Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach

Abstract

1. Introduction

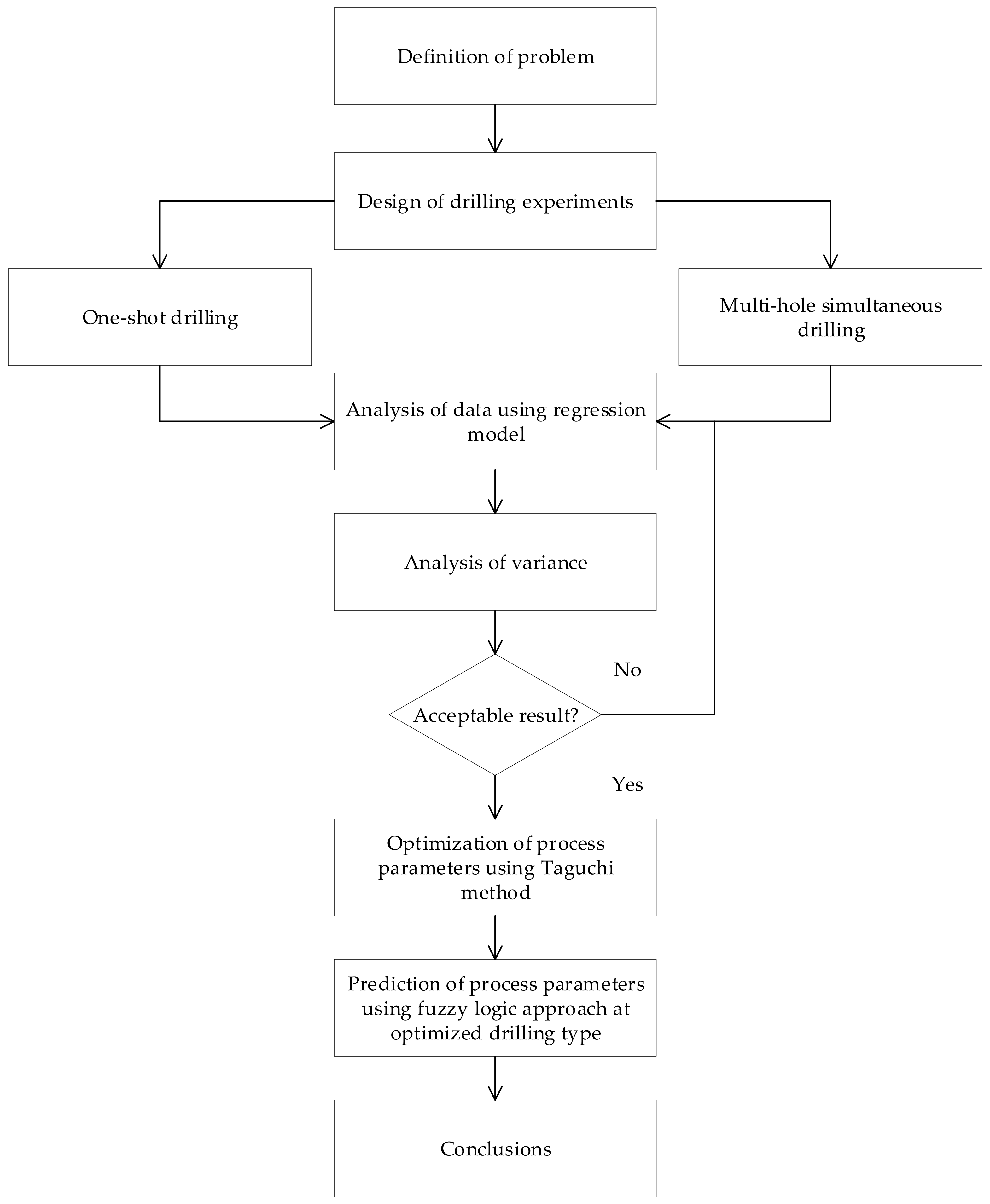

2. Materials and Methods

3. Results and Discussion

3.1. Regression Analysis

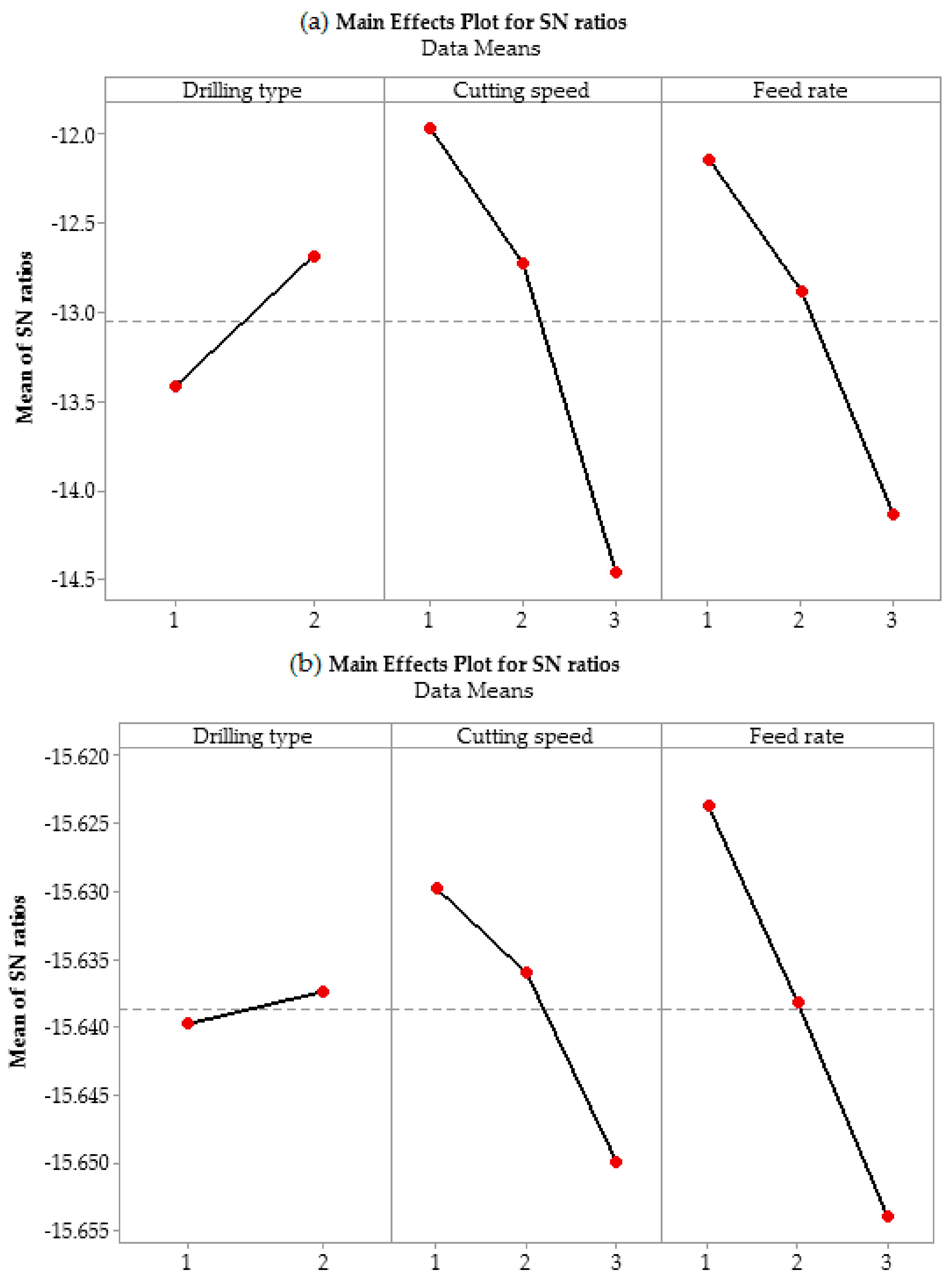

3.2. Optimization of Drilling Conditions Using Taguchi Analysis

3.3. Prediction of Surface Roughness and Hole Size at Optimal Levels

3.4. Analysis of Variance

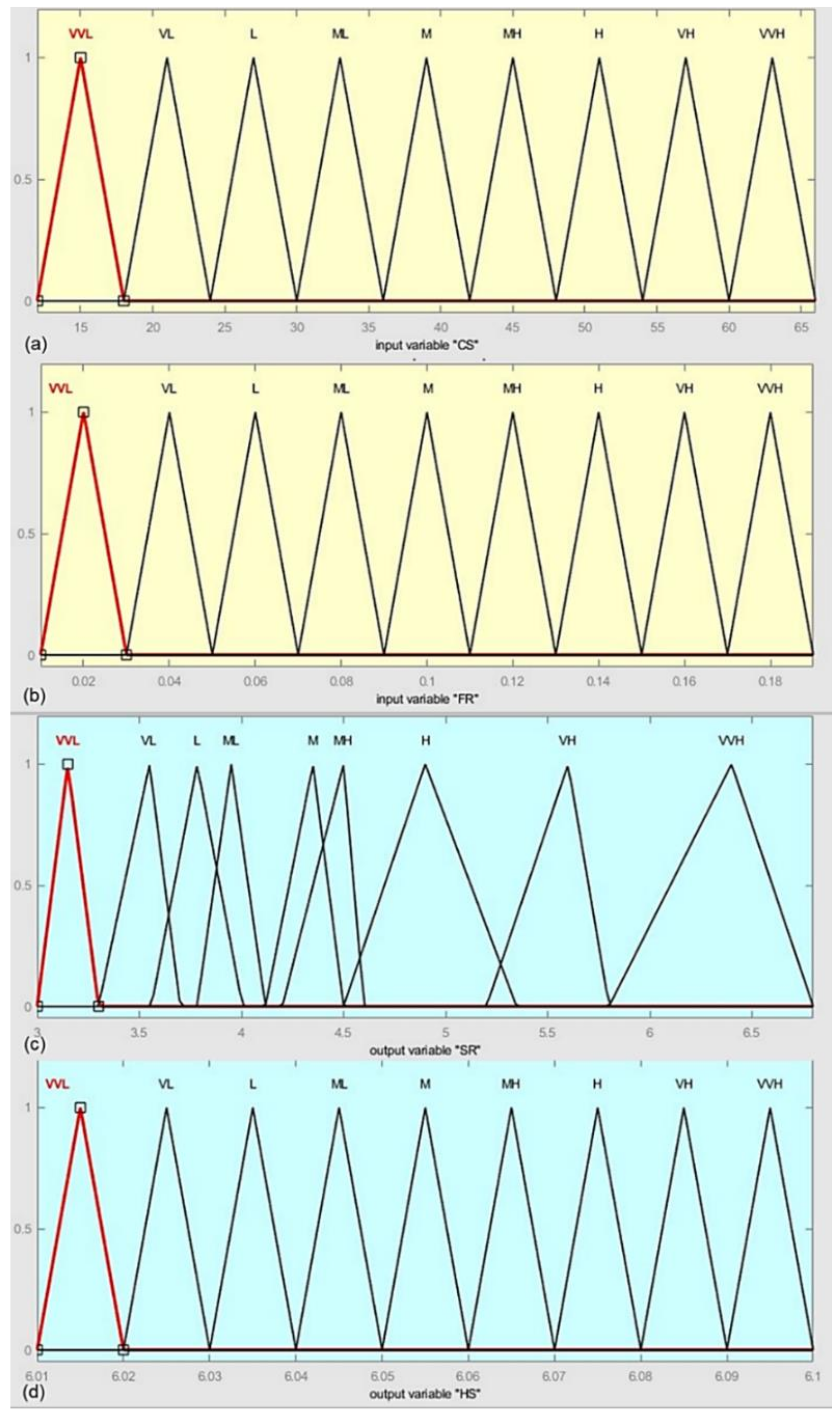

3.5. Fuzzy Modeling for Surface Roughness and Hole Size

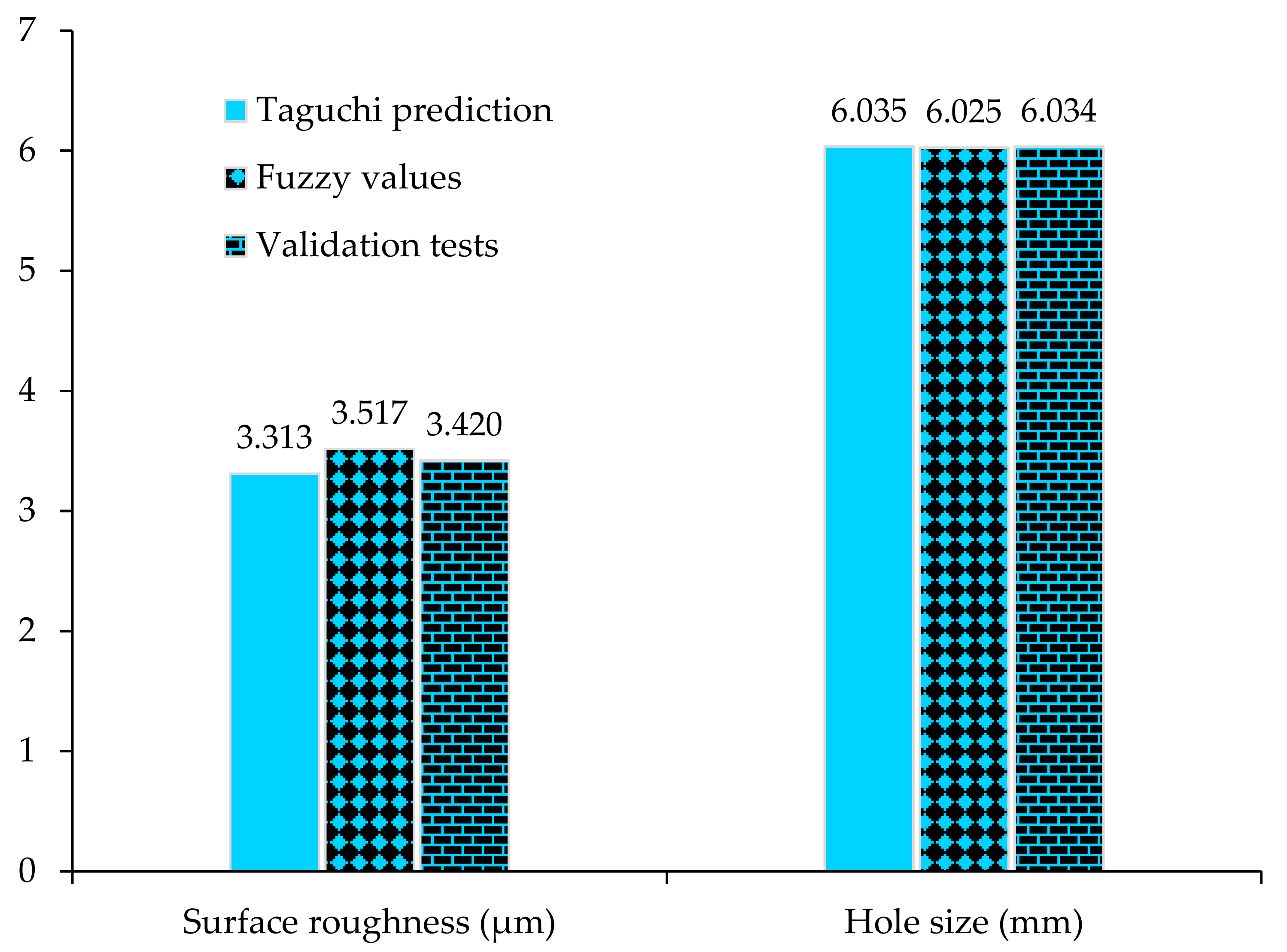

3.6. Validations of Results

4. Conclusions

- Cutting speed and feed rate in the drilling of Al5083 have a significant impact on both types of drilling process i.e., one-shot drilling and multi-hole drilling. A higher cutting speed generates more heat, which increases the temperature at the hole boundaries, where the chips can easily be clogged over the flutes of the drills. Furthermore, it is speculated that more vibration is likely to be present due to the rotary motion of the tool. In addition, the size of the chips increases with an increase in the feed rate. Therefore, a higher cutting speed and feed rate can affect both the surface roughness and hole size.

