Modification of the Properties of Polymer Composites in a Constant Magnetic Field Environment

Abstract

:1. Introduction

2. Materials and Methods

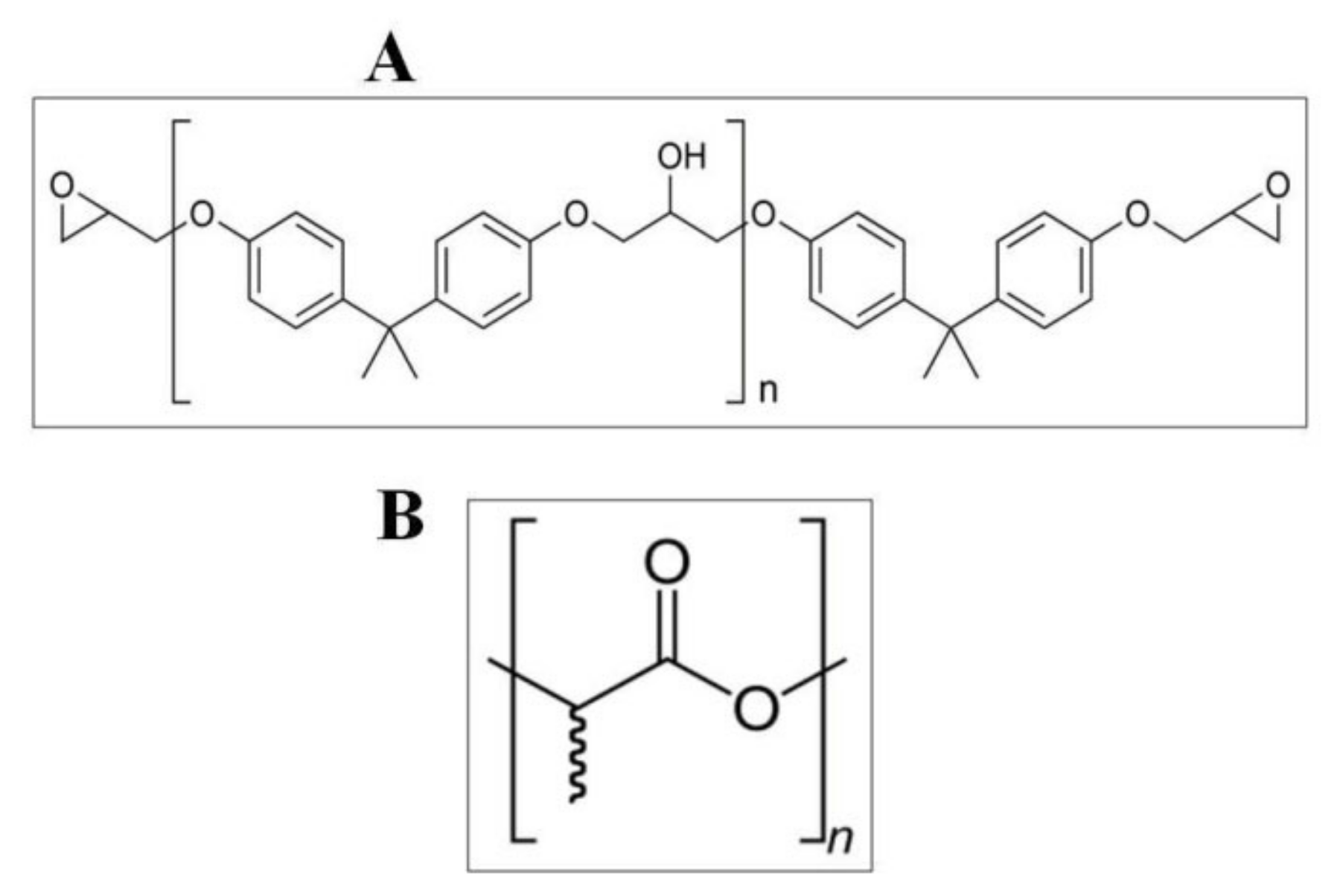

2.1. Preparation of Components

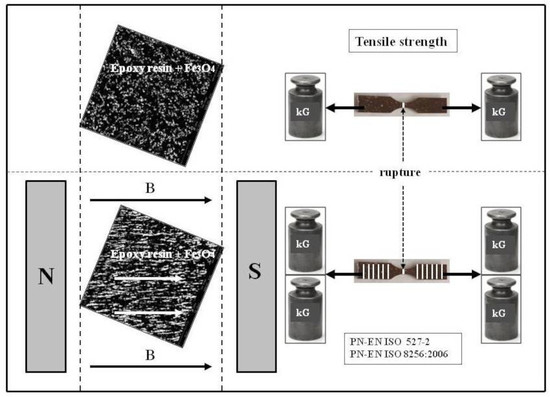

2.2. Preparation of Test Samples and Testing Procedure

2.3. Testing Methodology

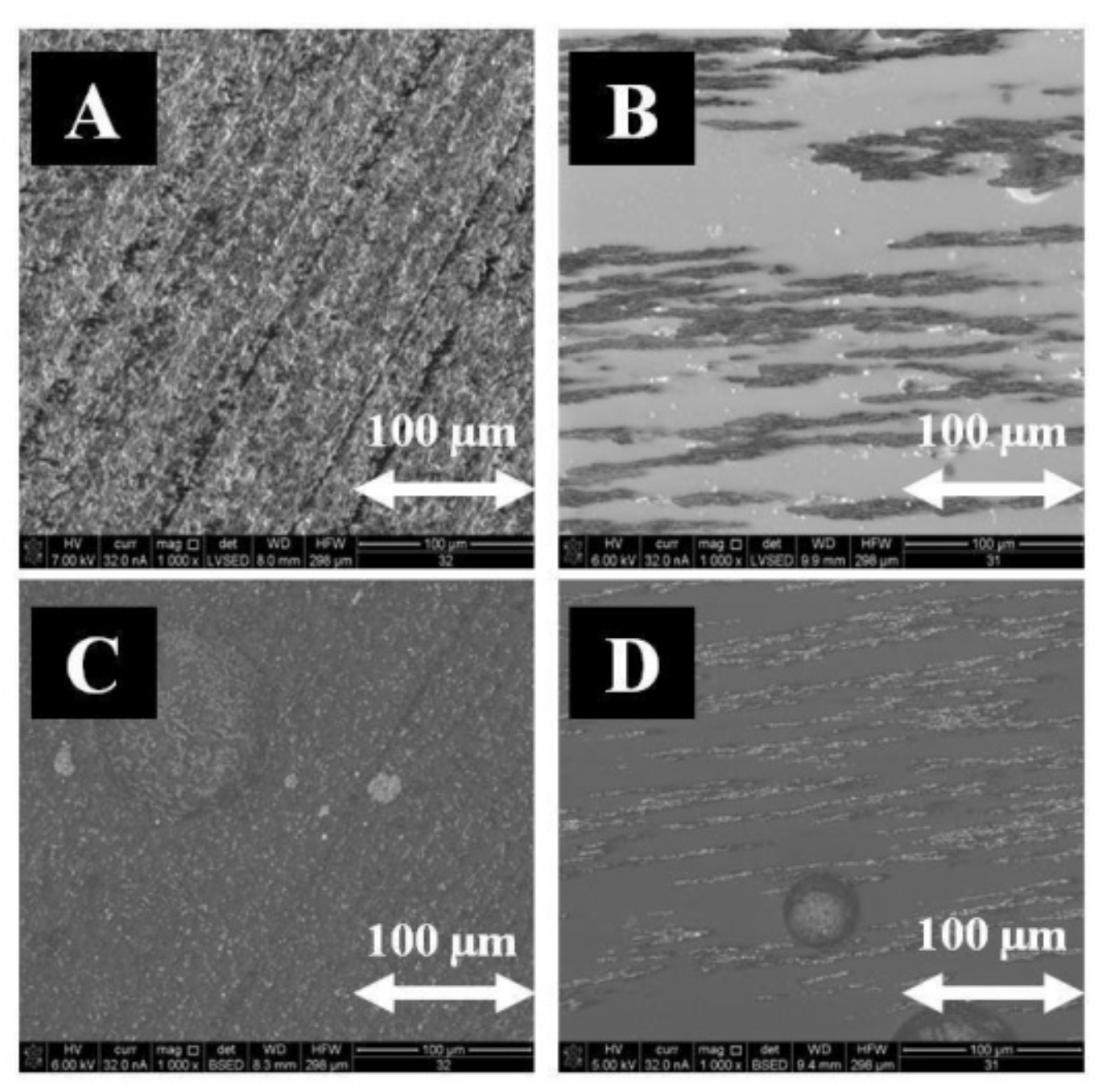

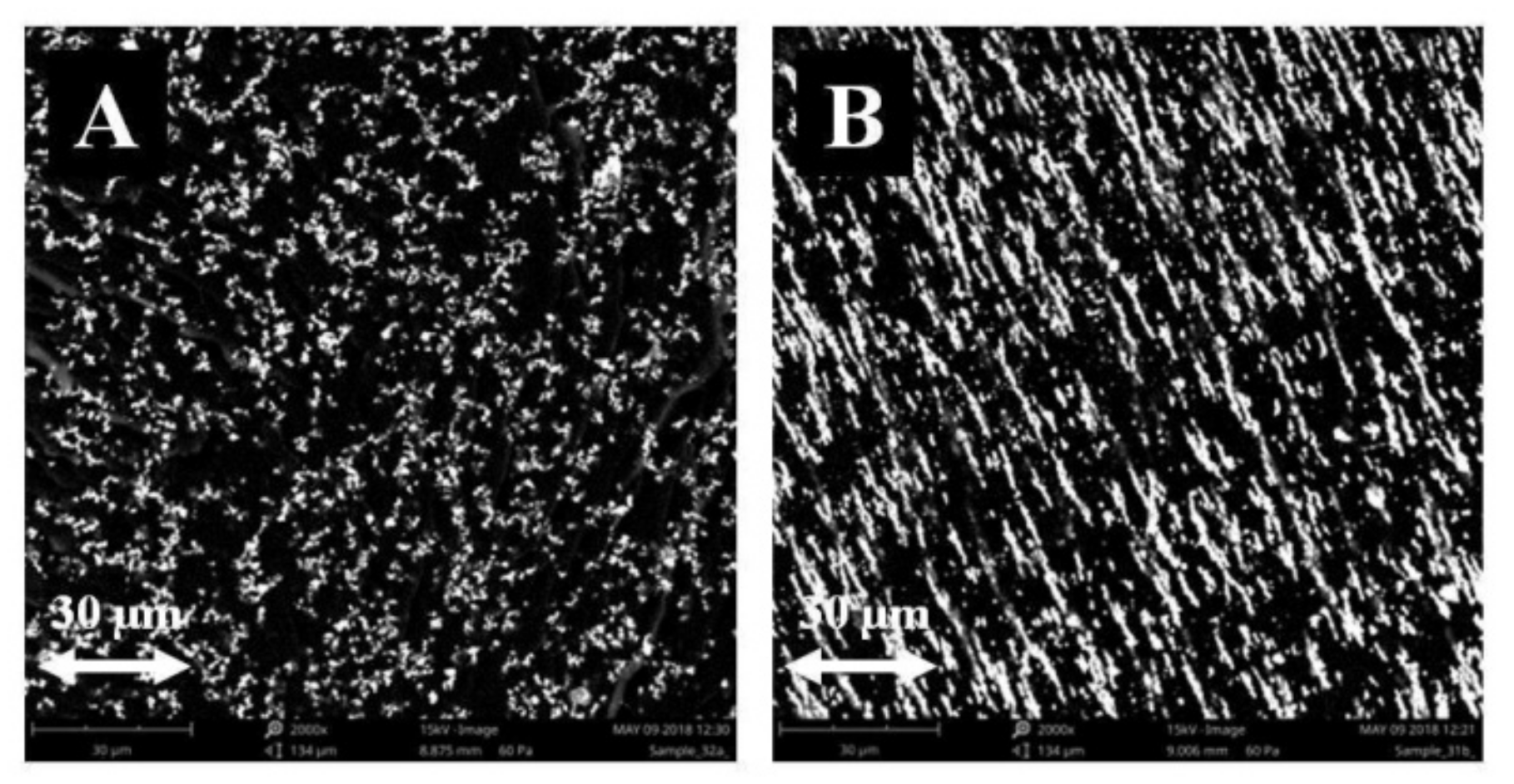

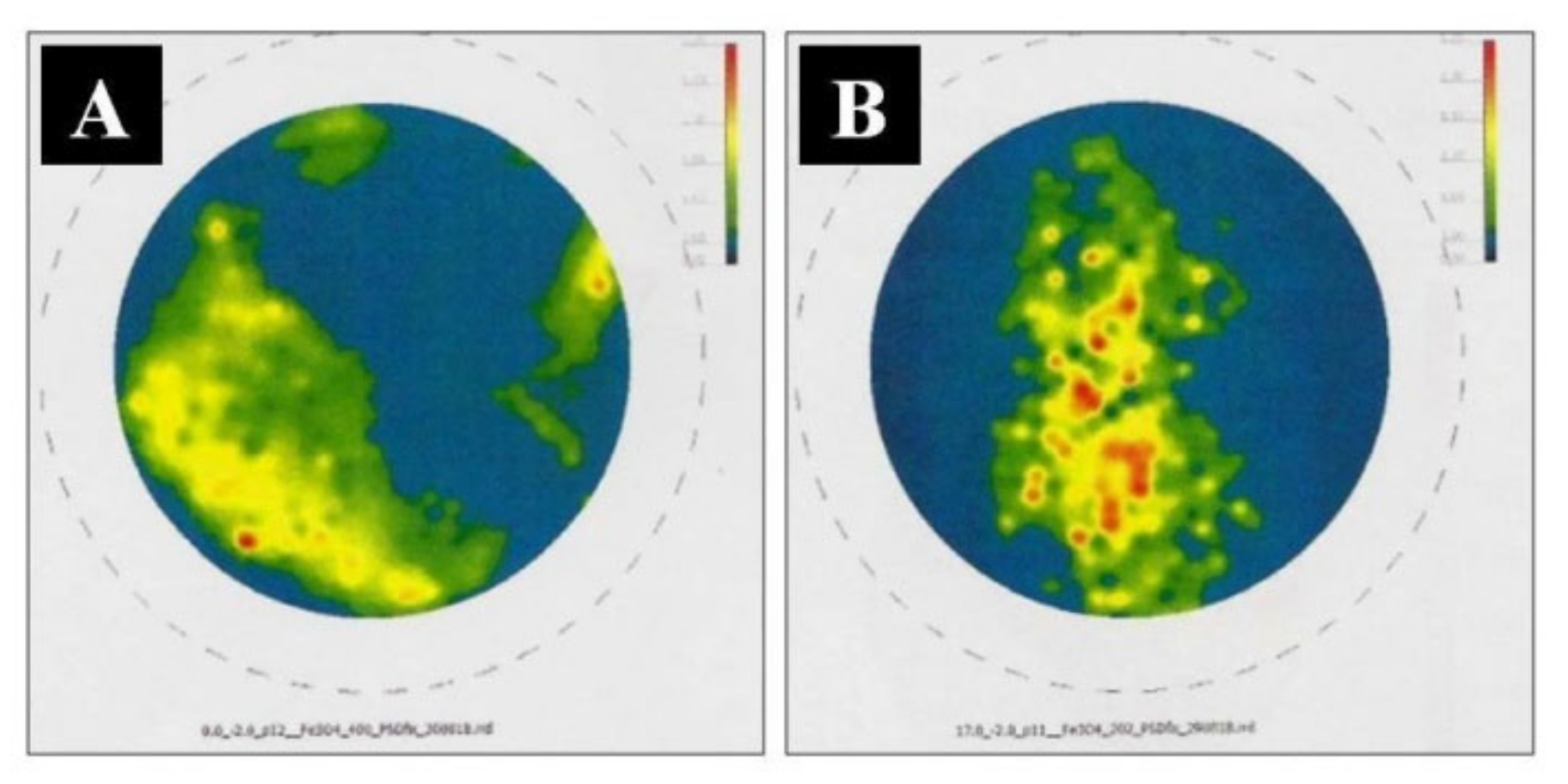

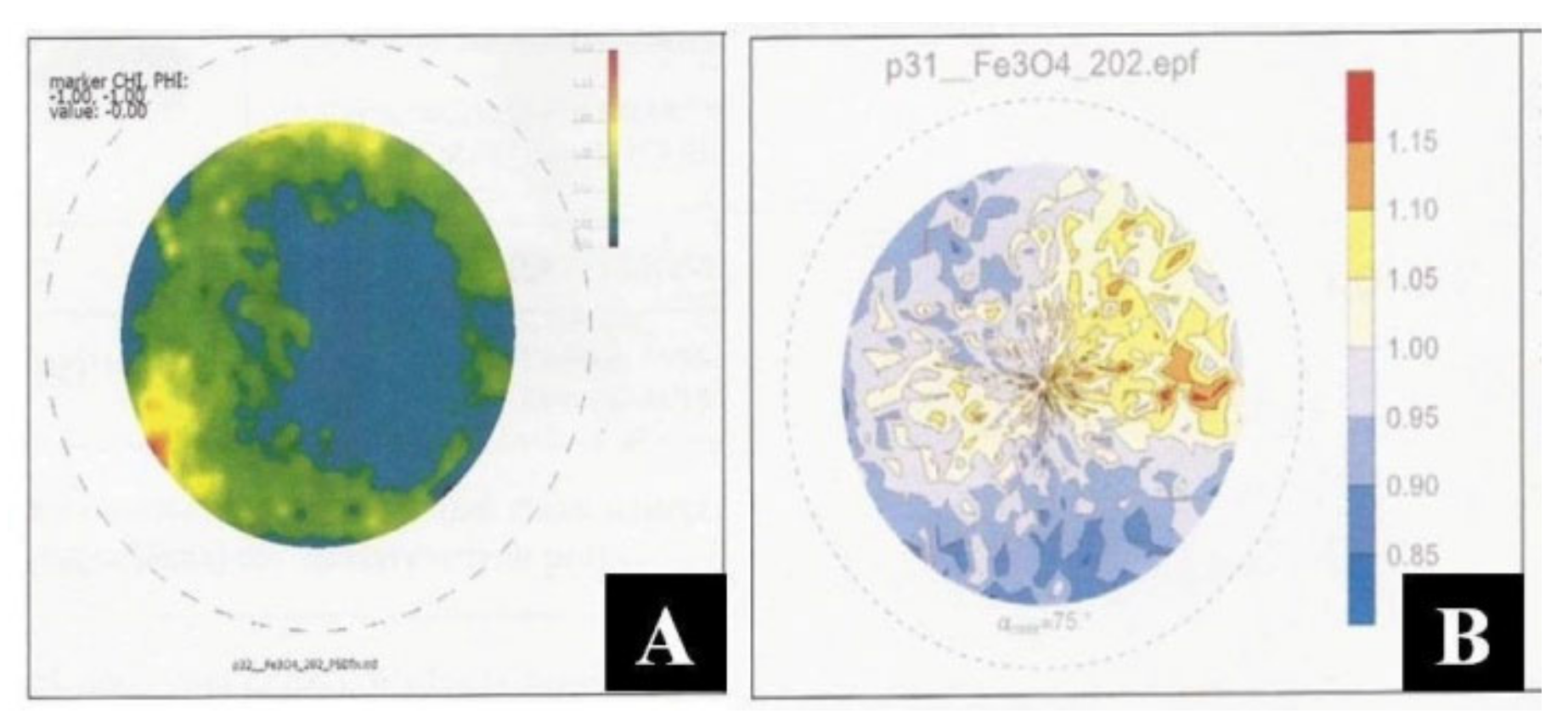

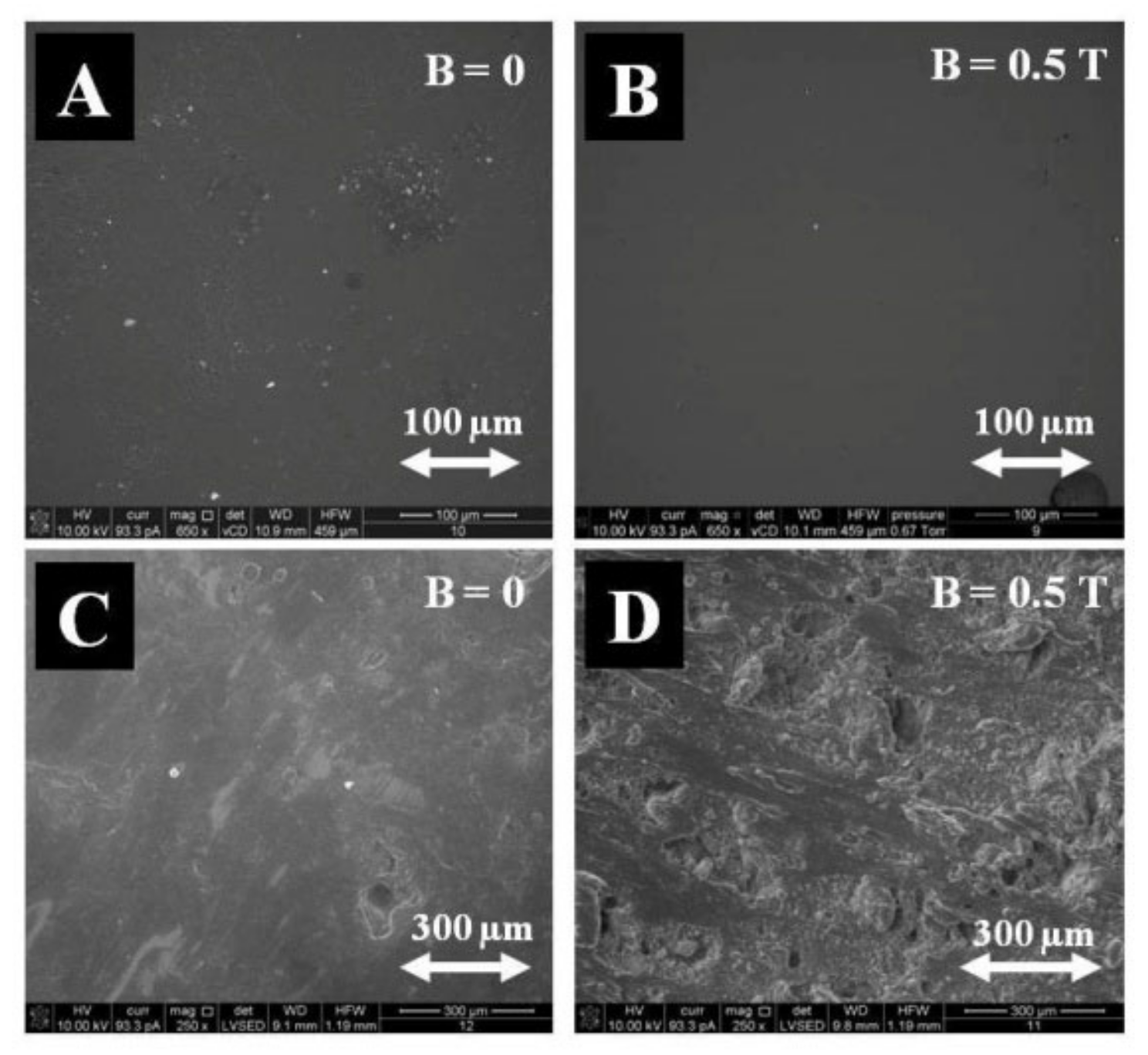

3. Results and Discussion

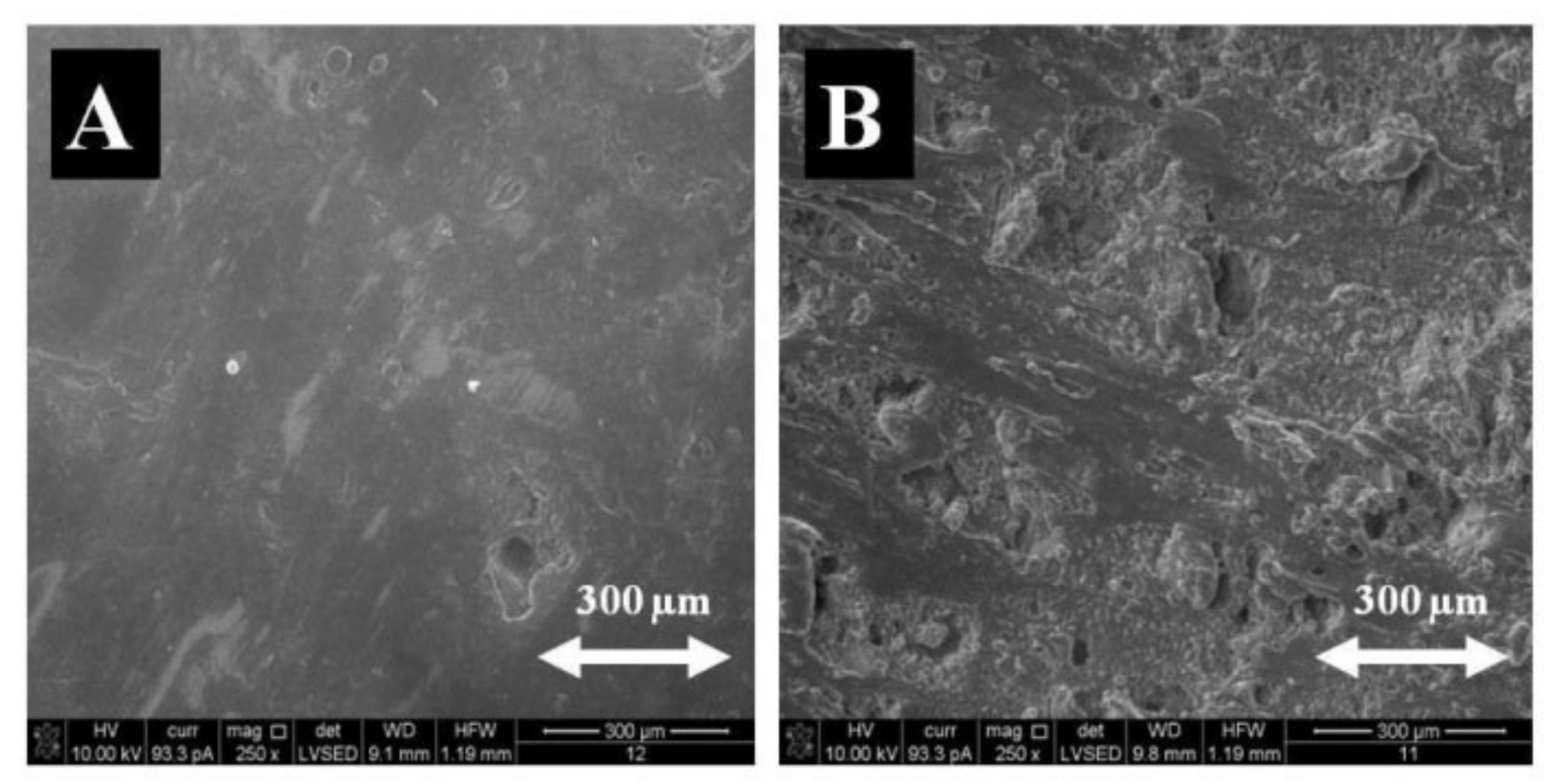

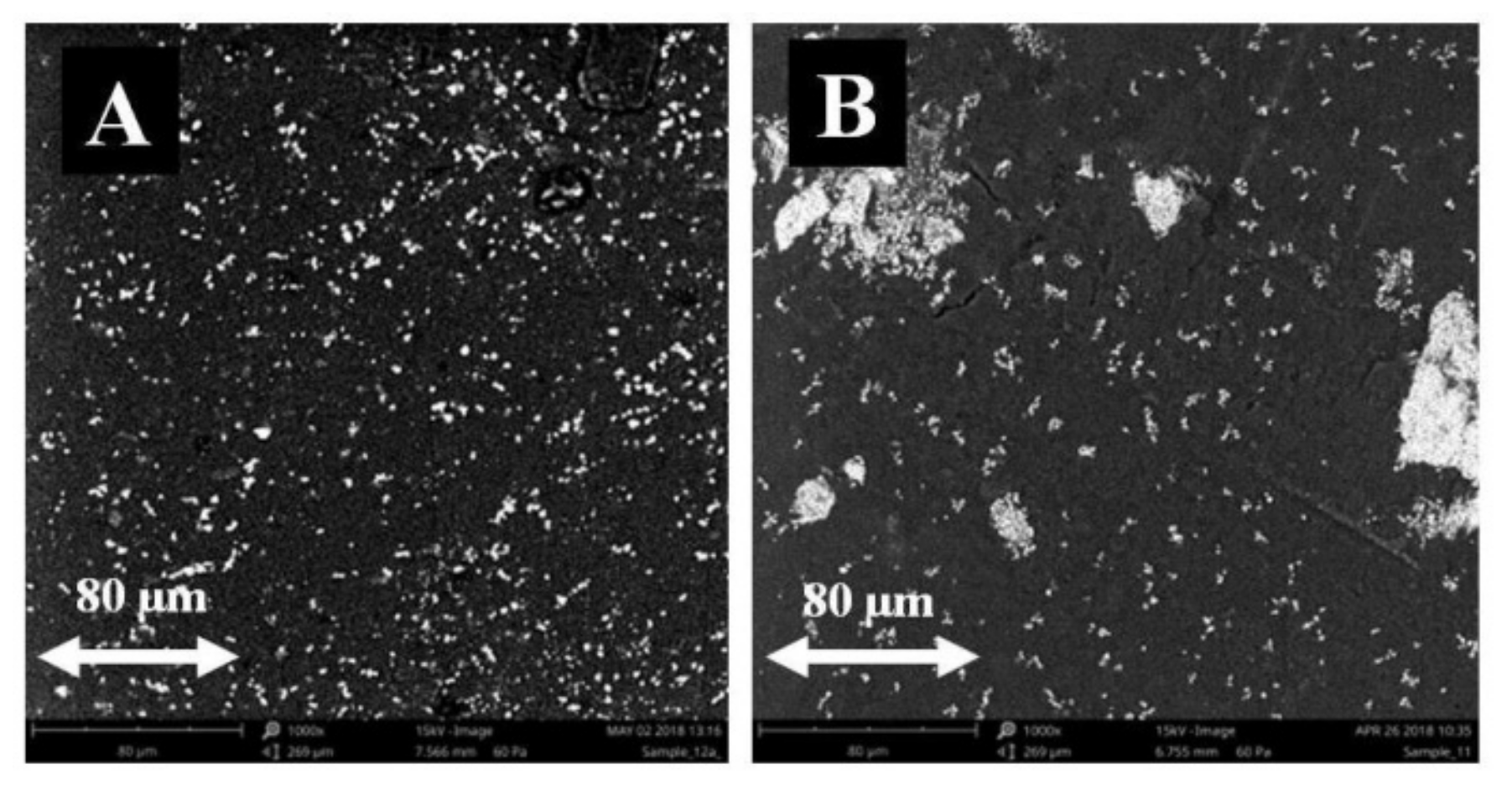

