Spin Coating and Micro-Patterning Optimization of Composite Thin Films Based on PVDF

Abstract

1. Introduction

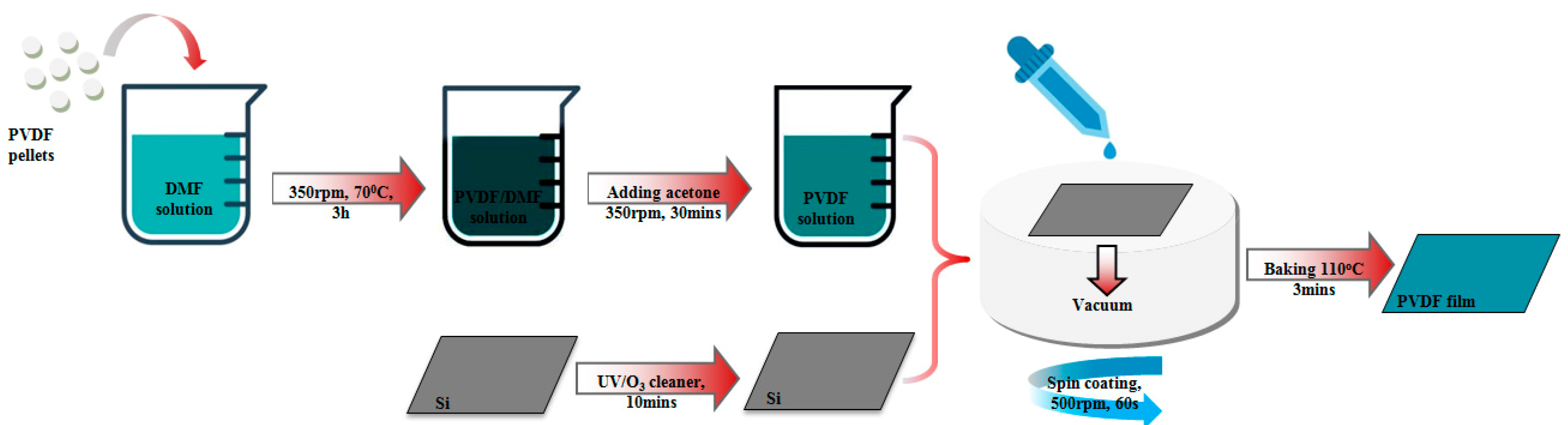

2. Materials and Methods

3. Results

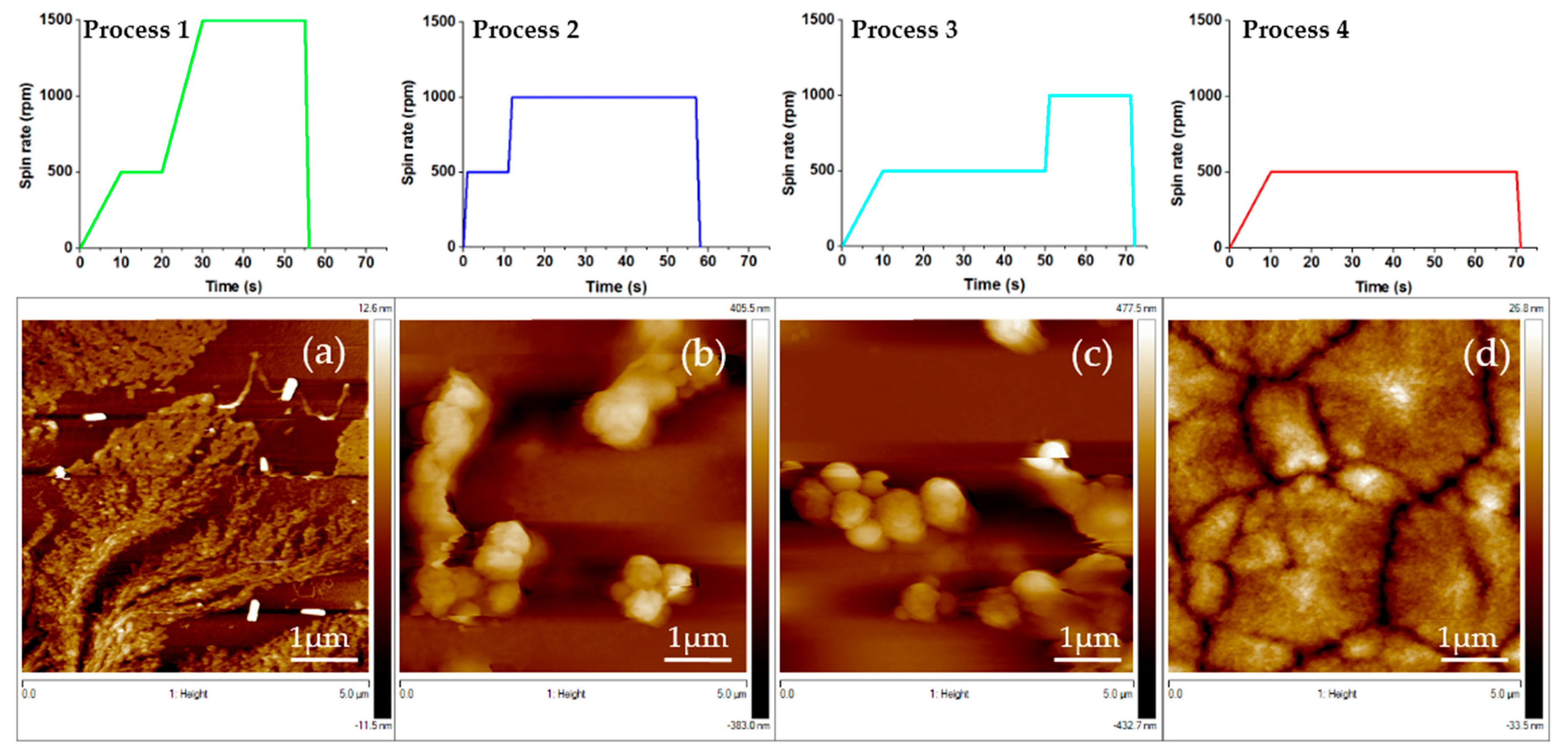

