Tensile Behavior of High-Strength, Strain-Hardening Cement-Based Composites (HS-SHCC) Reinforced with Continuous Textile Made of Ultra-High-Molecular-Weight Polyethylene

Abstract

1. Introduction

2. Materials under Investigation

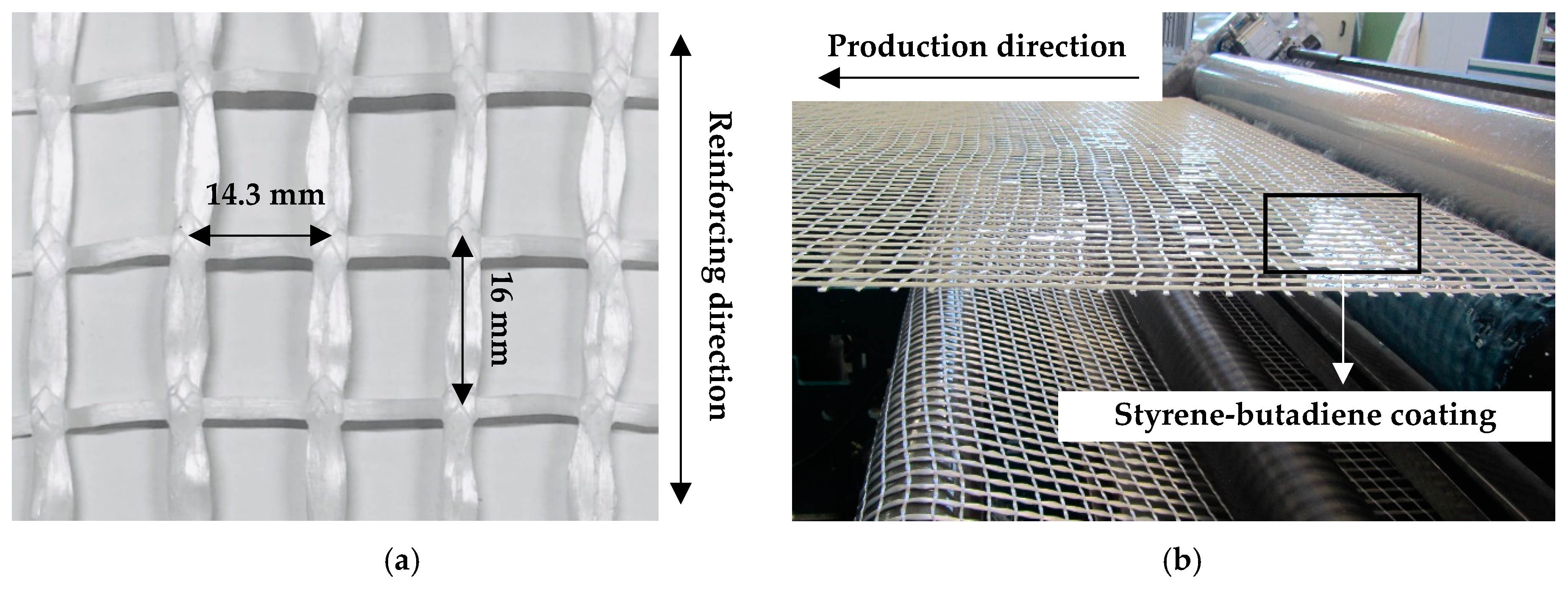

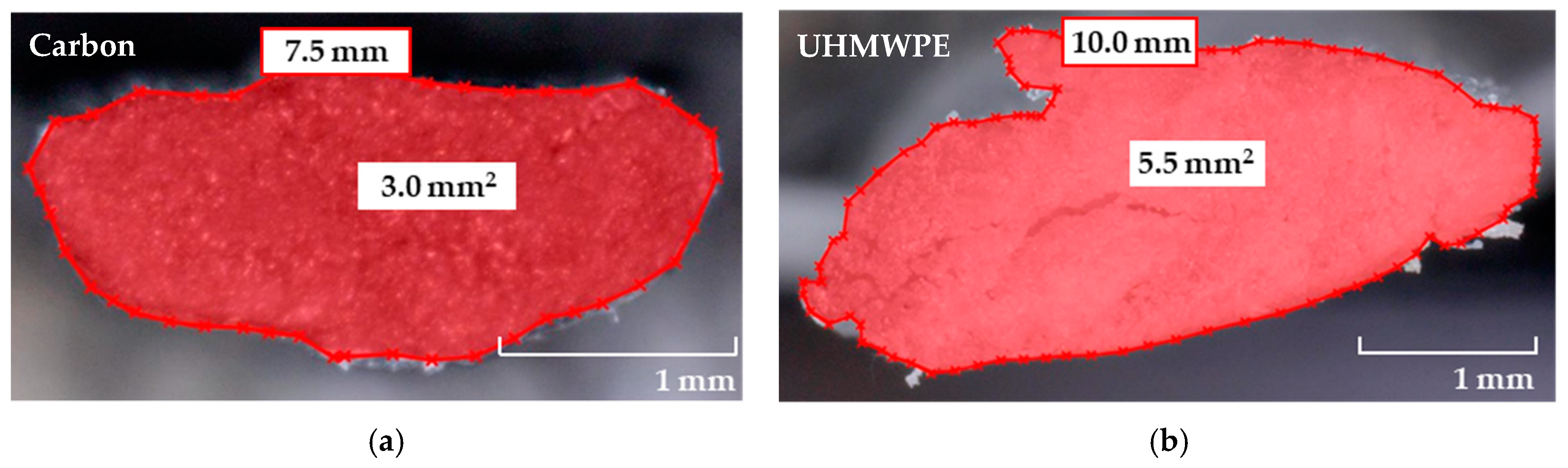

