Estimation and Optimization of Tool Wear in Conventional Turning of 709M40 Alloy Steel Using Support Vector Machine (SVM) with Bayesian Optimization

Abstract

:1. Introduction

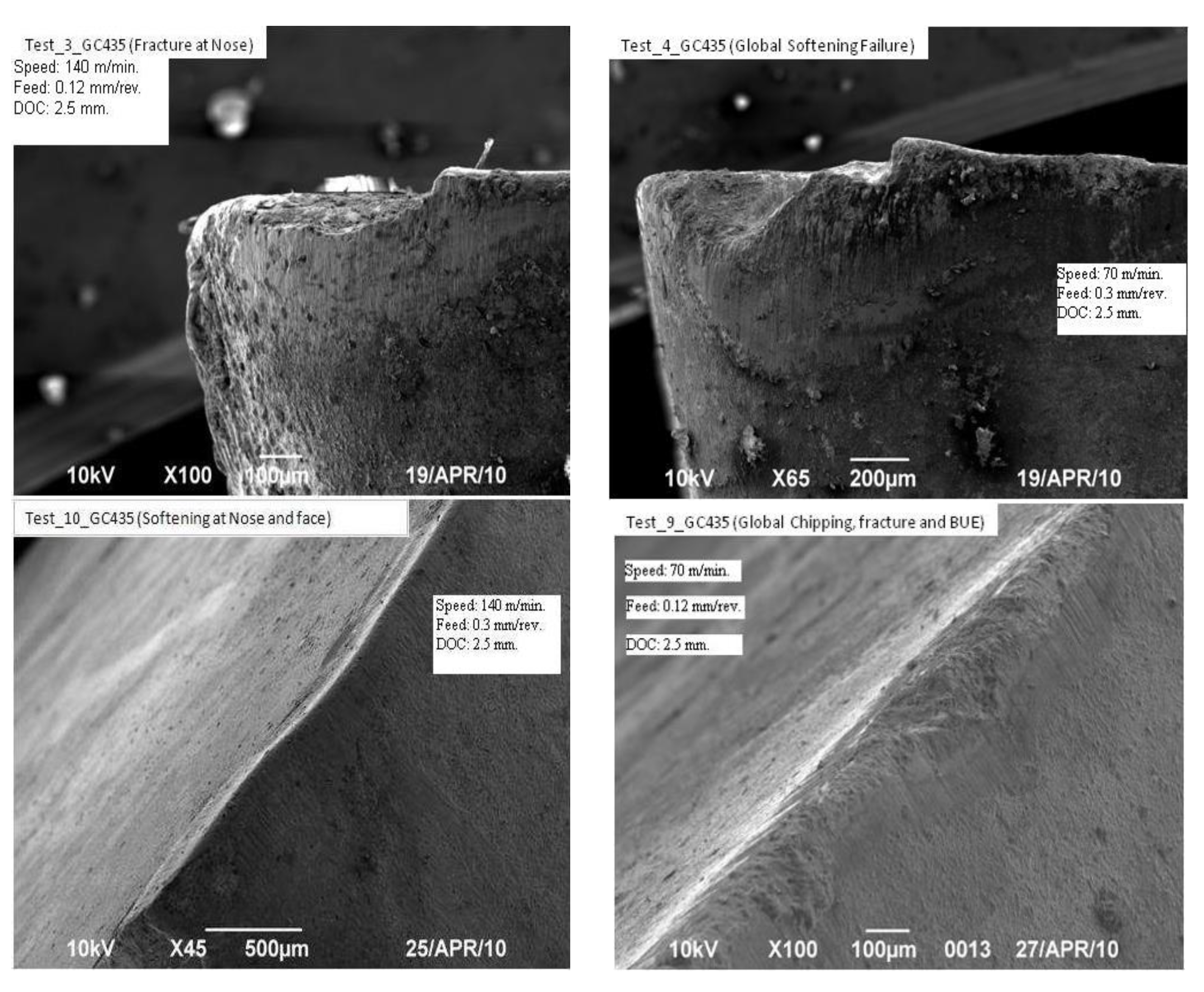

2. Materials and Methods

3. Methodology

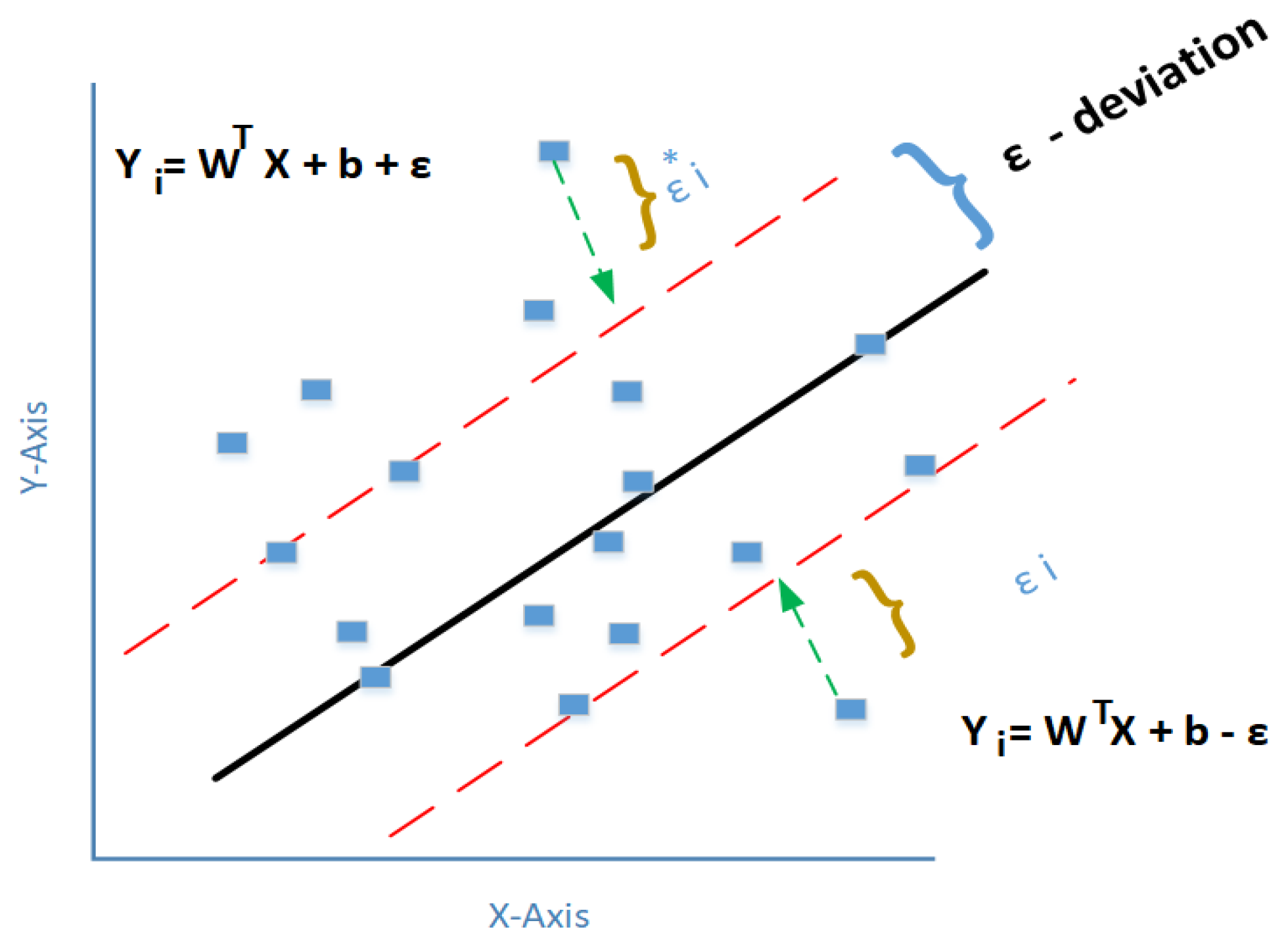

3.1. Support Vector Machine with Bayesian Optimization for Regression

