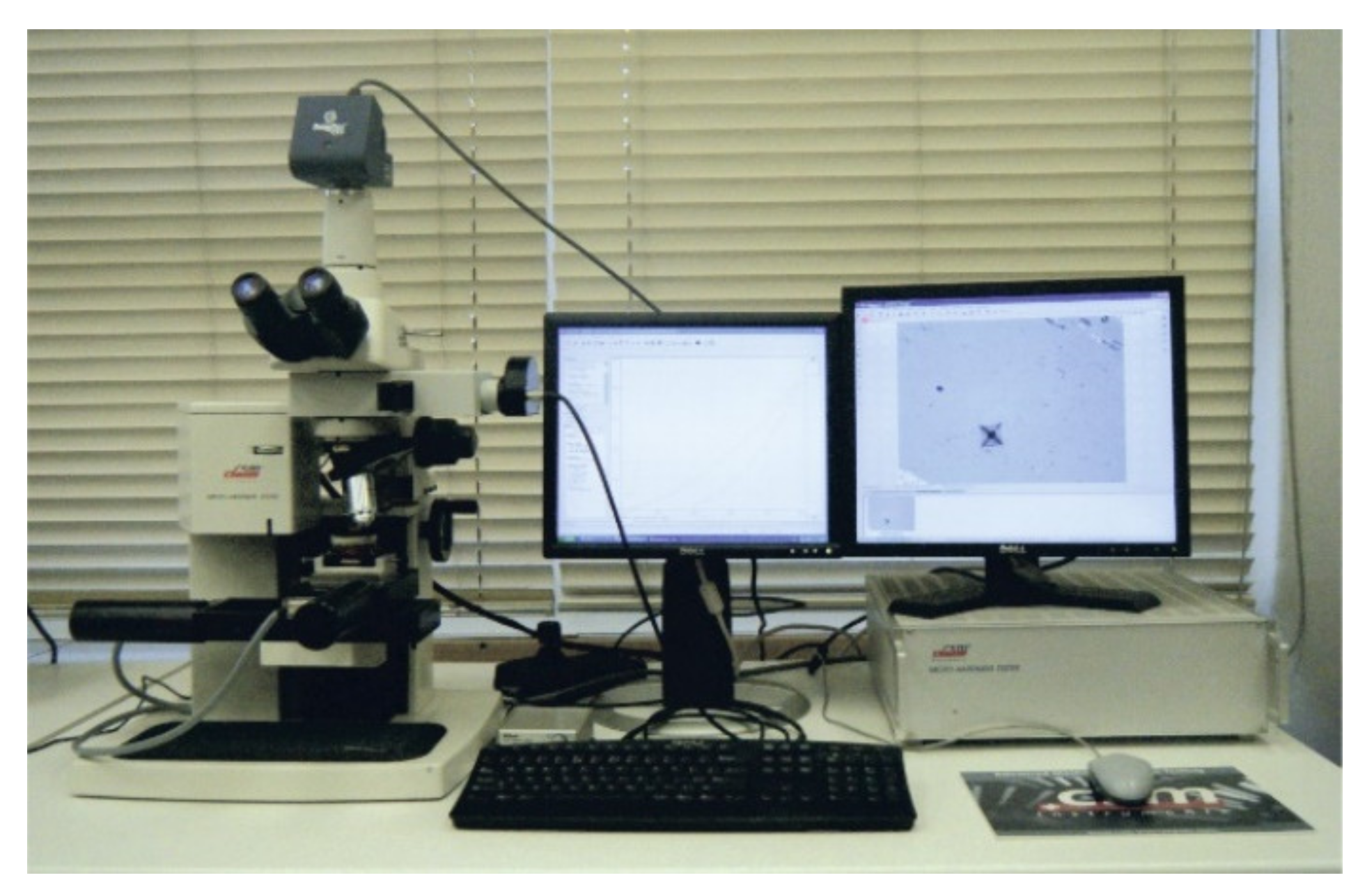

3.6. Microscale Strength Properties Tests

- –

- Vickers microhardness (Hv), calculated according to the formula (4):where:

- Fmax—maximum force (N).

- hc—indentation depth (μm).

- Ac—surface area of the obtained indentation (μm2).

- –

- standard modulus of elasticity (EIT), calculated according to the Power Law Method [49,69] from the formula (5):where:

- Ei—modulus of elasticity of the indenter—(constant, 1.141 GPa).

- vi—Poisson’s coefficient of the indenter (0.07).

- Er—reduced modulus of elasticity (which includes the influence of flexible deformation of the indenter under load).

- νs—Poisson’s coefficient of the examined sample.

- –

- the extent and nature of cracks and other damage occurring when the Vickers indenter is pressed against the examined material. This parameter is not described by any formulas, and its determination includes evaluation of surface deformation of the studied material by the observer. This may be used as the basis to evaluate such parameters as the brittleness of the examined material, since the sample returns to its initial position after the analysis, underneath the lens of an optical microscope, allowing observation and recording photographs of the location where the Vickers cone was pressed into the sample.

