Improvement of Bond Strength and Durability of Recycled Aggregate Concrete Incorporating High Volume Blast Furnace Slag

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- (1)

- Cement: Type I Portland cement obtained by Taiwan Cement Corporation Ltd., Taipei, Taiwan, with a specific gravity of 3.15. The basic properties of cement are shown in Table 1.

- (2)

- Blast furnace slag (BFS): Grade 120 of ground granulated blast furnace slag obtained from Advanced-Tek Systems Co., Ltd., Taipei, Taiwan. The basic properties of BFS are shown in Table 1.

- (3)

- Fine Aggregate (FA): Natural river sand with a specific gravity of 2.60 and fineness modulus of 2.40.

- (4)

- Coarse aggregate (CA): Crushed river stone with a specific gravity of 2.61, bulk density of 1470 kg/m3 and maximum size of 19 mm.

- (5)

- Recycled coarse aggregate (RCA): Crushed waste concrete with a specific gravity of 2.26, bulk density of 1280 kg/m3 and particle sizes of 5~20 mm.

- (6)

- Superplasticizer (SP): High performance water-reducing agent obtained from HI CON Chemical Admixture Taiwan Ltd., Taipei, which meets the CNS 12283 Type G with a specific gravity of 1.2 ± 0.02 and pH 7.0 ± 1.0.