3.2. Bayesian Optimization

4. Results and Discussion

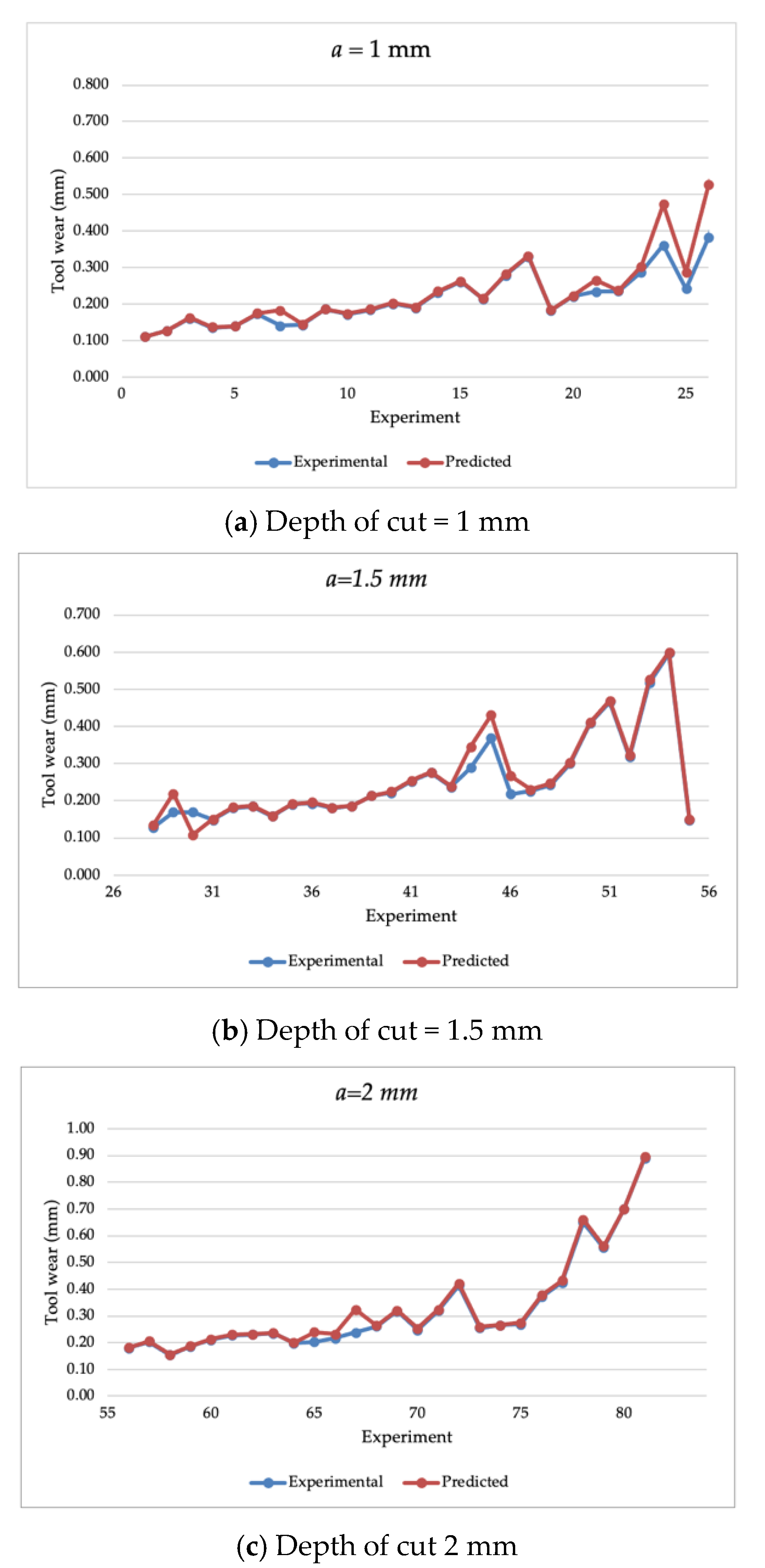

4.1. Training Dataset

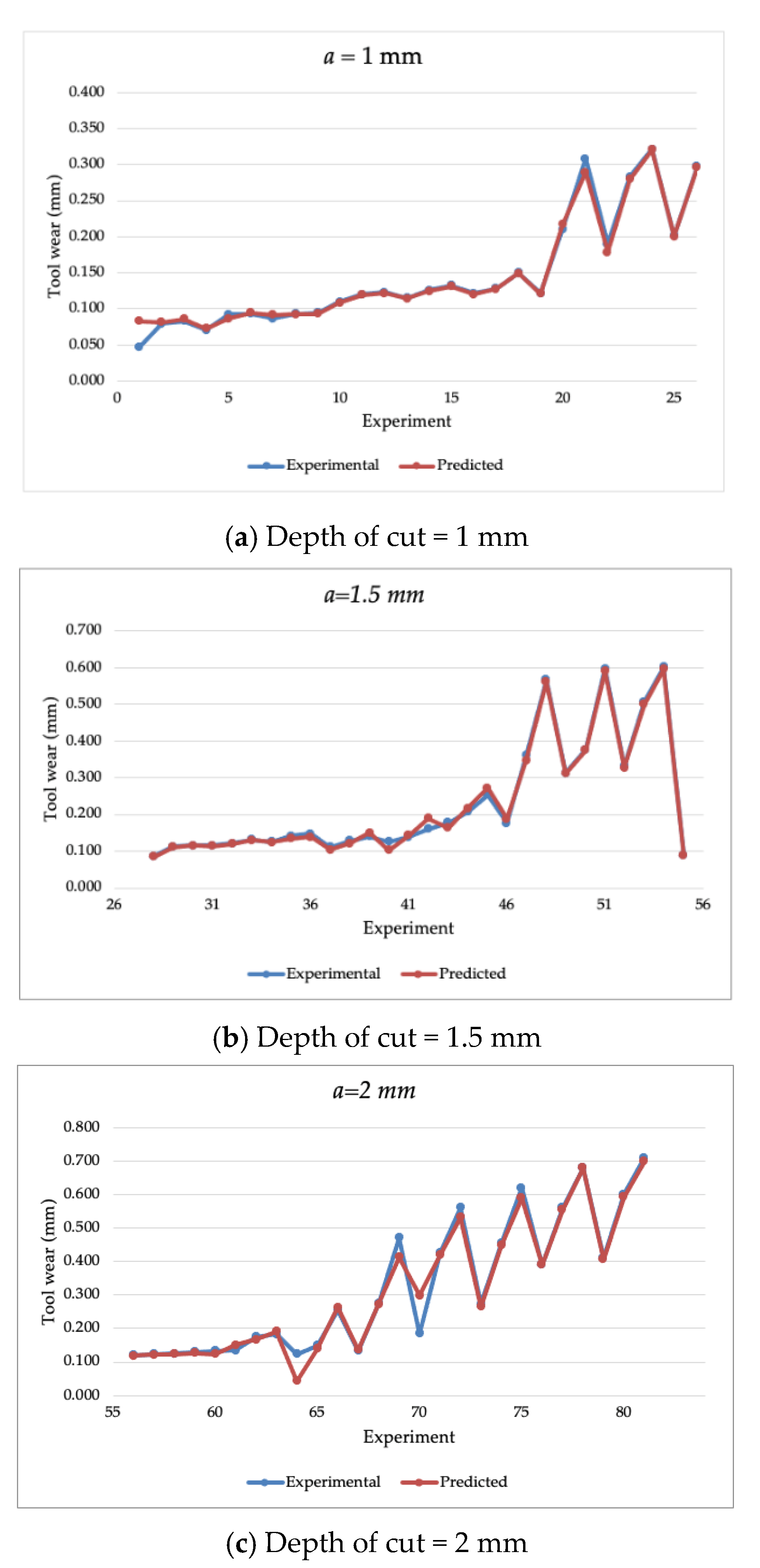

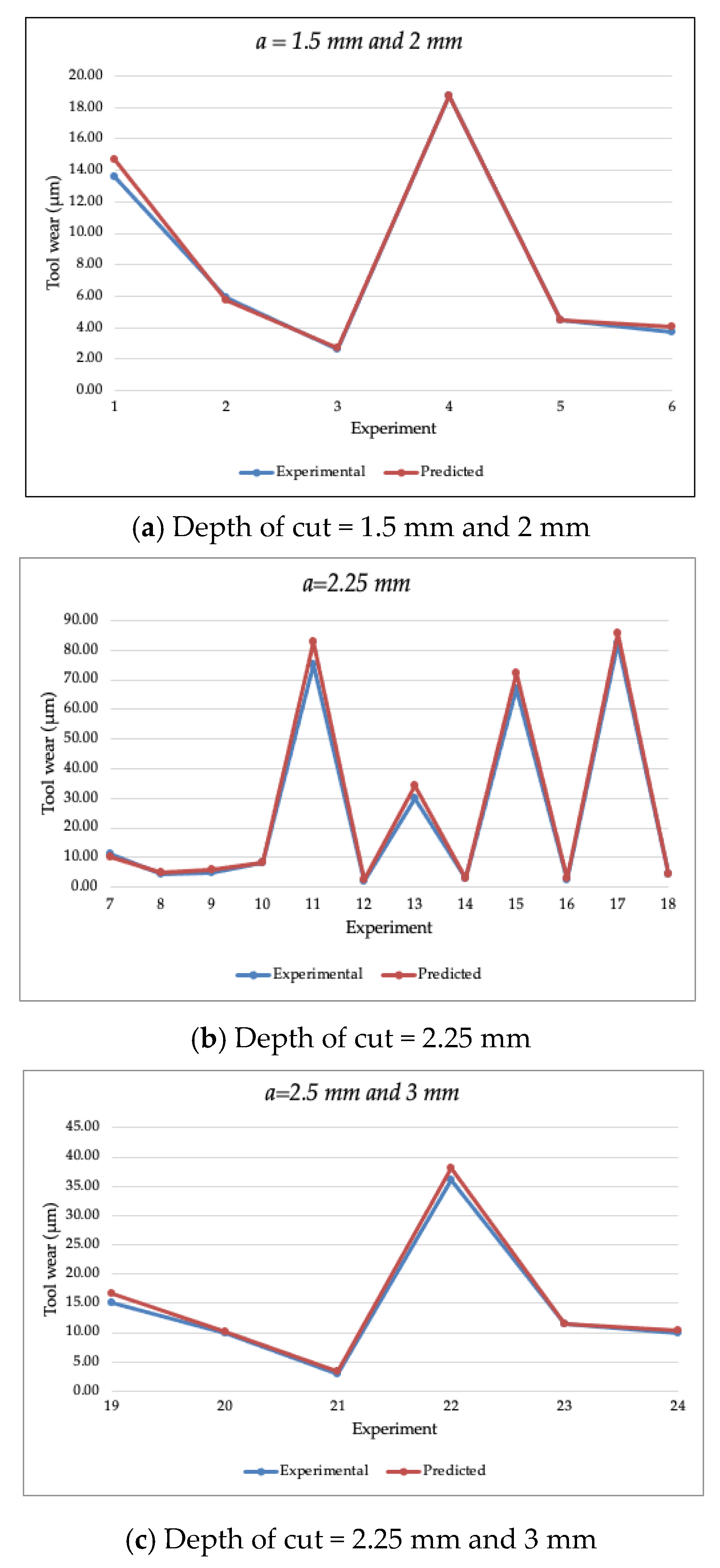

4.2. Validation Dataset

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| V | Cutting Speed (m/min) |

| f | Feed Rate (mm/rev) |

| d | Depth of Cut (mm) |

| Ra | Surface Roughness (µm/m) |

| MAE | Mean Root Square Error |

| RMSE | Root Mean Square Error |

| Nw | Nose Tool Wear (µm/min) |

| CVRMSE | Coefficient of the Variation of the Root Mean Square Error |

Appendix A

| Exp No. | Cutting Parameters | Cutting Length | CVD Coated Tool | PVD Coated WC | ||||

