Experimental Analysis of Tribological Processes in Friction Pairs with Laser Borided Elements Lubricated with Engine Oils

Abstract

1. Introduction

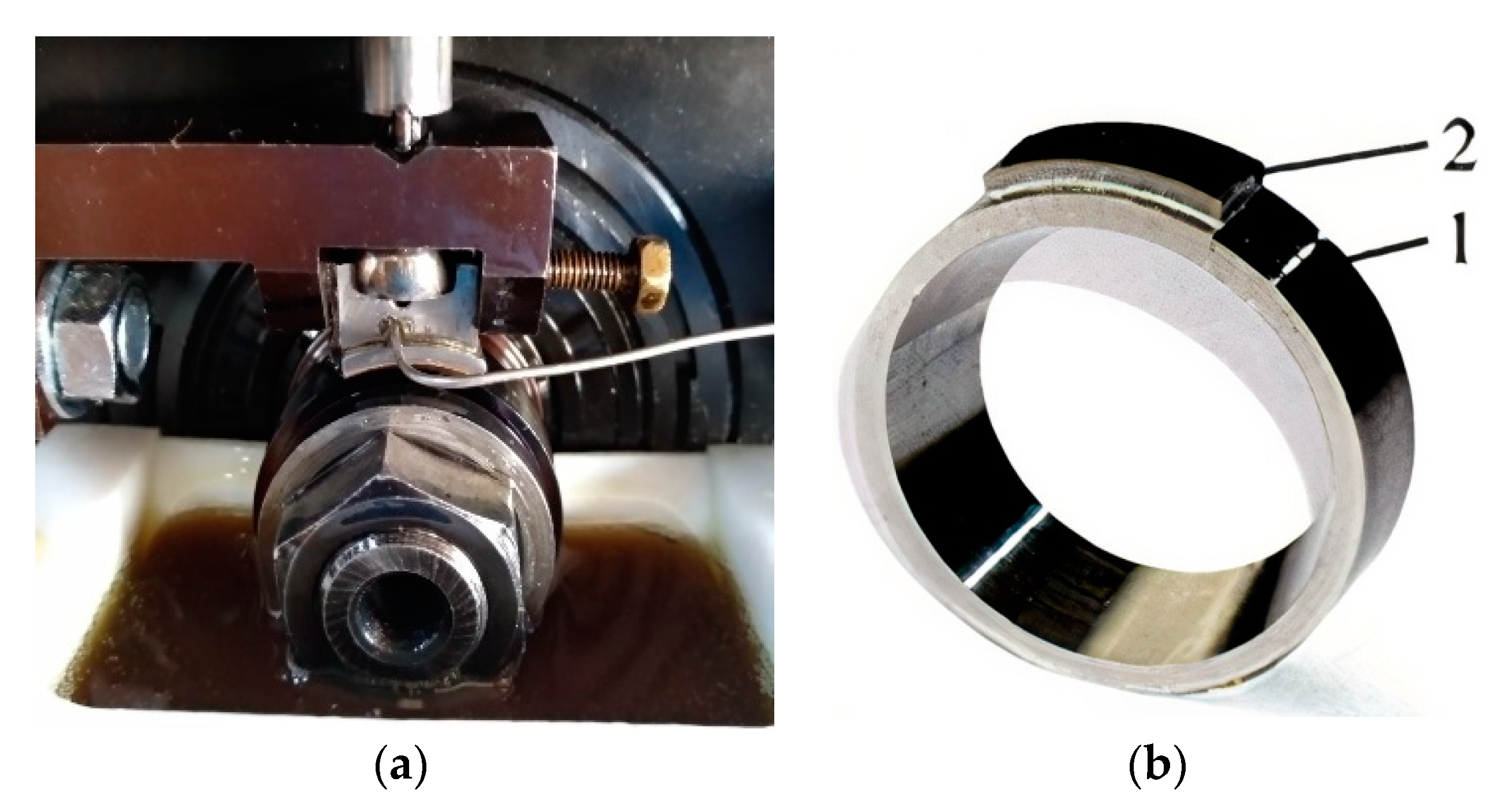

2. Materials and Methods

