Effect of Fibers on Durability of Concrete: A Practical Review

Abstract

1. Introduction

2. Deterioration Processes Affecting Fiber Reinforced Concrete

2.1. Fiber Reinforced Concrete Subjected to Chlorides

2.2. Fiber Reinforced Concrete Subjected to Carbonation

2.3. Fiber Reinforced Concrete Subjected to Alkali-Silica Reaction (ASR)

2.4. Fiber Reinforced Concrete Exposed to High Temperature

2.5. Fiber Reinforced Concrete Exposed to Freeze/Thaw Cycles

3. Remaining Service Life of FRC Infrastructures

4. Durability of Existing FRC Infrastructures

4.1. Performance of Traditional FRC Infrastructures—Ground and Suspended Slabs

4.2. Performance of Traditional FRC Infrastructures—Tunnel Linings

4.3. Infrastructure Retrofitted with FRC

5. Concluding Remarks

- A main durability enhancing feature of FRC is crack control which limits the rate at which deleterious substances such water, chlorides, and carbon dioxide ingress into structural elements, thereby prolonging the service life of the structure.

- There is evidence that also the propagation period is prolonged in R/FRC compared with RC. This applies to most dominant deterioration processes in infrastructures, which are carbonation and chloride-induced corrosion, and ASR-deterioration.

- Fibers in concrete may alter and improve resistance to other deterioration mechanisms. Corrosion induced by stray current in rail-infrastructure is reduced or prevented by the dispersed, non-interconnected fiber, compared with continuous steel bar reinforced structures. Polymeric fiber in FRC reduces of prevents explosive spalling in situations of fire, by melting and freeing up void space for expansion.

- As in RC, wide cracks in FRC or R/FRC lead to high deterioration rates. A typical threshold crack width is 0.1 mm. Crack widths in excess expose crack surfaces to ingress and subsequent high deterioration rates. Apart from low ingress and deterioration rates for fine cracks, self-healing of cracks up to this threshold may occur, further reducing deterioration processes.

- It is possible and essential to combine improved durability of FRC with enhanced mechanical integrity. Structural systems like link/connecting slabs on bridge infrastructure are excellent examples of efficient use of customized FRC design, combining sufficient deformability and crack control by fiber bridging toward medium- and long-term cost-efficiency by avoiding regular maintenance and repair interventions and safety in seismic events.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ASR | Alkali-silica reaction |

| CDF | Capillary suction, Internal damage and Freeze-thaw test |

| ECC/SHCC | Engineered, strain hardening cementitious materials |

| EDX | Energy dispersive x-ray spectroscopy |

| FRC | Fiber reinforced concrete |

| GF | Glass fiber |

| HMPE | High modulus polyethylene |

| HPFRC | High performance fiber-reinforced concrete |

| HPFRCC | High-performance fiber-reinforced cementitious composite |

| PE | Polyethylene |

| PP | Polypropylene |

| PVA | Polyvinyl alcohol |

| RCPT | Rapid chloride migration test |

| SEM | Scanning electron microscopy |

| UHPFRC | Ultra-high performance fiber-reinforced concrete |

References

- Li, V.C. From micromechanics to structural engineering. Doboku Gakkai Ronbunshu 1993, 1993, 1–12. [Google Scholar] [CrossRef]

- Van Zijl, G.P.; Slowik, V. A Framework for Durability Design with Strain-Hardening Cement-Based Composites (SHCC): State-of-the-Art Report of the RILEM Technical Committee 240-FDS; Springer: Berlin/Heidelberg, Germany, 2017; Volume 22. [Google Scholar]

- Van Zijl, G.P.; Wittmann, F.H. (Eds.) Durability of Strain-Hardening Fibre-Reinforced Cement-Based Composites (SHCC); Springer Science & Business Media: London, UK, 2010; Volume 4. [Google Scholar]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Brühwiler, E.; Denarié, E. Rehabilitation and strengthening of concrete structures using ultra-high performance fibre reinforced concrete. Struct. Eng. Int. 2013, 23, 450–457. [Google Scholar] [CrossRef]

