Microstructure and Properties of Heat Affected Zone in High-Carbon Steel after Welding with Fast Cooling in Water

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

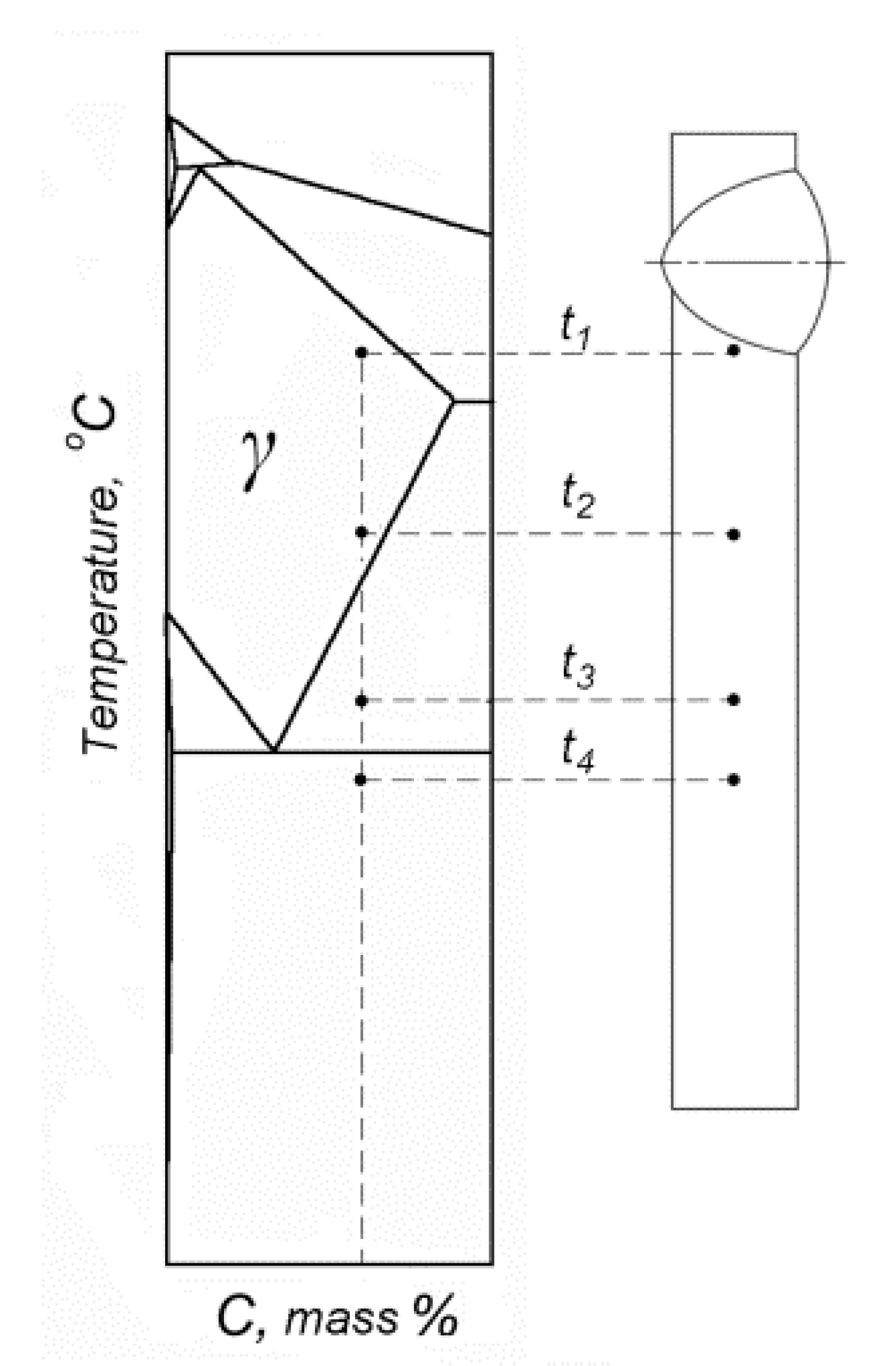

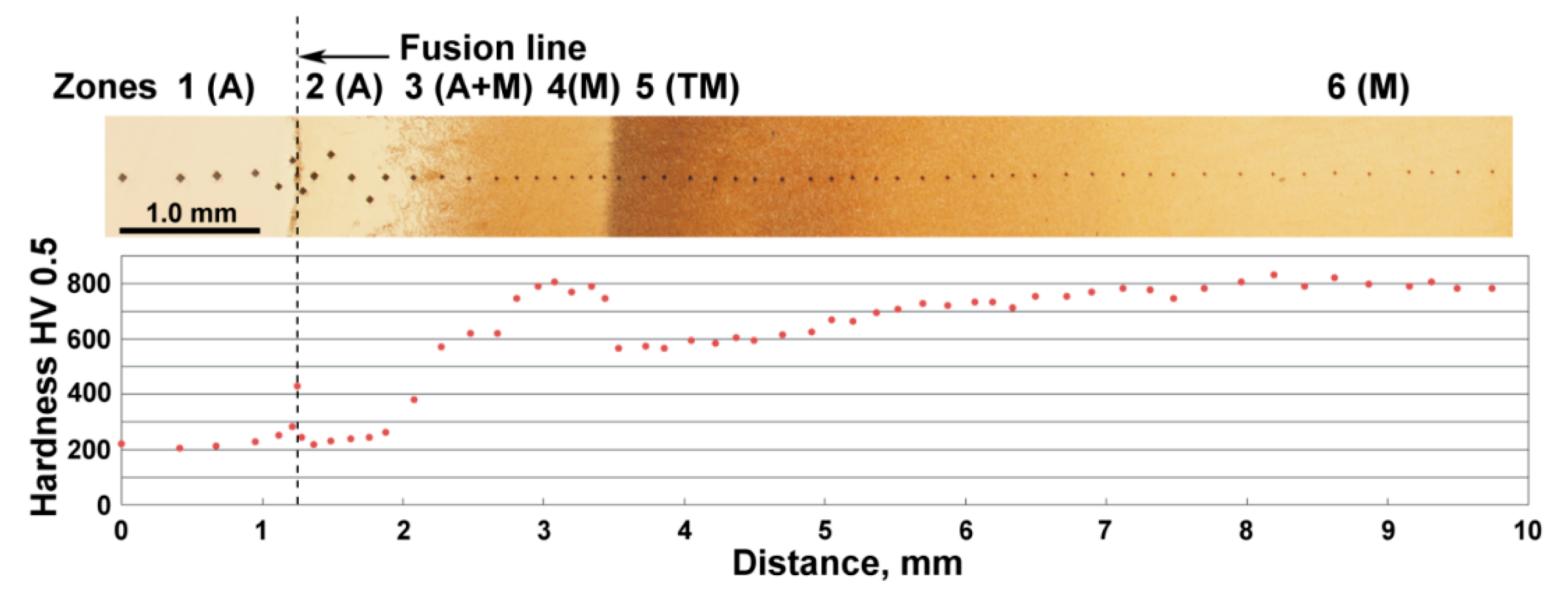

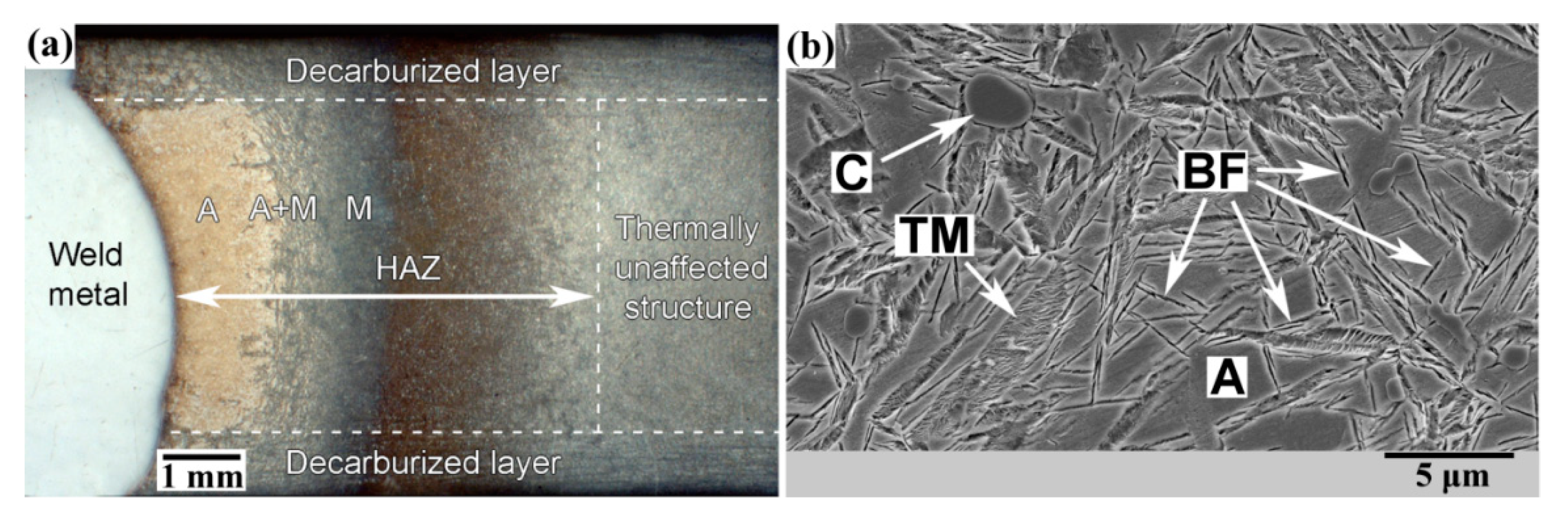

- Quenched 120Mn3Si2 steel may be successfully welded with rapid cooling in water. An austenitic layer is formed in