Recent Trends and Innovation in Additive Manufacturing of Soft Functional Materials

Abstract

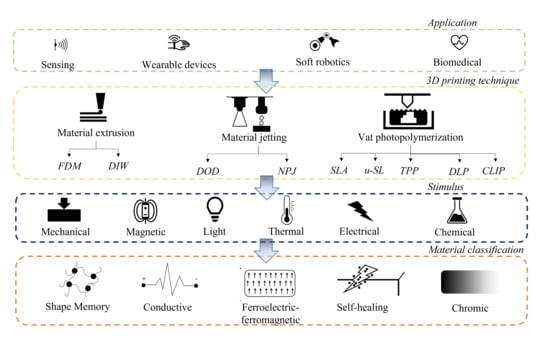

:1. Introduction

1.1. Material Extrusion

1.2. Vat Photopolymerization

1.3. Material Jetting

1.4. Other Additive Manufacturing Methods

2. Materials and Methods

2.1. Shape Memory Polymers

2.2. Self-Healing Materials

2.3. Electronic Polymers

2.4. Chromic Materials

2.5. Multifunctional Soft Materials

3. Applications

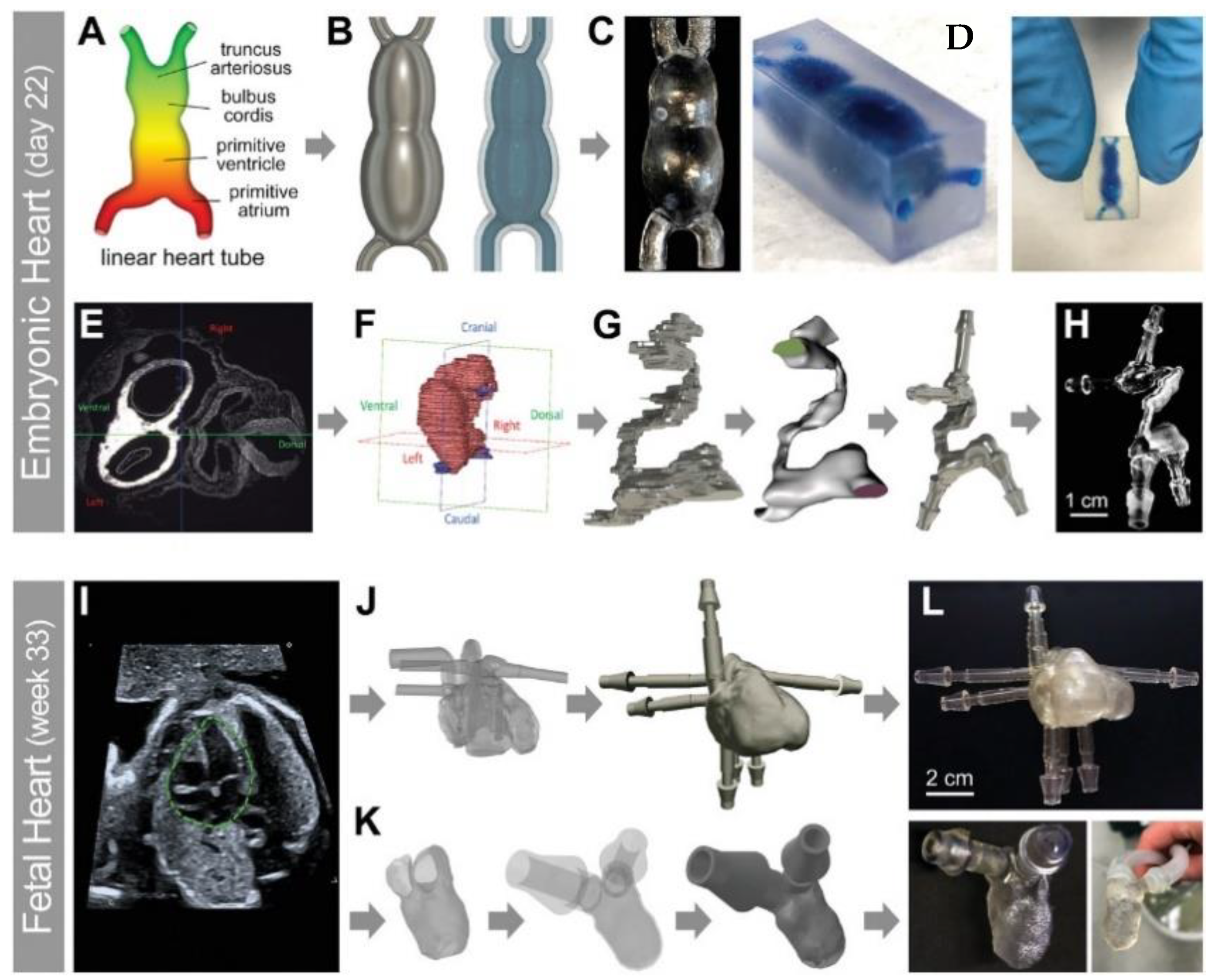

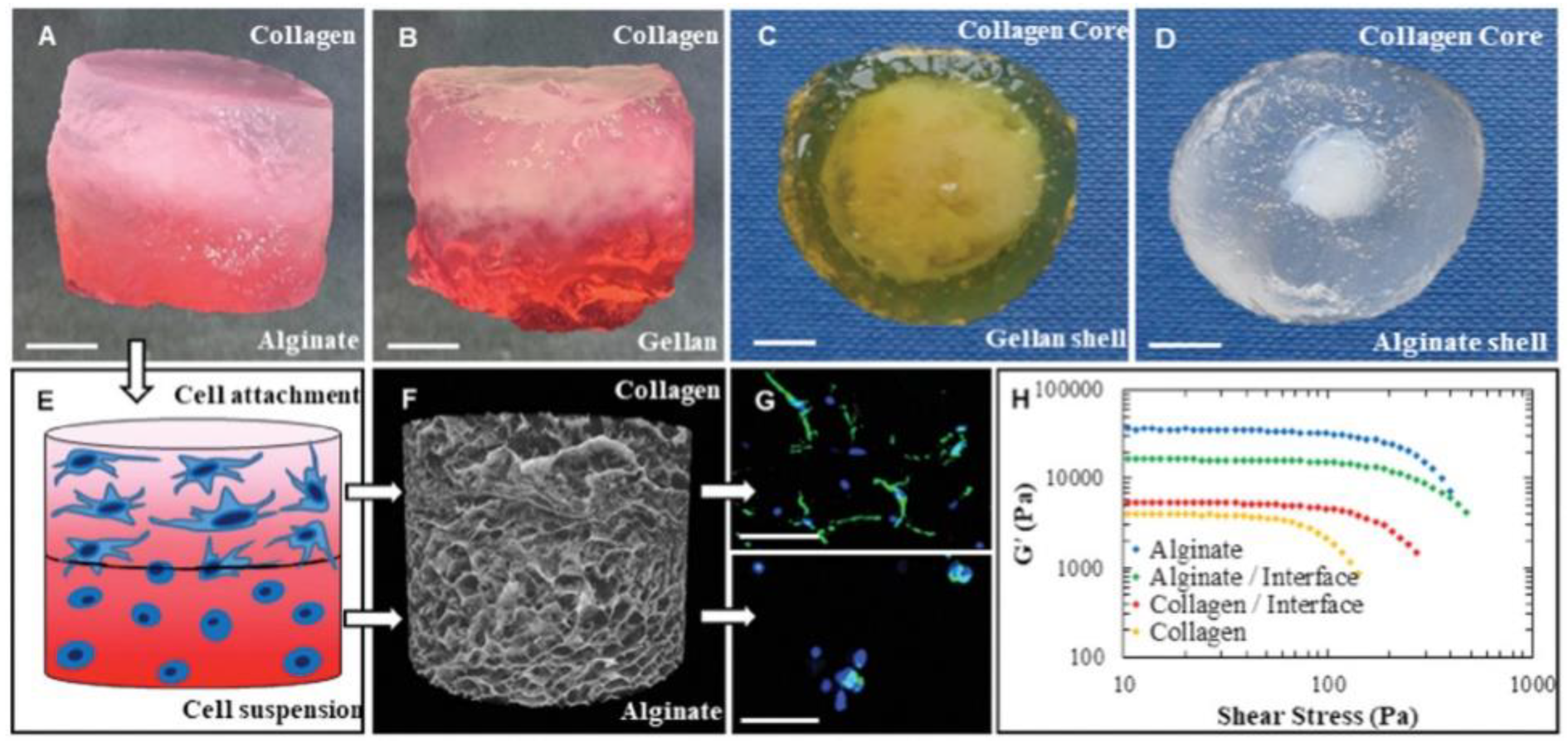

3.1. Biomaterials

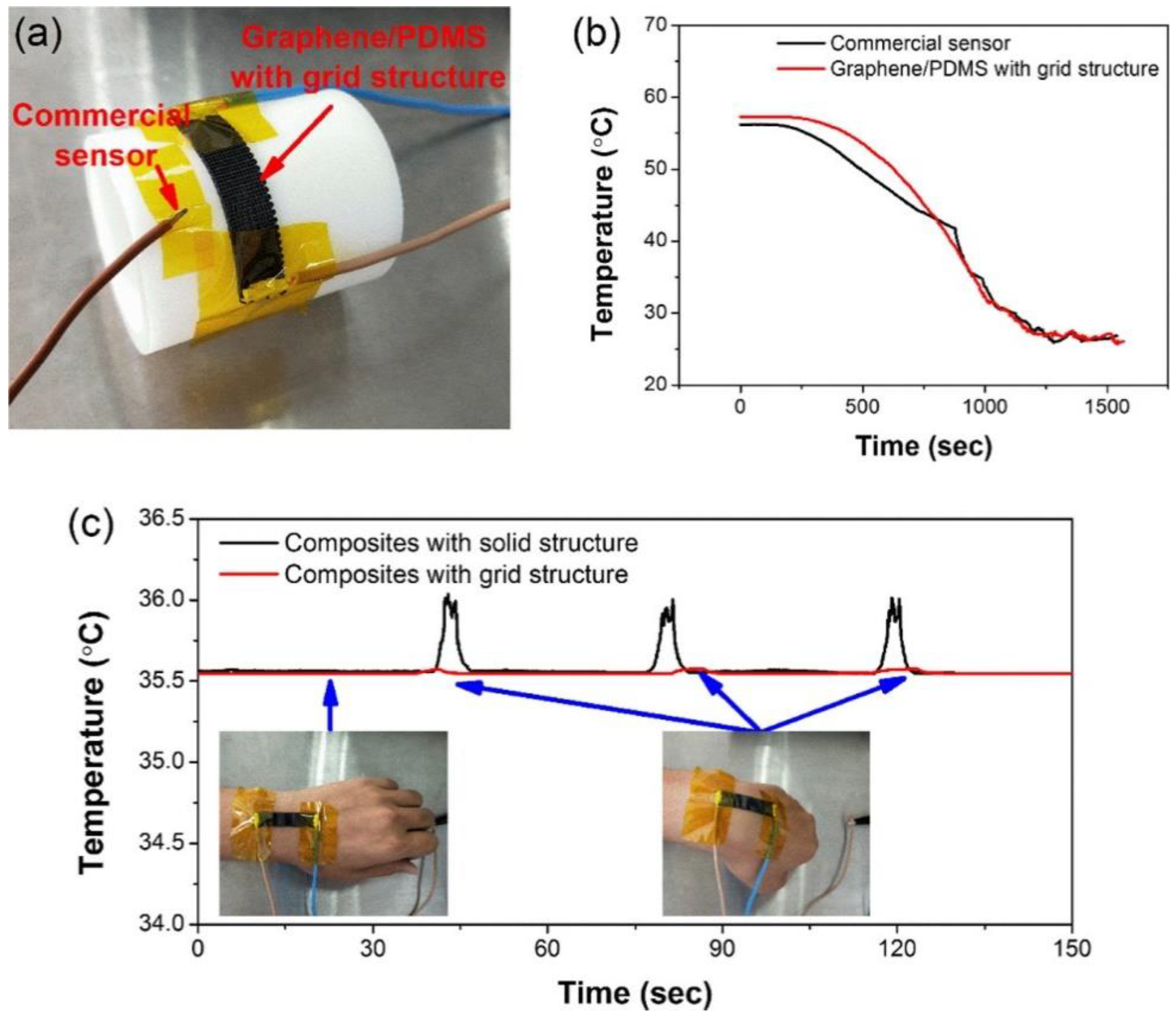

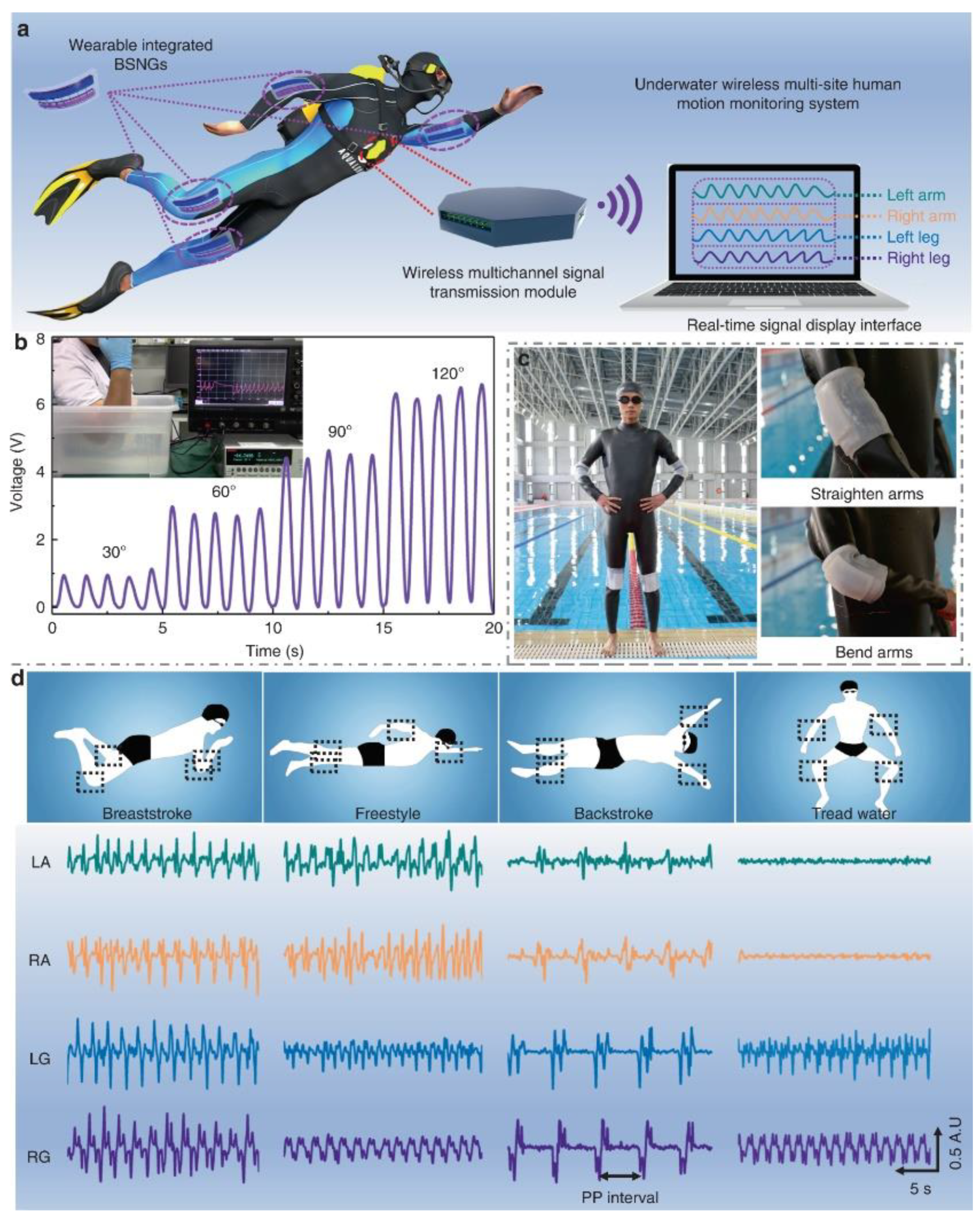

3.2. Sensors

3.3. Energy Harvesting

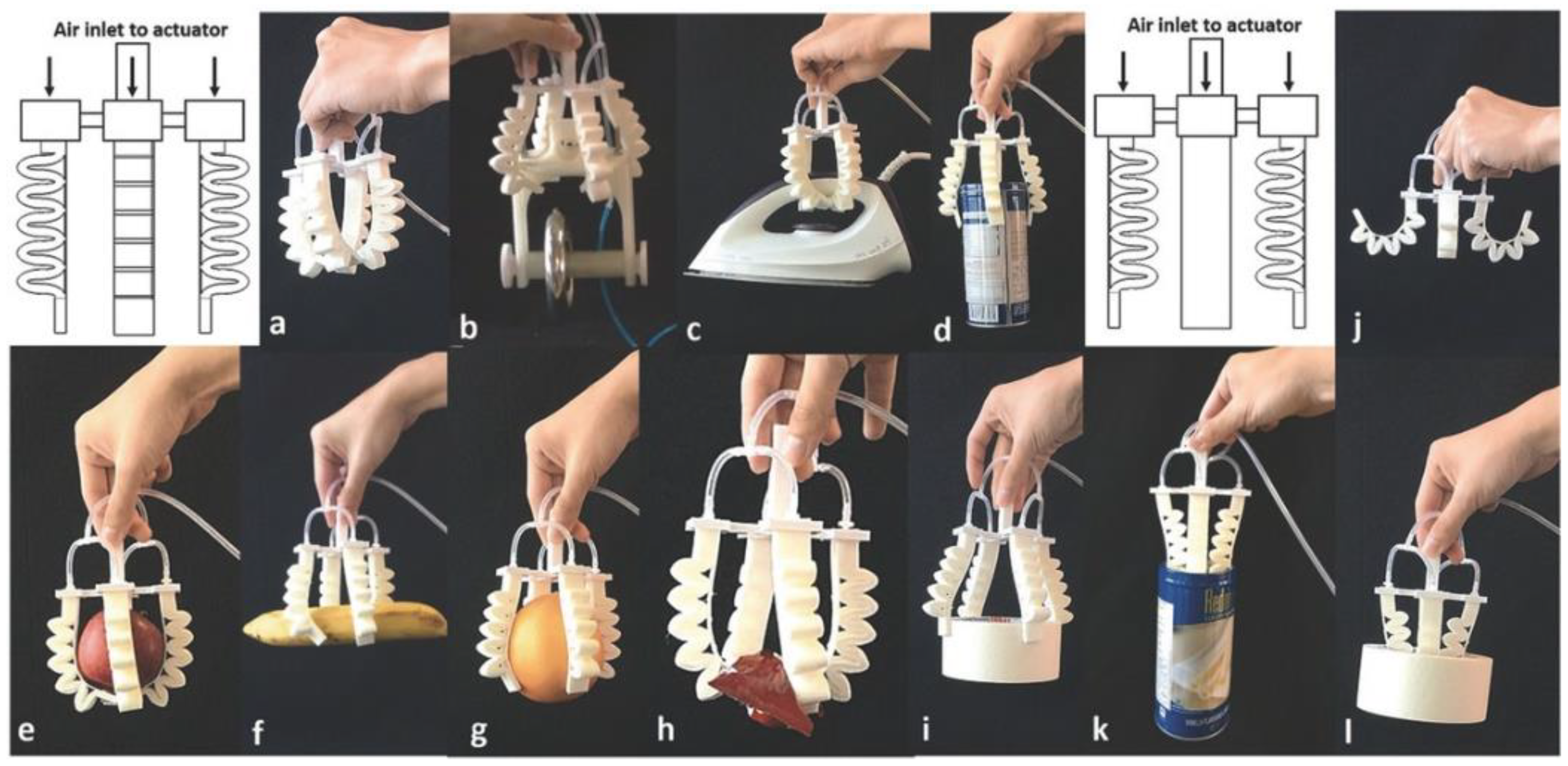

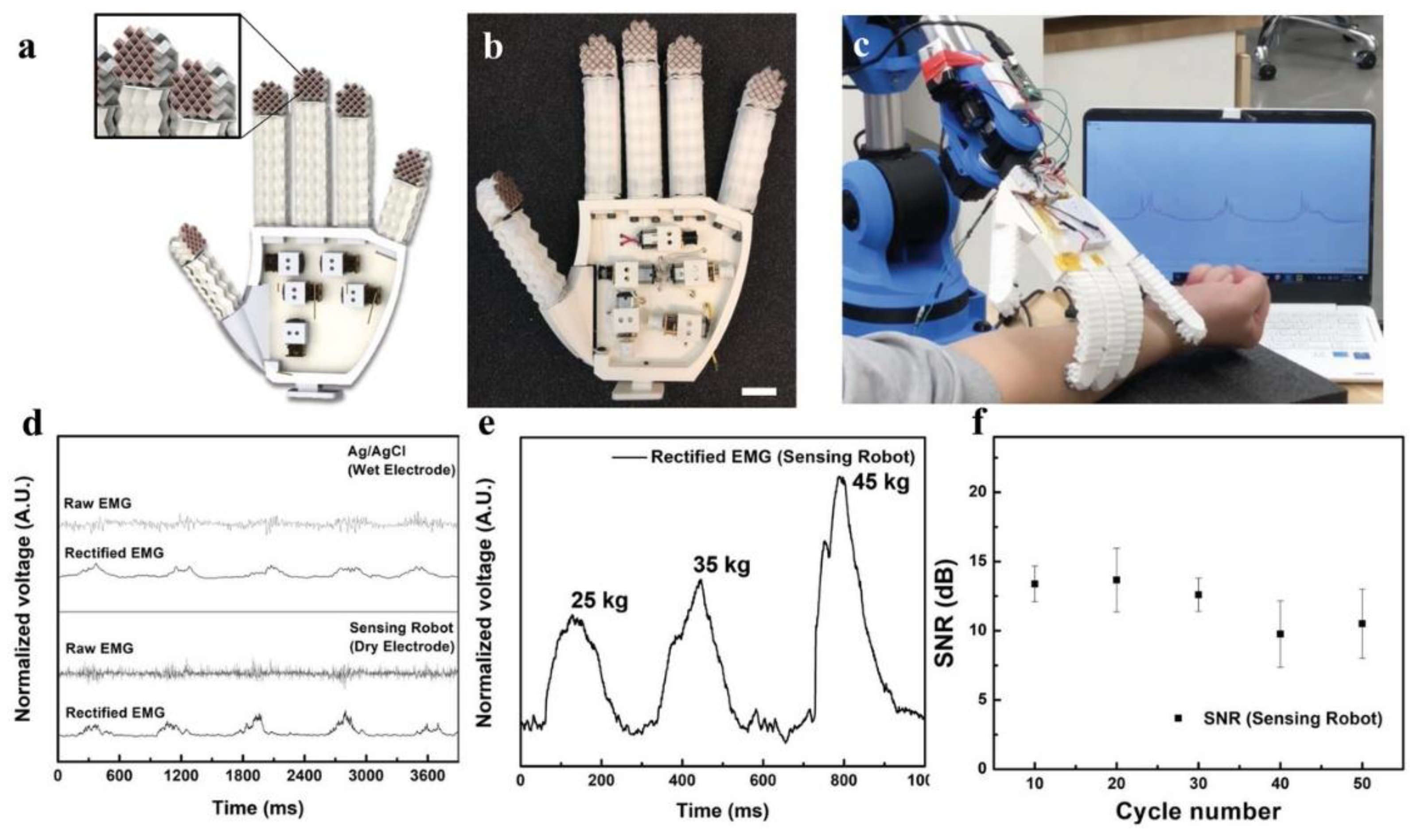

3.4. Soft Robotics

3.5. Optoelectronics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rus, D.; Tolley, M.T. Design, Fabrication and Control of Soft Robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, L.-Y.; Fu, J.; He, Y. A Review of 3D Printing Technologies for Soft Polymer Materials. Adv. Funct. Mater. 2020, 30, 2000187. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing Soft Matter in Three Dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Wang, M.; Liang, Y.; Ren, L.; Ren, L. Recent Progress in 4D Printing of Stimuli-Responsive Polymeric Materials. Sci. China Technol. Sci. 2020, 63, 532–544. [Google Scholar] [CrossRef]

- Hamidi, A.; Tadesse, Y. Single Step 3D Printing of Bioinspired Structures via Metal Reinforced Thermoplastic and Highly Stretchable Elastomer. Compos. Struct. 2019, 210, 250–261. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.; Shepherd, R.F. 3D Printing of Soft Robotic Systems. Nat. Rev. Mater. 2018, 3, 84–100. [Google Scholar] [CrossRef]

- Cheng, Y.; Chan, K.H.; Wang, X.-Q.; Ding, T.; Li, T.; Lu, X.; Ho, G.W. Direct-Ink-Write 3D Printing of Hydrogels into Biomimetic Soft Robots. ACS Nano 2019, 13, 13176–13184. [Google Scholar] [CrossRef]