- The ANOVA results revealed that for both drilling types, the cutting speed and feed rate are influential on the surface roughness and hole size, respectively. The percent influence of cutting speed on the surface roughness is 40.16%, whereas the feed rate has a 25.02% contribution. In the case of hole size, the deviation from the nominal drill size is more affected by the feed rate, which has a 61.31% contribution, and the significance of the cutting speed is 28.72%.

- The Taguchi method was shown to successfully analyze the optimal combination of process parameters for surface roughness and hole size, as achieved in multi-hole drilling with a lower cutting speed and feed rate. Therefore, in comparison to one-shot drilling, a poly-drill head can produce better hole quality and is capable of forming multi-holes simultaneously, which would help in acquiring good productivity even at the lower levels of drilling parameters.

- The fuzzy modeling successfully investigated the surface roughness and hole size in multi-hole drilling. The predicted data is closely correlated to the experimental results with a very small percentage error. Thus, the developed fuzzy model is reliable for the prediction of hole quality at different levels of process parameters, where notable savings in time and cost could be obtained.

- In regression analysis, the values of R2 are more than 80%, which shows that the responses with respect to the machining variables could be easily predicted. The validation experiment reveals that the developed model can be used for predicting better hole quality using a poly-drill head for multi-hole drilling. The average error between each comparison was found to be small and hence, the optimization by the Taguchi method and prediction of values for surface roughness and hole size using fuzzy logic are both acceptable.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Neseli, S. Optimization of process parameters with minimum thrust force and torque in drilling operation using Taguchi method. Adv. Mech. Eng. 2014, 6, 925382. [Google Scholar] [CrossRef]

- Kurt, M.; Bagci, E.; Kaynak, Y. Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int. J. Adv. Manuf. Technol. 2009, 40, 458–469. [Google Scholar] [CrossRef]

- Sun, D.; Lemoine, P.; Keys, D.; Doyle, P.; Malinov, S.; Zhao, Q.; Qin, X.; Jin, Y. Hole-making processes and their impacts on the microstructure and fatigue response of aircraft alloys. Int. J. Adv. Manuf. Technol. 2018, 94, 1719–1726. [Google Scholar] [CrossRef]

- Mohan, N.; Ramachandra, A.; Kulkarni, S. Influence of process parameters on cutting force and torque during drilling of glass–fiber polyester reinforced composites. Compos. Struct. 2005, 71, 407–413. [Google Scholar] [CrossRef]