4. Results

4.1. Coal Rank and Sample Characteristics

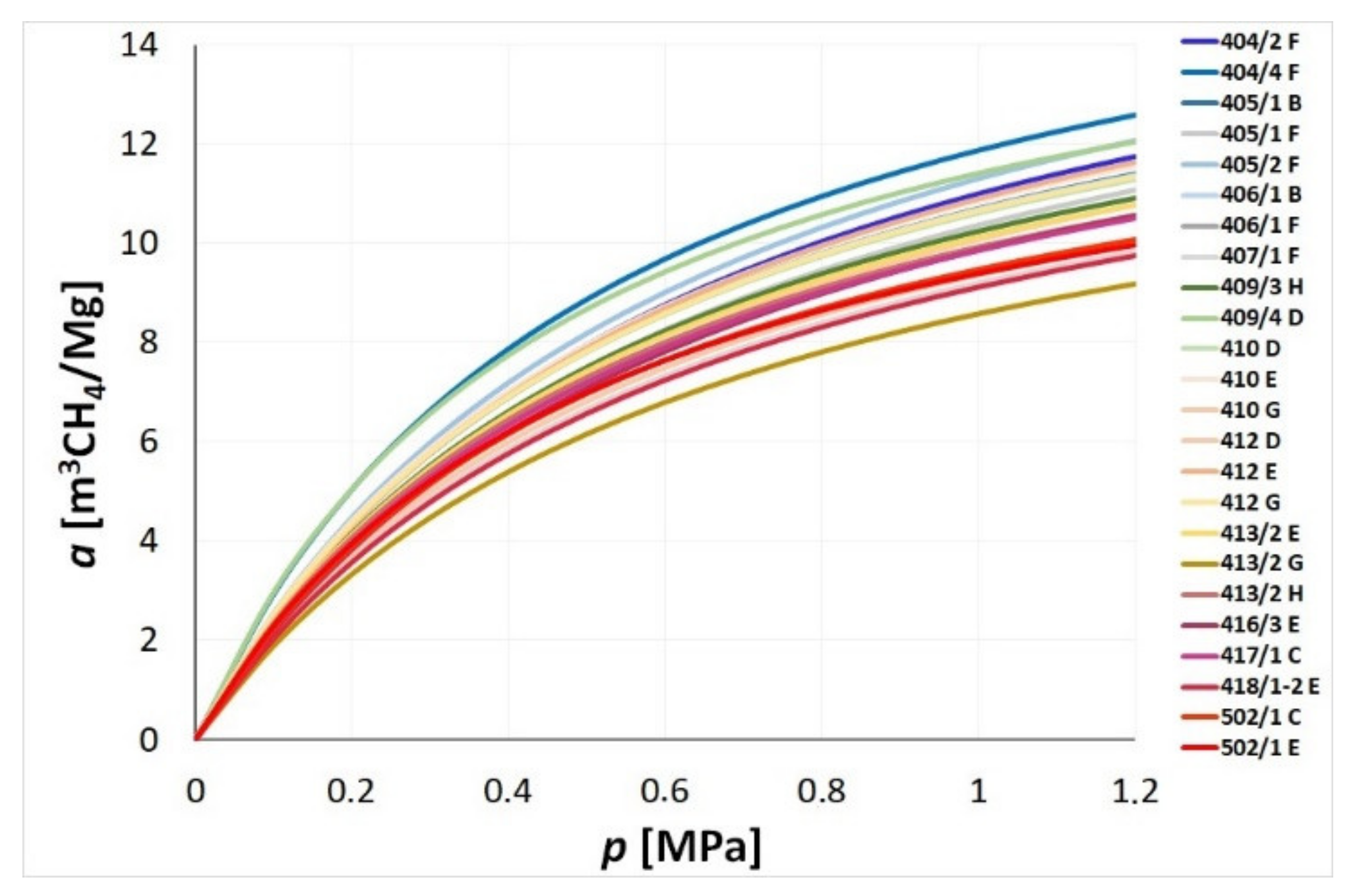

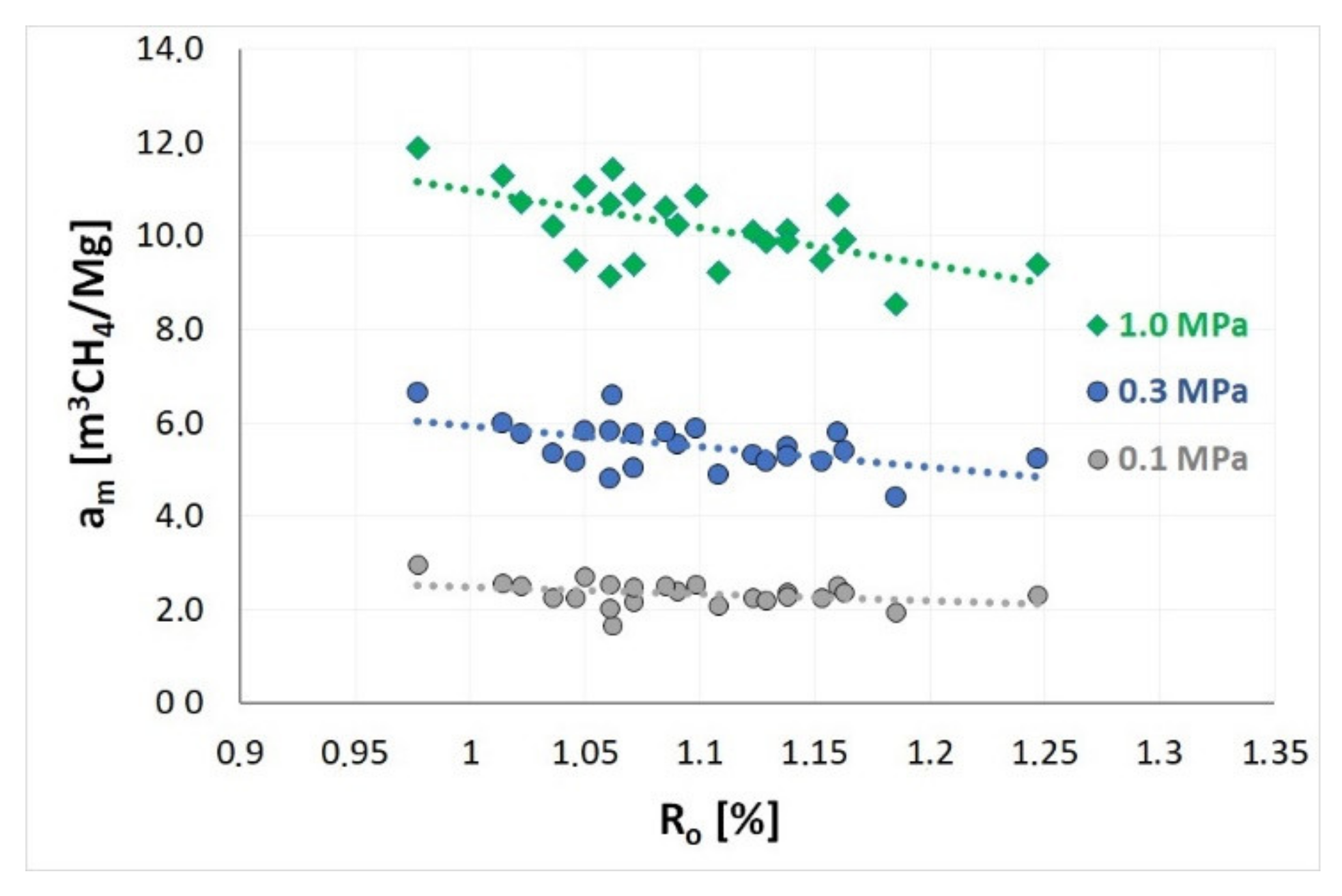

4.2. Sorption Test Results

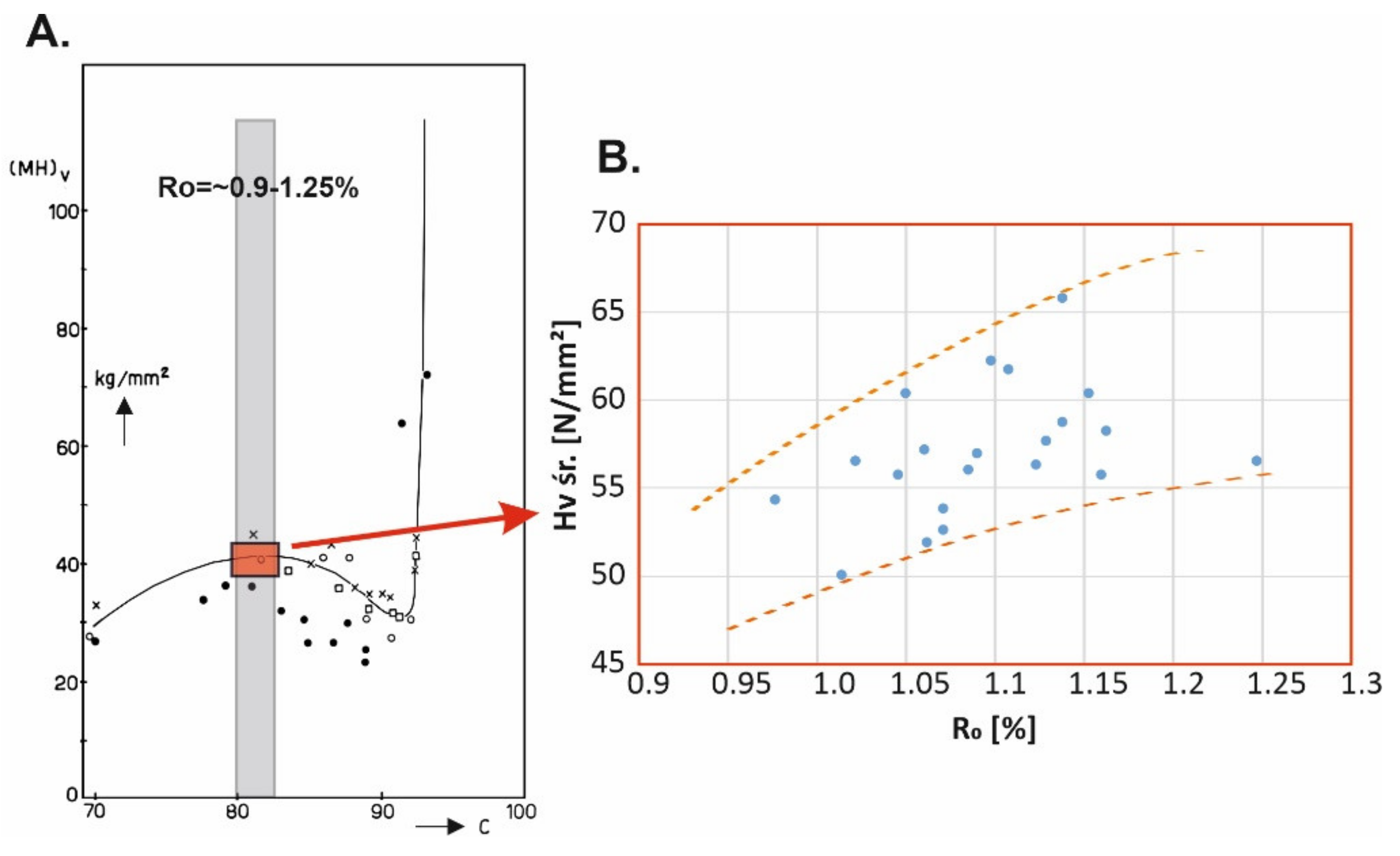

4.3. Microhardness

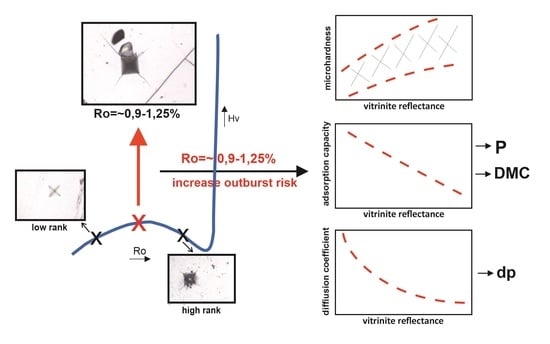

5. Discussion

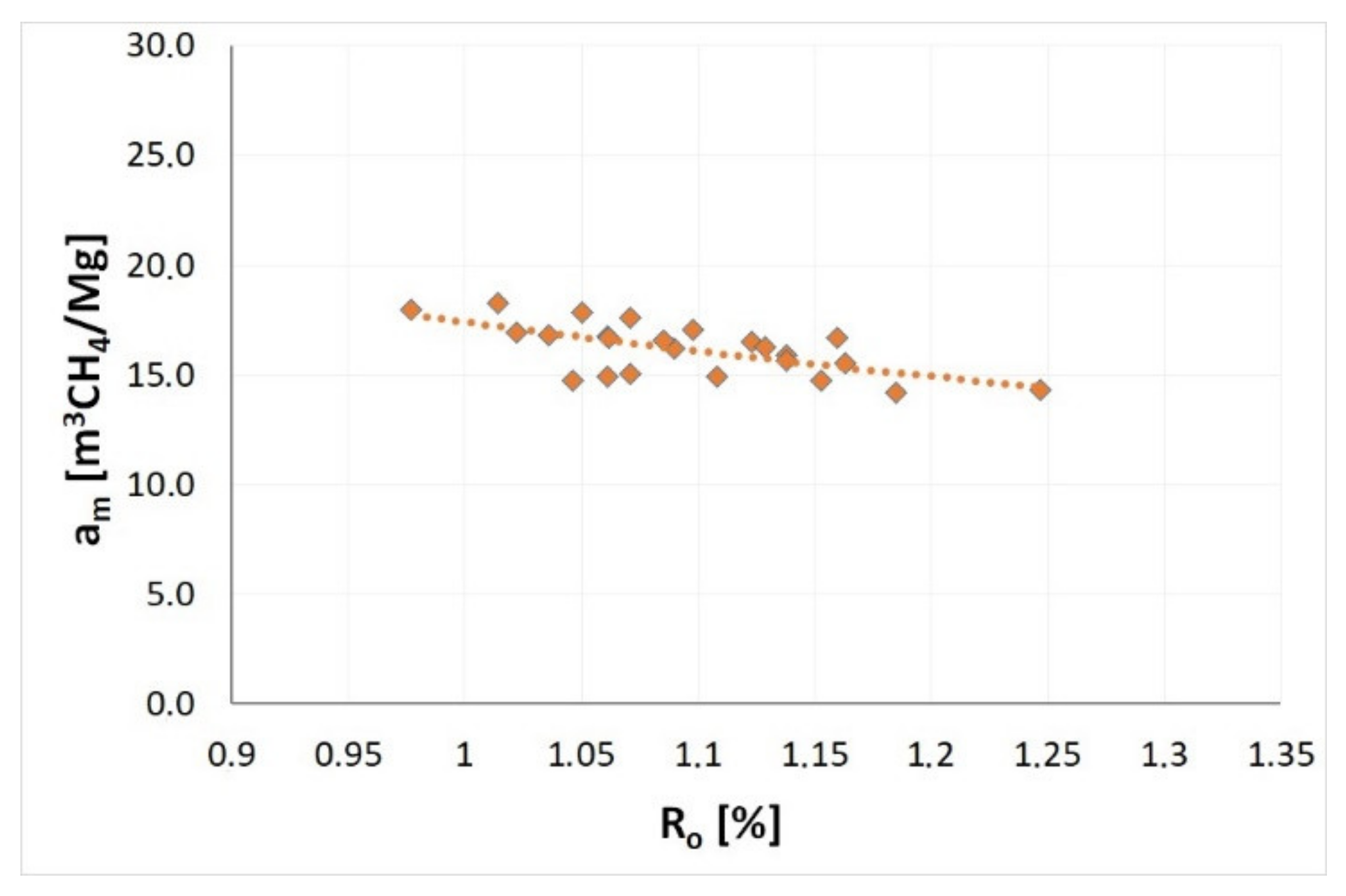

5.1. Influence of the Degree of Coalification on Accumulation Sorption Properties

5.2. Coal Seam Methane Pressure

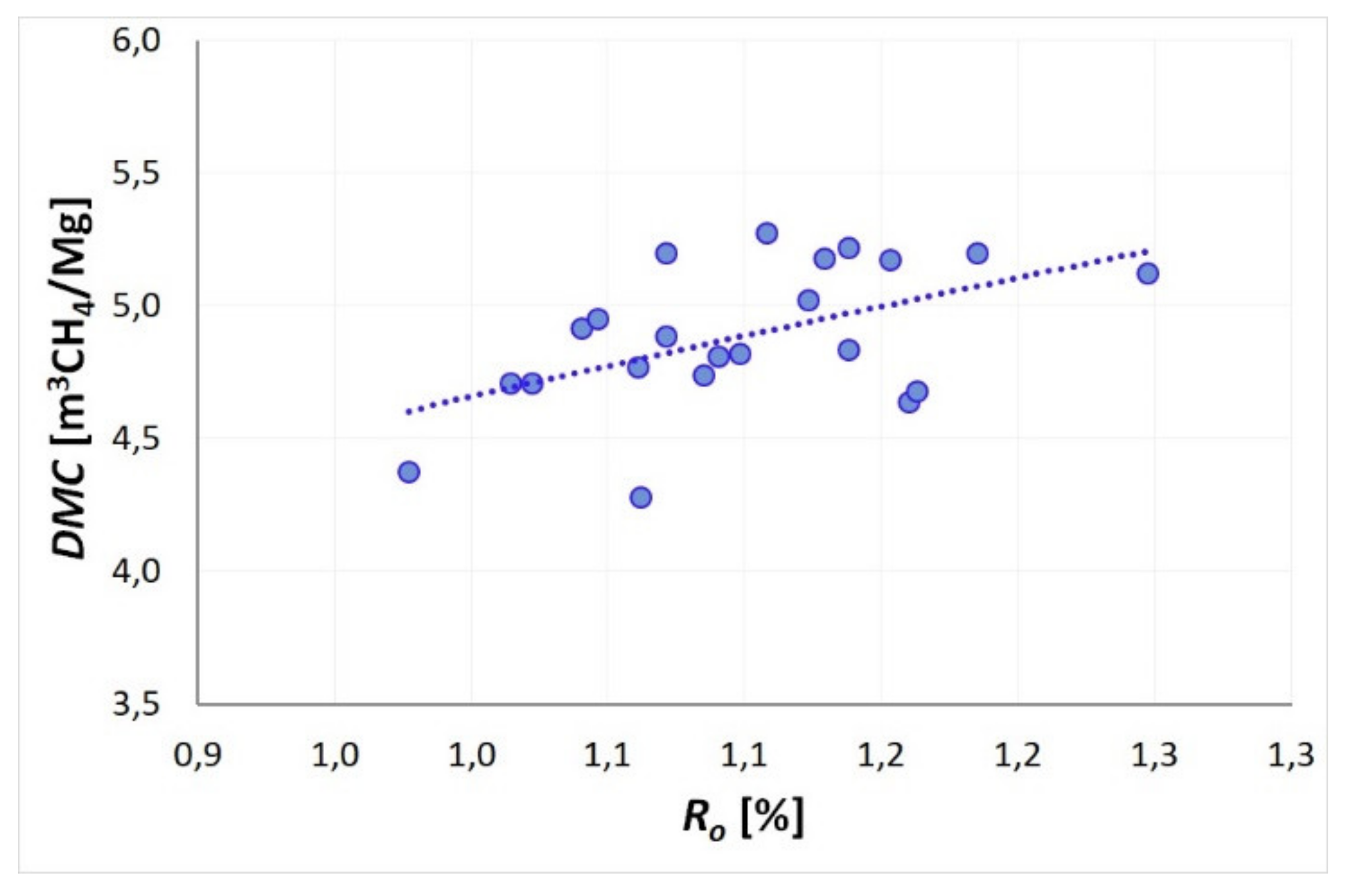

5.3. Desorbable Methane Content

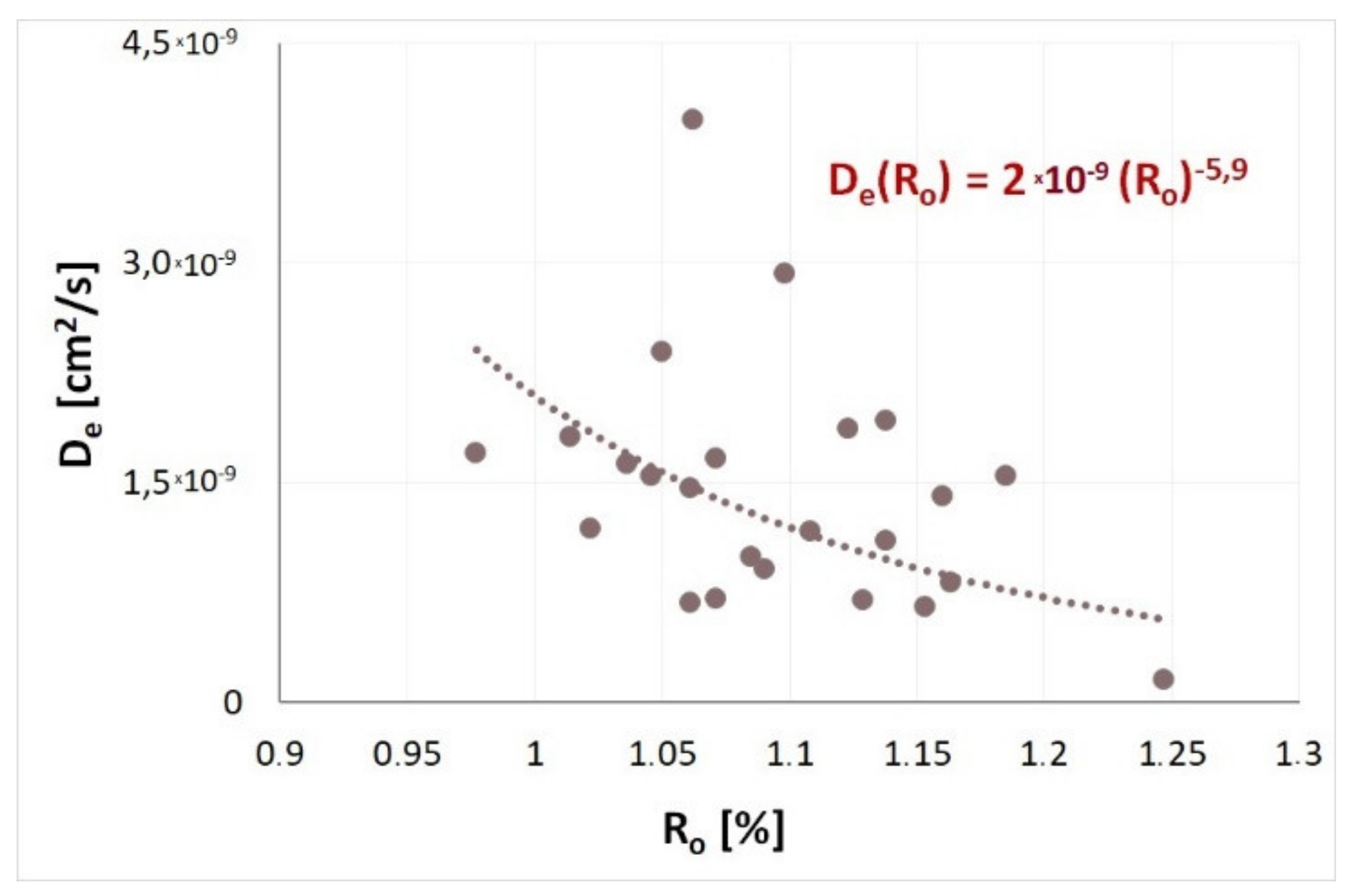

5.4. Influence of the Degree of Coalification on Kinetic Sorption Properties

5.5. Microhardness Properties and the Degree of Coalification

6. Conclusions

- increase of the equilibrium pressure of methane in highly coalified seams;

- increase of the desorbable methane content in the total methane content;

- a reduction in the measured methane desorption intensity indices from coal during work that made the seam available.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Trade Administration. 2021. Available online: https://www.trade.gov/ (accessed on 3 September 2021).

- Gawlik, L. The Polish power industry in energy transformation process. Miner. Econ. 2018, 31, 229–237. [Google Scholar] [CrossRef]

- Czerski, G.; Dziok, T.; Porada, S. Możliwości wykorzystania technologii zgazowania węgla do wytwarzania energii, paliw i produktów chemicznych. Polityka Energetyczna 2014, 17, 103–116. [Google Scholar]