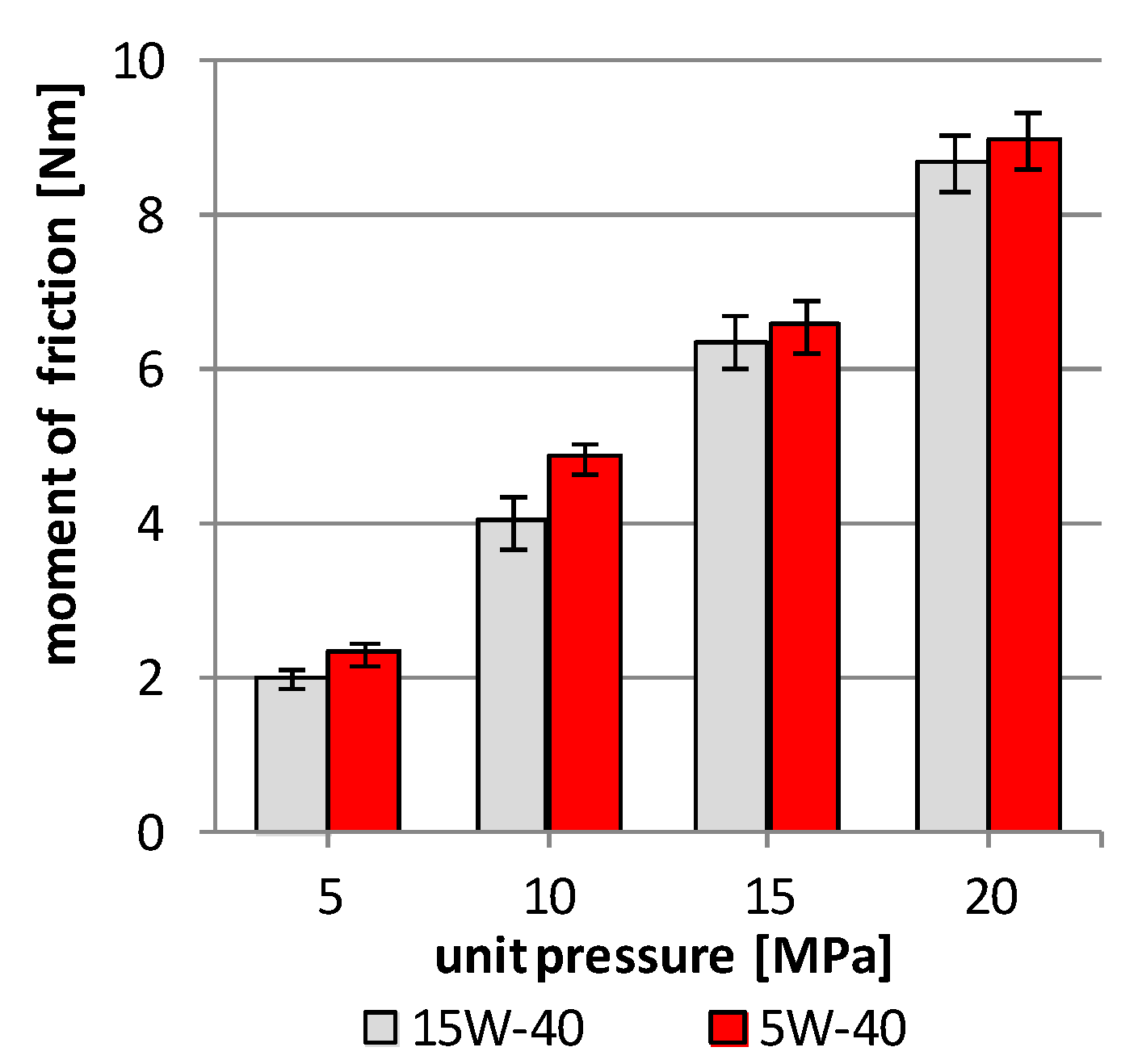

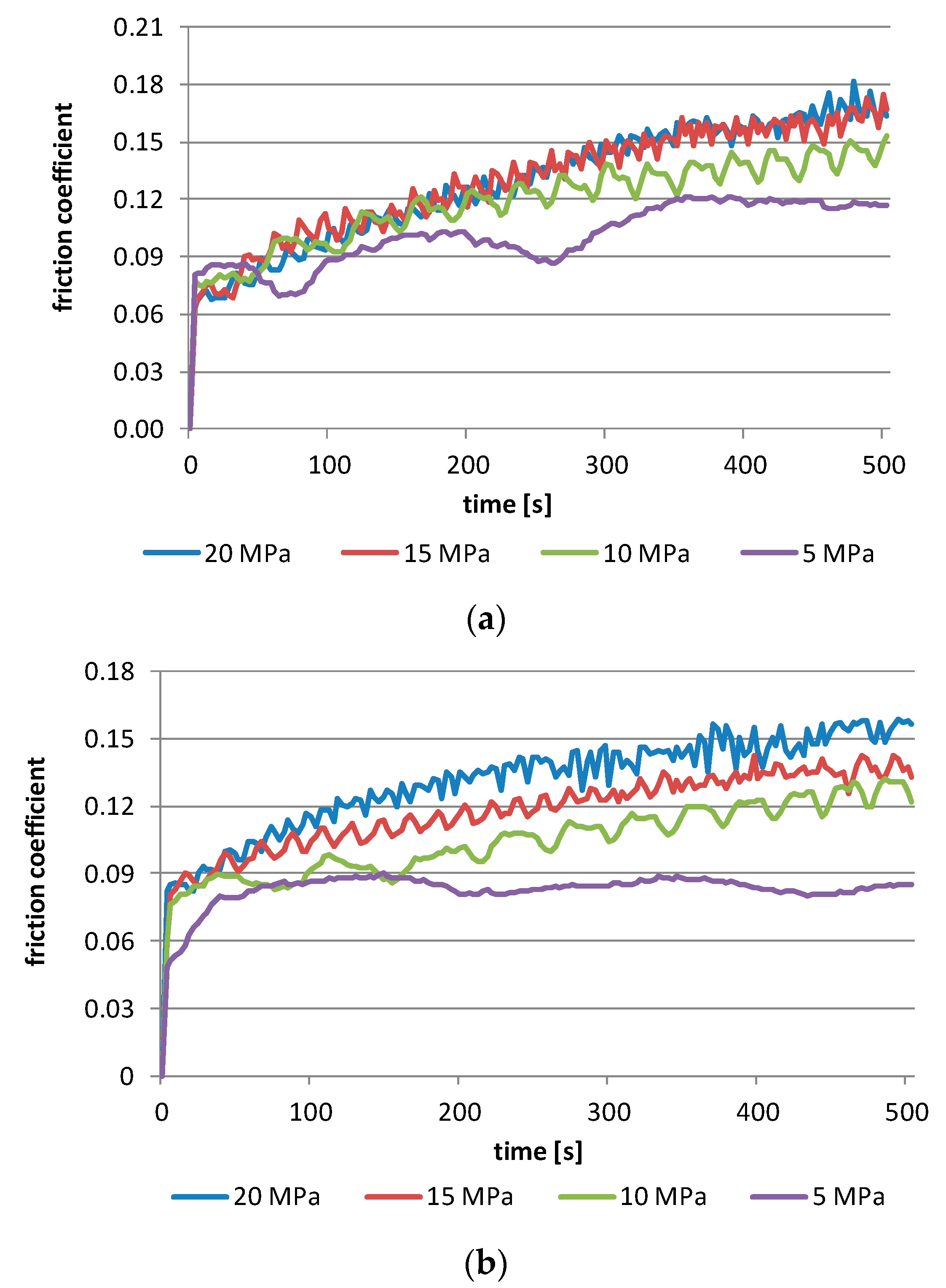

3. Results

4. Discussion

5. Conclusions

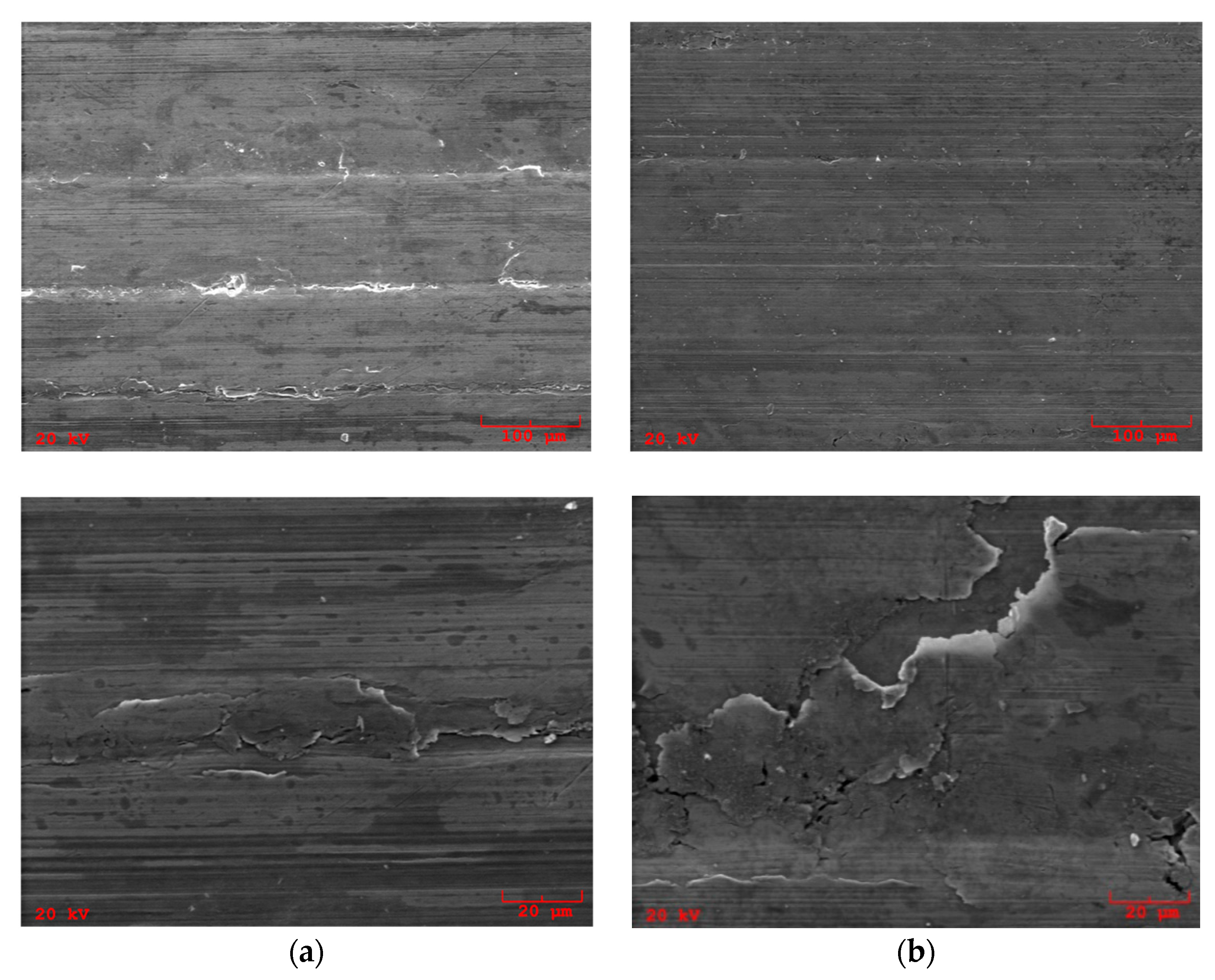

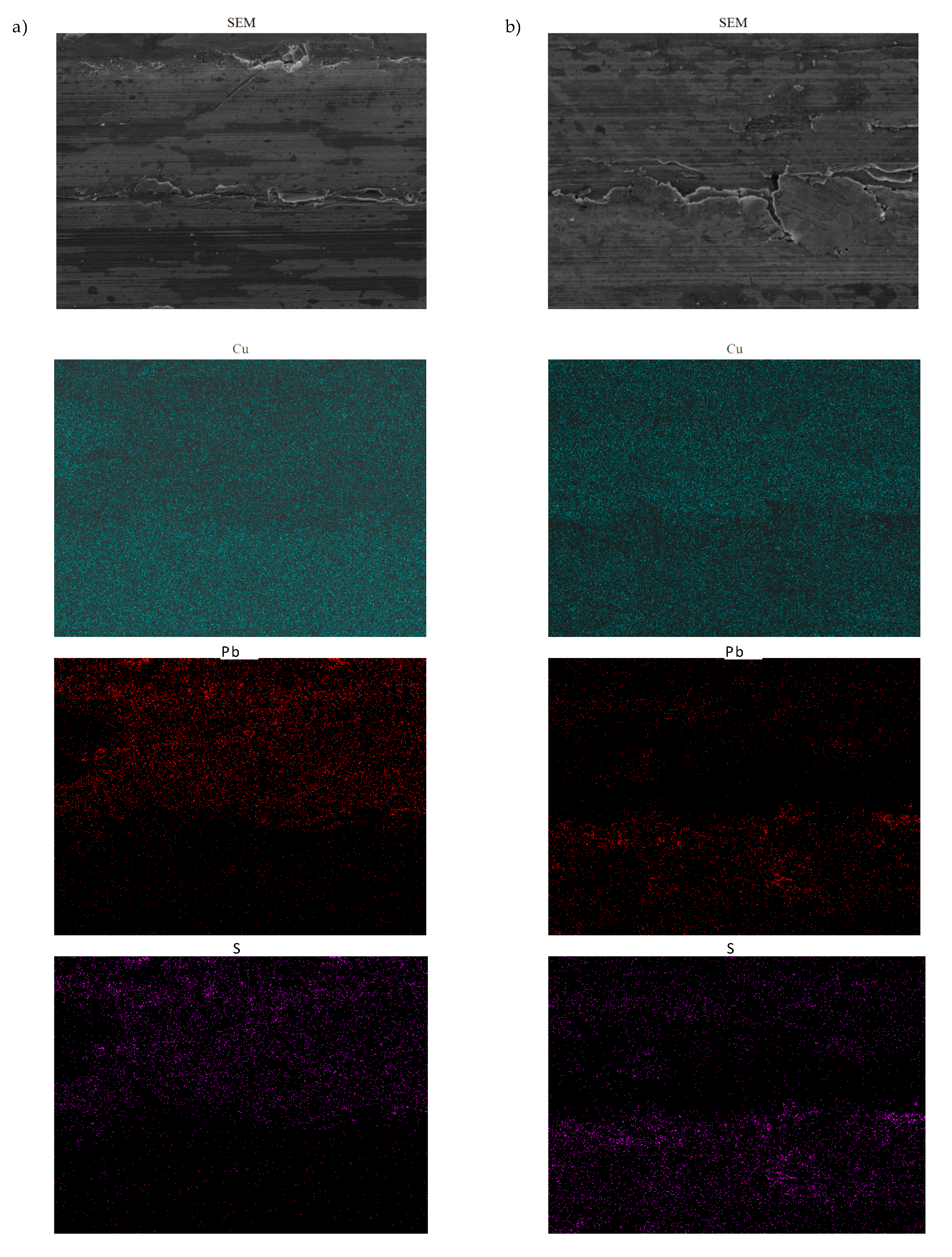

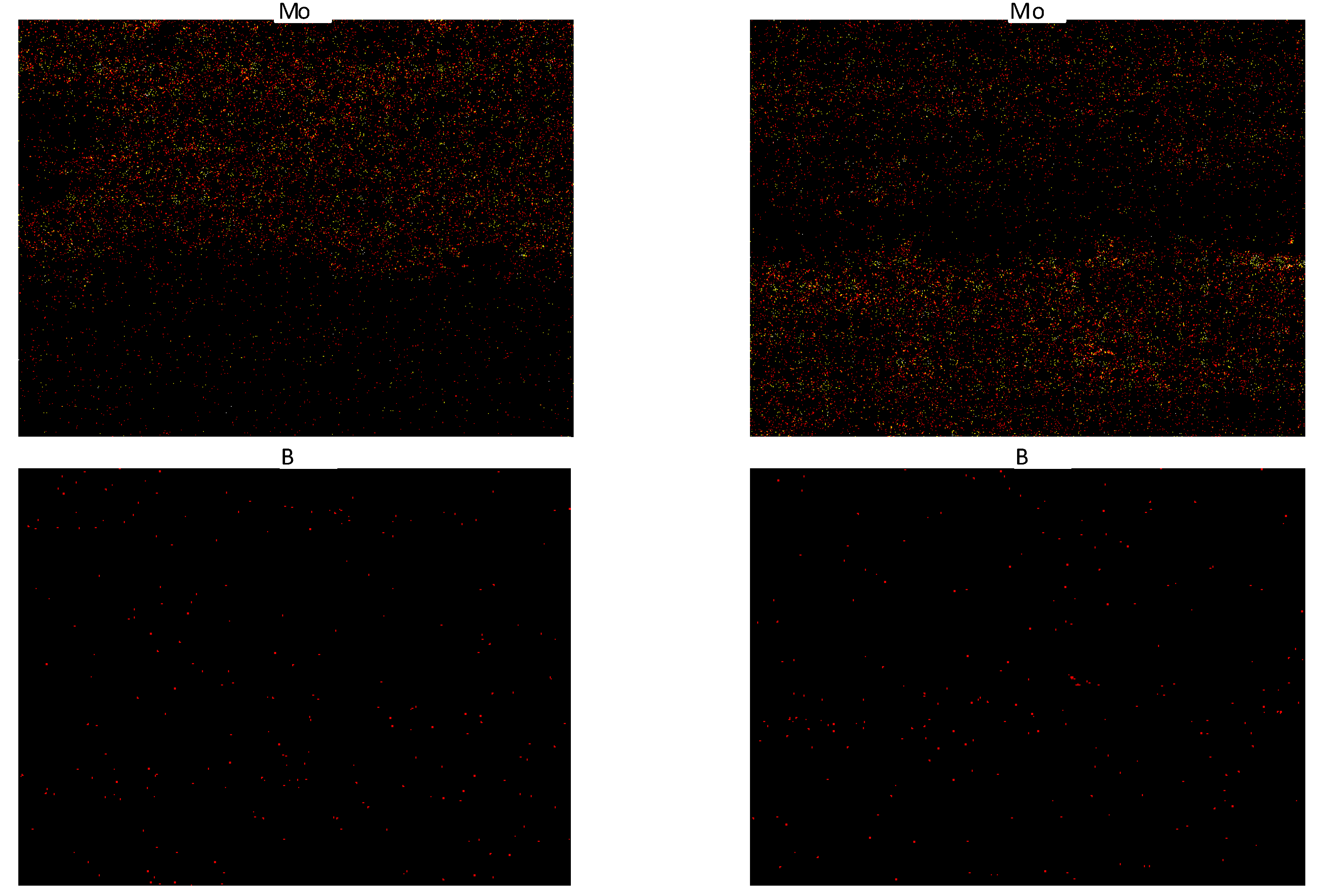