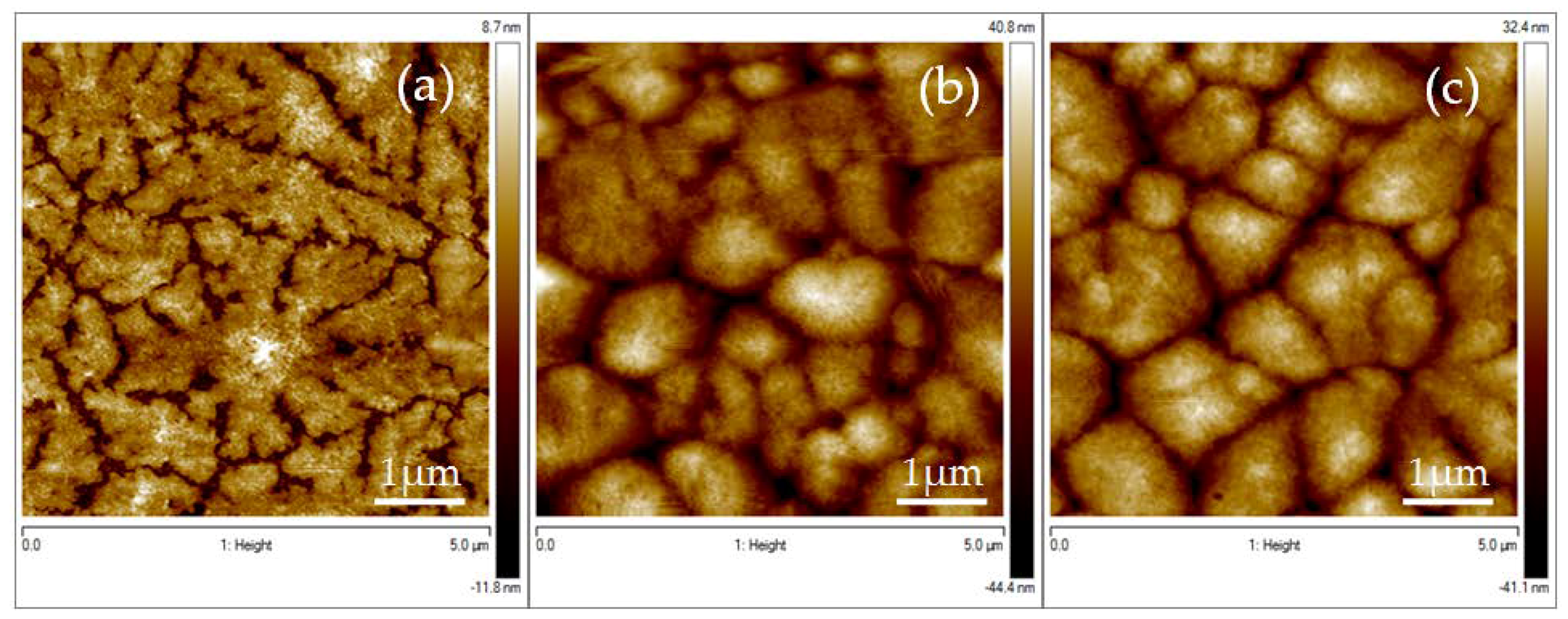

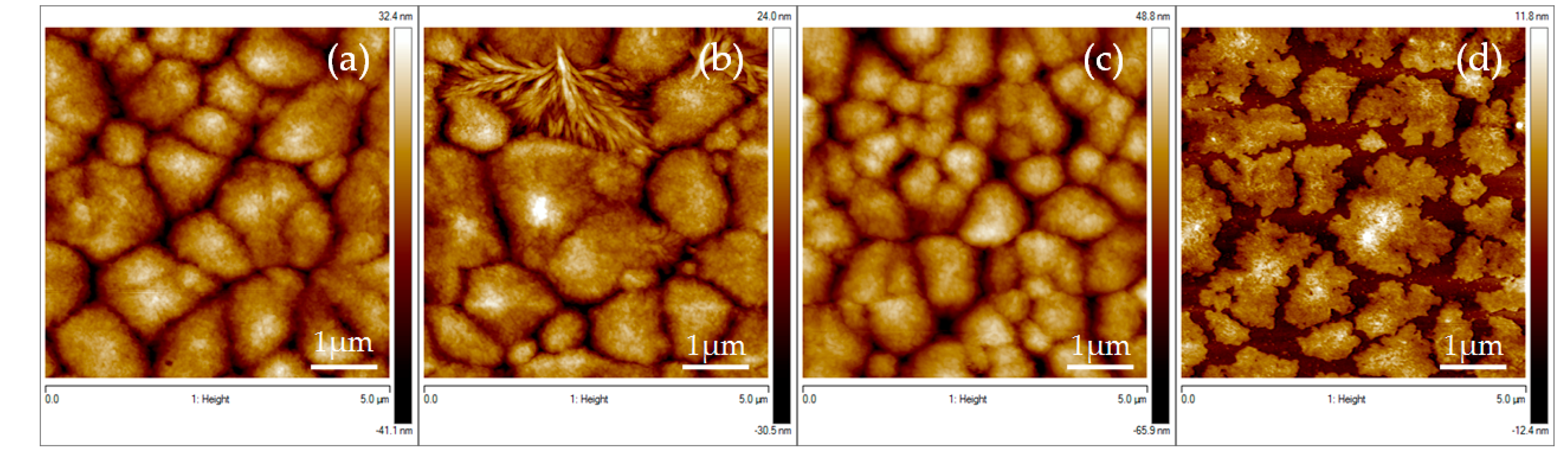

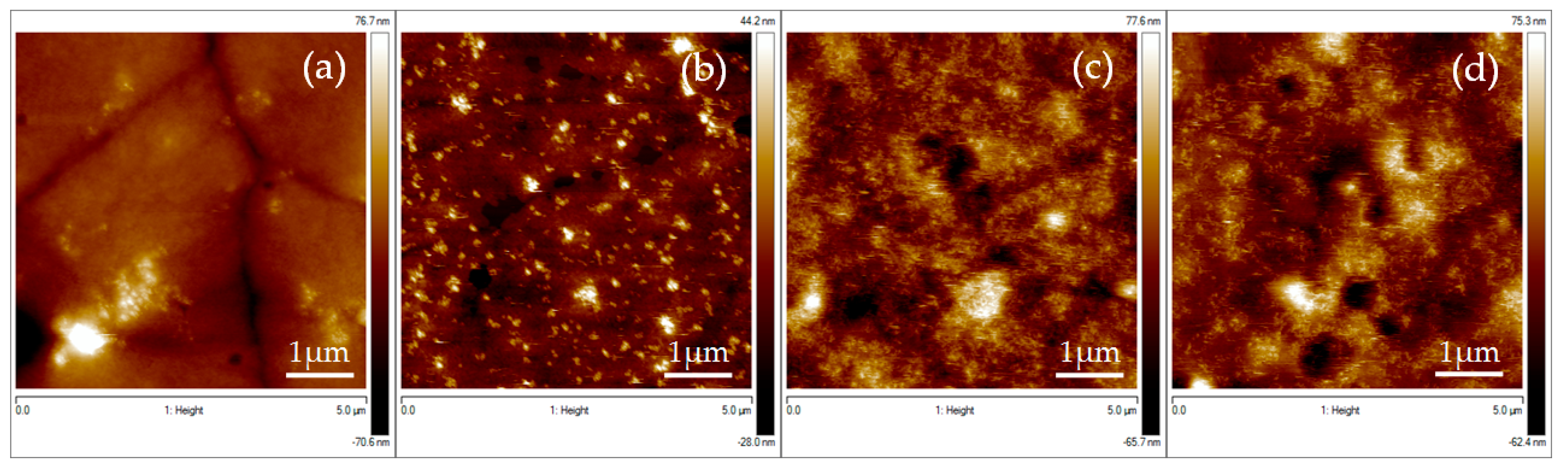

3.1. AFM Images Results

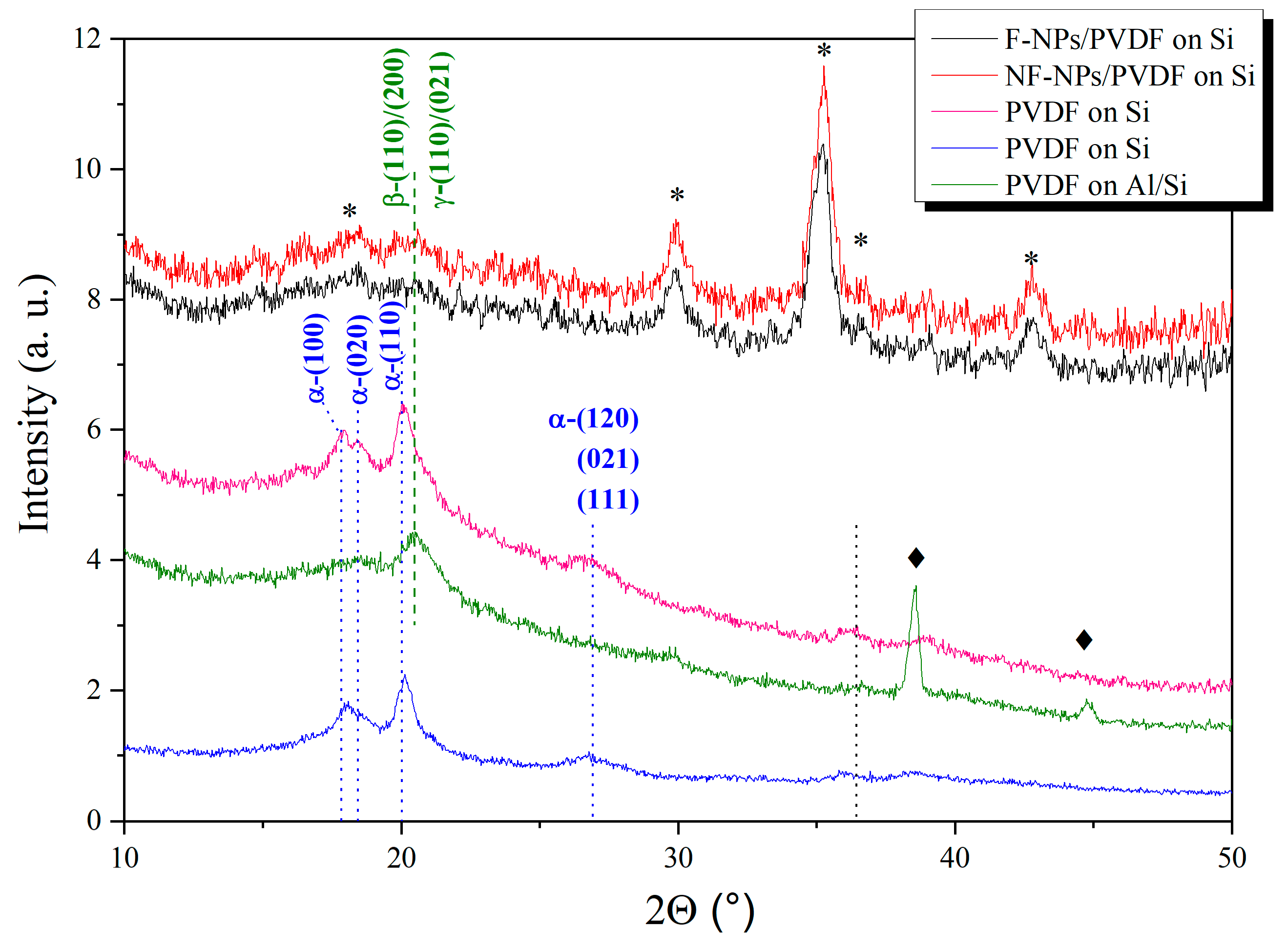

