Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus excelsior Wood in Compression

Abstract

1. Introduction

2. Materials and Methods

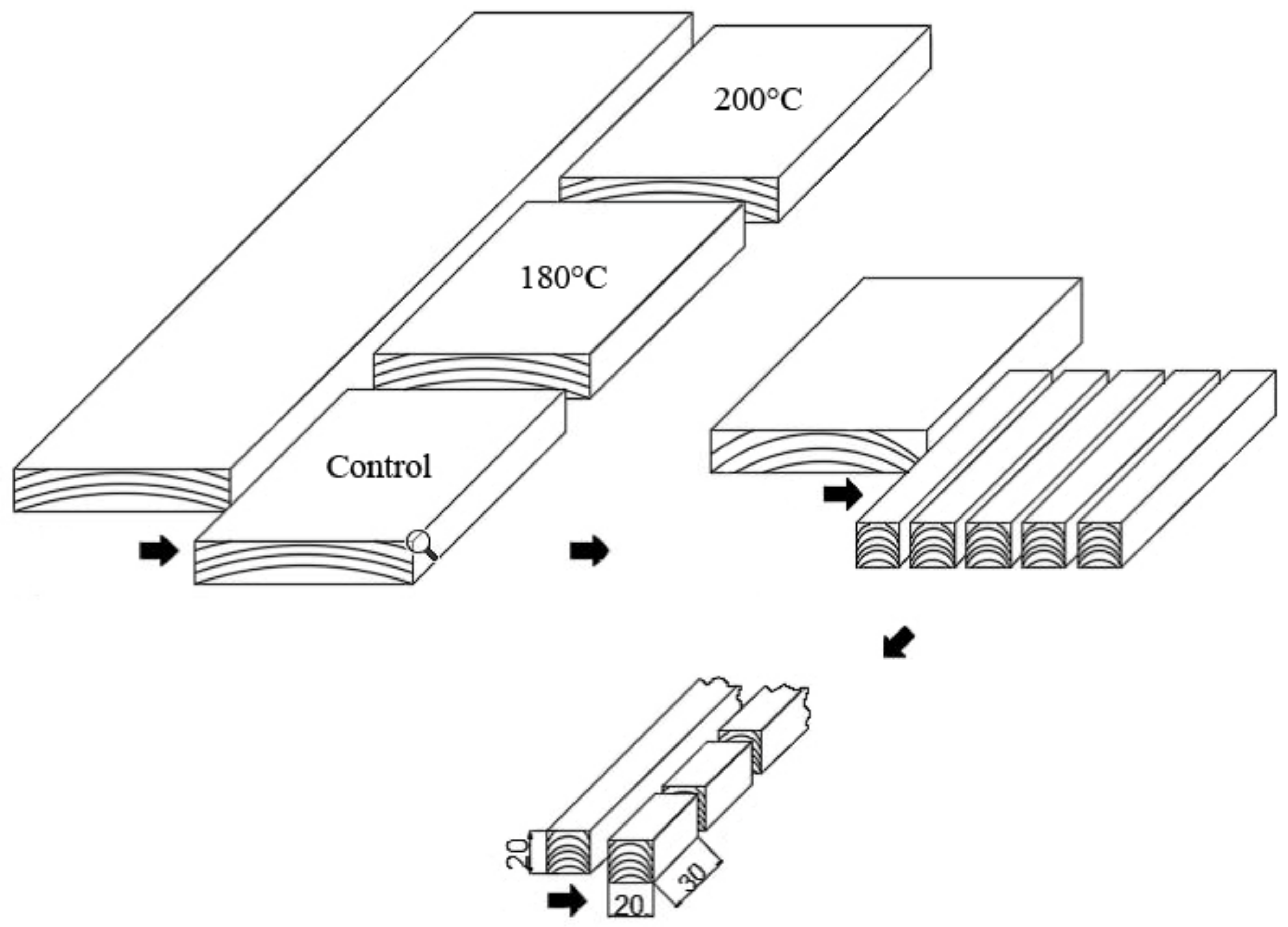

2.1. Thermal Modification and Wood Sampling

2.2. Conditioning of the Specimens

2.3. Compression Tests

2.4. Statistical Analysis

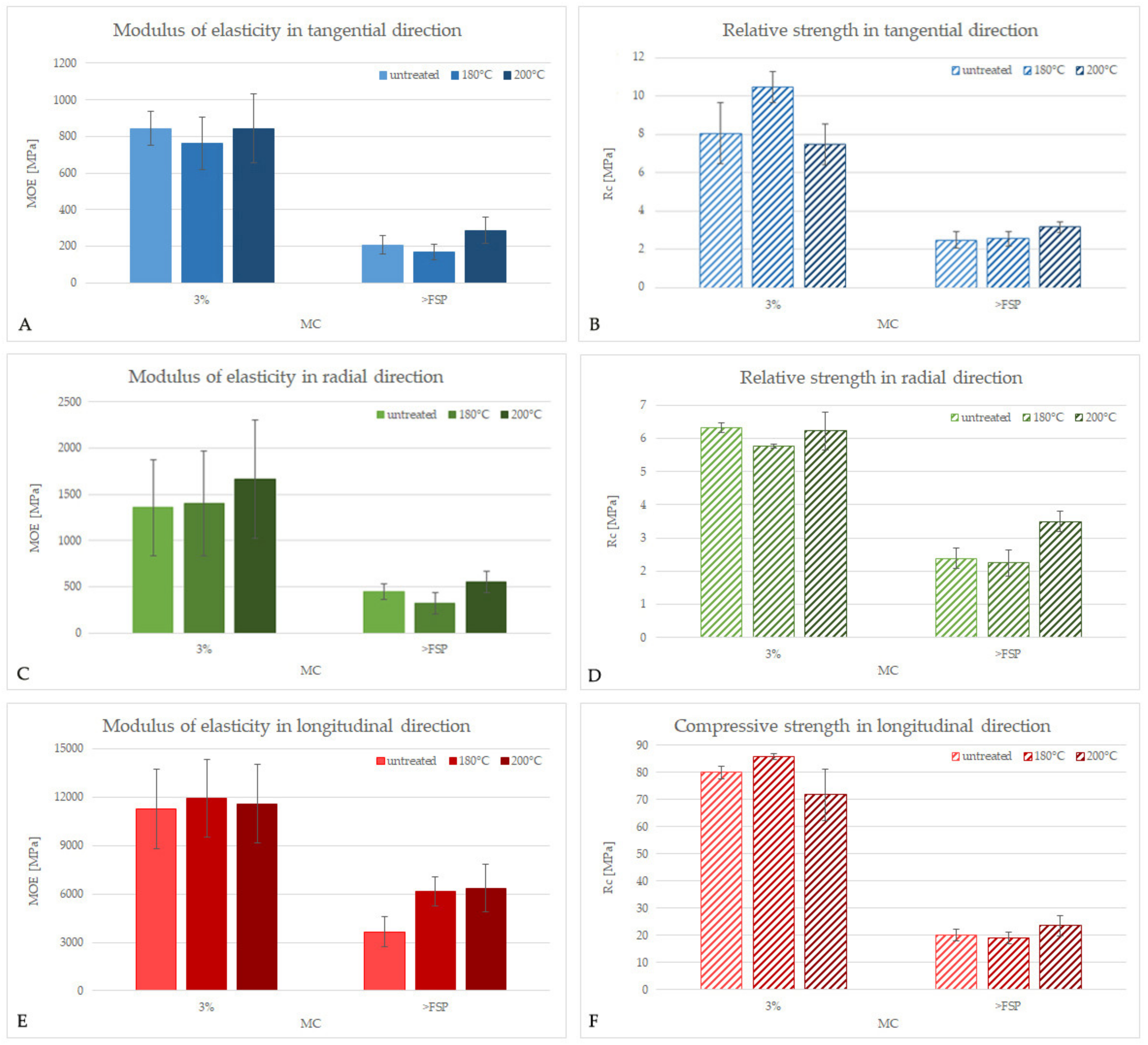

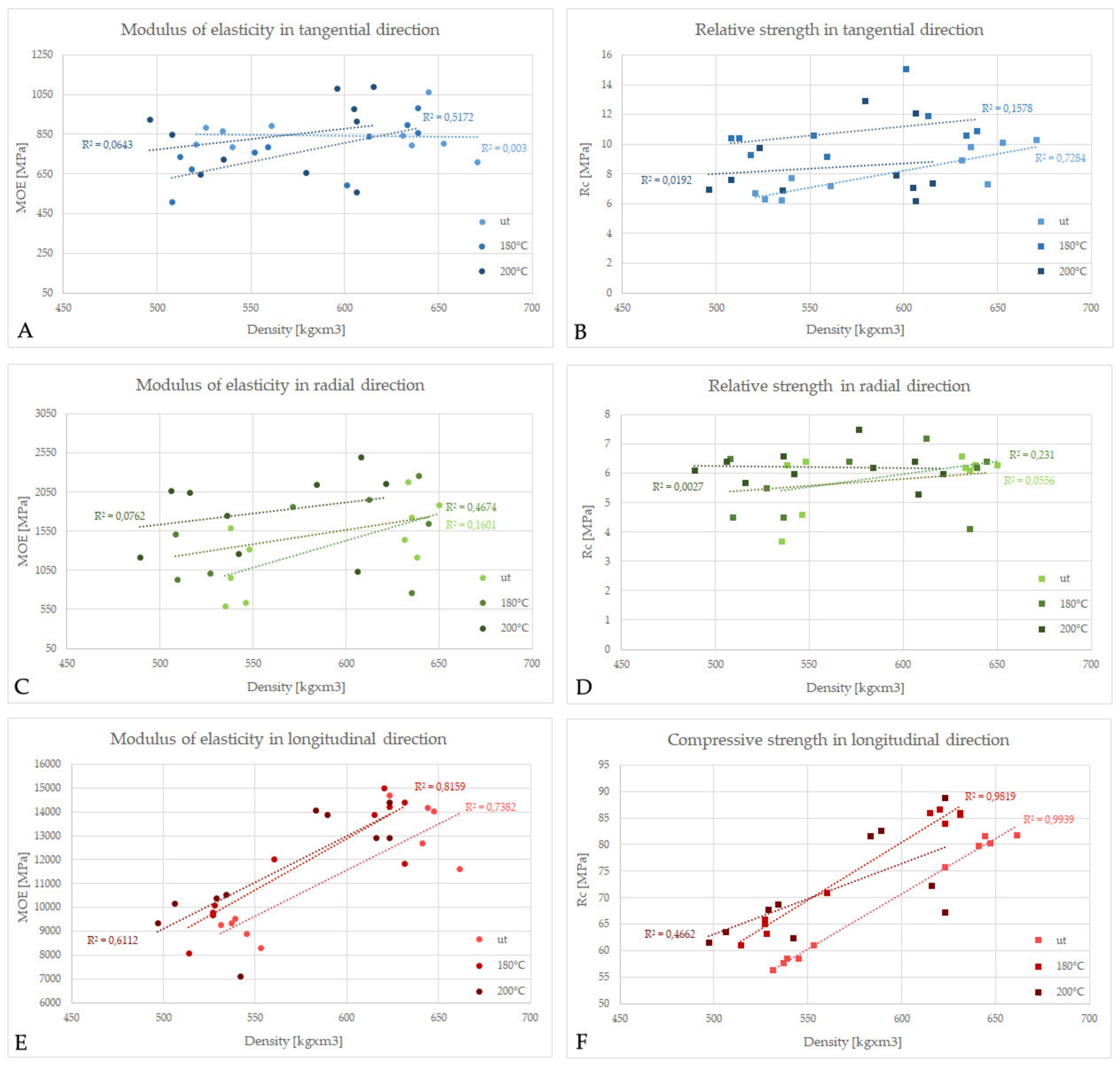

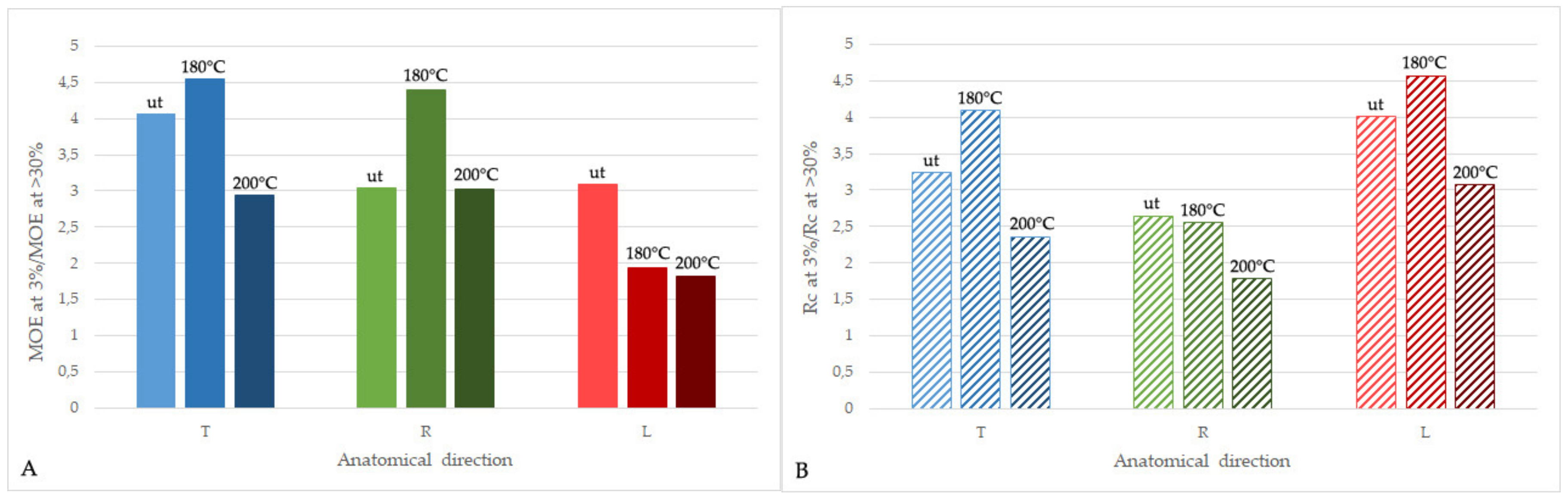

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Candelier, K.; Thévenon, M.-F.; Pétrissans, A.; Dumarcay, S.; Gérardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2015, 73, 559–570. [Google Scholar] [CrossRef]

