The Influence of Lime Solution in Kneading Water Substitution on Cement Roughcast and Mortar Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

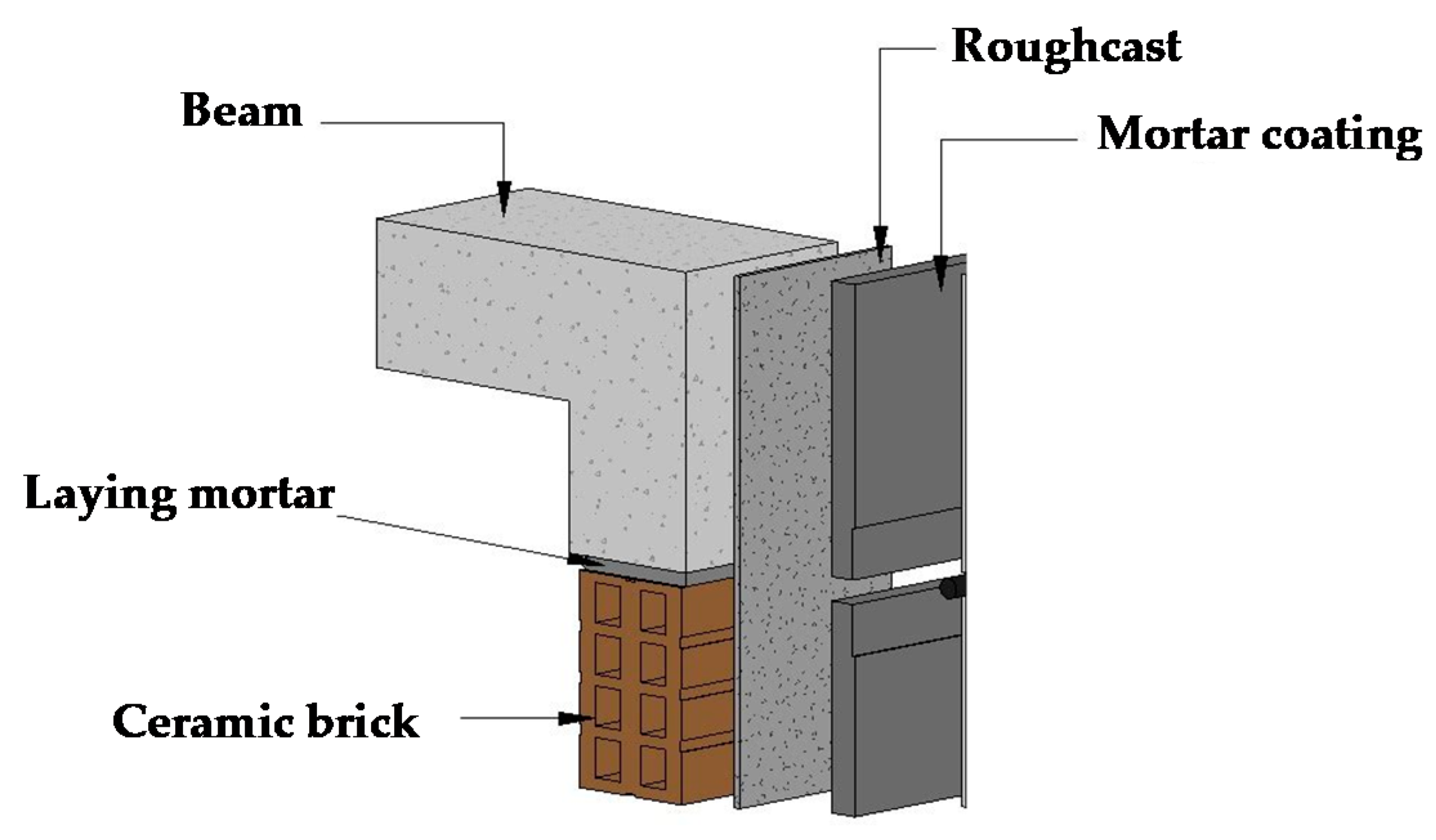

