Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Feedstock Filaments

2.2. Material Extrusion AM Trials

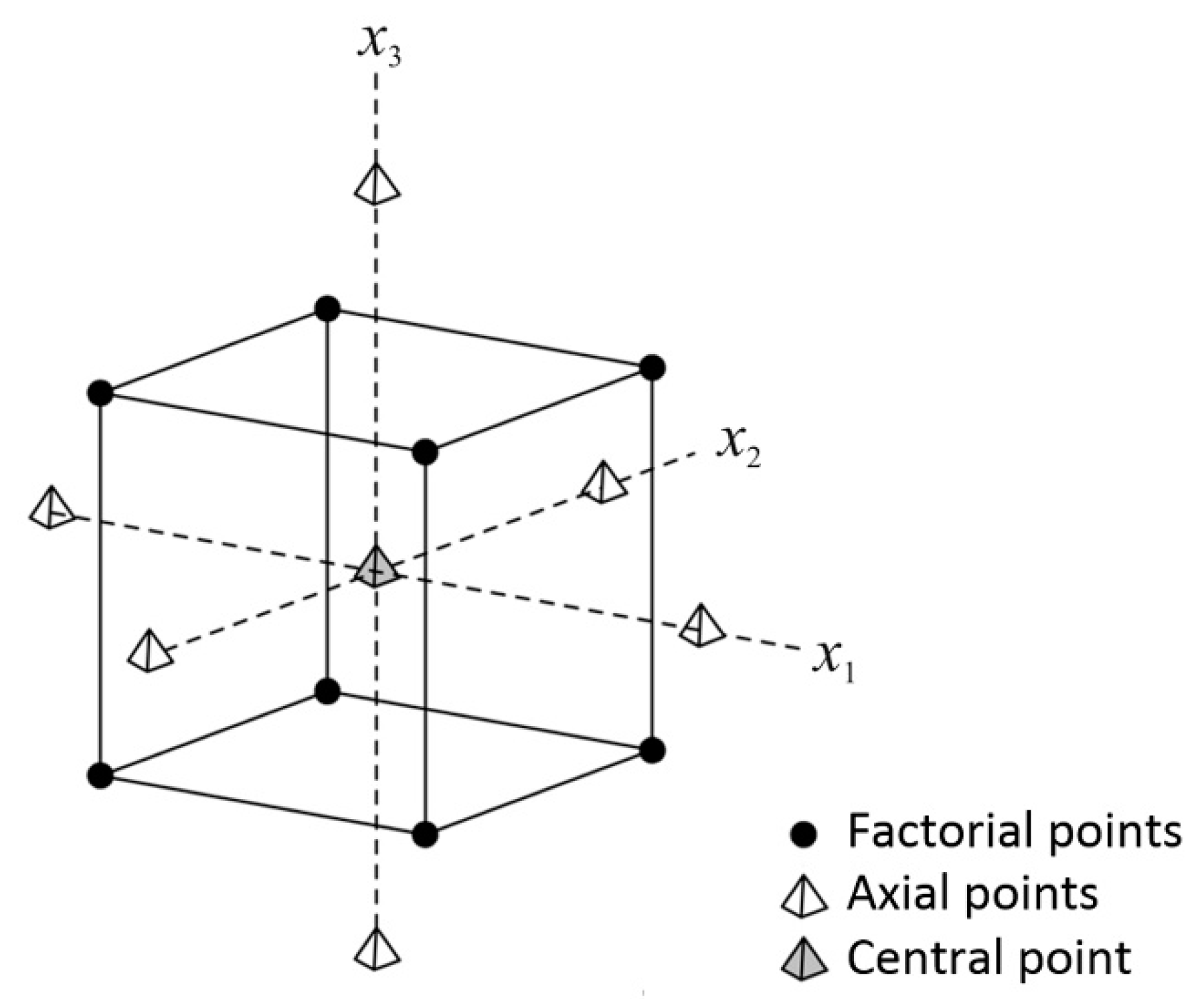

2.3. Design of Experiment (DoE)—Central Composite Design

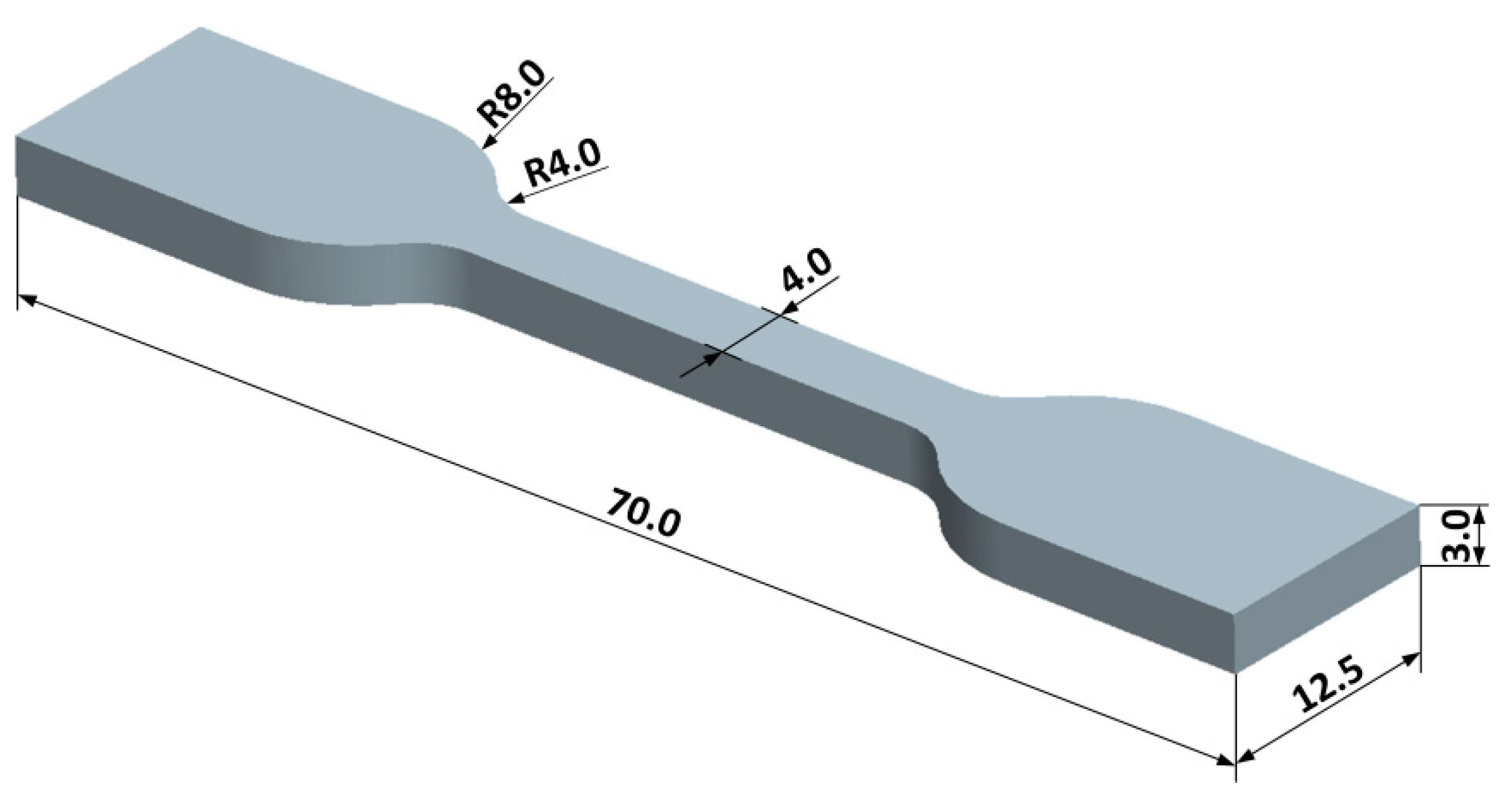

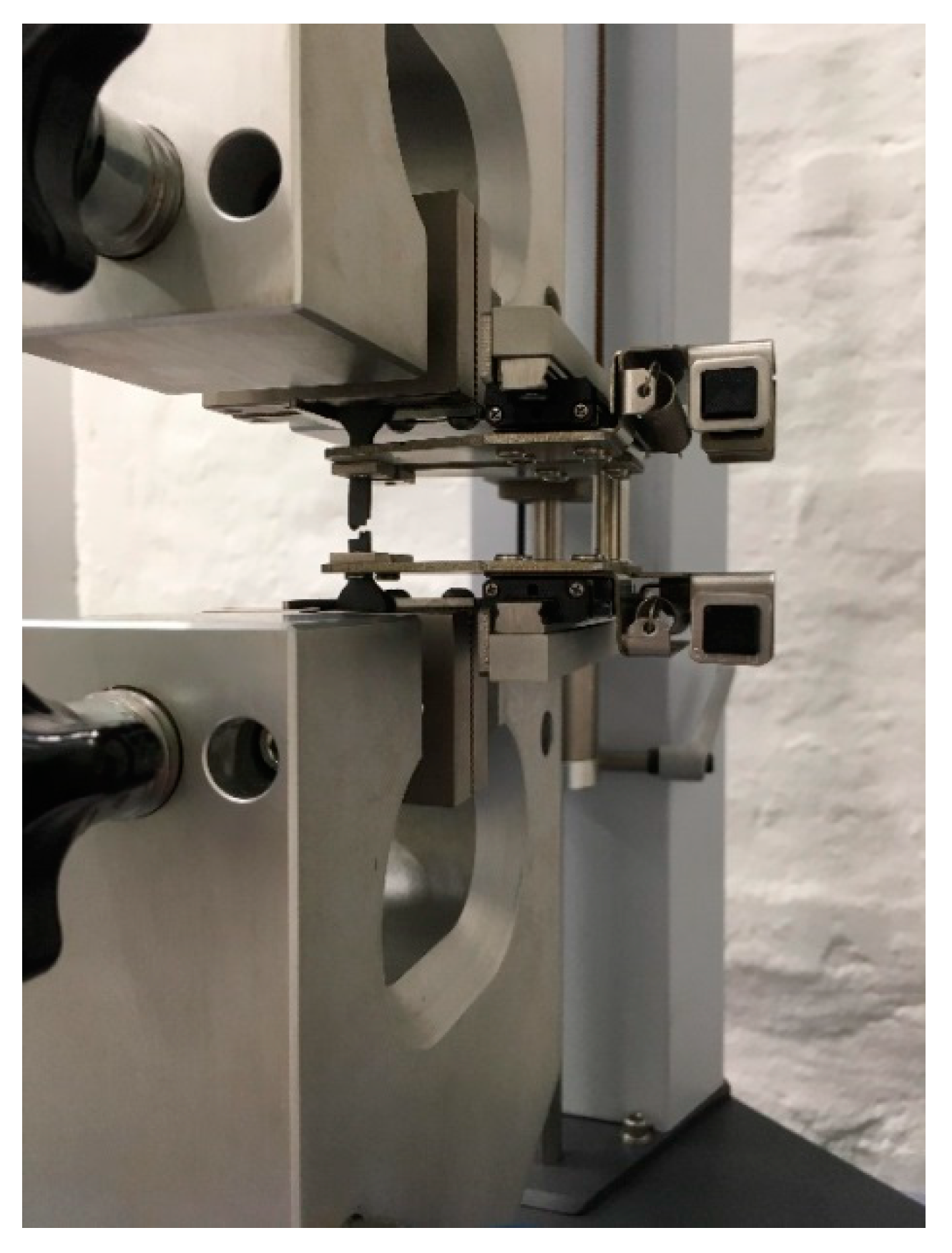