|---|---|---|---|---|---|---|---|---|

| d [mm] | V [m/min] | f [mm/rev] | L [mm] | Ra [μ/m] | Ra [ μ/m] | |||

| 1 | 1 | 30 | 0.052 | 40 | 1.82 | 0.110 | 1.32 | 0.047 |

| 2 | 1 | 30 | 0.052 | 80 | 1.94 | 0.127 | 1.54 | 0.079 |

| 3 | 1 | 30 | 0.052 | 120 | 2.12 | 0.16 | 1.68 | 0.083 |

| 4 | 1 | 30 | 0.104 | 40 | 2.15 | 0.135 | 2 | 0.07 |

| 5 | 1 | 30 | 0.104 | 80 | 2.18 | 0.139 | 2.4 | 0.092 |

| 6 | 1 | 30 | 0.104 | 120 | 2.48 | 0.173 | 2.6 | 0.093 |

| 7 | 1 | 30 | 0.162 | 40 | 3.3 | 0.14 | 3.72 | 0.086 |

| 8 | 1 | 30 | 0.162 | 80 | 3.6 | 0.143 | 4.1 | 0.093 |

| 9 | 1 | 30 | 0.162 | 120 | 3.8 | 0.186 | 4.18 | 0.094 |

| 10 | 1 | 60 | 0.052 | 40 | 1.76 | 0.172 | 1.3 | 0.11 |

| 11 | 1 | 60 | 0.052 | 80 | 1.9 | 0.184 | 1.45 | 0.12 |

| 12 | 1 | 60 | 0.052 | 120 | 2.04 | 0.201 | 1.5 | 0.123 |

| 13 | 1 | 60 | 0.104 | 40 | 1.9 | 0.189 | 1.76 | 0.115 |

| 14 | 1 | 60 | 0.104 | 80 | 2.1 | 0.232 | 1.98 | 0.126 |

| 15 | 1 | 60 | 0.104 | 120 | 2.3 | 0.261 | 2.16 | 0.132 |

| 16 | 1 | 60 | 0.162 | 40 | 3.5 | 0.214 | 4.12 | 0.121 |

| 17 | 1 | 60 | 0.162 | 80 | 3.85 | 0.279 | 4.22 | 0.128 |

| 18 | 1 | 60 | 0.162 | 120 | 4.1 | 0.330 | 4.34 | 0.15 |

| 19 | 1 | 90 | 0.052 | 40 | 1.4 | 0.183 | 1.28 | 0.121 |

| 20 | 1 | 90 | 0.052 | 80 | 1.6 | 0.221 | 1.4 | 0.21 |

| 21 | 1 | 90 | 0.052 | 120 | 2.3 | 0.234 | 1.68 | 0.308 |

| 22 | 1 | 90 | 0.104 | 40 | 2.25 | 0.235 | 1.94 | 0.19 |

| 23 | 1 | 90 | 0.104 | 80 | 2.3 | 0.287 | 2.24 | 0.283 |

| 24 | 1 | 90 | 0.104 | 120 | 2.7 | 0.361 | 2.44 | 0.321 |

| 25 | 1 | 90 | 0.162 | 40 | 4 | 0.242 | 4.68 | 0.201 |

| 26 | 1 | 90 | 0.162 | 80 | 4.3 | 0.383 | 4.74 | 0.297 |

| 27 | 1 | 90 | 0.162 | 120 | 4.9 | 0.586 | 5.08 | 0.38 |

| 28 | 1.5 | 30 | 0.052 | 40 | 2.04 | 0.128 | 2.02 | 0.086 |

| 29 | 1.5 | 30 | 0.052 | 80 | 2.1 | 0.169 | 2.2 | 0.112 |

| 30 | 1.5 | 30 | 0.052 | 120 | 2.15 | 0.17 | 2.4 | 0.116 |

| 31 | 1.5 | 30 | 0.104 | 40 | 2.18 | 0.148 | 2.24 | 0.115 |

| 32 | 1.5 | 30 | 0.104 | 80 | 2.2 | 0.18 | 2.32 | 0.121 |

| 33 | 1.5 | 30 | 0.104 | 120 | 2.58 | 0.185 | 2.72 | 0.132 |

| 34 | 1.5 | 30 | 0.162 | 40 | 3.64 | 0.158 | 4.16 | 0.126 |

| 35 | 1.5 | 30 | 0.162 | 80 | 4.24 | 0.19 | 4.32 | 0.142 |

| 36 | 1.5 | 30 | 0.162 | 120 | 4.5 | 0.193 | 4.4 | 0.148 |

| 37 | 1.5 | 60 | 0.052 | 40 | 1.82 | 0.181 | 1.64 | 0.111 |

| 38 | 1.5 | 60 | 0.052 | 80 | 1.98 | 0.186 | 1.7 | 0.129 |

| 39 | 1.5 | 60 | 0.052 | 120 | 2.06 | 0.214 | 1.86 | 0.14 |

| 40 | 1.5 | 60 | 0.104 | 40 | 2.08 | 0.221 | 2 | 0.126 |

| 41 | 1.5 | 60 | 0.104 | 80 | 2.15 | 0.252 | 2.26 | 0.138 |

| 42 | 1.5 | 60 | 0.104 | 120 | 2.47 | 0.276 | 2.4 | 0.16 |

| 43 | 1.5 | 60 | 0.162 | 40 | 4.16 | 0.237 | 4.18 | 0.178 |

| 44 | 1.5 | 60 | 0.162 | 80 | 4.32 | 0.289 | 4.4 | 0.207 |

| 45 | 1.5 | 60 | 0.162 | 120 | 4.75 | 0.369 | 4.52 | 0.253 |

| 46 | 1.5 | 90 | 0.052 | 40 | 2.4 | 0.218 | 1.94 | 0.177 |

| 47 | 1.5 | 90 | 0.052 | 80 | 2.58 | 0.226 | 2 | 0.36 |

| 48 | 1.5 | 90 | 0.052 | 120 | 2.6 | 0.243 | 2.06 | 0.567 |