- Klank, M. Przyszłość węgla—Nowe spojrzenie na jego wykorzystanie. Polityka Energetyczna 2007, 10, 41–49. [Google Scholar]

- Stala-Szlugaj, K. Trends in the consumption of hard coal in Polish households compared to EU households. Gospod. Surowcami Miner. 2016, 32, 5–22. [Google Scholar] [CrossRef][Green Version]

- Kędzior, S. Accumulation of coal-bed methane in the south-west part of the Upper Silesian Coal Basin (southern Poland). Int. J. Coal Geol. 2009, 80, 20–34. [Google Scholar] [CrossRef]

- Dutka, B. Effect of depth on the sorption capacity of coals affected by outburst hazard. Fuel 2021, 306, 121611. [Google Scholar] [CrossRef]

- Beamish, B.; Crosdale, P.J. Instantaneous outbursts in underground coal mines: An overview and association with coal type. Int. J. Coal Geol. 1998, 35, 27–55. [Google Scholar] [CrossRef]

- Wierzbicki, M.; Młynarczuk, M. Microscopic analysis of structure of coal samples collected after an gas and coal outbursts in the gallery D-6, coal seam 409/4 in the “Zofiówka” coal mine (upper silesian coal basin). Arch. Min. Sci. 2006, 51, 577–588. [Google Scholar]

- Wierzbicki, M.; Jakubów, A.; Tor, A. Wyrzut Metanu i Skał w Pochylni D Odstawczej W Pokładzie 358/1 Na Poziomie 1050 M W JSW S.A. KWK “Budryk”—Przyczyny: Okoliczności Skutki; Zagrożenia i Technologie, Central Mining Institute: Katowice, Poland, 2012. [Google Scholar]

