Surface Activation of Polylactic Acid-Based Wood-Plastic Composite by Atmospheric Pressure Plasma Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Plasma Treatment

2.3. Analysis

2.3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

2.3.2. X-ray Photoelectron Spectroscopy (XPS)

2.3.3. Contact Angle

2.3.4. Laser Scanning Microscopy (LSM)

2.3.5. Paint Adhesion/Pull-Off Strength/Cross-Cut Test

2.3.6. Statistical Analysis

3. Results

3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

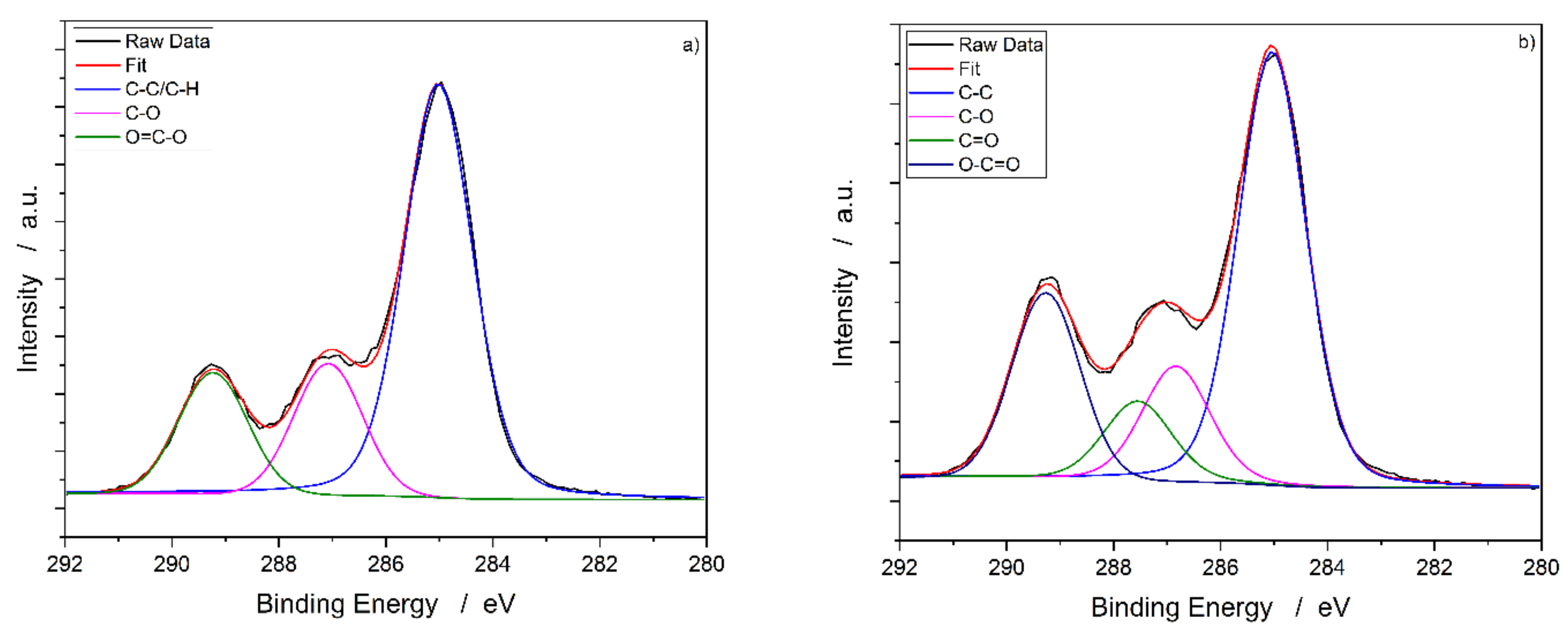

3.2. X-ray Photoelectron Spectroscopy (XPS)

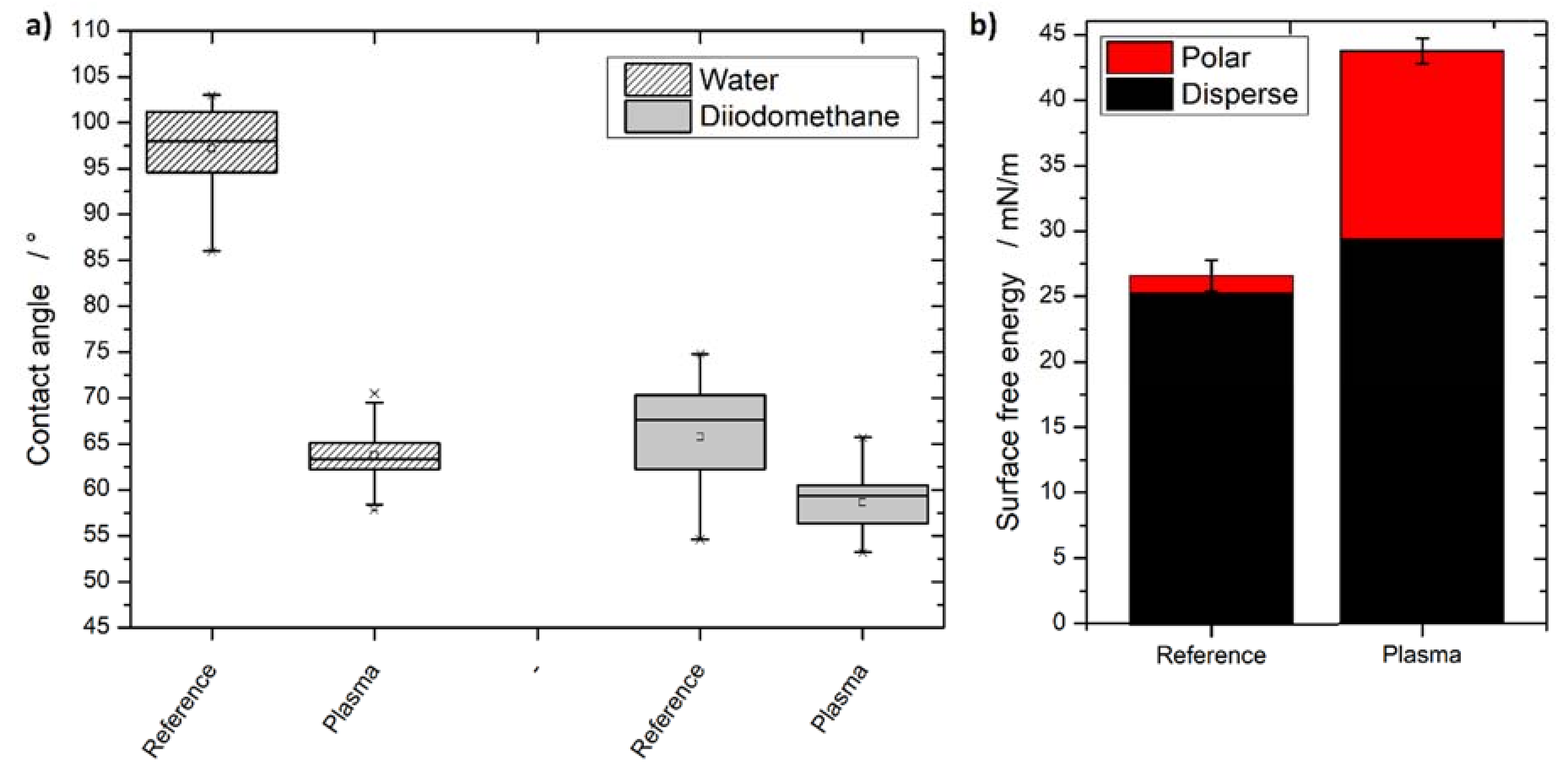

3.3. Contact Angle

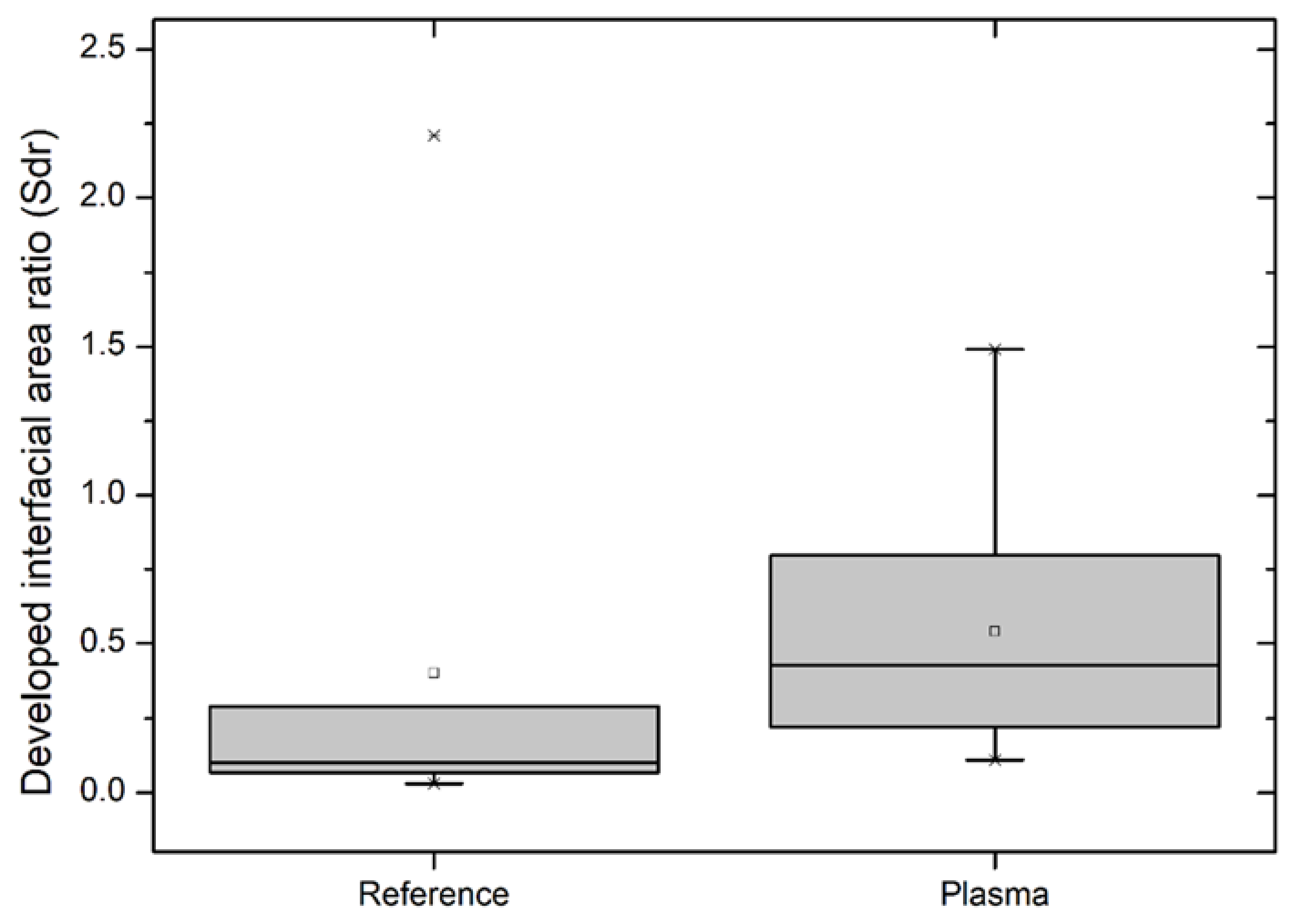