3.1. Effect of the Type of Polymer Used on Change in the Properties of the Resultant Composites in a Constant Magnetic Field and without a Magnetic Field

3.2. Effect of the Type of Filler Added to the Polymer on Change in the Properties of the Resultant Composites Obtained in a Constant Magnetic Field and without a Magnetic Field

3.3. Effect of the Percentage of Filler Added to the Polymer on Change in the Properties of the Resultant Composites in a Constant Magnetic Field and without a Magnetic Field

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. 2009, 364, 1977–1984. [Google Scholar] [CrossRef] [PubMed]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Cozar, A.; Echevarria, F.; Gonzalez-Gordillo, J.I.; Irigoien, X.; Ubeda, B.; Hernandez-Leon, S.; Palma, A.T.; Navarro, S.; Garcia-de-Lomas, J.; Ruiz, A.; et al. Plastic debris in the open ocean. Proc. Natl. Acad. Sci. USA 2014, 111, 10239–10244. [Google Scholar] [CrossRef] [Green Version]

- Mallakpour, S.; Sirous, F.; Mustansar Hussain, C. A journey to the world of fascinating ZnO nanocomposites made of chitosan, starch, cellulose, and other biopolymers: Progress in recent achievements in eco-friendly food packaging, biomedical, and water remediation technologies. Int. J. Biol. Macromol. 2021, 170, 701–716. [Google Scholar] [CrossRef] [PubMed]

- Kukhta, A.V.; Kuzhir, P.P.; Maksimenko, S.A.; Vorobyova, S.A.; Kukhta, I.N.; Pochtenny, A.E.; Taoubi, M.I.; Bistarelli, S.; Bellucci, S. Alignment