Discrete-Impulse Energy Supply in Milk and Dairy Product Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Object and Methods

- -

- Non-homogenized milk, as the object of hydrodynamic dispersion and homogenization;

- -

- Emulsions of milk and oil fats, with a fat phase 3.5–72.5%, as the object of fat emulsification and the investigation of system stability;

- -

- Cream cheese mass as the composite protein product originating from cottage cheese, the object of investigation being the emulsification and dispersion efficiency.

2.2. The Object and Methods for Estimating Homogenized Milk Quality

2.3. Preparation of Fat Emulsions

2.4. Product and Methods for the Investigation of the Rheological Parameters of the Cream Cheese Mass

2.5. Temperature Measurement

2.6. Vacuum Measurement

2.7. Analysis of Microstructure

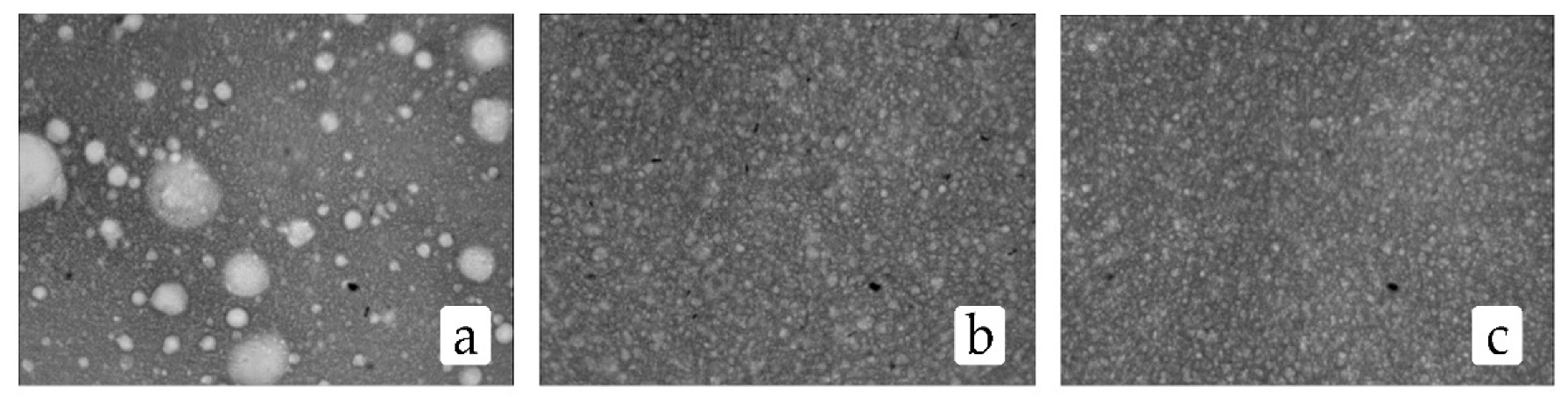

2.8. Investigation of the Rheological Characteristics

2.9. Analysis of Rheological Characteristics

3. Results

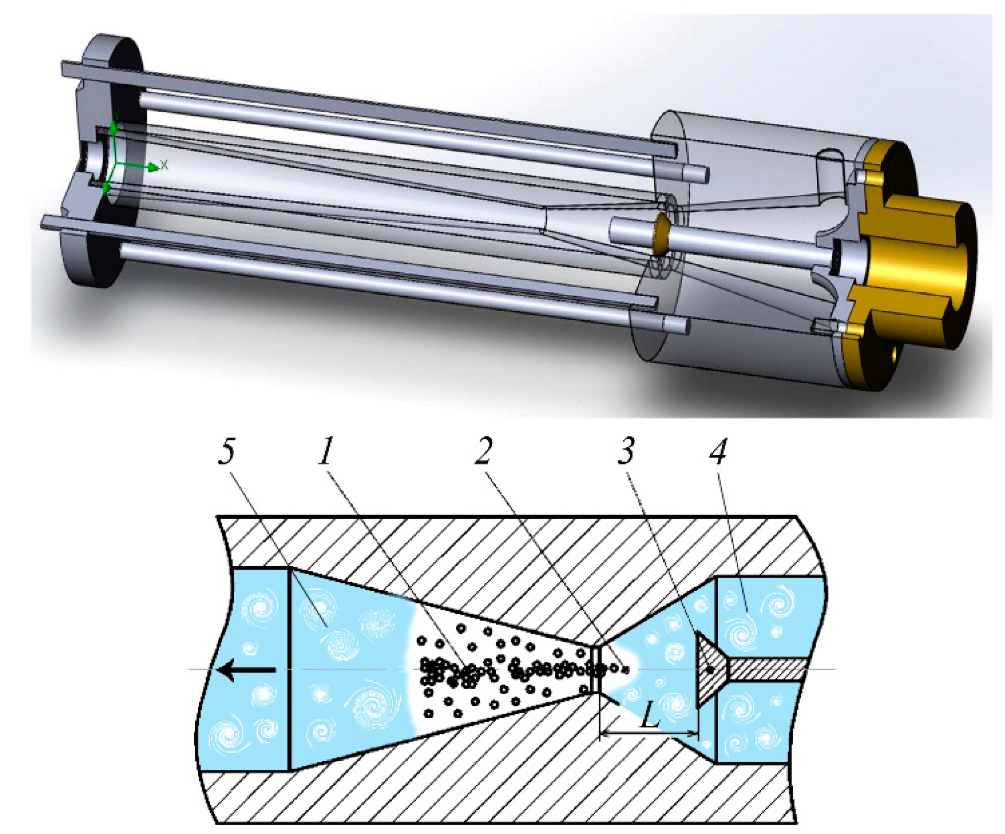

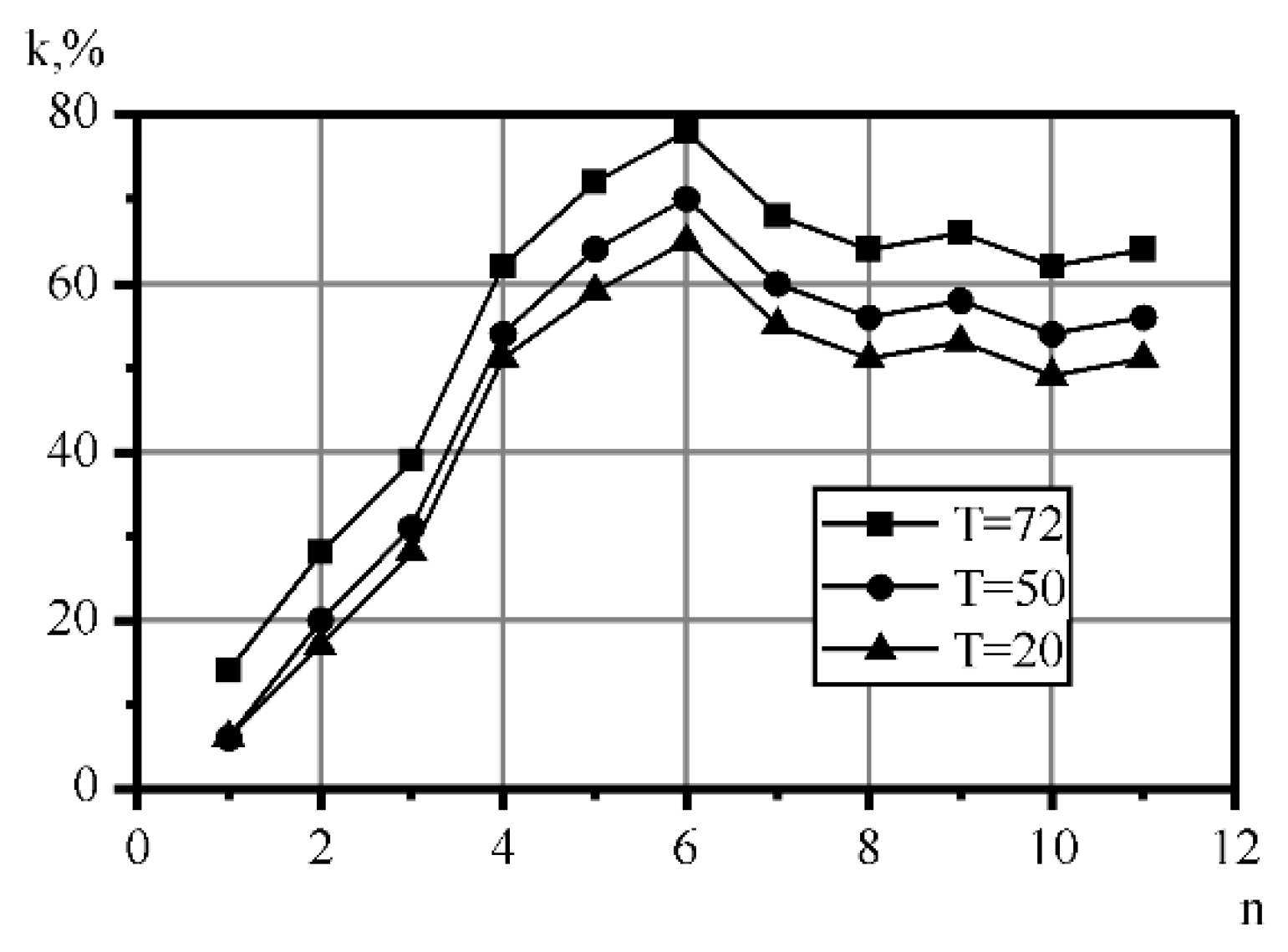

3.1. Milk Fat Homogenization Features in Milk

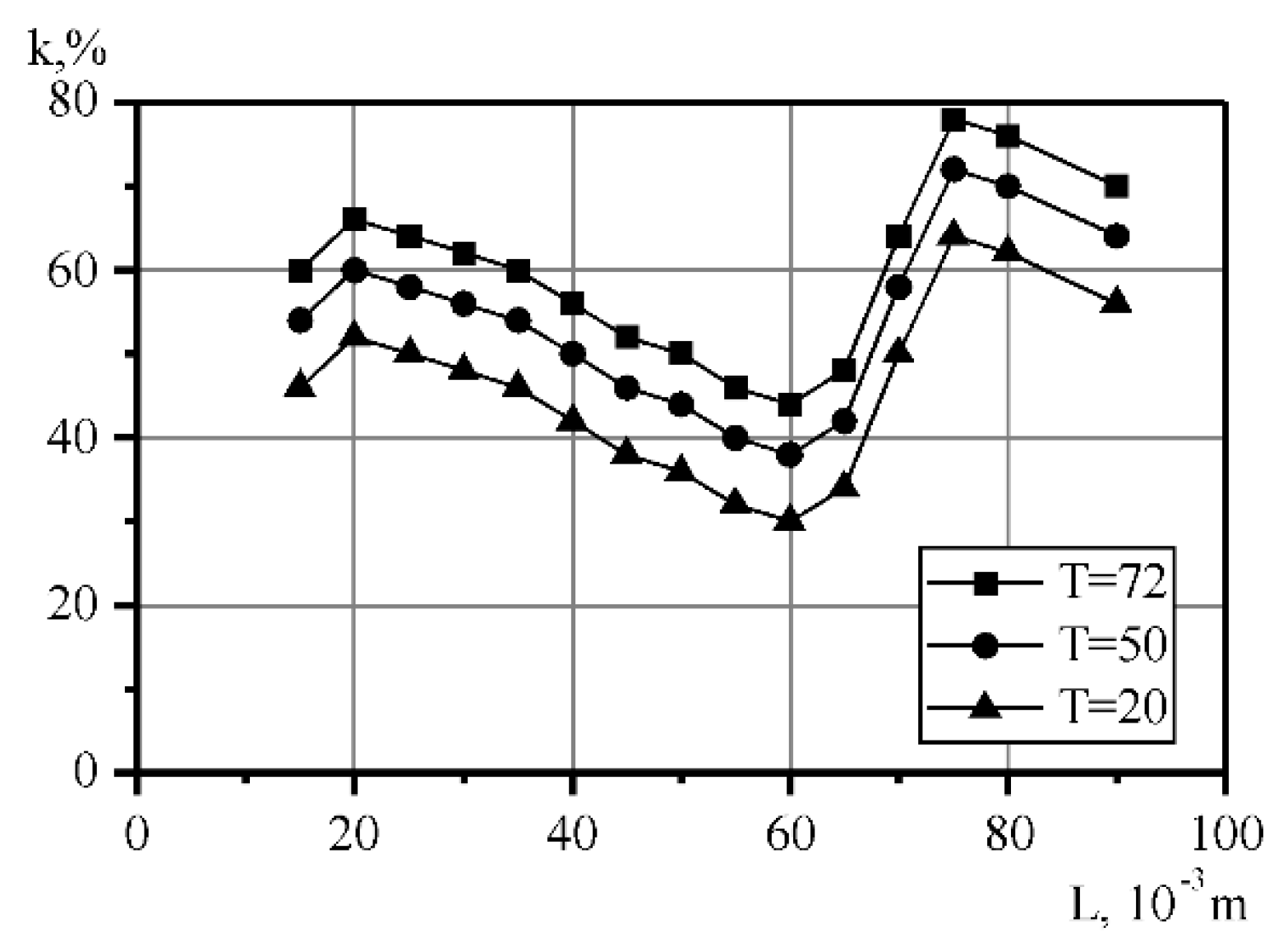