| 49 | 1.5 | 90 | 0.104 | 40 | 2.47 | 0.3 | 2.2 | 0.313 |

| 50 | 1.5 | 90 | 0.104 | 80 | 2.54 | 0.409 | 2.36 | 0.376 |

| 51 | 1.5 | 90 | 0.104 | 120 | 3.16 | 0.466 | 3.02 | 0.597 |

| 52 | 1.5 | 90 | 0.162 | 40 | 4.16 | 0.318 | 4.22 | 0.331 |

| 53 | 1.5 | 90 | 0.162 | 80 | 4.78 | 0.517 | 4.6 | 0.507 |

| 54 | 1.5 | 90 | 0.162 | 120 | 5.1 | 0.597 | 5.26 | 0.602 |

| 55 | 2 | 30 | 0.052 | 40 | 2.38 | 0.147 | 2.4 | 0.09 |

| 56 | 2 | 30 | 0.052 | 80 | 2.39 | 0.18 | 2.45 | 0.12 |

| 57 | 2 | 30 | 0.052 | 120 | 2.6 | 0.203 | 2.8 | 0.123 |

| 58 | 2 | 30 | 0.104 | 40 | 2.4 | 0.154 | 2.65 | 0.126 |

| 59 | 2 | 30 | 0.104 | 80 | 2.52 | 0.186 | 2.76 | 0.13 |

| 60 | 2 | 30 | 0.104 | 120 | 2.64 | 0.210 | 2.92 | 0.134 |

| 61 | 2 | 30 | 0.162 | 40 | 4.12 | 0.227 | 4.46 | 0.135 |

| 62 | 2 | 30 | 0.162 | 80 | 4.45 | 0.23 | 4.98 | 0.175 |

| 63 | 2 | 30 | 0.162 | 120 | 4.65 | 0.235 | 5.06 | 0.183 |

| 64 | 2 | 60 | 0.052 | 40 | 1.98 | 0.199 | 2.25 | 0.123 |

| 65 | 2 | 60 | 0.052 | 80 | 2.1 | 0.203 | 2.3 | 0.15 |

| 66 | 2 | 60 | 0.052 | 120 | 2.45 | 0.216 | 2.44 | 0.256 |

| 67 | 2 | 60 | 0.104 | 40 | 2.46 | 0.238 | 2.68 | 0.133 |

| 68 | 2 | 60 | 0.104 | 80 | 2.62 | 0.261 | 2.89 | 0.275 |

| 69 | 2 | 60 | 0.104 | 120 | 2.84 | 0.318 | 3.01 | 0.47 |

| 70 | 2 | 60 | 0.162 | 40 | 4.65 | 0.248 | 4.68 | 0.184 |

| 71 | 2 | 60 | 0.162 | 80 | 4.7 | 0.32 | 5.1 | 0.425 |

| 72 | 2 | 60 | 0.162 | 120 | 4.76 | 0.415 | 5.56 | 0.56 |

| 73 | 2 | 90 | 0.052 | 40 | 2.4 | 0.255 | 2.3 | 0.273 |

| 74 | 2 | 90 | 0.052 | 80 | 2.42 | 0.265 | 2.38 | 0.454 |

| 75 | 2 | 90 | 0.052 | 120 | 2.68 | 0.269 | 2.75 | 0.620 |

| 76 | 2 | 90 | 0.104 | 40 | 2.54 | 0.372 | 2.92 | 0.390 |

| 77 | 2 | 90 | 0.104 | 80 | 2.7 | 0.425 | 3.24 | 0.56 |

| 78 | 2 | 90 | 0.104 | 120 | 3.2 | 0.650 | 3.45 | 0.680 |

| 79 | 2 | 90 | 0.162 | 40 | 4.98 | 0.555 | 5.34 | 0.412 |

| 80 | 2 | 90 | 0.162 | 80 | 5.02 | 0.7 | 5.55 | 0.601 |

| 81 | 2 | 90 | 0.162 | 120 | 5.4 | 0.891 | 5.92 | 0.710 |

| Exp Num | CVD Coated | PVD Coated | ||

|---|---|---|---|---|

| Experimental | SVM | Experimental | SVM | |

| 1 | 0.110 | 0.110 | 0.047 | 0.083 |

| 2 | 0.127 | 0.128 | 0.079 | 0.082 |

| 3 | 0.16 | 0.163 | 0.083 | 0.086 |

| 4 | 0.135 | 0.137 | 0.07 | 0.072 |

| 5 | 0.139 | 0.140 | 0.092 | 0.086 |

| 6 | 0.173 | 0.175 | 0.093 | 0.094 |

| 7 | 0.14 | 0.182 | 0.086 | 0.092 |

| 8 | 0.143 | 0.145 | 0.093 | 0.092 |

| 9 | 0.186 | 0.186 | 0.094 | 0.093 |

| 10 | 0.172 | 0.173 | 0.11 | 0.109 |

| 11 | 0.184 | 0.186 | 0.12 | 0.119 |

| 12 | 0.201 | 0.203 | 0.123 | 0.121 |

| 13 | 0.189 | 0.191 | 0.115 | 0.114 |

| 14 | 0.232 | 0.236 | 0.126 | 0.125 |

| 15 | 0.261 | 0.263 | 0.132 | 0.131 |

| 16 | 0.214 | 0.215 | 0.121 | 0.120 |

| 17 | 0.279 | 0.282 | 0.128 | 0.127 |

| 18 | 0.330 | 0.332 | 0.15 | 0.149 |

| 19 | 0.183 | 0.184 | 0.121 | 0.120 |

| 20 | 0.221 | 0.223 | 0.21 | 0.217 |

| 21 | 0.234 | 0.266 | 0.308 | 0.289 |

| 22 | 0.235 | 0.237 | 0.19 | 0.178 |

| 23 | 0.287 | 0.303 | 0.283 | 0.280 |