2.2. Mixture Proportion and Specimen Preparation

2.3. Test Procedures

3. Experimental Results and Discussion

3.1. Fresh Properties of Concrete

3.2. Mechanical Properties of Concrete

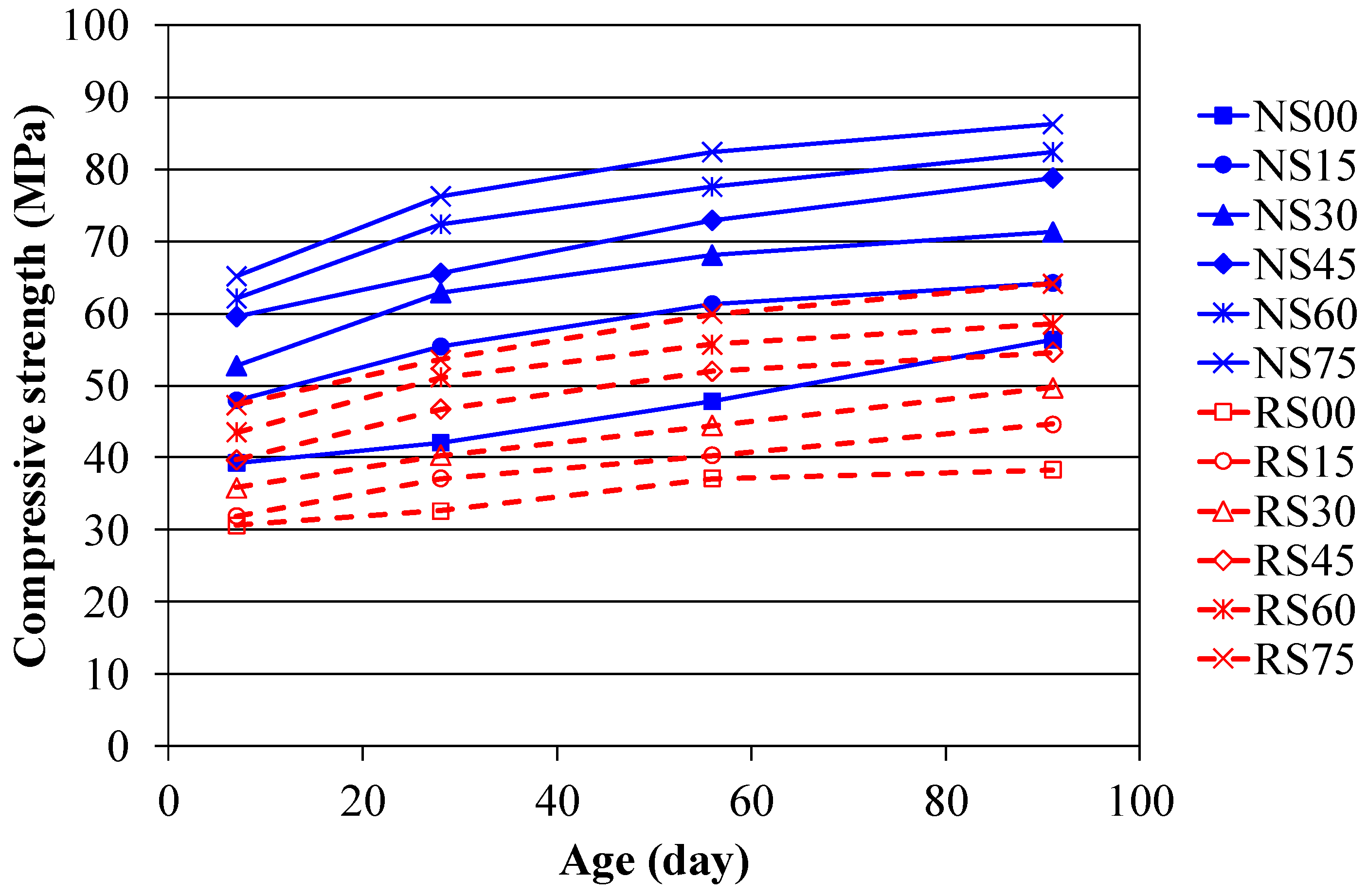

3.2.1. Compressive Strength