3.4. Laser Scanning Microscopy (LSM)

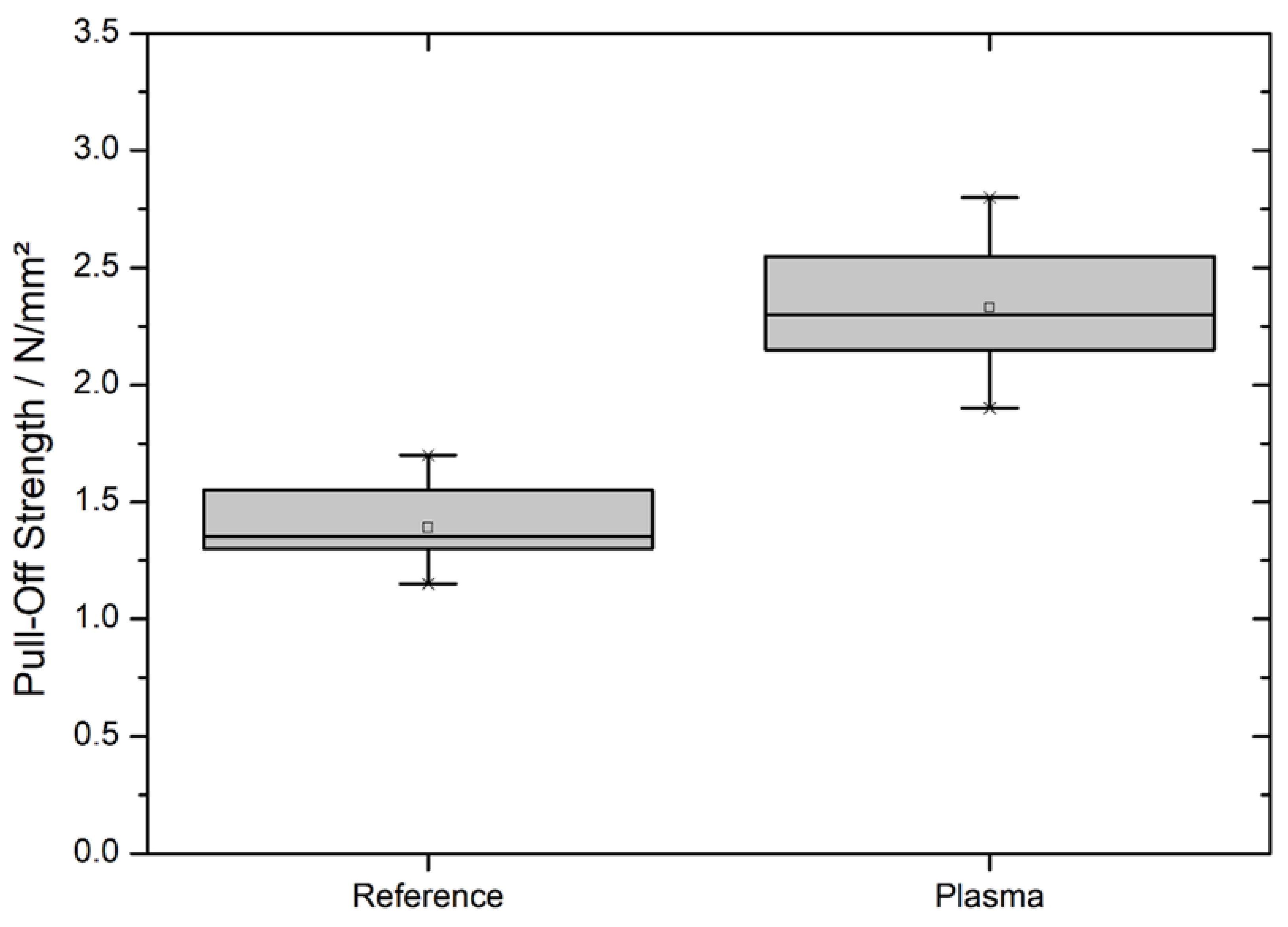

3.5. Paint Adhesion/Pull-Off Strength/Cross-Cut Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Device | Measured Quantity | Range | Accuracy |

|---|---|---|---|

| Perkin Elmer Frontier | 5 | 8300–350 cm−1 | 0.4 cm−1 |

| PHI 5000 VersaProbe II | 3 | - | 0.6 eV |

| Krüss G10 | 10 | 0–180° | 0.1° |

| KEYENCE VK-X100 | 5 | Area (100× magnification lens) 135 × 101 µm2 | Height (z-axis): 20 nm Width (x&y-axis): 30 nm |

| PosiTest AT-P | 3 | 0–12 N/mm2 | 0.1 N/mm2 |

References

- Wood Plastic Composite (WPC) Market—Global Trends & Segment Forecast to 2024—Bio-Based News. Available online: http://news.bio-based.eu/wood-plastic-composite-wpc-market-global-trends-segment-forecast-to-2024/ (accessed on 28 August 2020).

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Feifel, S.; Stübs, O.; Seibert, K.; Hartl, J. Comparing wood–polymer composites with solid wood: The case of sustainability of terrace flooring. Eur. J. Wood Prod. 2015, 73, 829–836. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Sauerbier, P.; Militz, H.; Mai, C. The effect of fibreboard (MDF) disintegration technique on wood polymer composites (WPC) produced with recovered wood particles. Compos. Part A Appl. Sci. Manuf. 2019, 118, 312–316. [Google Scholar] [CrossRef]

- Krause, K.C.; Sauerbier, P.; Koddenberg, T.; Krause, A. Utilization of Recycled Material Sources for Wood-Polypropylene Composites: Effect on Internal Composite Structure, Particle Characteristics and Physico-Mechanical Properties. Fibers 2018, 6, 86. [Google Scholar] [CrossRef]

- Sobczak, L.; Lang, R.W.; Haider, A. Polypropylene composites with natural fibers and wood—General mechanical property profiles. Compos. Sci. Technol. 2012, 72, 550–557. [Google Scholar] [CrossRef]

- Carus, M.; Partanen, A. Bioverbundwerkstoffe—Naturfaserverstärkte Kunststoffe (NFK) und Holz-Polymer-Werkstoffe (WPC). Fachagentur Nachwachsende Rohstoffe. 2020. Available online: https://mediathek.fnr.de/bioverbundwerkstoffe.html (accessed on 8 August 2020).