2.1. Two-Dimensional PE, Non-Crimp Textile

2.2. High-Strength SHCC

3. Experimental Program

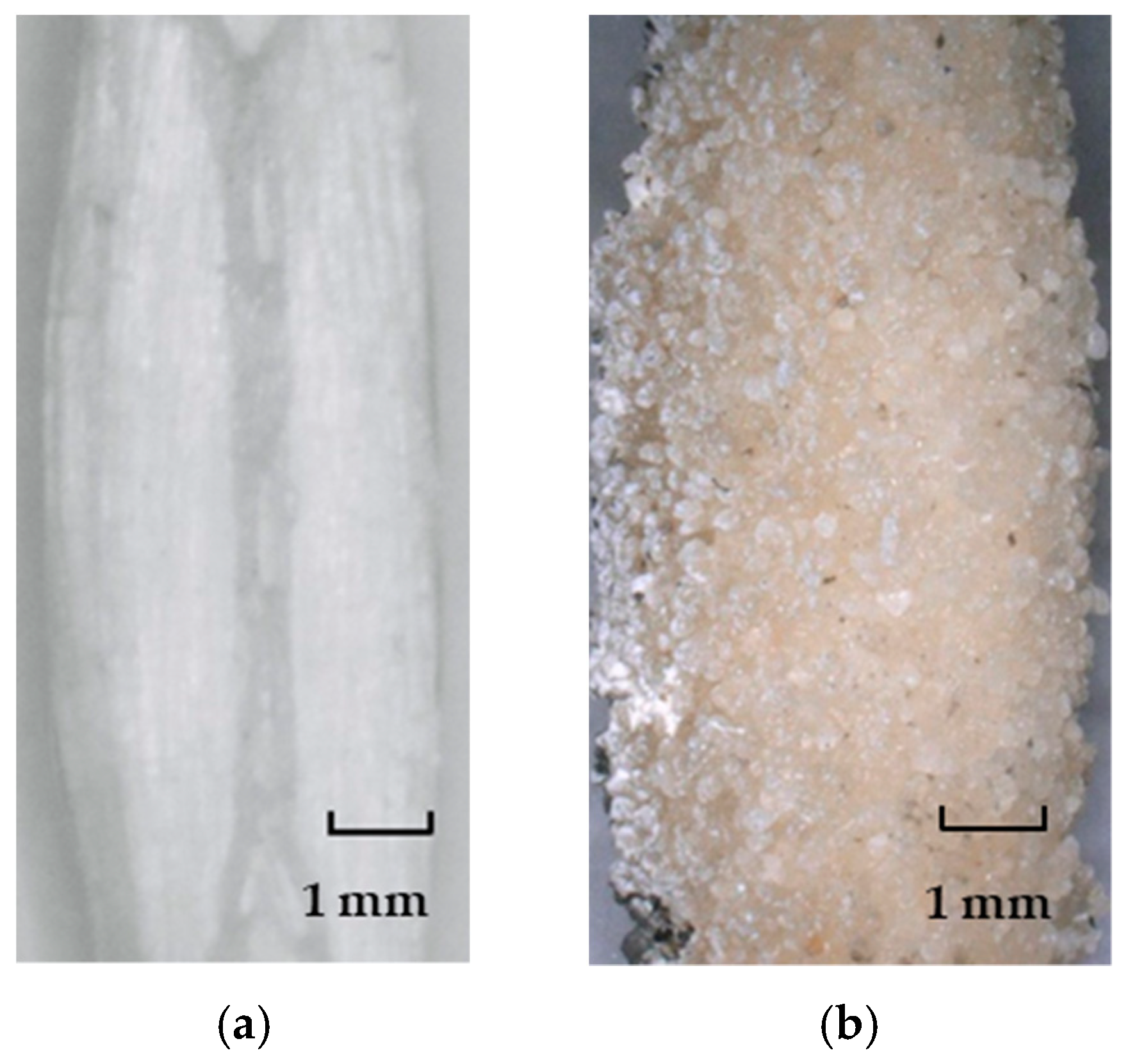

3.1. Specimen Production and Setup for Single-Yarn Pullout Experiments

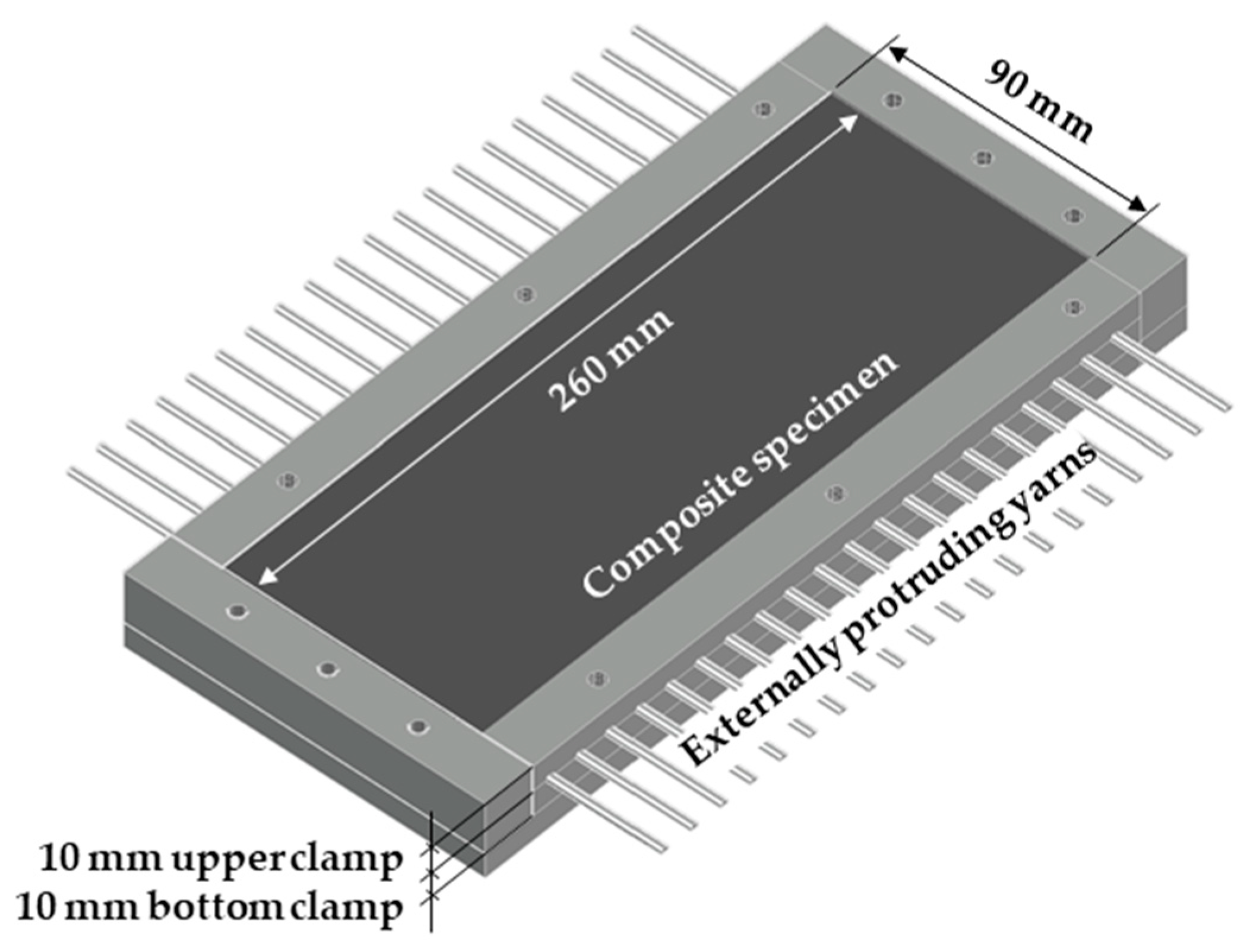

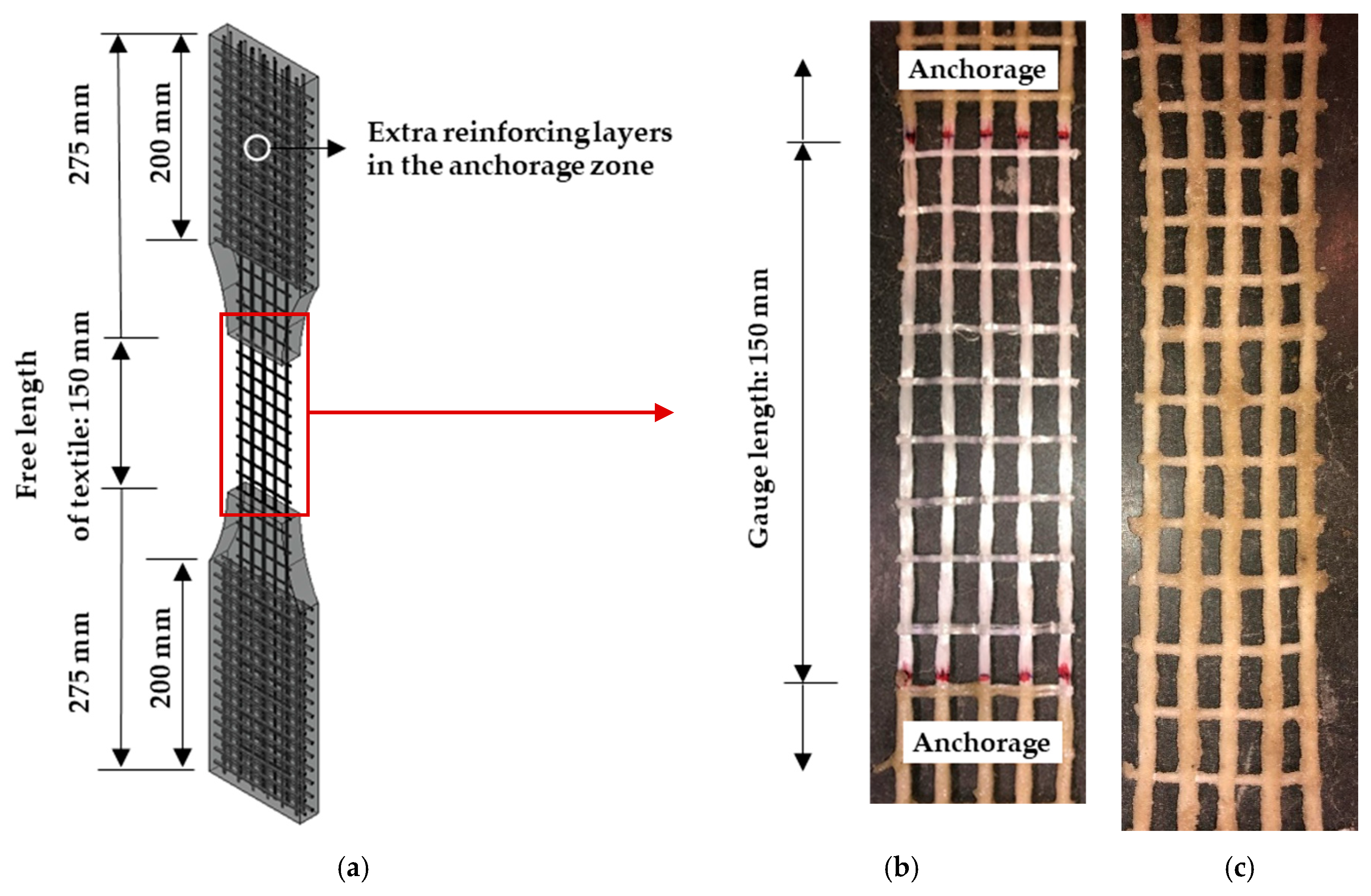

3.2. Production of In-Situ Textile Specimens for Tensile Testing