of polymer based magnetic composites in magnetic field. Prog. Org. Coat. 2019, 137, 105366. [Google Scholar] [CrossRef]

- Kharissova, O.V.; García, B.O.; Kharisov, B.I.; Méndez, U.O. Magnetic-graphene-based nanocomposites and respective applications. In Advances in Carbon Nanostructures; Adrian, M.T., Silva, A., Carabineiro, S., Eds.; IntechOpen: London, UK, 2016. [Google Scholar]

- Zhou, G.; Wang, D.-W.; Zhang, V.; Wu, Z.-S.; Wen, L.; Lu, G.Q.; Cheng, H.-M. Graphene—wrapped Fe3O4 anode material with improved reversible capacity and cyclic stability for lithium ion batteries. Chem. Mater. 2010, 22, 5306–5313. [Google Scholar] [CrossRef]

- Renteria, J.; Legedza, S.; Salgado, R.; Balandin, M.P.; Ramirez, S.; Saadah, M.; Kargar, F.; Balandin, A.A. Magnetically-functionalized self-aligning graphene fillers for high efficiency thermal management applications. Mater. Des. 2015, 88, 214–221. [Google Scholar] [CrossRef] [Green Version]

- Mishra, A.; Singh, V.K.; Mohanty, T. Coexistence of interfacial stress and chargé transfer in graphene oxide-based magnetic nanocomposites. J. Mat. Sci. 2017, 52, 7677–7687. [Google Scholar] [CrossRef]

- Diaz-Bleis, D.; Vales-Pinzón, C.; Freile-Pelegrín, Y.; Alvarado-Gil, J.J. Thermal characterization of magnetically aligned carbonyl iron/agar Composites. Carbohydr. Polym. 2014, 99, 84–90. [Google Scholar] [CrossRef] [PubMed]

