Coherent Investigation on a Smart Kinetic Wooden Façade Based on Material Passport Concepts and Environmental Profile Inquiry

Abstract

:1. Introduction

- What is the role of the kinetic façade in modern architecture today?

- How does the kinetic wooden façade contribute to modern building conception?

- Why is the material passport system required in creating the ecological kinetic façade?

- What is the evaluation of the environmental profile impact on the wooden façade?

2. Façade Analysis within the Thematic Area

2.1. Wooden Façade and Building Material Passport (BMP)

2.2. Wooden Façade and Environmental Profile Analysis (EPA)

3. Kinetic Façade Role in Modern Building Design

3.1. How Does the Smart Kinetic Wooden Façade (SKWF) Contribute to Modern Building Conception?

3.2. Bionic and Bioclimatic Concepts in the Adaptive Ecological Kinetic Façade

3.3. Macro-Climatic Action and Wooden Façade Reaction

4. Wooden Materials Use in Wooden Façade

4.1. Environmental Profile (EP) for a General Carpentry Material

4.2. Larix Wood Cladding

4.3. Cedarwood Cladding

4.4. Fiberboards

- porous

- solid

4.5. Chipboard

4.6. Plywood

5. Results

5.1. Material Passport (MP) for Wood Façade

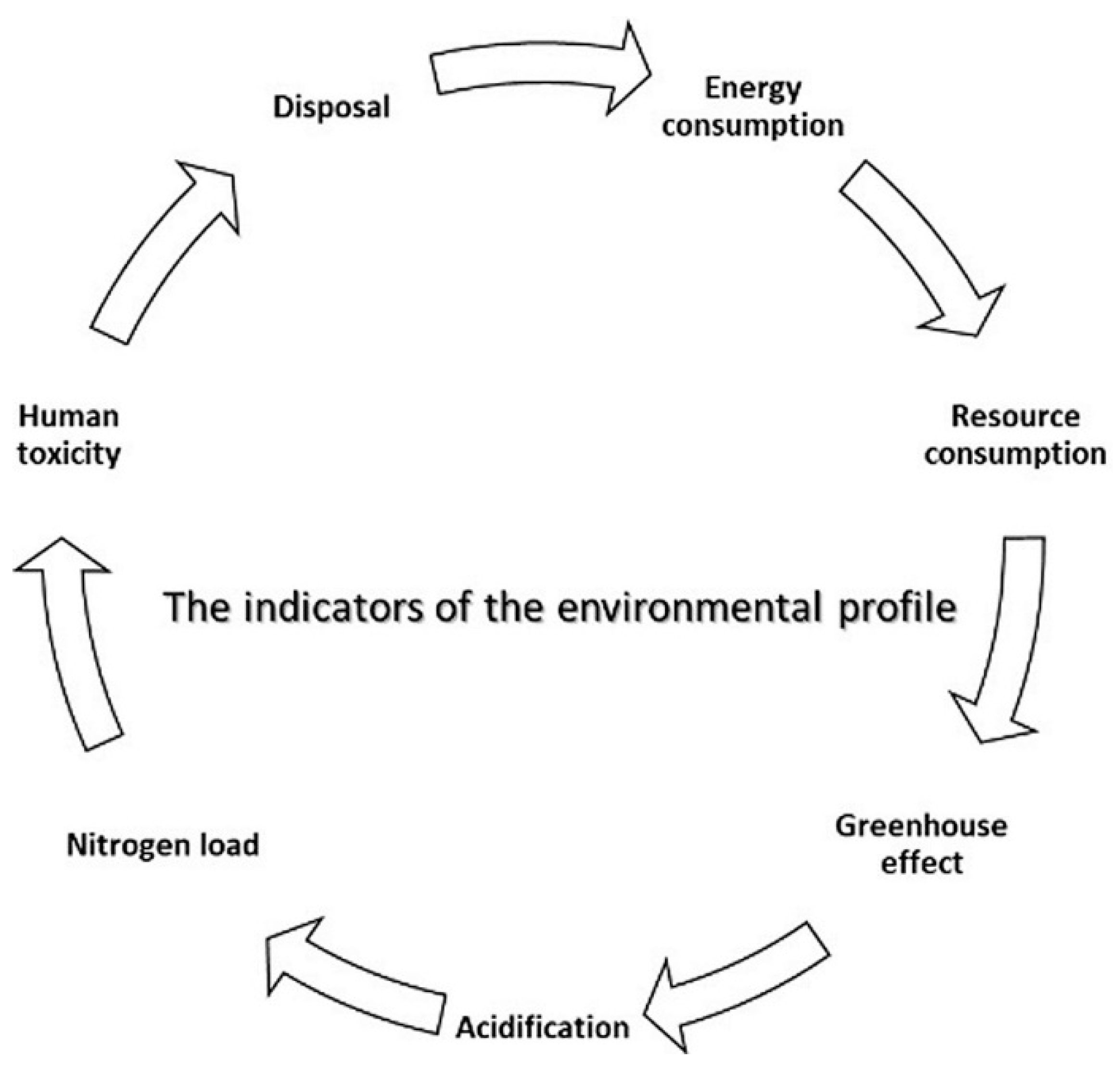

5.2. The Indicators of the Environmental Profile (EP)

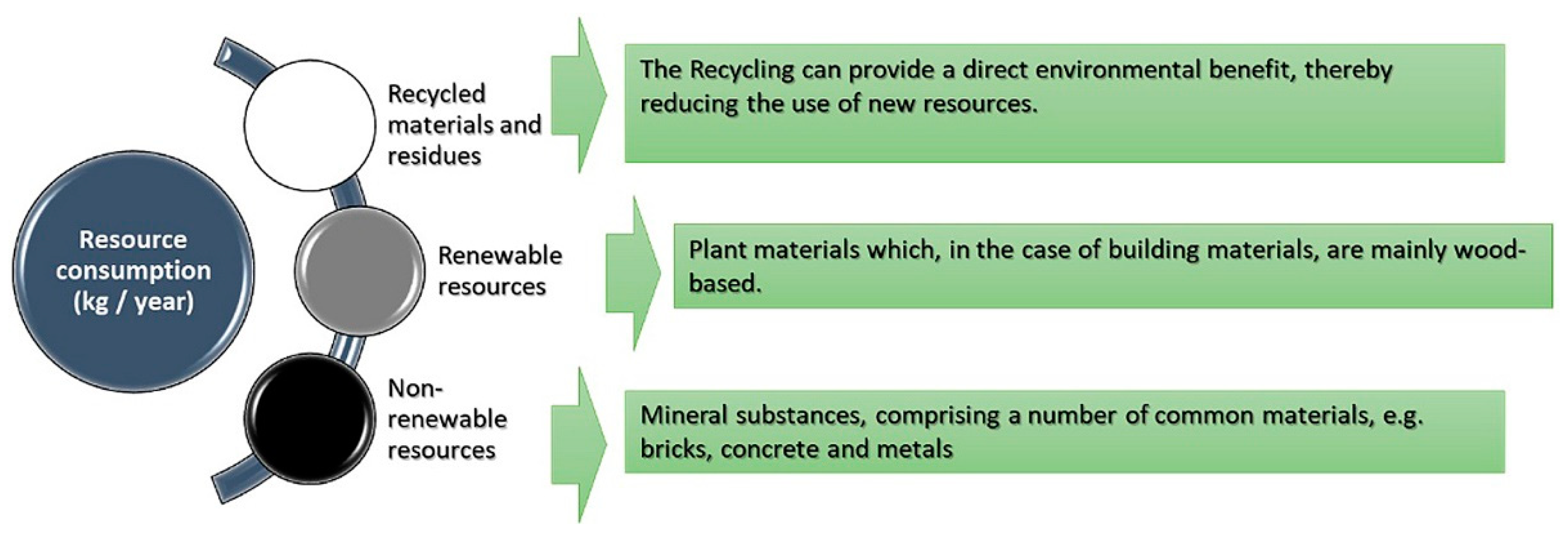

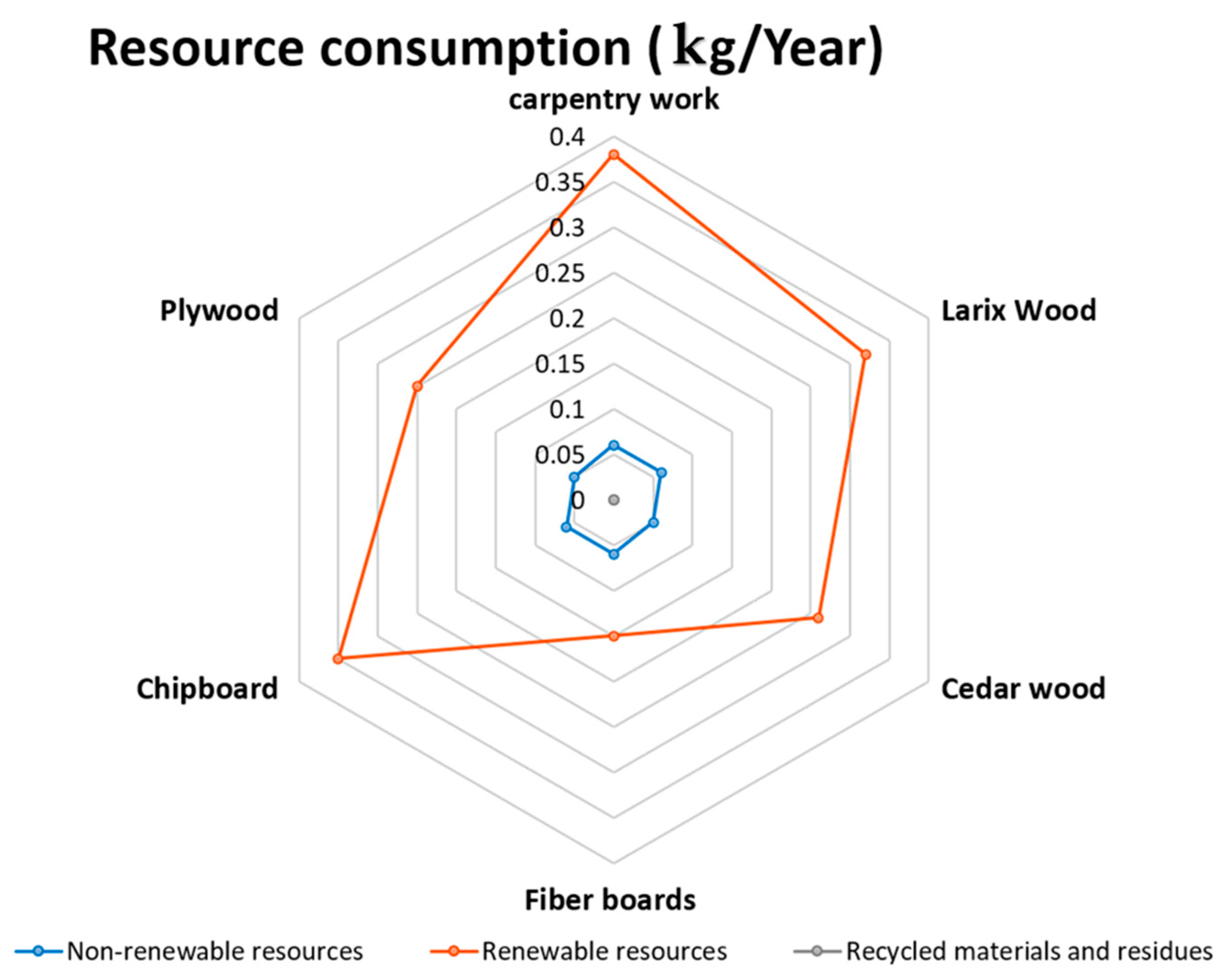

5.3. Resource Consumption

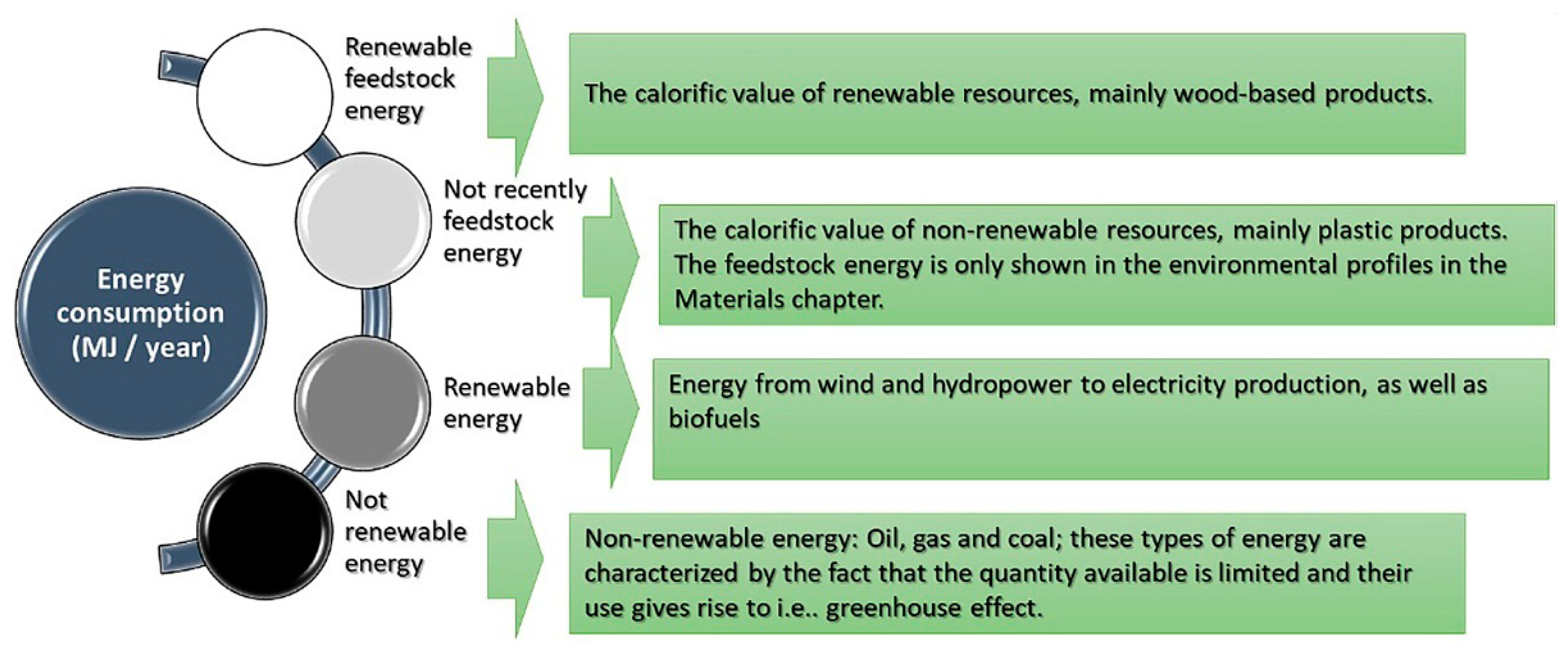

5.4. Energy Consumption

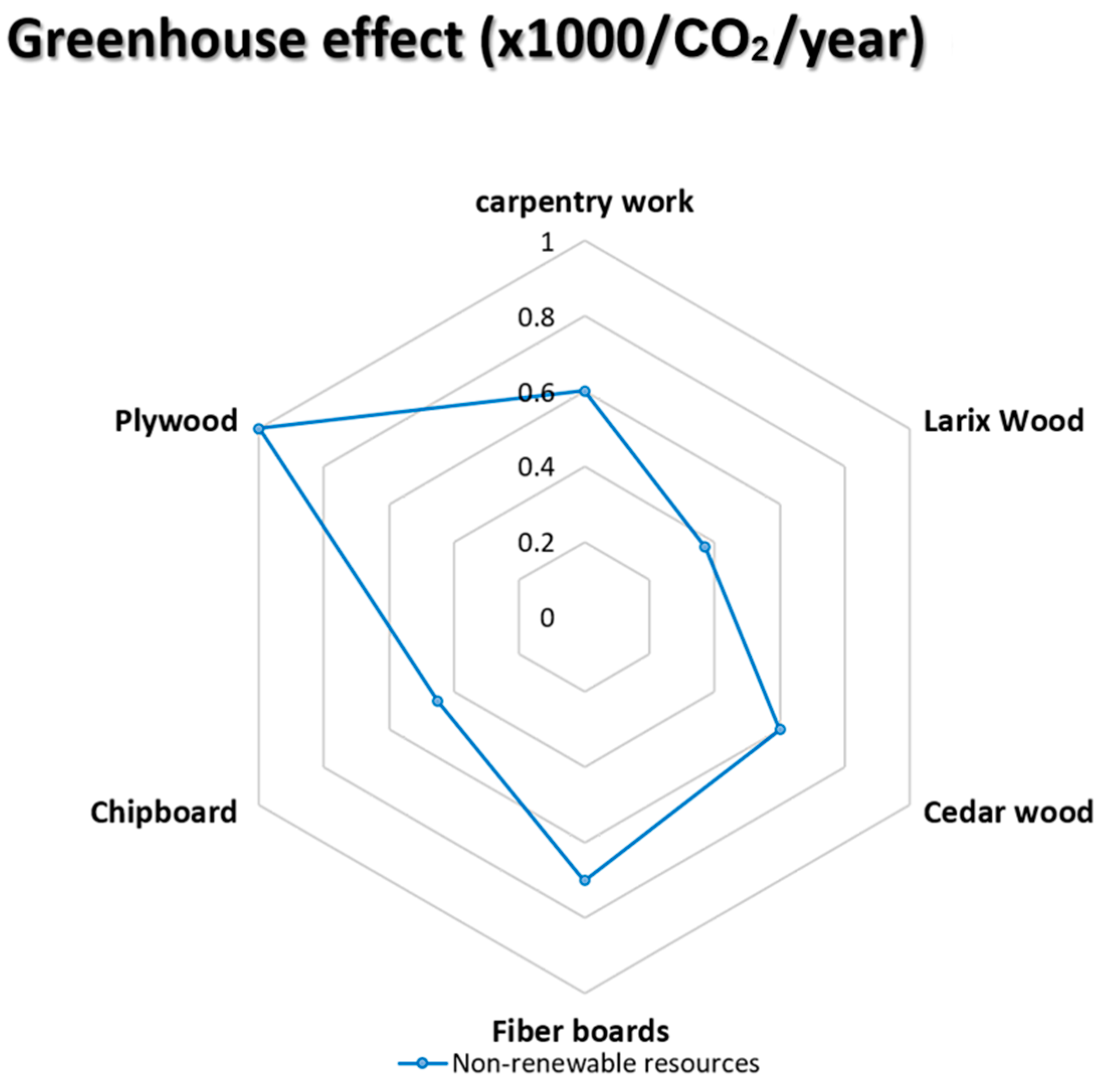

5.5. Greenhouse Effect (×1000/CO2/Year)

5.6. Acidification (gSO3/Year)

5.7. Nitrogen Load (gNO3/Year)

5.8. Human Toxicity (m3/Year)

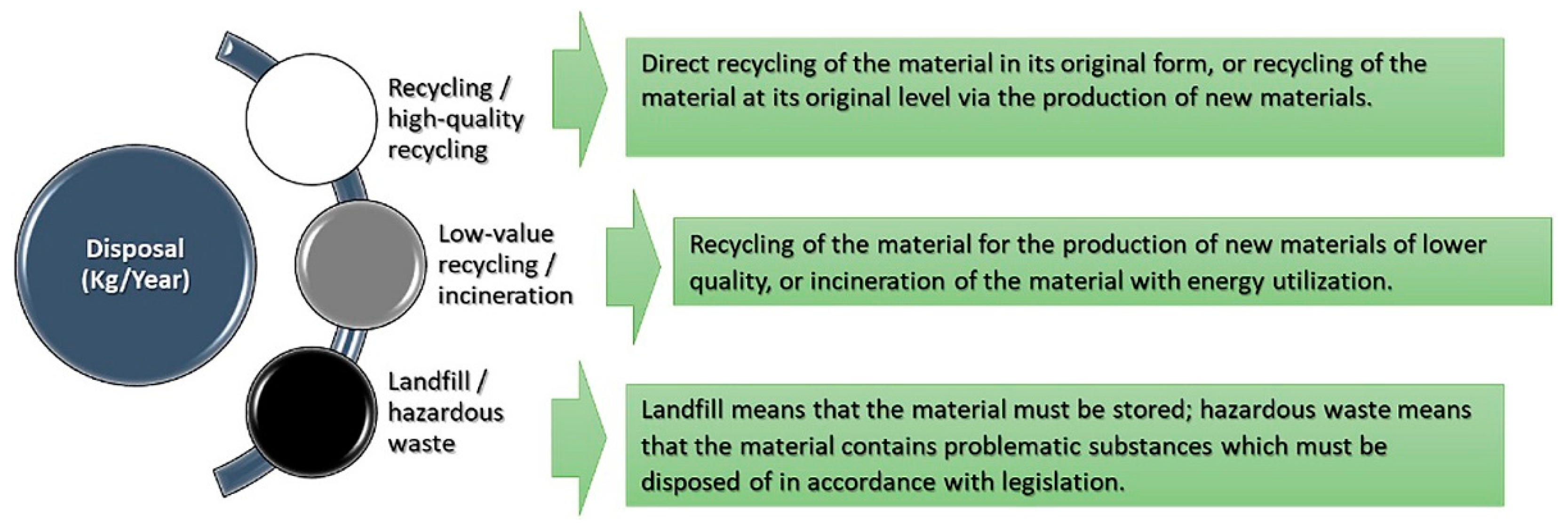

5.9. Disposal (kg/Year)

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Almusaed, A.; Almssad, A.; Alasadi, A. Analytical interpretation of energy efficiency concepts in the housing design process from hot climate. J. Build. Eng. 2019, 21, 254–266. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Hopkinson, P.; Chen, H.-M.; Zhou, K.; Wang, Y.; Lam, D.; Wong, Y. Recovery and reuse of structural products from end-of-life buildings. In Proceedings of the Institution of Civil Engineers—Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2019; Volume 172, pp. 119–128. [Google Scholar]