2.4. Tensile Testing

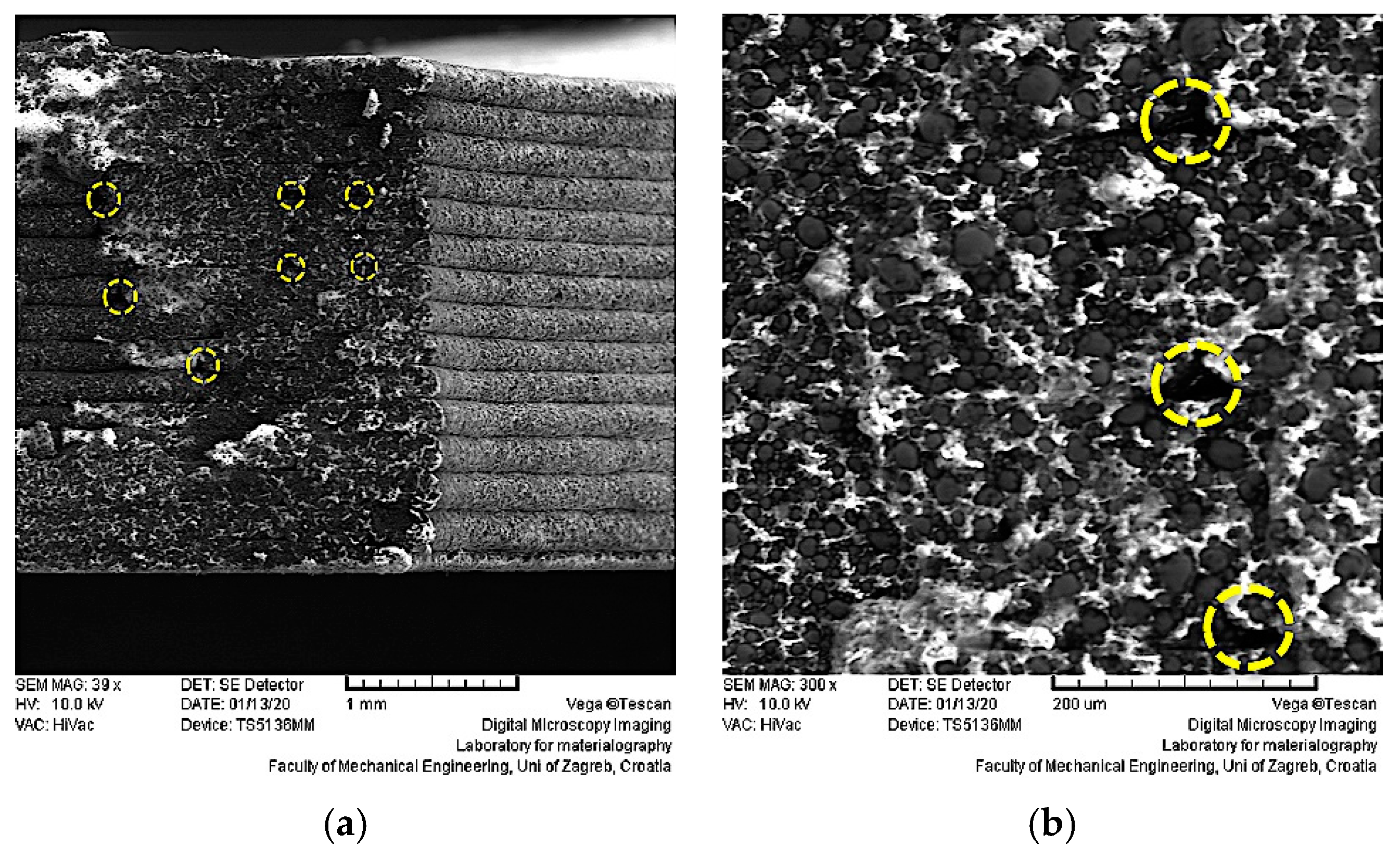

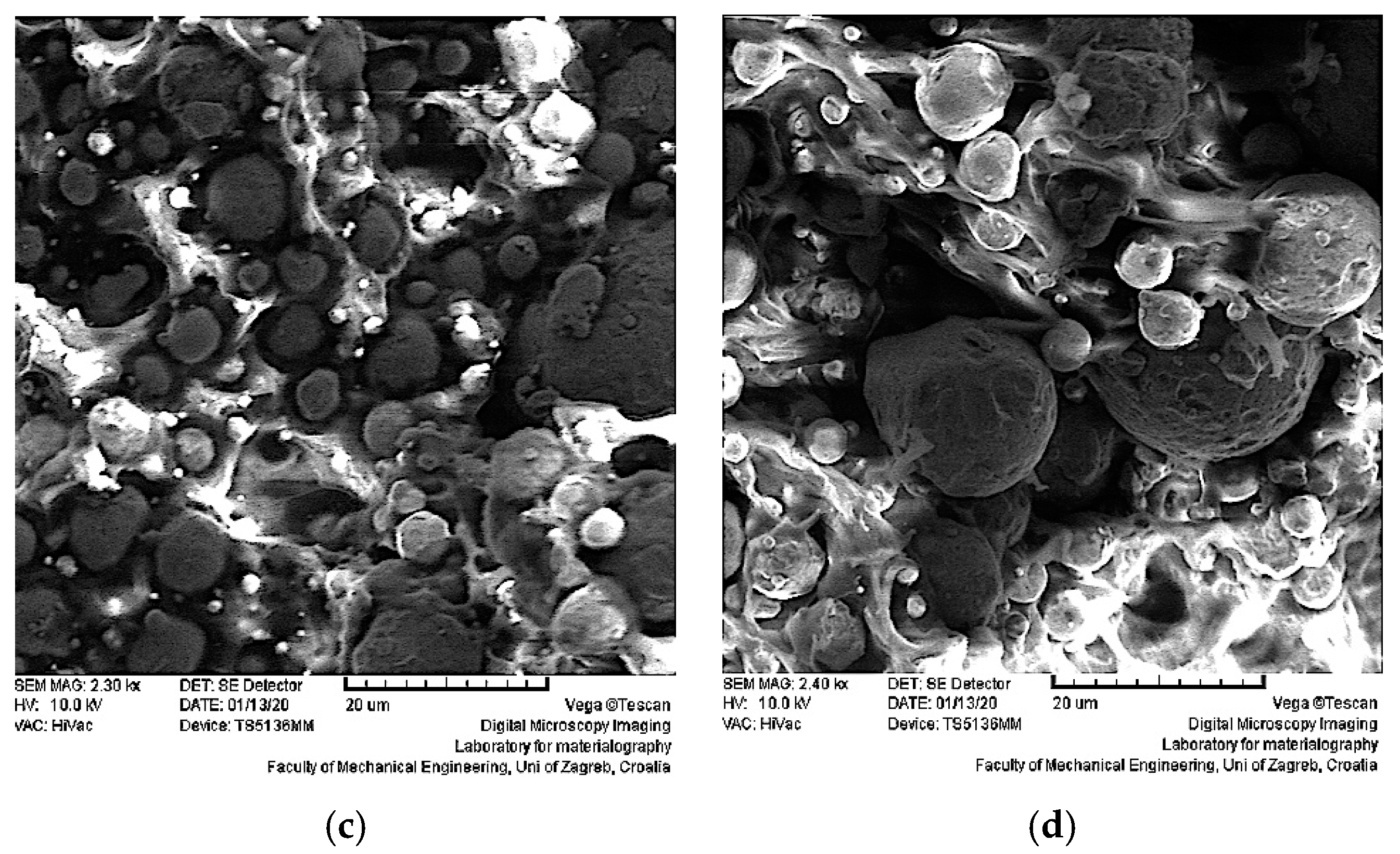

2.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

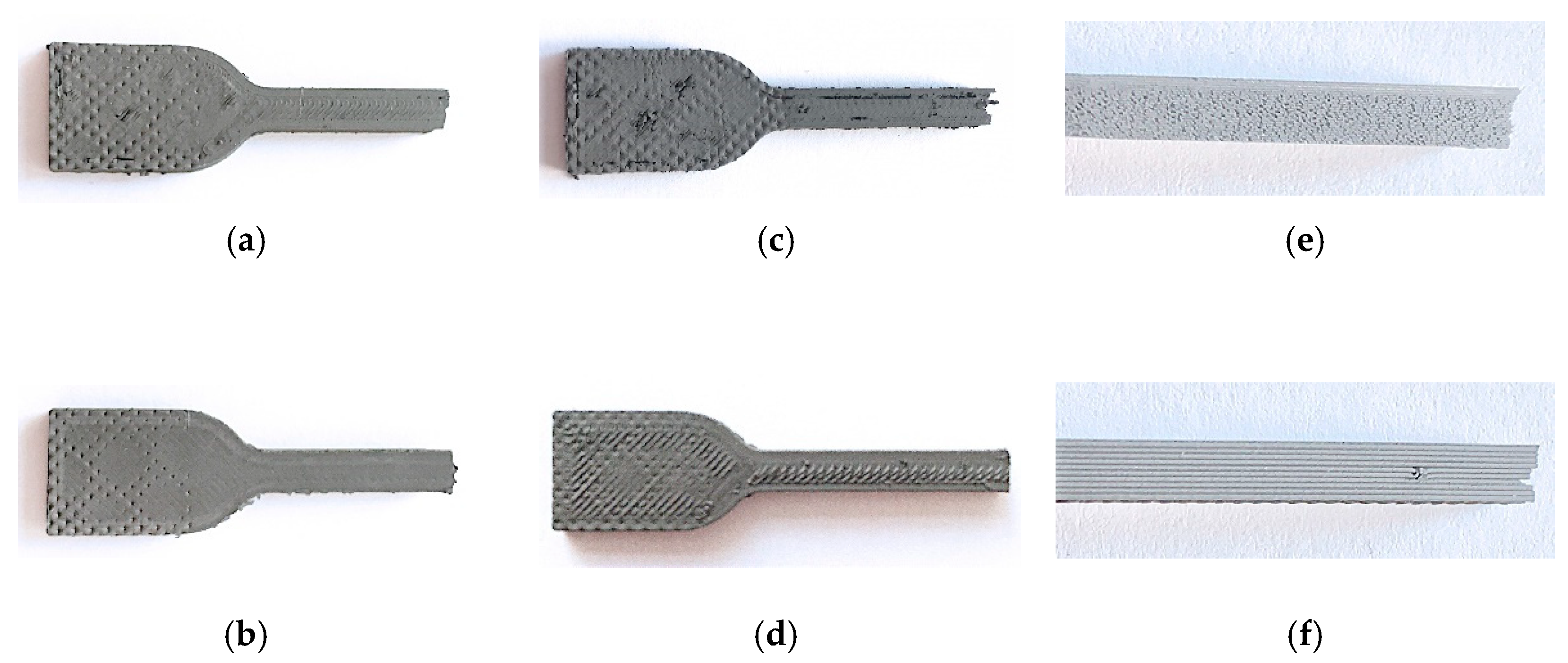

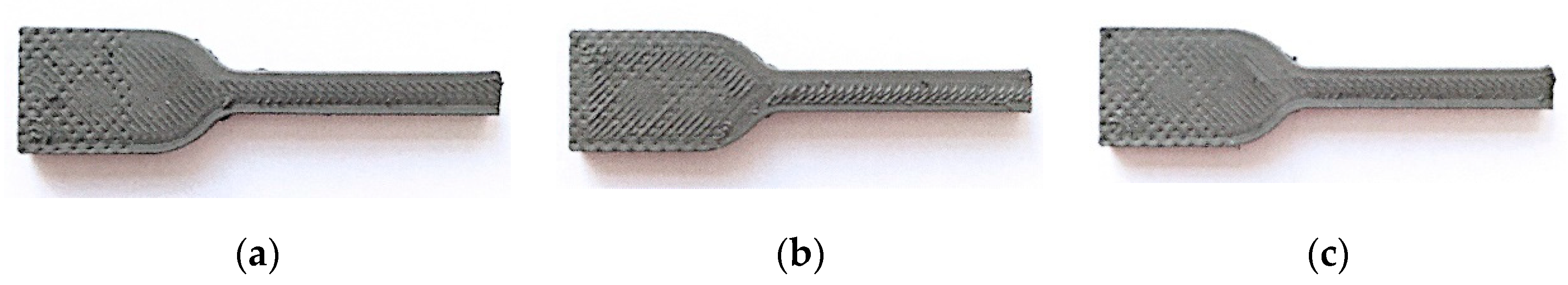