- Abshinova, M.A.; Lopatin, A.V.; Kazantseva, N.E.; Vilcáková, J.; Sáha, P. Correlation between the microstructure and the electromagnetic properties of carbonyl iron filled polymer composites. Compos. Part A 2007, 38, 2471–2485. [Google Scholar] [CrossRef]

- Filipcsei, G.; Csetneki, I.; Sziágyi, A.; Zrínyi, M. Magnetic field-responsive smart polymer composites. Adv. Polym. Sci. 2007, 206, 137–189. [Google Scholar]

- Jordan, A.; Scholz, R.; Wust, P.; Fahling, H.; Felix, R. Magnetic fluid hyperthermia (MFH): Cancer treatment with AC magnetic field induced excitation of biocompatible superparamagnetic nanoparticles. J. Magn. Magn. Mater. 1999, 201, 413–419. [Google Scholar] [CrossRef]

- Xia, C.; Peng, Y.; Yi, X.; Yao, Z.; Zhu, Y.; Hu, G. Improved magnetic properties of FeSiCr amorphous soft magnetic composites by adding carbonyl iron powder. J. Non-Cryst. Solids 2021, 559, 120673. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perigo, E.A.; Weidenfeller, B.; Kollar, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 1–37. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.Q.; Liu, L.; Chi, Q.; Zhang, Y.Q.; Chang, L.; Bi, F.Q.; Wang, X.M. The core-shell structured Fe-based amorphous magnetic powder cores with excellent Magnetic properties. Adv. Powder Technol. 2019, 30, 1504–1512. [Google Scholar] [CrossRef]

- Zheng, Y.Y.; Wang, Y.G.; Xia, G.T. Amorphous soft magnetic composite-cores with various orientations of the powder-flakes. J. Magn. Magn. Mater. 2015, 396, 97–101. [Google Scholar] [CrossRef]

- Chybczyńska, K.; Markiewicz, E.; Grząbka-Zasadzińska, A.; Borysiak, S. Dielectric, magnetic, and mechanical properties of composites consisting of biopolymer chitosan matrix and hybrid spinel/cellulose filler. Ceram. Int. 2019, 45, 9468–9476. [Google Scholar] [CrossRef]

- Bensebaa, F.; Zavaliche, F.; L’Ecuyer, P.; Cochrane, R.W.; Veres, T. Microwave synthesis and characterization of Co-ferrite nanoparticles. J. Colloid Interface Sci. 2004, 277, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Galland, S.; Andersson, R.L.; Salajkova, M.; Strom, V.; Olsson, R.T.; Berglund, L.A. Cellulose nanofibers decorated with magnetic nanoparticles-synthesis, structure and use in magnetized high toughness membranes for a prototype loudspeaker. J. Mater. Chem. 2013, C1, 7963–7972. [Google Scholar] [CrossRef] [Green Version]

- Babaei-Ghazvini, A.; Cudmore, B.; Dunlop, M.J.; Acharya, B.; Bissessur, R.; Ahmed, M.; Whelan, W.M. Effect of magnetic field alignment of cellulose nanocrystals in starch nanocomposites: Physicochemical and mechanical properties. Carbohydr. Polym. 2020, C1, 116688. [Google Scholar] [CrossRef]

- Chung, J.; Lee, J.; Baek, Y.; Shin, P.; Kim, Y. Magnetic field-induced enhancement of thermal conductivities in polymer composites by linear clustering of spherical particles. Composites 2018, 136, 215–221. [Google Scholar] [CrossRef]

- Fang, W.X.; He, Z.H.; Xu, X.Q.; Mao, Z.Q.; Shen, H. Magnetic-field-induced chain-like assembly structures of Fe3O4 nanoparticles. Europhys. Lett. 2007, 77, 68004. [Google Scholar] [CrossRef]

- Wang, M.; He, L.; Yin, Y. Magnetic field guided colloidal assembly. Mater. Today 2013, 16, 110–116. [Google Scholar] [CrossRef]

- Andreu, J.S.; Camacho, J.; Faraudo, F. Aggregation of superparamagnetic colloids in magnetic fields: The quest for the equilibrium state. Soft Matter. 2011, 7, 2336–2339. [Google Scholar] [CrossRef] [Green Version]

- Faraudo, J.; Andreu, J.S.; Calero, C.; Camacho, J. Predicting the self-assembly of superparamagnetic colloids under magnetic fields. Adv. Funct. Mater. 2016, 26, 3837–3858. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Rashidi, M.M.; Ganji, D.D. Effect of non-uniform magnetic field on forced convection heat transfer of Fe3O4-water nanofluid. Comput. Methods Appl. Mech. Eng. 2015, 294, 299–312. [Google Scholar] [CrossRef]

- Patel, J.; Parekh, K.; Upadhyay, R.V. Maneuvering thermal conductivity of magnetic nanofluids by tunable magnetic fields. J. Appl. Phys. 2015, 117, 243906. [Google Scholar] [CrossRef]

- Hu, S.; Hou, L.; Wang, K.; Liaoa, Z.; Fautrelle, Y.; Li, W.; Li, X. Formation mechanism of Gradient structure of aluminum matrix composite under static magnetic field during directional solidification. J. Mater. Res. Technol. 2020, 9, 4459–4468. [Google Scholar] [CrossRef]

- Lehmann, P.; Moreau, R.; Camel, D.; Bolcato, R. Modification of interdendritic Convection In directional solidification by a uniform magnetic field. Acta Mater. 1998, 46, 4067–4079. [Google Scholar] [CrossRef]

- Al-Harbi, L.M.; Darwish, M.S.A.; Khowdiary, M.M.; Stibor, I. Controlled Preparation of Thermally Stable Fe-Poly(dimethylsiloxane) Composite by Magnetic Induction Heating. Polymers 2018, 10, 507. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Lu, Q.; Lee, J.Y.; Choi, H.J. Polymer-Magnetic Composite Particles of Fe3O4/Poly(o-anisidine) and Their Suspension Characteristics under Applied Magnetic Fields. Polymers 2019, 11, 219. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hara, S.; Watanabe, S.; Takahashi, K.; Shimizu, S.; Ikake, H. Preparation of Crystallites for Oriented Poly(Lactic Acid) Films Using a Casting Method under a Magnetic Field. Polymers 2018, 10, 1083. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Umehara, Y.; Yamanaga, Y.; Akama, S.; Kato, S.; Kamoshita, S.; Kawai, M.; Mitsumata, T. Railway Actuator Made of Magnetic Elastomers and Driven by a Magnetic Field. Polymers 2018, 10, 1351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kusumi, R.; Teranishi, S.; Kimura, F.; Wada, M.; Kimura, T.; Horikawa, Y.; Kawai, T. Crystal Orientation of Poly(L-Lactic Acid) Induced by Magnetic Alignment of a Nucleating Agent. Polymers 2018, 10, 653. [Google Scholar] [CrossRef] [Green Version]