- Taguchi, G.K.S.; Konishi, S. Taguchi Methods: Orthogonal Arrays and Linear Graphs. Tools Qual. Eng.; American Supplier Institute: Dearborn, MI, USA, 1987. [Google Scholar]

- Hanif, M.I.; Aamir, M.; Ahmed, N.; Maqsood, S.; Muhammad, R.; Akhtar, R.; Hussain, I. Optimization of facing process by indigenously developed force dynamometer. Int. J. Adv. Manuf. Technol. 2019, 100, 1893–1905. [Google Scholar] [CrossRef]

- Yang, W.P.; Tarng, Y. Design optimization of cutting parameters for turning operations based on the Taguchi method. J. Mater. Process. Technol. 1998, 84, 122–129. [Google Scholar] [CrossRef]

- Vankanti, V.K.; Ganta, V. Optimization of process parameters in drilling of GFRP composite using Taguchi method. J. Mater. Res. Technol. 2014, 3, 35–41. [Google Scholar] [CrossRef]

- Ribeiro, J.E.; César, M.B.; Lopes, H. Optimization of machining parameters to improve the surface quality. Proced. Struct. Integr. 2017, 5, 355–362. [Google Scholar] [CrossRef]

- Anand, G.; Alagumurthi, N.; Elansezhian, R.; Palanikumar, K.; Venkateshwaran, N. Investigation of drilling parameters on hybrid polymer composites using grey relational analysis, regression, fuzzy logic, and ANN models. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 214. [Google Scholar] [CrossRef]