2.1.2. Substrate

2.1.3. Mortars

2.2. Methods

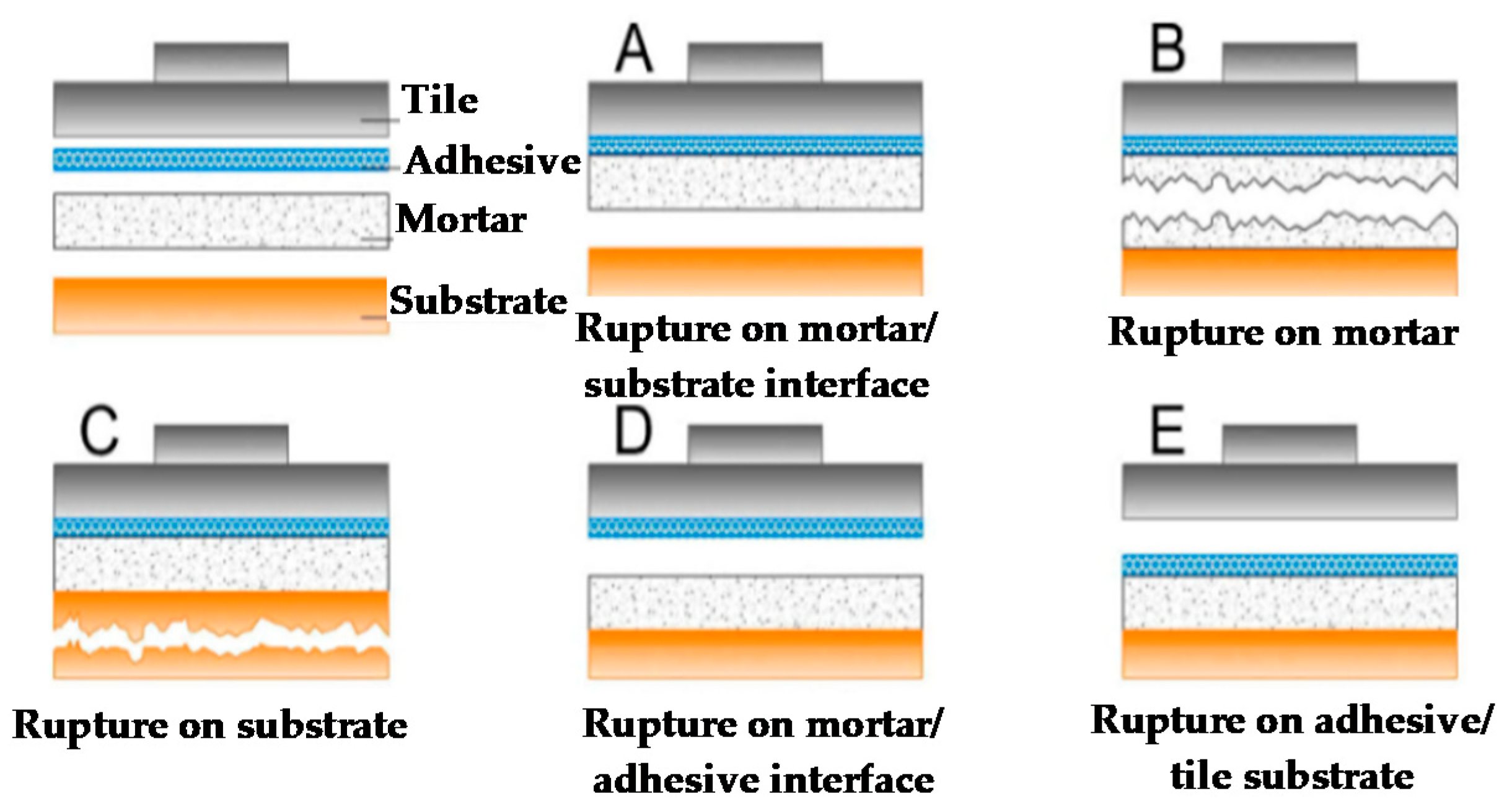

Bond Strength

3. Results and Discussion

3.1. Material Characterization Tests