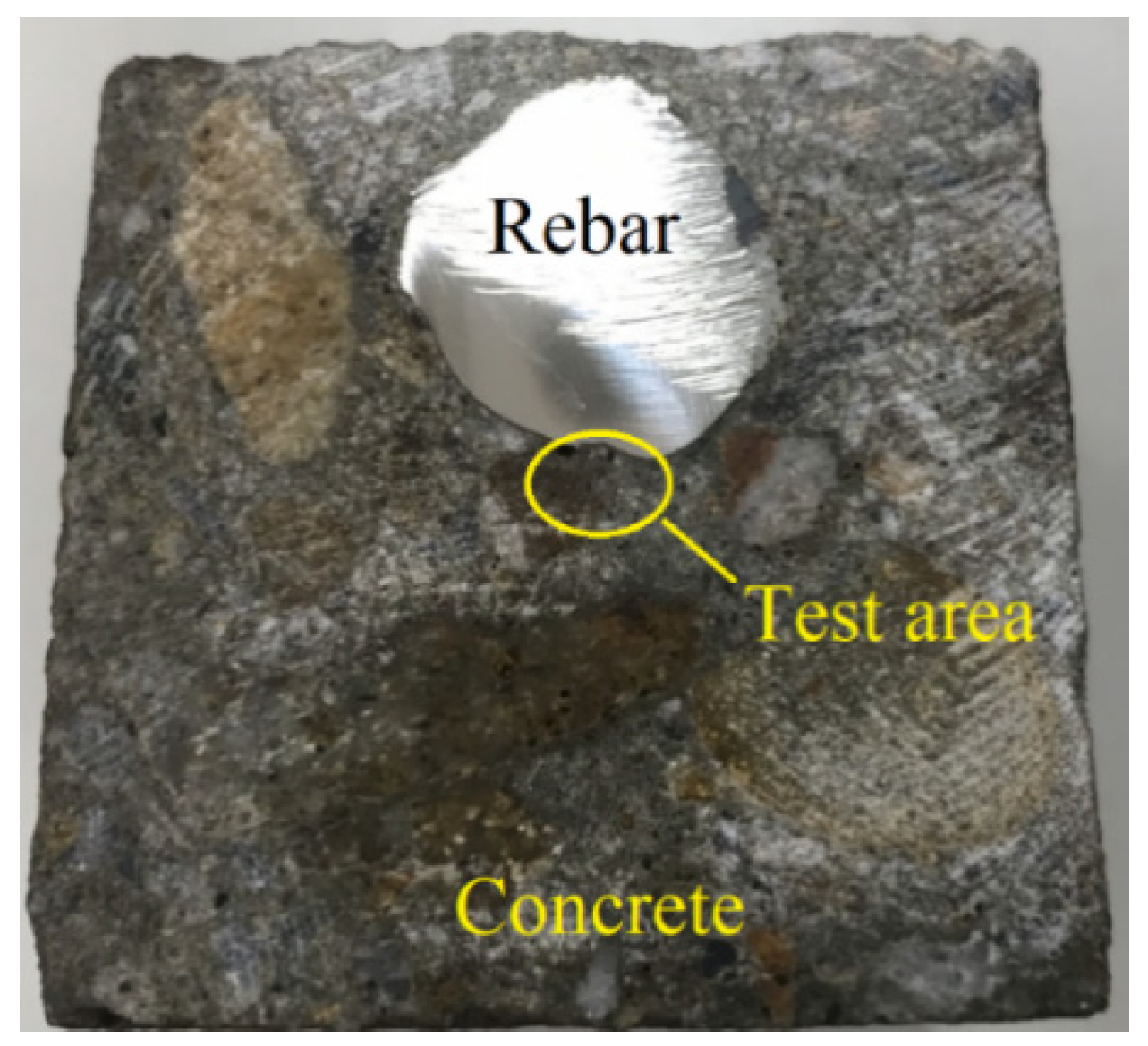

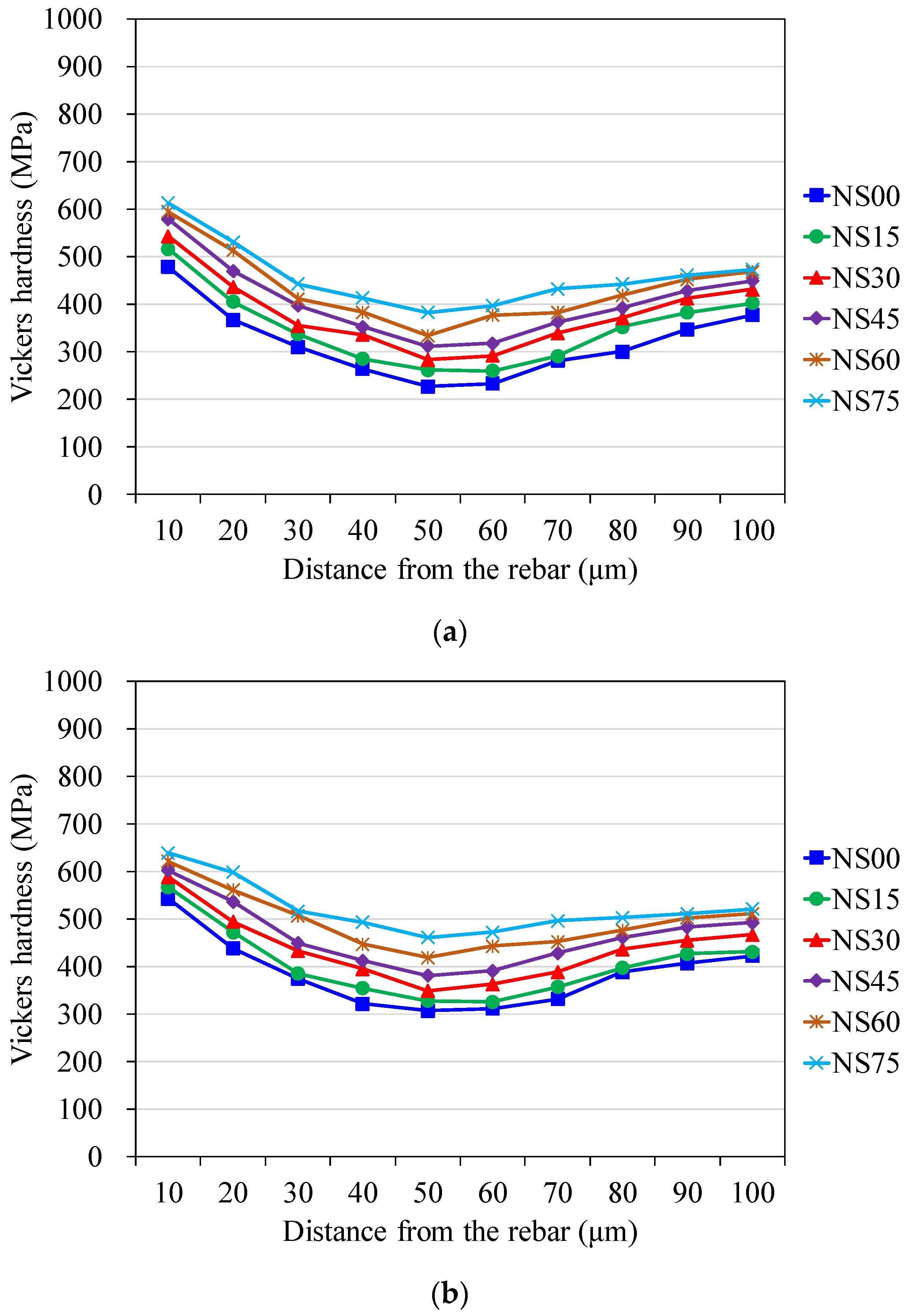

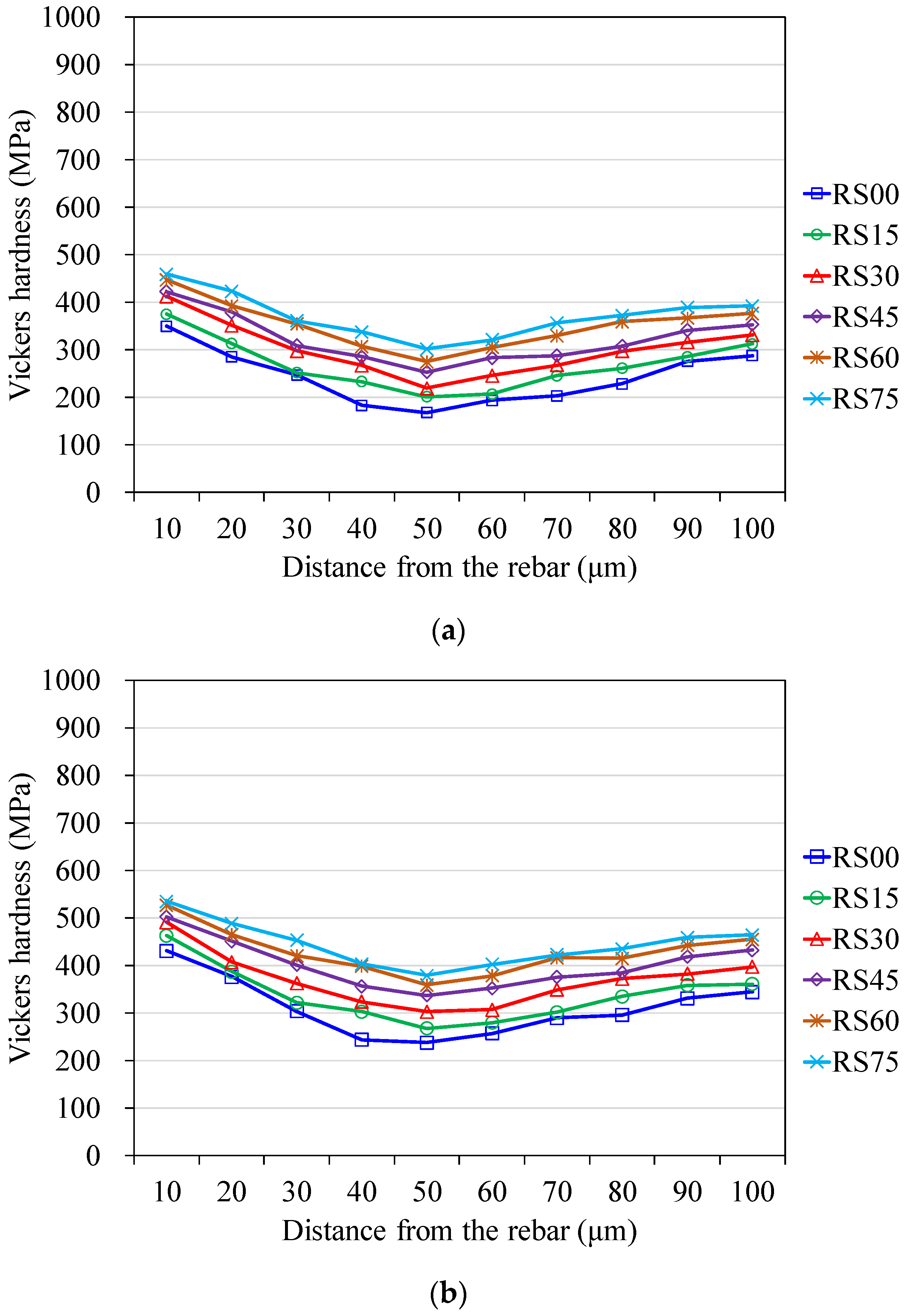

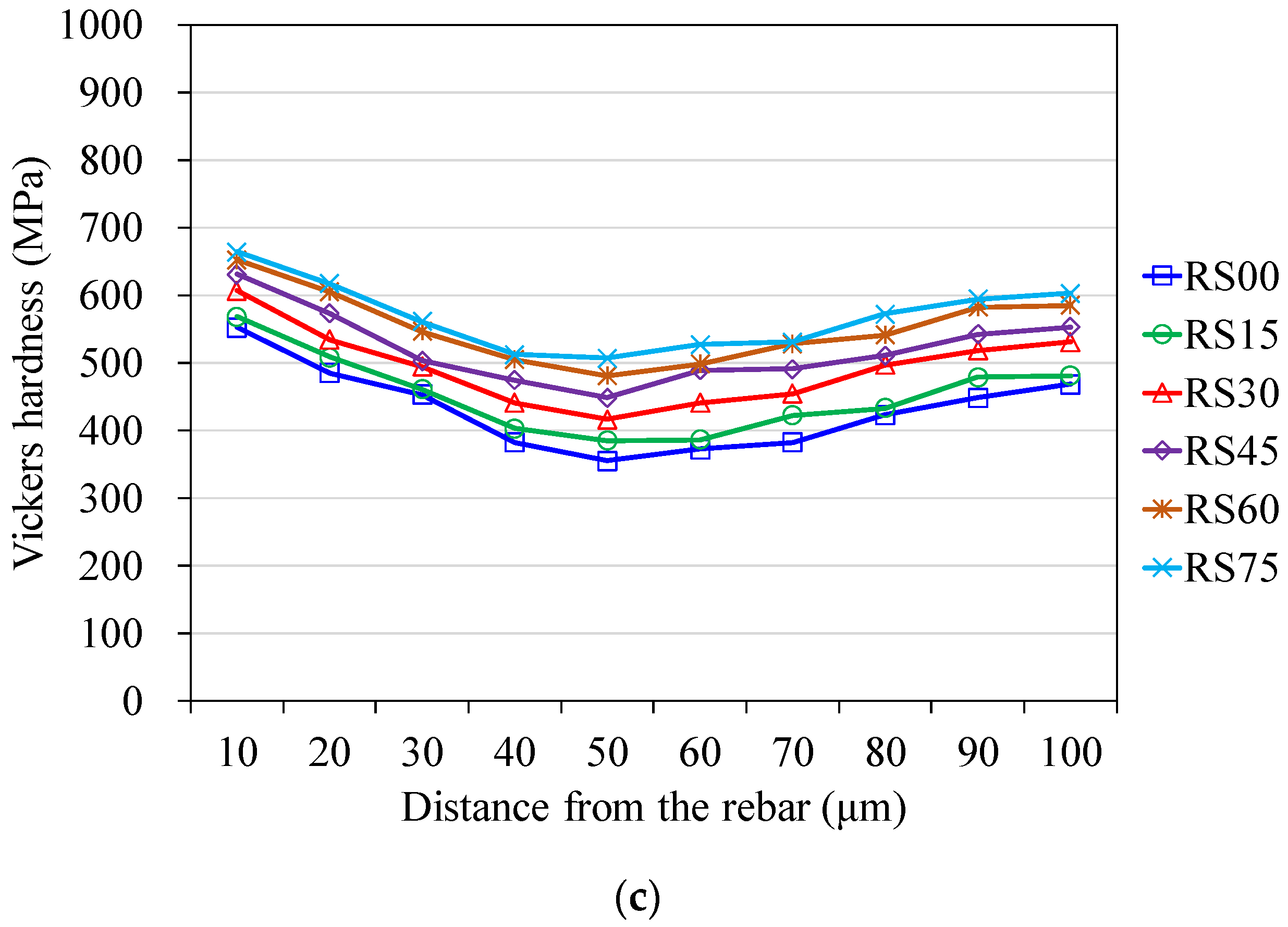

3.2.2. Properties of ITZ in Concrete

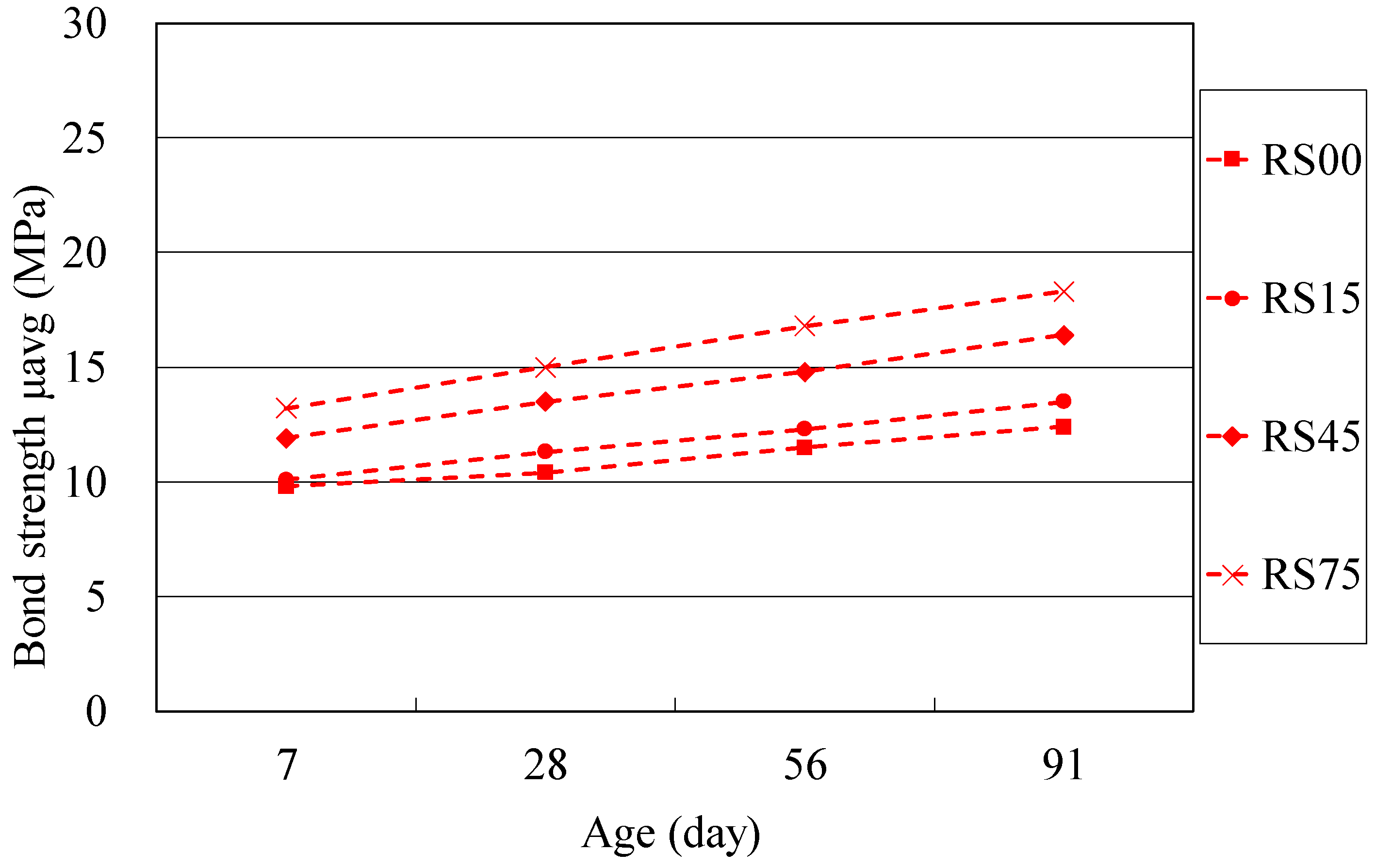

3.2.3. Bond Strength

3.3. Durability Properties