- Latha, B.; Senthilkumar, V.S. Modeling and Analysis of Surface Roughness Parameters in Drilling GFRP Composites Using Fuzzy Logic. Mater. Manuf. Process. 2010, 25, 817–827. [Google Scholar] [CrossRef]

- Aamir, M.; Waqas, M.; Iqbal, M.; Hanif, M.I.; Muhammad, R. Fuzzy logic approach for investigation of microstructure and mechanical properties of Sn96.5-Ag3.0-Cu0.5 lead free solder alloy. Solder. Surf. Mt. Technol. 2017, 29, 191–198. [Google Scholar] [CrossRef]

- Tolouei-Rad, M.; Zolfaghari, S. Productivity improvement using special-purpose modular machine tools. Int.J. Manuf. Res. 2009, 4, 219–235. [Google Scholar]

- Vafadar, A.; Tolouei-Rad, M.; Hayward, K.; Abhary, K. Technical feasibility analysis of utilizing special purpose machine tools. J. Manuf. Syst. 2016, 39, 53–62. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Nosrati, A. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: a review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Meral, G.; Sarıkaya, M.; Mia, M.; Dilipak, H.; Şeker, U. Optimization of hole quality produced by novel drill geometries using the Taguchi S/N approach. Int. J. Adv. Manuf. Technol. 2019, 101, 339–355. [Google Scholar] [CrossRef]

- Upputuri, H.B.; Nimmagadda, V.S.; Duraisamy, E. Optimization of drilling parameters on carbon fiber reinforced polymer composites using fuzzy logic. Mater. Today Proc. 2019. [Google Scholar] [CrossRef]

- Saravanakumar, A.; Sasikumar, P.; Nilavusri, N. Optimization of Machining Parameters using Taguchi Method for Surface Roughness. J. Mater. Environ. Sci 2016, 7, 1556–1561. [Google Scholar]

- Abhishek, K.; Datta, S.; Mahapatra, S.S. Optimization of thrust, torque, entry, and exist delamination factor during drilling of CFRP composites. Int. J. Adv. Manuf. Technol. 2015, 76, 401–416. [Google Scholar] [CrossRef]

- Çakıroğlu, R.; Acır, A. Optimization of cutting parameters on drill bit temperature in drilling by Taguchi method. Measurement 2013, 46, 3525–3531. [Google Scholar] [CrossRef]

- Azmi, A.I. Design of Fuzzy Logic Model for the Prediction of Tool Performance During Machining of Composite Materials. Proced. Eng. 2012, 38, 208–217. [Google Scholar] [CrossRef]

- Rajasekaran, T.; Palanikumar, K.; Vinayagam, B.K. Application of fuzzy logic for modeling surface roughness in turning CFRP composites using CBN tool. Product. Eng. 2011, 5, 191–199. [Google Scholar] [CrossRef]

- Kilickap, E. Modeling and optimization of burr height in drilling of Al-7075 using Taguchi method and response surface methodology. Int. J. Adv. Manuf. Technol. 2010, 49, 911–923. [Google Scholar] [CrossRef]

- C. Douglas, M. Design and Analysis of Experiments, 7th ed.; Wiley: New Delhi, India, 2011. [Google Scholar]

- Mudhukrishnan, M.; Hariharan, P.; Palanikumar, K. Measurement and analysis of thrust force and delamination in drilling glass fiber reinforced polypropylene composites using different drills. Measurement 2020, 149, 106973. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K. Optimization of machining parameters for surface roughness and burr height in drilling hybrid composites. Mater. Manuf. Process. 2012, 27, 320–328. [Google Scholar] [CrossRef]

- Davidson, M.J.; Balasubramanian, K.; Tagore, G. Surface roughness prediction of flow-formed AA6061 alloy by design of experiments. J. Mater. Process. Technol. 2008, 202, 41–46. [Google Scholar] [CrossRef]

- Giasin, K.; Hodzic, A.; Phadnis, V.; Ayvar-Soberanis, S. Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: experimental and finite element study. Int. J. Adv. Manuf. Technol. 2016, 87, 2041–2061. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Bagci, E. Evaluation of drilled hole quality in Al 2024 alloy. Int. J Adv. Manuf. Technol. 2008, 37, 1051–1060. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. An experimental study on drilling of unidirectional GLARE fibre metal laminates. Compos. Struct. 2015, 133, 794–808. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; French, T.; Phadnis, V. 3D finite element modelling of cutting forces in drilling fibre metal laminates and experimental hole quality analysis. Appl. Compos. Mater. 2017, 24, 113–137. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, K.; Sun, J.; Li, J.; Liu, Y.; Zheng, Y.; Chen, L. Evaluation of novel tool geometries in dry drilling aluminium 2024-T351/titanium Ti6Al4V stack. J. Mater. Process. Technol. 2018, 259, 270–281. [Google Scholar] [CrossRef]

- Roukema, J.C.; Altintas, Y. Generalized modeling of drilling vibrations. Part II: Chatter stability in frequency domain. Int. J. Mach. Tool. Manuf. 2007, 47, 1474–1485. [Google Scholar] [CrossRef]