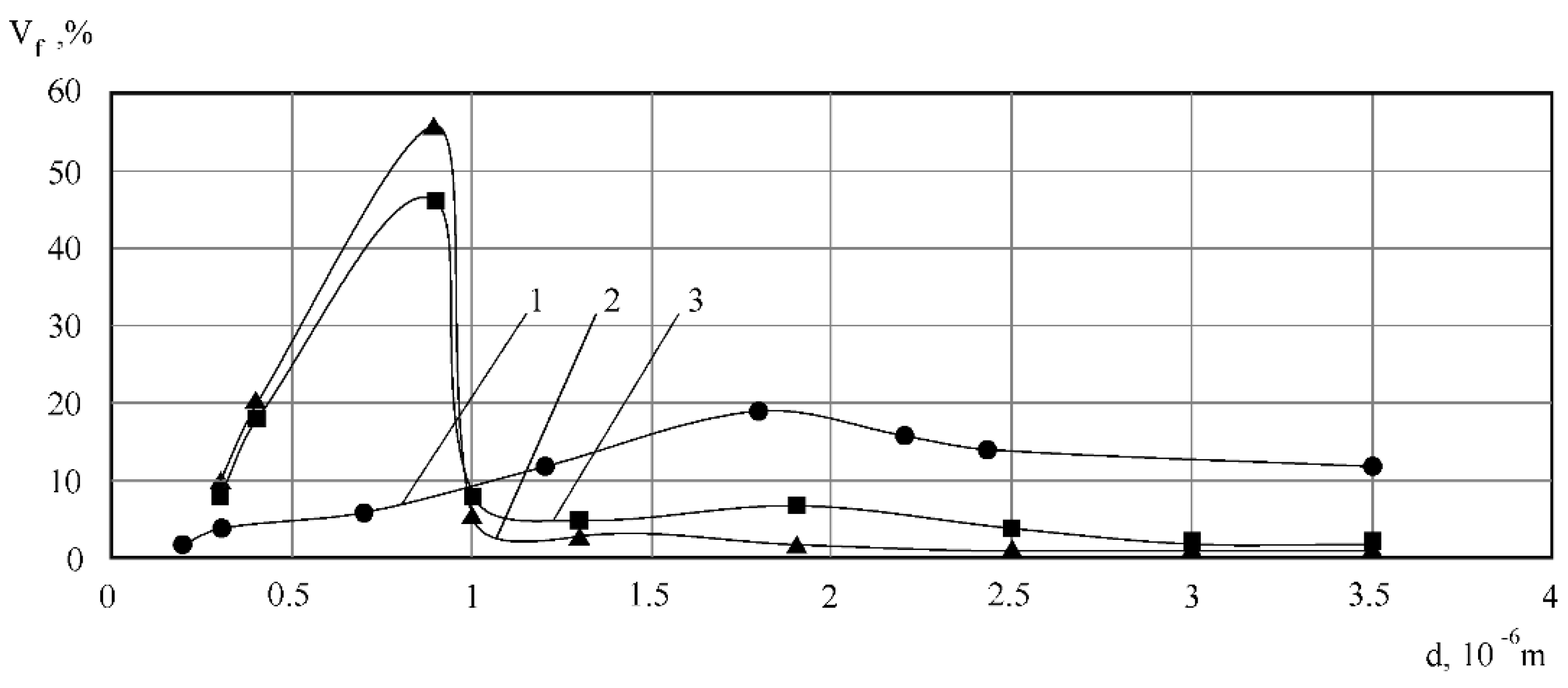

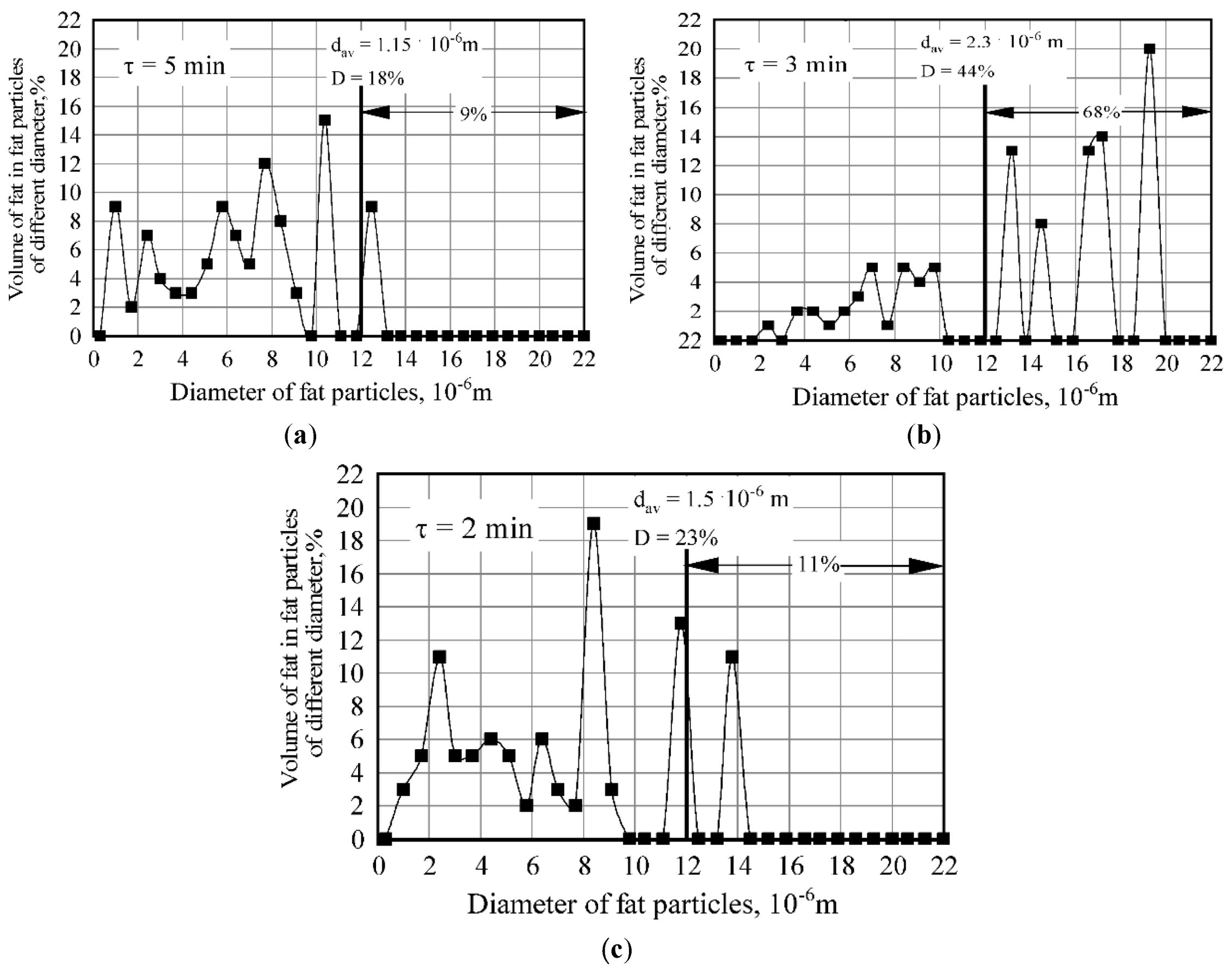

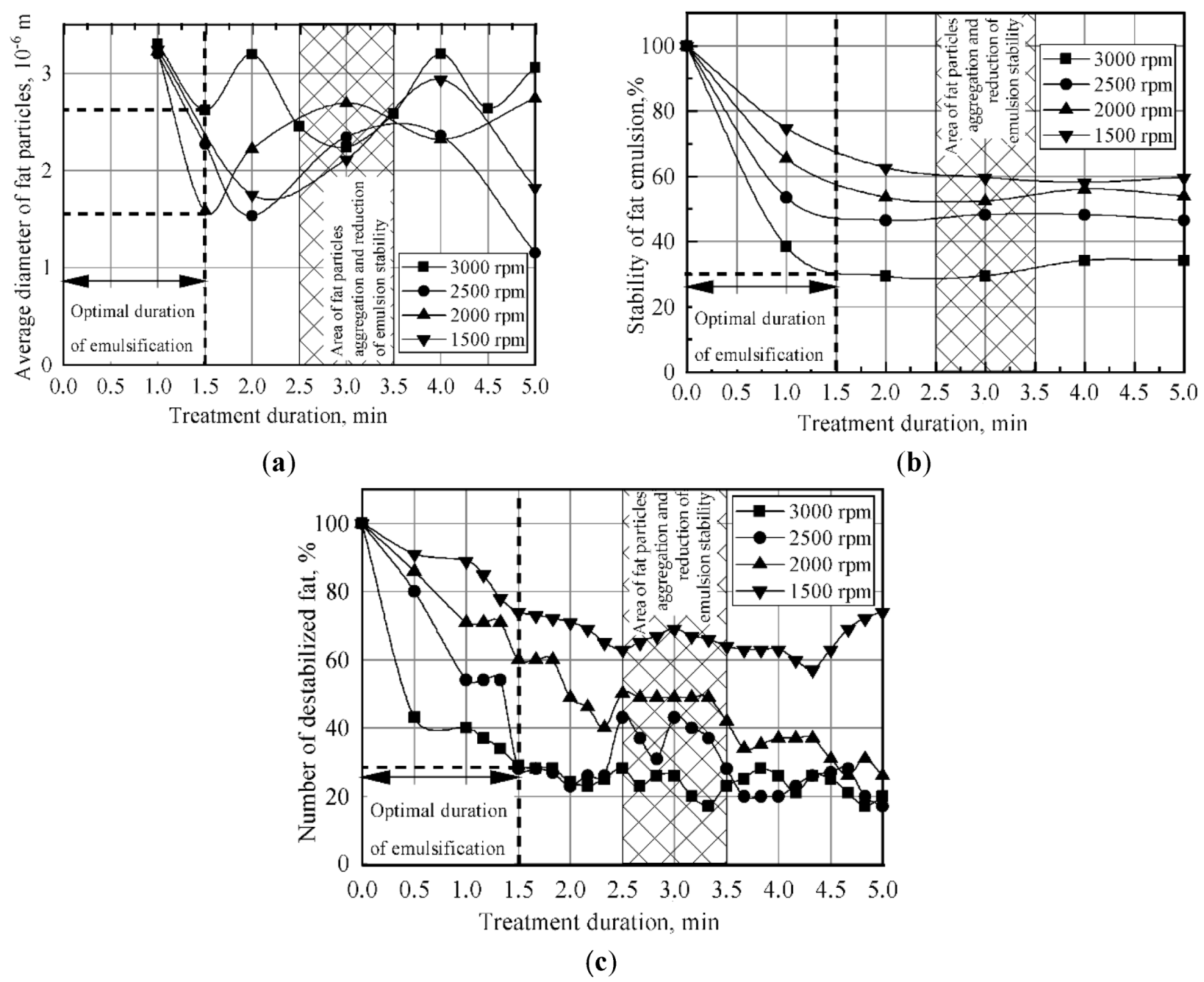

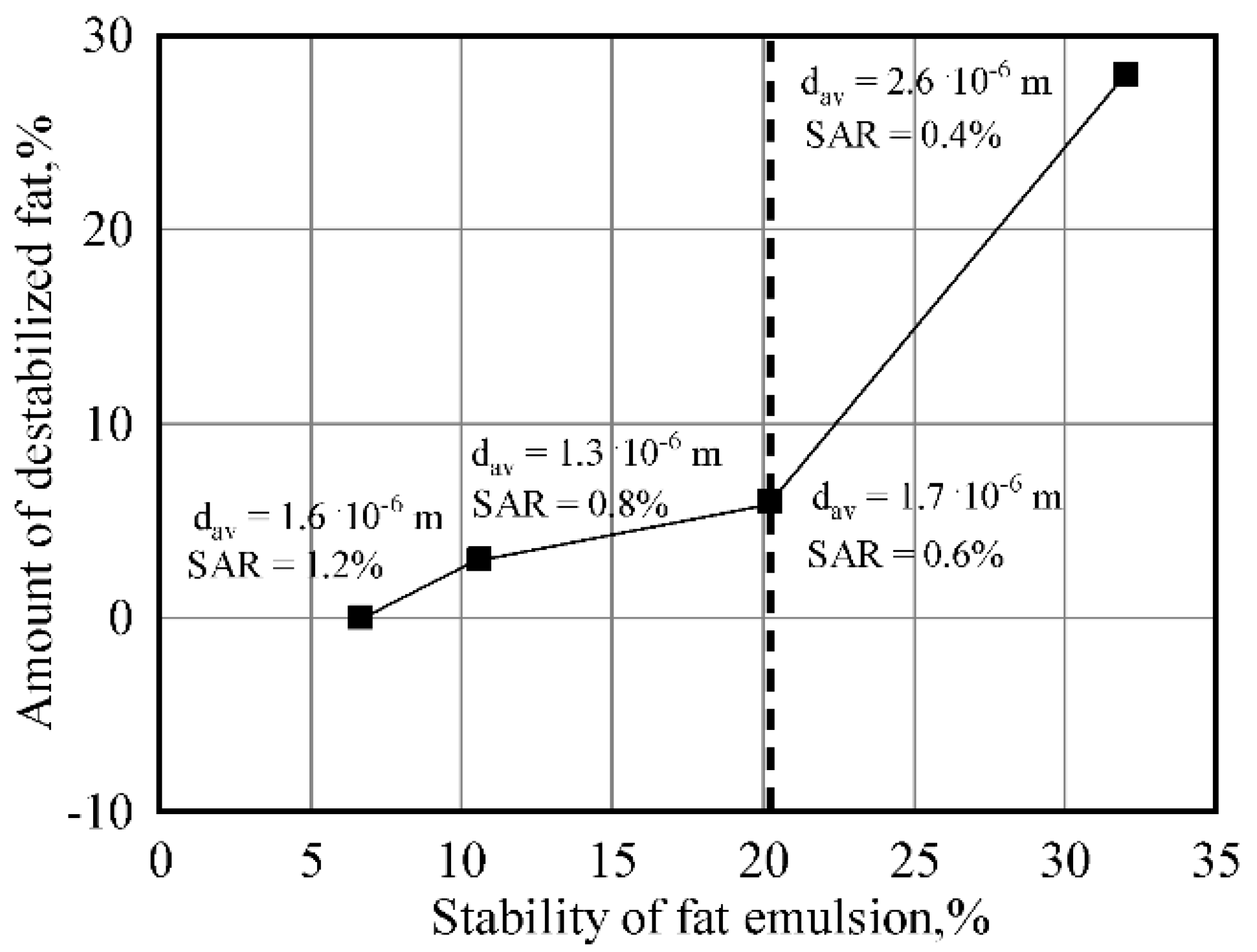

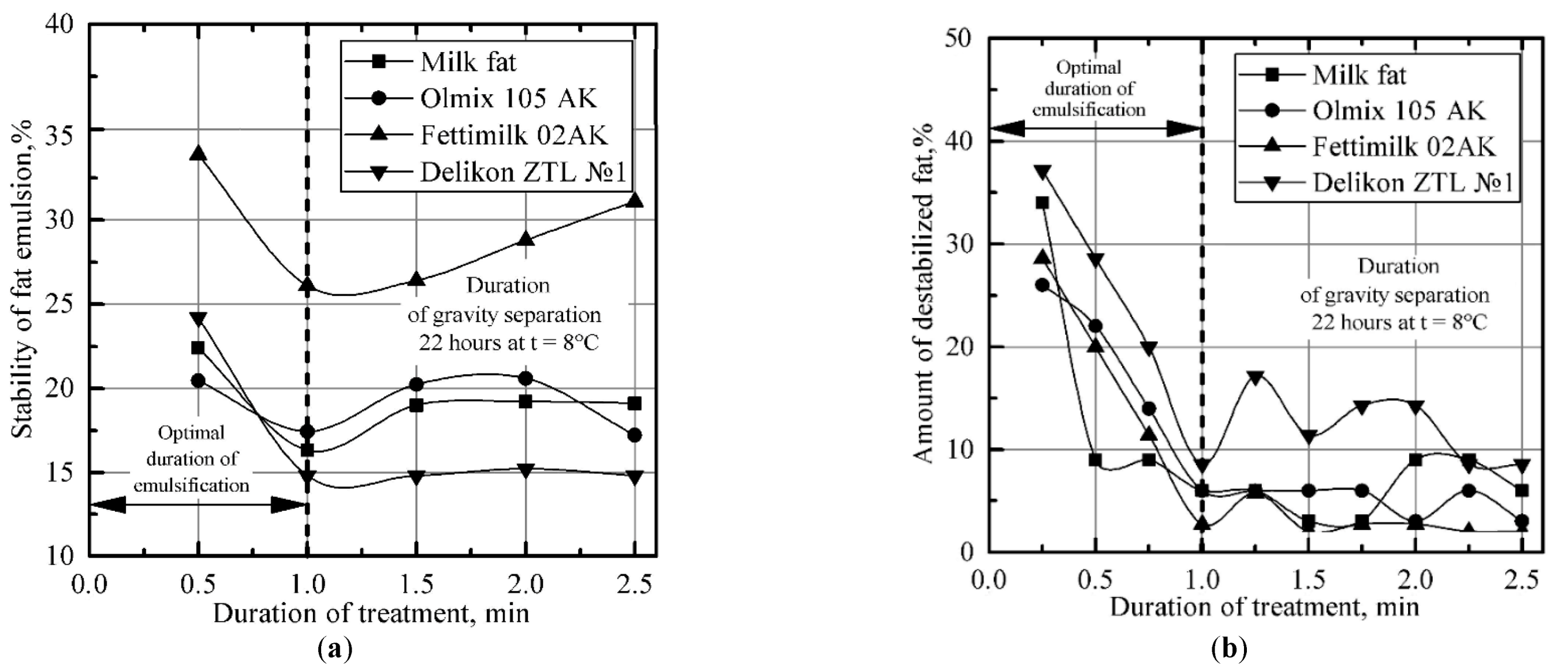

3.2. Patterns of Fat Dispersions Formation under Discrete-Impulse Energy Supply

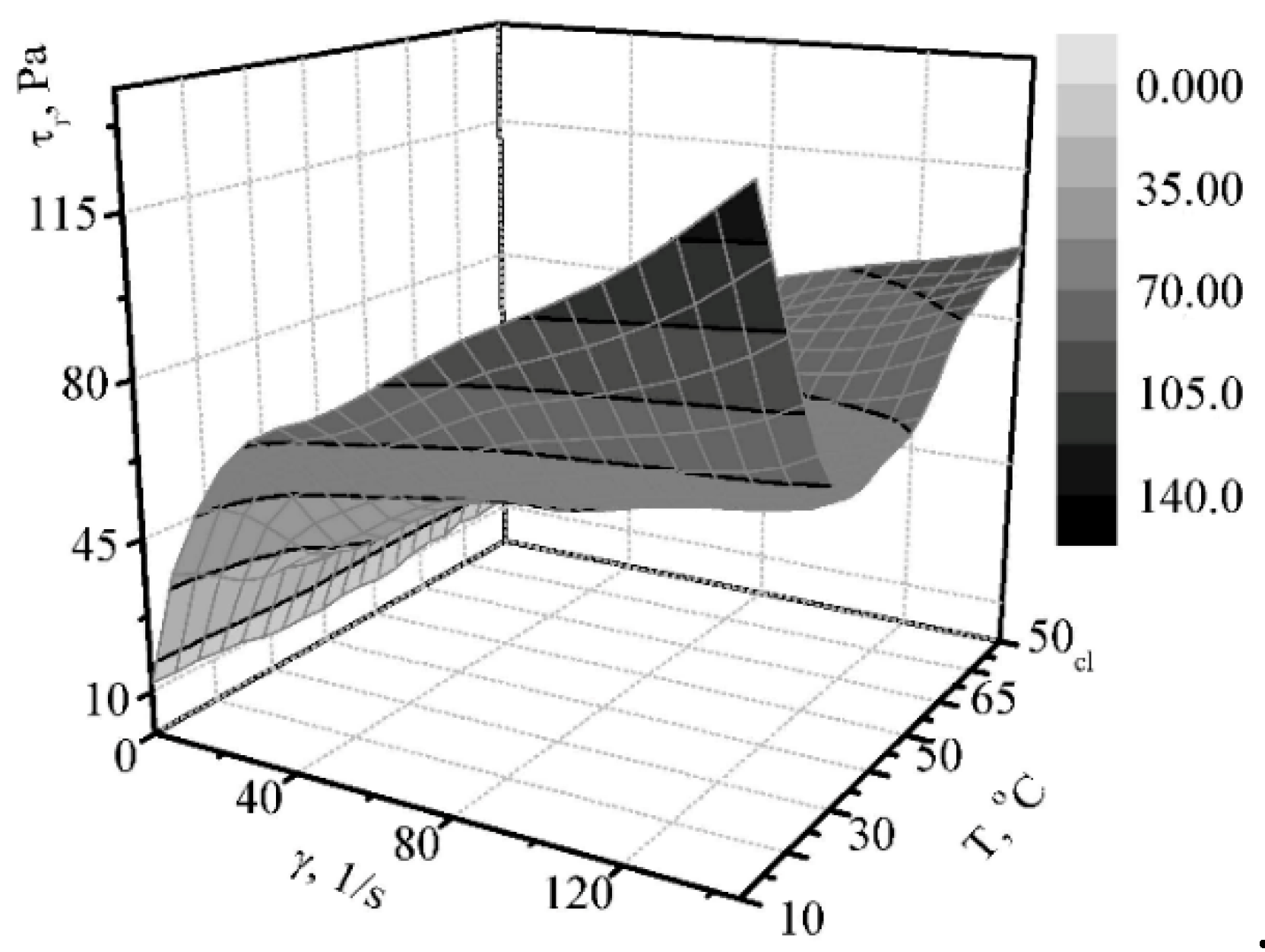

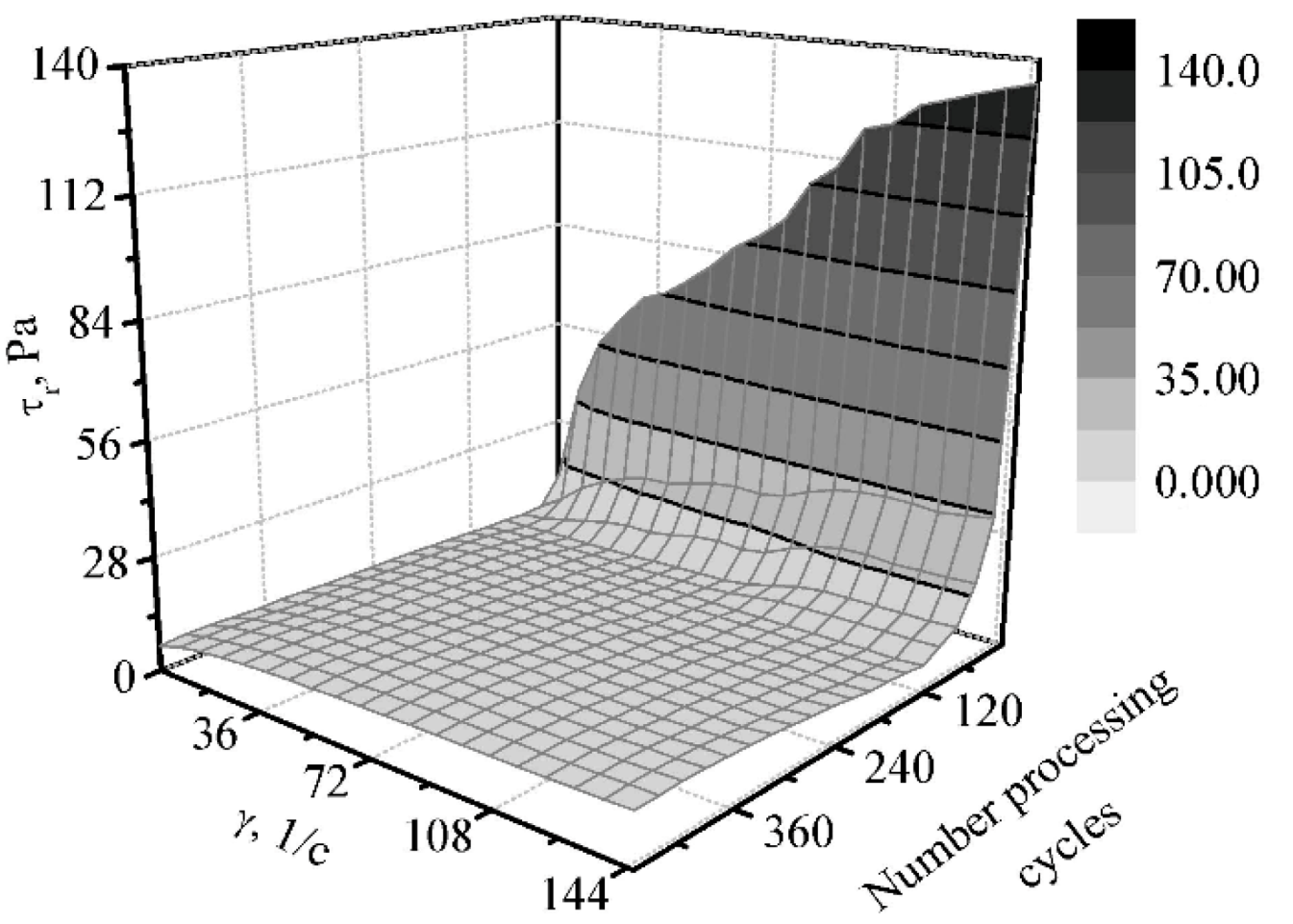

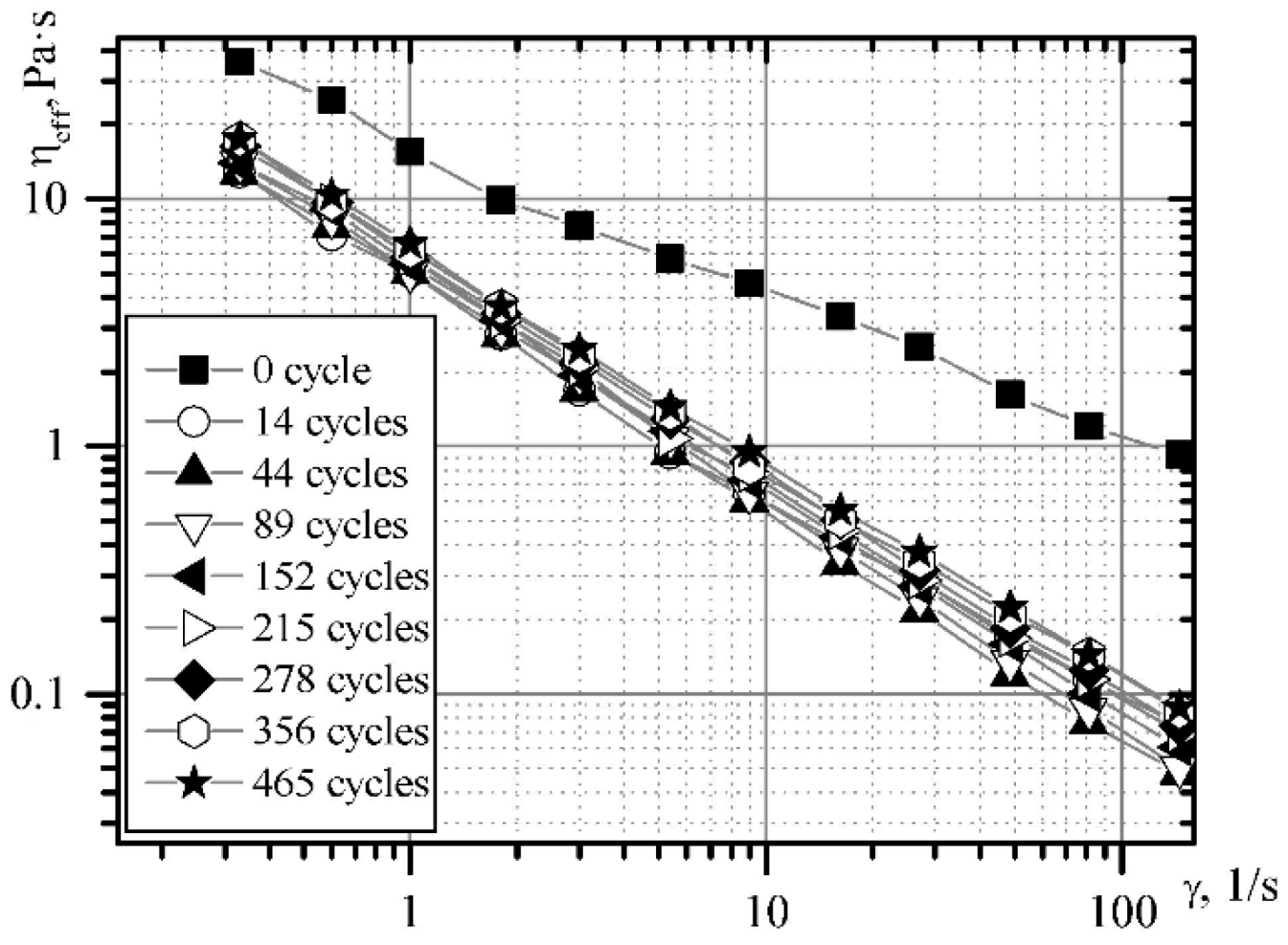

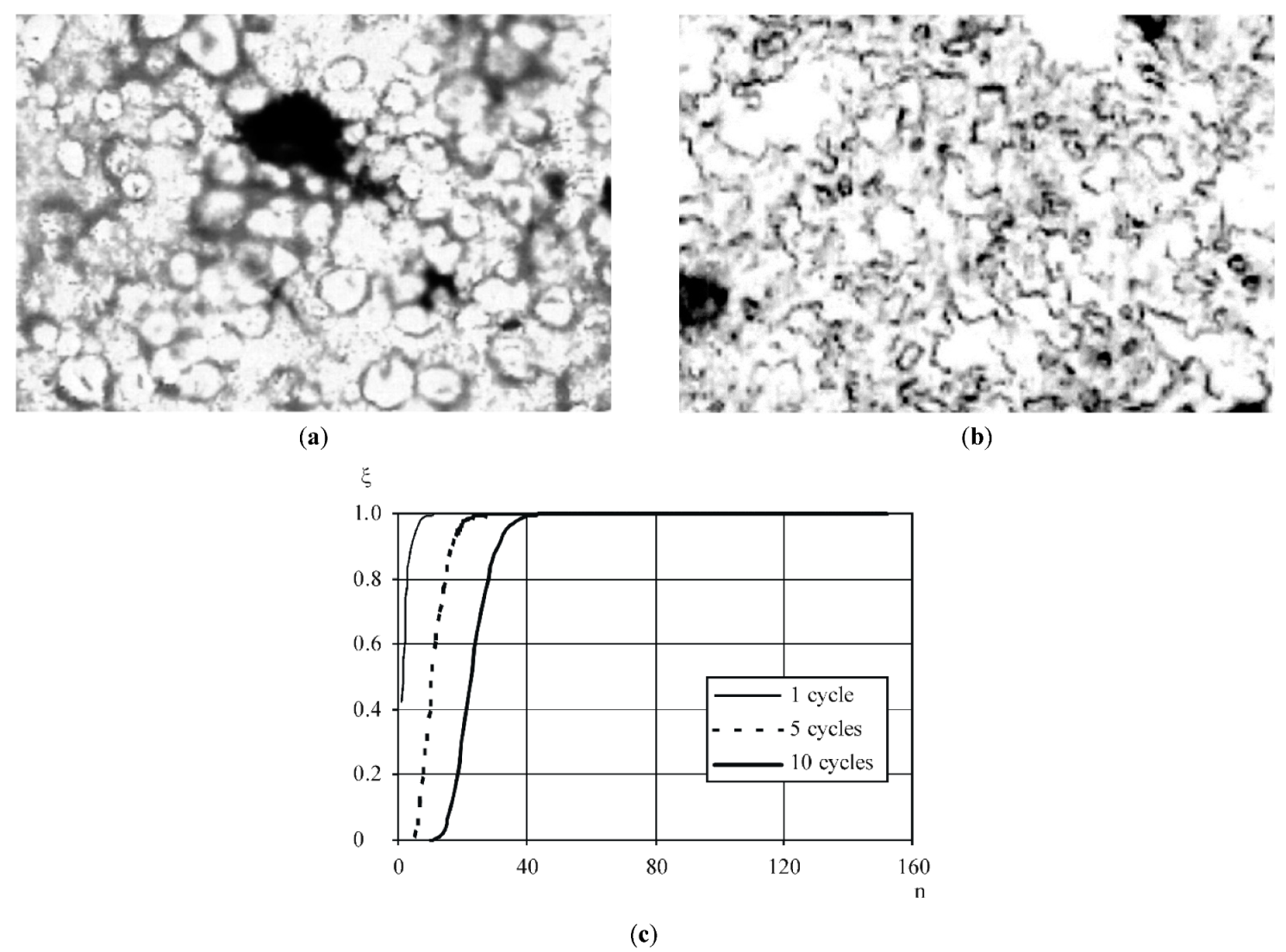

3.3. The Rheological Characteristics Variations of Cream Cheese Masses

4. Conclusions

- To obtain a milk emulsion dispersion equal to 0.8 m−6, six cycles of processing must take place under the mode of the developed cavitation specified by the great number of vapor-gaseous bubbles, the cavitation coefficient being λ = 2.5;

- While increasing temperature from 20 °C to 72 °C, the content of homogenized milk fat increased from 60% to 80% as a result of a decrease in the viscosity of the fat globules, the softening of their lipid layer, and the melting of the most refractory fractions of the milk fat. With an increase in temperature to 72 °C, partial thermal deaeration