the vicinity of the fusion line followed by mixed austenite– martensite structure, and finally, the layer of hard untempered martensite.

- Despite the presence of a hard martensitic layer, there were no cracks observed in HAZ. This is possibly due to a ductile austenitic layer separating themartensite from the fusion line.

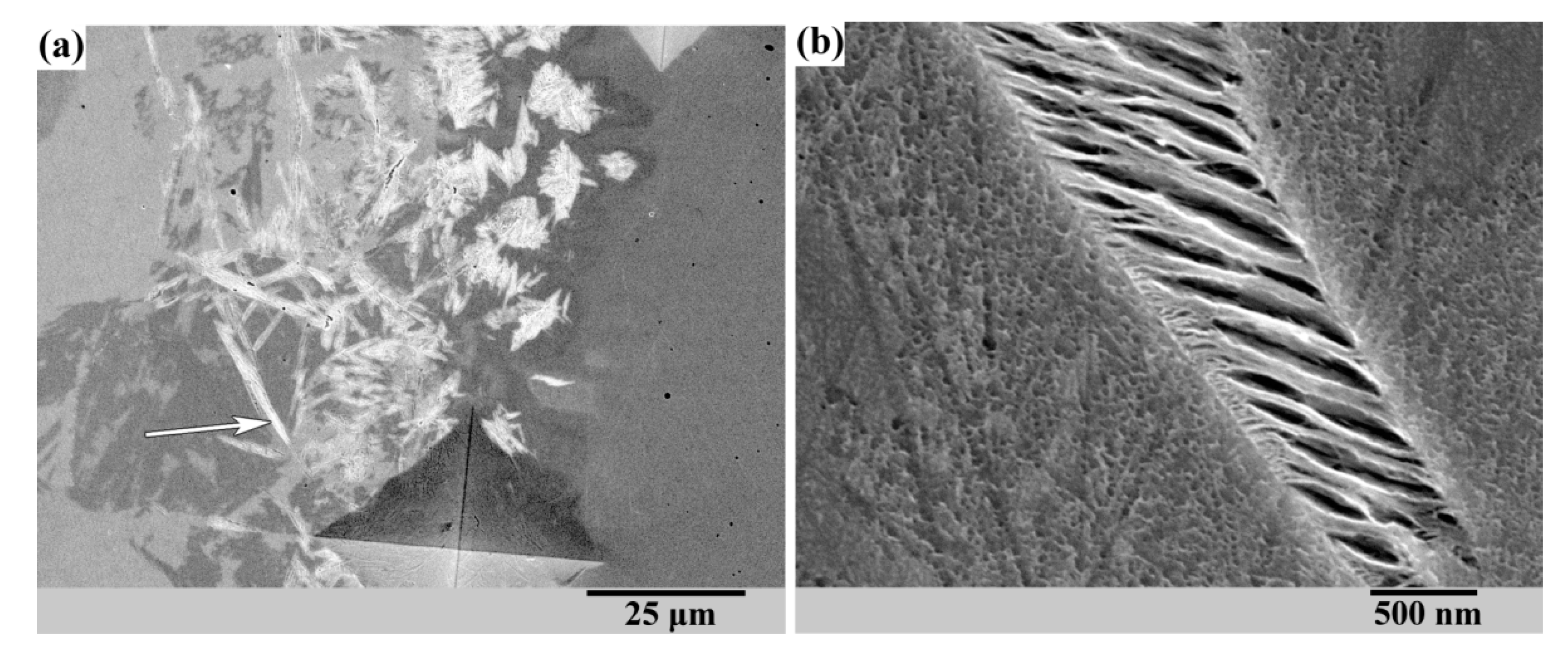

- A noticeable amount of martensite appears inside the fusion line despite the highly austenitic weld metal. This martensite is located in the unmelted grains of 120Mn3Si2 steel which are surrounded by remelted austenitic metal. SEM observation indicates typical structure of tempered martensite. Thus, martensite in the fusion line does not cause damage to the weld due to its temper and ductile austenitic metal which surrounds partially remelted grains.