- Majano-Majano, A.; Hughes, M.; Fernandez-Cabo, J.L. The fracture toughness and properties of thermally modified beech and ash at different moisture contents. Wood Sci. Technol. 2010, 46, 5–21. [Google Scholar] [CrossRef]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar]

- González-Peña, M.M.; Curling, S.F.; Hale, M.D. On the effect of heat on the chemical composition and dimensions of thermally-modified wood. Polym. Degrad. Stab. 2009, 94, 2184–2193. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Militz, H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz als Roh- und Werkst. 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Boonstra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Holz als Roh- und Werkst. 1998, 56, 149–153. [Google Scholar] [CrossRef]

- Yildiz, S.; Gümüşkaya, E. The effects of thermal modification on crystalline structure of cellulose in soft and hardwood. Build. Environ. 2007, 42, 62–67. [Google Scholar] [CrossRef]

- Yildiz, S.; Gezer, E.; Yildiz, U.C. Mechanical and chemical behavior of spruce wood modified by heat. Build. Environ. 2006, 41, 1762–1766. [Google Scholar] [CrossRef]

- Allegretti, O.; Brunetti, M.; Cuccui, I.; Ferrari, S.; Nocetti, M.; Terziev, N. Thermo-vacuum modification of spruce (Picea abies Karst.) and fir (Abies alba Mill.) wood. BioResources 2012, 7, 3656–3669. [Google Scholar]

- Candelier, K.; Dumarcay, S.; Pétrissans, A.; Desharnais, L.; Gérardin, P.; Pétrissans, M. Comparison of chemical composition and decay durability of heat treated wood cured under different inert atmospheres: Nitrogen or vacuum. Polym. Degrad. Stab. 2013, 98, 677–681. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Holz als Roh- und Werkst. 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Mania, P.; Majka, J.; Zborowska, M. The effect of thermo-mechanical treatment of moso bamboo (Phyllostachys pubescens) on its sorption and physicomechanical properties. Drv. Ind. 2019, 70, 265–272. [Google Scholar] [CrossRef]

- Mania, P.; Moliński, W.; Roszyk, E.; Górska, M. Optimization of Spruce (Picea abies L.) Wood Thermal Treatment Temperature to Improve Its Acoustic Properties. BioResources 2020, 15, 505–516. [Google Scholar]

- Dilik, T.; Hiziroglu, S. Bonding strength of heat treated compressed Eastern red cedar wood. Mater. Design 2012, 42, 317–320. [Google Scholar] [CrossRef]