- Liravi, F.; Toyserkani, E. Additive Manufacturing of Silicone Structures: A Review and Prospective. Addit. Manuf. 2018, 24, 232–242. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, X.; Ou, Z.; Lin, G.; Yin, J.; Liu, Z.; Zhang, L.; Liu, X. UV-Curable, 3D Printable and Biocompatible Silicone Elastomers. Prog. Org. Coat. 2019, 137, 105372. [Google Scholar] [CrossRef]

- Saleh, E.; Zhang, F.; He, Y.; Vaithilingam, J.; Fernandez, J.L.; Wildman, R.; Ashcroft, I.; Hague, R.; Dickens, P.; Tuck, C. 3D Inkjet Printing of Electronics Using UV Conversion. Adv. Mater. Technol. 2017, 2, 1700134. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D Printing via Active Composite Materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamidi, A.; Almubarak, Y.; Tadesse, Y. Multidirectional 3D-Printed Functionally Graded Modular Joint Actuated by TCPFL Muscles for Soft Robots. Bio-Des. Manuf. 2019, 2. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.Z.; Yu, W.W.; Deng, Y.H. Numerical Investigation of the Influence of Process Conditions on the Temperature Variation in Fused Deposition Modeling. Mater. Des. 2017, 130, 59–68. [Google Scholar] [CrossRef]

- Pierin, G.; Grotta, C.; Colombo, P.; Mattevi, C. Direct Ink Writing of Micrometric SiOC Ceramic Structures Using a Preceramic Polymer. J. Eur. Ceram. Soc. 2016, 36, 1589–1594. [Google Scholar] [CrossRef]

- Kuo, A.P.; Bhattacharjee, N.; Lee, Y.-S.; Castro, K.; Kim, Y.T.; Folch, A. High-Precision Stereolithography of Biomicrofluidic Devices. Adv. Mater. Technol. 2019, 4, 1800395. [Google Scholar] [CrossRef]

- Mostafa, K.G.; Nobes, D.S.; Qureshi, A.J. Investigation of Light-Induced Surface Roughness in Projection Micro-Stereolithography Additive Manufacturing (PµSLA). Procedia CIRP 2020, 92, 187–193. [Google Scholar] [CrossRef]

- Geng, Q.; Wang, D.; Chen, P.; Chen, S.-C. Ultrafast Multi-Focus 3-D Nano-Fabrication Based on Two-Photon Polymerization. Nat. Commun. 2019, 10, 2179. [Google Scholar] [CrossRef]

- Janusziewicz, R.; Tumbleston, J.R.; Quintanilla, A.L.; Mecham, S.J.; DeSimone, J.M. Layerless Fabrication with Continuous Liquid Interface Production. Proc. Natl. Acad. Sci. USA 2016, 113, 11703–11708. [Google Scholar] [CrossRef] [Green Version]