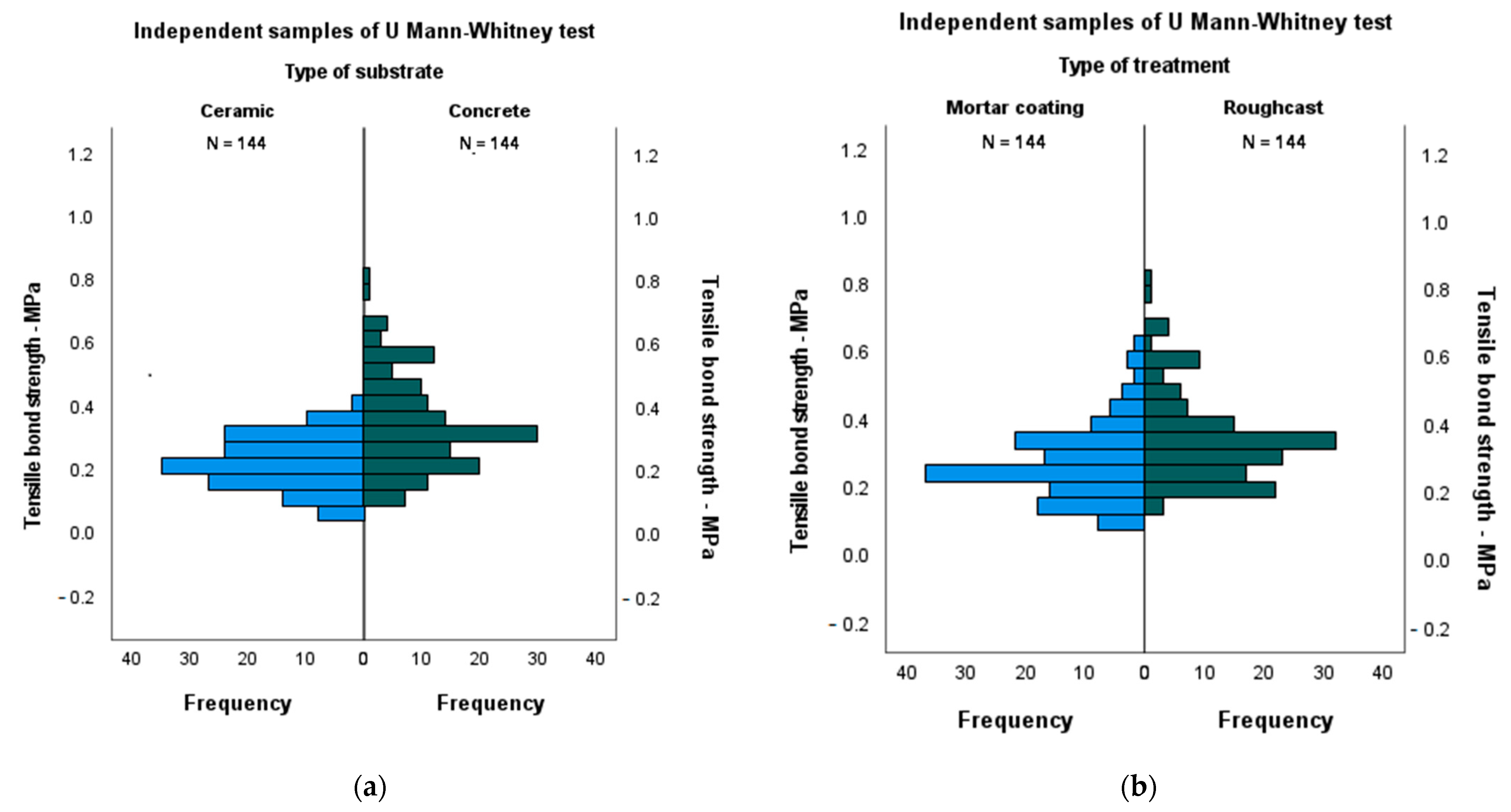

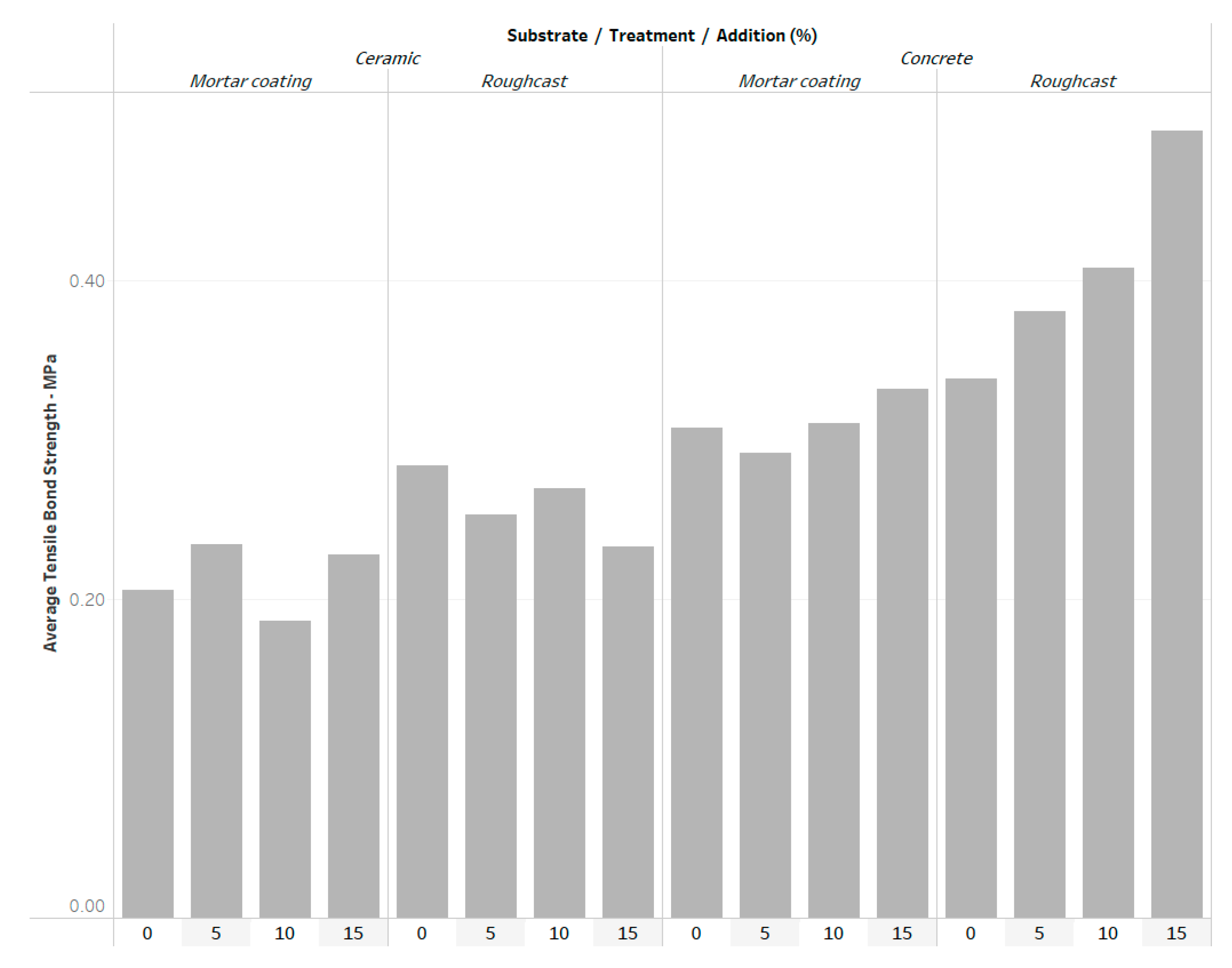

3.2. Tensile Bond Strength Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Carasek, H. Portland Cement-Based Mortar Adhesion to Porous Substrates-Evaluation of Intervening Factors and Contribution to the Study of the Binding Mechanism. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 1996. [Google Scholar]