- Hannouz, S.; Collet, R.; Butaud, J.C.; Bléron, L.; Candelier, K. Mechanical characterization of heat-treated ash wood in relation with structural timber standards. Pro Ligno 2015, 11, 13. [Google Scholar]

- Kocaefe, D.; Poncsak, S.; Boluk, Y. Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 2008, 3, 517–537. [Google Scholar]

- Boonstra, M.J.; Rijsdijk, J.; Sander, C.; Kegel, E.; Tjeerdsma, B.; Militz, H.; Van Acker, J.; Stevens, M. Microstructural and physical aspects of heat treated wood: Part 2. Maderas Ciencia y Tecnología 2006, 8, 209–217. [Google Scholar] [CrossRef]

- Candelier, K.; Hannouz, S.; Thévenon, M.-F.; Guibal, D.; Gérardin, P.; Pétrissans, M.; Collet, R. Resistance of thermally modified ash (Fraxinus excelsior L.) wood under steam pressure against rot fungi, soil-inhabiting micro-organisms and termites. Holz als Roh- und Werkst. 2016, 75, 249–262. [Google Scholar] [CrossRef]

- Oliver-Villanueva, J.-V.; Gascón-Garrido, P.; Ibiza-Palacios, M.D.S. Evaluation of thermally-treated wood of beech (Fagus sylvatica L.) and ash (Fraxinus excelsior L.) against Mediterranean termites (Reticulitermes spp.). Holz als Roh- und Werkst. 2013, 71, 391–393. [Google Scholar] [CrossRef]

- Tomak, E.D.; Ustaomer, D.; Yildiz, S.; Peşman, E. Changes in surface and mechanical properties of heat treated wood during natural weathering. Measurement 2014, 53, 30–39. [Google Scholar] [CrossRef]

- Zhou, Q.; Tu, D.; Liao, L.; Guo, Q. Variation of Equilibrium Moisture Content of Heat-treated Couratari oblongifolia, Fraxinus excelsior, and Quercus rubra Wood. BioResources 2012, 8, 182–188. [Google Scholar] [CrossRef][Green Version]

- Roffael, E.; Kraft, R. Einfluss der thermischen Modifizierung von Holz auf das Wasserrückhaltevermögen (WRV-Wert) Influence of thermal wood modification on the Water Retention Value (WRV). Holz als Roh- und Werkst. 2011, 70, 393–395. [Google Scholar] [CrossRef][Green Version]

- Govorčin, S.; Sinković, T.; Hrčka, R. Some Physical and Mechanical Properties of Recent and Heat Treated Ash–Fraxinus excelsior L. Šumar. List 2009, 133, 185–191. [Google Scholar]

- Sinković, T.; Govorčin, S.; Sedlar, T. Comparison of physical properties of heat treated and untreated hornbeam wood, beech wood, ash wood and oak wood. In Proceedings of the Hardwood Science and Technology—5th Conference on Hardwood Research and Utilisation in Europe, Sopron, Hungary, 10–11 September 2012. [Google Scholar]

- Pleschberger, H.; Teischinger, A.; Müller, U.; Hansmann, C. Change in fracturing and colouring of solid spruce and ash wood after thermal modification. Wood Mater. Sci. Eng. 2014, 9, 92–101. [Google Scholar] [CrossRef]

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Color stability of heat-treated wood during artificial weathering. Holz als Roh- und Werkst. 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Tomak, E.D.; Ustaomer, D.; Ermeydan, M.A.; Yildiz, S. An investigation of surface properties of thermally modified wood during natural weathering for 48 months. Measurement 2018, 127, 187–197. [Google Scholar] [CrossRef]

- Standfest, G.; Zimmer, B. The surface hardness of thermally treated woods. In Proceedings of the International Convention of the Forest Products Society, St. Louis, MO, USA, 22–24 June 2008; pp. 22–24. [Google Scholar]

- Moliński, W.; Roszyk, E.; Jablonski, A.; Puszynski, J.; Cegiela, J. Mechanical parameters of thermally modified ash wood determined by compression in radial direction. Maderas Ciencia y Tecnología 2016, 18, 577–586. [Google Scholar] [CrossRef][Green Version]

- Moliński, W.; Roszyk, E.; Jabtonski, A.; Puszynski, J.; Cegieta, J. Mechanical parameters of thermally modified ash wood determined on compression in tangential direction. Maderas Ciencia y Tecnología 2018, 20, 267–276. [Google Scholar] [CrossRef]