- Uddin, M.; Basak, A.; Pramanik, A.; Singh, S.; Krolczyk, G.M.; Prakash, C. Evaluating hole quality in drilling of Al 6061 alloys. Mater. 2018, 11, 2443. [Google Scholar] [CrossRef] [PubMed]

- Zerti, A.; Yallese, M.A.; Zerti, O.; Nouioua, M.; Khettabi, R. Prediction of machining performance using RSM and ANN models in hard turning of martensitic stainless steel AISI 420. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4439–4462. [Google Scholar] [CrossRef]

- Vinayagamoorthy, R.; Manoj, I.; Kumar, G.N.; Chand, I.S.; Kumar, G.S.C.; Kumar, K.S. A central composite design based fuzzy logic for optimization of drilling parameters on natural fiber reinforced composite. J. Mech. Sci. Technol. 2018, 32, 2011–2020. [Google Scholar] [CrossRef]

- Pedrycz, W. Fuzzy equalization in the construction of fuzzy sets. Fuzzy Set. Syst. 2001, 119, 329–335. [Google Scholar] [CrossRef]

- Ross, P.J. Taguchi techniques for quality engineering: loss function, orthogonal experiments, parameter and tolerance design; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

| Process | Material | Considered Process Parameters | Objectives | Optimization/Prediction Technique | Ref |

|---|---|---|---|---|---|

| OSD | AISI 4140 steel | DG, CS, and FR | CYL, PER, CON | Taguchi, ANOVA | [16] |

| OSD | CFRP | SS, FR, and D | TF, T, DL | ANOVA analysis, Fuzzy logic | [17] |

| OSD | Hybrid polymer composites | SS, FR, and D | TF, T, DL | Gray relational analysis, regression, fuzzy logic, and artificial neural network models | [10] |

| Milling | hardened Steel (steel 1.2738) | CS, FR, radial depth, and axial depth | SR | Taguchi optimization technique, ANOVA, | [9] |

| OSD | Al6063/Al2O3/Gr hybrid composite | SS, FR, and wt % of alumina | SR | Taguchi method | [18] |

| OSD | CFRP | SS, FR, and D | TF, T, DL | Taguchi method, Principal component analysis, Fuzzy inference system | [19] |

| OSD | GFRP | SS, FR, point angle, and chisel edge width | TF, T, SR, C | Taguchi, ANOVA | [8] |

| OSD | Al 7075 | Tool, FR, and CS | TEMP | Taguchi method, ANOVA | [20] |

| End milling | GRFP | SS, FR, and d | TL | Fuzzy logic | [21] |

| Turning | CFRP | CS, feed, and d | SR | Fuzzy rule-based modeling | [22] |

| OSD | Al-7075 | CS, FR, and point angle, | H, SR | Taguchi method and response surface methodology | [23] |

| OSD | GFRP | SS, FR, and D | SR | Fuzzy logic and ANOVA | [11] |

| OSD | Al 2024 | Drilling depth, FR, CS, and drilling tool | Diametral error, SR | Regression model, Taguchi optimization method, ANOVA | [2] |

| Levels | Process Parameters | ||

|---|---|---|---|

| Drilling Type | Cutting Speed | Feed Rate | |

| 1 | One-shot drilling | 19 | 0.04 |

| 2 | Multi-spindle drilling | 38 | 0.08 |

| 3 | – | 57 | 0.14 |

| Experiment No. | Control Factors | ||

|---|---|---|---|

| Drilling Type | Cutting Speed | Feed Rate | |

| 1 | One-shot drilling | 19 | 0.04 |

| 2 | 19 | 0.08 | |

| 3 | 19 | 0.14 | |

| 4 | 38 | 0.04 | |

| 5 | 38 | 0.08 | |

| 6 | 38 | 0.14 | |

| 7 | 57 | 0.04 | |

| 8 | 57 | 0.08 | |

| 9 | 57 | 0.14 | |

| 10 | Multi-spindle drilling | 19 | 0.04 |

| 11 | 19 | 0.08 | |

| 12 | 19 | 0.14 | |

| 13 | 38 | 0.04 | |

| 14 | 38 | 0.08 | |

| 15 | 38 | 0.14 | |

| 16 | 57 | 0.04 | |

| 17 | 57 | 0.08 | |

| 18 | 57 | 0.14 | |

| Trial No. | Orthogonal Array with Control Factors | Experimental Results | S/N Ratio | ||||

|---|---|---|---|---|---|---|---|

| Drilling Type | Cutting Speed | Feed Rate | Surface Roughness | Hole Size | Surface Roughness | Hole Size | |