- Brook, N.; Misra, B. A Critical Analysis of the Stamp Mill Method of Determining Protodyakonov Rock Strength and the Development of a Method of Determining a Rock Impact Hardness Number. In Proceedings of the 12th U.S. Symposium on Rock Mechanics, Rolla, MO, USA, 16–18 November 1970. [Google Scholar]

- Skoczylas, N.; Wierzbicki, M. Evaluation and management of the gas and rock outburst hazard in the light of international legal regulations. Arch. Min. Sci. 2014, 59, 1119–1129. [Google Scholar]

- Lama, R.D.; Bodziony, J. Management of outburst in underground coal mines. Int. J. Coal Geol. 1998, 35, 83–115. [Google Scholar]

- Godyń, K. The effect of tectonic discontinuities upon the internal structure of coal from some Upper Silesian Coal Basin coal seams of Pniówek, Borynia-Zofiówka and Brzeszcze. Biul. Państwowego Inst. Geol. 2012, 448, 215–228. [Google Scholar]

- Godyń, K. Characteristics of hard coal in the near-fault zones. Przegląd Górniczy 2013, 69, 45–53. [Google Scholar]

- Godyń, K. Structurally altered hard coal in the areas of tectonic disturbances—An initial attempt at classification. Arch. Min. Sci. 2016, 61, 677–694. [Google Scholar] [CrossRef]

- Lama, R.D.; Bodziony, J. Outbursts of Gas, Coal and Rock in Underground Coal Mines; Lama, R.D. & Associates: Wollongong, Australia, 1996. [Google Scholar]

- Shepherd, J.; Rixon, L.K.; Creasey, J.W. Analysis and Prediction of Geological Structures Associated with Outbursts at Collinsville, Queensland; Australian Institute of Mining and Metallurgy: Parkville, Australia, 1980; pp. 159–171. [Google Scholar]