- Kadry, H.; Wadnap, S.; Xu, C.; Ahsan, F. Digital Light Processing (DLP) 3D-Printing Technology and Photoreactive Polymers in Fabrication of Modified-Release Tablets. Eur. J. Pharm. Sci. 2019, 135, 60–67. [Google Scholar] [CrossRef]

- Bass, L.; Meisel, N.A.; Williams, C.B. Exploring Variability of Orientation and Aging Effects in Material Properties of Multi-Material Jetting Parts. Rapid Prototyp. J. 2016, 22, 826–834. [Google Scholar] [CrossRef]

- Oh, Y.; Bharambe, V.; Mummareddy, B.; Martin, J.; McKnight, J.; Abraham, M.A.; Walker, J.M.; Rogers, K.; Conner, B.; Cortes, P.; et al. Microwave Dielectric Properties of Zirconia Fabricated Using NanoParticle JettingTM. Addit. Manuf. 2019, 27, 586–594. [Google Scholar] [CrossRef]

- Sabahi, N.; Chen, W.; Wang, C.-H.; Kruzic, J.J.; Li, X. A Review on Additive Manufacturing of Shape-Memory Materials for Biomedical Applications. JOM 2020, 72, 1229–1253. [Google Scholar] [CrossRef]

- Lu, H.B.; Huang, W.M.; Yao, Y.T. Review of Chemo-responsive Shape Change/Memory Polymers. Pigment Resin Technol. 2013, 42, 237–246. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Yu, S.; Wei, J.; Su, P.-C. High Speed 4D Printing of Shape Memory Polymers with Nanosilica. Appl. Mater. Today 2020, 18, 100515. [Google Scholar] [CrossRef]

- Estelle, K.; Blair, D.; Evans, K.; Gozen, B.A. Manufacturing of Smart Composites with Hyperelastic Property Gradients and Shape Memory Using Fused Deposition. J. Manuf. Process. 2017, 28, 500–507. [Google Scholar] [CrossRef]

- Chen, K.; Kuang, X.; Li, V.; Kang, G.; Qi, H.J. Fabrication of Tough Epoxy with Shape Memory Effects by UV-Assisted Direct-Ink Write Printing. Soft Matter 2018, 14, 1879–1886. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, L.; Guo, Y.; Zhang, H.; Zhang, Z. Multi-Responsive Shape Memory Polymer Printed by Fused Deposition Modeling Technique. Express Polym. Lett. 2020, 14, 348–357. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Zheng, Z.; Liu, Y.; Leng, J. Magnetic Programming of 4D Printed Shape Memory Composite Structures. Compos. Part Appl. Sci. Manuf. 2019, 125, 105571. [Google Scholar] [CrossRef]