- Lacy, P.; Rutqvist, J. Waste to Wealth—The Circular Economy Advantage; Palgrave Macmillan: London, UK, 2015; pp. 3–18. [Google Scholar]

- BIS (Department for Business Innovation & Skills). Supply Chain Analysis into the Construction Industry: A Report for the Construction Industrial Strategy; BIS Research Paper, no. 145; Department for Business, Innovation and Skills: London, UK, 2013. [Google Scholar]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef] [Green Version]

- Grobman, Y.J.; Yekutiel, T.P. Autonomous Movement of Kinetic Cladding Components in Building Facades. In Proceedings of the 2nd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2020); Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2013; pp. 1051–1061. [Google Scholar]

- Almusaed, A.; Almssad, A. Efficient daylighting approach by means of light-shelve device adequate for habitat program in Aarhus City. Int. J. Smart Grid Clean Energy 2014, 3, 441–453. [Google Scholar] [CrossRef] [Green Version]

- Wanas, A.; Aly, S.; Farghal, A.; El-Dabaa, R. Use of Kinetic Facades to Enhance Daylight Performance in Office Buildings with Emphasis on Egypt Climate. J. Eng. Appl. Sci. 2015, 62, 339–361. [Google Scholar]

- Barozzi, M.; Lienhard, J.; Zanelli, A.; Monticelli, C. The sustainability of adaptive envelopes: Developments of kinetic archi-tecture. Procedia Eng. 2016, 155, 275–284. [Google Scholar] [CrossRef] [Green Version]

- Panya, D.S.; Kim, T.; Choo, A.S. A Methodology of Interactive Motion Facades Design through Parametric Strategies. Appl. Sci. 2020, 10, 1218. [Google Scholar] [CrossRef] [Green Version]

- De Luca, P.; Carbone, I.; Nagy, J.B. Green building materials: A review of state of the art studies of innovative materials. J. Green Build. 2017, 12, 141–161. [Google Scholar] [CrossRef]

- Bacha, C.B.; Bourbia, F. The effect of kinetic facades on energy efficiency in office buildings-hot dry climates. In Proceedings of the 11th Conference on Advanced Building Skins, Bern, Switzerland, 10–11 October 2016; pp. 458–468. [Google Scholar]