3.3.1. Resistance to Chloride-Ion Penetration

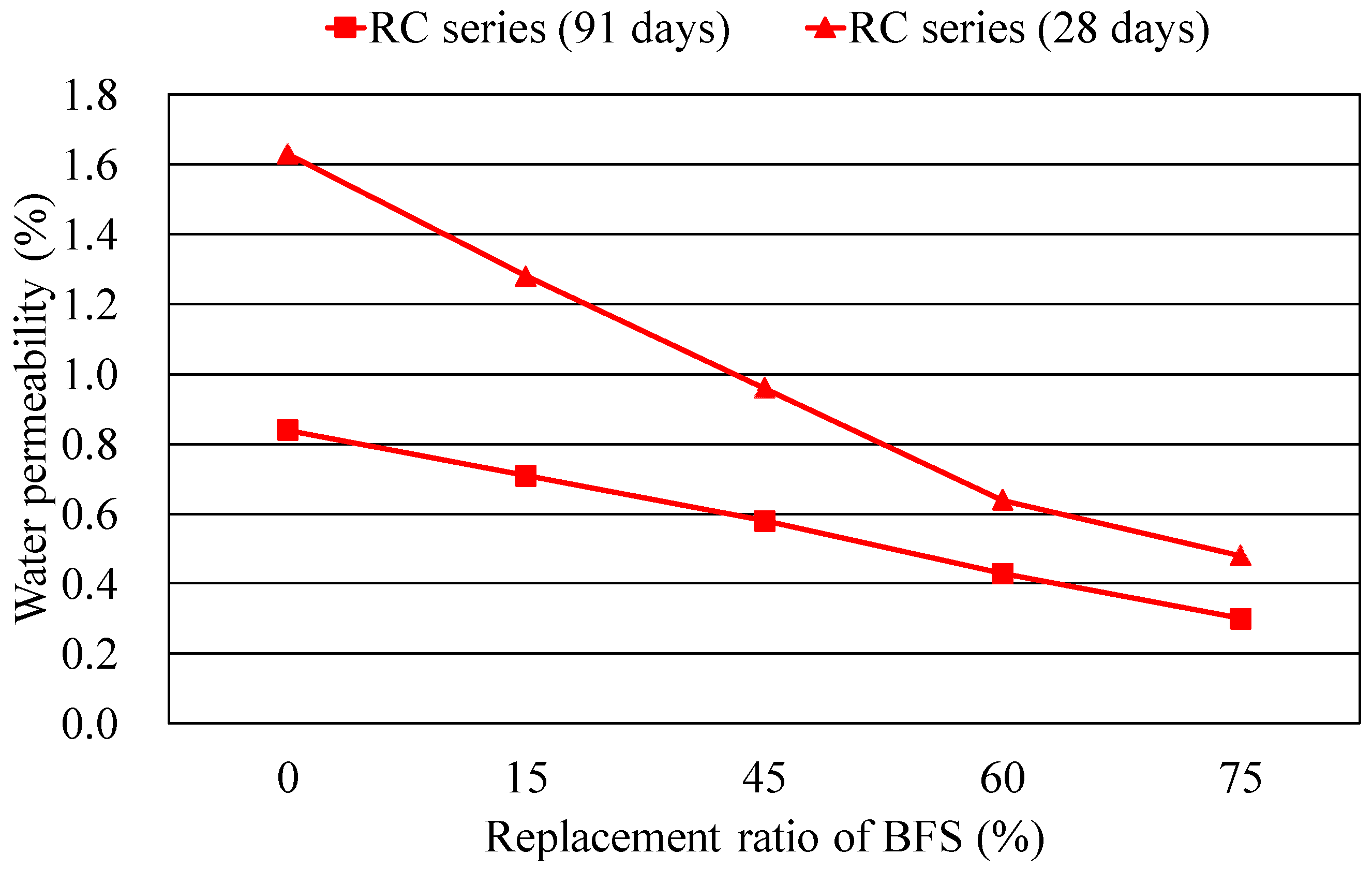

3.3.2. Water Permeability

4. Conclusions

- The strength development with age of the NAC and RAC mixtures presents a similar trend, in which the compressive strength of RAC series is lower than that of the corresponding NAC series, indicating that, despite the cement replacing BFS, the mixtures of RAC result in reduced strength. In addition, the strength gain at later ages for the BFS mixtures is higher than that of the reference mixture without BFS.