- Islam Shiblee, M.N.; Ahmed, K.; Khosla, A.; Kawakami, M.; Furukawa, H. 3D Printing of Shape Memory Hydrogels with Tunable Mechanical Properties. Soft Matter 2018, 14, 7809–7817. [Google Scholar] [CrossRef]

- Miao, J.-T.; Ge, M.; Peng, S.; Zhong, J.; Li, Y.; Weng, Z.; Wu, L.; Zheng, L. Dynamic Imine Bond-Based Shape Memory Polymers with Permanent Shape Reconfigurability for 4D Printing. ACS Appl. Mater. Interfaces 2019, 11, 40642–40651. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, H.-B.; Ni, Y.-P.; Fu, T.; Wu, W.-S.; Wang, X.-L.; Wang, Y.-Z. 3D Printable Robust Shape Memory PET Copolyesters with Fire Safety via π-Stacking and Synergistic Crosslinking. J. Mater. Chem. A 2019, 7, 17037–17045. [Google Scholar] [CrossRef]

- Keshavarzan, M.; Kadkhodaei, M.; Forooghi, F. An Investigation into Compressive Responses of Shape Memory Polymeric Cellular Lattice Structures Fabricated by Vat Polymerization Additive Manufacturing. Polym. Test. 2020, 91, 106832. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Wei, J.; Su, P.-C. 4D Printing of High Performance Shape Memory Polymer Using Stereolithography. Mater. Des. 2017, 126, 219–225. [Google Scholar] [CrossRef]

- Villacres, J.; Nobes, D.; Ayranci, C. Additive Manufacturing of Shape Memory Polymers: Effects of Print Orientation and Infill Percentage on Mechanical Properties. Rapid Prototyp. J. 2018, 24, 744–751. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Woo, B.H.; Kim, N.; Jun, Y.C. Multicolor 4D Printing of Shape-Memory Polymers for Light-Induced Selective Heating and Remote Actuation. Sci. Rep. 2020, 10, 6258. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.; Pei, E. A Taxonomy of Shape-Changing Behavior for 4D Printed Parts Using Shape-Memory Polymers. Prog. Addit. Manuf. 2019, 4, 167–184. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Wang, M.; Ying, S.; Gu, J. Fast Chemo-Responsive Shape Memory of Stretchable Polymer Nanocomposite Aerogels Fabricated by One-Step Method. Macromol. Mater. Eng. 2020, 305, 1900602. [Google Scholar] [CrossRef]

- Wang, K.; Jia, Y.-G.; Zhao, C.; Zhu, X.X. Multiple and Two-Way Reversible Shape Memory Polymers: Design Strategies and Applications. Prog. Mater. Sci. 2019, 105, 100572. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Triple Shape Memory Polymers by 4D Printing. Smart Mater. Struct. 2018, 27, 065010. [Google Scholar] [CrossRef] [Green Version]

- Li, A.; Challapalli, A.; Li, G. 4D Printing of Recyclable Lightweight Architectures Using High Recovery Stress Shape Memory Polymer. Sci. Rep. 2019, 9, 7621. [Google Scholar] [CrossRef]

- Peng, B.; Yang, Y.; Gu, K.; Amis, E.J.; Cavicchi, K.A. Digital Light Processing 3D Printing of Triple Shape Memory Polymer for Sequential Shape Shifting. ACS Mater. Lett. 2019, 1, 410–417. [Google Scholar] [CrossRef]

- Davidson, E.C.; Kotikian, A.; Li, S.; Aizenberg, J.; Lewis, J.A. 3D Printable and Reconfigurable Liquid Crystal Elastomers with Light-Induced Shape Memory via Dynamic Bond Exchange. Adv. Mater. 2020, 32, 1905682. [Google Scholar] [CrossRef]

- Kuang, X.; Chen, K.; Dunn, C.K.; Wu, J.; Li, V.C.F.; Qi, H.J. 3D Printing of Highly Stretchable, Shape-Memory, and Self-Healing Elastomer toward Novel 4D Printing. ACS Appl. Mater. Interfaces 2018, 10, 7381–7388. [Google Scholar] [CrossRef]

- Ko, E.S.; Kim, C.; Choi, Y.; Lee, K.Y. 3D Printing of Self-Healing Ferrogel Prepared from Glycol Chitosan, Oxidized Hyaluronate, and Iron Oxide Nanoparticles. Carbohydr. Polym. 2020, 245, 116496. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Gardea, F.; Sang, Z.; Lee, S.; Pharr, M.; Sukhishvili, S.A. A Tailorable Family of Elastomeric-to-Rigid, 3D Printable, Interbonding Polymer Networks. Adv. Funct. Mater. 2020, 30, 2002374. [Google Scholar] [CrossRef]

- Yu, K.; Xin, A.; Du, H.; Li, Y.; Wang, Q. Additive Manufacturing of Self-Healing Elastomers. NPG Asia Mater. 2019, 11, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Wallin, T.J.; Pikul, J.H.; Bodkhe, S.; Peele, B.N.; Murray, B.C.M.; Therriault, D.; McEnerney, B.W.; Dillon, R.P.; Giannelis, E.P.; Shepherd, R.F. Click Chemistry Stereolithography for Soft Robots That Self-Heal. J. Mater. Chem. B 2017, 5, 6249–6255. [Google Scholar] [CrossRef]

- Chen, H.; Hao, B.; Ge, P.; Chen, S. Highly Stretchable, Self-Healing, and 3D Printing Prefabricatable Hydrophobic Association Hydrogels with the Assistance of Electrostatic Interaction. Polym. Chem. 2020, 11, 4741–4748. [Google Scholar] [CrossRef]

- Liu, Z.; Hong, P.; Huang, Z.; Zhang, T.; Xu, R.; Chen, L.; Xiang, H.; Liu, X. Self-Healing, Reprocessing and 3D Printing of Transparent and Hydrolysis-Resistant Silicone Elastomers. Chem. Eng. J. 2020, 387, 124142. [Google Scholar] [CrossRef]

- Wang, Z.; An, G.; Zhu, Y.; Liu, X.; Chen, Y.; Wu, H.; Wang, Y.; Shi, X.; Mao, C. 3D-Printable Self-Healing and Mechanically Reinforced Hydrogels with Host–Guest Non-Covalent Interactions Integrated into Covalently Linked Networks. Mater. Horiz. 2019, 6, 733–742. [Google Scholar] [CrossRef]

- Kee, S.; Haque, M.A.; Corzo, D.; Alshareef, H.N.; Baran, D. Self-Healing and Stretchable 3D-Printed Organic Thermoelectrics. Adv. Funct. Mater. 2019, 29, 1905426. [Google Scholar] [CrossRef]

- Li, X.; Yu, R.; He, Y.; Zhang, Y.; Yang, X.; Zhao, X.; Huang, W. Self-Healing Polyurethane Elastomers Based on a Disulfide Bond by Digital Light Processing 3D Printing. ACS Macro Lett. 2019, 8, 1511–1516. [Google Scholar] [CrossRef]

- Kim, S.W.; Kim, D.Y.; Roh, H.H.; Kim, H.S.; Lee, J.W.; Lee, K.Y. Three-Dimensional Bioprinting of Cell-Laden Constructs Using Polysaccharide-Based Self-Healing Hydrogels. Biomacromolecules 2019, 20, 1860–1866. [Google Scholar] [CrossRef]

- Lei, J.; Li, X.; Wang, S.; Yuan, L.; Ge, L.; Li, D.; Mu, C. Facile Fabrication of Biocompatible Gelatin-Based Self-Healing Hydrogels. ACS Appl. Polym. Mater. 2019, 1, 1350–1358. [Google Scholar] [CrossRef]

- Senior, J.J.; Cooke, M.E.; Grover, L.M.; Smith, A.M. Fabrication of Complex Hydrogel Structures Using Suspended Layer Additive Manufacturing (SLAM). Adv. Funct. Mater. 2019, 29, 1904845. [Google Scholar] [CrossRef] [Green Version]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D Printing of Robotic Soft Actuators with Programmable Bioinspired Architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Pei, Q. Electronic Muscles and Skins: A Review of Soft Sensors and Actuators. Chem. Rev. 2017, 117, 11239–11268. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Kuang, X.; Deng, J.; Wang, Y.-C.; Wang, A.C.; Ding, W.; Lai, Y.-C.; Chen, J.; Wang, P.; Lin, Z.; et al. Shape Memory Polymers for Body Motion Energy Harvesting and Self-Powered Mechanosensing. Adv. Mater. 2018, 30, 1705195. [Google Scholar] [CrossRef]

- Christianson, C.; Goldberg, N.N.; Tolley, M.T. Elastomeric Diaphragm Pump Driven by Fluid Electrode Dielectric Elastomer Actuators (FEDEAs). In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) XX, Denver, CO, USA, 5–8 March 2018; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10594, p. 105940O. [Google Scholar]

- Zhao, Y.; Zha, J.-W.; Yin, L.-J.; Gao, Z.-S.; Wen, Y.-Q.; Dang, Z.-M. Remarkable Electrically Actuation Performance in Advanced Acrylic-Based Dielectric Elastomers without Pre-Strain at Very Low Driving Electric Field. Polymer 2018, 137, 269–275. [Google Scholar] [CrossRef]

- McCoul, D.; Rosset, S.; Schlatter, S.; Shea, H. Inkjet 3D Printing of UV and Thermal Cure Silicone Elastomers for Dielectric Elastomer Actuators. Smart Mater. Struct. 2017, 26, 125022. [Google Scholar] [CrossRef] [Green Version]

- Reitelshöfer, S.; Martin, S.; Nendel, F.; Schäfer, T.; Pham, D.; Franke, J. Accelerated Aerosol-Jet-Printing of Stretchable RGO-Electrodes for Stacked Dielectric Elastomers by Using a New Hybrid Atomizer. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) XXII, Online, 27 April–9 May 2020; International Society for Optics and Photonics: Bellingham, WA, USA, 2020; Volume 11375, p. 113751W. [Google Scholar]