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Lunt, J. Large-scale production, properties and commercial applications of polylactic acid polymers. Polym. Degrad. Stab. 1998, 59, 145–152. [Google Scholar] [CrossRef]

- Filaments.directory Releases Results of 2018 3D Printing Filament Survey. Available online: https://3dprint.com/210552/filaments-directory-2018-survey/ (accessed on 28 August 2020).

- Sauerbier, P.; Anderson, J.; Gardner, D.J. Surface Preparation and Treatment for Large-Scale 3D-Printed Composite Tooling Coating Adhesion. Coatings 2018, 8, 457. [Google Scholar] [CrossRef]

- Strobel, M.; Lyons, C.S.; Mittal, K.L. (Eds.) Plasma Surface Modification of Polymers: Relevance to Adhesion; VSP: Utrecht, The Netherlands, 1994; ISBN 978-90-6764-164-7. [Google Scholar]

- Altgen, D.; Bellmann, M.; Wascher, R.; Viöl, W.; Mai, C. Enhancing mechanical properties of particleboards using plasma treated wood particles. Eur. J. Wood Wood Prod. 2015, 73, 219–223. [Google Scholar] [CrossRef]

- Wascher, R.; Kühn, C.; Avramidis, G.; Bicke, S.; Militz, H.; Ohms, G.; Viöl, W. Plywood made from plasma-treated veneers: Melamine uptake, dimensional stability, and mechanical properties. J. Wood Sci. 2017, 63, 338–349. [Google Scholar] [CrossRef]

- Oporto, G.S.; Gardner, D.J.; Bernhardt, G.; Neivandt, D.J. Forced Air Plasma Treatment (FAPT) of Hybrid Wood Plastic Composite (WPC)—Fiber Reinforced Plastic (FRP) Surfaces. Compo. Interfaces 2009, 16, 847–867. [Google Scholar] [CrossRef]

- Hünnekens, B.; Krause, A.; Militz, H.; Viöl, W. Hydrophobic recovery of atmospheric pressure plasma treated surfaces of Wood-Polymer Composites (WPC). Eur. J. Wood Wood Prod. 2017, 75, 761–766. [Google Scholar] [CrossRef]

- Product Data Sheet WPC BIO PLA H60. Available online: https://www.jeluplast.com/wp-content/uploads/2013/09/WPC-BIO-PLA-H60-500-14.pdf (accessed on 25 August 2020).

- Ten Bosch, L.; Pfohl, K.; Avramidis, G.; Wieneke, S.; Viöl, W.; Karlovsky, P. Plasma-Based Degradation of Mycotoxins Produced by Fusarium, Aspergillus and Alternaria Species. Toxins 2017, 9, 97. [Google Scholar] [CrossRef] [PubMed]

- Owens, Wendt, Rabel and Kaelble (OWRK) Method. Available online: https://www.kruss-scientific.com/services/education-theory/glossary/owens-wendt-rabel-and-kaelble-owrk-method/ (accessed on 13 July 2018).

- European Committee for Standardization. DIN EN ISO 25178-2:2012-09 Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters (ISO 25178-2:2012); European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- ASTM International. ASTM D4541-02 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- European Committee for Standardization. DIN EN ISO 4624:2016-08 Paints and Varnishes—Pull-off Test for Adhesion (ISO 4624:2016); European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- European Committee for Standardization. DIN EN ISO 2409:2013-06 Paints and Varnishes—Cross-Cut Test (ISO 2409:2013); European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- Beamson, G.; Briggs, D. High Resolution XPS of Organic Polymers: The Scienta ESCA300 Database; Wiley: Chichester, UK; New York, NY, USA, 1992; ISBN 978-0-471-93592-6. [Google Scholar]

- Zhao, Y.; Fina, A.; Venturello, A.; Geobaldo, F. Effects of gas atmospheres on poly(lactic acid) film in acrylic acid plasma treatment. Appl. Surf. Sci. 2013, 283, 181–187. [Google Scholar] [CrossRef]