| 1 | 1 | 1 | 1 | 3.561 | 6.040 | −11.030 | −15.620 |

| 2 | 1 | 1 | 2 | 4.209 | 6.048 | −12.483 | −15.632 |

| 3 | 1 | 1 | 3 | 4.657 | 6.056 | −13.362 | −15.644 |

| 4 | 1 | 2 | 1 | 4.422 | 6.043 | −12.912 | −15.625 |

| 5 | 1 | 2 | 2 | 4.522 | 6.052 | −13.107 | −15.638 |

| 6 | 1 | 2 | 3 | 4.699 | 6.062 | −13.441 | −15.652 |

| 7 | 1 | 3 | 1 | 4.808 | 6.047 | −13.639 | −15.631 |

| 8 | 1 | 3 | 2 | 5.022 | 6.059 | −14.017 | −15.648 |

| 9 | 1 | 3 | 3 | 6.933 | 6.073 | −16.818 | −15.669 |

| 10 | 2 | 1 | 1 | 3.457 | 6.036 | −10.775 | −15.615 |

| 11 | 2 | 1 | 2 | 3.718 | 6.044 | −11.405 | −15.627 |

| 12 | 2 | 1 | 3 | 4.344 | 6.054 | −12.757 | −15.641 |

| 13 | 2 | 2 | 1 | 3.676 | 6.039 | −11.307 | −15.620 |

| 14 | 2 | 2 | 2 | 4.126 | 6.049 | −12.311 | −15.633 |

| 15 | 2 | 2 | 3 | 4.626 | 6.059 | −13.304 | −15.648 |

| 16 | 2 | 3 | 1 | 4.566 | 6.048 | −13.191 | −15.632 |

| 17 | 2 | 3 | 2 | 4.990 | 6.061 | −13.961 | −15.651 |

| 18 | 2 | 3 | 3 | 5.724 | 6.075 | −15.154 | −15.671 |

| Level | Surface Roughness | |||||

|---|---|---|---|---|---|---|

| Average Response Values | S/N Ratio Response Values | |||||

| Drilling Type | Cutting Speed | Feed Rate | Drilling Type | Cutting Speed | Feed Rate | |

| 1 | 4.759 | 3.991 a | 4.082 a | −13.423 | −11.969 a | −12.142 a |

| 2 | 4.358 a | 4.345 | 4.431 | −12.685 a | −12.730 | −12.881 |

| 3 | – | 5.340 | 5.164 | – | −14.463 | −14.139 |

| Level | Hole size | |||||

|---|---|---|---|---|---|---|

| Average Response Values | S/N Ratio Response Values | |||||

| Drilling Type | Cutting Speed | Feed Rate | Drilling Type | Cutting Speed | Feed Rate | |

| 1 | 6.053 | 6.046 a | 6.042 a | −15.640 | −15.630 a | −15.624 a |

| 2 | 6.052 a | 6.051 | 6.052 | −15.637 a | −15.636 | −15.638 |

| 3 | – | 6.060 | 6.063 | – | −15.650 | −15.654 |

| Source | Degrees of Freedom | Sequential Sum of Squares | Contribution | Adjusted Sum of Squares | Adjusted Mean Square | F-Value | P-Value |

|---|---|---|---|---|---|---|---|

| Model | 19 | 36.0261 | 82.08% | 36.0261 | 1.89611 | 8.2 | 0 |

| CS | 2 | 17.6251 | 40.16% | 17.6251 | 8.81254 | 38.09 | 0 |

| FR | 2 | 10.9826 | 25.02% | 10.9826 | 5.49129 | 23.74 | 0 |

| DT | 1 | 2.1673 | 4.94% | 2.1673 | 2.16731 | 9.37 | 0.004 |

| 2-Way Interactions | 8 | 2.4065 | 5.48% | 2.4065 | 0.30081 | 1.3 | 0.276 |

| CS x FR | 4 | 2.2008 | 5.01% | 2.2008 | 0.55019 | 2.38 | 0.071 |

| CS x DT | 2 | 0.0825 | 0.19% | 0.0825 | 0.04126 | 0.18 | 0.837 |

| FR x DT | 2 | 0.1232 | 0.28% | 0.1232 | 0.06159 | 0.27 | 0.768 |

| 3-Way Interactions | 4 | 1.5096 | 3.44% | 1.5096 | 0.3774 | 1.63 | 0.189 |

| CS x FR x DT | 4 | 1.5096 | 3.44% | 1.5096 | 0.3774 | 1.63 | 0.189 |

| Error | 34 | 7.8658 | 17.92% | 7.8658 | 0.23135 | – | – |

| Total | 53 | 43.8919 | 100.00% | – | – | – | – |

| Source | Degrees of Freedom | Sequential Sum of Squares | Contribution | Adjusted Sum of Squares | Adjusted Mean Square | F-Value | P-Value |

|---|---|---|---|---|---|---|---|

| Model | 19 | 0.00622 | 94.34% | 0.00622 | 0.000327 | 29.84 | 0 |

| CS | 2 | 0.001893 | 28.72% | 0.001893 | 0.000947 | 86.31 | 0 |

| FR | 2 | 0.004042 | 61.31% | 0.004042 | 0.002021 | 184.24 | 0 |

| DT | 1 | 0.000037 | 0.57% | 0.000037 | 0.000037 | 3.42 | 0.073 |

| 2-Way Interactions | 8 | 0.000211 | 3.21% | 0.000211 | 0.000026 | 2.41 | 0.035 |