- Almusaed, A.; Almssad, A.; Homod, R.Z.; Yitmen, I. Environmental Profile on Building Material Passports for Hot Climates. Sustainability 2020, 12, 3720. [Google Scholar] [CrossRef]

- Sodagar, B.; Gilroy-Scott, B.; Fieldson, R. Design for Sustainable Architecture and Environments. Int. J. Environ. Cult. Econ. Soc. Sustain. Annu. Rev. 2008, 4, 73–84. [Google Scholar] [CrossRef] [Green Version]

- Almusaed, A.; Almssad, A. Improvement of Thermal Insulation by Environmental Means. Eff. Therm. Insul. Oper. Factor A Passiv. Build. Model 2012, 1. [Google Scholar] [CrossRef] [Green Version]

- Ruggiero, G.; Marmo, R.; Nicolella, M. A Methodological Approach for Assessing the Safety of Historic Buildings’ Façades. Sustainability 2021, 13, 2812. [Google Scholar] [CrossRef]

- Burnard, M.D.; Kutnar, S. Wood and human stress in the built indoor environment: A review. Wood Sci. Technol. 2015, 49, 969–986. [Google Scholar] [CrossRef]

- Munir, M.T.; Pailhories, H.; Eveillard, M.; Aviat, F.; Lepelletier, D.; Belloncle, C.; Federighi, M. Antimicrobial Characteristics of Untreated Wood: Towards a Hygienic Environment. Health 2019, 11, 152–170. [Google Scholar] [CrossRef] [Green Version]