- The surface roughness of the SAE-48 bearing alloy and laser borided ring specimen shows tendencies to increase and a greater change was observed in the pairs lubricated with 5W-40 engine oil.

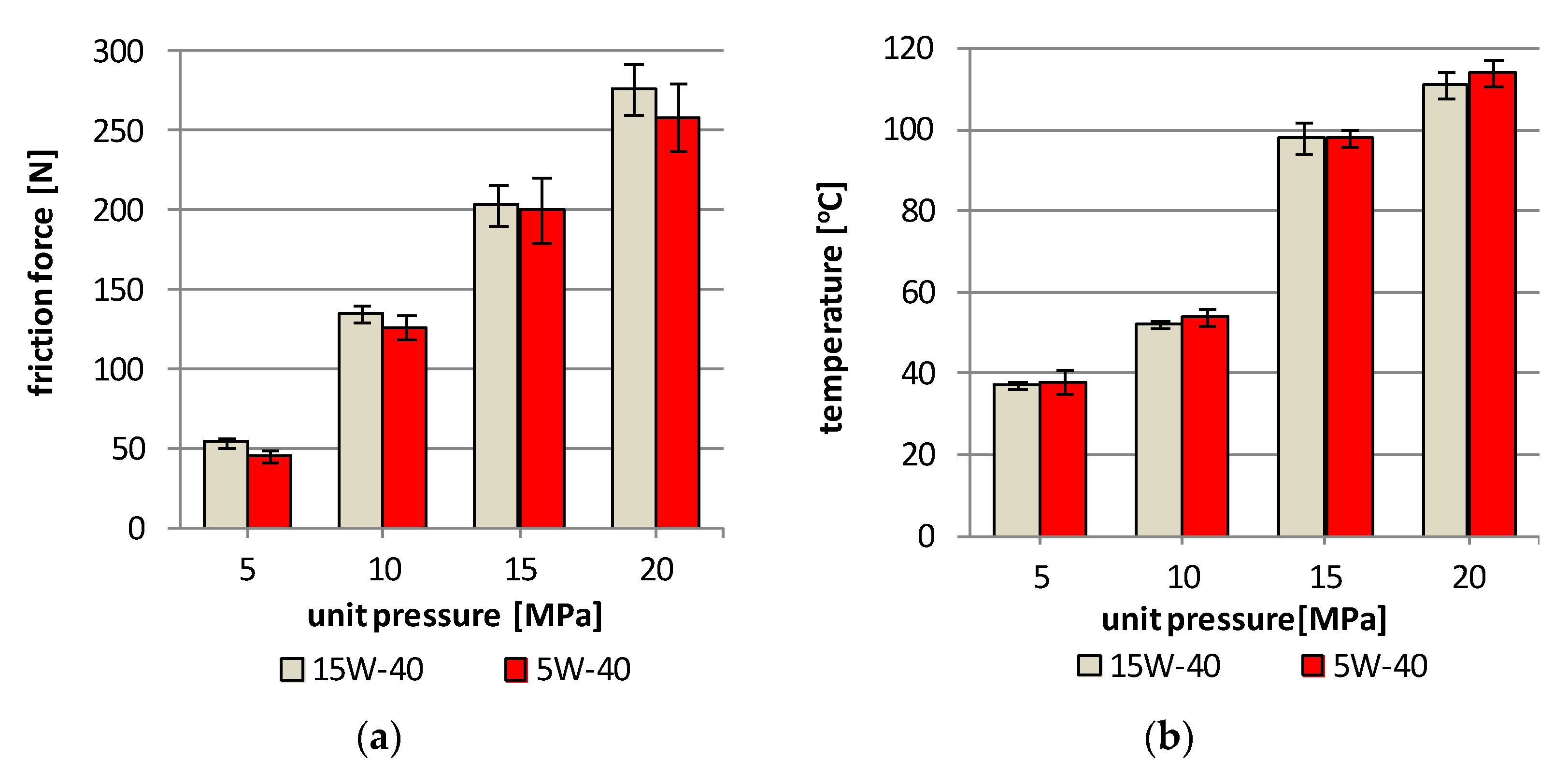

- Friction force in the pair lubricated with the 15W-40 engine oil is considerably higher than in the pair lubricated with the 5W-40 oil, and temperature in the friction area for both tested oils is of a comparable value level.