3.2. X-Ray Diffraction Data of Neat and Composite PVDF Films on Different Substrates

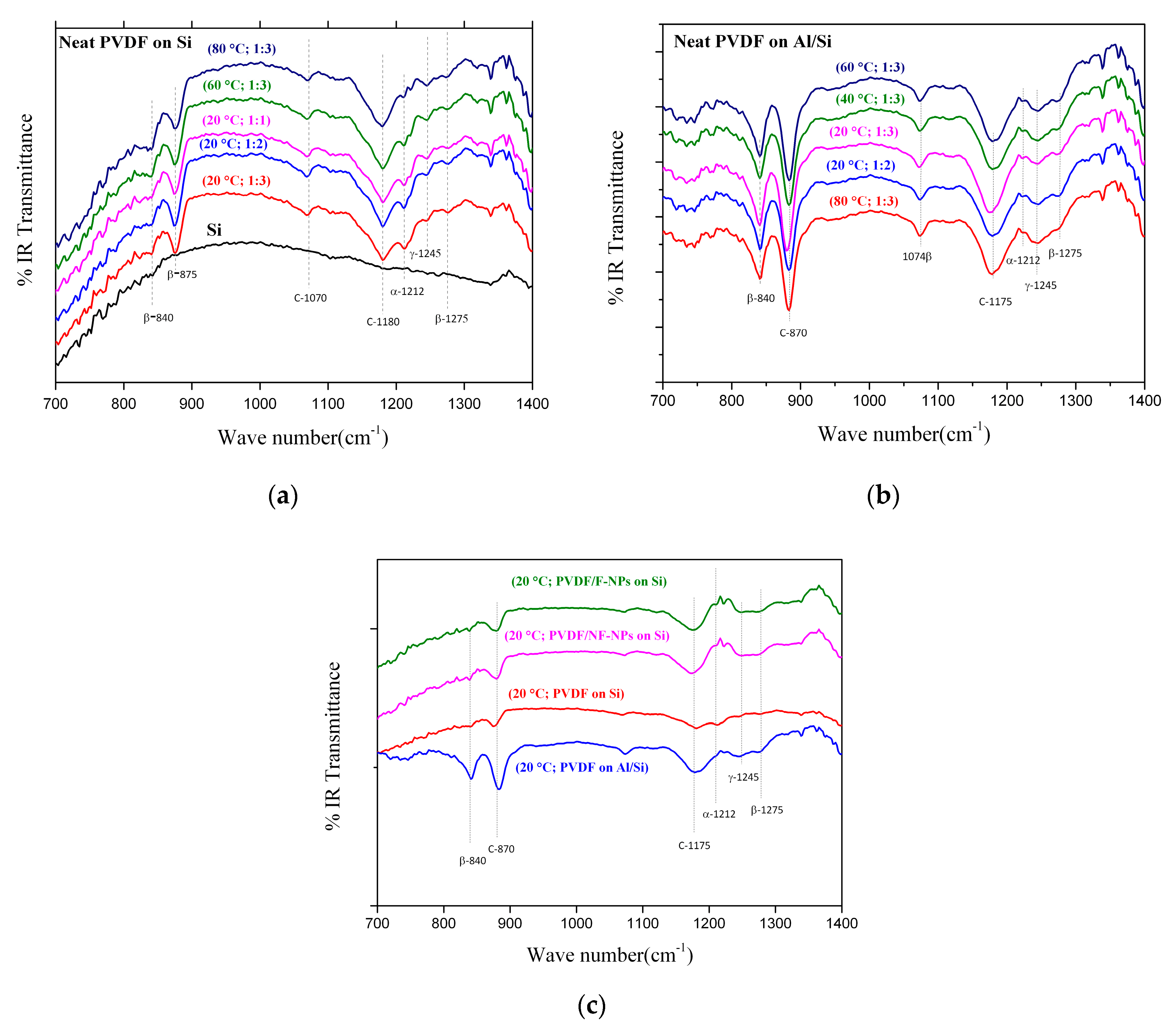

3.3. Infrared Transmittance of Neat and Composite PVDF Films on Different Substrates

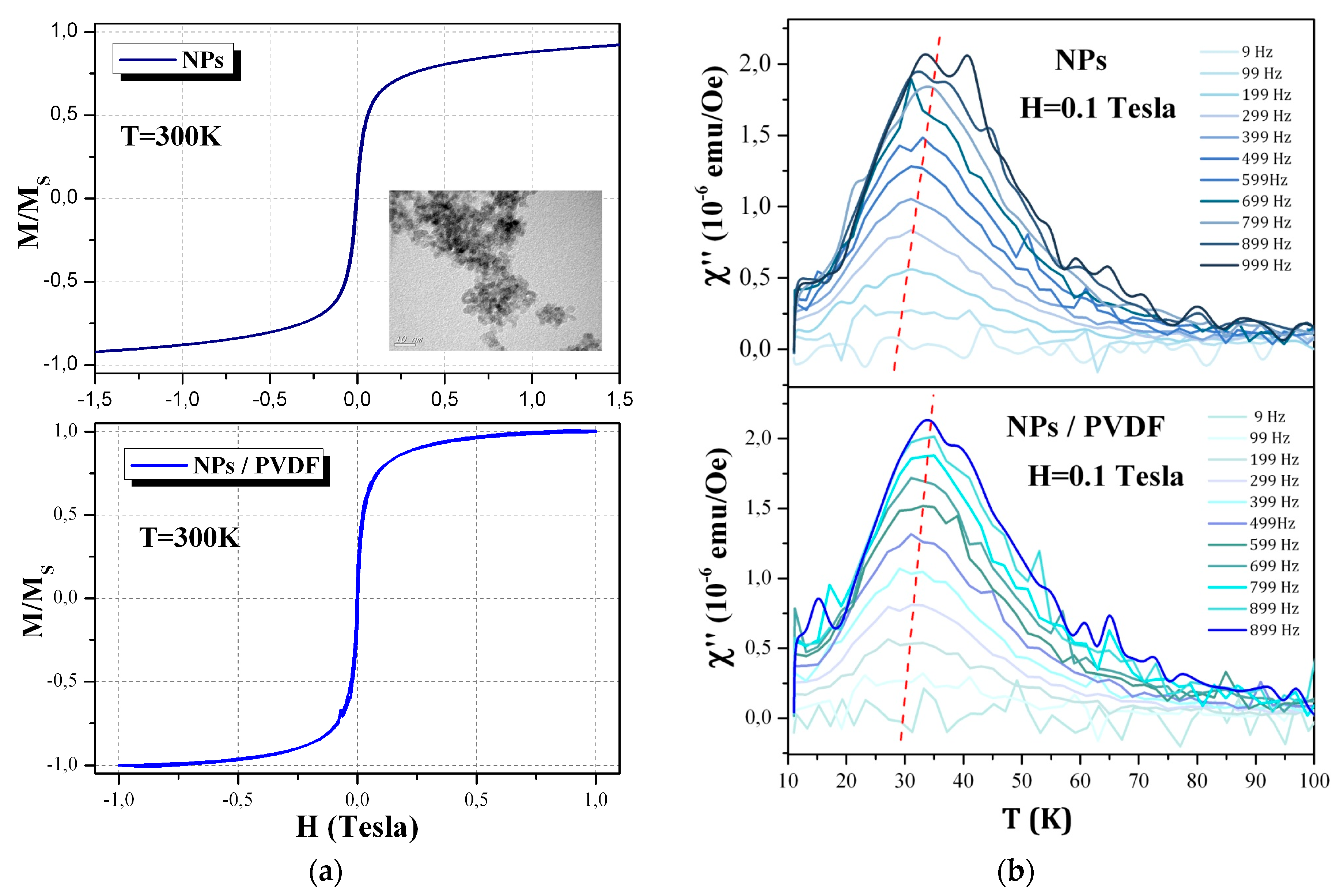