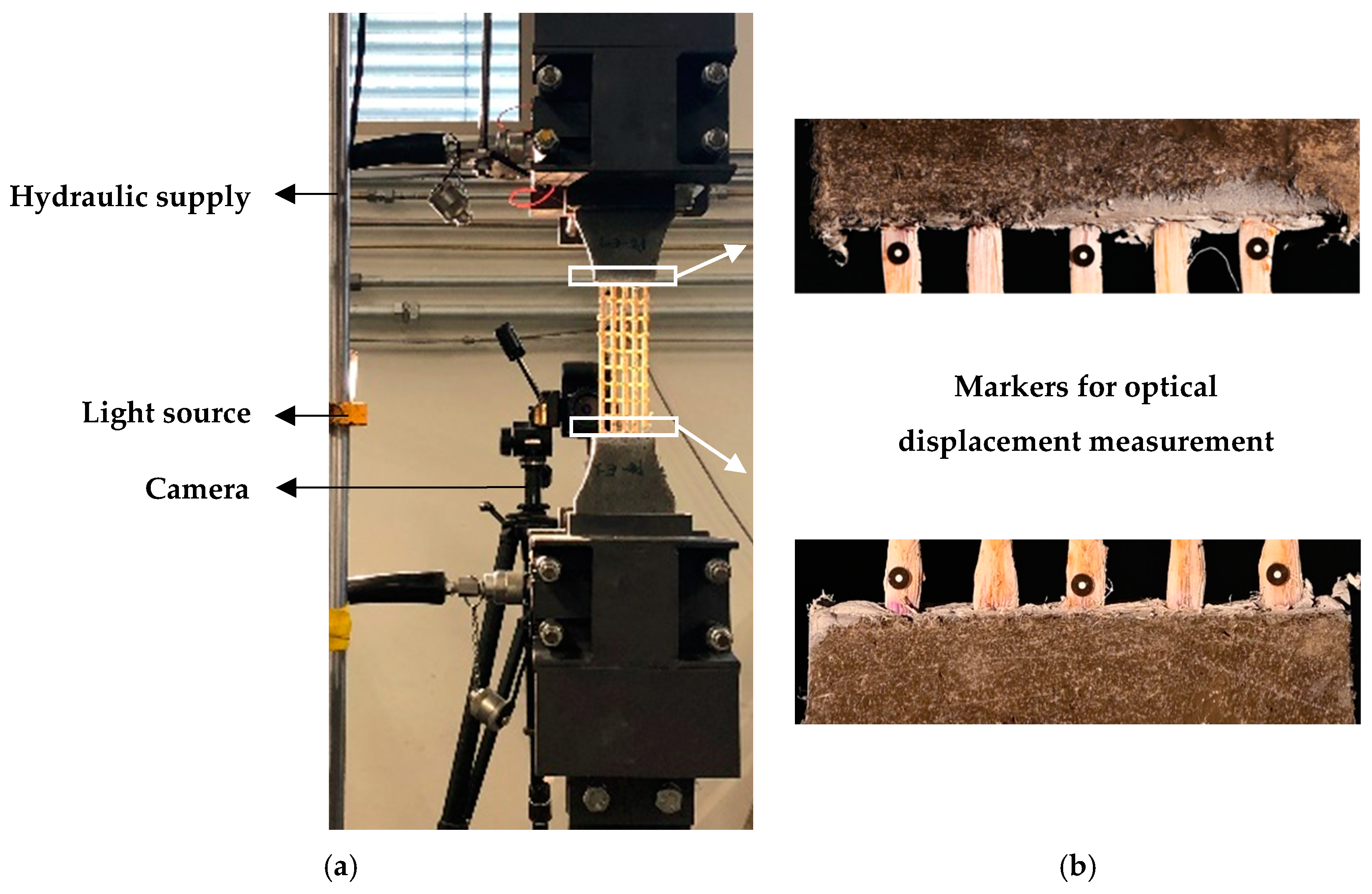

3.3. Testing Configuration for Composite Specimens

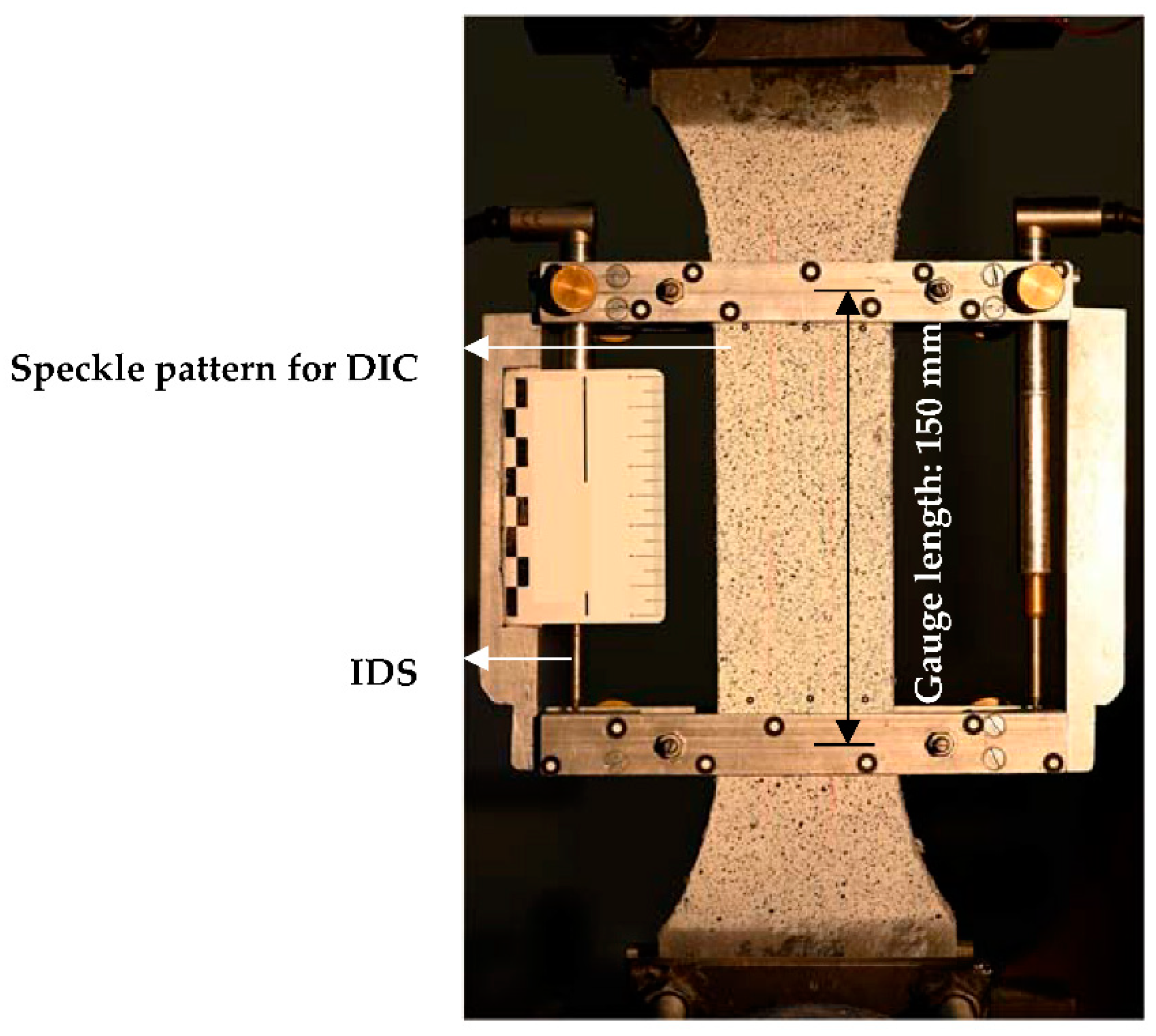

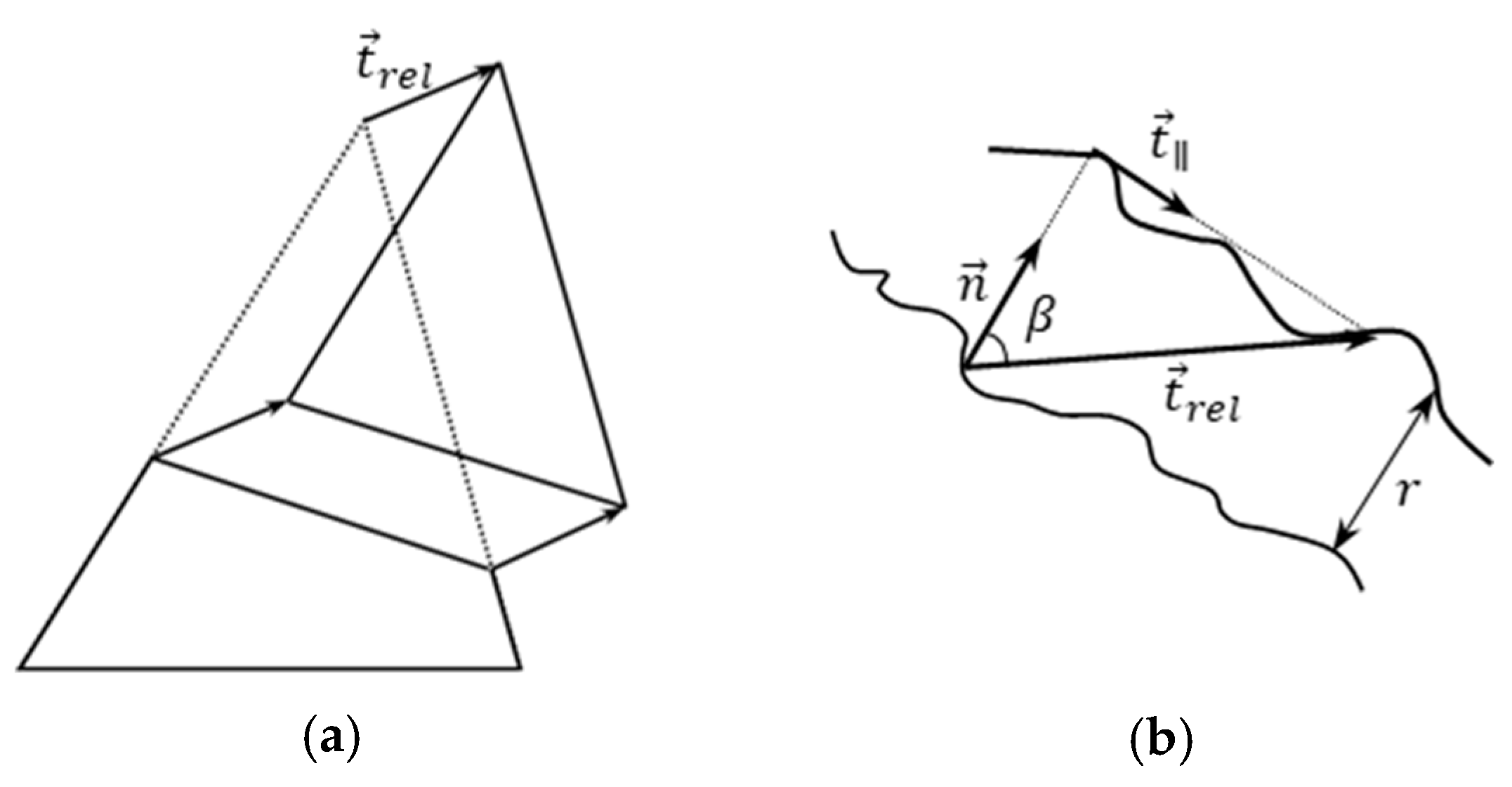

3.4. Optical Measurements and Crack Analysis

4. Results and Discussion

4.1. Single-Yarn Pullout Tests

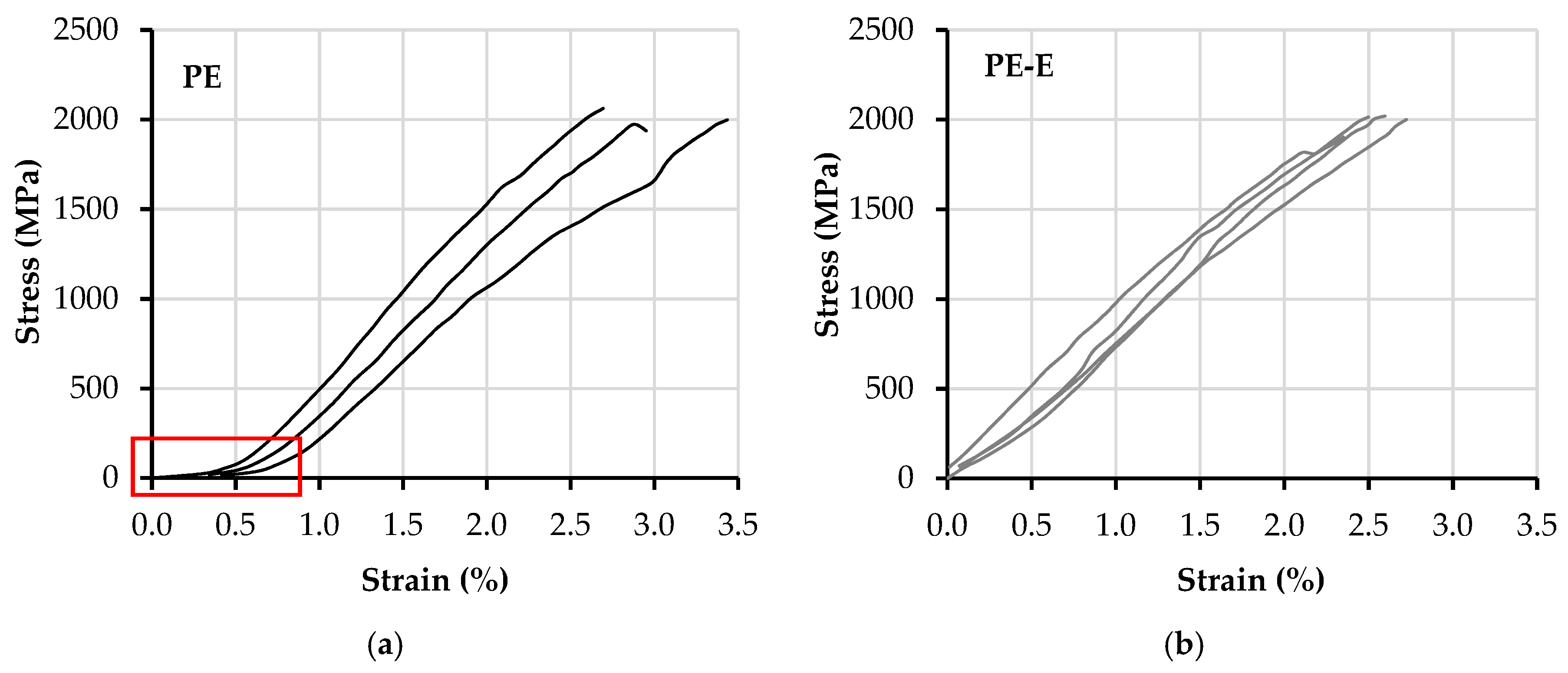