- Both of RAC and NAC mixtures incorporated with any BFS content show higher microhardness at ITZ than that of the correlated control mixture without BFS. Concrete at each age and containing more BFS presents higher microhardness at ITZ. This indicates that incorporating BFS makes the ITZ in concrete denser and stronger, especially at later ages.

- The bond strength of BFS concretes is higher than that for the reference concrete without BFS, which increases with the increase in BFS content. The rate of bond strength gains at long-term ages with respect to the 7-day strength increases with the increase in BFS content. This may be due to pozzolanic reaction of BFS, which enhances the strength properties of ITZ at the surface of steel bars, resulting in an improvement of the long-term bond strength of BFS concretes.

- Both RAC and NAC mixtures containing BFS present higher resistance to chloride ingress than that of the reference concrete without BFS, at all ages. The chloride-ion penetration value of the BFS-based concrete decreases with the increase in BFS content. Eventually, the mixture RS 75 comprising recycled aggregate and 75% BFS exhibits a pronounced resistance to chloride attack, revealing a chloride-ion penetration value of less than 1000 coulombs (very low permeability) at later ages.

- Incorporating BFS in concrete can inherently reduce the water permeability of concrete at all ages. Either RAC or NAC containing high volume BFS (>45%) at later ages may lead to lower water permeability, namely, superior durability to the concrete with BFS.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yaragal, S.C.; Teja, D.C.; Shaffi, M. Performance studies on concrete with recycled coarse aggregates. Adv. Concr. Constr. 2016, 4, 263–281. [Google Scholar] [CrossRef]

- Mao, Y.A.; Liu, J.H.; Shi, C.J. Autogenous shrinkage and drying shrinkage of recycled aggregate concrete: A review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Yang, K.H.; Chung, H.S.; Ashour, A.F. Influence of type and replacement level of recycled aggregates on concrete properties. ACI Mater. J. 2008, 105, 289–296. [Google Scholar]

- Limbachiya, M.C.; Leelawar, T.; Dhir, R.K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. Vol. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Parekh, D.N.; Modhera, C.D. Assessment of recycled aggregate concrete. J. Eng. Res. Stud. 2011, 2, 1–9. [Google Scholar]

- Gonza’lez-Fonteboa, B.; Martı´nez-Abella, F.; Eiras-Lo’pez, J.; Seara-Paz, S. Effect of recycled coarse aggregate on damage of recycled concrete. Mater. Struct. Vol. 2011, 44, 1759–1771. [Google Scholar] [CrossRef]

- ACI 232.2R, Report on the Use of Fly Ash in Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2018.

- ASTM C989, Standard Specification for Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars; ASTM International: West Conshohocken, PA, USA, 2005.

- CNS 12549, Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars; Chinese National Standards: Taipei, Taiwan, 2009.

- Ashish, D.K.; Singh, B.; Verma, S.K. The effect of attack of chloride and sulphate on ground granulated blast furnace slag concrete. Adv. Concr. Constr. 2016, 4, 107–121. [Google Scholar] [CrossRef]

- Kim, D.J.; Kim, C.Y.; Urgessac, G.; Choi, J.H.; Park, C.; Yeon, J.H. Durability and rheological characteristics of high-volume ground-granulated blast-furnace slag concrete containing CaCO3/anhydrate-based alkali activator. Constr. Build. Mater. 2019, 204, 10–19. [Google Scholar] [CrossRef]

- Duraman, S.B.; Richardson, I.G. Microstructure & properties of steel-reinforced concrete incorporating Portland cement and ground granulated blast furnace slag hydrated at 20 °C. Cem. Concr. Res. 2020, 137, 106193. [Google Scholar]

- Lee, J.H.; Lee, T.Y. Durability and engineering performance evaluation of CaO content and ratio of binary blended concrete containing ground granulated blast-furnace slag. Appl. Sci. 2020, 10, 2504. [Google Scholar] [CrossRef] [Green Version]

- Nicula, L.M.; Corbu, O.; Iliescu, M. Influence of blast furnace slag on the durability characteristic of road concrete such as freeze-thaw resistance. Procedia Manuf. 2020, 46, 194–201. [Google Scholar] [CrossRef]

- Djelloul, O.K.; Menadi, B.; Wardeh, G.; Kenai, S. Performance of self-compacting concrete made with coarse and fine recycled concrete aggregates and ground granulated blast-furnace slag. Adv. Concr. Constr. 2018, 6, 103–121. [Google Scholar]

- El-Hawary, M.; Al-Yaqout, A.; Nouh, K. Durability of recycled aggregate concrete incorporating slag. Waste Resour. Manag. 2019, 172, 107–117. [Google Scholar] [CrossRef]

- Khodair, Y.A.; Bommareddy, B. Self-consolidating concrete using recycled concrete aggregate and high volume of fly ash, and slag. Constr. Build. Mater. 2017, 153, 307–316. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of sustainable concrete using recycled coarse aggregate and ground granulated blast furnace slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Seara-Paz, S.; González-Fonteboa, B.; Eiras-López, J.; Herrador, M.F. Bond behavior between steel reinforcement and recycled concrete. Mater. Struct. 2013, 47, 323–334. [Google Scholar]

- Butler, L.; West, J.S.; Tighe, S.L. The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N. Bond, durability and microstructural characteristics of ground granulated blast furnace slag based recycled aggregate concrete. Constr. Build. Mater. 2019, 212, 578–595. [Google Scholar] [CrossRef]

- IS 10262, Concrete Mix Proportioning–Guidelines; Indian Standard: New Delhi, India, 2009.