- Torres, I.; Veiga, M.R.; Freitas, V.P. Influence of substrate characteristics on behavior of applied mortar. J. Mater. Civ. Eng. 2018, 30, 04018254. [Google Scholar] [CrossRef]

- Winslow, D.; Liu, D. The pore structure of paste in concert. Cem. Concr. Res. 1990, 20, 227–235. [Google Scholar] [CrossRef]

- Stolz, C.M.; Masuero, A.B.; Pagnussat, D.T.; Kirchleim, A.P. Influence of substrate texture on the tensile and shear bond strength of rendering mortars. Constr. Build. Mater. 2016, 128, 298–307. [Google Scholar] [CrossRef]

- Loh, W.K.; Crocombe, A.D.; Abdel Wahab, M.M.; Ashcroft, I.A. Environmental degradation of the interfacial fracture energy in an adhesively bonded joint. Eng. Fract. Mech. 2002, 69, 2113–2128. [Google Scholar] [CrossRef]

- Mota, J.M.F. Reinforcement of Resistant Masonry with Reinforced Mortar and Addition of Mettakaolin. Ph.D. Thesis, Universidade Federal de Pernambuco, Recife, Brazil, 2015. [Google Scholar]

- Botas, S.; Rosário, M.; Velosa, A. Air lime mortars for conservation of historic tiles: Bond strength of new mortars to old tiles. Constr. Build. Mater. 2017, 145, 426–434. [Google Scholar] [CrossRef]

- Haach, V.G.; Vasconcelos, G.; Lourenço, P.B. Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Constr. Build. Mater. 2011, 25, 2980–2987. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; França, B.R.; Alexandre, J.; Marvila, M.T.; Zanelato, E.B.; Xavier, G.C. Influence of sintering temperature of a ceramic substrate in mortar adhesion for civil construction. J. Build. Eng. 2018, 19, 342–348. [Google Scholar] [CrossRef]

- Hamdy, G.A.; El-Hariri, M.O.R.; Farag, M.F. Use of additives in mortar to enhance the compression and bond strength of masonry exposed to different environmental conditions. J. Build. Eng. 2019, 25, 100765. [Google Scholar] [CrossRef]

- Brocken, H.J.P.; Spiekman, M.E.; Pel, L.; Kopinga, K.; Larbi, J.A. Water extraction out of mortar during brick laying: A NMR study. Mater. Struct. Constr. 1998, 31, 49–57. [Google Scholar] [CrossRef]

- Costa e Silva, A.J.; Azevedo, A.A.C.; Souza, M.T.G. Influence of base preparation on the adhesion of mortar coatings on ceramic bricks. In Proceedings of the 7th Euro-American Congress on Construction Pathology, Rehabilitation Technology and Heritage Management, Rehabend 2018, Cáceres, Spain, 15–18 May 2018. [Google Scholar]

- Mota, J.M.F.; Costa e Silva, A.J.; Carasek, H.; Barbosa, F.R. Work analysis of the adhesion resistance of mortar coatings with the preparation of the substrate with lime and roughcast solution. In X Congreso Latinoamericano de Patología Y XII Congreso de Calidad en la Construcción; CONPAT: Valparaíso, Chile, 2009. [Google Scholar]

- Bonavetti, V.; Donza, H.; Menendez, G.; Cabrera, O.; Irassar, E.F. Limestone filler cement in low w/c concrete: A rational use of energy. Cem. Concr. Res. 2003, 33, 865–871. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem. Concr. Res. 2006, 36, 264–277. [Google Scholar] [CrossRef]