- Cao, Y.; Mitchell, G.D.; Davis, A.; Wang, D. Deformation metamorphism of bituminous and anthracite coals from China. Int. J. Coal Geol. 2000, 43, 227–242. [Google Scholar] [CrossRef]

- Li, H.; Ogawa, Y.; Shimada, S. Mechanism of methane flow through sheared coals and its role in methane recovery. Fuel 2003, 82, 1271–1279. [Google Scholar] [CrossRef]

- Skiba, M. The influence of the discrepancies in the observers’ decisions on the process of identification of maceral groups using artificial neural networks. J. Sustain. Min. 2016, 15, 151–155. [Google Scholar] [CrossRef]

- Skiba, M.; Młynarczuk, M. Estimation of coal’s sorption parameters using artificial neural networks. Materials 2020, 13, 5422. [Google Scholar] [CrossRef] [PubMed]

- Godyń, K.; Kožušníková, A. Microhardness of coal from near-fault zones in coal seams threatened with gas-geodynamic phenomena, Upper Silesian Coal Basin, Poland. Energies 2019, 12, 1756. [Google Scholar] [CrossRef]

- Godyń, K.; Dutka, B. The impact of the degree of coalification on the sorption capacity of coals from the Zofiówka Monocline. Arch. Min. Sci. 2018, 63, 727–746. [Google Scholar]

- Dutka, B.; Godyń, K. Predicting variability of methane pressure with depth of coal seam. Przemysł Chem. 2018, 97, 1344–1348. [Google Scholar]

- Laxminarayana, C.; Crosdale, P. Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int. J. Coal Geol. 1999, 40, 309–325. [Google Scholar] [CrossRef]