- Majhi, R.K.; Nayak, A.N. Production of sustainable concrete utilising high-volume blast furnace slag and recycled aggregate with lime activator. J. Clean. Prod. 2020, 255, 120188. [Google Scholar] [CrossRef]

- Soylev, T.A.; François, R. Quality of steel-concrete interface and corrosion of reinforcing steel. Cement and Concrete Research 2003, 33, 1407–1415. [Google Scholar] [CrossRef]

- Horne, A.T.; Richardson, I.G.; Brydson, R.M.D. Quantitative analysis of the microstructure of interfaces in steel reinforced concrete. Cem. Concr. Res. 2007, 37, 1613–1623. [Google Scholar] [CrossRef]

- Chen, F.J.; Li, C.Q.; Baji, H.; Ma, B.G. Quantification of steel-concrete interface in reinforced concrete using Backscattered Electron imaging technique. Constr. Build. Mater. 2018, 179, 420–429. [Google Scholar] [CrossRef]

- Igarashi, S.B.A.; Bentur, A.; Mindess, S. Microhardness testing of cementation materials. Adv. Cem. Based Mater. 1996, 4, 48–57. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Prentice Hall: Hoboken, NJ, USA, 2003; pp. 78–79. [Google Scholar]

- ACI 211.1, Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1991.

- ASTM C39/C39M, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C234, Standard Test Method for Comparing Concretes on the Basis of the Bond Developed with Reinforcing Steel; ASTM International: West Conshohocken, PA, USA, 1991.

- ASTM C 1202, Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2012.

- IS 3085, Method of Test for Permeability of Cement Mortar and Concrete; Indian Standard: New Delhi, India, 1965.

- ASTM E384, Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 2017.

| Components | Cement | Blast Furnace Slag |

|---|---|---|

| SiO2 (%) | 21.4 | 38.1 |

| Al2O3 (%) | 4.9 | 7.5 |

| Fe2O3 (%) | 3.8 | 0.3 |

| CaO (%) | 64.2 | 39.9 |

| MgO (%) | 1.1 | 10.6 |

| Na2O (%) | 0.2 | 0.4 |

| SO3 (%) | 2.1 | 0.2 |

| Loss on ignition (%) | 2.1 | 1.4 |

| Specific surface area (m2/kg) | 336 | 538 |

| Specific gravity | 3.15 | 2.90 |

| Mixture | w/cm | Water | Cement | BFS b | FA | NCA | RCA | SP |

|---|---|---|---|---|---|---|---|---|

| kg/m3 | ||||||||

| NS00 a | 0.50 | 210 | 420 | 0 | 800 | 860 | 0 | 1.1 |

| NS15 | 0.46 | 193 | 357 | 63 | 839 | 860 | 0 | 1.0 |

| NS30 | 0.42 | 176 | 294 | 126 | 878 | 860 | 0 | 1.8 |

| NS45 | 0.38 | 160 | 231 | 189 | 918 | 860 | 0 | 2.6 |

| NS60 | 0.34 | 143 | 168 | 252 | 956 | 860 | 0 | 3.6 |

| NS75 | 0.30 | 126 | 105 | 315 | 995 | 860 | 0 | 6.3 |

| RS00 | 0.50 | 210 | 420 | 0 | 793 | 0 | 750 | 1.1 |

| RS15 | 0.46 | 193 | 357 | 63 | 832 | 0 | 750 | 1.5 |

| RS30 | 0.42 | 176 | 294 | 126 | 871 | 0 | 750 | 2.3 |

| RS45 | 0.38 | 160 | 231 | 189 | 910 | 0 | 750 | 3.6 |

| RS60 | 0.34 | 143 | 168 | 252 | 950 | 0 | 750 | 5.9 |

| RS75 | 0.30 | 126 | 105 | 315 | 989 | 0 | 750 | 8.7 |

| Mixture | Slump (mm) | Unit Weight (kg/m3) | Air Content (%) |

|---|---|---|---|

| NS00 | 225 | 2314 | 2.1 |

| NS15 | 210 | 2303 | 1.2 |

| NS30 | 220 | 2289 | 1.4 |

| NS45 | 210 | 2285 | 2.3 |

| NS60 | 250 | 2267 | 3.2 |

| NS75 | 250 | 2236 | 3.4 |

| RS00 | 215 | 2284 | 2.0 |

| RS15 | 220 | 2273 | 1.8 |

| RS30 | 250 | 2261 | 2.2 |

| RS45 | 235 | 2238 | 3.1 |

| RS60 | 230 | 2231 | 4.1 |

| RS75 | 200 | 2215 | 4.8 |

| Mixture | w/cm | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|

| 7 Days | 28 Days | 56 Days | 91 Days | ||

| NS00 | 0.50 | 39.2 (100%) | 42.1 (107%) | 47.8 (122%) | 56.3 (130%) |

| NS15 | 0.46 | 47.9 (100%) | 55.4 (115%) | 61.3 (128%) | 64.2 (134%) |

| NS30 | 0.42 | 52.8 (100%) | 62.9 (119%) | 68.1 (129%) | 71.3 (135%) |

| NS45 | 0.38 | 59.5 (100%) | 65.6 (110%) | 72.9 (123%) | 78.8 (133%) |

| NS60 | 0.34 | 62.1 (100%) | 72.3 (116%) | 77.5 (125%) | 82.4 (133%) |

| NS75 | 0.30 | 65.2 (100%) | 76.2 (116%) | 82.4 (126%) | 86.2 (132%) |

| RS00 | 0.50 | 30.6 (100%) | 32.6 (106%) | 37.1 (121%) | 38.3 (125%) |

| RS15 | 0.46 | 31.9 (100%) | 37.1 (116%) | 40.3 (126%) | 44.6 (139%) |

| RS30 | 0.42 | 35.8 (100%) | 40.3 (112%) | 44.4 (124%) | 49.7 (138%) |

| RS45 | 0.38 | 39.7 (100%) | 46.7 (118%) | 52.0 (130%) | 54.6 (137%) |

| RS60 | 0.34 | 43.5 (100%) | 51.1 (117%) | 55.7 (128%) | 58.5 (135%) |

| RS75 | 0.30 | 47.3 (100%) | 53.6 (111%) | 59.9 (127%) | 64.1 (136%) |

| Mixture | Age (day) | Concrete Strength (MPa) | Bond Strength μavg (MPa) | Age (day) | Concrete Strength (MPa) | Bond Strength μavg (MPa) |