of the product occurred, as a result of which cavitation bubble initiation processes became easier, their number became greater, and, as a result, the number of local microreactors of local or discrete transformation increased as well.

- Having obtained a dispersion of less than 4 × 10−6 m with medium-sized fat globules, their dissipation and aggregation subsequently took place; over a dispersion period of 60–75 s, with a surface-active substance content of 0.6%, a stable fat emulsion was achieved;

- When the mass portion of the fat phase was increased from 3.5 to 35%, the duration of the process increased as a result of the greater degree of emulsion destabilization. At the same time, when the fat comprises different kinds of fat, there is an insufficient effect on the emulsification, the dispersion efficiency, or the duration of processing;

- No clear dependence was found between the revolution velocity of the emulsification apparatus rotor and the dispersion of the emulsion fat phase, although some confusion was caused by the emulsion dispersion result obtained when the processing velocity was 3000 rpm. The average sizes of the fat globules were greater than those in emulsions obtained under slower revolutions. Additionally, the data obtained proved that while being processed in the emulsification apparatus (with a rotor velocity of 1500–3000 rpm), a finely dispersed fat emulsion with globule sizes commensurable with those of the plain milk cream could be obtained in 90 s.

- The conventional parameters required to achieve technological stability for the production of fat emulsion spreads with dispersion and stability commensurable to those of plain milk creams were: emulsification temperature 50–70 °C, surface-active substance content 0.6% without vacuuming, treatment power 455–220 Vt, emulsion device rotor velocity 3000 rpm (18.8 m/s); treatment duration 60–75 s, power expenditure 1.9–3.3 kJ/kg.

- The crushing of the complex protein product structure occurs during the first 20 cycles of product processing. Mass heating was performed by the heat supplied from outside and by the mechanical work in the rotor–stator couple;

- The rheological characteristics of the product under the action of mechanical and thermal factors were presented on the basis of Ostwald-de-Waele’s and Herschel–Bulkley’s equations;