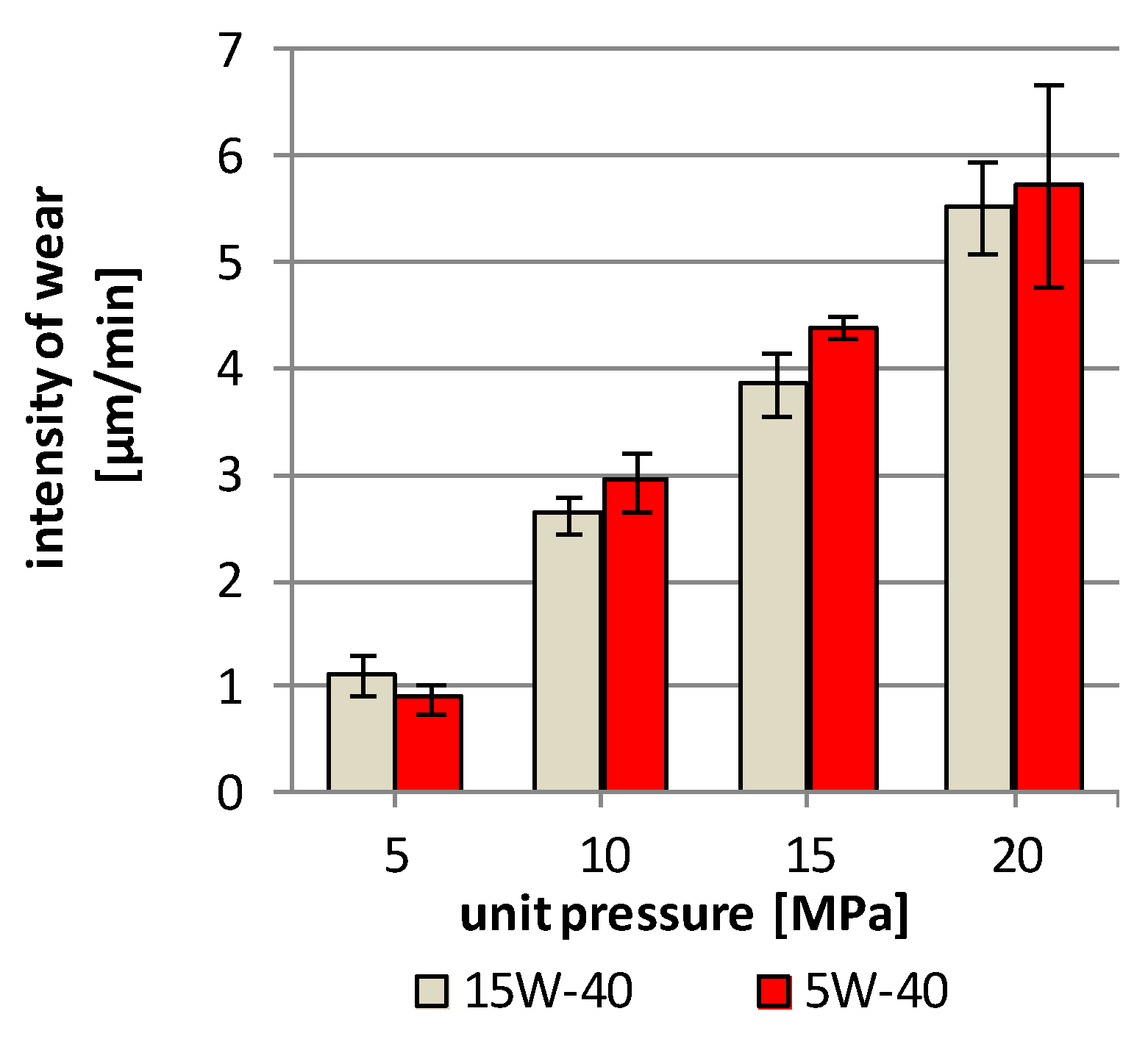

- The application of the 5W-40 oil in the sliding pair with the laser borided surface layer causes a significant increase of wear of the SAE-48 bearing alloy, together with the increase of unit load in the friction area.