- Costa, E.B.C.; França, M.S.; Bergossi, F.L.N.; Borges, R.K. Squeeze flow of mortars on brick substrate and its relation with bond strength. Constr. Build. Mater. 2020, 265, 120298. [Google Scholar] [CrossRef]

- NBR 16997. Portland Cement-Requirements. Brazilian Association of Technical Standards; Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2018. [Google Scholar]

- NBR 15900-1. Mixing Water for Concrete Part 1: Requirements. Brazilian Association of Technical Standards; Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2009. [Google Scholar]

- ASTM C67-17. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile. American Society for Testing and Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- NBR 15270-1. Ceramic Components-Clay Blocks and Bricks for Masonry Part 1: Requirements. Brazilian Association of Technical Standards; Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2017. [Google Scholar]

- NBR 12118. Hollow Concrete Blocks for Concrete masonry—Test methods. Brazilian Association of Technical Standards; Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Silva, V. Adhesion of Roughcast in Structural Concretes-Improvement of the Microstructure of the Interface Zone by the Addition of Rice Husk Silica. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 2004. [Google Scholar]

- NBR 13528-3. Render Made of Inorganic Mortars Applied on Walls-Determination of Tensile Bond Strength Part 3: Surface Adhesion; Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Paes, I.N.L. Evaluation of Water Transport in Mortar Coatings in the Initial Moments after Application. Ph.D. Thesis, Universidade de Brasília, Brasília-DF, Brazil, 2004. [Google Scholar]

- Green, K.M.; Carter, M.; Hoff, W.; Wilson, M. The effects of lime and admixtures on the water-retaining properties of cement mortars. Cem. Concr. Res. 1999, 29, 1743–1747. [Google Scholar] [CrossRef]

- NBR 13279. Mortars Applied on Walls and Ceilings-Determination of the Flexural and the Compressive Strength in the Hardened Stage; Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2005. [Google Scholar]

| Physical Characterization | Apparent Density (g/cm3) | 1.2 g/cm3 | |

| Specific Mass (g/cm3) | 3.09 g/cm3 | ||

| Compressive strength | 28 days (MPa) | 39.5 | |

| Chemical Characterization (%) | Potential composition of the clinked | 3CaOSiO2, C3S | 20–70 |

| 2CaOSiO2, C2S | 10–60 | ||

| 3CaOAl2O3, C3A | 1–15 | ||

| 4CaOAl2O3Fe2O3, C4AF | 5–15 | ||

| SiO2–silicon dioxide | 22.94 | ||

| CaO–calcium oxide | 57.61 | ||

| MgO–magnesium oxide | 3.99 | ||

| Al2O3–aluminum oxide | 5.60 | ||

| Fe2O3–iron oxide | 3.99 | ||

| P2O5–phosphorous pentoxide | 0.37 | ||

| K2O–potassium oxide | 1.68 | ||

| CaO/free lime | 0–2 | ||

| MgO/SO3 | 0–6 | ||

| Composition | Limestone |

|---|---|

| CO2 | ≤2.21 |

| Ca(OH)2 | ≥92.5% |

| SO3 | ≤0.05 |

| Mg(OH) | ≤5.0% |

| SiO2 | ≤1.3% |

| Relative Humidity | ≤2.0% |

| Apparent Density | 0.56 g/cm3 |

| Unit Mass | 1.3 g/cm3 |

| Fineness module | 2.28 |

| Maximum diameter | 2.36 mm |

| Powder content | 2.38% |

| Base | Dimension (mm) | Total Absorption (%) | Compressive Strength (MPa) | Initial Rate of Absorption-IRA (g/cm2min) |