- It was proposed that the degree of mechanical treatment of the product be determined by the factor, that is, the relation of the sufficiently treated mass volume to the general mass volume;

- An equation for the assessment of the degree of mechanical treatment of any part of the product was proposed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| maximum globule size formed during emulsification, m | |

| dispersion phase surface tension, N/m | |

| dispersion phase density, kg/m3 | |

| rate turbulent fluctuation, m/s | |

| distance between the nozzle and the obstacle curve, m | |

| number of intervals | |

| number of calculated fat globules | |

| shear stress, Pa | |

| cylinder constant, scale Pa/unit | |

| measuring device scale factors | |

| effective viscosity (Pa · s) | |

| shear rate gradient, s−1 | |

| shear stress between the products layers, Pa | |

| viscosity at the unit value of the rate gradient, Pa·s | |

| relative rate gradient being numerically equal to the shear rate, s−1 | |

| flow index | |

| mean fat globule diameter, m | |

| fat globule diameter, m | |

| fat globules dispersion | |

| coefficient of variation | |

| volume per cent of fat globules of given size in the suspension, % | |

| product temperature, °C | |

| boundary shear rate, Pa | |

| coefficient being proportional to viscosity | |

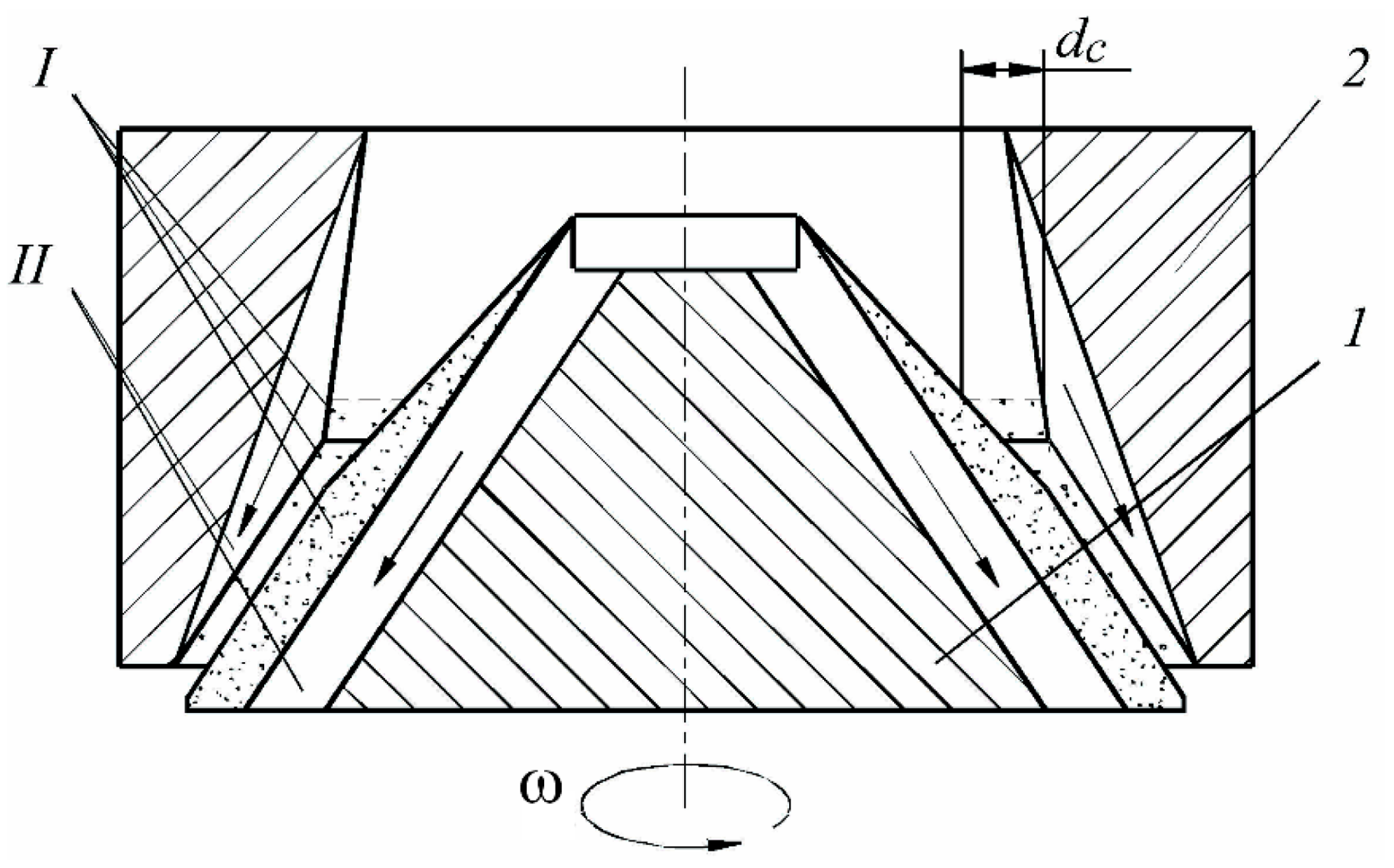

| width of the product treatment zone in the rotor–stator pair | |

| volume of the loaded mass, m3 | |

| rotor rotation frequency, rad/sec | |

| coefficient of proportionality | |

| running volume of the treated material, m3 | |

| product circulation cycle in the rotor–stator pair | |

| mechanical treatment number of cycles needed | |

| mechanical treatment number of cycles at this stage | |

| numerical coefficient | |

| volume of mechanical processed material at an arbitrary stage of processing of raw, m3 | |

| index (coefficient) of mechanical treatment in cyclical apparatus |

References

- Dolinsky, A.A.; Ivanitsky, G.K. The principle of discrete-pulse energy input—New approach to the development of efficient power-saving technologies. Ann. Rev. Heat Transfer. 2013, 13, 151–194. [Google Scholar] [CrossRef]