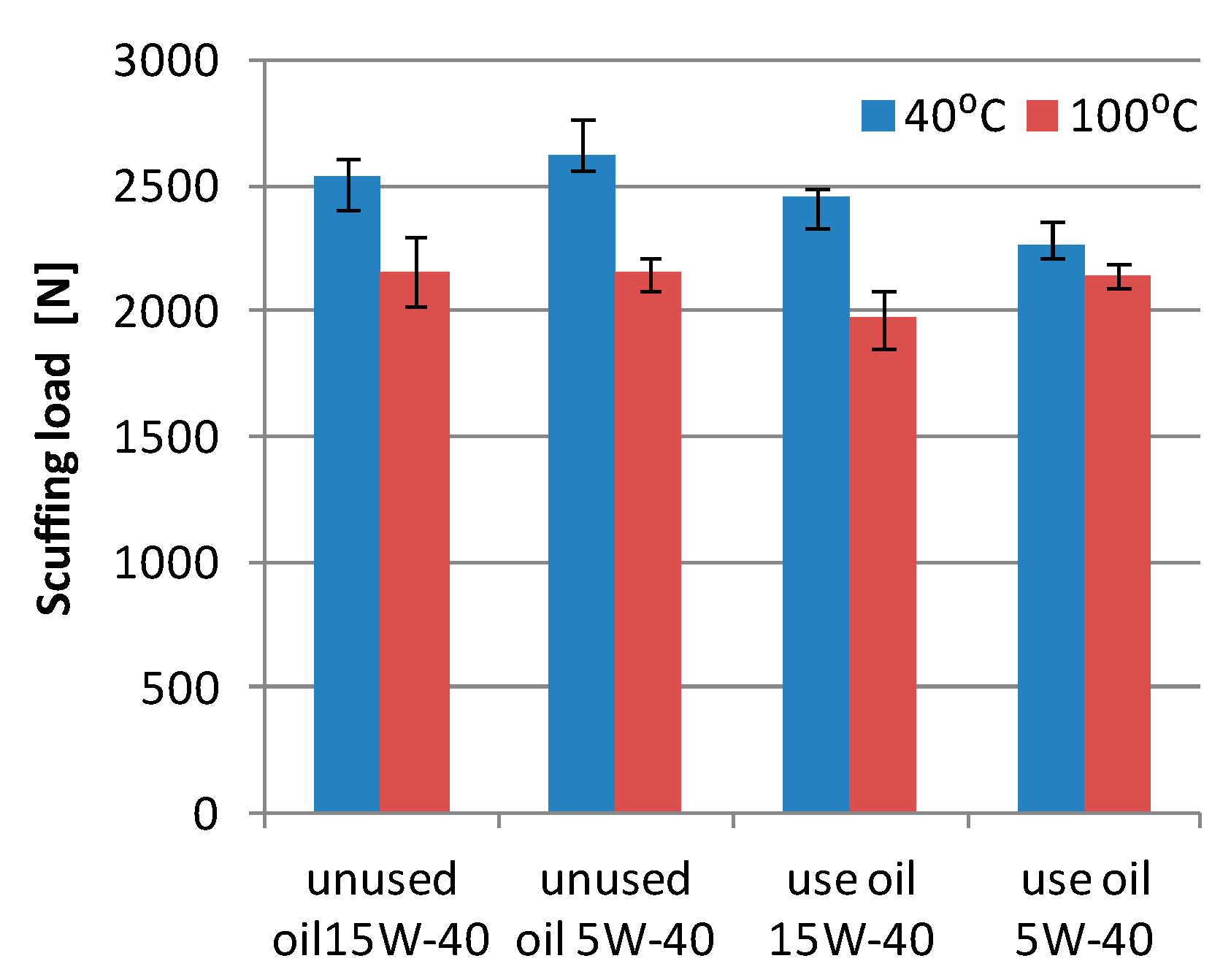

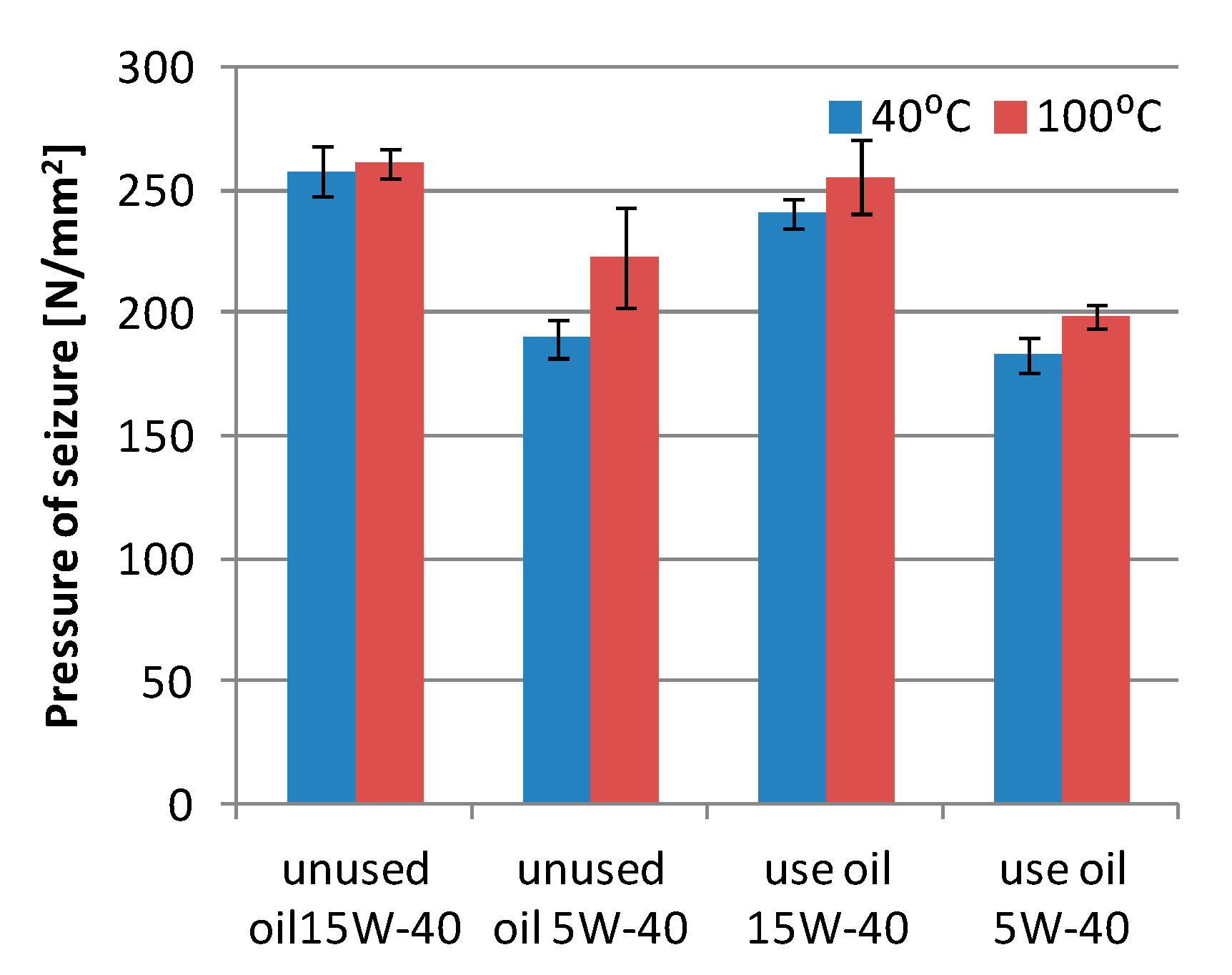

- The processes of wear lead to the destruction of engine oil and the deterioration of their resistance to scuffing, especially during the operation under low temperature.

- Lubrication of the friction pair with laser borided surface layer with the 15W-40 oil is more advantageous because it causes smaller changes in the geometrical structure of the cooperating surface layers, lower friction pair starting resistance and lower wear at a comparable temperature in the friction area.

Author Contributions

Funding

Conflicts of Interest

References

- Yu, J.; Song, B. Effects of heating time on the microstructure and properties of an induction cladding coating. Results Phys. 2018, 11, 212–218. [Google Scholar] [CrossRef]

- Makuch, N.; Dziarski, P.; Kulka, M.; Piasecki, A.; Tuliński, M.; Majchrowski, R. Influence of niobium and molybdenum addition on microstructure and wear behavior of laser borided layers produced on Nimonic 80A alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 322–337. [Google Scholar] [CrossRef]

- Sui, Q.; Zhou, H.; Bao, H.; Zhang, P.; Yuan, Y.; Meng, C. Wear behavior of quenched iron with various shapes and unit processed through two step laser alloying of C powder. Opt. Laser Technol. 2018, 104, 103–111. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, C.; Zhang, M. Effect of heat treatments on the microstructural evolution and tribological behaviors of a NiCrSiB/Y2O3 alloy fabricated by laser additive manufacturing. Mater. Character. 2020, 165, 110401. [Google Scholar] [CrossRef]

- Zhang, D.; Cui, X.; Jin, G.; Feng, X.; Lu, B.; Song, Q.; Yuan, C. Effect of in-situ synthesis of multilayer graphene on the microstructure and tribological performance of laser cladded Ni-based coatings. Appl. Surf. Sci. 2019, 495, 143581. [Google Scholar] [CrossRef]

- Xu, X.; Lu, H.F.; Luo, K.Y.; Yao, J.H.; Xu, L.Z.; Lu, J.Z.; Lu, Y.F. Mechanical properties and electrochemical corrosion resistance of multilayer laser cladded Fe-based composite coatings on 4Cr5MoSiV1 steel. J. Mater. Proc. Tech. 2020, 284, 116736. [Google Scholar] [CrossRef]

- Yan, S.X.; Dong, S.Y.; Xu, B.S.; Wang, Y.J.; Ren, W.B.; Fang, J.X. Effect of preheating temperature on microstructure and property of laser clad ni-based alloy coating on gray cast iron substrate. J. Mater. Eng. 2015, 43, 30–36. [Google Scholar]

- Zhou, S.F.; Dai, X.Q.; Zheng, H.Z. Microstructure and wear resistance of Fe-based WC coating by multi-track overlapping laser induction hybrid rapid cladding. Opt. Laser. Technol. 2012, 44, 190–197. [Google Scholar] [CrossRef]

- Mohan, D.G.; Gopi, S. Induction assisted friction stir welding: A review. Aust. J. Mech. Eng. 2020, 1, 119–123. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C.L.; Zhang, C.H.; Guan, M.; Tan, J.Z. Laser surface alloying of FeCoCrAlNi high entropy alloy on 304 stainless steel to enhance corrosion and cavitation erosion resistance. Opt. Laser Technol. 2016, 84, 23–31. [Google Scholar]

- Adebiyi, D.I.; Popoola, A.P.I. Mitigation of abrasive wear damage of Ti–6Al–4V by laser surface alloying. Mater. Des. 2015, 74, 67–75. [Google Scholar] [CrossRef]

- Yan, H.; Wang, A.; Xiong, Z.; Xu, K.; Huang, Z. Microstructure and wear resistance of composite layers on a ductile iron with multicarbide by laser surface alloying. Appl. Surf. Sci. 2010, 256, 7001–7009. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Li, G. Surface performance and physical properties of nanoscale ceramics reinforced laser alloying composite coatings. Compos. Part B 2014, 57, 86–90. [Google Scholar] [CrossRef]