3.1. Fused Filament Fabrication of Specimens

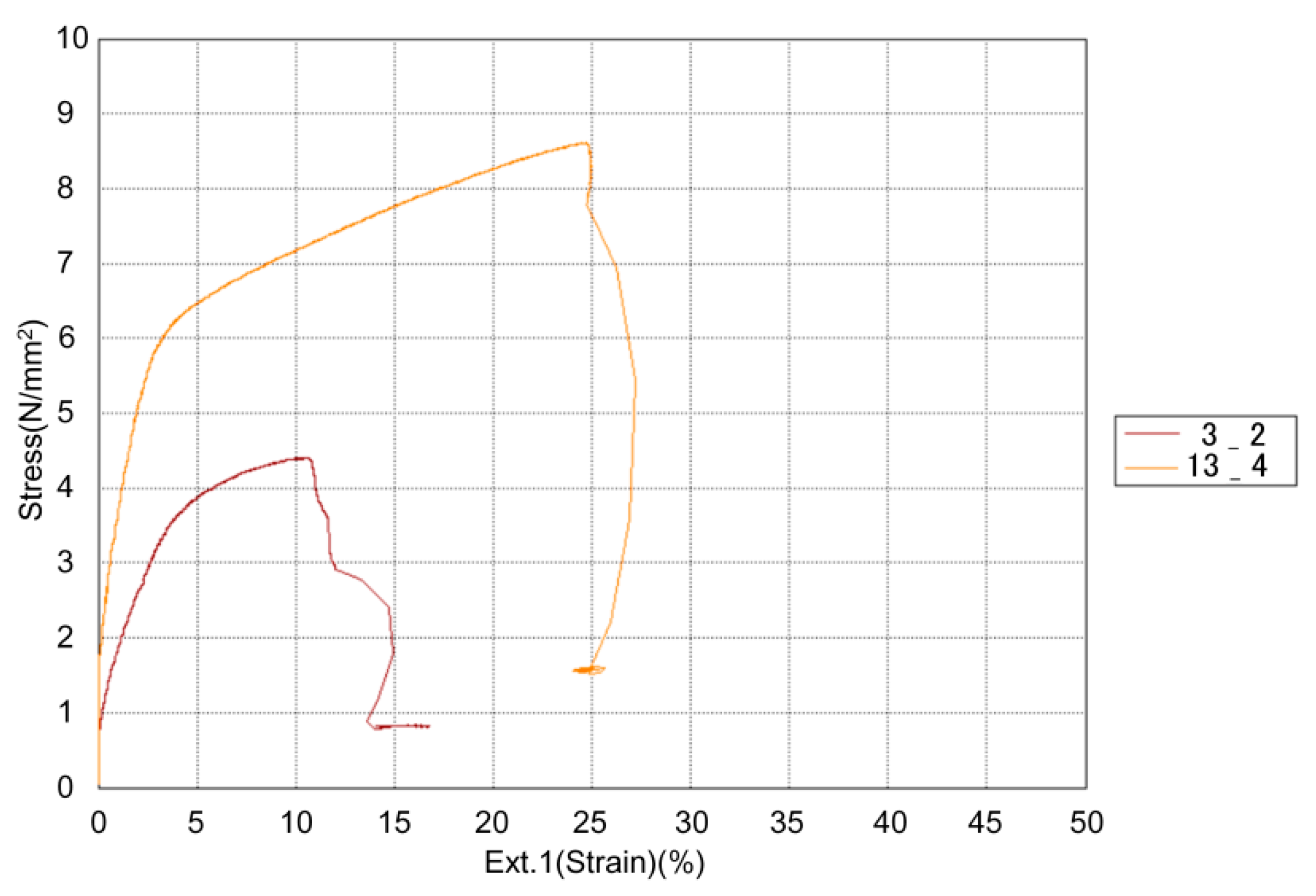

3.2. Tensile Properties of 3D-Printed Green Parts

3.3. Statistical Analysis of Tensile Testing Results

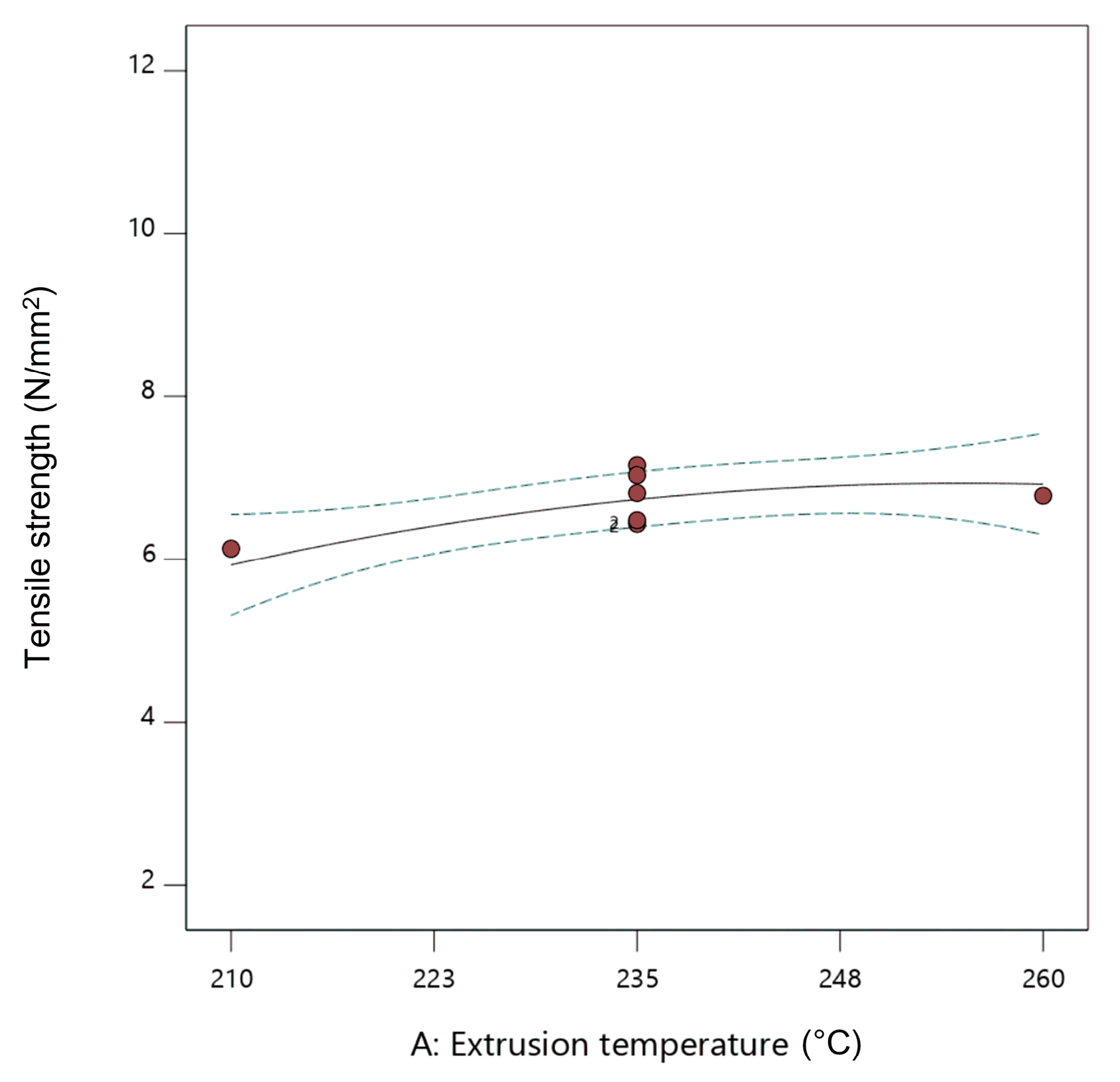

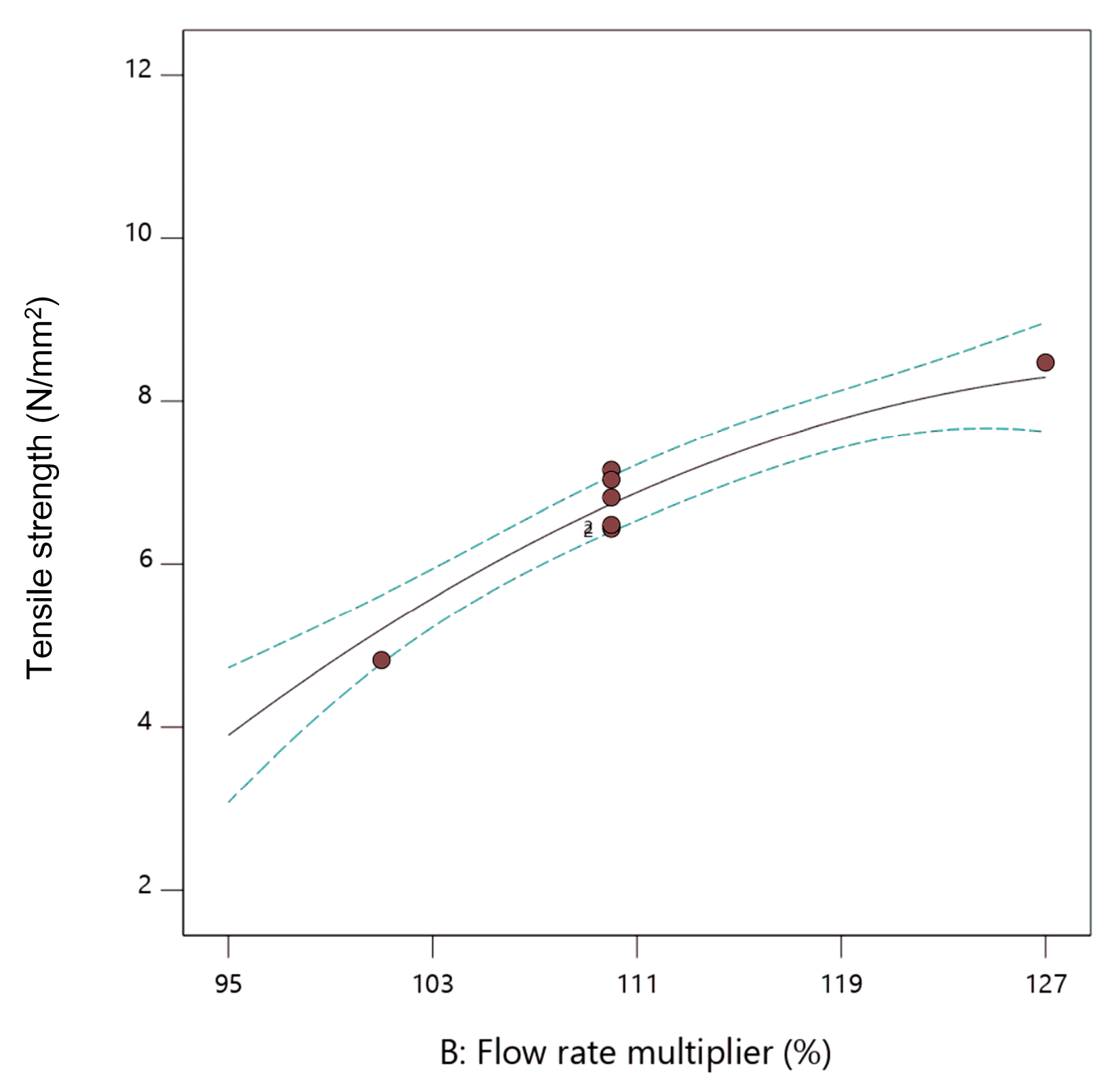