- Yüksek, I. The Evaluation of Building Materials in Terms of Energy Efficiency. Period. Polytech. Civ. Eng. 2015, 59, 45–58. [Google Scholar] [CrossRef] [Green Version]

- Sekularac, J.I.; Sekularac, N.; Tovarovic, J.C. Wood as element of facade cladding in modern architecture. Tech. Technollogies Educ. Manag. 2012, 7, 1304–1310. [Google Scholar]

- Solovev, V. Reasonable choice of materials for project management in transport construction. IOP Conf. Series Mater. Sci. Eng. 2021, 1103, 012036. [Google Scholar] [CrossRef]

- Zhukov, A.D.; Smirnova, T.V.; Naumova, N.V.; Mustafayev, R.M. Sistemy ekologicheski ustoychivogo stroitel’stva [Environ-mentally Sustainable Building Systems]. Stroitel’stvo: Nauka i obrazovanie [Construction: Science and Education]. 2013. Available online: http://nso-journal.ru/public/journals/1/issues/2013/03/4.pdf (accessed on 6 April 2021).

- Khoshnava, S.M.; Rostami, R.; Zin, R.M.; Štreimikienė, D.; Mardani, A.; Ismail, M. The Role of Green Building Materials in Reducing Environmental and Human Health Impacts. Int. J. Environ. Res. Public Health 2020, 17, 2589. [Google Scholar] [CrossRef]

- Lawson, B. Embodied Energy of Building Materials. The Environmental Design Guide, Pro 2; Royal Australian Institute of Architects: Canberra, Australia, 1998; pp. 4–5. [Google Scholar]

- Haupt, M.; Hellweg, S. Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. 2019, 1, 100005. [Google Scholar] [CrossRef]

- Kibert, C. The next generation of sustainable construction. Build. Res. Inf. 2007, 35, 595–601. [Google Scholar] [CrossRef]

- Assefa, Y.; Staggenborg, S.A.; Prasad, V.P.V. Grain Sorghum Water Requirement and Responses to Drought Stress: A Review. Crop Manag. 2010, 9, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Shahda, M.M.M. Vision and Methodology to Support Sustainable Architecture through Building Technology in the Digital Era. Int. J. Environ. Sci. Sustain. Dev. 2018, 2, 1–14. [Google Scholar] [CrossRef]

- Fakourian, F.; Asefi, M. Environmentally responsive kinetic façade for educational buildings. J. Green Build. 2019, 14, 165–186. [Google Scholar] [CrossRef]

- Thayer, R. Gray World, Green Heart: Technology, Nature, and the Sustainable Landscape; John Wiley & Sons: New York, NY, USA, 1994; pp. 101–110. [Google Scholar]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Dwek, M. Integration of Material Circularity in Product Design. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 2017. [Google Scholar]

- Munaro, M.R.; Fischer, A.C.; de Azevedo, N.C.; Tavares, S.F. Proposal of a building material passport and its application feasibility to the wood frame constructive system in Brazil. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 225, p. 012018. [Google Scholar]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of A Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef] [Green Version]

- Romano, R.; Aelenei, L.; Aelenei, D.; Mazzucchelli, E.S. What is an adaptive façade? Analysis of Recent Terms and definitions from an international perspective. J. Facade Des. Eng. 2018, 6, 65–76. [Google Scholar]

- Youssef, M.M.; De Temmerman, N.; Brebbia, C.A. Kinetic behavior, the dynamic potential through architecture and design. Int. J. Comput. Methods Exp. Meas. 2017, 5, 607–618. [Google Scholar] [CrossRef]

- Pingale, T.B.; Damugade, S.Y.; Jirge, N.D. Visual Communication in Architecture. Int. J. Eng. Res. Technol. 2017, 10, 123–126. [Google Scholar]

- Shahin, H.S.M. Adaptive building envelopes of multistory buildings as an example of high performance building skins. Alex. Eng. J. 2019, 58, 345–352. [Google Scholar] [CrossRef]

- Salama, W. Design of concrete buildings for disassembly: An explorative review. Int. J. Sustain. Built Environ. 2017, 6, 617–635. [Google Scholar] [CrossRef]

- Harry, S. Dynamic Adaptive Building Envelopes—An Innovative and State-of-The-Art Technology. Creative Space 2016, 3, 167–184. [Google Scholar] [CrossRef]

- Hart, J.; Pomponi, F. More Timber in Construction: Unanswered Questions and Future Challenges. Sustainability 2020, 12, 3473. [Google Scholar] [CrossRef] [Green Version]

- Suchomel, J.; Belanová, K.; Gejdoš, M.; Němec, M.; Danihelová, A.; Mašková, Z. Analysis of fungi in wood chip storage piles. BioResources 2014, 9, 4410–4420. [Google Scholar] [CrossRef]

- Kuru, A.; Oldfield, P.; Bonser, S.; Fiorito, F. A Framework to Achieve Multifunctionality in Biomimetic Adaptive Building Skins. Buildings 2020, 10, 114. [Google Scholar] [CrossRef]

- Omer, A.M. Built Environment: Relating the Benefits of Renewable Energy Technologies. Int. J. Automot. Mech. Eng. 2012, 5, 561–575. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, K.; Cheng, T.; Zhou, Q.; Qin, L.; Wang, S. Influence of Climate Change in Reliability Analysis of High Rise Building. Math. Probl. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Tiryaki, S.; Bardak, S.; Aydin, A.; Nemli, G. Analysis of volumetric swelling and shrinkage of heat treated woods: Experimental and artificial neural network modeling approach. Maderas. Ciencia y tecnología 2016, 18. [Google Scholar] [CrossRef] [Green Version]