- Mohr, R.; Kratz, K.; Weigel, T.; Lucka-Gabor, M.; Moneke, M.; Lendlein, A. Initiation of shape-memory effect by inductive heating of magnetic nanoparticles in thermoplastic polymers. Proc. Natl. Acad. Sci. USA 2006, 103, 3540–3545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kudisch, B.; Maiuri, M.; Moretti, L.; Oviedo, M.B.; Wangf, L.; Oblinsky, D.G.; Prud’hommef, R.K.; Wong, B.M.; McGill, S.A.; Scholes, G.D. Ring currents modulate optoelectronic properties of aromatic chromophores at 25 T. Proc. Natl. Acad. Sci. USA 2020, 117, 11289–11298. [Google Scholar] [CrossRef]

- Tellgren, E.I.; Laestadius, A.; Helgaker, T.; Kvaal, S.; Teale, A.M. Uniform magnetic fields in density-functional theory. J. Chem. Phys. 2018, 148, 024101. [Google Scholar] [CrossRef]

- Ashkan, S.; Ziabari, M.; Babamoradi, M.; Hajizadeh, Z.; Maleki, A. The effect of magnetic field on the magnetic and hyperthermia properties of bentonite/Fe3O4 nanocomposite. Physica B 2020, 588, 412167. [Google Scholar]

- Zverev, V.S.; Gupalo, M.A.; Mauser, N.J.; Kantorovich, S.S.; Novak, E.V. The influence of an applied magnetic field on the clusters formed by Stockmayer supracolloidal magnetic polymers. J. Magn. Magn. Mater. 2021, 521, 167445. [Google Scholar] [CrossRef]

- Majewski, P.W.; Gopinadhan, M.; Osuji, C.O. The Effects of Magnetic Field Alignment on Lithium Ion Transport in a Polymer Electrolyte Membrane with Lamellar Morphology. Polymers 2019, 11, 887. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamato, M.; Kimura, T. Magnetic Processing of Diamagnetic Materials. Polymers 2020, 12, 1491. [Google Scholar] [CrossRef] [PubMed]

- Ramajo, L.A.; Cristóbal, A.A.; Botta, P.M.; Porto López, J.M.; Reboredo, M.M.; Castro, M.S. Dielectric and magnetic response of Fe3O4/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 388–393. [Google Scholar] [CrossRef]

- Ghigna, T.; Zannoni, M.; Jones, M.E.; Simonetto, A. Permittivity and permeability of epoxy–magnetite powder composites at microwave frequencies. J. Appl. Phys. 2020, 127, 045102. [Google Scholar] [CrossRef] [Green Version]

- Klapiszewski, Ł.; Podkościelna, B.; Goliszek, M.; Kubiak, A.; Młynarczyk, K.; Jesionowski, T. Synthesis, characterization and aging tests of functional rigid polymeric biocomposites with kraft lignin. Int. J. Biol. Macromol. 2021, 178, 344–353. [Google Scholar] [CrossRef]

- Borowski, G.; Klepka, T.; Pawłowska, M.; Lavagnolo, M.C.; Oniszczuk, T.; Wójtowicz, A.; Combrzyński, M. Effect of flax fibers addition on the mechanical properties and biodegradability of biocomposites based on thermoplastic starch. Arch. Environ. Prot. 2020, 46, 74–82. [Google Scholar]

| Magnetic Induction | Area Number | Carbon (C) | Oxygen (O) | Iron (Fe) |

|---|---|---|---|---|

| B = 0 T | 1 | 48.58 | 49.30 | 2.12 |

| 2 | 48.70 | 48.21 | 3.09 | |

| 48.64 | 48.75 | 2.61 | ||

| B = 0.5 T | 1 | 43.66 | 44.20 | 12.26 |

| 2 | 45.48 | 44.28 | 10.11 | |

| 44.57 | 44.24 | 11.19 |

| Magnetic Induction | Area Number | Carbon (C) | Oxygen (O) | Iron (Fe) |

|---|---|---|---|---|

| B = 0 T | 1 | 66.90 | 26.98 | 6,12 |

| 2 | 67.25 | 28.44 | 4.31 | |

| 67.07 | 27.71 | 5.22 | ||

| B = 0.5 T | 1 | 63.81 | 24.94 | 11.25 |

| 2 | 62.58 | 23.69 | 13.73 | |

| 63.19 | 24.31 | 12.50 |

| Ordinal Number | Type of Composite | Absorptivity (%) | |

|---|---|---|---|

| B = 0 T | B = 0.5 T | ||

| 1 | Epidian 5 | 0.1224 | 0.1417 |

| 2 | Epidian 5 + Fe3O4 (10% b.w.) | 0.1014 | 0.2070 |

| 3 | PLA | 0.2780 | 0.4607 |

| 4 | PLA + Fe3O4 (10% b.w.) | 0.6232 | 1.4820 |

| Ordinal Number | Type of Composite | Frost Resistance (%) | |

|---|---|---|---|

| B = 0 T | B = 0.5 T | ||

| 1 | Epidian 5 | 0.07959 | 0.03450 |

| 2 | Epidian 5 + Fe3O4 (10% b.w.) | 0.09480 | 0.00022 |

| 3 | PLA | 0.21097 | 0.00101 |

| 4 | PLA + Fe3O4 (10% b.w.) | 0.08898 | 0.00024 |

| Magnetic Induction | Area Number | Carbon (C) | Oxygen (O) | Iron (Fe) | Sodium (Na) |

|---|---|---|---|---|---|

| B = 0 T | PLA and starch | 58.27 | 41.03 | - | 0.70 |

| PLA and Fe3O4 | 48.64 | 48.75 | 2.61 | - | |

| B = 0.5 T | PLA and starch | 47.88 | 51.93 | - | 0.19 |

| PLA and Fe3O4 | 44.57 | 44.24 | 11.19 | - |

| Ordinal Number | Type of Composite | Average of Water Absorption (%) | |

|---|---|---|---|

| B = 0 T | B = 0.5 T | ||

| 1 | Epidian 5 | 0.1224 | 0.1417 |

| 2 | Epidian 5 + Avicel PH-1010 (10% b.w.) | 0.2588 | 0.2791 |

| 3 | Epidian 5 + Fe3O4 (10% b.w.) | 0.1014 | 0.2070 |

| 4 | PLA | 0.2780 | 0.4607 |

| 5 | PLA + starch (10% b.w.) | 0.2246 | 0.8108 |

| 6 | PLA + Fe3O4 (10% b.w.) | 0.6232 | 1.4820 |

| Ordinal Number | Type of Composite | Average of Frost Resistance (%) | |

|---|---|---|---|

| B = 0 T | B = 0.5 T | ||

| 1 | Epidian 5 | 0.07959 | 0.03450 |

| 2 | Epidian 5 + Avicel PH-1010 (10% b.w.) | 0.22112 | 0.07115 |

| 3 | Epidian 5 + Fe3O4 (10% b.w.) | 0.09480 | 0.00022 |

| 4 | PLA | 0.21097 | 0.00101 |

| 5 | PLA + starch (10% b.w.) | 0.04176 | 0.01154 |

| 6 | PLA + Fe3O4 (10% b.w.) | 0.08898 | 0.00024 |

| Ordinal Number | Type of Composite | Magnetic Induction B (T) | Stress during Stretching σm (MPa) | Elongation When Stretching εm (%) |