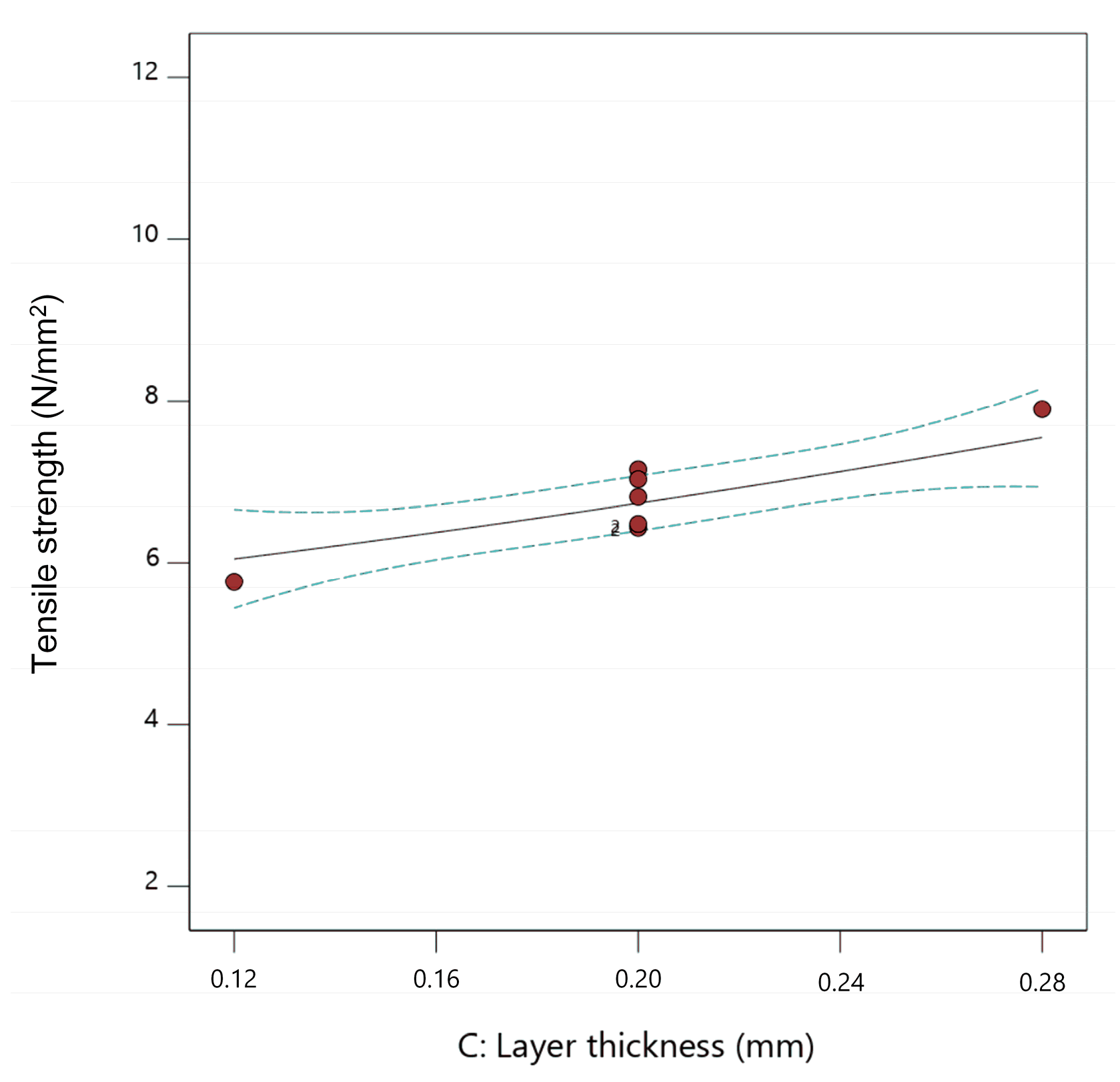

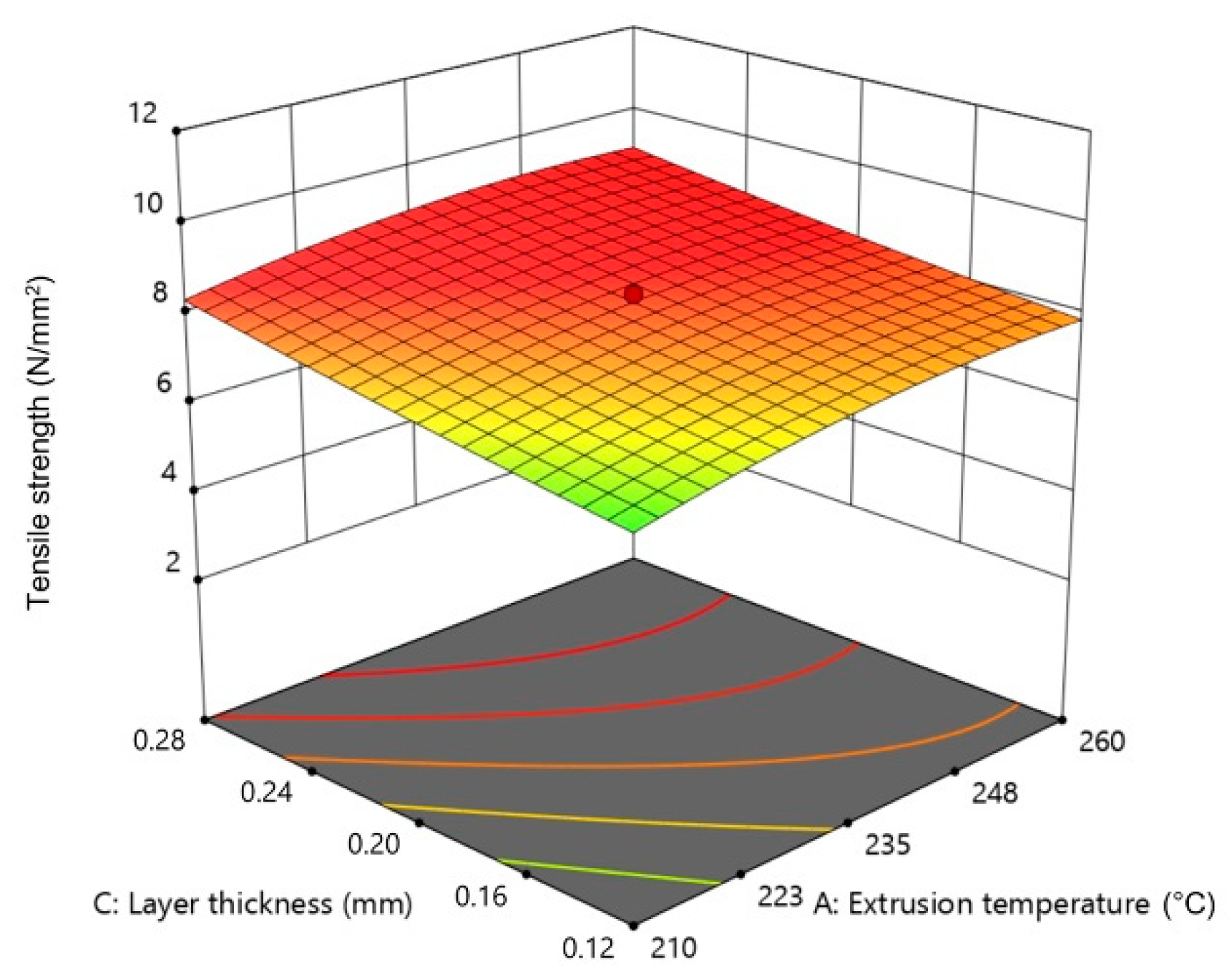

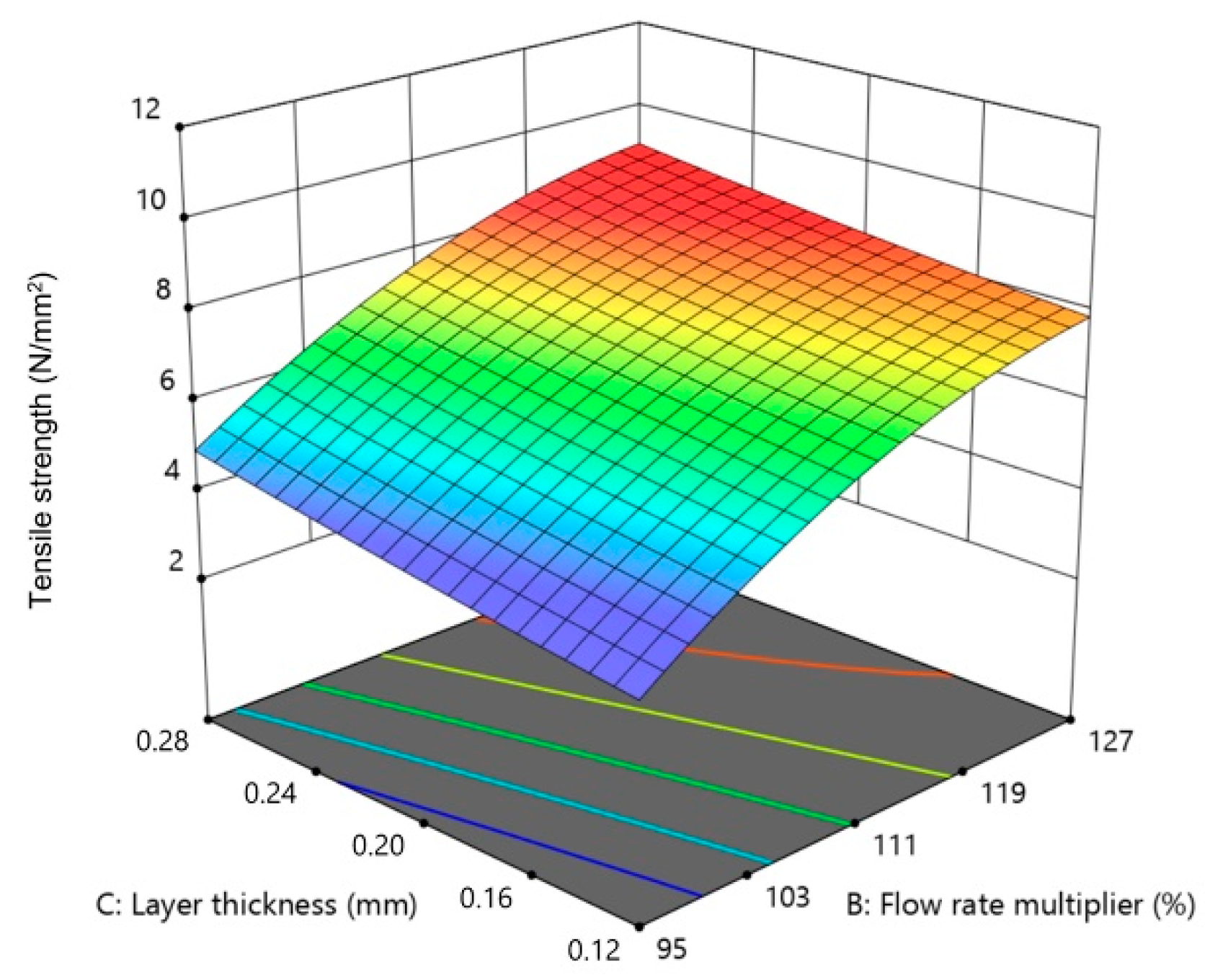

3.3.1. Statistical Analysis of Tensile Strength

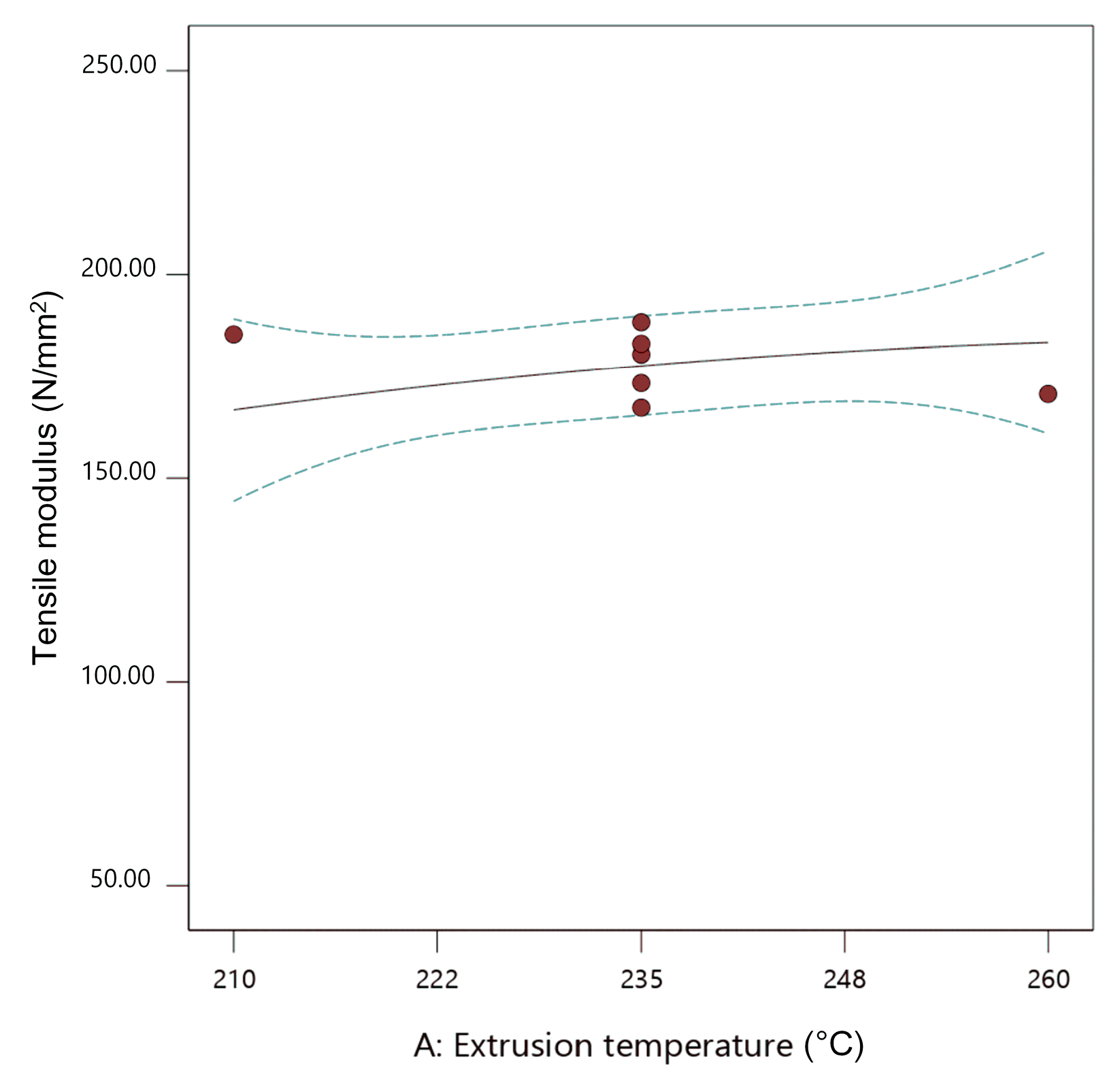

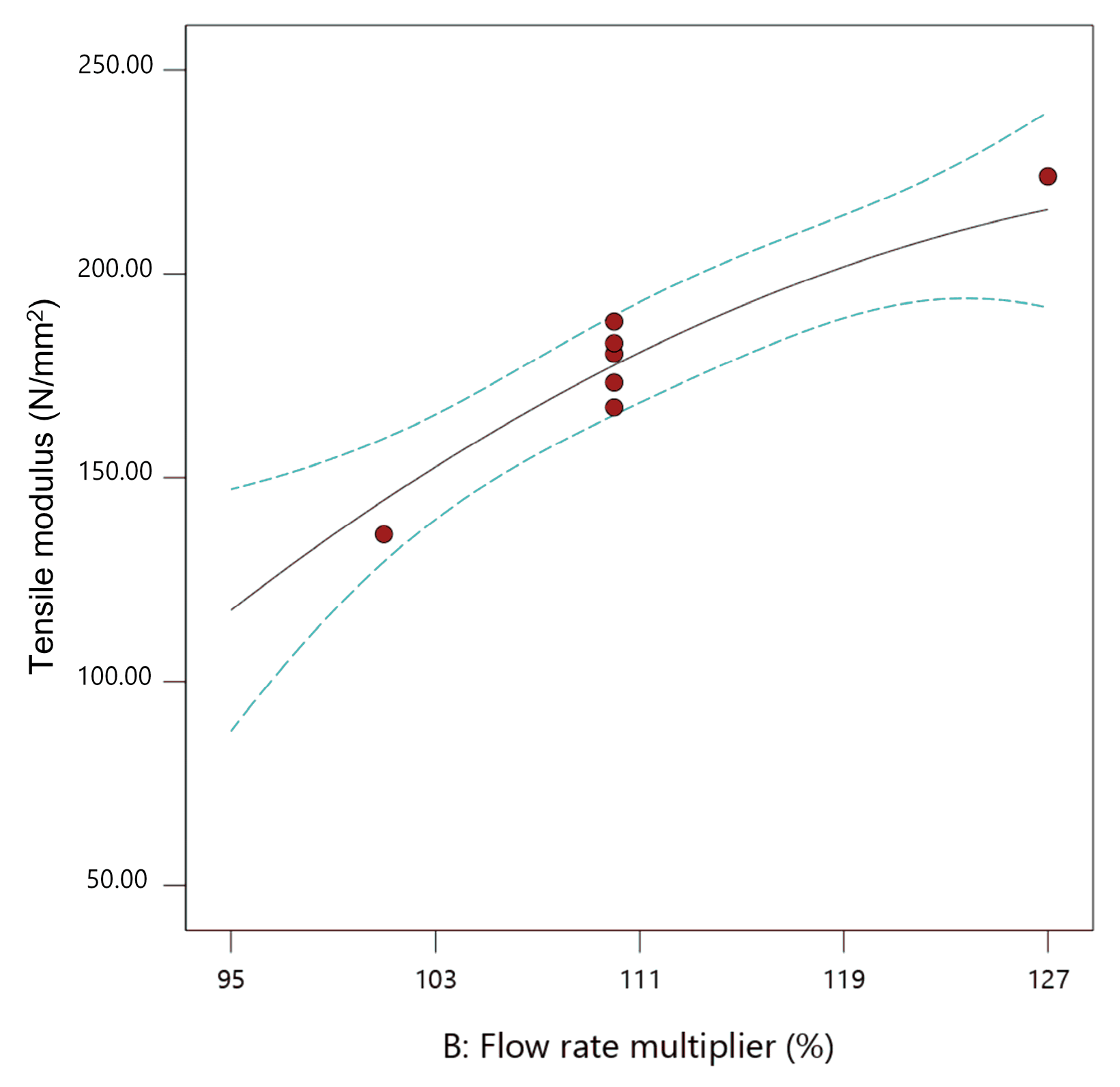