- Haghiashtiani, G.; Habtour, E.; Park, S.-H.; Gardea, F.; McAlpine, M.C. 3D Printed Electrically-Driven Soft Actuators. Extreme Mech. Lett. 2018, 21, 1–8. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, M.; Cao, X.; Zhang, Z.; Chen, X.; Xiao, Y.; Liang, Y.; Wong, T.-W.; Li, T.; Xu, Z. Fabrication and Modeling of Dielectric Elastomer Soft Actuator with 3D Printed Thermoplastic Frame. Sens. Actuators Phys. 2019, 292, 112–120. [Google Scholar] [CrossRef]

- Liu, K.; Chen, S.; Chen, F.; Zhu, X. A Unidirectional Soft Dielectric Elastomer Actuator Enabled by Built-In Honeycomb Metastructures. Polymers 2020, 12, 619. [Google Scholar] [CrossRef] [Green Version]

- Costa, P.; Oliveira, J.; Horta-Romarís, L.; Abad, M.-J.; Moreira, J.A.; Zapiráin, I.; Aguado, M.; Galván, S.; Lanceros-Mendez, S. Piezoresistive Polymer Blends for Electromechanical Sensor Applications. Compos. Sci. Technol. 2018, 168, 353–362. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, Z.; Han, Z.; Zhang, X.; Zhou, Z.; Zhang, J.; Luo, X.; Wang, P.; Zhao, C.; Li, Y. Effects of Non-Covalent Interactions on the Properties of 3D Printed Flexible Piezoresistive Strain Sensors of Conductive Polymer Composites. Compos. Interfaces 2020, 1–15. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Pötschke, P.; Ameli, A. Bidirectional and Stretchable Piezoresistive Sensors Enabled by Multimaterial 3D Printing of Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Polymers 2018, 11, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, R.; Xia, T.; Wu, B.; Yuan, J.; Ma, L.; Cheng, G.J.; Liu, F. Highly Sensitive Flexible Piezoresistive Sensor with 3D Conductive Network. ACS Appl. Mater. Interfaces 2020, 12, 35291–35299. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Guan, X.; Huang, H.; Wang, H.; Lin, W.; Peng, Z. Full 3D Printing of Stretchable Piezoresistive Sensor with Hierarchical Porosity and Multimodulus Architecture. Adv. Funct. Mater. 2019, 29, 1807569. [Google Scholar] [CrossRef]

- Abshirini, M.; Charara, M.; Saha, M.C.; Altan, M.C.; Liu, Y. Optimization of 3D Printed Elastomeric Nanocomposites for Flexible Strain Sensing Applications; American Society of Mechanical Engineer: New York, NY, USA, 2020. [Google Scholar]

- Wong, J.; Gong, A.T.; Defnet, P.A.; Meabe, L.; Beauchamp, B.; Sweet, R.M.; Sardon, H.; Cobb, C.L.; Nelson, A. 3D Printing Ionogel Auxetic Frameworks for Stretchable Sensors. Adv. Mater. Technol. 2019, 4, 1900452. [Google Scholar] [CrossRef]

- 3D Printable Strain Sensors from Deep Eutectic Solvents and Cellulose Nanocrystals|ACS Applied Materials & Interfaces. Available online: https://pubs.acs.org/doi/10.1021/acsami.0c11152 (accessed on 22 October 2020).

- Li, J.; Huang, H.; Morita, T. Stepping Piezoelectric Actuators with Large Working Stroke for Nano-Positioning Systems: A Review. Sens. Actuators Phys. 2019, 292, 39–51. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y.; Khellil, K.; Lachat, R. On the Use of In-Situ Piezoelectric Sensors for the Manufacturing and Structural Health Monitoring of Polymer-Matrix Composites: A Literature Review. Compos. Struct. 2019, 215, 127–149. [Google Scholar] [CrossRef]

- Li, J.; Long, Y.; Yang, F.; Wei, H.; Zhang, Z.; Wang, Y.; Wang, J.; Li, C.; Carlos, C.; Dong, Y.; et al. Multifunctional Artificial Artery from Direct 3D Printing with Built-In Ferroelectricity and Tissue-Matching Modulus for Real-Time Sensing and Occlusion Monitoring. Adv. Funct. Mater. 2020, 30, 2002868. [Google Scholar] [CrossRef]

- Yao, D.; Cui, H.; Hensleigh, R.; Smith, P.; Alford, S.; Bernero, D.; Bush, S.; Mann, K.; Wu, H.F.; Chin-Nieh, M.; et al. Achieving the Upper Bound of Piezoelectric Response in Tunable, Wearable 3D Printed Nanocomposites. Adv. Funct. Mater. 2019, 29, 1903866. [Google Scholar] [CrossRef]

- Song, X.; He, L.; Yang, W.; Wang, Z.; Chen, Z.; Guo, J.; Wang, H.; Chen, L. Additive Manufacturing of Bi-Continuous Piezocomposites With Triply Periodic Phase Interfaces for Combined Flexibility and Piezoelectricity. J. Manuf. Sci. Eng. 2019, 141, 111004. [Google Scholar] [CrossRef]

- Gonzalez, D.; Garcia, J.; Newell, B. Electromechanical Characterization of a 3D Printed Dielectric Material for Dielectric Electroactive Polymer Actuators. Sens. Actuators Phys. 2019, 297, 111565. [Google Scholar] [CrossRef]

- Rohde, R.C.; Basu, A.; Okello, L.B.; Barbee, M.H.; Zhang, Y.; Velev, O.D.; Nelson, A.; Craig, S.L. Mechanochromic Composite Elastomers for Additive Manufacturing and Low Strain Mechanophore Activation. Polym. Chem. 2019, 10, 5985–5991. [Google Scholar] [CrossRef]

- Chen, J.; Xu, L.; Yang, M.; Chen, X.; Chen, X.; Hong, W. Highly Stretchable Photonic Crystal Hydrogels for a Sensitive Mechanochromic Sensor and Direct Ink Writing. Chem. Mater. 2019, 31, 8918–8926. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Ye, H.; Duan, G.; Duan, H.; Ge, Q.; Wang, Z. Color-Changeable Four-Dimensional Printing Enabled with Ultraviolet-Curable and Thermochromic Shape Memory Polymers. ACS Appl. Mater. Interfaces 2021, 13, 18120–18127. [Google Scholar] [CrossRef]

- Zhou, Y.; Layani, M.; Wang, S.; Hu, P.; Ke, Y.; Magdassi, S.; Long, Y. Fully Printed Flexible Smart Hybrid Hydrogels. Adv. Funct. Mater. 2018, 28, 1705365. [Google Scholar] [CrossRef]

- Cai, G.; Cheng, X.; Layani, M.; Tan, A.W.M.; Li, S.; Eh, A.L.-S.; Gao, D.; Magdassi, S.; Lee, P.S. Direct Inkjet-Patterning of Energy Efficient Flexible Electrochromics. Nano Energy 2018, 49, 147–154. [Google Scholar] [CrossRef]

- Yao, Y.; Yin, C.; Hong, S.; Chen, H.; Shi, Q.; Wang, J.; Lu, X.; Zhou, N. Lanthanide-Ion-Coordinated Supramolecular Hydrogel Inks for 3D Printed Full-Color Luminescence and Opacity-Tuning Soft Actuators. Chem. Mater. 2020, 32, 8868–8876. [Google Scholar] [CrossRef]

- Lendlein, A.; Trask, R.S. Multifunctional Materials: Concepts, Function-Structure Relationships, Knowledge-Based Design, Translational Materials Research. Multifunct. Mater. 2018, 1, 010201. [Google Scholar] [CrossRef]

- Salonitis, K.; Pandremenos, J.; Paralikas, J.; Chryssolouris, G. Multifunctional Materials: Engineering Applications and Processing Challenges. Int. J. Adv. Manuf. Technol. 2010, 49, 803–826. [Google Scholar] [CrossRef]

- Read “Frontiers of Engineering: Reports on Leading-Edge Engineering from the 2004 NAE Symposium on Frontiers of Engineering”. Available online: https://www.nap.edu/read/11220/chapter/1 (accessed on 15 November 2020).

- Whitesides, G.M. Soft Robotics. Angew. Chem. Int. Ed. 2018, 57, 4258–4273. [Google Scholar] [CrossRef]

- Additive Manufacturing of Functionally Graded Materials—A Review|Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S0921509319309955?token=A3BC1920689C5B11B56D0A09575AB630D672AB223722688F9714331BCB53691D997EA1723A126C6289A5E7BD21D056E4&originRegion=us-east-1&originCreation=20210429171150 (accessed on 29 April 2021).