|---|---|---|---|---|

| 1 | Epidian 5 | 0 | 20.1 | 2.0 |

| 0.5 | 18.6 | 1.6 | ||

| 2 | Epidian 5 + Fe3O4 (10% b.w.) | 0 | 16.2 | 1.1 |

| 0.5 | 12.9 | 0.75 | ||

| 3 | Epidian 5 + Avicel PH-1010 (10% b.w.) | 0 | 23.8 | 1.6 |

| 0.5 | 20.7 | 1.7 |

| Ordinal Number | Type of Composite | Magnetic Induction B (T) | Young’s Modulus E (N/m2)(Pa∙10−5) |

|---|---|---|---|

| 1 | Epidian 5 | 0 | 1.32 |

| 0.5 | 1.16 | ||

| 2 | Epidian 5 + Fe3O4 (10% b.w.) | 0 | 1.47 |

| 0.5 | 1.72 | ||

| 3 | Epidian 5 + Avicel PH-1010 (10% b.w.) | 0 | 1.49 |

| 0.5 | 1.22 |

| Ordinal Number | Type of Composite | Magnetic Induction B (T) | Stress during Bending σfM (MPa) | Elongation in Bending εfB (%) |

|---|---|---|---|---|

| 1 | Epidian 5 | 0 | 12.6 | 3.3 |

| 0.5 | 14.2 | 2.1 | ||

| 2 | Epidian 5 + Fe3O4 (10% b.w.) | 0 | 30.6 | 1.3 |

| 0.5 | 41.4 | 1.9 | ||

| 3 | Epidian 5 + Avicel PH-1010 (10% b.w.) | 0 | 50.7 | 1.9 |

| 0.5 | 48.5 | 2.7 |

| Ordinal Number | Type of Composite | Magnetic Induction B (T) | Impact Strength U (kJ/m2) |

|---|---|---|---|

| 1 | Epidian 5 | 0 | 2.61 |

| 0.5 | 2.94 | ||

| 2 | Epidian 5 + Fe3O4 (10% b.w.) | 0 | 3.68 |

| 0.5 | 4.94 | ||

| 3 | Epidian 5 + Avicel PH-1010(10% b.w.) | 0 | 3.78 |

| 0.5 | 3.82 |

| Ordinal Number | Type of Composite | Admixture Content (%) | Stress during Stretching σm (MPa) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | 20.1 | 18.6 |

| 10 | 16.2 | 12.9 | ||

| 20 | 16.5 | 13.7 | ||

| 30 | 18.0 | 15.2 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | 20.1 | 18.6 |

| 10 | 23.8 | 20.7 | ||

| 20 | 24.0 | 21.1 | ||

| 30 | 25.1 | 22.5 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Young’s Modulus E (N/m2)(Pa∙10−5) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | 1.32 | 1.16 |

| 10 | 1.47 | 1.72 | ||

| 20 | 2.17 | 2.44 | ||

| 30 | 1.50 | 1.81 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | 1.32 | 1.16 |

| 10 | 1.49 | 1.22 | ||

| 20 | 1.79 | 1.53 | ||

| 30 | 1.48 | 1.20 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Stress during Bending σfM (MPa) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | 12.6 | 14.2 |

| 10 | 30.6 | 41.4 | ||

| 20 | 48.4 | 55.3 | ||

| 30 | 41.4 | 49.1 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | 12.6 | 14.2 |

| 10 | 50.7 | 48.5 | ||

| 20 | 22.9 | 21.6 | ||

| 30 | 16.8 | 16.1 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Impact Strength U (kJ/m2) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | 2.61 | 2.94 |

| 10 | 3.68 | 4.94 | ||

| 20 | 4.01 | 5.46 | ||

| 30 | 2.84 | 3.75 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | 2.61 | 2.94 |

| 10 | 3.78 | 3.82 | ||

| 20 | 7.35 | 8.05 | ||

| 30 | 3.80 | 4.08 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Absorptivity (%) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | 0.4083 | 0.4189 |

| 10 | 0.2491 | 0.2328 | ||

| 20 | 0.3012 | 0.3057 | ||

| 30 | 0.2488 | 0.2523 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | 0.4083 | 0.4189 |

| 10 | 0.3769 | 0.2786 | ||

| 20 | 0.5027 | 0.4170 | ||

| 30 | 0.8927 | 0.5238 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Frost Resistance (%) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | −0.0408 | −0.5363 |

| 10 | −0.0464 | 0.9349 | ||

| 20 | −0.0305 | −1.0590 | ||

| 30 | −0.0480 | 6.0255 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | −0.0408 | −0.5363 |

| 10 | −0.0716 | −0.4740 | ||

| 20 | −0.1025 | −0.9349 | ||

| 30 | −0.2160 | −5.1313 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Chemical Resistance (%) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | 0.0378 | 0.5092 |

| 10 | 0.1704 | 0.0865 | ||

| 20 | 0.1300 | 0.0791 | ||

| 30 | 0.0295 | 0.0208 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | 0.0378 | 0.5092 |

| 10 | 0.0432 | 0.0196 | ||

| 20 | 0.1135 | 0.0197 | ||

| 30 | 0.0039 | 0.0274 | ||

| Ordinal Number | Type of Composite | Admixture Content (%) | Chemical Resistance (%) | |

|---|---|---|---|---|

| B = 0 T | B = 0.5 T | |||

| 1 | Epidian 5 + Fe3O4 | 0 | −0.2714 | 0.3830 |

| 10 | −0.4050 | 0.0059 | ||

| 20 | −0.4192 | 0.0473 | ||

| 30 | −0.3748 | −0.0156 | ||

| 2 | Epidian 5 + Avicel PH-1010 | 0 | −0.2714 | 0.3830 |

| 10 | −0.2815 | −0.0071 | ||

| 20 | −0.3283 | −0.0129 | ||

| 30 | −0.3500 | 0.0343 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miękoś, E.; Cichomski, M.; Zieliński, M.; Klepka, T.; Sroczyński, D.; Fenyk, A. Modification of the Properties of Polymer Composites in a Constant Magnetic Field Environment. Materials 2021, 14, 3806. https://doi.org/10.3390/ma14143806

Miękoś E, Cichomski M, Zieliński M, Klepka T, Sroczyński D, Fenyk A. Modification of the Properties of Polymer Composites in a Constant Magnetic Field Environment. Materials. 2021; 14(14):3806. https://doi.org/10.3390/ma14143806

Chicago/Turabian StyleMiękoś, Ewa, Michał Cichomski, Marek Zieliński, Tomasz Klepka, Dariusz Sroczyński, and Anna Fenyk. 2021. "Modification of the Properties of Polymer Composites in a Constant Magnetic Field Environment" Materials 14, no. 14: 3806. https://doi.org/10.3390/ma14143806

APA StyleMiękoś, E., Cichomski, M., Zieliński, M., Klepka, T., Sroczyński, D., & Fenyk, A. (2021). Modification of the Properties of Polymer Composites in a Constant Magnetic Field Environment. Materials, 14(14), 3806. https://doi.org/10.3390/ma14143806