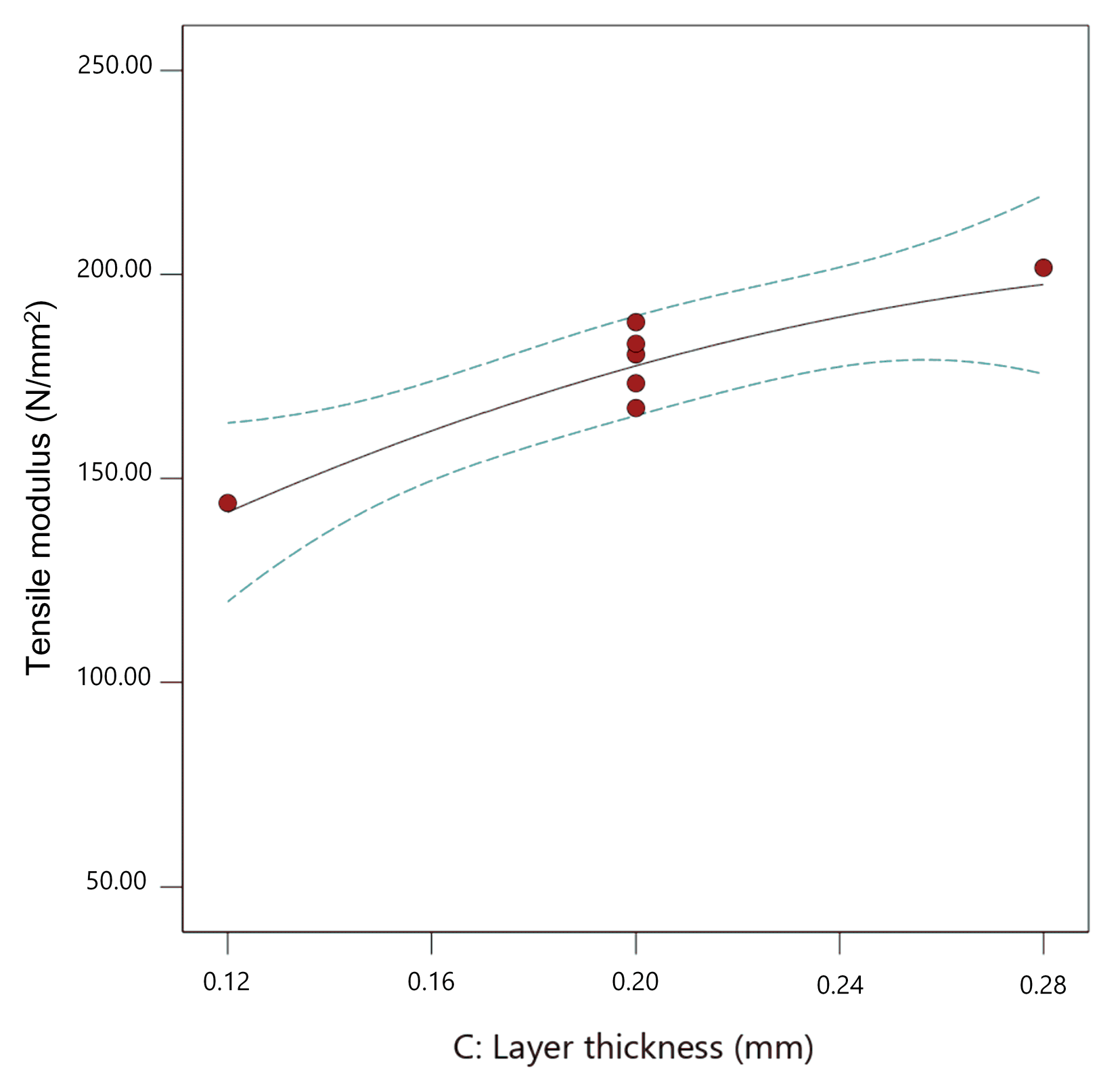

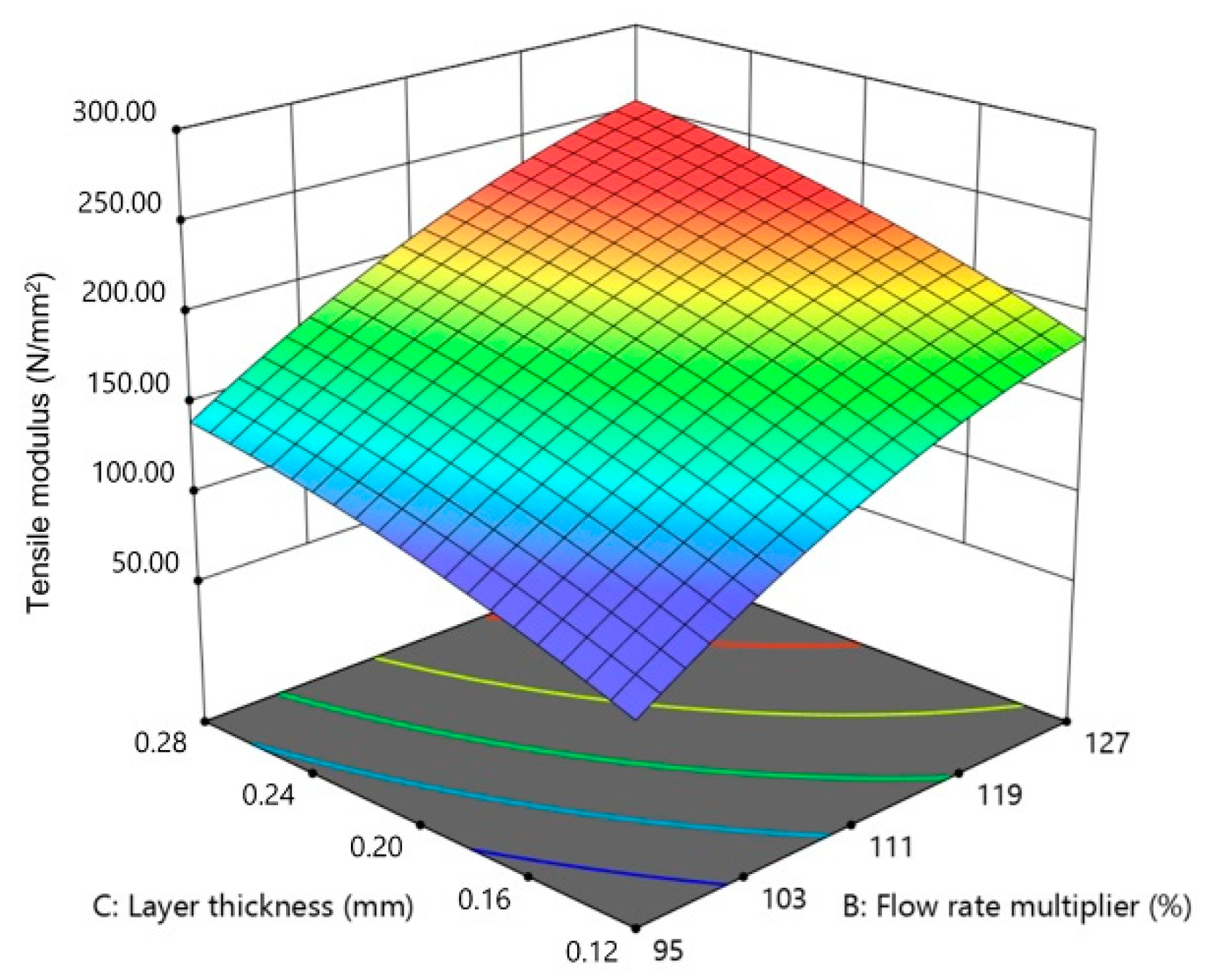

3.3.2. Statistical Analysis of Tensile Modulus

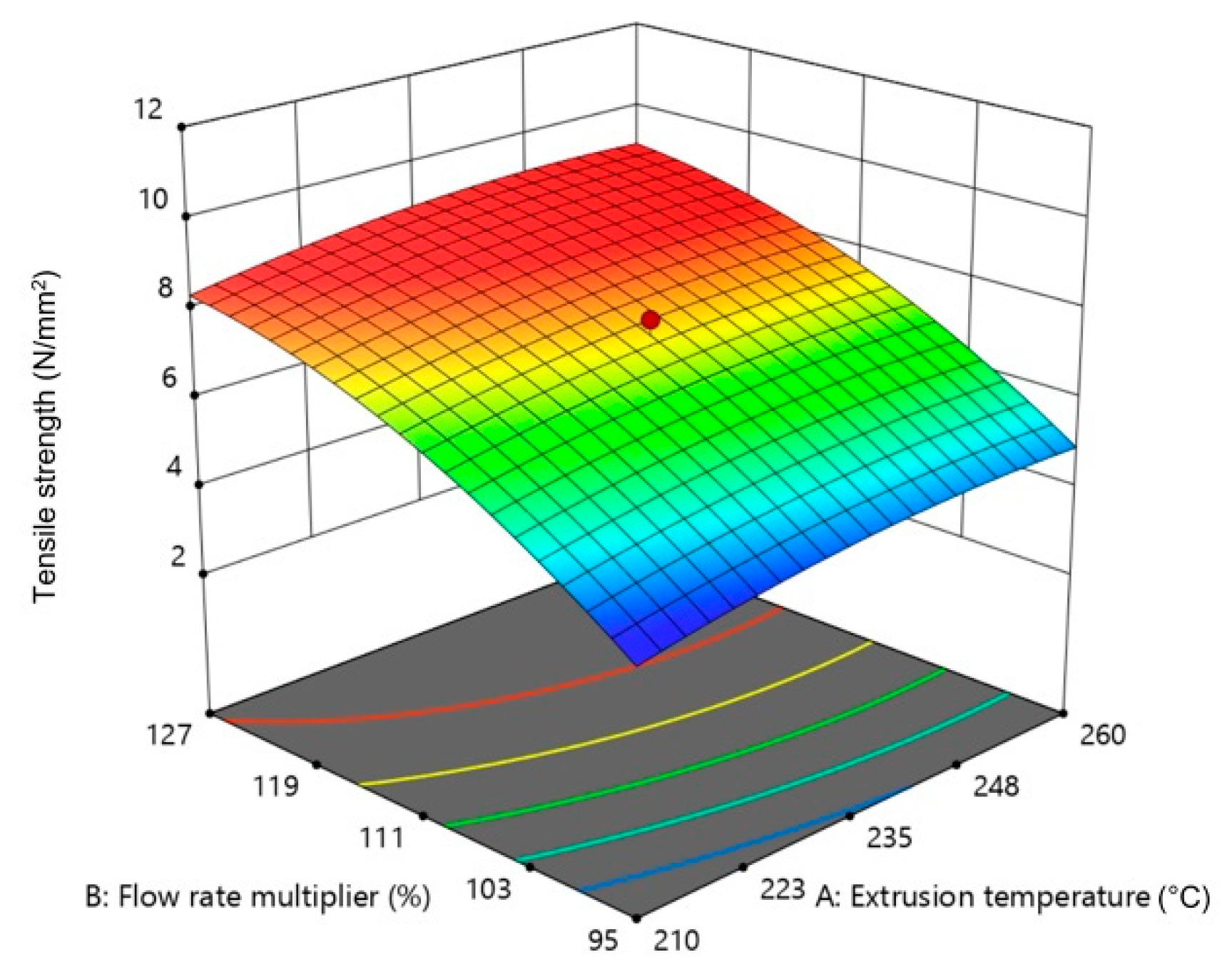

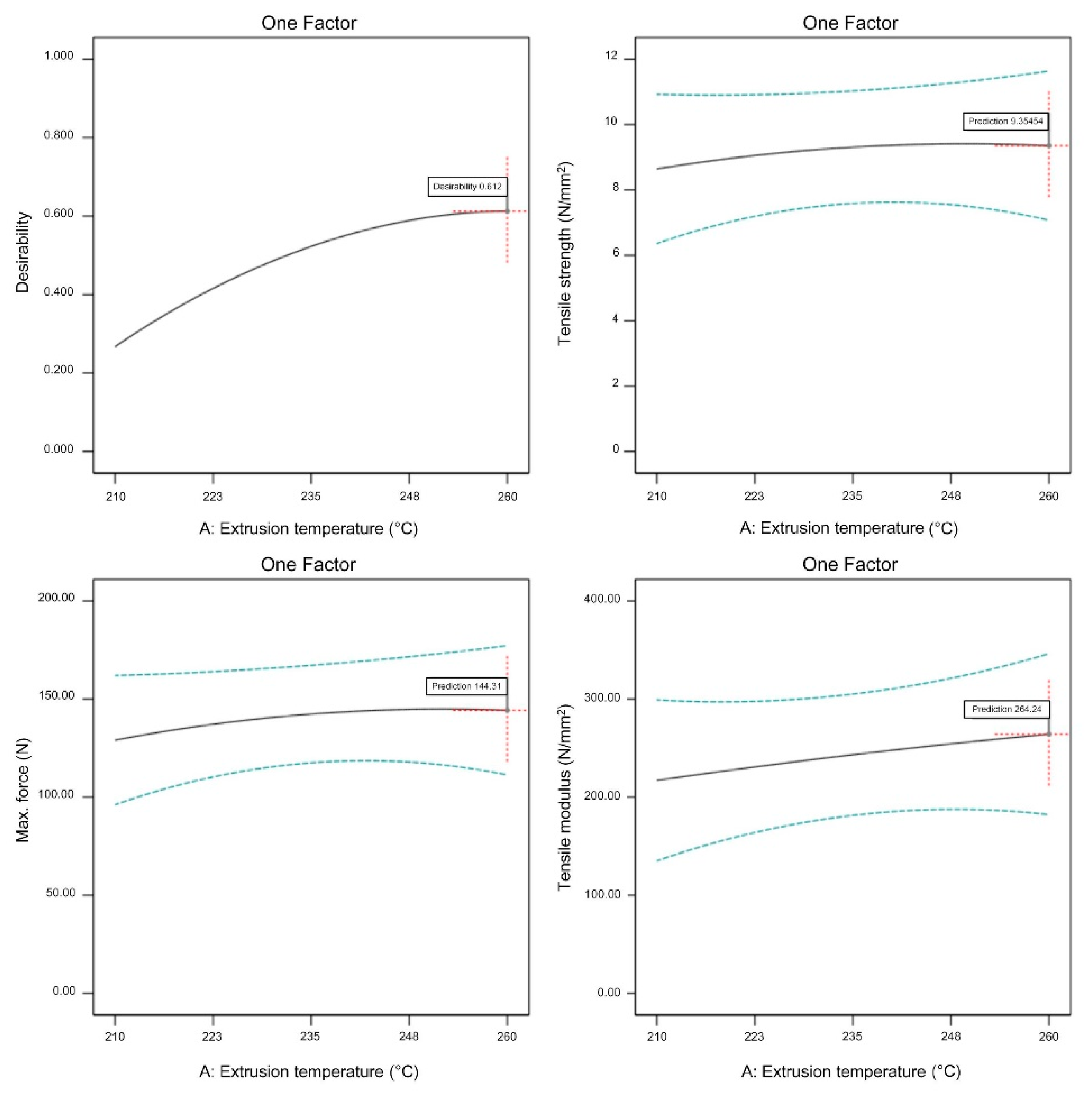

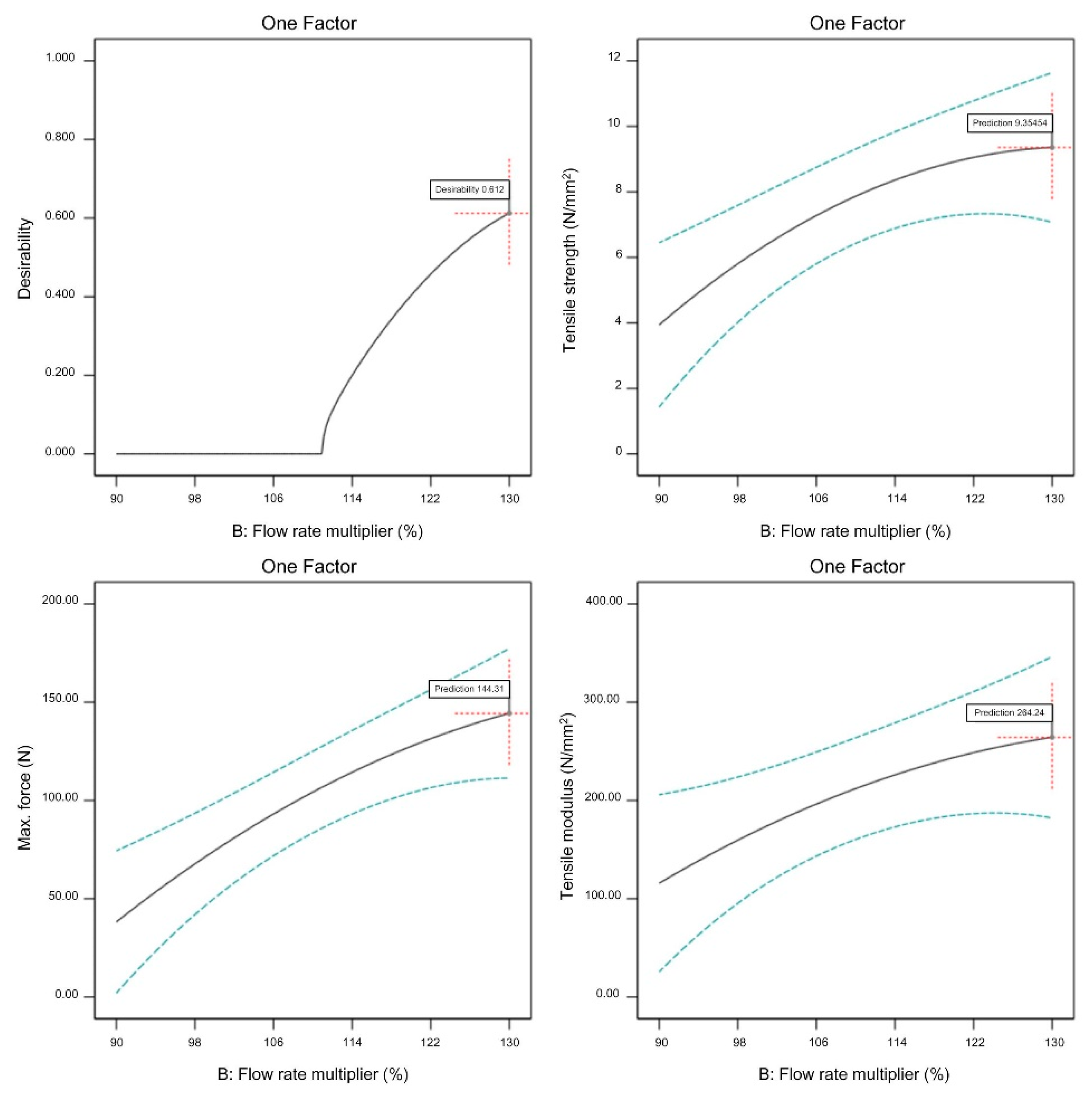

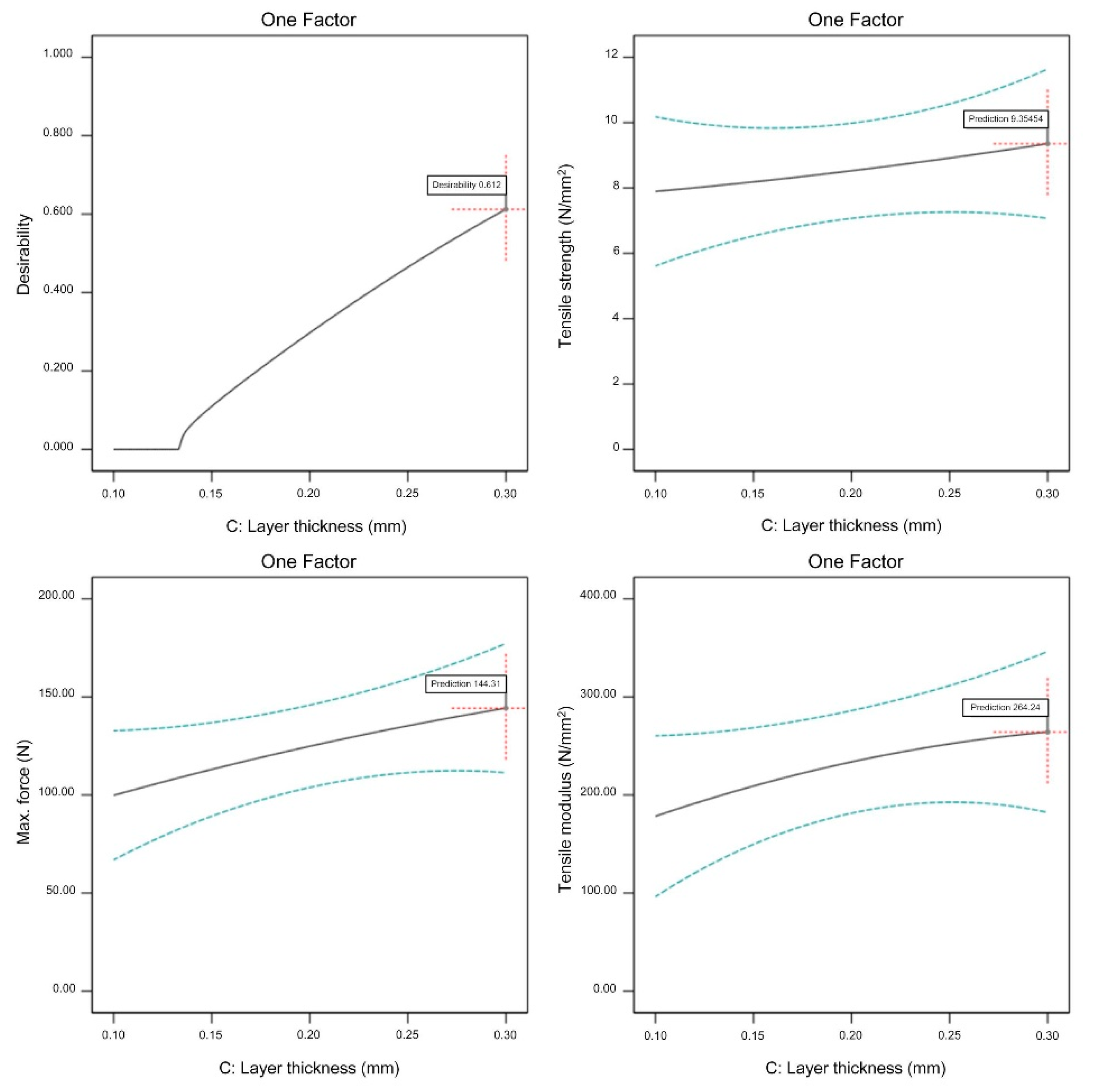