- Bragov, A.; Petrov, Y.V.; Karihaloo, B.L.; Konstantinov, A.Y.; Lamzin, D.; Lomunov, A.; Smirnov, I. Dynamic strengths and toughness of an ultra high performance fibre reinforced concrete. Eng. Fract. Mech. 2013, 110, 477–488. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Alsous, G.; Muja, E.; Li, H.; Drechsler, A.; Frenzel, R.; Synytska, A.; Mechtcherine, V. Tailoring the crack-bridging behavior of strain-hardening cement-based composites (SHCC) by chemical surface modification of poly (vinyl alcohol)(PVA) fibers. Cem. Concr. Compos. 2020, 114, 103722. [Google Scholar] [CrossRef]

- Tran, N.T.; Tran, T.K.; Kim, D.J. High rate response of ultra-high-performance fiber-reinforced concretes under direct tension. Cem. Concr. Res. 2015, 69, 72–87. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Shin, H.-O.; Yang, J.-M.; Yoon, Y.-S. Material and bond properties of ultra high performance fiber reinforced concrete with micro steel fibers. Compos. Part B Eng. 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Buttignol, T.E.T.; Sousa, J.; Bittencourt, T.N. Ultra High-Performance Fiber-Reinforced Concrete (UHPFRC): A review of material properties and design procedures. Rev. Ibracon De Estrut. E Mater. 2017, 10, 957–971. [Google Scholar] [CrossRef]

- Li, V.C.; Horikoshi, T.; Ogawa, A.; Torigoe, S.; Saito, T. Micromechanics-based durability study of polyvinyl alcohol-engineered cementitious composite. Mater. J. 2004, 101, 242–248. [Google Scholar]

- Paul, S.C.; van Zijl, G.P. Mechanically induced cracking behaviour in fine and coarse sand strain hardening cement based composites (SHCC) at different load levels. J. Adv. Concr. Technol. 2013, 11, 301–311. [Google Scholar] [CrossRef]

- Dahake, A.; Charkha, K. Effect of steel fibers on the strength of concrete. J. Eng. Sci. Manag. Educ. 2016, 9, 45–51. [Google Scholar]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHP-FRC with low fiber contents. Mater. Struct. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, X.; He, G.; Shang, Q.; Xu, J.; Sun, Y. Mechanical properties of steel fiber-reinforced concrete by vibratory mixing technology. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Boshoff, W.P. Tensile creep of macro-synthetic fibre reinforced concrete (MSFRC) under uni-axial tensile loading. Cem. Concr. Compos. 2015, 55, 62–69. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of steel and macro-synthetic fibers on concrete properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef]

- Sorelli, L.G.; Meda, A.; Plizzari, G.A. Steel fiber concrete slabs on ground: A structural matter. Aci Struct. J. 2006, 103, 551. [Google Scholar]

- Kaur, P.; Talwar, M. Different types of Fibres used in FRC. Int. J. Adv. Res. Comput. Sci. 2017, 8, 380–383. [Google Scholar] [CrossRef]

- Torres, J.A.; Lantsoght, E.O.L. Influence of fiber content on shear capacity of fiber-reinforced concrete beams. Fibers 2019, 7, 102. [Google Scholar] [CrossRef]

- Abambres, M.; Lantsoght, E.O.L. ANN-based shear capacity of steel fiber-reinforced concrete beams without stirrups. Fibers 2019, 7, 88. [Google Scholar] [CrossRef]

- Lantsoght, E.O.L. How do steel fibers improve the shear capacity of reinforced concrete beams without stirrups? Compos. Part B Eng. 2019, 175, 107079. [Google Scholar] [CrossRef]

- Kohoutková, A.; Broukalová, I. Structural Applications of fibre reinforced concrete in the czech republic. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012001. [Google Scholar] [CrossRef]

- Luković, M.; Hordijk, D.A.; Huang, Z.; Schlangen, E. Strain hardening cementitious composite (SHCC) for crack width control in reinforced concrete beams. Heron 2019, 64, 181. [Google Scholar]