- Dolinsky, A.A.; Ivanitsky, G.K. Use of discrete-pulse energy input in various production processes. In Proceedings of the International Conference on Transport Phenomena Science and Technology; Higher Education Press: Beijing, China, 1992; pp. 89–100. [Google Scholar]

- Costa, A.L.R.; Gomes, A.; De Andrade, C.C.P.; Cunha, R.L. Emulsifier functionality and process engineering: Progress and challenges. Food Hydrocoll. 2017, 68, 69–80. [Google Scholar] [CrossRef]

- Akhtar, M.; Murray, B.S.; Dowu, S. A novel continuous process for making mayonnaise and salad cream using the spinning disc reactor: Effect of heat treatment. Food Hydrocoll. 2014, 42, 223–228. [Google Scholar] [CrossRef]

- Santana, R.C.; Perrechil, F.A.; Cunha, R.L. High- and low-energy emulsifications for food applications: A focus on process parameters. Food Eng. Rev. 2013, 5, 107–121. [Google Scholar] [CrossRef]

- Yang, Y.; Marshall-Breton, C.; Leser, M.E.; Sher, A.A.; McClements, D.J. Fabrication of ultrafine edible emulsions: Comparison of high-energy and low-energy homogenization methods. Food Hydrocoll. 2012, 29, 398–406. [Google Scholar] [CrossRef]

- Vial, C.; Stiriba, Y.; Trad, Z. CFD simulation of flow and mixing in-inline rotor-stator mixers with complex fluids. Can. J. Chem. Eng. 2014, 93, 391–403. [Google Scholar] [CrossRef]

- Dolinsky, A.A.; Ivanitsky, G.K. Theoretical justification of discrete-pulse energy input principle—I. The model of the dynamics of single vapor bubble. Heat-Process Eng. 1995, 17, 28. [Google Scholar]

- Luhovskyi, O.F.; Chukhraev, N.V. Ultrasonic Cavitation in Modern Technologies; Publishing and Printing Center “Kyiv University”: Kyiv, Ukraine, 2007; 244p. [Google Scholar]

- Vitenko, T.M.; Humnitsky, Y.M. The effect of the vapor-gas phase on the kinetics of dissolution under cavitation conditions. East Eur. J. Adv. Technol. 2009, 3/6, 4–8. [Google Scholar]

- Hinze, J.O. Fundamentals of the hydrodynamic mechanism of splitting in dispersion processes. AIChE J. 1955, 13, 289–295. [Google Scholar] [CrossRef]

- Clark, M.M. Drop breakup in a turbulent flow—II. Experiments in a small mixing vessels. Chem. Eng. Sci. 1988, 43, 681–692. [Google Scholar] [CrossRef]

- Young, C.H.; Korchinsky, W.J. Modelling Drop-side mass transfer in agitated polydispersed liquid-liquid systems. Chem. Eng. Sci. 1989, 44, 2355–2361. [Google Scholar] [CrossRef]

- Hesketh, R.P.; Etchells, A.W.; Russel, T.W.F. Bubble breakage in pipeline flow. Chem. Eng. Sci. 1991, 46, 1–9. [Google Scholar] [CrossRef]

- Lagisetty, J.S.; Das, T.K.; Kumar, R.; Gandhi, K.S. Breakage of viscous and non-Newtonian drops in stirred dispersions. Chem. Eng. Sci. 1986, 41, 65–72. [Google Scholar] [CrossRef]

- Jareš, J.; Prochazka, J. Break-up of droplets in Karr reciproting plate extraction column. Chem. Eng. Sci. 1987, 42, 283–292. [Google Scholar] [CrossRef]

- Dolinsky, A.A.; Ivanitsky, G.K. Heat and Mass Transfer and Hydrodynamics in Vapor-Liquid Media. Thermophysical Fundamentals of Discrete-Impulse Energy Input; Monograph; Naukova Dumka: Kyiv, Ukraine, 2008; 382p. [Google Scholar]

- Basok, B.; Dolinsky, A.; Ivanitsky, G.; Ryzhkova, T. Dynamics of single droplets moving throught liquid media. In Proceedings of the International Symposium on Liquid-Liquid Two-Phase Flow and Transport Phenomena, Antalya, Turkey, 5–10 November 1997; Session 3. pp. 26–28. [Google Scholar]

- Suslick, K.S. Sonochemistry. In Kirk-Othmer Enciclopedia of Cemical Technology, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1996; p. 516. [Google Scholar]

- Suslick, K.S. Sonochemistry. Science 1990, 247, 1439–1445. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, G.; Nie, Y.; Ji, J. Hydrodynamic cavitation as an efficient method for the formation of sub-100 nm O/W emulsions with high stability. Chin. J. Chem. Eng. 2016, 24, 1477–1480. [Google Scholar] [CrossRef]

- Agrawal, N.; Maddikeri, G.L.; Pandit, A.B. Sustained release formulations of citronella oil nanoemulsion using cavitational techniques. Ultrason. Sonochem. 2017, 36, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Carpenter, J.; George, S.; Saharan, V.K. Low pressure hydrodynamic cavitating device for producing highly stable oil in water emulsion: Effect of geometry and cavitation number. Chem. Eng. Process. Process Intensif. 2017, 116, 97–104. [Google Scholar] [CrossRef]

- Crudo, D.; Bosco, V.; Cavaglia, G.; Mantegna, S.; Battaglia, L.; Cravotto, G. Process Intensification in the food industry: Hydrodynamic and acoustic cavitation in fresh milk treatment. Process intensification. Agro Food Ind. Hi Tech 2014, 25, 55–59. [Google Scholar]

- Matsumiya, K.; Horiguchi, S.; Kosugi, T.; Mutoh, T.A.; Nambu, Y.; Nishimura, K.; Matsumura, Y. Effects of heat treatment and homogenization on milk fat globules and proteins in whipping creams. Food Struct. 2017, 12, 94–102. [Google Scholar] [CrossRef]

- Aval, M.Z.; Akbarian, M.; Hosseinpou, A. Nano cavitation: A novel technology in food science to improve edible oil, nanoemulsion, dairy production and water treatment: A review. Indian J. Fundam. Appl. Life Sci. 2016, 6, 651–656, ISSN 22316345. Available online: www.cibtech.org/sp.ed/jls/2016/02/jls.htm (accessed on 20 July 2021).

- Phipps, L.W. Cavitation and separated flow in a simple homogenizing valve and their influence on the break-up of fat globules in milk. J. Dairy Res. 1974, 41, 1–8. [Google Scholar] [CrossRef]

- Vitenko, T.; Drozdziel, P.; Horodyskyi, N. Numerical modeling of a static cavitation module. Appl. Mech. Mater. 2016, 817, 64–69. [Google Scholar] [CrossRef]

- Vitenko, T.; Drozdziel, P.; Gorodysky, N. Erosive impact of vapor-gas phase on the working surface in hydrodynamic type cavitation mode. Diagnostyka 2016, 17, 3–8. [Google Scholar]

- Jasinska, M.; Bałdyga, J.; Cooke, M.; Kowalski, A.J. Specific features of power characteristics of in-line rotor–stator mixers. Chem. Eng. Process. 2015, 91, 43–56. [Google Scholar] [CrossRef]

- Santana, R.C.; Perrechil, F.A.; Sato, A.C.K.; Cunha, R.L. Emulsifying properties of collagen fibers: Effect of pH, protein concentration and homogenization pressure. Food Hydrocoll. 2011, 25, 604–612. [Google Scholar] [CrossRef]

- Gazolu-Rusanova, D.; Lesov, I.; Tcholakova, S.; Denkov, N.; Ahtchi, B. Food grade nanoemulsions preparation by rotor-stator homogenization. Food Hydrocoll. 2019, 102, 105579. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Guan, X.; Ren, Y.; Yang, N.; Li, J.; Kunkelmann, C.; Schreiner, E.; Holtze, C.; Mülheims, K.; Sachweh, B. Mesoscale modeling of emulsification in rotor-stator devices. Chem. Eng. Sci. 2019, 193, 171–183. [Google Scholar] [CrossRef]

- El-Jaby, U.; McKenna, T.F.L.; Cunningham, F.M. Miniemulsification—An analysis of the use of rotor stators as emulsification devices. Macromol. Symp. 2007, 259, 1–9. [Google Scholar] [CrossRef]