- Manecki, A.; Muszyński, M. Przewodnik do Petrografii; Uczelniane Wydawnictwo Naukowo-Dydaktyczne AGH: Kraków, Poland, 2008. [Google Scholar]

- Stach, E.; Mackowsky, M.-T.; Teichmuller, M.; Taylor, G.H.; Chandra, D.; Teichmuller, R. Stach’s Textbook of Coal Petrology; Gebruder Borntraeger: Stuttgart, Germany, 1982. [Google Scholar]

- Van Krevelen, D.W.; Schuyer, J. Węgiel. Chemia węgla i jego struktura; PWN: Warsaw, Poland, 1959. [Google Scholar]

- Godyń, K.; Dutka, B.; Chuchro, M.; Młynarczuk, M. Synergy of parameters determining the optimal properties of coal as a natural sorbent. Energies 2020, 13, 1967. [Google Scholar] [CrossRef]

- Gray, I. Reservoir engineering in coal seams: Part. 1—The physical process of gas storage and movement in coal seams. SPE Reserv. Eng. 1987, 2, 1. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Dutka, B. CO2 and CH4 sorption properties of granular coal briquettes under in situ states. Fuel 2019, 247, 228–236. [Google Scholar] [CrossRef]

- Skoczylas, N. Determining the gas permeability coefficient of a porous medium by means of the bubble-counting flow meter. Meas. Sci. Technol. 2015, 26, 085004. [Google Scholar] [CrossRef]

- Skoczylas, N. Analyzing the parameters of the coal—Gas system using a low-cost device based on a flowmeter. Adsorpt. Sci. Technol. 2015, 33, 769–782. [Google Scholar] [CrossRef]

- Skoczylas, N.; Topolnicki, J. The coal-gas system—The effective diffusion coefficient. Int. J. Oil Gas Coal Technol. 2016, 12, 412–424. [Google Scholar] [CrossRef]

- Charrière, D.; Pokryszka, Z.; Behra, P. Effect of pressure and temperature on diffusion of CO2 and CH4 into coal from the Lorraine basin (France). Int. J. Coal Geol. 2010, 81, 373–380. [Google Scholar] [CrossRef]

- Wierzbicki, M. Changes in the sorption/diffusion kinetics of a coal-methane system caused by different temperatures and pressures. Gospod. Surowcami Miner. 2013, 29, 155–168. [Google Scholar] [CrossRef][Green Version]

- Xu, H.; Tang, D.; Zhao, J.; Li, S.; Tao, S. A new laboratory method for accurate measurement of the methane diffusion coefficient and its influencing factors in the coal matrix. Fuel 2015, 158, 239–247. [Google Scholar] [CrossRef]

- Wierzbicki, M.; Dutka, B. The influence of temperature changes of the structurally deformed coal—Methane system on the total methane content. Arch. Min. Sci. 2010, 55, 547–560. [Google Scholar]

- Mukherjee, A.K.; Alam, M.M.; Ghose, S. Microhardness characteristics of Indian coal and lignite. Fuel 1989, 68, 670–674. [Google Scholar] [CrossRef]

- Tora, B.; Fecko, P.; Nowak, A.; Tajchman, Z. Investigation on dependence of grindability on chosen parameters of hard coal. Górnictwo Geoinżynieria 2010, 34, 285–292. [Google Scholar]

- Yuzo, S.; Hidemasa, H. Microhardness of coal immersed in various solvents. Bull. Chem. Soc. Jpn. 1962, 35, 1238–1239. [Google Scholar]

- Eremin, I.V.; Lebedev, V.V.; Cikarev, A.D. Petrografija i Fizičeskije Svojstva Uhlej; Nedra: Moskva, Russia, 1980. [Google Scholar]

- Van Krevelen, D.W. Coal–Typology–Physics–Chemistry–Constitution; Elsevier: Amsterdam, The Netherlands, 1993. [Google Scholar]

- Beneš, K. Měření mikrotvrdosti uhelně-petrografických složek a mikrolitotypů Hanemanovým mikrotvrdoměrem. In Sborník Vědeckých Prací Vysoké Školy Báňské; Technické Univerzity Ostrava/Transactions of the VŠB—Technical University of Ostrava: Ostrava, Czech Republic, 1957; Volume 3, pp. 47–51. [Google Scholar]

- Das, B. Microhardness Study of Coal with Special Reference to Mechanism of Dust Genesis. Master’s Thesis, Vysoká Škola Báňská, Ostrava, Czech Republic, 1968. [Google Scholar]

- Martinec, P.; Kožušníková, A. Mikrotvrdost černých uhlí ostravsko-karvinského revíru–dosa-vadní stav a možnosti dalšího rozvoje problematiky. Documenta Geonica. In Proceedings of the 6th Czech-Polish Conference of the Upper Silesian Coal Basin, Ostrava, Czech Republic, 11–13 October 2006; pp. 111–119. [Google Scholar]

- Kožušníková, A. Determination of microhardness and elastic modulus of coal components by using indentation method. Geolines 2009, 22, 40–43. [Google Scholar]

- Bukowska, M.; Ćmiel, S. The characteristic of changes of Carboniferous rocks properties in non-continuous tectonic zones in the Upper Silesian Coal Basin. Górnictwo Geoinżynieria 2011, 35, 111–119. [Google Scholar]

- Ćmiel, S.R. Charakterystyka Epigenetycznych Zmian Węgla w Pokładach w Strefach Uskokowych Górnośląskiego Zagłębia Węglowego; Wydawnictwo Uniwersytetu Śląskiego: Katowice, Poland, 2009. [Google Scholar]

- Godyń, K.; Kralova, L. Application of Vickers micro hardness measurements for hard coal analysis focusing on the F part of the Borynia–Zofiówka–Jastrzębie mine, Zofiówka Section. Trans. Strata Mech. Res. Inst. 2017, 19, 25–33. [Google Scholar]

- Hower, J.C.; Trinkle, E.J.; Raione, R.P. Vickers microhardness of telovitrinite and pseudovitrinite from high volatile bituminous Kentucky coals. Int. J. Coal Geol. 2008, 75, 76–80. [Google Scholar] [CrossRef]

- Given, P.H. The use of DAF and DMMF ultimate analyses of coals. Fuel 1976, 55, 256. [Google Scholar] [CrossRef]

- Kus, J.; Misz-Kennan, M. Coal weathering and laboratory (artificial) coal oxidation. Int. J. Coal Geol. 2017, 171, 12–36. [Google Scholar] [CrossRef]

- Markova, K.; Valceva, S. Oxidation of some Bulgarian coals. Influence of low-temperature oxidation on the microhardness and reflectivity of some brown coals. Fuel 1983, 62, 942–945. [Google Scholar] [CrossRef]

- Nandi, B.N.; Ciavaglia, L.A.; Montgomery, D.S. The variation of the microhardness and reflectance of coal under conditions of oxidation simulating weathering. J. Microsc. 1977, 109, 93–103. [Google Scholar] [CrossRef]

- Gabzdyl, W. Geologia Złóż Węgla: Złoża Świata; Polska Agencja Ekologiczna: Warsaw, Poland, 1994. [Google Scholar]