- Almusaed, A. Intelligent Sustainable Strategies upon Passive Bioclimatic Houses: From Basra (Iraq) to Skanderbeg (Denmark): Postdoc Research; Arkitektskole i Århus: Aarhus, Denmark, 2004; p. 173. [Google Scholar]

- O’Brien, M.; Bringezu, S. What Is a Sustainable Level of Timber Consumption in the EU: Toward Global and EU Benchmarks for Sustainable Forest Use. Sustainability 2017, 9, 812. [Google Scholar] [CrossRef] [Green Version]

- Moezzipour, B.; Ahmadi, M.; Abdolkhani, A.; Doosthoseini, K. Chemical changes of wood fibers after hydrothermal recycling of MDF wastes. J. Indian Acad. Wood Sci. 2017, 14, 133–138. [Google Scholar] [CrossRef]

- Ghazouani, A.; Xia, W.; Ben Jebli, M.; Shahzad, U. Exploring the Role of Carbon Taxation Policies on CO2 Emissions: Contextual Evidence from Tax Implementation and Non-Implementation European Countries. Sustainability 2020, 12, 8680. [Google Scholar] [CrossRef]

- Risbrudt, C.D.; Ross, R.J.; Blankenburg, J.J.; Nelson, C.A. Forest Products Laboratory: Supporting the nation’s armed forces with valuable wood research for 90 years. For. Prod. J. 2007, 57, 6–14. [Google Scholar]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Petersen, E.H.; Krogh, H.; Dinesen, J. Miljødata for Udvalgte Bygningsdele. SBI Forlag-Rapport 296; Statens Byggeforskning-Sinstitut: Hørsholm, Denmark, 1998. [Google Scholar]

- Vek, V.; Balzano, A.; Poljanšek, I.; Humar, M.; Oven, P. Improving Fungal Decay Resistance of Less Durable Sapwood by Impregnation with Scots Pine Knotwood and Black Locust Heartwood Hydrophilic Extractives with Antifungal or Antioxidant Properties. Forests 2020, 11, 1024. [Google Scholar] [CrossRef]

- Momohara, I.; Ota, Y.; Sotome, K.; Nishimura, T. Assessment of decay risk of airborne wood-decay fungi II: Relation between isolated fungi and decay risk. J. Wood Sci. 2011, 58, 174–179. [Google Scholar] [CrossRef]

- Harlow, B.A.; Duursma, R.A.; Marshall, J.D. Leaf longevity of western red cedar (Thuja plicata) increases with depth in the canopy. Tree Physiol. 2005, 25, 557–562. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Orlowski, K.A.; Dudek, P.; Chuchala, D.; Blacharski, W.; Przybylinski, T. The Design Development of the Sliding Table Saw Towards Improving its Dynamic Properties. Appl. Sci. 2020, 10, 7386. [Google Scholar] [CrossRef]

- Antov, P.; Krišt’ák, L.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef] [PubMed]

- Pirayesh, H.; Moradpour, P.; Sepahvand, S. Particleboard from wood particles and sycamore leaves: Physico-mechanical properties. Eng. Agric. Environ. Food 2015, 8, 38–43. [Google Scholar] [CrossRef]

- Dziurka, D.; Mirski, R.; Dukarska, D.; Derkowski, A. Possibility of using the expanded polystyrene and rape straw to the manufacture of lightweight particleboards. Maderas. Cienc. Tecnol. 2015, 17, 647–656. [Google Scholar] [CrossRef] [Green Version]

- Aydin, I. Effects of veneer drying at high temperature and chemical treatments on equilibrium moisture content of plywood. Maderas. Cienc. Tecnol. 2014, 16, 445–452. [Google Scholar] [CrossRef]

- Xiong, X.; Niu, Y.; Zhou, Z.; Ren, J. Development and Application of a New Flame-Retardant Adhesive. Polymers 2020, 12, 2007. [Google Scholar] [CrossRef] [PubMed]

- BRASIL, Ministério das Cidades. Diretriz SINAT nº 005—Revisão 02—Sistemas Construtivos Estruturados em Peças Leves de Madeira Maciça Serrada, com Fechamentos em Chapas—Sistemas Leves Tipo “Light Wood Framing”; PBQP-H: Brasília, Brasil, 2017; p. 73. [Google Scholar]

- Forsberg, A.; von Malmborg, F. Tools for environmental assessment of the built environment. Build. Environ. 2004, 39, 223–228. [Google Scholar] [CrossRef]

- Liedtke, C.; Bienge, K.; Wiesen, K.; Teubler, J.; Greiff, K.; Lettenmeier, M.; Rohn, H. Resource Use in the Production and Consumption System—The MIPS Approach. Resources 2014, 3, 544–574. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Xue, B.; Pang, J.; Chen, X. The Decoupling of Resource Consumption and Environmental Impact from Economic Growth in China: Spatial Pattern and Temporal Trend. Sustainability 2016, 8, 222. [Google Scholar] [CrossRef] [Green Version]