- El-Jaby, U.; Cunningham, M.; McKenna, T.F.L. Comparison of emulsification devices for the production of miniemulsions. Ind. Eng. Chem. Res. 2009, 48, 10147–10151. [Google Scholar] [CrossRef]

- Kumar, K.S.; Moholkar, V.S. Conceptual design of a novel hydrodynamic cavitation reactor. Chem. Eng. Sci. 2007, 62, 2698–2711. [Google Scholar] [CrossRef]

- Gogate, P.R.; Pandit, A.B. Engineering design methods for cavitation reactors II: Hydrodynamic cavitation. AIChE J. 2000, 46, 1641–1649. [Google Scholar] [CrossRef]

- Pegu, K.; Arya, S.S. Comparative assessment of HTST, hydrodynamic cavitation and ultrasonication on physico-chemical properties, microstructure, microbial and enzyme inactivation of raw milk. Innov. Food Sci. Emerg. Technol. 2021, 69, 102640. [Google Scholar] [CrossRef]

- Dastane, G.G.; Thakkar, H.; Shah, R.; Perala, S.; Raut, J.; Pandit, A.B. Single and multiphase CFD simulations for designing cavitating venturi. Chem. Eng. Res. Des. 2009, 149, 1–12. [Google Scholar] [CrossRef]

- Gazes, N. A magnetostriction oscillator producing intense audible sound and some effects obtained. J. Appl. Phys. 1932, 3, 209–229. [Google Scholar]

- Chambers, L.A. Soft curd character induced in milk by intense sonic vibration. J. Dairy Sci. 1936, 19, 29–47. [Google Scholar] [CrossRef]

- Chambers, L.A. Sonic homogenization of milk and ice cream mix. J. Dairy Sci. 1937, 20, 450–451. [Google Scholar]

- Söllner, K. Experiments to demonstrate cavitation caused by ultrasonic waves. Trans. Faraday Soc. 1936, 32, 1537–1539. [Google Scholar] [CrossRef]

- Ertugay, M.F.; Sengul, M.; Sengul, M. Effect of ultrasound treatment on milk homogenization and particle size distribution of fat. Turk. J. Vet. Anim. Sci. 2004, 28, 303–308. [Google Scholar]

- Bosiljkov, T.; Tripalo, B.; Brincic, M.; Jezek, D.; Karlovic, S.; Jagust, I. Influence of high intensity ultrasound with different probe diameter on the degree of homogenization (variance) and physical properties of cow milk. Afr. J. Biotechnol. 2011, 10, 34–41. [Google Scholar]

- Nakorchevskiy, A.I.; Basok, B.I.; Ryzhova, T.S. Hydrodynamics of rotary-pulsation devices. IFZh 2002, 75, 58–68. [Google Scholar]

- Qian, C.; McClements, D.J. Formation of nanoemulsions stabilized by model food-grade emulsifiers using high-pressure homogenization: Factors affecting particle size. Food Hydrocoll. 2011, 25, 1000–1008. [Google Scholar] [CrossRef]

- Lee, S.J.; McClements, D.J. Fabrication of protein-stabilized nanoemulsions using a combined homogenization and amphiphilic solvent dissolution/evaporation approach. Food Hydrocoll. 2010, 24, 560–569. [Google Scholar] [CrossRef]

- Jafari, S.M.; He, Y.; Bhandari, B. Optimization of nano-emulsions production by microfluidization. Eur. Food Res. Technol. 2006, 225, 733–741. [Google Scholar] [CrossRef]

- Ramisetty, K.A.; Shyamsunder, R. Effect of ultrasonication on stability of oil in water emulsions. Int. J. Drug Deliv. 2011, 3, 133–142. [Google Scholar]

- Wooster, T.J.; Golding, M.; Sanguansri, P. Impact of oil type on nanoemulsion formation and ostwald ripening stability. Langmuir 2008, 24, 12758–12765. [Google Scholar] [CrossRef]

- Yuan, Y.; Gao, Y.; Zhao, J.; Mao, L. Characterization and stability evaluation of β-carotene nanoemulsions prepared by high pressure homogenization under various emulsifying conditions. Food Res. Int. 2008, 41, 61–68. [Google Scholar] [CrossRef]

- Leong, T.S.H.; Wooster, T.J.; Kentish, S.E.; Ashokkumar, M. Minimising oil droplet size using ultrasonic emulsification. Ultrason. Sonochem. 2009, 16, 721–727. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vitenko, T.; Droździel, P.; Horodysky, N. Hydrodynamics features in cavitation devices under tangent medium input. In Proceedings of the Innovative Technologies in Engineering Production (ITEP’18), Bojnice, Slovak Republic, 11–13 September 2018; Volume 244. [Google Scholar]

- Mourad, G.; Bettache, G.; Samir, M. Composition and nutritional value of raw milk. J. Issues Biol. Sci. Pharm. Res. 2014, 2350, 1588. [Google Scholar] [CrossRef]

- Mulder, H.; Walstra, P. The Milk Fat Globule. Emulsion Science as Applied to Milk Products and Comparable Foods; Commonwealth Agricultural Bureaus Farmham Royal: Backs, UK; Centre for Agricultural Publishing and Documentation: Wageningen, The Netherlands, 1974; 296p.

- Ukraine Import and Manufacturing. DSTU 2857-94: Thermoelectric Converters. General Specifications; Ukraine Import and Manufacturing: Kyiv, Ukraine, 1994.

- GOST. GOST 2405-88: Pressure Gauges, Vacuum Gauges, Pressure-Vacuum Gauges, Pressure Meters, Draft Gauges and Draft-Pressure Gauges; Standartinform: Moscow, Russia, 2008.

- Brinkhorst, S.; Von Lavante, E.; Güler, D.; Wendt, G. Experimental investigation of cavitating herschel venturi-tube configuration. In Proceedings of the 17th International Flow Measurement Conference, Sydney, Australia, 26–29 September 2016. [Google Scholar]

- Kolmogorov, A.N. The crushing of droplets in a turbulent flow. Rep. AN SSSR 1949, 66, 825–828. [Google Scholar]

- Baranaev, M.K.; Teverovskiy, E.N.; Tregubova, E.L. On the size of minimal pulsations in a turbulent flow. DAN 1949, 66, 821–824. [Google Scholar]

- Grace, H. Dispersion phenomena in high viscosity immiscible fluid systems and application of static mixers as dispersion devices in such systems. Chem. Eng. Commun. 1982, 14, 225–277. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Gandhi, K.S. Alternative mechanism of drop breakage in stirred vessels. Chem. Eng. Sci. 1991, 46, 2483–2490. [Google Scholar] [CrossRef]

- Clark, M.M. Drop breakup in a turbulent flow. I. Conceptual and modeling considerations. Chem. Eng. Sci. 1988, 43, 671–679. [Google Scholar] [CrossRef]

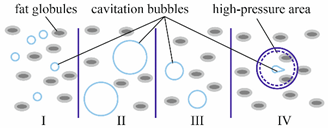

| Turbulent drop dispersion: isotropic and viscous. The mechanism of isotropic dispersion turbulence is followed by the stress fluctuations caused by the microvorticity. Under the viscous mechanism it is caused by the shear stress of greater vorticity [60] (turbulent regime zone). Turbulence caused by the pulsation and buffeting of the vapor–gaseous cavitation bubbles. |  |

| In the cavitation zone, fluctuation cavitation bubbles arise, which, colliding with the dispersion phase drops, are buffeting. Cumulation sprays formed in the bubbles strike the fat globule and break it into small ones. The fat globule pulls into the bubble and crashes into the dispersion phase fat globule. |  |

| Fat phase dispersion caused by the high location pressure differential (impact waves) during the cavitation bubbles buffeting. I—cavitation bubble formation, II—bubble of the maximum size, III—sizes decrease, IV—bubble explosion followed by the cumulation spray. |  |

| Circulation Cycle | Mechanical Processing of the Product (Number of Cycles) | |||

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | |

| 0 | ||||

| 1 | ||||

| 2 | ||||

| 3 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Droździel, P.; Vitenko, T.; Voroshchuk, V.; Narizhnyy, S.; Snizhko, O. Discrete-Impulse Energy Supply in Milk and Dairy Product Processing. Materials 2021, 14, 4181. https://doi.org/10.3390/ma14154181

Droździel P, Vitenko T, Voroshchuk V, Narizhnyy S, Snizhko O. Discrete-Impulse Energy Supply in Milk and Dairy Product Processing. Materials. 2021; 14(15):4181. https://doi.org/10.3390/ma14154181

Chicago/Turabian StyleDroździel, Paweł, Tetiana Vitenko, Viktor Voroshchuk, Sergiy Narizhnyy, and Olha Snizhko. 2021. "Discrete-Impulse Energy Supply in Milk and Dairy Product Processing" Materials 14, no. 15: 4181. https://doi.org/10.3390/ma14154181

APA StyleDroździel, P., Vitenko, T., Voroshchuk, V., Narizhnyy, S., & Snizhko, O. (2021). Discrete-Impulse Energy Supply in Milk and Dairy Product Processing. Materials, 14(15), 4181. https://doi.org/10.3390/ma14154181