3.4. Magnetic Properties of the Composite Thin Films

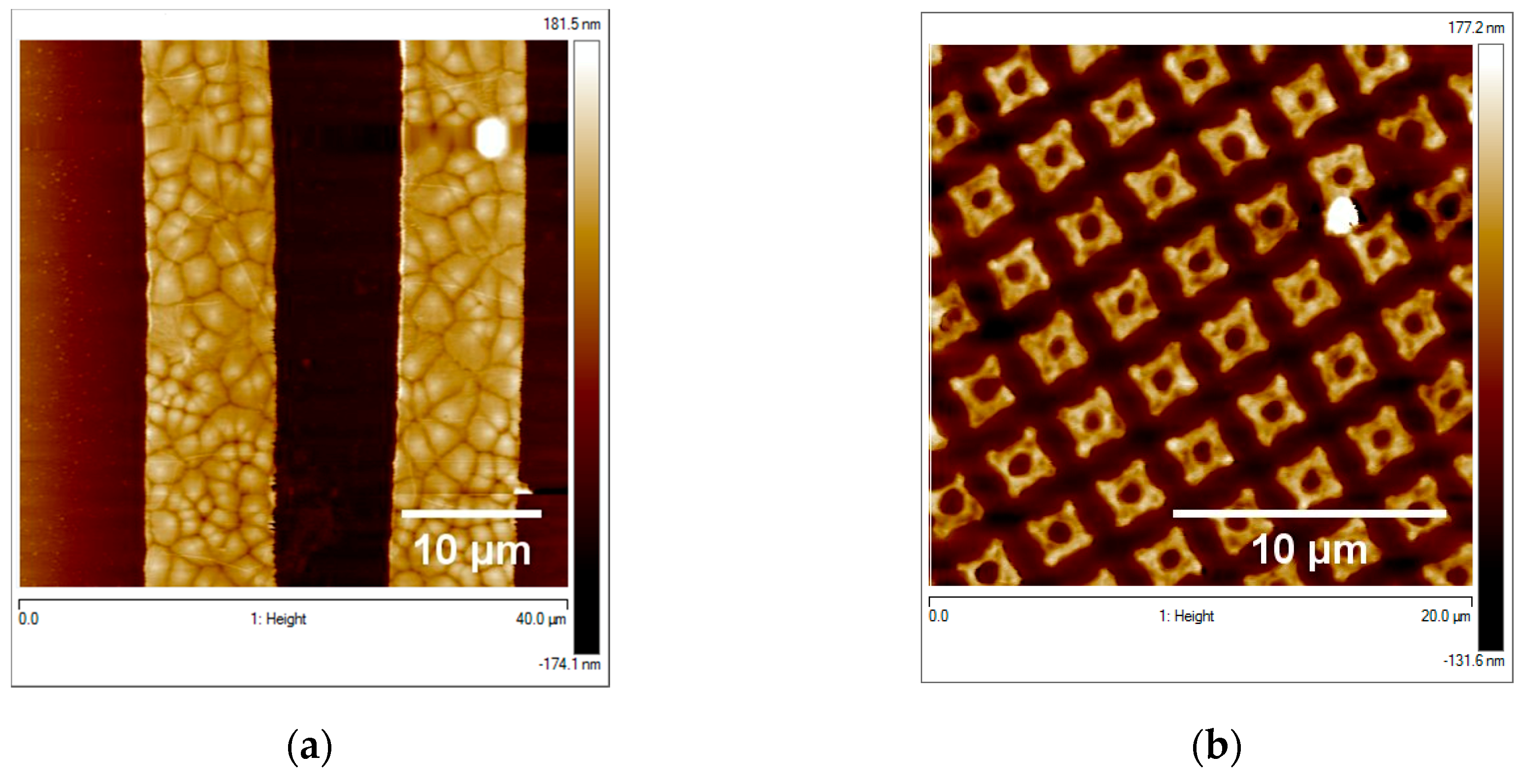

3.5. Micro-Structuration of the PVDF Thin Films

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

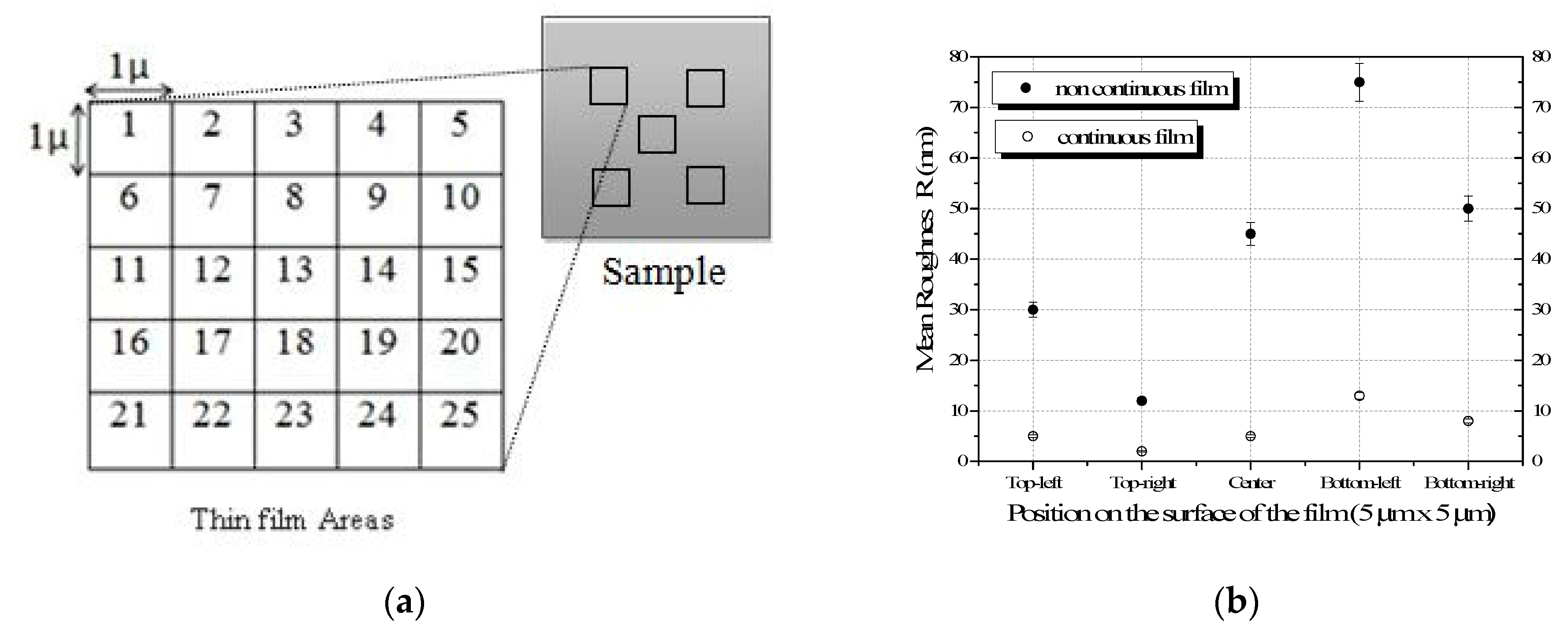

Appendix A: Analysis of the Thin Film Roughness

References

- Martins, P.; Lanceros-Méndez, S. Polymer-based Magnetoelectric Materials. Adv. Funct. Mater. 2013, 23, 3371–3385. [Google Scholar] [CrossRef]