- Prince, M.; Arjun, S.L.; Surya, R.; Gopalakrishnan, P. Experimental Investigations on the Effects of Multicomponent Laser Boriding on steels. Mater. Today Proc. 2018, 5, 25276–25284. [Google Scholar] [CrossRef]

- Klopotov, A.A.; Ivanov, Y.F.; Potekaev, A.I.; Abzaev, Y.A.; Kalashnikov, M.P.; Chumaevskii, A.V.; Volokitin, O.G.; Teresov, A.D.; Vlasov, V.A.; Klopotov, V.D. The use of low-temperature plasma in a combined technology for the formation of wear-resistant boron-containing coatings. Surf. Coat. Technol. 2020, 389, 125576. [Google Scholar]

- Misra, D.; Dhakar, B.; Anusha, E.; Shariff, S.M.; Mukhopadhyay, S.; Chatterje, S. Evaluation of nanomechanical and tribological properties of laser surface alloyed boride-nitride-carbide ceramic matrix composite coatings. Cer. Int. 2018, 44, 17050–17061. [Google Scholar] [CrossRef]

- Hu, G.; Meng, H.M.; Liu, J.Y. Microstructure and corrosion resistance of induction melted Fe-based alloy coating. Surf. Coat. Technol. 2014, 251, 300–306. [Google Scholar] [CrossRef]

- Gök, M.S.; Küçük, Y.; Erdoğan, A.; Öge, M.; Kanca, E.; Günen, A. Dry sliding wear behavior of borided hot work tool steel at elevated temperatures. Surf. Coat. Technol. 2017, 328, 54–62. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, I. Wear and corrosion behaviour of laser surface engineered AISI H13 hot working tool steel. Surf. Coat. Technol. 2015, 261, 69–78. [Google Scholar] [CrossRef]

- Sashank, S.; Dinesh Babu, P.; Marimuthu, P. Experimental studies of laser borided low alloy steel and optimization of parameters using response surface methodology. Surf. Coat. Technol. 2019, 363, 255–264. [Google Scholar]

- Wei, X.; Chen, Z.; Zhong, J.; Wang, L.; Hou, Z.; Zhang, Y.; Tan, F. Facile preparation of nanocrystalline Fe2B coating by direct electrospark deposition of coarse-grained Fe2B electrode material. J Alloys Comp. 2017, 717, 31–40. [Google Scholar] [CrossRef]

- Aguilar-Hurtado, J.Y.; Vargas-Uscategui, A.; Paredes-Gil, K.; Palma-Hillerns, R.; Tobar, M.J.; Amado, J.M. Boron addition in a non-equiatomic Fe50Mn30Co10Cr10 alloy manufactured by laser cladding: Microstructure and wear abrasive resistance. Appl. Surf. Sci. 2020, 515, 146084. [Google Scholar] [CrossRef]

- Kulka, M.; Mikołajczak, D.; Makuch, N.; Dziarski, P.; Miklaszewski, A. Wear resistance improvement of austenitic 316L steel by laser alloying with boron. Surf. Coat. Technol. 2016, 291, 292–313. [Google Scholar] [CrossRef]

- Kulka, M.; Makuch, N.; Dziarski, P.; Mikołajczak, D.; Przestacki, D. Gradient boride layers formed by diffusion carburizing and laser boriding. Opt. Lasers Eng. 2015, 67, 163–175. [Google Scholar]

- Bendoumi, A.; Makuch, N.; Chegroune, R.; Kulka, M.; Keddam, M.; Dziarski, P.; Przestacki, D. The effect of temperature distribution and cooling rate on microstructure and microhardness of laser re-melted and laser-borided carbon steels with various carbon concentrations. Surf. Coat. Technol. 2020, 387, 125541. [Google Scholar] [CrossRef]

- Günen, A.; Kanca, E.; Çakir, H.; Karakaş, M.S.; Göke, M.S.; Küçük, Y.; Demir, M. Effect of borotitanizing on microstructure and wear behavior of Inconel 625. Surf. Coat. Technol. 2017, 311, 374–382. [Google Scholar] [CrossRef]

- Kulka, M.; Dziarski, P.; Makuch, N.; Piasecki, A.; Miklaszewski, A. Microstructure and properties of laser-borided Inconel 600-alloy. Appl. Surf. Sci. 2013, 284, 757–771. [Google Scholar] [CrossRef]

- Dziarski, P.; Kulka, M.; Mikołajczak, D.; Makuch, N. Corrosion resistance of laser-borided Inconel 600 alloy. Inżyn. Mater. 2017, 3, 149–156. [Google Scholar]

- Makuch, N.; Piasecki, A.; Dziarski, P.; Kulka, M. Influence of laser alloying with boron and niobium on microstructure and propertiesof Nimonic 80A-alloy. Opt. Laser. Technol. 2015, 75, 229–239. [Google Scholar] [CrossRef]

- Eder, S.J.; Ielchici, C.; Krenn, S.; Brandtner, D. An experimental framework for determining wear in porous journal bearings operated in the mixed lubrication regime. Tribol. Intern. 2018, 123, 1–9. [Google Scholar]

- García, A.; Cadenas, M.; Fernandez, M.R.; Noriega, A. Tribological effects of the geometrical properties of plasma spray coatings partially melted by laser. Wear 2013, 305, 1–7. [Google Scholar] [CrossRef]

- Habib, K.A.; Cano, D.L.; Heredia, J.A.; Mira, J.S. Effect of post coating technique on microstructure; microhardness and the mixed lubrication regime parameters of thermally sprayed NiCrBSi coatings. Surf. Coat. Technol. 2019, 358, 824–832. [Google Scholar] [CrossRef]

- Akchurin, A.; Bosman, R.; Lugt, P.M.; Drogen, M. Analysis of wear particles formed in boundary-lubricated sliding contacts. Tribol. Lett. 2016, 63, 16. [Google Scholar] [CrossRef]

- Nehme, G.; Mourhatch, R.; Aswath, P.B. Effect of contact load and lubricant volume on the properties of tribofilms formed under boundary lubrication in a fully formulated oil under extreme load conditions. Wear 2010, 268, 1129–1147. [Google Scholar] [CrossRef]

- Schouwenaars, R.; Jacobo, V.H.; Ortiz, A. Microstructure aspect of wear in soft tribological alloys. Wear 2007, 263, 727–735. [Google Scholar] [CrossRef]

- Dudek, K.; Szczypinski-Sala, W.; Lubas, J. Influence of laser boriding on the friction and wear of sliding couples with bearing alloys. Surf. Rev. Lett. 2020, 27, 1950084. [Google Scholar]

- Piasecki, A.; Kotkowiak, M.; Makuch, N.; Kulka, M. Wear behavior of self-lubricating boride layers produced on Inconel 600-alloy by laser alloying. Wear 2019, 426, 919–933. [Google Scholar] [CrossRef]