4.2. Uniaxial Tension Tests on Textile Specimens

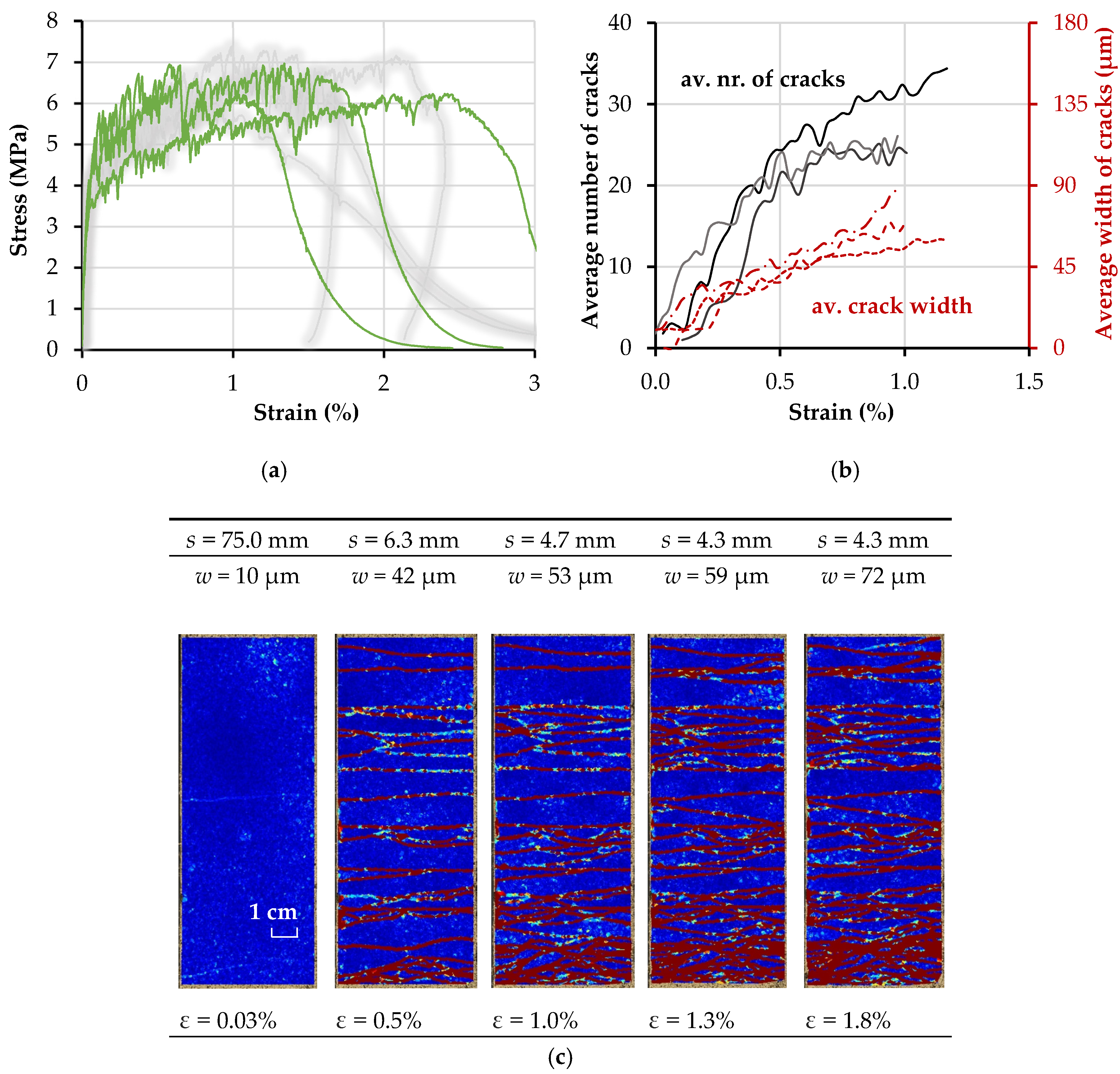

4.3. Uniaxial Tension Tests on HS-SHCC

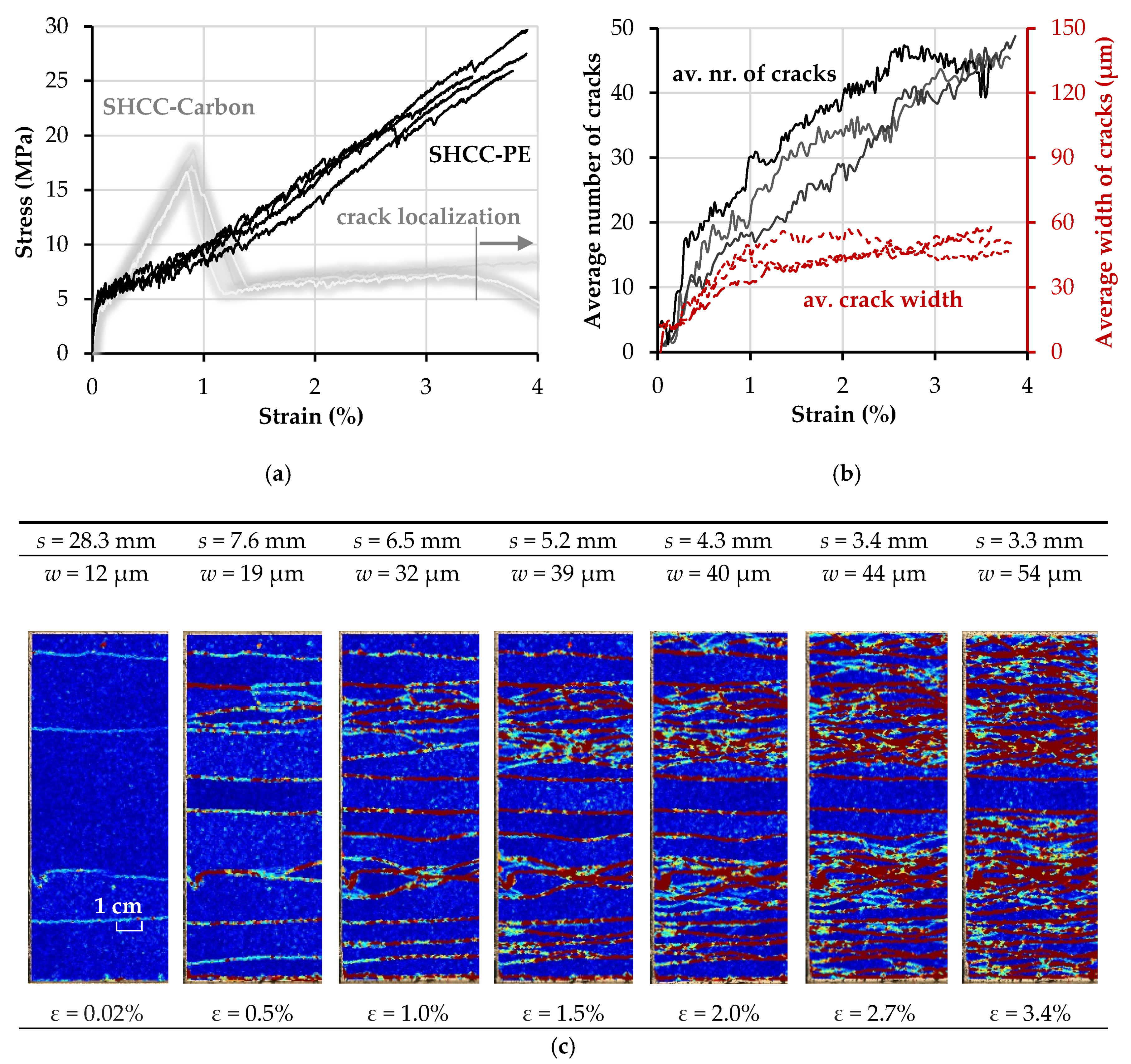

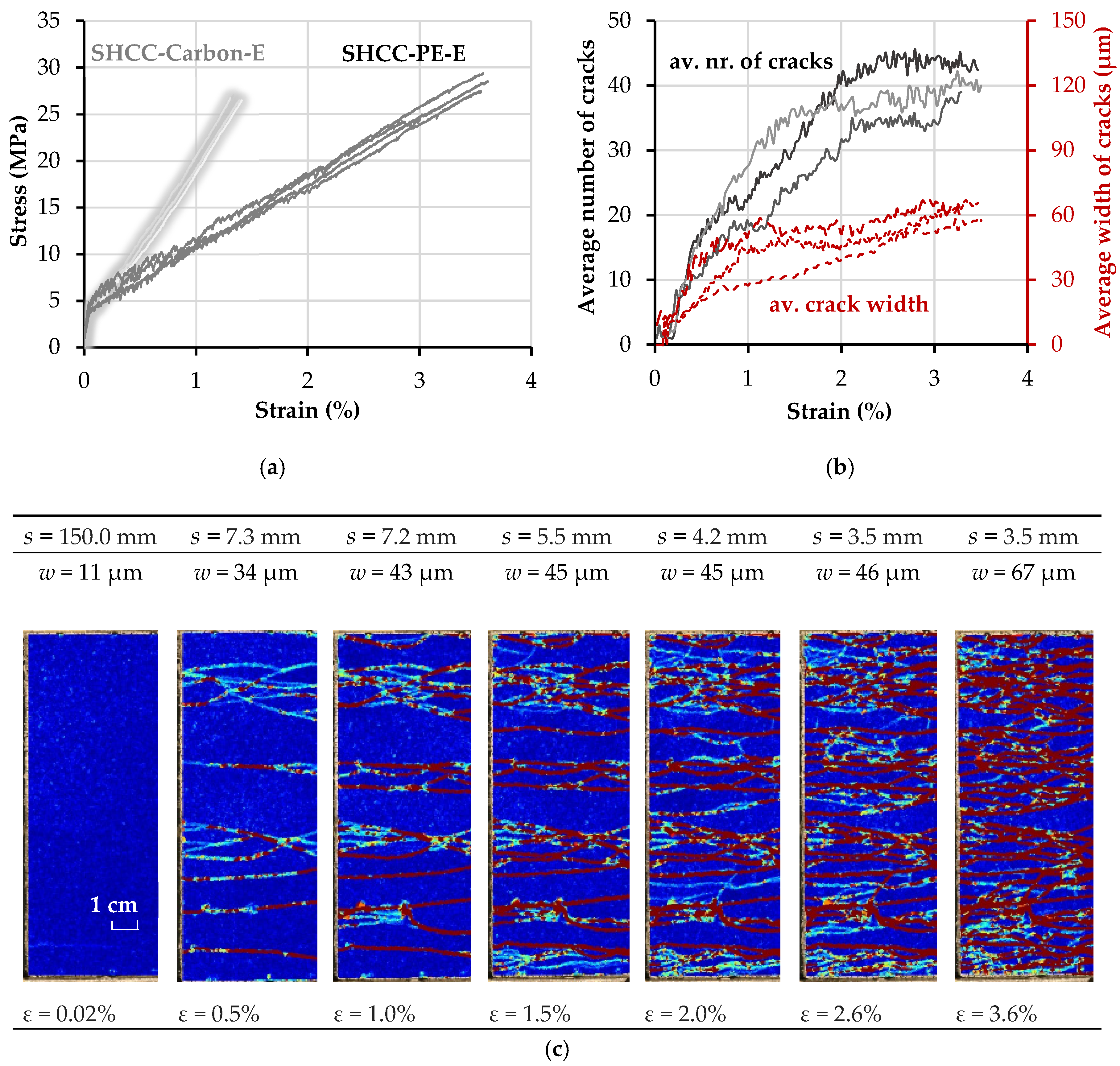

4.4. Uniaxial Tension Tests on Hybrid Fiber-Reinforced Composites

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Curosu, I.; Mechtcherine, V.; Hering, M.; Curbach, M. Mineral-bonded composites for enhanced structural impact safety—Overview of the format, goals and achievements of the research group GRK 2250. In Proceedings of the 10th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Bayonne, France, 23–26 June 2019. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel Cement-Based Composites for the Strengthening and Repair of Concrete Structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Peled, A. Pre-Tensioning of Fabrics in Cement-Based Composites. Cem. Concr. Res. 2007, 37, 805–813. [Google Scholar] [CrossRef]