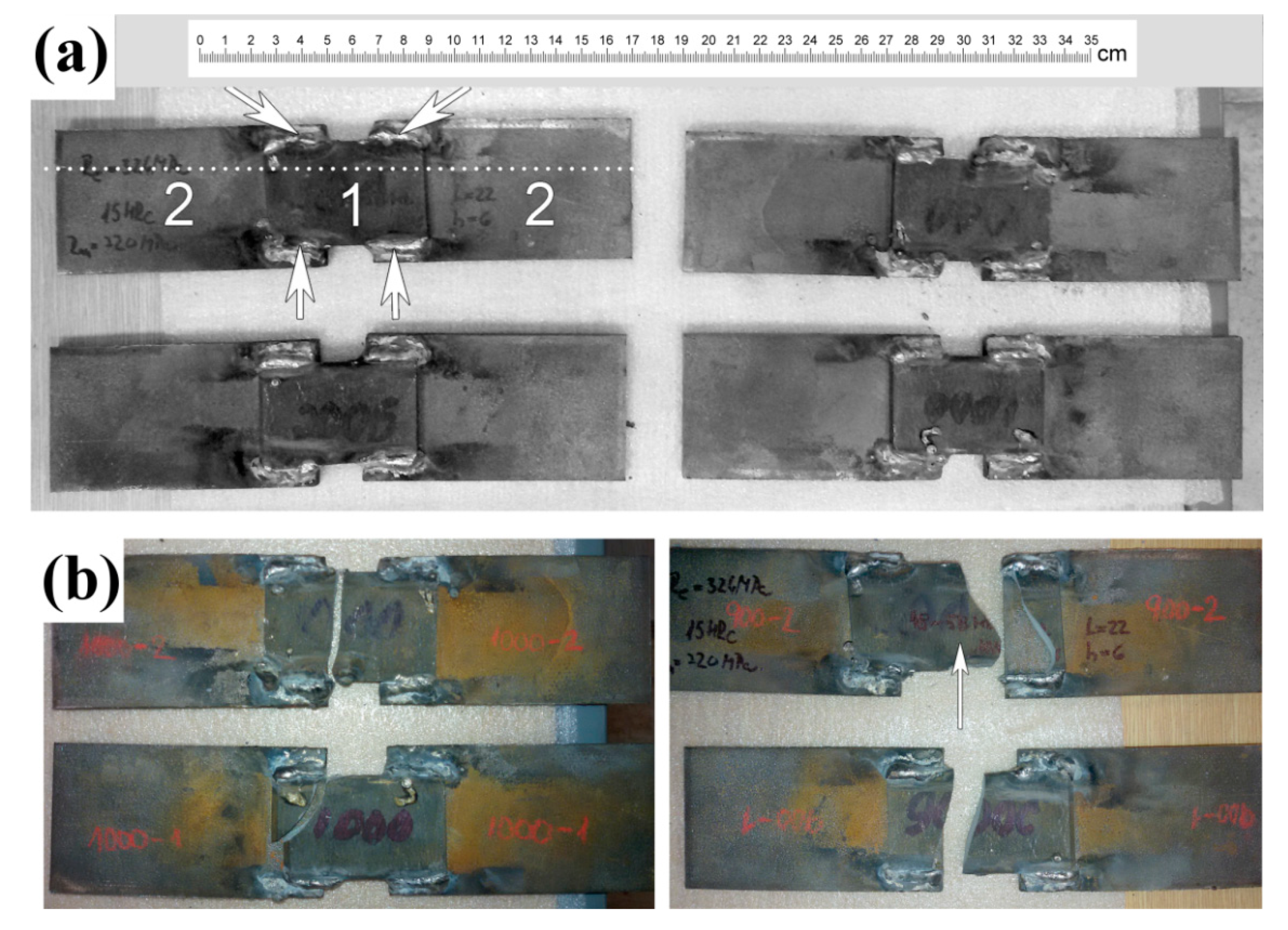

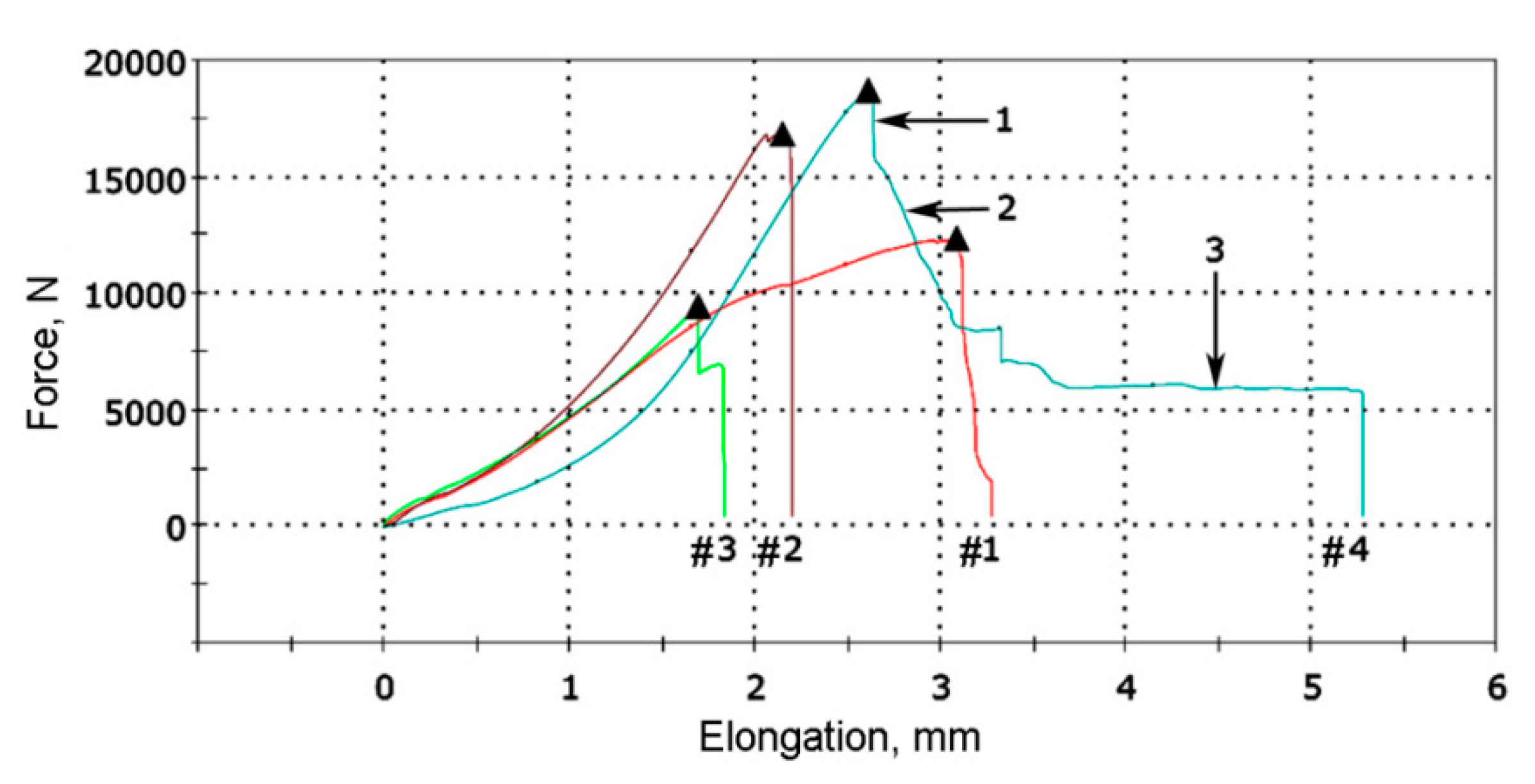

- The UTS of welding joints 209 ± 27 MPa were for 120Mn3Si2 steel samples as a result of ISO 4136 tests. Further research is needed to find ways to increase the UTS of the welding joints of high-carbon steels by appropriate thermal or other treatments.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lindegaard-Andersen, A.; Vedel, T.; Jeppesen, L.; Gottlieb, B. Film-based X-ray tomography combined with digital image processing: Investigation of an ancient pattern-welded sword. NDT Int. 1988, 21, 407–410. [Google Scholar] [CrossRef]

- David, S.A.; DebRoy, T. Current issues and problems in welding science. Science 1992, 257, 497–502. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Hu, S.J.; Sun, L.; Freiheit, T. Intelligent welding system technologies: State-of-the-art review and perspectives. J. Manuf. Syst. 2020, 56, 373–391. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Terva, J.; Kuokkala, V.-T.; Valtonen, K.; Siitonen, P. Effects of compression and sliding on the wear and energy consumption in mineral crushing. Wear 2018, 398–399, 116–126. [Google Scholar] [CrossRef]