| 24 | 0.361 | 0.473 | 0.321 | 0.320 |

| 25 | 0.242 | 0.288 | 0.201 | 0.200 |

| 26 | 0.383 | 0.528 | 0.297 | 0.296 |

| 27 | 0.586 | 0.687 | 0.38 | 0.377 |

| 28 | 0.128 | 0.135 | 0.086 | 0.085 |

| 29 | 0.169 | 0.220 | 0.112 | 0.111 |

| 30 | 0.17 | 0.108 | 0.116 | 0.116 |

| 31 | 0.148 | 0.150 | 0.115 | 0.114 |

| 32 | 0.18 | 0.183 | 0.121 | 0.119 |

| 33 | 0.185 | 0.186 | 0.132 | 0.129 |

| 34 | 0.158 | 0.160 | 0.126 | 0.124 |

| 35 | 0.19 | 0.191 | 0.142 | 0.134 |

| 36 | 0.193 | 0.196 | 0.148 | 0.139 |

| 37 | 0.181 | 0.181 | 0.111 | 0.104 |

| 38 | 0.186 | 0.186 | 0.129 | 0.121 |

| 39 | 0.214 | 0.214 | 0.14 | 0.151 |

| 40 | 0.221 | 0.224 | 0.126 | 0.103 |

| 41 | 0.252 | 0.255 | 0.138 | 0.143 |

| 42 | 0.276 | 0.276 | 0.16 | 0.190 |

| 43 | 0.237 | 0.239 | 0.178 | 0.163 |

| 44 | 0.289 | 0.346 | 0.207 | 0.217 |

| 45 | 0.369 | 0.431 | 0.253 | 0.272 |

| 46 | 0.218 | 0.267 | 0.177 | 0.189 |

| 47 | 0.226 | 0.230 | 0.36 | 0.348 |

| 48 | 0.243 | 0.247 | 0.567 | 0.561 |

| 49 | 0.3 | 0.304 | 0.313 | 0.311 |

| 50 | 0.409 | 0.411 | 0.376 | 0.376 |

| 51 | 0.466 | 0.469 | 0.597 | 0.590 |

| 52 | 0.318 | 0.322 | 0.331 | 0.327 |

| 53 | 0.517 | 0.526 | 0.507 | 0.501 |

| 54 | 0.597 | 0.600 | 0.602 | 0.596 |

| 55 | 0.147 | 0.149 | 0.09 | 0.088 |

| 56 | 0.18 | 0.182 | 0.12 | 0.119 |

| 57 | 0.203 | 0.205 | 0.123 | 0.121 |

| 58 | 0.154 | 0.155 | 0.126 | 0.124 |

| 59 | 0.186 | 0.188 | 0.13 | 0.128 |

| 60 | 0.210 | 0.213 | 0.134 | 0.123 |

| 61 | 0.227 | 0.231 | 0.135 | 0.151 |

| 62 | 0.23 | 0.231 | 0.175 | 0.167 |

| 63 | 0.235 | 0.236 | 0.183 | 0.191 |

| 64 | 0.199 | 0.199 | 0.123 | 0.044 |

| 65 | 0.203 | 0.240 | 0.15 | 0.140 |

| 66 | 0.216 | 0.232 | 0.256 | 0.263 |

| 67 | 0.238 | 0.324 | 0.133 | 0.137 |

| 68 | 0.261 | 0.265 | 0.275 | 0.272 |

| 69 | 0.318 | 0.322 | 0.47 | 0.413 |

| 70 | 0.248 | 0.253 | 0.184 | 0.299 |

| 71 | 0.32 | 0.324 | 0.425 | 0.419 |

| 72 | 0.415 | 0.421 | 0.56 | 0.531 |

| 73 | 0.255 | 0.259 | 0.273 | 0.265 |

| 74 | 0.265 | 0.266 | 0.454 | 0.448 |

| 75 | 0.269 | 0.274 | 0.620 | 0.590 |

| 76 | 0.372 | 0.378 | 0.390 | 0.390 |

| 77 | 0.425 | 0.432 | 0.56 | 0.553 |

| 78 | 0.650 | 0.660 | 0.680 | 0.680 |

| 79 | 0.555 | 0.561 | 0.412 | 0.407 |

| 80 | 0.7 | 0.701 | 0.601 | 0.592 |

| 81 | 0.891 | 0.895 | 0.710 | 0.699 |

References

- Bagga, P.J.; Makhesana, M.A.; Patel, K.M. Tool wear monitoring in turning using image processing techniques. Mater. Today Proc. 2021, 44, 771–775. [Google Scholar] [CrossRef]

- Amrita, M.A.; Rukmini Srikant, R.; VSN, V. Optimisation of cutting parameters for cutting temperature and tool wear in turning AISI4140 under different cooling conditions. Adv. Mater. Process. Technol. 2020, 2020, 1–19. [Google Scholar]

- Qian, Y.; Tian, J.; Liu, L.; Zhang, Y.; Chen, Y. A tool wear predictive model based on SVM. In Proceedings of the 2010 Chinese Control and Decision Conference, Xuzhou, China, 26–28 May 2010; pp. 1213–1217. [Google Scholar]