- Ma, J.; Hu, J.; Li, Z.; Nan, C.-W. Recent Progress in Multiferroic Magnetoelectric Composites: From Bulk to Thin Films. Adv. Mater. 2011, 23, 1062–1087. [Google Scholar] [CrossRef] [PubMed]

- Rodel, J.; Jo, W.; Seifert, K.T.P.; Anto, E.-M.; Granzow, T.; Damjanovic, D. Perspective on the Development of Lead-free Piezoceramics. J. Am. Cerm. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free Piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Katsouras, I.; Piliego, C.; Glasser, G.; Lieberwirth, I.; Blom, P.W.M.; Leeuw, D.M.D. Controlling the Microstructure of Poly(vinylidene-fluoride)(PVDF) Thin Film for Microelectronics. J. Mater. Chem. C 2013, 1, 7695–7702. [Google Scholar] [CrossRef]

- Barcikowski, S.; Baranowski, T.; Durmus, Y.; Wiedwald, U.; Gokce, B. Solid Solution Magnetic FeNi Nanostrand-Polymer Composites by Connecting-Coarsening Assembly. J. Mater. Chem. C 2015, 3, 10699–10704. [Google Scholar] [CrossRef]

- Nan, C.W. Magnetoelectric Effect in Composites of Piezoelectric and Piezomagnetic Phases. Phys. Rev. B 1994, 50, 6082–6088. [Google Scholar] [CrossRef]

- Wang, B.Y.; Wang, H.T.; Singh, S.B.; Shao, Y.C.; Wang, Y.F.; Chuang, C.H.; Yeh, P.H.; Chiou, J.W.; Pao, C.W.; Tsai, H.M.; et al. Effect of Geometry on the Magnetic Properties of CoFe2O4-PbTiO3 Multiferroic Composites. RSC Adv. 2013, 3, 7884–7893. [Google Scholar] [CrossRef]

- Martins, P.; Lasheras, A.; Gutierrez, J.; Barandiaran, J.M.; Orue, I.; Lanceros-Mendez, S. Optimizing Piezoelectric and Magnetoelectric Responses on CoFe2O4/P(VDF-TrFE) Nanocomposites. J. Phys. D: Appl. Phys. 2011, 44, 495303. [Google Scholar] [CrossRef]

- Martins, P.; Gonçalves, R.; Lanceros-Mendez, S.; Lasheras, A.; Gutiérrez, J.; Barandiáran, J.M. Effect of Filler Dispersion and Dispersion Method on the Piezoelectric and Magnetoepectric Response of CoFe2O4/P(VDF-TrFE) Nanocomposites. Appl. Surf. Sci. 2014, 313, 215–219. [Google Scholar] [CrossRef]

- Akutagawa, T.; Koshinaka, H.; Sato, D.; Takeda, S.; Noro, S.-I.; Takahashi, H.; Kumai, R.; Tokura, Y.; Nakamura, T. Ferroelectricity and Polarity Control in Solid-State Flip-Flop Supramolecular Rotators. Nat. Mater. 2009, 8, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Ren, S. Intergrated Charge Transfer in Organic Ferroelectric for Flexible Multisensing Materials. Small 2016, 12, 4502–4507. [Google Scholar] [CrossRef] [PubMed]

- Shi, P.-P.; Tang, Y.-Y.; Li, P.-F.; Liao, W.-Q.; Wang, Z.-X.; Ye, Q.; Xiong, R.-G. Symmetry Breaking in Molecular Ferroelectrics. Chem. Soc. Rev. 2016, 45, 3811–3827. [Google Scholar] [CrossRef] [PubMed]

- Andrade, V.M.; Amirov, A.; Yusupov, D.; Pimentel, B.; Barroca, N.; Pires, A.L.; Belo, J.H.; Pereira, A.M.; Valente, M.A.; Araújo, J.P.; et al. Multicaloric effect in a multiferroic composite of Gd5(Si,Ge)4 microparticles embedded into a ferroelectric PVDF matrix. Sci Rep. 2019, 9, 18308. [Google Scholar] [CrossRef]

- Zhu, L. Exploring Strategies for High Dielectric Constant and Low Loss Polymer Dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef]

- Jayakumar, O.D.; Mandal, B.P.; Majeed, J.; Lawes, G.; Naik, R.; Tyagi, A.K. Inorganic-Organic Multilferroic Hybrid Thin Films of Fe3O4 and PVDF with Significant Magneto-dielectric Coupling. J. Mater. Chem. C 2013, 1, 3710–3715. [Google Scholar] [CrossRef]

- Jin, J.; Lu, S.G.; Chanthad, C.; Zhang, Q.; Haque, M.A.; Wang, Q. Multiferroic Polymer Composites with Greatly Enhanced Magnetoelectric Effect under a Low Magnetic Bias. Adv. Mater. 2011, 23, 3853–3858. [Google Scholar] [CrossRef]

- Kasisomayajula, S.; Jadhav, N.; Gelling, V.J. In-Situ Preparation and Characterization of a Conductive and Magnetic Nanocomposite of Polypyrrole and Copper Hydroxychloride. RSC Adv. 2016, 6, 967–977. [Google Scholar] [CrossRef]

- Martins, P.; Moya, X.; Phillips, L.C.; Narayan, S.K.; Mathur, N.D.; Mendez, S.L. Linear anhysteretic direct magnetoelectric effect in Ni0.5Zn0.5Fe2O4 /poly(vinylidene fluoridetrifluoroethylene) 0-3 nanocomposites. J. Phys. D Appl. Phys. 2011, 44, 482001–482005. [Google Scholar] [CrossRef]

- Lovinger, A.J. Poly(vinylidene Fluoride). In Developments in Crystalline Polymers-1; Bassett, D.C., Ed.; Applied Science Publishers LTD: Essex, UK, 1982; pp. 195–273. [Google Scholar]

- Halary, J.L.; Jarray, J.; Fatnassi, M.; Ben Cheikh Larbi, F. Amorphous and Semicrystalline Blends of Poly(vinylidene fluoride) and Poly(methyl methacrylate): Characterization and Modeling of the Mechanical Behavior. J. Eng. Mater. Technol. 2012, 134, 010910. [Google Scholar] [CrossRef]