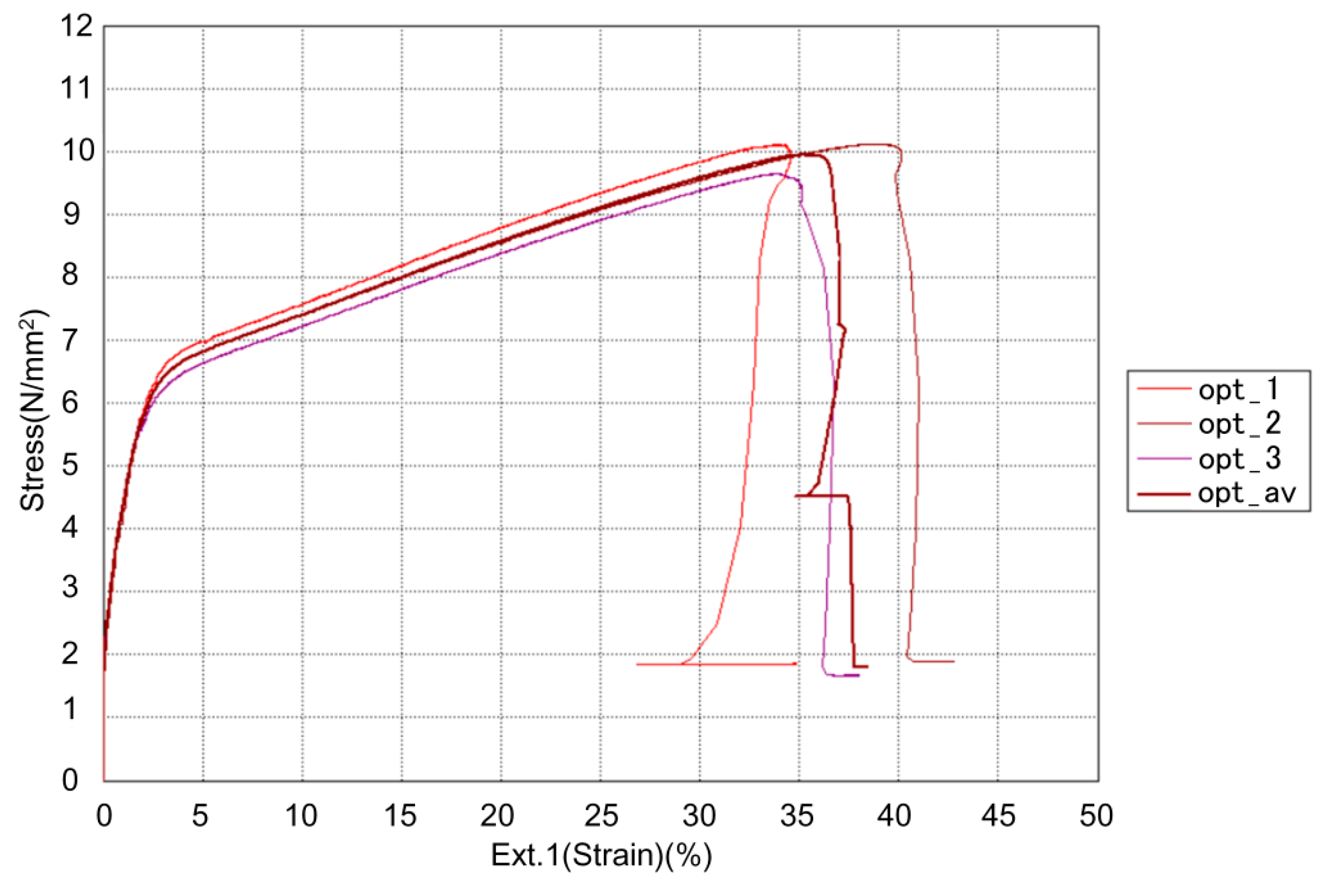

3.4. Statistical Model for Optimization

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of Fused Deposition Modeling parts by CNC machining. Robot. Comput.-Integr. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