- Babu, M.P.; Prasad, B.S. Experimental Investigation to Predict Tool Wear and Vibration Displacement in Turning—A Base for Tool Condition Monitoring. J. Manuf. Sci. Prod. 2016, 16, 103–114. [Google Scholar] [CrossRef]

- Çelik, Y.H.; Kilickap, E.; Güney, M. Investigation of cutting parameters affecting on tool wear and surface roughness in dry turning of Ti-6Al-4V using CVD and PVD coated tools. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2085–2093. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of progressive tool wear for determining of optimized machining parameters in turning. Measurement 2019, 140, 427–436. [Google Scholar] [CrossRef]

- Alajmi, M.S.; Almeshal, A.M. Prediction and Optimization of Surface Roughness in a Turning Process Using the ANFIS-QPSO Method. Materials 2020, 13, 2986. [Google Scholar] [CrossRef]

- Pourmostaghimi, V.; Zadshakoyan, M.; Badamchizadeh, M.A. Intelligent model-based optimization of cutting parameters for high-quality turning of hardened AISI D2. Artif. Intell. Eng. Des. Anal. Manuf. 2020, 34, 1–9. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N.; Duan, C.; Lu, L.; Chen, D. Relevance vector machine for tool wear prediction. Mech. Syst. Signal Process. 2019, 127, 573–594. [Google Scholar] [CrossRef]

- Alajmi, M.S.; Almeshal, A.M. Predicting the Tool Wear of a Drilling Process Using Novel Machine Learning XGBoost-SDA. Materials 2020, 13, 4952. [Google Scholar] [CrossRef] [PubMed]

- Alajmi, M.S.; Almeshal, A.M. Modeling of Cutting Force in the Turning of AISI 4340 Using Gaussian Process Regression Algorithm. Appl. Sci. 2021, 11, 4055. [Google Scholar] [CrossRef]

- Alajmi, M.S.; Almeshal, A.M. Least Squares Boosting Ensemble and Quantum-Behaved Particle Swarm Optimization for Predicting the Surface Roughness in Face Milling Process of Aluminum Material. Appl. Sci. 2021, 11, 2126. [Google Scholar] [CrossRef]

- Jurkovic, Z.; Cukor, G.; Brezocnik, M.; Brajkovic, T. A comparison of machine learning methods for cutting parameters prediction in high-speed turning process. J. Intell. Manuf. 2018, 29, 1683–1693. [Google Scholar] [CrossRef]

- Twardowski, P.; Wiciak-Pikuła, M. Prediction of Tool Wear Using Artificial Neural Networks during Turning of Hardened Steel. Materials 2019, 12, 3091. [Google Scholar] [CrossRef] [Green Version]

- McParland, D.; Baron, S.; O’Rourke, S.; Dowling, D.; Ahearne, E.; Parnell, A. Prediction of tool-wear in turning of medical grade cobalt chromium molybdenum alloy (ASTM F75) using non-parametric Bayesian models. J. Intell. Manuf. 2019, 30, 1259–1270. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yan, J.; Li, C.; Gao, R.X.; Zhao, R. Deep heterogeneous GRU model for predictive analytics in smart manufacturing: Application to tool wear prediction. Comput. Ind. 2019, 111, 1–14. [Google Scholar] [CrossRef]

- Sheng, J. A modeling method for turning parameters coupling based on minimum cutting tool wear. Int. J. Adv. Manuf. Technol. 2015, 76, 705–712. [Google Scholar] [CrossRef]

- Zheng, G.; Xu, R.; Cheng, X.; Zhao, G.; Li, L.; Zhao, J. Effect of cutting parameters on wear behavior of coated tool and surface roughness in high-speed turning of 300M. Measurement 2018, 125, 99–108. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Ullah, A.M.M.S.; Matarazzo, D. Tool-wear prediction and pattern-recognition using artificial neural network and DNA-based computing. J. Intell. Manuf. 2015, 28, 1285–1301. [Google Scholar] [CrossRef]

- Chang, W.; Wu, S.; Hsu, J. Investigated iterative convergences of neural network for prediction turning tool wear. Int. J. Adv. Manuf. Technol. 2020, 106, 2939–2948. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Zhao, R.; Gao, R.X. Physics guided neural network for machining tool wear prediction. J. Manuf. Syst. 2020, 57, 298–310. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, Y.; Jiri, G. Predicting tool wear with multi-sensor data using deep belief networks. Int. J. Adv. Manuf. Technol. 2018, 99, 1917–1926. [Google Scholar] [CrossRef]

- Wu, X.; Li, J.; Jin, Y.; Zheng, S. Modeling and analysis of tool wear prediction based on SVD and BiLSTM. Int. J. Adv. Manuf. Technol. 2020, 106, 4391–4399. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, F.; Habibullah, M.S.; Ahmed, J.; Das, A.K.; Zhou, Y.; Ho, C.L. Predicting tool wear size across multi-cutting conditions using advanced machine learning techniques. J. Intell. Manuf. 2020, 2020, 1–14. [Google Scholar] [CrossRef]

- Sandvik Tools Catalog, Sandvik Coromant. 2021. Available online: https://www.sandvik.coromant.com/en-gb/downloads (accessed on 24 June 2021).

- Geethanjali, K.S.; Ramesha, C.M.; Chandan, B.R. Comparative Studies on Machinability of MCLA Steels EN19 and EN24 Using Taguchi Optimization Techniques. Mater. Today Proc. 2018, 5, 25705–25712. [Google Scholar] [CrossRef]

- West York Steel 709M40 Alloy Steel Datasheet, West York Steel. 2021. Available online: https://www.westyorkssteel.com/files/709m40.pdf (accessed on 24 June 2021).

- Steel Grades Online Database. 2021. Available online: https://www.steel-grades.com/Steel-Grades/specialsteel/74/7897/709M40.html (accessed on 24 June 2021).