- Peled, A.; Bentur, A. Geometrical Characteristics and Efficiency of Textile Fabrics for Reinforcing Cement Composites. Cem. Concr. Res. 2000, 30, 781–790. [Google Scholar] [CrossRef]

- Mobasher, B.; Dey, V.; Cohen, Z.; Peled, A. Correlation of Constitutive Response of Hybrid Textile Reinforced Concrete from Tensile and Flexural Tests. Cem. Concr. Compos. 2014, 53, 148–161. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites (ECC). J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Li, V.C. From Michromechanics to Structural Engineering—The Design of Cementitious Composites for Civil Engineering Applications. Jpn. Soc. Civil. Eng. 1993, 10, 37–48. [Google Scholar]

- Mechtcherine, V.; Millon, O.; Butler, M.; Thoma, K. Mechanical Behaviour of Strain Hardening Cement-Based Composites under Impact Loading. Cem. Concr. Compos. 2011, 33, 1–11. [Google Scholar] [CrossRef]

- Sasi, E.A.; Peled, A. Three Dimensional (3D) Fabrics as Reinforcements for Cement-Based Composites. Compos. Part A 2015, 74, 153–165. [Google Scholar] [CrossRef]

- Peled, A.; Zhu, D.; Mobasher, B. Impact Behavior of 3D Fabric Reinforced Cementitious Composites. In RILEM Bookseries 2: High Performance Fiber Reinforced Cement Composites 6; Parra-Montesinos, G.J., Reinhardt, H.W., Naaman, A.E., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 543–550. [Google Scholar] [CrossRef]

- Barhum, R.; Mechtcherine, V. Effect of Short, Dispersed Glass and Carbon Fibres on the Behaviour of Textile-Reinforced Concrete under Tensile Loading. Eng. Fract. Mech. 2012, 92, 56–71. [Google Scholar] [CrossRef]

- De Andrade Silva, F.; Butler, M.; Mechtcherine, V.; Zhu, D.; Mobasher, B. Strain Rate Effect on the Tensile Behaviour of Textile-Reinforced Concrete under Static and Dynamic Loading. Mater. Sci. Eng. A 2011, 528, 1727–1734. [Google Scholar] [CrossRef]

- Hering, M.; Bracklow, F.; Scheerer, S.; Curbach, M. Reinforced Concrete Plates under Impact Load—Damage Quantification. Materials 2020, 13, 4554. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmann, C.; Michel, S. Tensile Behavior of High-Strength Strain-Hardening Cement-Based Composites (HS-SHCC) Made with High-Performance Polyethylene, Aramid and PBO Fibers. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

- Dyneema, D. HDPE Ultra High Molecular Weight Polyethylene Fiber from DSM Dyneema. Available online: https://issuu.com/eurofibers/docs/name8f0d44 (accessed on 9 January 2020).

- Liu, X.; Yu, W. Evaluation of the Tensile Properties and Thermal Stability of Ultrahigh-Molecular-Weight Polyethylene Fibers. J. Appl. Polym. Sci. 2005, 97, 310–315. [Google Scholar] [CrossRef]

- Liu, X.; Yu, W. Evaluating the Thermal Stability of High Performance Fibers by TGA. J. Appl. Polym. Sci. 2006, 99, 937–944. [Google Scholar] [CrossRef]

- Peijs, T.; Smets, E.A.M.; Govaert, L.E. Strain Rate and Temperature Effects on Energy Absorption of Polyethylene Fibres and Composites. Appl. Compos. Mater. 1994, 1, 35–54. [Google Scholar] [CrossRef]

- Govaert, L.E.; Peijs, T. Tensile Strength and Work of Fracture of Oriented Polyethylene Fibre. Polymer 1995, 36, 4425–4431. [Google Scholar] [CrossRef]

- Curosu, I.; Mechtcherine, V.; Millon, O. Effect of Fiber Properties and Matrix Composition on the Tensile Behavior of Strain-Hardening Cement-Based Composites (SHCCs) Subject to Impact Loading. Cem. Concr. Res. 2016, 82, 23–35. [Google Scholar] [CrossRef]

- Curosu, I.; Mechtcherine, V.; Forni, D.; Cadoni, E. Performance of Various Strain-Hardening Cement-Based Composites (SHCC) Subject to Uniaxial Impact Tensile Loading. Cem. Concr. Res. 2017, 102, 16–28. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, D.; Zhang, H.; Li, G.; Mobasher, B. Tensile Behaviors of Basalt, Carbon, Glass, and Aramid Fabrics under Various Strain Rates. J. Mater. Civ. Eng. 2016, 28, 04016081. [Google Scholar] [CrossRef]

- Zhu, D.; Mobasher, B.; Rajan, S.D. Dynamic Tensile Testing of Kevlar 49 Fabrics. J. Mater. Civ. Eng. 2011, 23, 230–239. [Google Scholar] [CrossRef]

- Zhu, D.; Peled, A.; Mobasher, B. Dynamic Tensile Testing of Fabric-Cement Composites. Constr. Build. Mater. 2011, 25, 385–395. [Google Scholar] [CrossRef]

- Gong, T.; Heravi, A.A.; Alsous, G.; Curosu, I.; Mechtcherine, V. The Impact-Tensile Behavior of Cementitious Composites Reinforced with Carbon Textile and Short Polymer Fibers. Appl. Sci. 2019, 9, 4048. [Google Scholar] [CrossRef]

- Gong, T.; Ahmed, A.H.; Curosu, I.; Mechtcherine, V. Tensile Behavior of Hybrid Fiber Reinforced Composites Made of Strain-Hardening Cement-Based Composites (SHCC) and Carbon Textile. Constr. Build. Mater. 2020, 262, 120913. [Google Scholar] [CrossRef]

- Peled, A.; Mobasher, B. Pultruded Fabric-Cement Composites. Mater. J. 2005, 102, 15–23. [Google Scholar]

- Gong, T.; Heravi, A.A.; Curosu, I.; Mechtcherine, V. Effect of textile reinforcement on the tensile behavior of Strain-Hardening Cement-Based Composites (SHCC) under quasi-static and impact loading. In Proceedings of the 5th International Conference on Protective Structures, Poznan, Poland, 19–23 August 2018; pp. 558–566. [Google Scholar]

- Gong, T.; Hamza, A.A.; Curosu, I.; Mechtcherine, V. On the synergetic action between Strain-Hardening Cement-Based Composites (SHCC) and carbon textile reinforcement under tensile loading. In Proceedings of the 10th International Conference on Fracture Mechanics of Concrete and Concrete Structures (FraMCoS-X), Bayonne, France, 23–26 June 2019. [Google Scholar] [CrossRef]