|---|---|---|---|---|---|---|

| NS00 | 7 | 39.2 | 12.7 (100%) | 56 | 47.8 | 15.1 (119%) |

| NS15 | 47.9 | 14.3 (100%) | 61.2 | 17.2 (120%) | ||

| NS45 | 59.5 | 16.6 (100%) | 72.9 | 20.5 (123%) | ||

| NS75 | 65.2 | 20.1(100%) | 80.4 | 25.6 (127%) | ||

| RS00 | 30.6 | 9.8 (100%) | 38.1 | 11.5 (117%) | ||

| RS15 | 31.9 | 10.1 (100%) | 41.3 | 12.3 (122%) | ||

| RS45 | 39.7 | 11.9 (100%) | 52.0 | 14.8 (124%) | ||

| RS75 | 47.3 | 13.2 (100%) | 59.9 | 16.8 (127%) | ||

| NS00 | 28 | 42.1 | 13.9 (109%) | 91 | 56.3 | 16.3 (128%) |

| NS15 | 55.4 | 16.0 (112%) | 64.2 | 18.7 (131%) | ||

| NS45 | 65.6 | 18.8 (113%) | 78.8 | 22.1 (133%) | ||

| NS75 | 76.2 | 23.4 (116%) | 85.2 | 27.1 (135%) | ||

| RS00 | 32.6 | 10.4 (106%) | 41.3 | 12.4 (126%) | ||

| RS15 | 37.1 | 11.3 (111%) | 44.6 | 13.5 (134%) | ||

| RS45 | 46.2 | 13.5 (113%) | 54.8 | 16.4 (138%) | ||

| RS75 | 52.6 | 15.0 (114%) | 63.5 | 18.3 (139%) |

| Mixture | Total Charge Passed (Coulombs) * | Age (Days) | ||

|---|---|---|---|---|

| 28 Days | 56 Days | 91 Days | ||

| NS00 | 9605 | 6567 | 6182 | high/high/high ** |

| NS15 | 6941 | 5589 | 5068 | high/high/high |

| NS45 | 3562 | 3042 | 2928 | moderate/moderate/moderate |

| NS60 | 2266 | 1478 | 1416 | moderate/low/low |

| NS75 | 1446 | 1109 | 1076 | low/low/low |

| RS00 | 10,506 | 8329 | 8014 | high/high/high |

| RS15 | 6214 | 4813 | 4139 | high/high/high |

| RS45 | 2973 | 2299 | 2136 | moderate/moderate/moderate |

| RS60 | 1507 | 1385 | 922 | low/low/very low |

| RS75 | 938 | 861 | 581 | very low/very low/very low |

| Mixture | Compressive Strength (MPa) | Water Permeability (%) | ||||

|---|---|---|---|---|---|---|

| 28 Days | 56 Days | 91 Days | 28 Days | 56 Days | 91 Days | |

| NS00 | 42.1 | 47.8 | 51.3 | 0.52 | 0.47 | 0.46 |

| NS15 | 55.4 | 61.3 | 64.2 | 0.46 | 0.41 | 0.40 |

| NS45 | 65.6 | 72.9 | 78.8 | 0.36 | 0.28 | 0.21 |

| NS60 | 72.3 | 77.5 | 82.4 | 0.25 | 0.22 | 0.16 |

| NS75 | 76.2 | 82.4 | 86.2 | 0.15 | 0.13 | 0.09 |

| RS00 | 32.6 | 39.1 | 38.3 | 0.84 | 0.81 | 0.79 |

| RS15 | 37.1 | 40.3 | 44.6 | 0.71 | 0.68 | 0.57 |

| RS45 | 46.7 | 52.0 | 54.6 | 0.58 | 0.49 | 0.38 |

| RS60 | 51.1 | 55.7 | 58.5 | 0.43 | 0.32 | 0.21 |

| RS75 | 52.6 | 59.9 | 64.1 | 0.30 | 0.23 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.-K.; Wu, C.-H. Improvement of Bond Strength and Durability of Recycled Aggregate Concrete Incorporating High Volume Blast Furnace Slag. Materials 2021, 14, 3708. https://doi.org/10.3390/ma14133708

Lin S-K, Wu C-H. Improvement of Bond Strength and Durability of Recycled Aggregate Concrete Incorporating High Volume Blast Furnace Slag. Materials. 2021; 14(13):3708. https://doi.org/10.3390/ma14133708

Chicago/Turabian StyleLin, Shu-Ken, and Chung-Hao Wu. 2021. "Improvement of Bond Strength and Durability of Recycled Aggregate Concrete Incorporating High Volume Blast Furnace Slag" Materials 14, no. 13: 3708. https://doi.org/10.3390/ma14133708

APA StyleLin, S.-K., & Wu, C.-H. (2021). Improvement of Bond Strength and Durability of Recycled Aggregate Concrete Incorporating High Volume Blast Furnace Slag. Materials, 14(13), 3708. https://doi.org/10.3390/ma14133708