- Totten, G.E. (Ed.) Friction, Lubrication, and Wear Technology; ASM International: Materials Park, OH, USA, 2017. [Google Scholar] [CrossRef]

- Brezinová, J.; Draganovská, D.; Guzanová, A.; Balog, P.; Viňáš, J. Influence of the hardfacing welds structure on their wear resistance. Metals 2016, 6, 36. [Google Scholar] [CrossRef]

- Viňáš, J.; Greš, M.; Vaško, T. Cladding of wear-resistant layers in metallurgy and engineering. Mater. Sci. Forum 2016, 862, 41–48. [Google Scholar] [CrossRef]

- Heydartaemeh, M.; Karamoozian, M.; Potgieter, H. Application of nano high-entropy alloys to reduce energy consumption and wear of copper oxide and high-grade iron ores in heavy mining industries—A case study. Minerals 2020, 10, 16. [Google Scholar] [CrossRef]

- Falat, L.; Džupon, M.; Ťavodová, M.; Hnilica, R.; Ľuptáčiková, V.; Čiripová, L.; Homolová, V.; Ďurišinová, K. Microstructure and abrasive wear resistance of various alloy hardfacings for application on heavy-duty chipper tools in forestry shredding and mulching operations. Materials 2019, 12, 2212. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Podgornik, B.; Brunčko, M.; Kirbiš, P. Wear Resistance of High C High Si Steel with Low Retained Austenite Content and Kinetically Activated Bainite. Metals 2020, 10, 672. [Google Scholar] [CrossRef]

- Gonzalez-Pociño, A.; Alvarez-Antolin, F.; Asensio-Lozano, J. Optimization of Thermal Processes Applied to Hypoeutectic White Cast Iron containing 25% Cr Aimed at Increasing Erosive Wear Resistance. Metals 2020, 10, 359. [Google Scholar] [CrossRef]

- Efremenko, V.; Shimizu, K.; Pastukhova, T.; Chabak, Y.; Brykov, M.; Kusumoto, K.; Efremenko, A. Three-body abrasive wear behaviour of metastable spheroidal carbide cast irons with different chromium contents. IJMR 2017, 109, 147–156. [Google Scholar] [CrossRef]

- Ťavodová, M.; Džupon, M.; Kalincová, D.; Hnilicová, M. Deformation of exposed tool parts for crushing of undesirable advance growth. Acta Technol. Agric. 2018, 21, 166–173. [Google Scholar] [CrossRef]

- Orečný, M.; Buršák, M.; Šebek, M.; Falat, L. Influence of Hardness, Matrix and Carbides in Combination with Nitridation on Abrasive Wear Resistance of X210Cr12 Tool Steel. Metals 2016, 6, 236. [Google Scholar] [CrossRef]

- Korobov, I.; Pimenova, O.; Filippov, M.; Khadyev, M.; Ozerets, N.; Mikhailov, S.; Morozov, S.; Davydov, I.; Razikov, N. Characteristics of strain-induced martensitic transformation in welded joints with the structure of metastable austenite. Procedia Struct. Integr. 2019, 14, 34–43. [Google Scholar] [CrossRef]

- Chung, Y.D.; Fujii, H.; Ueji, R.; Tsuji, N. Friction stir welding of high carbon steel with excellent toughness and ductility. Scr. Mater. 2010, 63, 223–226. [Google Scholar] [CrossRef]

- Li, H.; Liu, D.; Song, Y.; Yan, Y.; Guo, N.; Feng, J. Microstructure and mechanical properties of underwater wet welded high-carbon-equivalent steel Q460 using austenitic consumables. J. Mater. Process. Technol. 2017, 249, 149–157. [Google Scholar] [CrossRef]

- Talaş, Ş. The assessment of carbon equivalent formulas in predicting the properties of steel weld metals. Mater. Des. 2010, 31, 2649–2653. [Google Scholar] [CrossRef]

- Luo, J.; Xiang, J.; Liu, D.; Li, F.; Xue, K. Radial friction welding interface between brass and high carbon steel. J. Mater. Process. Technol. 2012, 212, 385–392. [Google Scholar] [CrossRef]

- Sahin, M. Joining with friction welding of high-speed steel and medium-carbon steel. J. Mater. Process. Technol. 2005, 168, 202–210. [Google Scholar] [CrossRef]