| CS × FR | 4 | 0.000148 | 2.24% | 0.000148 | 0.000037 | 3.37 | 0.02 |

| CS × DT | 2 | 0.000061 | 0.93% | 0.000061 | 0.00003 | 2.78 | 0.076 |

| FR × DT | 2 | 0.000002 | 0.04% | 0.000002 | 0.000001 | 0.11 | 0.896 |

| 3-Way Interactions | 4 | 0.000003 | 0.04% | 0.000003 | 0.000001 | 0.06 | 0.992 |

| CS × FR × DT | 4 | 0.000003 | 0.04% | 0.000003 | 0.000001 | 0.06 | 0.992 |

| Error | 34 | 0.000373 | 5.66% | 0.000373 | 0.000011 | – | – |

| Total | 53 | 0.006593 | 100% | – | - | – | – |

| Membership Function Type | Variable | Fuzzy Input | Fuzzy Output | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cutting Speed | Feed Rate | Surface Roughness | Hole Size | ||||||

| Parameter | Range | Parameter | Range | Parameter | Range | Parameter | Range | ||

| Triangular | VVL | (12 15 18) | (12 66) | (0.01 0.02 0.03) | (0.01 0.19) | (3 3.15 3.3) | (3 6.8) | (6.01 6.015 6.02) | (6.01 6.1) |

| VL | (18 21 24) | (12 66) | (0.03 0.04 0.05) | (0.01 0.19) | (3.3 3.55 3.7) | (3 6.8) | (6.02 6.025 6.03) | (6.01 6.1) | |

| L | (24 27 30) | (12 66) | (0.05 0.06 0.07) | (0.01 0.19) | (3.559 3.783 4.005) | (3 6.8) | (6.03 6.035 6.04) | (6.01 6.1) | |

| ML | (30 33 36] | (12 66) | (0.07 0.08 0.09) | (0.01 0.19) | (3.783 3.95 4.117) | (3 6.8) | (6.04 6.045 6.05) | (6.01 6.1) | |

| M | (36 39 42) | (12 66) | (0.09 0.1 0.11) | (0.01 0.19] | (4.117 4.35 4.5) | (3 6.8] | (6.05 6.055 6.06) | (6.01 6.1) | |

| MH | (42 45 48) | (12 66) | (0.11 0.12 0.13) | (0.01 0.19) | (4.2 4.5 4.6) | (3 6.8) | (6.06 6.065 6.07) | (6.01 6.1) | |

| H | (48 51 54) | (12 66) | (0.13 0.14 0.15) | (0.01 0.19) | (4.5 4.9 5.347) | (3 6.8) | (6.07 6.075 6.08) | (6.01 6.1) | |

| VH | (54 57 60) | (12 66) | (0.15 0.16 0.17) | (0.01 0.19) | (5.2 5.6 5.8) | (3 6.8) | (6.08 6.085 6.09) | (6.01 6.1) | |

| VVH | (60 63 66) | (12 66) | (0.17 0.18 0.19) | (0.01 0.19) | (5.8 6.4 6.8) | (3 6.8) | (6.09 6.095 6.1) | (6.01 6.1) | |

| Hole Number | Cutting Speed | Feed Rate | Surface Roughness | Hole Size | ||||

|---|---|---|---|---|---|---|---|---|

| Experimental Values | Fuzzy Results | % Error | Experimental Values | Fuzzy Results | % Error | |||

| 1 | 19 | 0.04 | 3.457 | 3.517 | −1.736 | 6.036 | 6.025 | 0.182 |

| 2 | 19 | 0.08 | 3.718 | 3.774 | −1.506 | 6.044 | 6.038 | 0.101 |

| 3 | 19 | 0.14 | 4.344 | 4.622 | −6.400 | 6.055 | 6.057 | −0.035 |

| 4 | 38 | 0.04 | 3.676 | 3.888 | −5.767 | 6.039 | 6.039 | −0.003 |

| 5 | 38 | 0.08 | 4.126 | 4.136 | −0.242 | 6.048 | 6.050 | −0.028 |

| 6 | 38 | 0.14 | 4.626 | 4.745 | −2.572 | 6.060 | 6.066 | −0.092 |

| 7 | 57 | 0.04 | 4.566 | 4.728 | −3.548 | 6.048 | 6.055 | −0.116 |

| 8 | 57 | 0.08 | 4.990 | 4.962 | 0.561 | 6.061 | 6.065 | −0.064 |

| 9 | 57 | 0.14 | 5.724 | 5.170 | 9.679 | 6.075 | 6.080 | −0.082 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aamir, M.; Tu, S.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach. Materials 2020, 13, 680. https://doi.org/10.3390/ma13030680

Aamir M, Tu S, Tolouei-Rad M, Giasin K, Vafadar A. Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach. Materials. 2020; 13(3):680. https://doi.org/10.3390/ma13030680

Chicago/Turabian StyleAamir, Muhammad, Shanshan Tu, Majid Tolouei-Rad, Khaled Giasin, and Ana Vafadar. 2020. "Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach" Materials 13, no. 3: 680. https://doi.org/10.3390/ma13030680

APA StyleAamir, M., Tu, S., Tolouei-Rad, M., Giasin, K., & Vafadar, A. (2020). Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach. Materials, 13(3), 680. https://doi.org/10.3390/ma13030680