- Chen, Z.; Zhao, D.; Liu, B.; Nian, G.; Li, X.; Yin, J.; Qu, S.; Yang, W. 3D Printing of Multifunctional Hydrogels. Adv. Funct. Mater. 2019, 29, 1900971. [Google Scholar] [CrossRef]

- Bodkhe, S.; Ermanni, P. 3D Printing of Multifunctional Materials for Sensing and Actuation: Merging Piezoelectricity with Shape Memory. Eur. Polym. J. 2020, 132, 109738. [Google Scholar] [CrossRef]

- Darabi, M.A.; Khosrozadeh, A.; Mbeleck, R.; Liu, Y.; Chang, Q.; Jiang, J.; Cai, J.; Wang, Q.; Luo, G.; Xing, M. Skin-Inspired Multifunctional Autonomic-Intrinsic Conductive Self-Healing Hydrogels with Pressure Sensitivity, Stretchability, and 3D Printability. Adv. Mater. 2017, 29, 1700533. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Ren, J.; Rong, L.; Cao, P.-F.; Advincula, R.C. 3D Printed Multifunctional, Hyperelastic Silicone Rubber Foam. Adv. Funct. Mater. 2019, 29, 1900469. [Google Scholar] [CrossRef]

- Tang, J.; Yin, Q.; Shi, M.; Yang, M.; Yang, H.; Sun, B.; Guo, B.; Wang, T. Programmable Shape Transformation of 3D Printed Magnetic Hydrogel Composite for Hyperthermia Cancer Therapy. Extreme Mech. Lett. 2021, 46, 101305. [Google Scholar] [CrossRef]

- Ge, Q.; Chen, Z.; Cheng, J.; Zhang, B.; Zhang, Y.-F.; Li, H.; He, X.; Yuan, C.; Liu, J.; Magdassi, S.; et al. 3D Printing of Highly Stretchable Hydrogel with Diverse UV Curable Polymers. Sci. Adv. 2021, 7, eaba4261. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Y.; Luo, C.; Zhai, C.; Li, Z.; Zhang, Y.; Yuan, T.; Dong, S.; Zhang, J.; Fan, W. Crosslinker-Free Silk/Decellularized Extracellular Matrix Porous Bioink for 3D Bioprinting-Based Cartilage Tissue Engineering. Mater. Sci. Eng. C 2021, 118, 111388. [Google Scholar] [CrossRef]

- Butler, H.M.; Naseri, E.; MacDonald, D.S.; Andrew Tasker, R.; Ahmadi, A. Optimization of Starch- and Chitosan-Based Bio-Inks for 3D Bioprinting of Scaffolds for Neural Cell Growth. Materialia 2020, 12, 100737. [Google Scholar] [CrossRef]

- Oliveira, E.P.; Malysz-Cymborska, I.; Golubczyk, D.; Kalkowski, L.; Kwiatkowska, J.; Reis, R.L.; Oliveira, J.M.; Walczak, P. Advances in Bioinks and in Vivo Imaging of Biomaterials for CNS Applications. Acta Biomater. 2019, 95, 60–72. [Google Scholar] [CrossRef]

- Zadpoor, A.A.; Malda, J. Additive Manufacturing of Biomaterials, Tissues, and Organs. Ann. Biomed. Eng. 2017, 45, 1–11. [Google Scholar] [CrossRef]

- Tytgat, L.; Van Damme, L.; Van Hoorick, J.; Declercq, H.; Thienpont, H.; Ottevaere, H.; Blondeel, P.; Dubruel, P.; Van Vlierberghe, S. Additive Manufacturing of Photo-Crosslinked Gelatin Scaffolds for Adipose Tissue Engineering. Acta Biomater. 2019, 94, 340–350. [Google Scholar] [CrossRef]

- Zhu, W.; Qu, X.; Zhu, J.; Ma, X.; Patel, S.; Liu, J.; Wang, P.; Lai, C.S.E.; Gou, M.; Xu, Y.; et al. Direct 3D Bioprinting of Prevascularized Tissue Constructs with Complex Microarchitecture. Biomaterials 2017, 124, 106–115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mollica, P.A.; Booth-Creech, E.N.; Reid, J.A.; Zamponi, M.; Sullivan, S.M.; Palmer, X.-L.; Sachs, P.C.; Bruno, R.D. 3D Bioprinted Mammary Organoids and Tumoroids in Human Mammary Derived ECM Hydrogels. Acta Biomater. 2019, 95, 201–213. [Google Scholar] [CrossRef] [PubMed]

- Cetnar, A.D.; Tomov, M.L.; Ning, L.; Jing, B.; Theus, A.S.; Kumar, A.; Wijntjes, A.N.; Bhamidipati, S.R.; Do, K.P.; Mantalaris, A.; et al. Patient-Specific 3D Bioprinted Models of Developing Human Heart. Adv. Healthc. Mater. 2020, 4, 2001169. [Google Scholar] [CrossRef]

- Chimene, D.; Kaunas, R.; Gaharwar, A.K. Hydrogel Bioink Reinforcement for Additive Manufacturing: A Focused Review of Emerging Strategies. Adv. Mater. 2020, 32, 1902026. [Google Scholar] [CrossRef] [PubMed]

- Jose, R.R.; Rodriguez, M.J.; Dixon, T.A.; Omenetto, F.; Kaplan, D.L. Evolution of Bioinks and Additive Manufacturing Technologies for 3D Bioprinting. ACS Biomater. Sci. Eng. 2016, 2, 1662–1678. [Google Scholar] [CrossRef]

- Xin, S.; Chimene, D.; Garza, J.E.; Gaharwar, A.K.; Alge, D.L. Clickable PEG Hydrogel Microspheres as Building Blocks for 3D Bioprinting. Biomater. Sci. 2019, 7, 1179–1187. [Google Scholar] [CrossRef]

- Ling, Y.; An, T.; Yap, L.W.; Zhu, B.; Gong, S.; Cheng, W. Disruptive, Soft, Wearable Sensors. Adv. Mater. 2020, 32, 1904664. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Liu, Z.; Matsuhisa, N.; Qi, D.; Leow, W.R.; Yang, H.; Yu, J.; Chen, G.; Liu, Y.; Wan, C.; et al. Auxetic Mechanical Metamaterials to Enhance Sensitivity of Stretchable Strain Sensors. Adv. Mater. 2018, 30, 1706589. [Google Scholar] [CrossRef]

- Nag, A.; Feng, S.; Mukhopadhyay, S.C.; Kosel, J.; Inglis, D. 3D Printed Mould-Based Graphite/PDMS Sensor for Low-Force Applications. Sensors Actuators A Phys. 2018, 280, 523–534. [Google Scholar] [CrossRef]

- Asymmetric Structure Based Flexible Strain Sensor for Simultaneous Detection of Various Human Joint Motions|ACS Applied Electronic Materials. Available online: https://pubs.acs.org/doi/abs/10.1021/acsaelm.9b00386 (accessed on 21 October 2020).

- Kisic, M.; Blaz, N.; Zivanov, L.; Damnjanovic, M. Elastomer Based Force Sensor Fabricated by 3D Additive Manufacturing. AIP Adv. 2020, 10, 015017. [Google Scholar] [CrossRef]

- Multi-Material 3D Printing of a Soft Pressure Sensor|Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S2214860419305238?token=B81C23A18C57D3A0C17FE0D40A7A57082C6CF8AE00D7C310530B9CBA394D7CA66DBD4BD558AC9EBE9154CA53647EEAFB (accessed on 10 January 2021).

- Hohimer, C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. 3D Printed Conductive Thermoplastic Polyurethane/Carbon Nanotube Composites for Capacitive and Piezoresistive Sensing in Soft Pneumatic Actuators. Addit. Manuf. 2020, 34, 101281. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, X.; Han, Z.; Zhang, Z.; Zhou, Z.; Harkin-Jones, E.; Zhang, J.; Luo, X.; Wang, P.; Zhao, C.; et al. 3D Printed High-Performance Flexible Strain Sensors Based on Carbon Nanotube and Graphene Nanoplatelet Filled Polymer Composites. J. Mater. Sci. 2020, 55, 15769–15786. [Google Scholar] [CrossRef]

- 3D-Printed Highly Stable Flexible Strain Sensor Based on Silver-Coated-Glass Fiber-Filled Conductive Silicon Rubber|Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S0264127520303221?token=79DD1D0239D01AACCB524D928DF87E8B65CCFA749FB69A6490AD6DCA72A49E6D4DE364D0F7B433EDA8DFAE14E90FA9FE (accessed on 12 October 2020).

- Shi, G.; Lowe, S.E.; Teo, A.J.T.; Dinh, T.K.; Tan, S.H.; Qin, J.; Zhang, Y.; Zhong, Y.L.; Zhao, H. A Versatile PDMS Submicrobead/Graphene Oxide Nanocomposite Ink for the Direct Ink Writing of Wearable Micron-Scale Tactile Sensors. Appl. Mater. Today 2019, 16, 482–492. [Google Scholar] [CrossRef]

- Abshirini, M.; Charara, M.; Liu, Y.; Saha, M.C.; Altan, M.C. Additive Manufacturing of Polymer Nanocomposites with In-Situ Strain Sensing Capability; American Society of Mechanical Engineer: New York, NY, USA, 2019. [Google Scholar]

- Davoodi, E.; Fayazfar, H.; Liravi, F.; Jabari, E.; Toyserkani, E. Drop-on-Demand High-Speed 3D Printing of Flexible Milled Carbon Fiber/Silicone Composite Sensors for Wearable Biomonitoring Devices. Addit. Manuf. 2020, 32, 101016. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, X.; Harkin-Jones, E.; Zhu, W.; Zhou, Z.; Shen, Y.; Li, Y.; Zhao, C.; Wang, P. Synergistic Effects of Hybrid Conductive Nanofillers on the Performance of 3D Printed Highly Elastic Strain Sensors. Compos. Part Appl. Sci. Manuf. 2020, 129, 105730. [Google Scholar] [CrossRef]

- Taherkhani, B.; Azizkhani, M.B.; Kadkhodapour, J.; Anaraki, A.P.; Rastgordani, S. Highly Sensitive, Piezoresistive, Silicone/Carbon Fiber-Based Auxetic Sensor for Low Strain Values. Sens. Actuators Phys. 2020, 305, 111939. [Google Scholar] [CrossRef]

- Yin, X.-Y.; Zhang, Y.; Cai, X.; Guo, Q.; Yang, J.; Wang, Z.L. 3D Printing of Ionic Conductors for High-Sensitivity Wearable Sensors. Mater. Horiz. 2019, 6, 767–780. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Zhang, Q.; Zheng, K.; Xu, J.; Xu, W.; Shang, E.; Jiang, J.; Zhang, J.; Liu, Y. 3D-Printed Graphene/Polydimethylsiloxane Composites for Stretchable and Strain-Insensitive Temperature Sensors. ACS Appl. Mater. Interfaces 2019, 11, 1344–1352. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Xie, B.; Chu, M.; Sun, H.; Hao, S.; Chen, Y.; Chen, Y. 3D Printing of Flexible Liquid Sensor Based on Swelling Behavior of Hydrogel with Carbon Nanotubes. Adv. Mater. Technol. 2019, 4, 1800476. [Google Scholar] [CrossRef]

- Kiziroglou, M.E.; Yeatman, E.M. Materials and techniques for energy harvesting. In Functional Materials for Sustainable Energy Applications; Elsevier: Amsterdam, The Netherlands, 2012; pp. 541–572. ISBN 978-0-85709-059-1. [Google Scholar]