- Drucker, H.; Burges, C.J.; Kaufman, L.; Smola, A.J.; Vapnik, V. Support vector regression machines. Adv. Neural Inf. Process. Syst. 1996, 28, 779–784. [Google Scholar]

- Guo, Y.; Li, X.; Bai, G.; Ma, J. Time Series Prediction Method Based on LS-SVR with Modified Gaussian RBF. In Proceedings of the International Conference on Neural Information Processing, Lake Tahoe, NV, USA, 3–6 December 2012; pp. 9–17. [Google Scholar]

- Teh, Y.W.; Seeger, M.; Jordan, M. Semiparametric latent factor models. In Proceedings of the Tenth International Workshop on Artificial Intelligence and Statistics, Savannah, Georgia, Bridgetown, Barbados, 6–8 January 2005; pp. 565–568. [Google Scholar]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; MIT Press: Cambridge, MA, USA, 2006; p. 68. [Google Scholar]

- Wang, D.; Wang, C.; Xiao, J.; Xiao, Z.; Chen, W.; Havyarimana, V. Bayesian optimization of support vector machine for regression prediction of short-term traffic flow. Intell. Data Anal. 2019, 23, 481–497. [Google Scholar] [CrossRef]

- Sonawane, G.D.; Sargade, V.G. Evaluation and multi-objective optimization of nose wear, surface roughness and cutting forces using grey relation analysis (GRA). J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 557. [Google Scholar] [CrossRef]

| Composition | (Wt%) | Mechanical Properties | Values |

|---|---|---|---|

| 0.44 | Tensile strength | 850–1000 | |

| 0.99 | 650 | ||

| 0.25 | Hardness | 248–302 | |

| 0.85 | Elongation % | 13 | |

| <0.04 | Impact test | 50 | |

| <0.04 | Density | 421 |

| Experiment Trial | [m/min] | [mm/rev] | [mm] | [µm/min] |

|---|---|---|---|---|

| T1 | 102.67 | 0.2 | 1.5 | 13.6 |

| T2 | 103.4 | 0.2 | 1.5 | 5.88 |

| T3 | 72.35 | 0.12 | 2 | 2.65 |

| T4 | 145 | 0.3 | 2 | 18.75 |

| T5 | 148.22 | 0.12 | 2 | 4.48 |

| T6 | 72.69 | 0.3 | 2 | 3.7 |

| T7 | 104 | 0.2 | 2.25 | 11 |

| T8 | 104.72 | 0.2 | 2.25 | 4.6 |

| T9 | 103.67 | 0.2 | 2.25 | 5 |

| T10 | 103.06 | 0.2 | 2.25 | 8.33 |

| T11 | 206 | 0.2 | 2.25 | 75 |

| T12 | 50 | 0.2 | 2.25 | 2.14 |

| T13 | 101.71 | 0.6 | 2.25 | 30 |

| T14 | 104.15 | 0.06 | 2.25 | 2.91 |

| T15 | 206 | 0.2 | 2.25 | 66.7 |

| T16 | 50.36 | 0.2 | 2.25 | 2.5 |

| T17 | 103.55 | 0.6 | 2.25 | 82.41 |

| T18 | 104.8 | 0.06 | 2.25 | 4.55 |

| T19 | 145.89 | 0.12 | 2.5 | 15 |

| T20 | 72 | 0.3 | 2.5 | 10 |

| T21 | 72.32 | 0.12 | 2.5 | 2.97 |

| T22 | 144.72 | 0.3 | 2.5 | 36.14 |

| T23 | 104.66 | 0.2 | 3 | 11.54 |

| T24 | 103.75 | 0.2 | 3 | 10 |

| Metric | Training Dataset | |

|---|---|---|

| PVD Coated | CVD Coated | |

| MAPE % | 5.630 | 5.096 |

| RMSE % | 1.936 | 3.040 |

| CVRMSE % | 11.619 | 20.326 |

| Data | Actual | Estimated |

|---|---|---|

| 1 | 13.60 | 14.683 |

| 2 | 5.88 | 5.731 |

| 3 | 2.65 | 2.736 |

| 4 | 18.75 | 18.691 |

| 5 | 4.48 | 4.492 |

| 6 | 3.70 | 4.046 |

| 7 | 11.00 | 10.385 |

| 8 | 4.60 | 4.681 |

| 9 | 5.00 | 5.684 |

| 10 | 8.33 | 8.463 |

| 11 | 75.00 | 82.834 |

| 12 | 2.14 | 2.309 |

| 13 | 30.00 | 33.981 |

| 14 | 2.91 | 2.994 |

| 15 | 66.70 | 72.202 |

| 16 | 2.50 | 2.928 |

| 17 | 82.41 | 85.384 |

| 18 | 4.55 | 4.607 |

| 19 | 15.00 | 16.600 |

| 20 | 10.00 | 10.211 |

| 21 | 2.97 | 3.354 |

| 22 | 36.14 | 38.199 |

| 23 | 11.54 | 11.472 |

| 24 | 10.00 | 10.354 |

| Metric | Validation Dataset |

|---|---|

| MAPE % | 6.13 |

| RMSE % | 2.29 |

| CVRMSE % | 9.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alajmi, M.S.; Almeshal, A.M. Estimation and Optimization of Tool Wear in Conventional Turning of 709M40 Alloy Steel Using Support Vector Machine (SVM) with Bayesian Optimization. Materials 2021, 14, 3773. https://doi.org/10.3390/ma14143773

Alajmi MS, Almeshal AM. Estimation and Optimization of Tool Wear in Conventional Turning of 709M40 Alloy Steel Using Support Vector Machine (SVM) with Bayesian Optimization. Materials. 2021; 14(14):3773. https://doi.org/10.3390/ma14143773

Chicago/Turabian StyleAlajmi, Mahdi S., and Abdullah M. Almeshal. 2021. "Estimation and Optimization of Tool Wear in Conventional Turning of 709M40 Alloy Steel Using Support Vector Machine (SVM) with Bayesian Optimization" Materials 14, no. 14: 3773. https://doi.org/10.3390/ma14143773

APA StyleAlajmi, M. S., & Almeshal, A. M. (2021). Estimation and Optimization of Tool Wear in Conventional Turning of 709M40 Alloy Steel Using Support Vector Machine (SVM) with Bayesian Optimization. Materials, 14(14), 3773. https://doi.org/10.3390/ma14143773