- Oikonomou, E.K.; Tencé-Girault, S.; Gérard, P.; Norvez, S. Swelling of semi-crystalline PVDF by a PMMA-based nanostructured diblock copolymer: Morphology and mechanical properties. Polymer 2015, 76, 89–97. [Google Scholar] [CrossRef]

- Martins, P.; Costa, C.; Lanceros-Mendez, S. Nucleation of Electroactive β-phase Poly(vinilidene fluoride) with CoFe2O4 and NiFe2O4 Nanofillers: A New Method for the Preparation of Multiferroic Nanocomposites. Appl. Phys. Mater. Sci. Process 2011, 103, 233–237. [Google Scholar] [CrossRef]

- Chu, B.; Lin, M.; Neese, B.; Zhou, X.; Chen, Q.; Zhang, Q.M. Large Enhancement in Polarization Response and Energy Density of Poly(Vinylidene Fluoride-Trifluoroethylene Chlorofluoroethylene) by Interface Effect in Nanocomposites. Appl. Phys. Lett. 2007, 91, 122909. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, T.; Wu, C.; Qui, L.; Hu, R.; Li, J.; Cansiz, S.; Zhang, L.; Cui, C.; Zhu, G.; et al. Facile surface functionalization of hydrophobic magnetic nanoparticles. J. Am. Chem. Soc. 2014, 136, 12552–12555. [Google Scholar] [CrossRef] [PubMed]

- Osman, C.B.; Barthas, E.; Decorse, P.; Mammeri, F. Surface functionalization of CoFe2O4 nanoparticles for driving the crystallization of the electroactive β-PVDF through judicious tailoring of the hybrid interface. Colloids Surf. A Physicochem. Eng. Asp. 2019, 577, 405–411. [Google Scholar] [CrossRef]

- Zhang, J.X.; Dai, J.Y.; So, L.C.; Sun, C.L.; Lo, C.Y.; Or, S.W.; Chan, H.L.W. The effect of magnetic nanoparticles on the morphology, ferroelectric, and magnetoelectric behaviors of CFO/P(VDF-TrFE) 0–3 nanocomposites. J. Appl. Phys. 2009, 105, 054102. [Google Scholar] [CrossRef]

- Osman, C.B.; Nowak, S.; Garcia-Sanchez, A.; Charles, Y.; Ammar-Merah, S.; Mercone, S.; Mammeri, F. In Situ Monitored Stretching Induced α to β Allotropic Transformation of Flexible Poly(Vinylidene Fluoride)-CoFe2O4 Hybrid Films: The Role of Nanoparticles Inclusion. Eur. Polym. J. 2016, 84, 602–611. [Google Scholar] [CrossRef]

- Chen, S.; Li, X.; Yao, K.; Tay, F.E.H.; Kumar, A.; Zeng, K. Self-Polarized Ferroelectric PVDF Homopolymer Ultra-Thin Films Derived from Langmuir–Blodgett Deposition. Polymer 2012, 53, 1404–1408. [Google Scholar] [CrossRef]

- Ramasundaram, S.; Yoon, S.; Kim, K.J.; Lee, J.S. Direct Preparation of Nanoscale Thin Film of Poly (Vinylidene Fluoride) Containing Beta Crystalline Phase by Heat-Controlled Spin Coating. Macromol. Chem. Phys. 2008, 209, 2516–2526. [Google Scholar] [CrossRef]

- Rashid, A.N.; Gunter, P. Self-assembled organic supramolecular thin films for nonlinear optics. Org. Electron. 2004, 5, 147–155. [Google Scholar] [CrossRef]

- Onah, E.J.; Oertel, U.; Froeck, C.; Kratzmuller, T.; Steinert, V.; Bayer, T.; Hartmann, L.; Haubler, L.; Lunkwitz, K. Ultrathin Films from Fluoride Containing Polymers: Fabrication and Characterization. Macromol. Mater. Eng. 2002, 287, 412–419. [Google Scholar] [CrossRef]

- Abdullah, I.Y.; Yahaya, M.; Jumali, M.H.H.; Shanschool, H.M. Influence of the spinning rate on the β−phase formation in poly (vinylidene fluoride) (PVDF) films. In AIP Conference Proceedings 1838, 020016; American Institute of Physiscs: College Park, MD, USA, 2017. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Minas, G.; Costa, C.M.; Tavares, C.J.; Lanceros-Mendez, S. Micro and nano-film of poly(vinylidene fluoride) with controlled thickness, morphology and electro-active crystalline phase for sensor and actuator applications. Smart Mater. Struct. 2011, 20, 087002. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendeza, S. Electroactive Phases of Poly(vinylidene fluoride): Determination, Processing and Applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- He, X.; Yao, K. Crystallization mechanism and piezoelectric properties of solution-derived ferroelectric poly(Vinylidene fluoride) thin films. Appl. Phys. Lett. 2006, 89, 112909. [Google Scholar] [CrossRef]

- Ourry, L.; Marchesini, S.; Bibani, M.; Mercone, S.; Ammar, S.; Mammeri, S. Influence of nanoparticle size and concentration on the electro-active phase content of PVDF in PVDF–CoFe2O4-based hybrid films. Phys. Status Solidi A 2015, 212, 252–258. [Google Scholar] [CrossRef]

- Figlarz, M.; Fievet, F.; Lagier, J.-P. Google Patents (EU patent N°0113281, USA patent N°4539041). Available online: https://patents.google.com/patent/US4539041A/en (accessed on 3 September 1985).

- Valenzuela, R.; Beji, Z.; Herbst, F.; Ammar, S. Ferromagnetic resonance behavior of spark plasma sintered Ni-Zn ferrite produced by a chemical route. J. Appl. Phys. 2011, 109, 07A329. [Google Scholar] [CrossRef]

- Poul, L.; Ammar, S.; Jouini, N.; Fievet, F.; Villain, F. Synthesis of inorganic compounds (metal, oxide and hydroxide) in polyol medium: A versatileroute related to the sol–gel process. J. Sol–Gel Sci. Technol. 2003, 26, 261–265. [Google Scholar] [CrossRef]

- Imine, S.; Schoenstein, F.; Mercone, S.; Zaghrioui, M.; Bettahar, N.; Jouini, N. Bottom-up and new compaction processes: A way to tunable properties of nanostructured cobalt ferrite ceramics. J. Eur. Ceram. Soc. 2011, 31, 2943–2955. [Google Scholar] [CrossRef]

- Chkoundali, S.; Ammar, S.; Jouini, N.; Fievet, F.; Molinie, P.; Danot, M.; Villain, F.; Greneche, J.-M. Nickel ferrite nanoparticles: Elaboration in polyol medium via hydrolysis, and magnetic properties. J. Phys.: Condens. Matter. 2004, 16, 4357–4372. [Google Scholar] [CrossRef]