- EN ISO/ASTM. Additive manufacturing—General principles—Terminology; Austrian Standards Institute: Wien, Austria, 2017; öNORM EN ISO/ASTM (öNORM EN ISO/ASTM 52900:2017-01). [Google Scholar]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J.; Green, D.J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies. 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; ISBN 978-1-4939-2113-3. [Google Scholar]

- Allahverdi, M.; Danforth, S.C.; Jafari, M.A.; Safari, A. Processing of advanced electroceramic components by fused deposition technique. J. Eur. Ceram. Soc. 2001, 21, 1485–1490. [Google Scholar] [CrossRef]

- Nestle, N.; Hermant, M.-C.; Schimdt, K. Mixture for Use in a Fused Filament Fabrication Process. U.S. Patent 14/806,102, 28 January 2016. [Google Scholar]

- Arburg GmbH & Co KG. Freeformer System: No Mold Required for a Fully Functional Part. Available online: https://www.arburg.com/us/us/products-and-services/additive-manufacturing/freeformer-system/ (accessed on 19 July 2017).

- Koslow, T. Pollen Introduces Pam: Their New Professional-Grade Multi-Material 3D Printer. Available online: https://3dprint.com/140595/pollen-pam-multi-material/ (accessed on 22 August 2017).

- Agarwala, M.K.; van Weeren, R.; Bandyopadhyay, A.; Safari, A.; Danforth, S.C.; Priedeman, W.R. Filament Feed Materials for Fused Deposition Processing of Ceramics and Metals. In Solid Freeform Fabrication Symposium, Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 1996; Bourell, D.L., Berger, C., Marcus, H.L., Crawford, R.H., Barlow, J.W., Eds.; The University of Texas at Austin: Austin, TX, USA, 1996. [Google Scholar]

- Agarwala, M.K.; van Weeren, R.; Bandyopadhyay, A.; Whalen, P.J.; Safari, A.; Danforth, S.C. Fused Deposition of Ceramics and Metals: An Overview. In Solid Freeform Fabrication Symposium, Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 1996; Bourell, D.L., Berger, C., Marcus, H.L., Crawford, R.H., Barlow, J.W., Eds.; The University of Texas at Austin: Austin, TX, USA, 1996. [Google Scholar]

- Crump, S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 07/429,012, 30 October 1989. [Google Scholar]

- Danforth, S.C.; Agarwala, M.K.; Bandyopadhyay, A.; Langrana, N.A.; Jamalabad, V.R.; Safari, A.; van Weeren, R. Solid Freeform Fabrication Methods. U.S. Patent 5738817, 14 April 1998. [Google Scholar]

- Danforth, S.C.; Agarwala, M.K.; Bandyopadhyay, A.; Langrana, N.A.; Jamalabad, V.R.; Safari, A.; van Weeren, R.; Priedeman, W.R. Solid Freeform Fabrication Methods. U.S. Patent 5900207, 4 May 1999. [Google Scholar]

- Wohlers, T. Desktop Metal: A Rising Star of Metal AM Targets Speed, Cost and High-Volume Production; Metal AM, Inovar Communications Ltd.: Shrewsbury, UK, 2017; pp. 89–92. Available online: http://www.metal-am.com/wp-content/uploads/sites/4/2017/06/MAGAZINE-Metal-AM-Summer-2017-PDF-sp.pdf (accessed on 11 July 2017).

- EVO-Tech GmbH. FMP: Filament Metal Printing. Available online: http://evo-tech.eu/de/Filament-Metal-Printing (accessed on 22 August 2017).

- Campbell, I.; Wohlers, T. Markforged: Taking a Different Approach to Metal Additive Manufacturing; Metal AM, Inovar Communications Ltd.: Shrewsbury, UK, 2017; pp. 113–115. Available online: http://www.metal-am.com/wp-content/uploads/sites/4/2017/06/MAGAZINE-Metal-AM-Summer-2017-PDF-sp.pdf (accessed on 11 July 2017).

- AIM3D GmbH. Edelstahl. Available online: http://www.aim3d.de/materialien/edelstaehle/ (accessed on 7 July 2017).

- Van der Schaaf, P.; Inderbitzin, B.; Hermant, M.-C.; Schoemer, M. Filaments Based on a Coated Core Material. U.S. Patent 2018/0202076 A1, 7 July 2016. [Google Scholar]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Gorantla, S.; Popp, U.; Okolo, B.; Schulze, V. Process porosity and mechanical performance of fused filament fabricated 316L stainless steel. RPJ 2019, 27, 1319–1327. [Google Scholar] [CrossRef]

- Gong, H.; Crater, C.; Ordonez, A.; Ward, C.; Waller, M.; Ginn, C.; Chang, G. Material Properties and Shrinkage of 3D Printing Parts using Ultrafuse Stainless Steel 316LX Filament. MATEC Web Conf. 2018, 249, 1001. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Arbeiter, F.; Schlauf, T.; Kukla, C.; Holzer, C. Tensile properties of sintered 17-4PH stainless steel fabricated by material extrusion additive manufacturing. Mater. Lett. 2019, 248, 165–168. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Godec, D.; Guran, R.; Spoerk, M.; Kukla, C.; Holzer, C. 3D printing conditions determination for feedstock used in fused filament fabrication (FFF) of 17-4PH stainless steel parts. Metalurgija 2018, 57, 117–120. [Google Scholar]

- Wu, G.; Langrana, N.A.; Sadanji, R.; Danforth, S.C. Solid freeform fabrication of metal components using fused deposition of metals. Mater. Des. 2002, 23, 97–105. [Google Scholar] [CrossRef]

- Singh, P.; Shaikh, Q.; Balla, V.K.; Atre, S.V.; Kate, K.H. Estimating Powder-Polymer Material Properties Used in Design for Metal Fused Filament Fabrication (DfMF3). JOM 2019, 11, 840. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Duretek, I.; Holzer, C.; Arbeiter, F.; Kukla, C. Filler Content and Properties of Highly Filled Filaments for Fused Filament Fabrication of Magnets. In Proceedings of the ANTEC 2017, Anaheim, CA, USA, 8–10 May 2017; Society of Plastics Engineers, Ed.; Society of Plastics Engineers: Newtown, CT, USA, 2017; pp. 1–4, ISBN 978-0-692-88309-9. [Google Scholar]

- Dehdari Ebrahimi, N.; Ju, Y.S. Thermal conductivity of sintered copper samples prepared using 3D printing-compatible polymer composite filaments. Addit. Manuf. 2018, 24, 479–485. [Google Scholar] [CrossRef]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Nötzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef]

- Rane, K.; Petrò, S.; Strano, M. Evolution of porosity and geometrical quality through the ceramic extrusion additive manufacturing process stages. Addit. Manuf. 2020, 32, 101038. [Google Scholar] [CrossRef]

- Griffin, E.A.; McMillin, S. Selective Laser Sintering and Fused Deposition Modeling Processes for Functional Ceramic Parts. In Solid Freeform Fabrication Symposium, Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 1995; Marcus, H.L., Ed.; The University of Texas at Austin: Austin, TX, USA, 1995. [Google Scholar]

- Fan, N.C.; Chen, Y.Y.; Wei, W.C.J.; Liu, B.H.; Wang, A.B.; Luo, R.C. Porous Al2O3 catalyst carrier by 3D additive manufacturing for syngas reforming. J. Ceram. Process. Res. 2017, 18, 676–682. [Google Scholar]

- Agarwala, M.K.; Jamalabad, V.R.; Langrana, N.A.; Safari, A.; Whalen, P.J.; Danforth, S.C. Structural quality of parts processed by fused deposition. Rapid Prototyp. J. 1996, 2, 4–19. [Google Scholar] [CrossRef]

- Iyer, S.; McIntosh, J.J.; Bandyopadhyay, A.; Langrana, N.A.; Safari, A.; Danforth, S.C.; Clancy, R.B.; Gasdaska, C.J.; Whalen, P.J. Microstructural Characterization and Mechanical Properties of Si3N4 Formed by Fused Deposition of Ceramics. Int. J. Appl. Ceram. Technol. 2008, 5, 127–137. [Google Scholar] [CrossRef]

- McNulty, T.F.; Mohammadi, F.; Bandyopadhyay, A.; Shanefield, D.J.; Danforth, S.C.; Safari, A. Development of a binder formulation for fused deposition of ceramics. Rapid Prototyp. J. 1998, 4, 144–150. [Google Scholar] [CrossRef]

- Jafari, M.A.; Han, W.; Mohammadi, F.; Safari, A.; Danforth, S.C.; Langrana, N.A. A novel system for fused deposition of advanced multiple ceramics. Rapid Prototyp. J. 2000, 6, 161–175. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Das, K.; Marusich, J.; Onagoruwa, S. Application of fused deposition in controlled microstructure metal-ceramic composites. Rapid Prototyp. J. 2006, 12, 121–128. [Google Scholar] [CrossRef]

- Gorjan, L.; Blugan, G.; Graule, T.; Kuebler, J. Effectiveness of wick-debinding inside powder bed for ceramic laminates made by tape casting. Powder Technol. 2015, 273, 197–202. [Google Scholar] [CrossRef]

- Bose, A.; Schuh, C.A.; Tobia, J.C.; Tuncer, N.; Mykulowycz, N.M.; Preston, A.; Barbati, A.C.; Kernan, B.; Gibson, M.A.; Krause, D.; et al. Traditional and additive manufacturing of a new Tungsten heavy alloy alternative. Int. J. Refract. Met. Hard Mater. 2018, 73, 22–28. [Google Scholar] [CrossRef]

- Lengauer, W.; Duretek, I.; Fürst, M.; Schwarz, V.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Kitzmantel, M.; Neubauer, E.; Lieberwirth, C.; et al. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int. J. Refract. Met. Hard Mater. 2019, 82, 141–149. [Google Scholar] [CrossRef]

- Berger, C.; Abel, J.; Pötschke, J.; Moritz, T. Properties of Additive Manufactured Hardmetal Components Produced by Fused Filament Fabrication (FFF). In Proceedings of the Euro PM2018, Bilbao, Spain, 14–18 October 2018; EPMA, Ed.; European Powder Metallurgy Association (EMPA): Shrewsbury, UK, 2018. ISBN 978-1-899072-50-7. [Google Scholar]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of Metal-Ceramic Components. JoVE 2019, 143, e57693. [Google Scholar] [CrossRef]

- Elkins, K.; Nordby, H.; Janak, C.; Gray, R.W.; Bøhn, H.H.; Baird, D.G. Soft Elastomers for Fused Deposition Modeling. In Proceedings of the 8th Solid Freeform Fabrication Symposium, Austin, TX, USA, 11–13 August 1997; pp. 441–448. [Google Scholar]

- Kukla, C.; Duretek, I.; Schuschnigg, S.; Gonzalez-Gutierrez, J.; Holzer, C. Properties for PIM Feedstocks Used in Fused Filament Fabrication. In Proceedings of the World PM2016 Congress & Exhibition, Hamburg, Germany, 9–13 October 2016; EPMA, Ed.; European Powder Metallurgy Association (EMPA): Shrewsbury, UK, 2016. ISBN 9781899072484. [Google Scholar]