- Osika, R. Budowa Geologiczna Polski, Tom VI; Złoża Surowców Mineralnych; Instytut Geologiczny Warszawa Wydawnictwa Geologiczne: Warsaw, Poland, 1987. [Google Scholar]

- Kotas, A. Coalbed methane potential of the Upper Silesian Coal Basin, Poland; Prace Państwowego Instytutu Geologicznego Polish Geological Institute: Warsaw, Poland, 1994; p. 81, CXLII0866-9465. [Google Scholar]

- Probierz, K.; Marcisz, M.; Sobolewski, A. Od Torfu do Węgli Koksowych Monokliny Zofiówki w Obszarze Jastrzębia (Południowo-Zachodnia Część Górnośląskiego Zagłębia Węglowego); Wydawnictwo Instytutu Chemicznej Przeróbki Węgla: Zabrze, Poland, 2012. [Google Scholar]

- Praca zbiorowa pod kierunkiem, dr. hab. inż. Józefa Kabiesza. Report on the State of Basic Natural and Technical Hazards in Hard Coal Mining in 2018; Główny Instytut Górnictwa: Katowice, Poland, 2019. [Google Scholar]

- The Polish Geological Institute—National Research Institute. Available online: http://geoportal.pgi.gov.pl (accessed on 8 April 2019).

- Dutka, B.; Godyń, K. Coalification as a process determining the methane adsorption ability of coal seams. Arch. Mining Sci. 2021, 66, 181–195. [Google Scholar]

- Klika, Z.; Serenčíšová, J.; Kožušníková, A.; Kolomazník, I.; Študentová, S.; Vontorová, J. Multivariate statistical assessment of coal properties. Fuel Process. Technol. 2014, 128, 119–127. [Google Scholar] [CrossRef]

- Timofejew, D.P. Adsorptionskinetik; Lipsk VEB: Berlin, Germany, 1967. [Google Scholar]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford Science Publication: Oxford, UK, 1975. [Google Scholar]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using loadand displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1580. [Google Scholar] [CrossRef]

- UN-ECE. International Classification of In-Seam Coals; ECE UN Geneva: New York, NY, USA, 1998. [Google Scholar]

- Levy, J.H.; Day, S.J.; Killingley, J.S. Methane capacities of Bowen Basin coals related to coal properties. Fuel 1997, 76, 813–819. [Google Scholar] [CrossRef]

- Prinz, D.; Pyckhout-Hintzen, W.; Littke, R. Development of the meso and macroporous structure of coals with rank as analyzed with small angle neutron scattering and adsorption experiments. Fuel 2004, 83, 547–556. [Google Scholar] [CrossRef]

- Dutta, P.; Bhowmik, S.; Das, S. Methane and carbon dioxide sorption on a set of coals from India. Int. J. Coal Geol. 2011, 85, 289–299. [Google Scholar] [CrossRef]

- Levine, J.R. Coalification: The Evolution of Coal as Source Rock and Reservoir; Law, B.E., Rice, D.D., Eds.; Hydrocarbons from Coal; American Association of Petroleum Geologists, AAPG Studies in Geology: Tuscalosa, AL, USA, 1993; Volume 38, pp. 39–77. [Google Scholar]

- Zarębska, K.; Dudzińska, A. Możliwości Magazynowania CO2 w Pokładach Węgli Kamiennych—Weryfikacja Danych Eksperymentalnych; Mineral Resources Management: Krakow, Poland, 2008; Volume 24, pp. 347–355. [Google Scholar]

- Wierzbicki, M. Effect of selected simplifications of the unipore model upon the result of the study of the diffusion coefficient. Arch. Min. Sci. 2011, 56, 761–776. [Google Scholar]

| Sample | Part | Seam | Lithostratigraphy | Formation | Age | R0, % | Vdaf, % | Ad, % | Wt, % |

|---|---|---|---|---|---|---|---|---|---|

| 404/2 F | F | 404/2 | załęskie | Siltstone | Westphalian A | 1.050 | 25.29 | 5.01 | 2.09 |

| 404/4 F | F | 404/4 | załęskie | 0.977 | 24.78 | 6.00 | 1.84 | ||

| 405/1 B | B | 405/1 | załęskie | 1.022 | 28.45 | 10.19 | 1.36 | ||

| 405/1 F | F | 405/1 | załęskie | 1.036 | 20.58 | 11.57 | 1.19 | ||

| 405/2 F | F | 405/2 | załęskie | 1.014 | 22.33 | 15.68 | 1.16 | ||

| 406/1 B | B | 406/1 | załęskie | 1.061 | 20.92 | 2.69 | 1.59 | ||

| 406/1 F | F | 406/1 | załęskie | 1.046 | 27.84 | 2.58 | 1.95 | ||

| 407/1 F | F | 407/1 | rudzkie | Upper Silesian Sandstone | Namurian C | 1.108 | 23.25 | 6.31 | 1.13 |