- Majka, J.; Roszyk, E. Swelling restraint of thermally modified ash wood perpendicular to the grain. Holz als Roh- und Werkst. 2018, 76, 1129–1136. [Google Scholar] [CrossRef]

- Finnish ThermoWood Association. Thermowood Handbook; International ThermoWood Association: Helsinki, Finland, 2003. [Google Scholar]

- ISO. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 17: Determination of Ultimate Stress in Compression Parallel to Grain; ISO 13061-17:2017; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- ISO. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 5: Determination of Strength in Compression Perpendicular to Grain; ISO/FDIS 13061-5:2020; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Kačíková, D.; Kačík, F.; Čabalová, I.; Durkovic, J. Effects of thermal treatment on chemical, mechanical and colour traits in Norway spruce wood. Bioresour. Technol. 2013, 144, 669–674. [Google Scholar] [CrossRef] [PubMed]

- Forest Products Laboratory. Wood Handbook: Wood as an Engineering Material; USDA Forest Service: Madison, WI, USA, 2010; Volume 190. [Google Scholar]

- Kollmann, F.F.P.; Côté, W.A., Jr. Principles of Wood Science and Technology; Springer-Verlag: Berlin/Heidelberg, Germany, 1968. [Google Scholar]

- Niemz, P.; Clauss, S.; Michel, F.; Hansch, D.; Hansel, A. Physical and mechanical properties of common ash (Fraxinus excelsior L.). Wood Res. 2014, 59, 671–682. [Google Scholar]

- Kollmann, F.; Schneider, A. On the sorption behaviour of heat stabilized wood. Holz als Roh- Werkst. 1963, 21, 77–85. [Google Scholar] [CrossRef]

- Moliński, W.; Fabisiak, E.; Szwaba, T. Properties of thermally modified ash wood (Fraxinus americana) in the aspect of its affinity to water. For. Wood Technol. 2010, 72, 27–31. [Google Scholar]

- Boonstra, M.J.; Tjeerdsma, B. Chemical analysis of heat treated softwoods. Holz als Roh- und Werkst. 2006, 64, 204–211. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Acker, J.; Tjeerdsma, B.F.; Kegel, E.V. Strength properties of thermally modified softwoods and its relation to polymeric structural wood constituents. Ann. For. Sci. 2007, 64, 679–690. [Google Scholar] [CrossRef]

| eMC | Treatment Applied | Density (kg × m−3) | MC (%) | MOET (MPa) | RcT (MPa) | MOER (MPa) | RcR (MPa) | MOEL (MPa) | RcL (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| 3% | ut | 591 ± 53 | 3.6 ± 0.1 | 844 ± 94 a | 8.1 ± 1.6 a | 1356 ± 521 a | 6.3 ± 0.2 a | 11265 ± 2473 a | 79.9 ± 2.4 a |

| 180 °C | 579 ± 51 | 2.7 ± 0.1 | 764 ± 143 a | 10.5 ± 0.8 b | 1405 ± 567 a | 5.8 ± 0.1 a | 11910 ± 2410 a | 85.7 ± 1.0b | |

| 200 °C | 563 ± 45 | 2.6 ± 0.1 | 844 ± 187 a | 7.5 ± 1.1 a | 1666 ± 638 a | 6.2 ± 0.6 a | 11589 ± 2421 a | 71.7 ± 9.5 a | |

| >FSP | ut | 930 ± 64 | 97.1 ± 9.5 | 207 ± 50 a | 2.5 ± 0.4 a | 446 ± 88 a | 2.4 ± 0.3 a | 3643 ± 937 a | 19.9 ± 2.2 a |

| 180 °C | 903 ± 50 | 85.7 ± 4.0 | 168 ± 42 a | 2.6 ± 0.4 a | 319 ± 117 a | 2.3 ± 0.40 a | 6137 ± 902 b | 18.8 ± 2.0 a | |

| 200 °C | 833 ± 44 | 68.7 ± 4.4 | 287 ± 70 b | 3.2 ± 0.3 b | 551 ± 112 b | 3.5 ± 0.3 b | 6342 ± 1470 b | 23.3 ± 3.8 b |