- Manvatkar, V.; De, A.; Svensson, L.-E.; DebRoy, T. Cooling rates and peak temperatures during friction stir welding of a high-carbon steel. Scr. Mater. 2015, 94, 36–39. [Google Scholar] [CrossRef]

- Khodir, S.A.; Morisada, Y.; Ueji, R.; Fujii, H. Microstructures and mechanical properties evolution during friction stir welding of SK4 high carbon steel alloy. Mater. Sci. Eng. A 2012, 558, 572–578. [Google Scholar] [CrossRef]

- Choi, D.-H.; Lee, C.-Y.; Ahn, B.-W.; Choi, J.-H.; Yeon, Y.-M.; Song, K.; Hong, S.-G.; Lee, W.-B.; Kang, K.-B.; Jung, S.-B. Hybrid Friction Stir Welding of High-carbon Steel. J. Mater. Sci. Technol. 2011, 27, 127–130. [Google Scholar] [CrossRef]

- Ascari, A.; Fortunato, A. Nanosecond pulsed laser welding of high carbon steels. Opt. Laser Technol. 2014, 56, 25–34. [Google Scholar] [CrossRef]

- Hesse, O.; Liefeith, J.; Kunert, M.; Kapustyan, A.; Brykov, M.; Efremenko, V. Bainite in steels with high resistance against abrasive wear [Bainit in Stählen mit hohem Widerstand gegen Abrasivverschleiß]. Tribol. Schmier. 2016, 63, 5–13. [Google Scholar]

- Efremenko, V.G.; Hesse, O.; Friedrich, T.; Kunert, M.; Brykov, M.N.; Shimizu, K.; Zurnadzhy, V.I.; Šuchmann, P. Two-body abrasion resistance of high-carbon high-silicon steel: Metastable austenite vs nanostructured bainite. Wear 2019, 418–419, 24–35. [Google Scholar] [CrossRef]

- Handbuch der Sonderstahlkunde. Von Ed. Houdremont. 3. Aufl., unter Mitarbeit von H.-J. Wiester. Bd. 1; Springer, Berlin u. Verlag Stahleisen: Düsseldorf, Germany, 1956; p. 874 S. [CrossRef]

- Kalinin, Y.; Brykov, M.; Petryshynets, I.; Efremenko, V.; Hesse, O.; Kunert, M.; Andrushchenko, M.; Osipov, M.; Berezhnyy, S.; Bykovskiy, O. Structure of high-carbon steel after welding with rapid cooling. Acta Metall. Slovaca 2019, 25, 114–122. [Google Scholar] [CrossRef]

- Hamatani, H.; Miyazaki, Y.; Otani, T.; Ohkita, S. Minimization of heat-affected zone size in welded ultra-fine grained steel under cooling by liquid nitrogen during laser welding. Mater. Sci. Eng. A 2006, 426, 21–30. [Google Scholar] [CrossRef]

- Jellinghaus, W. Anregung der Zwischenstufen-Umwandlung des Stahles durch kleine Mengen von α-Eisen. Arch. Eisenhüttenwes. 1952, 23, 459–470. [Google Scholar] [CrossRef]

- Goodenow, R.H.; Barkalow, R.H.; Hehemann, R.F. Bainite transformations in hypoeutectoid steels. In Physical Properties of Martensite and Bainite, Special Report 93; Iron and Steel Institute: London, UK, 1969; pp. 135–141. [Google Scholar]

- Toji, Y.; Matsuda, H.; Raabe, D. Effect of Si on the acceleration of bainite transformation by pre-existing martensite. Acta Mater. 2016, 116, 250–262. [Google Scholar] [CrossRef]

- Zurnadzhy, V.I.; Efremenko, V.G.; Petryshynets, I.; Shimizu, K.; Brykov, M.N.; Kushchenko, I.V.; Kudin, V.V. Mechanical properties of carbide-free lower bainite in complex-alloyed constructional steel: Effect of bainitizing treatment parameters. Kov. Mater. 2020, 58, 129–140. [Google Scholar] [CrossRef]

- Zurnadzhy, V.I.; Efremenko, V.G.; Wu, K.M.; Petryshynets, I.; Shimizu, K.; Zusin, A.M.; Brykov, M.N.; Andilakhai, V.A. Tailoring strength/ductility combination in 2.5 wt% Si-alloyed middle carbon steel produced by the two-step Q-P treatment with a prolonged partitioning stage. Mater. Sci. Eng. A 2020, 791, 139721. [Google Scholar] [CrossRef]