- Kim, M.C.; Masuoka, T. Degradation properties of PLA and PHBV films treated with CO2-plasma. React. Funct. Polym. 2009, 69, 287–292. [Google Scholar] [CrossRef]

- Yumitori, S. Correlation of C1s chemical state intensities with the O1s intensity in the XPS analysis of anodically oxidized glass-like carbon samples. J. Mater. Sci. 2000, 35, 139–146. [Google Scholar] [CrossRef]

- Molina, R.; Espinós, J.P.; Yubero, F.; Erra, P.; González-Elipe, A.R. XPS analysis of down stream plasma treated wool: Influence of the nature of the gas on the surface modification of wool. Appl. Surf. Sci. 2005, 252, 1417–1429. [Google Scholar] [CrossRef]

- Renner, G.; Schmidt, T.C.; Schram, J. Characterization and Quantification of Microplastics by Infrared Spectroscopy. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2017; Volume 75, pp. 67–118. ISBN 978-0-444-63898-4. [Google Scholar]

- Liston, E.M. Plasma Treatment for Improved Bonding: A Review. J. Adhes. 1989, 30, 199–218. [Google Scholar] [CrossRef]

- X-Ray Photoelectron Spectroscopy (XPS) Surface Analysis Technique. Available online: https://www.phi.com/surface-analysis-techniques/xps-esca.html (accessed on 27 August 2020).

- Vergne, C.; Buchheit, O.; Eddoumy, F.; Sorrenti, E.; Di Martino, J.; Ruch, D. Modifications of the Polylactic Acid Surface Properties by DBD Plasma Treatment at Atmospheric Pressure. J. Eng. Mater. Technol. 2011, 133, 030903. [Google Scholar] [CrossRef]

- Sauerbier, P.; Köhler, R.; Renner, G.; Militz, H. Plasma Treatment of Polypropylene-Based Wood–Plastic Composites (WPC): Influences of Working Gas. Polymers 2020, 12, 1933. [Google Scholar] [CrossRef] [PubMed]

- Neděla, O.; Slepička, P.; Švorčík, V. Surface Modification of Polymer Substrates for Biomedical Applications. Materials 2017, 10, 1115. [Google Scholar] [CrossRef] [PubMed]

- Paragkumar, N.T.; Edith, D.; Six, J.-L. Surface characteristics of PLA and PLGA films. Appl. Surf. Sci. 2006, 253, 2758–2764. [Google Scholar] [CrossRef]

- Busscher, H.J.; Van, A.W.J.; Bobr, P.D.; Jono, H.P.D.; Arends, J. The effect of surface roughenlng of polymers on measured contact angles of liquids. Colloid Surf. 1984, 319–331. [Google Scholar] [CrossRef]

- Petrie, E.M. Handbook of Adhesives and Sealants. In McGraw-Hill Handbooks, 2nd ed.; McGraw-Hill: New York, NY, USA, 2007; ISBN 978-0-07-147916-5. [Google Scholar]

| Specimen | C–C/C–H/at% | C–O/at% | C=O/at% | O–C=O/at% |

|---|---|---|---|---|

| Reference | 64.5 | 18.5 | - | 17 |

| Plasma treated | 50.4 | 16.2 | 10 | 23.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sauerbier, P.; Köhler, R.; Renner, G.; Militz, H. Surface Activation of Polylactic Acid-Based Wood-Plastic Composite by Atmospheric Pressure Plasma Treatment. Materials 2020, 13, 4673. https://doi.org/10.3390/ma13204673

Sauerbier P, Köhler R, Renner G, Militz H. Surface Activation of Polylactic Acid-Based Wood-Plastic Composite by Atmospheric Pressure Plasma Treatment. Materials. 2020; 13(20):4673. https://doi.org/10.3390/ma13204673

Chicago/Turabian StyleSauerbier, Philipp, Robert Köhler, Gerrit Renner, and Holger Militz. 2020. "Surface Activation of Polylactic Acid-Based Wood-Plastic Composite by Atmospheric Pressure Plasma Treatment" Materials 13, no. 20: 4673. https://doi.org/10.3390/ma13204673

APA StyleSauerbier, P., Köhler, R., Renner, G., & Militz, H. (2020). Surface Activation of Polylactic Acid-Based Wood-Plastic Composite by Atmospheric Pressure Plasma Treatment. Materials, 13(20), 4673. https://doi.org/10.3390/ma13204673