| Direction | Effect | SS | df | MS | F | p-Value |

|---|---|---|---|---|---|---|

| Perpendicular to the grain | Intercept | 42,869,394 | 1 | 42,869,394 | 400.2830 | 0.000 |

| Moisture content (a) | 13,725,849 | 1 | 13,725,849 | 128.1619 | 0.000 | |

| Temperature of modification (b) | 629,926 | 1 | 629,926 | 5.8818 | 0.018 | |

| Anatomical direction (c) | 3,795,272 | 1 | 3,795,272 | 35.4375 | 0.000 | |

| a × b | 601 | 1 | 601 | 0.0056 | 0.940 | |

| a × c | 1,079,301 | 1 | 1,079,301 | 10.0777 | 0.002 | |

| b × c | 71,365 | 1 | 71,365 | 0.6664 | 0.417 | |

| a × b × c | 1443 | 1 | 1443 | 0.0135 | 0.908 | |

| Error | 7,175,547 | 67 | 107,098 | |||

| Intercept | 3.24 × 109 | 1 | 3.24 × 109 | 883.88 | 0.000 | |

| Longitudinal to the grain | Moisture content (a) | 3.04 × 108 | 1 | 3.04 × 108 | 82.93 | 0.000 |

| Modification temperature (b) | 3.31 × 104 | 1 | 3.31 × 104 | 0.01 | 0.925 | |

| a × b | 6.92 × 105 | 1 | 6.92 × 105 | 0.19 | 0.666 | |

| Error | 1.32 × 108 | 36 | 3.66 × 106 |

| Direction | Effect | SS | df | MS | F | p-Value |

|---|---|---|---|---|---|---|

| Perpendicular to the grain | Intercept | 1986.241 | 1 | 1986.241 | 4358.716 | 0.000 |

| Moisture content (a) | 398.813 | 1 | 398.813 | 875.178 | 0.000 | |

| Temperature of modification (b) | 0.639 | 1 | 0.639 | 1.402 | 0.241 | |

| Anatomical direction (c) | 42.039 | 1 | 42.039 | 92.253 | 0.000 | |

| a × b | 21.639 | 1 | 21.639 | 47.486 | 0.000 | |

| a × c | 40.585 | 1 | 40.585 | 89.061 | 0.000 | |

| b × c | 18.596 | 1 | 18.596 | 40.808 | 0.000 | |

| a × b × c | 9.477 | 1 | 9.477 | 20.796 | 0.000 | |

| Error | 30.532 | 67 | 0.456 | |||

| Intercept | 79,584.5 | 1 | 79,584.5 | 2506.564 | 0.000 | |

| Longitudinal to the grain | Moisture content (a) | 26,597.4 | 1 | 26,597.4 | 837.702 | 0.000 |

| Modification temperature (b) | 179.74 | 1 | 179.74 | 5.661 | 0.024 | |

| a × b | 691.92 | 1 | 691.92 | 21.792 | 0.000 | |

| Error | 984.26 | 31 | 31.75 |

| eMC | Treatment Applied | EL/ET | EL/ER | ET/ER |

|---|---|---|---|---|

| 3% | Ut | 13.4 | 8.3 | 0.622 |

| 180 °C | 15.6 | 8.5 | 0.544 | |

| 200 °C | 13.7 | 6.9 | 0.507 | |

| >FSP | Ut | 17.6 | 8.2 | 0.464 |

| 180 °C | 36.5 | 19.2 | 0.527 | |

| 200 °C | 22.1 | 11.5 | 0.521 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roszyk, E.; Stachowska, E.; Majka, J.; Mania, P.; Broda, M. Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus excelsior Wood in Compression. Materials 2020, 13, 1647. https://doi.org/10.3390/ma13071647

Roszyk E, Stachowska E, Majka J, Mania P, Broda M. Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus excelsior Wood in Compression. Materials. 2020; 13(7):1647. https://doi.org/10.3390/ma13071647

Chicago/Turabian StyleRoszyk, Edward, Elżbieta Stachowska, Jerzy Majka, Przemysław Mania, and Magdalena Broda. 2020. "Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus excelsior Wood in Compression" Materials 13, no. 7: 1647. https://doi.org/10.3390/ma13071647

APA StyleRoszyk, E., Stachowska, E., Majka, J., Mania, P., & Broda, M. (2020). Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus excelsior Wood in Compression. Materials, 13(7), 1647. https://doi.org/10.3390/ma13071647