| 409/3 H | H | 409/3 | rudzkie | 1.090 | 19.89 | 6.73 | 1.28 | ||

| 409/4 D | D | 409/4 | rudzkie | 1.062 | 29.08 | 20.20 | 1.12 | ||

| 410 D | D | 410 | rudzkie | 1.085 | 17.81 | 8.78 | 1.44 | ||

| 410 E | E | 410 | rudzkie | 1.098 | 20.79 | 7.54 | 1.57 | ||

| 410 G | G | 410 | rudzkie | 1.071 | 20.20 | 5.56 | 0.88 | ||

| 412 D | D | 412 | rudzkie | 1.123 | 19.34 | 21.61 | 0.82 | ||

| 412 E | E | 412 | rudzkie | 1.071 | 19.42 | 11.77 | 1.39 | ||

| 412 G | G | 412 | rudzkie | 1.160 | 17.40 | 4.38 | 1.06 | ||

| 413/2 E | E | 413/2 | rudzkie | 1.138 | 18.35 | 3.49 | 1.31 | ||

| 413/2 G | G | 413/2 | rudzkie | 1.185 | 18.71 | 4.28 | 1.62 | ||

| 413/2 H | H | 413/2 | rudzkie | 1.163 | 25.01 | 10.27 | 0.92 | ||

| 416/3 E | E | 416/3 | rudzkie | 1.129 | 19.17 | 9.57 | 1.00 | ||

| 417/1 C | C | 417/1 | rudzkie | 1.138 | 18.33 | 12.25 | 1.39 | ||

| 418 E | E | 418 | rudzkie | 1.061 | 16.54 | 8.02 | 1.32 | ||

| 502/1 C | C | 502/1 | siodłowe | Namurian B | 1.153 | 21.44 | 8.76 | 1.08 | |

| 502/1 E | E | 502/1 | siodłowe | 1.247 | 13.82 | 6.48 | 1.15 |

| Sample | am [m3CH4/g] | pL [MPa] | t0.5 [s] | De [cm2/s] |

|---|---|---|---|---|

| 404/2 F | 17.814 | 0.620 | 650 | 2.39 × 10−9 |

| 404/4 F | 17.966 | 0.512 | 915 | 1.70 × 10−9 |

| 405/1 B | 16.920 | 0.580 | 1310 | 1.19 × 10−9 |

| 405/1 F | 16.801 | 0.620 | 950 | 1.63 × 10−9 |

| 405/2 F | 18.254 | 0.615 | 860 | 1.81 × 10−9 |

| 406/1 B | 16.751 | 0.565 | 1060 | 1.46 × 10−9 |

| 406/1 F | 14.727 | 0.554 | 1000 | 1.55 × 10−9 |

| 407/1F | 14.910 | 0.617 | 1330 | 1.17 × 10−9 |

| 409/3 H | 16.183 | 0.577 | 1705 | 9.11 × 10−10 |

| 409/4 D | 16.680 | 0.460 | 390 | 3.98 × 10−9 |

| 410 D | 16.557 | 0.560 | 1570 | 9.89 × 10−10 |

| 410E | 17.072 | 0.573 | 530 | 2.93 × 10−9 |

| 410 G | 15.012 | 0.600 | 2200 | 7.06 × 10−10 |

| 412 D | 16.492 | 0.633 | 831 | 1.87 × 10−9 |

| 412 E | 17.600 | 0.616 | 930 | 1.67 × 10−9 |

| 412 G | 16.680 | 0.565 | 1100 | 1.41 × 10−9 |

| 413/2 E | 15.907 | 0.570 | 807 | 1.92 × 10−9 |

| 413/2 G | 14.154 | 0.648 | 1000 | 1.55 × 10−9 |

| 413/2 H | 15.512 | 0.561 | 1900 | 8.17 × 10−10 |

| 416/3 E | 16.258 | 0.647 | 2220 | 6.99 × 10−10 |

| 417/1 C | 15.649 | 0.587 | 1410 | 1.10 × 10−9 |

| 418 E | 14.885 | 0.633 | 2270 | 6.84 × 10−10 |

| 502/1 C | 14.750 | 0.557 | 2382 | 6.52 × 10−10 |

| 502/1 E | 14.326 | 0.524 | 10,000 | 1.55 × 10−10 |

| Coal Sample | Hv [N/mm2] | Eit [GPa] | Hv Max [N/mm2] | Eit Max [GPa] | Hv Min [N/mm2] | Eit Min [GPa] |

|---|---|---|---|---|---|---|

| 404/4 F | 54.32 | 5.70 | 61.00 | 6.17 | 42.83 | 4.94 |

| 405/2 F | 50.04 | 5.65 | 64.49 | 6.44 | 40.40 | 5.01 |

| 405/1 B | 56.51 | 5.79 | 64.77 | 6.38 | 46.72 | 5.27 |

| 406/1 F | 55.71 | 6.00 | 66.40 | 6.63 | 44.03 | 5.02 |

| 404/2 F | 60.37 | 5.30 | 74.96 | 6.23 | 35.12 | 3.99 |

| 406/1 B | 57.18 | 6.07 | 67.95 | 6.84 | 41.76 | 4.89 |

| 418 E | 64.44 | 6.46 | 76.59 | 7.19 | 47.80 | 5.62 |

| 409/4 D | 51.89 | 5.58 | 62.34 | 6.21 | 43.57 | 5.02 |

| 410 G | 53.86 | 5.95 | 62.52 | 6.66 | 43.47 | 5.25 |

| 412 E | 52.59 | 5.65 | 64.19 | 6.36 | 43.37 | 5.05 |

| 410 D | 56.07 | 5.94 | 69.86 | 6.77 | 46.62 | 5.22 |

| 409/3 H | 56.96 | 6.19 | 71.63 | 7.04 | 42.56 | 5.30 |

| 410 E | 62.2 | 6.05 | 76.25 | 6.66 | 58.29 | 5.74 |

| 407/1 F | 61.75 | 6.15 | 69.79 | 6.91 | 51.30 | 5.17 |

| 412 D | 56.3 | 5.98 | 75.52 | 6.87 | 44.24 | 4.94 |

| 416/3 E | 57.67 | 5.99 | 65.63 | 6.68 | 44.42 | 5.31 |

| 413/2 E | 58.71 | 6.04 | 73.44 | 6.84 | 41.94 | 5.04 |

| 417/1 C | 65.75 | 6.46 | 73.00 | 7.07 | 46.72 | 5.21 |

| 502/1 C | 60.39 | 5.98 | 73.85 | 6.47 | 45.04 | 5.25 |

| 412 G | 55.75 | 5.88 | 68.56 | 6.19 | 41.82 | 5.07 |

| 413/2 H | 58.21 | 6.63 | 65.86 | 7.14 | 44.29 | 5.75 |

| 413/2 G | 47.43 | 5.63 | 67.20 | 6.83 | 39.97 | 4.98 |

| 502/1 E | 56.51 | 5.79 | 64.77 | 6.38 | 46.72 | 5.27 |

| Low-Rank Coals (wg Godyń et al. [30]) | Medium-Rank Coals | High-Rank Coals (wg Godyń et al. [30]) | |

|---|---|---|---|

| Ro | 0.78–0.85% | 0.98–1.25% | 1.85–2.03% |

| Average value of Hv | 69.25 | 57.42 | 57.11 |

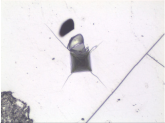

| Photographs after measurement |  |  |  |

| Notes | The coals have the highest microhardness and the Vickers cone leaves a small mark. indicating that low-rank coal does not show a tendency to break under the applied load. The samples are slightly deformed. showing a certain plasticity at a high value of (Hv). | A significant decrease of microhardness was observed. The Vickers cone indentation leaves clear marks of the performed measurement. Extensive cracks running from the tops of the indentations were observed. sometimes accompanied by separated material fragments. The damage indicates that this material is crushed very easily. | A slight Hv decrease occurs. A Vickers pyramid trace is formed on the sample surface, and the cracks around the indentation are not as spectacular as in medium-rank samples. Cracks and separated fragments are visible. but most coal changes are focused in the indentation and nearby. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Godyń, K.; Dutka, B. Sorption and Micro-Scale Strength Properties of Coals Susceptible to Outburst Caused by Changes in Degree of Coalification. Materials 2021, 14, 5807. https://doi.org/10.3390/ma14195807

Godyń K, Dutka B. Sorption and Micro-Scale Strength Properties of Coals Susceptible to Outburst Caused by Changes in Degree of Coalification. Materials. 2021; 14(19):5807. https://doi.org/10.3390/ma14195807

Chicago/Turabian StyleGodyń, Katarzyna, and Barbara Dutka. 2021. "Sorption and Micro-Scale Strength Properties of Coals Susceptible to Outburst Caused by Changes in Degree of Coalification" Materials 14, no. 19: 5807. https://doi.org/10.3390/ma14195807

APA StyleGodyń, K., & Dutka, B. (2021). Sorption and Micro-Scale Strength Properties of Coals Susceptible to Outburst Caused by Changes in Degree of Coalification. Materials, 14(19), 5807. https://doi.org/10.3390/ma14195807