- Hauschild, M. Baggrund for Miljøvurdering af Produkter; Instituttet for Produktudvikling, Danmarks Tekniske Universitet: Lungby, Denmark, 1996; pp. 1–81. [Google Scholar]

- Jensen, A.A.; Hoffman, L.; Møller, B.; Schmidt, A.; Christiansen, K.; Elkington, J. Life cycle assessment. A guide to approaches, experiences and information sources. Environ. Issues Ser. 1997, 6, 237–262. [Google Scholar]

- Dinesen, J.; Krogh, H.; Traberg-Borup, S. Livscyklusbaseret Bygningsprojektering: Opgørelse af Bygningers Energiforbrug og Energirelaterede Miljøpåvirkninger [Life-Cycle-Based Building Design. Calculation of Building’s Energy Consumption and Energy Related Environmental Impacts]; SBI forlag: Hørsholm, Denmark, 1997; pp. 1–57. [Google Scholar]

- Skovgaard, M.; Rasmussen, F.N.; Sørensen, C.G.; Birgisdottir, H. Brugervejledning til LCAbyg: Beregning af Bygningers Miljøprofiler; SBI, Statens Byggeforskningsin-stitut, Aalborg Universitet: København, Denmark, 2015; pp. 12–15. [Google Scholar]

- Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data- and stakeholder management framework for the implementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350. [Google Scholar] [CrossRef]

- Ullah, Z.; Al-Turjman, F.; Mostarda, L.; Gagliardi, R. Applications of Artificial Intelligence and Machine learning in smart cities. Comput. Commun. 2020, 154, 313–323. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Rombouts, L.J.; Ragas, A.M.; van de Meent, D. Human-toxicological effect and damage factors of car-cinogenic and noncarcinogenic chemicals for life cycle impact assessment. Integr. Environ. Assess. Manag. Int. J. 2005, 1, 181–244. [Google Scholar] [CrossRef]

- Andriulaitytė, I.; Vilnius Gediminas Technical University; Valentukeviciene, M. Circular economy in buildings. Bud. o Zoptymalizowanym Potencjale Energetycznym 2020, 10, 23–29. [Google Scholar] [CrossRef]

- Tooze, J.; Baurley, S.; Phillips, R.; Smith, P.; Foote, E.; Silve, S. Open Design: Contributions, Solutions, Processes and Projects. Des. J. 2014, 17, 538–559. [Google Scholar] [CrossRef] [Green Version]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Sharp, N. The First and the Fastest: Comparing Robin Knox-Johnston and Ellen MacArthur’s Historic Round-the-World Voyages; The History Press: Cheltenham, UK, 2018. [Google Scholar]

- Stahel, W. The Performance Economy; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2010. [Google Scholar]

- Petersen, K.H.; Napp, N.; Stuart-Smith, R.; Rus, D.; Kovac, M. A review of collective robotic construc-tion. Sci. Robot. 2019, 4. [Google Scholar] [CrossRef]

- Brand, S. How Buildings Learn: What Happens after They’re Built; Penguin Putnam Inc.: New York, NY, USA, 1995. [Google Scholar]

- Brand, S. Whole Earth Catalog; Point Foundation: New York, NY, USA, 1968. [Google Scholar]

- Duffy, F. Measuring Building Performance. Facilities 1990, 8, 17–20. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. LCA of different building lifetime shearing layers for the allocation of green points. Eco-Archit. V Harmon. Archit. Nat. 2014, 142, 459. [Google Scholar] [CrossRef]

- Agrawal, V.V.; Atasu, A.; Van Wassenhove, L.N. OM Forum—New Opportunities for Operations Management Research in Sustainability. Manuf. Serv. Oper. Manag. 2019, 21, 1–12. [Google Scholar] [CrossRef]

- Petrovski, A.; Petrovska-Hristovska, L.; Ivanovic-Sekularac, J.; Šekularac, N. Assessment of the sus-tainability of façade refurbishment. Therm. Sci. 2019, 24, 991–1006. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almusaed, A.; Yitmen, I.; Almsaad, A.; Akiner, İ.; Akiner, M.E. Coherent Investigation on a Smart Kinetic Wooden Façade Based on Material Passport Concepts and Environmental Profile Inquiry. Materials 2021, 14, 3771. https://doi.org/10.3390/ma14143771

Almusaed A, Yitmen I, Almsaad A, Akiner İ, Akiner ME. Coherent Investigation on a Smart Kinetic Wooden Façade Based on Material Passport Concepts and Environmental Profile Inquiry. Materials. 2021; 14(14):3771. https://doi.org/10.3390/ma14143771

Chicago/Turabian StyleAlmusaed, Amjad, Ibrahim Yitmen, Asaad Almsaad, İlknur Akiner, and Muhammed Ernur Akiner. 2021. "Coherent Investigation on a Smart Kinetic Wooden Façade Based on Material Passport Concepts and Environmental Profile Inquiry" Materials 14, no. 14: 3771. https://doi.org/10.3390/ma14143771

APA StyleAlmusaed, A., Yitmen, I., Almsaad, A., Akiner, İ., & Akiner, M. E. (2021). Coherent Investigation on a Smart Kinetic Wooden Façade Based on Material Passport Concepts and Environmental Profile Inquiry. Materials, 14(14), 3771. https://doi.org/10.3390/ma14143771