- Hegger, J.; Will, N.; Bruckermann, O.; Voss, S. Load-Bearing Behaviour and Simulation of Textile Reinforced Concrete. Mater. Struct. Constr. 2006, 39, 765–776. [Google Scholar] [CrossRef]

- Liebold, F.; Maas, H.-G. Sub-Pixel Accuracy Crack Width Determination on Concrete Beams in Load Tests by Triangle Mesh Geometry Analysis. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, 4, 193–200. [Google Scholar] [CrossRef]

- Liebold, F.; Maas, H.-G. Strategy for Crack Width Measurement of Multiple Crack Patterns in Civil Engineering Material Testing Using a Monocular Image Sequence Analysis. PFG J. Photogramm. Remote Sens. Geoinf. Sci. 2020, 88, 219–238. [Google Scholar] [CrossRef]

- Liebold, F.; Maas, H.-G. Advanced Spatio-Temporal Filtering Techniques for Photogrammetric Image Sequence Analysis in Civil Engineering Material Testing. ISPRS J. Photogramm. Remote Sens. 2016, 111, 13–21. [Google Scholar] [CrossRef]

- Datasheet TUDALIT BZT2. Available online: www.solutions-in-textile.com (accessed on 28 October 2019).

- Heravi, A.A.; Fuchs, A.; Gong, T.; Curosu, I.; Kaliske, M.; Mechtcherine, V. Mechanical Characterization of Textile Reinforced Cementitious Composites under Impact Tensile Loading Using the Split-Hopkinson Tension Bar. Cem. Concr. Compos. 2020, 114, 103769. [Google Scholar] [CrossRef]

- Ackermann, F. Digital Image Correlation: Performance and Potential Application in Photogrammetry. Photogramm. Rec. 1984, 11, 429–439. [Google Scholar] [CrossRef]

- Sueki, S.; Soranakom, C.; Mobasher, B.; Peled, A. Pullout-Slip Response of Fabrics Embedded in a Cement Paste Matrix. J. Mater. Civ. Eng. 2007, 19, 718–727. [Google Scholar] [CrossRef]

- Cohen, Z.; Peled, A. Controlled Telescopic Reinforcement System of Fabric-Cement Composites—Durability Concerns. Cem. Concr. Res. 2010, 40, 1495–1506. [Google Scholar] [CrossRef]

- Dvorkin, D.; Peled, A. Effect of Reinforcement with Carbon Fabrics Impregnated with Nanoparticles on the Tensile Behavior of Cement-Based Composites. Cem. Concr. Res. 2016, 85, 28–38. [Google Scholar] [CrossRef]

- Hinzen, M.; Brameshuber, W. Improvement of serviceability and strength of textile reinforced concrete by using short fibres. In Textile Concrete—Theory and Practice: Proceedings of the 4th Colloquium on Textile Reinforced Structures (CTRS4) and the 1st User Conference; Curbach, M., Jesse, F., Eds.; Technische Universität Dresden: Dresden, Germany, 2009; pp. 261–272. [Google Scholar]

| Parameter | Warp Yarn | Weft Yarn |

|---|---|---|

| Average yarn count (tex) | 2112 | 528 |

| Effective yarn cross-section (mm2) | 2.180 | 0.545 |

| Components | Content in (kg/m3) |

|---|---|

| CEM I 52.5R-SR3/NA (Holcim, Rapperswil-Jona, Switzerland) | 1460 |

| Elkem 971-U silica fume (Elkem, Oslo, Norway) | 292 |

| Quartz sand 0.06–0.2 mm (Strobel Quarzsand GmbH, Freihung, Germany) | 145 |

| Superplasticizer Glenium ACE 460 (BASF, Ludwigshafen am Rhein, Germany) | 45 |

| Water | 315 |

| UHMWPE SK62 fiber—2% vol. (DSM, Heerlen, the Netherlands) | 20 |

| Textile Material | Peak Pullout Load (N) | Slip at Peak Load (mm) | Average Bond Strength (MPa) |

|---|---|---|---|

| PE | 375.0 (43.5) | 0.8 (0.1) | 1.3 (0.2) |

| Parameter | PE | PE-E |

|---|---|---|

| Strain capacity (%) | 3.0 (0.4) | 2.5 (0.2) |

| Tensile strength (MPa) | 2011.3 (45.5) | 1984.3 (55.3) |

| Peak load (kN) | 21.9 (0.5) | 21.6 (0.6) |

| Composite | First-Crack Stress (MPa) | Tensile Strength (MPa) | Strain Capacity (%) | Work-to-Fracture (kJ/m3) | Peak Load (kN) |

|---|---|---|---|---|---|

| SHCC | 2.7 (1.3) | 6.7 (0.4) | 1.4 (0.9) | 79.2 (47.4) | 7.9 (0.4) |

| SHCC-PE | 3.3 (1.1) | 27.1 (1.9) | 3.8 (0.2) | 570.6 (70.2) | 29.2 (1.3) |

| SHCC-PE-E | 2.5 (0.8) | 27.5 (2.1) | 3.4 (0.3) | 547.2 (64.2) | 30.0 (2.2) |

| Parameter | SHCC | SHCC-PE | SHCC-PE-E |

|---|---|---|---|

| Average crack spacing s (mm) | 5.3 (0.9) | 3.0 (0.2) | 3.5 (0.2) |

| Average crack width w (µm) | 88.3 (20.6) | 55.7 (3.3) | 68.3 (2.0) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, T.; Curosu, I.; Liebold, F.; Vo, D.M.P.; Zierold, K.; Maas, H.-G.; Cherif, C.; Mechtcherine, V. Tensile Behavior of High-Strength, Strain-Hardening Cement-Based Composites (HS-SHCC) Reinforced with Continuous Textile Made of Ultra-High-Molecular-Weight Polyethylene. Materials 2020, 13, 5628. https://doi.org/10.3390/ma13245628

Gong T, Curosu I, Liebold F, Vo DMP, Zierold K, Maas H-G, Cherif C, Mechtcherine V. Tensile Behavior of High-Strength, Strain-Hardening Cement-Based Composites (HS-SHCC) Reinforced with Continuous Textile Made of Ultra-High-Molecular-Weight Polyethylene. Materials. 2020; 13(24):5628. https://doi.org/10.3390/ma13245628

Chicago/Turabian StyleGong, Ting, Iurie Curosu, Frank Liebold, Duy M. P. Vo, Konrad Zierold, Hans-Gerd Maas, Chokri Cherif, and Viktor Mechtcherine. 2020. "Tensile Behavior of High-Strength, Strain-Hardening Cement-Based Composites (HS-SHCC) Reinforced with Continuous Textile Made of Ultra-High-Molecular-Weight Polyethylene" Materials 13, no. 24: 5628. https://doi.org/10.3390/ma13245628

APA StyleGong, T., Curosu, I., Liebold, F., Vo, D. M. P., Zierold, K., Maas, H.-G., Cherif, C., & Mechtcherine, V. (2020). Tensile Behavior of High-Strength, Strain-Hardening Cement-Based Composites (HS-SHCC) Reinforced with Continuous Textile Made of Ultra-High-Molecular-Weight Polyethylene. Materials, 13(24), 5628. https://doi.org/10.3390/ma13245628