- Seol, M.-L.; Ivaškevičiūtė, R.; Ciappesoni, M.A.; Thompson, F.V.; Moon, D.-I.; Kim, S.J.; Kim, S.J.; Han, J.-W.; Meyyappan, M. All 3D Printed Energy Harvester for Autonomous and Sustainable Resource Utilization. Nano Energy 2018, 52, 271–278. [Google Scholar] [CrossRef]

- Li, J.; Wong, W.-Y.; Tao, X. Recent Advances in Soft Functional Materials: Preparation, Functions and Applications. Nanoscale 2020, 12, 1281–1306. [Google Scholar] [CrossRef] [PubMed]

- Ou, C.; Jing, Q.; Busolo, T.; Kar-Narayan, S. Chapter 13 - Manufacturing routes toward flexible and smart energy harvesters and sensors based on functional nanomaterials. In Advances in Nanostructured Materials and Nanopatterning Technologies; Guarino, V., Focarete, M.L., Pisignano, D., Eds.; Advanced Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 381–437. ISBN 978-0-12-816865-3. [Google Scholar]

- Zou, Y.; Tan, P.; Shi, B.; Ouyang, H.; Jiang, D.; Liu, Z.; Li, H.; Yu, M.; Wang, C.; Qu, X.; et al. A Bionic Stretchable Nanogenerator for Underwater Sensing and Energy Harvesting. Nat. Commun. 2019, 10, 2695. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, K.; Zhang, L.; Kuang, X.; Li, V.; Lei, M.; Kang, G.; Wang, Z.L.; Qi, H.J. Dynamic Photomask-Assisted Direct Ink Writing Multimaterial for Multilevel Triboelectric Nanogenerator. Adv. Funct. Mater. 2019, 29, 1903568. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

- Yuan, X.; Gao, X.; Yang, J.; Shen, X.; Li, Z.; You, S.; Wang, Z.; Dong, S. The Large Piezoelectricity and High Power Density of a 3D-Printed Multilayer Copolymer in a Rugby Ball-Structured Mechanical Energy Harvester. Energy Environ. Sci. 2020, 13, 152–161. [Google Scholar] [CrossRef]

- Keong, B.A.W.; Hua, R.Y.C. A Novel Fold-Based Design Approach toward Printable Soft Robotics Using Flexible 3D Printing Materials. Adv. Mater. Technol. 2018, 3, 1700172. [Google Scholar] [CrossRef]

- Tognato, R.; Armiento, A.R.; Bonfrate, V.; Levato, R.; Malda, J.; Alini, M.; Eglin, D.; Giancane, G.; Serra, T. A Stimuli-Responsive Nanocomposite for 3D Anisotropic Cell-Guidance and Magnetic Soft Robotics. Adv. Funct. Mater. 2019, 29, 1804647. [Google Scholar] [CrossRef]

- Hu, F.; Lyu, L.; He, Y. A 3D Printed Paper-Based Thermally Driven Soft Robotic Gripper Inspired by Cabbage. Int. J. Precis. Eng. Manuf. 2019, 20, 1915–1928. [Google Scholar] [CrossRef]

- Vogt, D.M.; Becker, K.P.; Phillips, B.T.; Graule, M.A.; Rotjan, R.D.; Shank, T.M.; Cordes, E.E.; Wood, R.J.; Gruber, D.F. Shipboard Design and Fabrication of Custom 3D-Printed Soft Robotic Manipulators for the Investigation of Delicate Deep-Sea Organisms. PLOS ONE 2018, 13, e0200386. [Google Scholar] [CrossRef]

- Neumann, W.; Pusch, T.P.; Siegfarth, M.; Schad, L.R.; Stallkamp, J.L. CT and MRI Compatibility of Flexible 3D-Printed Materials for Soft Actuators and Robots Used in Image-Guided Interventions. Med. Phys. 2019, 46, 5488–5498. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Khoo, S.Y.; Kouzani, A.Z. Polyelectrolyte Soft Actuators: 3D Printed Chitosan and Cast Gelatin. 3D Print. Addit. Manuf. 2018, 5, 138–150. [Google Scholar] [CrossRef]

- Ang, B.W.K.; Yeow, C. Design and Characterization of a 3D Printed Soft Robotic Wrist Sleeve with 2 DoF for Stroke Rehabilitation. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 577–582. [Google Scholar]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R.; et al. Molecularly-Engineered, 4D-Printed Liquid Crystal Elastomer Actuators. Adv. Funct. Mater. 2019, 29, 1806412. [Google Scholar] [CrossRef]

- Han, D.; Farino, C.; Yang, C.; Scott, T.; Browe, D.; Choi, W.; Freeman, J.W.; Lee, H. Soft Robotic Manipulation and Locomotion with a 3D Printed Electroactive Hydrogel. ACS Appl. Mater. Interfaces 2018, 10, 17512–17518. [Google Scholar] [CrossRef]

- Roach, D.J.; Kuang, X.; Yuan, C.; Chen, K.; Qi, H.J. Novel Ink for Ambient Condition Printing of Liquid Crystal Elastomers for 4D Printing. Smart Mater. Struct. 2018, 27, 125011. [Google Scholar] [CrossRef]

- Kim, T.-H.; Vanloo, J.; Kim, W.S. 3D Origami Sensing Robots for Cooperative Healthcare Monitoring. Adv. Mater. Technol. 2021, 6, 2000938. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.; Majditehran, H.; Patel, D.K.; Majidi, C.; Bergbreiter, S. Electromechanical Characterization of 3D Printable Conductive Elastomer for Soft Robotics. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020; pp. 318–324. [Google Scholar]

- Manthrammel, M.A.; Yahia, I.S.; Shkir, M.; AlFaify, S.; Zahran, H.Y.; Ganesh, V.; Yakuphanoglu, F. Novel Design and Microelectronic Analysis of Highly Stable Au/Indigo/n-Si Photodiode for Optoelectronic Applications. Solid State Sci. 2019, 93, 7–12. [Google Scholar] [CrossRef]

- Mariappan, S.M.; Shkir, M.; Alshahrani, T.; Elangovan, V.; Algarni, H.; AlFaify, S. Insight on the Optoelectronics and Enhanced Dielectric Properties of Strontium Decorated PbI2 Nanosheets for Hot Carrier Solar Cell Applications. J. Alloys Compd. 2021, 859, 157762. [Google Scholar] [CrossRef]

- Zhang, H.; Rogers, J.A. Recent Advances in Flexible Inorganic Light Emitting Diodes: From Materials Design to Integrated Optoelectronic Platforms. Adv. Opt. Mater. 2019, 7, 1800936. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Su, R.; Jeong, J.; Guo, S.-Z.; Qiu, K.; Joung, D.; Meng, F.; McAlpine, M.C. 3D Printed Polymer Photodetectors. Adv. Mater. 2018, 30, 1803980. [Google Scholar] [CrossRef] [PubMed]

- Black Phosphorus Ink Formulation for Inkjet Printing of Optoelectronics and Photonics|Nature Communications. Available online: https://www.nature.com/articles/s41467-017-00358-1 (accessed on 1 February 2021).

- Allen, B.; Grant, P.S.; Isakov, D.; Stevens, C.J.; Wu, Y. 3D-Printed Optical Devices with Refractive Index Control for Microwave Applications. TechConnect Briefs 2018, 4, 92–95. [Google Scholar]

- Loke, G.; Yuan, R.; Rein, M.; Khudiyev, T.; Jain, Y.; Joannopoulos, J.; Fink, Y. Structured Multimaterial Filaments for 3D Printing of Optoelectronics. Nat. Commun. 2019, 10, 4010. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Printing Technology | Specific Methodology | Deposition | Feature Size | Materials | Features | Drawbacks |

|---|---|---|---|---|---|---|

| Material Extrusion | Fuse Deposition Modeling | Line | ≈200 µm [13] | Thermoplastics |

|

|

| Direct Ink Write | Line | ≈120 µm [14] | Thermoplastics Thermosets Elastomers Hydrogels Nanoparticles |

|

| |

| Vat Photopolymerization | Stereolithography | Light single point | ≈50 µm [15] | Thermoset Elastomers Acrylate resins Nanoparticles |

|

|

| Micro-Stereolithography | Light single point | ≈10 µm [16] | ||||

| Two-Photon Polymerization | Light single point | ≈0.3 µm [17] | ||||

| Continuous Liquid Interface Production | Light entire layer | ≈0.4 µm [18] | Thermoplastic Acrylate resins Nanoparticles |

|

| |

| Digital Light Processing | Light entire layer | ≈200 µm [19] | ||||

| Material Jetting | Drop on Demand | Drop | ≈32 µm [20] | Polymers Thermoplastic Acrylate resins Elastomers Nanoparticles |

|

|

| Nanoparticle Jetting | Drop | ≈10 µm [21] |

| Materials | Technique | Glass Transition Temperature (°C) | Elastic Modulus (MPa) | Elongation at Break (%) | Durability (Cycles) | Shape Fixity (%) | Shape Recovery (%) | Elastic Modulus (MPa) | Elongation at Break (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| tBA, DEGDA with nanosilica fillers | DLP | 56.23 | - | 85.2 | 10 | 100 | 90-97 | - | 85.2 | [24] |

| filaflex embedded with polycaprolactone | FDM | 70 | 48 | 700 | 10 | 76 | 97 | 48 | 700 | [25] |

| N-butyl Acrylate | UV-assisted DIW | 95.2 | 610 | 25.4 (Ultimate strain) | 3 | 97.1 | 98.5 | 610 | 25.4 (Ultimate strain) | [26] |

| Polycyclooctene with boron nitrate and MWCNT | FDM | 70 | 3.85 (Storage modulus) | - | - | 98.9 | 99.2 | 3.85 (Storage modulus) | - | [27] |

| Polylactic acid (PLA)/Fe3O4 composites | FDM | 66.6 | 1600 (Storage modulus) | - | - | 96.8 | 96.3 | 1600 (Storage modulus) | - | [28] |

| poly(dimethyl acrylamide-costearyl acrylate and/or lauryl acrylate) (PDMAAm-co-SA) | SLA | - | - | - | 3 | 99.8 | 87.6 | - | - | [29] |