|---|---|---|---|---|

| Ceramic brick | 90 × 190 × 190 | 14.6 | 2.8 | 0.0605 |

| Concrete block | 90 × 190 × 390 | 6.4 | 4.0 | 0.0845 |

| Mortar Specimens | Tensile Strength (MPa) | Compressive Strength (MPa) | ||

|---|---|---|---|---|

| M_0% | 0.79 | 0.86 ± 0.09 | 1.49 | 1.98 ± 0.32 |

| 0.99 | 1.73 | |||

| 0.79 | 2.22 | |||

| 0.80 | 2.43 | |||

| 0.95 | 2.26 | |||

| -- | 1.75 | |||

| M_5% | 1.07 | 1.11 ± 0.04 | 2.28 | 2.40 ± 0.11 |

| 1.08 | 2.36 | |||

| 1.19 | 2.55 | |||

| 1.12 | 2.55 | |||

| 1.08 | 2.43 | |||

| -- | 2.21 | |||

| M_10% | 1.37 | 1.34 ± 0.06 | 3.77 | 3.23 ± 0.19 |

| 1.25 | 3.13 | |||

| 1.39 | 3.19 | |||

| 1.28 | 2.95 | |||

| 1.39 | 3.27 | |||

| -- | 3.06 | |||

| M_15% | 1.28 | 1.40 ± 0.11 | 4.34 | 3.88 ± 0.28 |

| 1.59 | 3.73 | |||

| 1.33 | 3.97 | |||

| 1.49 | 3.84 | |||

| 1.31 | 3.22 | |||

| -- | 4.18 | |||

| Levene Statistic | df1 | df2 | Sig. | ||

|---|---|---|---|---|---|

| Tensile bond strength residuals a | Based on average | 3.910 | 15 | 272 | <0.001 |

| Based on median | 2.752 | 15 | 272 | <0.010 | |

| Based on median with gl adjusted | 2.752 | 15 | 172.155 | <0.011 | |

| Based on trimmed average | 3.701 | 15 | 272 | <0.001 | |

| Kolmogorov-Smirnov a | Shapiro-Wilk | |||||

|---|---|---|---|---|---|---|

| Statistic | Gl | Sig. | Statistic | gl | Sig. | |

| Tensile bond strength residuals | 0.057 | 288 | <0.023 | 0.985 | 288 | <0.004 |

| Type of Substrate (Concrete or Ceramic) | Type of Treatment (Roughcast or Mortar Coating) | |

|---|---|---|

| Tensile bond strength | Tensile bond strength | |

| Mann–Whitney, U | 5224.000 | 7180.500 |

| Wilcoxon, W | 15,664.000 | 17,620.500 |

| Z | −7.280 | −4.511 |

| Significance Sig. (2 tales) | <0.001 | <0.001 |

| Tensile Bond Strength | |

|---|---|

| Kruskal-Wallis, H | 0.979 |

| Df | 3 |

| Significance | 0.806 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, A.M.; Silva, Â.J.C.e.; Mota, J.M.F.; Delgado, J.M.P.Q.; Silva, F.A.N.; Azevedo, A.C. The Influence of Lime Solution in Kneading Water Substitution on Cement Roughcast and Mortar Coating. Materials 2021, 14, 4174. https://doi.org/10.3390/ma14154174

Santos AM, Silva ÂJCe, Mota JMF, Delgado JMPQ, Silva FAN, Azevedo AC. The Influence of Lime Solution in Kneading Water Substitution on Cement Roughcast and Mortar Coating. Materials. 2021; 14(15):4174. https://doi.org/10.3390/ma14154174

Chicago/Turabian StyleSantos, André M., Ângelo J. Costa e Silva, João M. F. Mota, João M. P. Q. Delgado, Fernando A. N. Silva, and António C. Azevedo. 2021. "The Influence of Lime Solution in Kneading Water Substitution on Cement Roughcast and Mortar Coating" Materials 14, no. 15: 4174. https://doi.org/10.3390/ma14154174

APA StyleSantos, A. M., Silva, Â. J. C. e., Mota, J. M. F., Delgado, J. M. P. Q., Silva, F. A. N., & Azevedo, A. C. (2021). The Influence of Lime Solution in Kneading Water Substitution on Cement Roughcast and Mortar Coating. Materials, 14(15), 4174. https://doi.org/10.3390/ma14154174