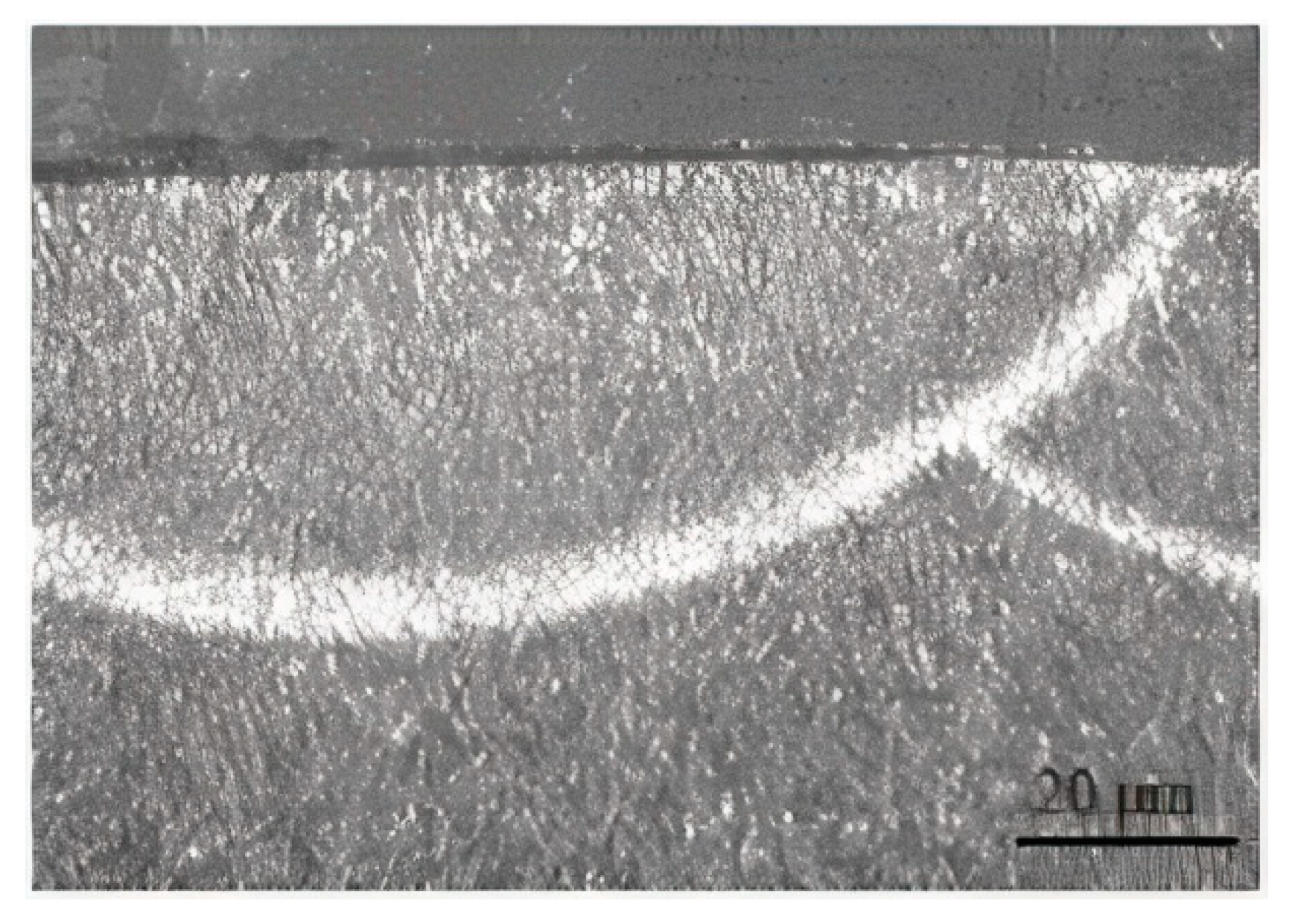

- Dziedzic, A.; Lubas, J.; Bochnowski, W.; Adamiak, S. The mechanisms of tribological wear in lubricated sliding bearings composed of soft bearing alloys with borided steel. Proc. Inst. Mechan. Eng. Part J J. Eng. Tribol. 2016, 230, 350–363. [Google Scholar] [CrossRef]

- Lubas, J. Practical application of boron-modified sliding pairs in I.C. engine. Tribol. Int. 2010, 43, 2046–2050. [Google Scholar] [CrossRef]

| Material | C | Cr | Mn | Si | Fe | Pb | Cu |

|---|---|---|---|---|---|---|---|

| AISI 5045 | 0.46 | 0.5 | 0.65 | <0.4 | Balance | - | - |

| SAE-48 | - | - | - | - | 26–33 | Balance |

| Operating temperature Tmax (°C) | 170 |

| Load Pmax (N/mm2) | 140 |

| Tensile Strength (N/mm2) | 200 |

| Sliding Speed V-oil Lubricated (m/s) | 8 |

| Alloy Hardness (HB) | 30–45 |

| Parameter | 5W-0 Synthetic Oil | 15W-40 Mineral Oil |

|---|---|---|

| Kinematic Viscosity at 100 °C | 13.7 mm2/s | 14.5 mm2/s |

| Viscosity Index | 178 | 133 |

| HTHS Dynamic Viscosity at 150 °C | 3.6 mPa·s | 3.8 mPa·s |

| Specification | API-SL/SJ/CF/CD ACEA-A3-98/B3-98/B4-98 ACEA-A3/B4-04 | API SJ/CF ACEA A3-02/B3-98 |

| Engine Oil | 5W-40 Synthetic Oil | 15W-40 Mineral Oil | ||

|---|---|---|---|---|

| Parameter | Value [μm] | Change [%] | Value [μm] | Change [%] |

| Ra | 0.31 | 3 | 0.32 | 7 |

| Rz DIN | 3.4 | 26 | 3.2 | 19 |

| Sm | 82 | 49 | 89 | 62 |

| Engine Oil | 5W-40 Synthetic Oil | 15W-40 Mineral Oil | ||

|---|---|---|---|---|

| Parameter | Value [μm] | Change [%] | Value [μm] | Change [%] |

| Ra | 0.89 | 78 | 0.72 | 44 |

| Rz DIN | 7.1 | 137 | 5.5 | 83 |

| Sm | 140 | 192 | 123 | 156 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lubas, J.; Szczypiński-Sala, W.; Woś, P.; Zielińska, E.; Miernik, K. Experimental Analysis of Tribological Processes in Friction Pairs with Laser Borided Elements Lubricated with Engine Oils. Materials 2020, 13, 5810. https://doi.org/10.3390/ma13245810

Lubas J, Szczypiński-Sala W, Woś P, Zielińska E, Miernik K. Experimental Analysis of Tribological Processes in Friction Pairs with Laser Borided Elements Lubricated with Engine Oils. Materials. 2020; 13(24):5810. https://doi.org/10.3390/ma13245810

Chicago/Turabian StyleLubas, Janusz, Wojciech Szczypiński-Sala, Paweł Woś, Edyta Zielińska, and Krzysztof Miernik. 2020. "Experimental Analysis of Tribological Processes in Friction Pairs with Laser Borided Elements Lubricated with Engine Oils" Materials 13, no. 24: 5810. https://doi.org/10.3390/ma13245810

APA StyleLubas, J., Szczypiński-Sala, W., Woś, P., Zielińska, E., & Miernik, K. (2020). Experimental Analysis of Tribological Processes in Friction Pairs with Laser Borided Elements Lubricated with Engine Oils. Materials, 13(24), 5810. https://doi.org/10.3390/ma13245810