- Zurnadzhy, V.I.; Efremenko, V.G.; Brykov, M.N.; Gavrilova, V.G.; Tsvetkova, E.V. Volumetric changes at heating in steel 60Si2CrV subjected to Q&P treatment. Izv. Vyss. Uchebnykh Zaved. Chernaya Metall. 2019, 62, 42–48. [Google Scholar] [CrossRef]

- Forsström, D.; Jonsén, P. Calibration and validation of a large scale abrasive wear model by coupling DEM-FEM: Local failure prediction from abrasive wear of tipper bodies during unloading of granular material. Eng. Fail. Anal. 2016, 66, 274–283. [Google Scholar] [CrossRef]

- Zurnadzhy, V.I.; Efremenko, V.G.; Brykov, M.N.; Petryshynets, I.; Pastukhova, T.V.; Kussa, R.A. The Metastability of Retained Austenite in Multiphase Steel during Abrasive Wear. J. Frict. Wear 2020, 41, 119–124. [Google Scholar] [CrossRef]

- Malinov, L.S.; Malysheva, I.E.; Klimov, E.S.; Kukhar, V.V.; Balalayeva, E.Y. Effect of Particular Combinations of Quenching, Tempering and Carburization on Abrasive Wear of Low-Carbon Manganese Steels with Metastable Austenite. Mater. Sci. Forum 2019, 945, 574–578. [Google Scholar] [CrossRef]

- Malinov, L.S.; Malinov, V.L.; Burova, D.V. Impact of Metastable Austenite on the Wear Resistance of Tool Steel. J. Frict. Wear 2018, 39, 349–353. [Google Scholar] [CrossRef]

- Šebek, M.; Falat, L.; Orečný, M.; Petryshynets, I.; Kováč, F.; Černík, M. Abrasive wear resistance of modified X37CrMoV5-1 hot work tool steel after conventional and laser heat treatment. IJMR 2018, 109, 460–468. [Google Scholar] [CrossRef]

- Koval’, A.D.; Brykov, M.N. Abrasive wear of ferricarbonic alloys during frictional heating. J. Frict. Wear 2010, 31, 228–233. [Google Scholar] [CrossRef]

- Siepak, J. The influence of contact stress on the wear of a carburized steel case with a high content of retained austenite. Wear 1982, 80, 301–305. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Han, J.; Ping, D.; Zhao, X. Microstructure of ultrahigh carbon martensite. Progress Nat. Sci. Mater. Int. 2018, 28, 749–753. [Google Scholar] [CrossRef]

| Sample # | Maximal Load, N | UTS, N/mm2 | Location of Damage |

|---|---|---|---|

| 1 | 32,634 | 236 | HAZ of steel 120Mn3Si2 |

| 2 | 25,186 | 195 | |

| 3 | 31,948 | 231 | |

| 4 | 20,972 | 152 | |

| 5 | 31,360 | 232 | |

| 6 | 22,638 | 174 | |

| 7 | 37,730 | 290 | |

| 8 | 21,560 | 161 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brykov, M.N.; Petryshynets, I.; Džupon, M.; Kalinin, Y.A.; Efremenko, V.G.; Makarenko, N.A.; Pimenov, D.Y.; Kováč, F. Microstructure and Properties of Heat Affected Zone in High-Carbon Steel after Welding with Fast Cooling in Water. Materials 2020, 13, 5059. https://doi.org/10.3390/ma13225059

Brykov MN, Petryshynets I, Džupon M, Kalinin YA, Efremenko VG, Makarenko NA, Pimenov DY, Kováč F. Microstructure and Properties of Heat Affected Zone in High-Carbon Steel after Welding with Fast Cooling in Water. Materials. 2020; 13(22):5059. https://doi.org/10.3390/ma13225059

Chicago/Turabian StyleBrykov, Michail Nikolaevich, Ivan Petryshynets, Miroslav Džupon, Yuriy Anatolievich Kalinin, Vasily Georgievich Efremenko, Natalia Alekseevna Makarenko, Danil Yurievich Pimenov, and František Kováč. 2020. "Microstructure and Properties of Heat Affected Zone in High-Carbon Steel after Welding with Fast Cooling in Water" Materials 13, no. 22: 5059. https://doi.org/10.3390/ma13225059

APA StyleBrykov, M. N., Petryshynets, I., Džupon, M., Kalinin, Y. A., Efremenko, V. G., Makarenko, N. A., Pimenov, D. Y., & Kováč, F. (2020). Microstructure and Properties of Heat Affected Zone in High-Carbon Steel after Welding with Fast Cooling in Water. Materials, 13(22), 5059. https://doi.org/10.3390/ma13225059