- Bayraktar, Ö.; Uzun, G.; Çakiroğlu, R.; Guldas, A. Experimental study on the 3D-printed plastic parts and predicting the mechanical properties using artificial neural networks. Polym. Adv. Technol. 2017, 28, 1044–1051. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Cajner, H.; Sapkota, J.; Holzer, C. Parametric optimization of intra- and inter-layer strengths in parts produced by extrusion-based additive manufacturing of poly(lactic acid). J. Appl. Polym. Sci. 2017, 134, 45401. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Reddy, B.V.; Reddy, N.V.; Ghosh, A. Fused deposition modelling using direct extrusion. Virtual Phys. Prototyp. 2007, 2, 51–60. [Google Scholar] [CrossRef]

- Álvarez, K.; Lagos, R.F.; Aizpun, M. Investigating the influence of infill percentage on the mechanical properties of fused deposition modelled ABS parts. Ing. Investig. 2016, 36, 110. [Google Scholar] [CrossRef]

- Spoerk, M.; Sapkota, J.; Weingrill, G.; Fischinger, T.; Arbeiter, F.; Holzer, C. Shrinkage and Warpage Optimization of Expanded-Perlite-Filled Polypropylene Composites in Extrusion-Based Additive Manufacturing. Macromol. Mater. Eng. 2017, 12, 1700143. [Google Scholar] [CrossRef]

- Kukla, C.; Gonzalez-Gutierrez, J.; Duretek, I.; Schuschnigg, S.; Holzer, C. Effect of Particle Size on the Properties of Highly-Filled Polymers for Fused Filament Fabrication. In Proceedings of the 32nd Annual Meeting of the Polymer Processing Scociety, 32nd PPS International Conference, Lyon, France, 25–29 July 2016; Polymer Processing Society (PPS): St. Lawrence, KS, USA, 2016; pp. 274–277. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology. Process and Product Optimization Using Designed Experiments, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; ISBN 978-0-470-17446-3. [Google Scholar]

- Draper, N.R. Rotatable Designs and Rotatability. In Encyclopedia of Statistics in Quality and Reliability; Ruggeri, F., Kenett, R., Faltin, F.W., Eds.; John Wiley: Chichester, UK, 2007; p. 195. ISBN 9780470018613. [Google Scholar]

- Tronvoll, S.A.; Welo, T.; Elverum, C.W. The effects of voids on structural properties of fused deposition modelled parts: A probabilistic approach. Int. J. Adv. Manuf. Technol. 2018, 97, 3607–3618. [Google Scholar] [CrossRef]

- Patanwala, H.S.; Hong, D.; Vora, S.R.; Bognet, B.; Ma, A.W.K. The microstructure and mechanical properties of 3D printed carbon nanotube-polylactic acid composites. Polym. Compos. 2018, 39, E1060–E1071. [Google Scholar] [CrossRef]

- Beran, T.; Mulholland, T.; Henning, F.; Rudolph, N.; Osswald, T.A. Nozzle clogging factors during fused filament fabrication of spherical particle filled polymers. Addit. Manuf. 2018, 23, 206–214. [Google Scholar] [CrossRef]

- Torres, J.; Cole, M.; Owji, A.; DeMastry, Z.; Gordon, A.P. An approach for mechanical property optimization of fused deposition modeling with polylactic acid via design of experiments. Rapid Prototyp. J. 2016, 22, 387–404. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Analysis of tensile strength of a fused filament fabricated PLA part using an open-source 3D printer. Int. J. Adv. Manuf. Technol. 2019, 101, 1525–1536. [Google Scholar] [CrossRef]

- Luzanin, O.; Movrin, D.; Stathopoulos, V.; Pandis, P.; Radusin, T.; Guduric, V. Impact of processing parameters on tensile strength, in-process crystallinity and mesostructure in FDM-fabricated PLA specimens. Rapid Prototyp. J. 2019, 25, 1398–1410. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Tavitov, A.G.; Urzhumtsev, O.D.; Vakulik, A.H. Increasing of Strength of FDM (FFF) 3D Printed Parts by Influencing on Temperature-Related Parameters of the Process. Rapid Prototyp. J. 2018. [Google Scholar] [CrossRef]

- Zekavat, A.R.; Jansson, A.; Larsson, J.; Pejryd, L. Investigating the effect of fabrication temperature on mechanical properties of fused deposition modeling parts using X-ray computed tomography. Int. J. Adv. Manuf. Technol. 2019, 100, 287–296. [Google Scholar] [CrossRef]

| Particle Size | Distribution |

|---|---|

| D10 (μm) | 4.2 |

| D50 (μm) | 12.3 |

| D90 (μm) | 28.2 |

| Trial Number | Factor 1: Extrusion Temperature (°C) | Factor 2: Flow Rate Multiplier (°C) | Factor 3: Layer Thickness (mm) |

|---|---|---|---|

| 1 | 220 | 120 | 0.25 |

| 2 | 235 | 110 | 0.12 |

| 3 | 220 | 101 | 0.15 |

| 4 | 250 | 101 | 0.15 |

| 5 | 260 | 110 | 0.20 |

| 6 | 235 | 110 | 0.28 |

| 7 | 210 | 110 | 0.20 |

| 8 | 220 | 120 | 0.15 |

| 9 | 250 | 101 | 0.25 |

| 10 | 235 | 95 | 0.20 |

| 11 | 235 | 110 | 0.20 |

| 12 | 235 | 110 | 0.20 |

| 13 | 235 | 127 | 0.20 |

| 14 | 235 | 110 | 0.20 |

| 15 | 235 | 110 | 0.20 |

| 16 | 250 | 120 | 0.25 |

| 17 | 235 | 110 | 0.20 |

| 18 | 250 | 120 | 0.15 |

| 19 | 220 | 101 | 0.25 |

| Trial Number | Tensile Strength ± SD (N/mm2) | Maximal Force ± SD (N) | Tensile Modulus ± SD (N/mm2) | Mass (g) |

|---|---|---|---|---|

| 1 | 7.67 ± 0.51 | 109.12 ± 6.77 | 194.70 ± 29.01 | 6.57 |

| 2 | 5.76 ± 0.15 | 74.32 ± 1.88 | 143.97 ± 9.55 | 5.10 |

| 3 | 4.40 ± 0.20 | 56.54 ± 2.30 | 114.75 ± 9.78 | 4.80 |

| 4 | 5.23 ± 0.23 | 62.36 ± 2.90 | 134.16 ± 14.94 | 4.90 |

| 5 | 6.78 ± 0.37 | 90.63 ± 5.19 | 170.62 ± 29.26 | 5.70 |

| 6 | 7.90 ± 0.49 | 106.61 ± 7.41 | 201.65 ± 17.02 | 6.30 |

| 7 | 6.13 ± 0.22 | 82.17 ± 3.95 | 185.30 ± 22.08 | 5.70 |

| 8 | 6.97 ± 0.26 | 91.14 ± 3.90 | 167.77 ± 25.42 | 5.70 |

| 9 | 5.89 ± 0.33 | 74.93 ± 4.12 | 166.99 ± 30.59 | 5.70 |

| 10 | 4.82 ± 0.25 | 62.58 ± 2.98 | 136.08 ± 17.87 | 5.10 |

| 11 | 7.15 ± 0.31 | 95.37 ± 3.65 | 173.34 ± 14.94 | 5.80 |

| 12 | 7.03 ± 0.33 | 93.60 ± 5.25 | 180.41 ± 17.55 | 5.80 |

| 13 | 8.47 ± 0.13 | 124.51 ± 2.31 | 223.92 ± 12.65 | 6.70 |

| 14 | 6.82 ± 0.23 | 94.14 ± 3.48 | 188.30 ± 17.11 | 5.80 |

| 15 | 6.44 ± 0.41 | 84.55 ± 5.60 | 183.01 ± 25.80 | 5.67 |

| 16 | 8.32 ± 0.48 | 116.80 ± 6.95 | 230.50 ± 21.69 | 6.70 |

| 17 | 6.48 ± 0.18 | 86.79 ± 2.49 | 167.25 ± 10.40 | 5.80 |

| 18 | 7.73 ± 0.24 | 101.81 ± 2.74 | 187.32 ± 16.04 | 5.80 |

| 19 | 5.18 ± 0.37 | 65.35 ± 4.75 | 148.62 ± 11.14 | 5.43 |

| Trial Number | Factor 1: Extrusion Temperature | Factor 2: Flow Rate Multiplier | Factor 3: Layer Thickness |

|---|---|---|---|

| The worst trials (combinations of parameters in coded form) | |||

| 3 | −1 | −1 | −1 |

| 10 | 0 | −1.68 | 0 |

| The best trials (combinations of parameters in coded form) | |||

| 13 | 0 | 1.68 | 0 |

| 16 | 1 | 1 | 1 |

| Source | Sum of Squares | DoF | Mean Square | F-Value | p-Value | Remark |

|---|---|---|---|---|---|---|

| Model | 23.56 | 9 | 2.62 | 21.49 | <0.0001 | Significant |

| A—Extrusion temperature | 1.20 | 1 | 1.20 | 9.84 | 0.0120 | Significant |

| B—Flow rate multiplier | 18.56 | 1 | 18.56 | 152.31 | <0.0001 | Significant |

| C—Layer thickness | 2.86 | 1 | 2.86 | 23.51 | 0.0009 | Significant |

| AB | 0.0015 | 1 | 0.0015 | 0.0119 | 0.9154 | |

| AC | 0.0064 | 1 | 0.0064 | 0.0524 | 0.8241 | |

| BC | 0.0058 | 1 | 0.0058 | 0.0477 | 0.8320 | |

| A² | 0.1682 | 1 | 0.1682 | 1.38 | 0.2701 | |

| B² | 0.6866 | 1 | 0.6866 | 5.63 | 0.0417 | Significant |

| C² | 0.0072 | 1 | 0.0072 | 0.0592 | 0.8132 | |

| Residual | 1.10 | 9 | 0.1219 | |||

| Lack of fit | 0.6840 | 5 | 0.1368 | 1.33 | 0.4038 | Not significant |

| Pure Error | 0.4127 | 4 | 0.1032 | |||

| Corrected Total | 24.66 | 18 |

| Source | Sum of Squares | DoF | Mean Square | F-Value | p-Value | Remark |

|---|---|---|---|---|---|---|

| Model | 14,316.59 | 9 | 1590.73 | 10.11 | 0.0010 | Significant |

| A—Extrusion temperature | 355.08 | 1 | 355.08 | 2.26 | 0.1674 | |

| B—Flow rate multiplier | 9204.05 | 1 | 9204.05 | 58.47 | <0.0001 | Significant |

| C—Layer thickness | 4001.95 | 1 | 4001.95 | 25.42 | 0.0007 | Significant |

| AB | 51.60 | 1 | 51.60 | 0.3278 | 0.5810 | |

| AC | 28.91 | 1 | 28.91 | 0.1837 | 0.6783 | |

| BC | 1.33 | 1 | 1.33 | 0.0085 | 0.9288 | |

| A² | 11.75 | 1 | 11.75 | 0.0747 | 0.7908 | |

| B² | 225.21 | 1 | 225.21 | 1.43 | 0.2622 | |

| C² | 115.74 | 1 | 115.74 | 0.7352 | 0.4134 | |

| Residual | 1416.72 | 9 | 157.41 | |||

| Lack of fit | 1143.52 | 5 | 228.70 | 3.35 | 0.1325 | Not significant |

| Pure Error | 273.20 | 4 | 68.30 | |||

| Corrected Total | 15,733.31 | 18 |

| Parameter/Property | Goal | Lower Limit | Upper Limit | Importance |

|---|---|---|---|---|

| A: Extrusion temperature | Is in range | 200 °C | 260 °C | 3 |

| B: Flow rate multiplier | Is in range | 90% | 130% | 3 |

| C: Layer thickness | Is in range | 0.1 mm | 0.3 mm | 3 |

| Tensile strength | Maximize | 8 N/mm2 | 12 N/mm2 | 5 |

| Maximum tensile force | Maximize | 100 N | 160 N | 5 |

| Tensile modulus | Maximize | 200 N/mm2 | 270 N/mm2 | 5 |

| Parameter/Property | Goal | Unit |

|---|---|---|

| A: Extrusion temperature | 260 | °C |

| B: Flow rate multiplier | 130 | % |

| C: Layer thickness | 0.3 | mm |

| Tensile strength | 9.36 | N/mm2 |

| Maximum tensile force | 144.31 | N |

| Tensile modulus | 264.24 | N/mm2 |

| Property | Value ± sd | Unit | Variance from Estimated |

|---|---|---|---|

| Tensile strength | 9.95 ± 0.27 | N/mm2 | +6.3 |

| Maximum tensile force | 132.27 ± 2.86 | N | −8.3 |

| Tensile modulus | 275.14 ± 6.22 | N/mm2 | +4.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Godec, D.; Cano, S.; Holzer, C.; Gonzalez-Gutierrez, J. Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel. Materials 2020, 13, 774. https://doi.org/10.3390/ma13030774

Godec D, Cano S, Holzer C, Gonzalez-Gutierrez J. Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel. Materials. 2020; 13(3):774. https://doi.org/10.3390/ma13030774

Chicago/Turabian StyleGodec, Damir, Santiago Cano, Clemens Holzer, and Joamin Gonzalez-Gutierrez. 2020. "Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel" Materials 13, no. 3: 774. https://doi.org/10.3390/ma13030774

APA StyleGodec, D., Cano, S., Holzer, C., & Gonzalez-Gutierrez, J. (2020). Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel. Materials, 13(3), 774. https://doi.org/10.3390/ma13030774