- Ammar, S.; Jouini, N.; Fievet, F.; Stephan, O.; Marhic, C.; Richard, M.; Villain, F.; Cartier dit Moulin, C.H.; Brice, S.; Sainctavit, P.H. Influence of the synthesis parameters on the cationic distribution of ZnFe2O4 nanoparticles obtained by forced hydrolysis in polyol medium. J. Non-Cryst Solids. 2004, 345–346, 658–662. [Google Scholar] [CrossRef]

- Seol, D.; Kim, B.; Kim, Y. Non-piezoelectric effects in piezoresponse force microscopy. Curr. Appl. Phys. 2017, 17, 661–674. [Google Scholar] [CrossRef]

- Sanwlani, S.; Bala, M.; Jyotsona, S.; Sheet, G. The role of substrates and environment in piezoresponse force microscopy: A case study with regular glass slides. Solid State Commun. 2016, 246, 17–22. [Google Scholar] [CrossRef]

- Zhao, D.-L.; Lv, Q.; Shen, Z.-M. Fabrication and microwave absorbing properties of Ni–Zn spinel ferrites. J. Alloys Compd. 2009, 480, 634–638. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Fortunato, M.; Chandraiahgari, C.R.; De Bellis, G.; Ballirano, P.; Sarto, F.; Tamburrano, A.; Sarto, M.S. Piezoelectric Effect and Electroactive Phase Nucleation in Self-Standing Films of Unpoled PVDF Nanocomposite Films. Nanomaterials 2018, 8, 743–758. [Google Scholar] [CrossRef] [PubMed]

- Miki, H.; Morimoto, K.; Tamaki, T.; Tsuchitani, S. Reactive ion etching of poly (vinylidene fluoride) and its optimization. IJETR 2015, 3, 327–333. [Google Scholar]

- Jana, S.; Garain, S.; Sen, S.; Mandal, D. The influence of hydrogen bonding on the dielectric constant and the piezoelectric energy harvesting performance of hydrated metal salt mediated PVDF films. Phys. Chem. Chem. Phys. 2015, 17, 17429–17436. [Google Scholar] [CrossRef]

- Manohara, H.M.; Morikawa, E.; Choi, J.; Sprunger, P.T. Pattern transfer by direct photo etching of poly(vinylidene fluoride) using X-rays. J. Microelectromech. S. 1999, 8, 417–422. [Google Scholar] [CrossRef]

- Bartnik, A.; Fiedorowicz, H.; Jarock, R.; Kostecki, J.; Szczurek, M.; Wachulak, P.W. Efficient micromachining of poly(vinylidene fluoride) using a laser-plasma EUV source. Appl. Phys. A 2012, 106, 551–555. [Google Scholar] [CrossRef]

- Shao, J.Y.; Chen, X.M.; Tian, H.M.; Wang, C.H.; Lu, B.H. Nanoimprint lithography for the manufacturing of flexible electronics. Sci. China Technol. Sci. 2019, 62, 175–198. [Google Scholar] [CrossRef]

- Jiang, Y.; Shiono, S.; Hamada, H.; Fujita, T.; Zhang, D.; Maenaka, K. Reactive ion etching of poly(vinylidene fluoride-trifluoroethylene) copolymer for flexible piezoelectric devices. Chin. Sci. Bull. 2013, 58, 2091–2094. [Google Scholar] [CrossRef]

| DMF/Acetone Volume Ratio | Homogeneity | Mean Roughness (Ra) | Mean Thickness |

|---|---|---|---|

| 1:1 | non-continuous | 7 nm | 113 nm |

| 1:2 | continuous | 12 nm | 101 nm |

| 1:3 | continuous | 10 nm | 90 nm |

| Substrate Temperature (±5%) | Substrate Type | Homogeneity | Mean Roughness (Ra) | Mean Thickness |

|---|---|---|---|---|

| RT (20 ± 1) °C | doped silicon Al/silicon | continuous continuous | 10 nm 9 nm | 85 nm 101 nm |

| (40 ± 2) °C | doped silicon Al/silicon | continuous continuous | 6 nm 11 nm | 70 nm 92 nm |

| (60 ± 3) °C | doped silicon Al/silicon | continuous continuous | 4 nm 12 nm | 90 nm 99 nm |

| (80 ± 4) °C | doped silicon Al/silicon | non-continuous non-continuous | 3 nm 3 nm | 83 nm 79 nm |

| NPs wt % | Categories of NPs | Homogeneity | Mean Roughness (Ra) | Mean Thickness |

|---|---|---|---|---|

| 0.5 | Non-functionalized Functionalized | Continuous Continuous | 4 nm 6 nm | 76 nm 80 nm |

| 1 | Non-functionalized Functionalized | Continuous Continuous | 13 nm 14 nm | 121 nm 97 nm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, A.N.; Solard, J.; Nong, H.T.T.; Ben Osman, C.; Gomez, A.; Bockelée, V.; Tencé-Girault, S.; Schoenstein, F.; Simón-Sorbed, M.; Carrillo, A.E.; et al. Spin Coating and Micro-Patterning Optimization of Composite Thin Films Based on PVDF. Materials 2020, 13, 1342. https://doi.org/10.3390/ma13061342

Nguyen AN, Solard J, Nong HTT, Ben Osman C, Gomez A, Bockelée V, Tencé-Girault S, Schoenstein F, Simón-Sorbed M, Carrillo AE, et al. Spin Coating and Micro-Patterning Optimization of Composite Thin Films Based on PVDF. Materials. 2020; 13(6):1342. https://doi.org/10.3390/ma13061342

Chicago/Turabian StyleNguyen, Anh Ngoc, Jeanne Solard, Huyen Thi Thanh Nong, Chirine Ben Osman, Andres Gomez, Valérie Bockelée, Sylvie Tencé-Girault, Frédéric Schoenstein, Maite Simón-Sorbed, Anna Esther Carrillo, and et al. 2020. "Spin Coating and Micro-Patterning Optimization of Composite Thin Films Based on PVDF" Materials 13, no. 6: 1342. https://doi.org/10.3390/ma13061342

APA StyleNguyen, A. N., Solard, J., Nong, H. T. T., Ben Osman, C., Gomez, A., Bockelée, V., Tencé-Girault, S., Schoenstein, F., Simón-Sorbed, M., Carrillo, A. E., & Mercone, S. (2020). Spin Coating and Micro-Patterning Optimization of Composite Thin Films Based on PVDF. Materials, 13(6), 1342. https://doi.org/10.3390/ma13061342