| 2-Methacryloyloxy 4-formylbenzoate | DLP | 57 | 57 ± 4.0 | 39.30 ± 1.0 | 3 | 97.5 ± 0.30 | 91.4 ± 0.20 | 57 ± 4.0 | 39.30 ± 1.0 | [30] |

| Poly(ethylene terephthalate) (PET) | FDM | 85–100 | - | 45 | 7 | 100 | 90–98 | - | 45 | [31] |

| poly(ethylene glycol) dimethacrylate (PEGDMA), isobornyl acrylate and 2-ethylhexyl acrylate | DLP | 125 | - | - | 10 | 92.6 | 95.3 | - | - | [32] |

| Materials | Tensile Strength | Max Strain | Technique | Application | Self-Healing | Stimulus | Healing Time | Efficiency | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Semi-interpenetrating polymer network elastomer | 5 MPa | 600% | UV-assisted DIW | Biomedical Devices | Embedded semicrystalline thermoplastic | Heat at 80 °C | 20 min | <30% | [43] |

| Ferrogel | - | 288% | DIW Bioprinting | Drug Delivery and Tissue Engineering | Reversible Imine Bond Formation | No Stimulus | 10 min | ~95% | [44] |

| Dynamic Covalent Polymer Networks | 3.3 MPa | 140% | FDM | - | Diels–Alder Reaction | Heat at 80 °C Deionized Water at RT | 12 h | 96% ~70% | [45] |

| Photoelastomer Ink | 16 kPa | 130% | SLA | Soft Actuators, Structural Composites, Architected Electronics | Disulfide Exchange | Heat at 60 °C | 2 h | 100% | [46] |

| Fluid Elastic Actuators | 13–129 kPa | 45–400% | SLA | Soft Robotics | Unreacted Prepolymer Resin | Sunlight ~15,000 cd m2 | 30 s | - | [47] |

| Physically Crosslinked Hydrogels | 95 kPa | 1300% | SLA | Flexible Devices, Soft Robotics, Tissue Engineering | Hydrophobic Association | Contact | 6 h | ~100% | [48] |

| Silicone Elastomer | ~225 kPa | ~330% | SLA | Endurable Wearables, Flexible Electronics | Ionic Bonding | Heat at 100 °C | 12 h | >90% | [49] |

| Host–Guest Supramolecular Hydrogel | 0.3–0.5 MPa | 70% | DIW | Biomedical | Host–Guest Interactions | Mechanical Stress | 1 h | Up to 80% | [50] |

| PEDOT:PSS with Polymeric Surfactant | 3 MPa | 35% | DIW | Energy Harvesting | Surfactant | Electrical Current 10–3 A | 1 s | 85% electrical output | [51] |

| Polyurethane Elastomer | 3.39 ± 0.09 MPa | 400.38% | DLP | - | Disulfide Exchange | Heat at 80 °C | 12 h | 95% First healing | [52] |

| Material | Application | Role of Printed Material | Young’s Modulus or Elasticity | Max Strain | Printing Technique | Performance | Ref. |

|---|---|---|---|---|---|---|---|

| Silicone elastomer | Dielectric actuator | Actuating layer | ≈700 kPa | 600% | DOD | A maximum areal strain of 6.1% at an electric field of 84.0 V/μm | [61] |

| Reduced graphene oxide-elastomer nanocomposites | Dielectric actuator | Flexible electrode layer | - | 104% | Aerosol Jet Printing | Electrodes with a maximum stretchability of 100% could be bonded to dielectric layers without losing conductivity | [62] |

| Thermoplastic polyurethane/carbon nanotubes/silver nanoparticles composites | Dielectric actuator | Actuating material | 3.44 MPa in print direction | Up to 800% in print direction | FDM | Dielectric constant of 6.32 and a radial extension of 4.69% at an applied 4.67 kV | [79] |

| Barium titanate filled silicone elastomer | Dielectric actuator | Actuating layer | 39.82 kPa | >100% | DIW | Maximum tip displacement of 6 times its thickness at 5.44 kV Blocking force of 17.27 mN and deflection of 0.85 mm under a 0.12 g mass with a 5 kV applied | [63] |

| Thermoplastic elastomer | Dielectric actuator | Elastic frame | - | - | FDM | A tilt angle of 128° and a blocked force of 24 mN were measured when driven by 6 kV | [64] |

| Thermoplastic polyurethane | Dielectric actuator | Elastic frame | - | - | FDM | Honeycomb structures could achieve a longitudinal strain of 15.8% and transverse strain of −0.97% at a driving voltage of 7.5 kV | [65] |

| Thermoplastic polyurethane and multiwalled carbon nanotubes | Piezoresistive sensors | Sensor and electrodes | - | >100% | FDM | Anisotropic electrical resistance responses to strain with gauge factors between 1.5 and 3 | [68] |

| Thermoplastic polyurethane and carbon nanotubes | Piezoresistive sensor | Sensor | ≈1 MPa at a strain of 30% | - | FDM | Consistent 50% change in developed current during 1500 cycles of 5% strain | [67] |

| Thermoplastic elastomer | Piezoresistive sensor | Sensor body | - | 800% | FDM | Pressure sensitivity as high as 136.8 kPa−1 at pressures <200 Pa and GF of 6.85 at stretching | [69] |

| Thermoplastic polyurethane, carbon black, and silver composites | Piezoresistive sensor | Substrate, sensor, and electrode layers | - | 600% for TPU, 120% for electrode layer | DIW | Low sensitivity to in-plane stretching of (R/R0 < 7%) and pressure sensitivity of 5.54 kPa−1 at low pressures (<10 kPa) | [70] |

| PDMS and multi-walled CNT | Piezoresistive sensor | Conductive pattern | - | >70% | DIW | GF of 13.01 with linear responses up to 70% tensile strain | [71] |

| Ionogels | Piezoresistive sensor | Sensor | Tensile strength of 0.81 MPa at 242% strain | 242% | DIW | ≈40% change in electrical current under a 29% elongation | [72] |

| Cellulose nanocrystals and deep eutectic solvent ionogel | Piezoresistive sensor | Sensor | 0.20 MPa | At least 790% | DIW | Up to a 3.3 GF in the strain range up to 300% strain | [73] |

| Barium titanate | Piezoelectric sensor | Sensing lattice | - | - | Ceramic slurry DLP | Compressibility up to at least 10% and direct relationship between recorded voltage and applied strain | [78] |

| Polyvinylidene fluoride and sodium potassium niobate | Piezoelectric sensor | Sensor | <1.0 MPa for designed structure | 40% | FDM | Pressure sensitivity of 2.295 mV kPa−1 and ability to self-power | [76] |

| Lead Zirconate Titanate | Piezoelectric sensor | Sensor | Compliance up to 3 × 10−8 Pa | - | Ceramic slurry DLP | Variable piezoelectric charge constant up to 110 pC/N and sensitivity to pressure and extension with high conformability to surfaces | [77] |

| Materials | Matrix | Response Type | Technique | Applied Stimuli | Color-Change | Absorbance Wavelength (nm) | Reversibility | Ref. |

|---|---|---|---|---|---|---|---|---|

| Spiropyran | Polydimethylsiloxane | Mechanochromic | DIW | Off-white to Purple | Yes | [80] | ||

| Poly(butyl acrylate) | Polyacrylamide | Mechanochromic and Hydrochromic | DIW | Compression: 5.7 kPa | Entire Wavelength Spectrum Colors | 500–900 | Yes | [81] |

| Polyethyleneimine-co-poly(acrylic acid) | Polyethylene glycol diacrylate | Hydrochromic | DIW | Blue-Green, and Red | 400–650 | Yes | [81] | |

| Polyurethane acrylate | Isobornyl acrylate | Thermochromic | Projection Micro Stereolithography | 74.2–81.7 °C | Black, Red, Blue, Yellow, White | 400–800 | Yes | [82] |

| Poly(N-isopropylacrylamide) | Silica-alumina based gel | Thermochromic and Electrochromic | DIW | >60 °C and 0.6–1.8 Amp (2~6 V) | Transparent to Opaque State | 1400–1900 | Yes | [83] |

| Poly(3,4 ethylenedioxythiophene)-poly(styrene sulfonate) (PEDOT:PSS)/silver (Ag) | Grid/polyethylene terephthalate | Electrochromic | IJ | −0.6–0 V | Transparent, Black | 633 | Yes | [84] |

| Materials | Modulus | Max Strain (%) | Technique | Application | Functionalities | Ref. |

|---|---|---|---|---|---|---|

| Polyacrylamide | 17 KPa | 574 | DIW | Biocompatible Soft Robotics | Magnetic response | [91] |

| Polyacrylamide with Carbomer | 40 KPa | 260 | DIW | Biocompatible Soft Robotics | Magnetic response | [91] |

| PLA-PEA | 125 MPa | 2.5 | DIW | Actuation and Sensing | Shape memory effect and piezoelectric effect | [92] |

| Polypyrrole (PPy) | 498 kPa | 1500 | DIW | Sensor | Self-healing | [93] |

| Polydimethylsiloxane (PDMS) | 160 kPa | 210 | DIW | Sensor | Superhydrophobicity | [94] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Regis, J.E.; Renteria, A.; Hall, S.E.; Hassan, M.S.; Marquez, C.; Lin, Y. Recent Trends and Innovation in Additive Manufacturing of Soft Functional Materials. Materials 2021, 14, 4521. https://doi.org/10.3390/ma14164521

Regis JE, Renteria A, Hall SE, Hassan MS, Marquez C, Lin Y. Recent Trends and Innovation in Additive Manufacturing of Soft Functional Materials. Materials. 2021; 14(16):4521. https://doi.org/10.3390/ma14164521

Chicago/Turabian StyleRegis, Jaime Eduardo, Anabel Renteria, Samuel Ernesto Hall, Md Sahid Hassan, Cory Marquez, and Yirong Lin. 2021. "Recent Trends and Innovation in Additive Manufacturing of Soft Functional Materials" Materials 14, no. 16: 4521. https://doi.org/10.3390/ma14164521

APA StyleRegis, J. E., Renteria, A., Hall, S. E., Hassan, M. S., Marquez, C., & Lin, Y. (2021). Recent Trends and Innovation in Additive Manufacturing of Soft Functional Materials. Materials, 14(16), 4521. https://doi.org/10.3390/ma14164521