- Verbruggen, S.; Remy, O.; Wastiels, J.; Tysmans, T. Stay-in-place formwork of TRC designed as shear reinforcement for concrete beams. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Rokugo, K.; Kanda, T.; Yokota, H.; Sakata, N. Applications and recommendations of high performance fiber reinforced cement composites with multiple fine cracking (HPFRCC) in Japan. Mater. Struct. 2009, 42, 1197. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composite (ECC): Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Del Vecchio, C.; Di Ludovico, M.; Balsamo, A.; Prota, A. Seismic retrofit of real beam-column joints using fiber-reinforced cement composites. J. Struct. Eng. 2018, 144, 04018026. [Google Scholar] [CrossRef]

- Hashash, Y.M.; Hook, J.J.; Schmidt, B.; John, I.; Yao, C. Seismic design and analysis of underground structures. Tunn. Undergr. Space Technol. 2001, 16, 247–293. [Google Scholar] [CrossRef]

- Porco, F.; Ruggieri, S.; Uva, G. Seismic assessment of irregular existing building: Appraisal of the influence of compressive strength variation by means of nonlinear conventional and multimodal static analysis. Ing. Sismica 2018, 35, 64–86. [Google Scholar]

- Ruggieri, S.; Perrone, D.; Leone, M.; Uva, G.; Aiello, M.A. A prioritization RVS methodology for the seismic risk assessment of RC school buildings. Int. J. Disaster Risk Reduct. 2020, 51, 101807. [Google Scholar] [CrossRef]

- Boyd, A.; Skalny, J. Environmental deterioration of concrete. Environ. Deterior. Mater. 2007, 28, 143–184. [Google Scholar]

- Örnek, C.; Leygraf, C.; Pan, J. Passive film characterisation of duplex stainless steel using scanning Kelvin probe force microscopy in combination with electrochemical measurements. Npj Mater. Degrad. 2019, 3, 1–8. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, O. Critical chloride content in reinforced concrete- A review. Cem. Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Ann, K.Y.; Song, H.-W. Chloride threshold level for corrosion of steel in concrete. Corros. Sci. 2007, 49, 4113–4133. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M. Carbonation of cement paste: Understanding, challenges, and opportunities. Constr. Build. Mater. 2016, 117, 285–301. [Google Scholar] [CrossRef]

- Stefanoni, M.; Angst, U.; Elsener, B. Corrosion rate of carbon steel in carbonated concrete—A critical review. Cem. Concr. Res. 2018, 103, 35–48. [Google Scholar] [CrossRef]

- Bardal, E. Corrosion and Protection; Springer Science & Business Media: London, UK, 2007. [Google Scholar]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R. Corrosion of Steel in Concrete; Wiley Online Library: Hoboken, NJ, USA, 2013; Volume 392. [Google Scholar]

- Küter, A. Management of Reinforcement corrosion: A Thermodynamic Approach; Technical University of Denmark: Lyngby, Denmark, 2009. [Google Scholar]

- Šavija, B. Experimental and Numerical Investigation of Chloride Ingress in Cracked Concrete; Delft University of Technology: Delft, The Netherlands, 2014. [Google Scholar]

- Blagojević, A. The Influence of Cracks on the Durability and Service Life of Reinforced Concrete Structures in relation to Chloride-Induced Corrosion: A Look from a Different Perspective; Delft Univeristy of Technology: Delft, The Netherlands, 2016. [Google Scholar]

- Vasanelli, E.; Micelli, F.; Aiello, M.A.; Plizzari, G. Long term behavior of FRC flexural beams under sustained load. Eng. Struct. 2013, 56, 1858–1867. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kojima, Y. Effect of fine crack width and water cement ratio of SHCC on chloride ingress and rebar corrosion. Cem. Concr. Compos. 2017, 80, 235–244. [Google Scholar] [CrossRef]

- Miyazato, S.; Hiraishi, Y. Durability against steel corrosion of HPFRCC with bending cracks. J. Adv. Concr. Technol. 2013, 11, 135–143. [Google Scholar] [CrossRef]

- Micelli, F.; Candido, L.; Vasanelli, E.; Aiello, M.A.; Plizzari, G. Effects of short fibers on the long-term behavior of RC/FRC beams aged under service loading. Appl. Sci. 2019, 9, 2540. [Google Scholar] [CrossRef]

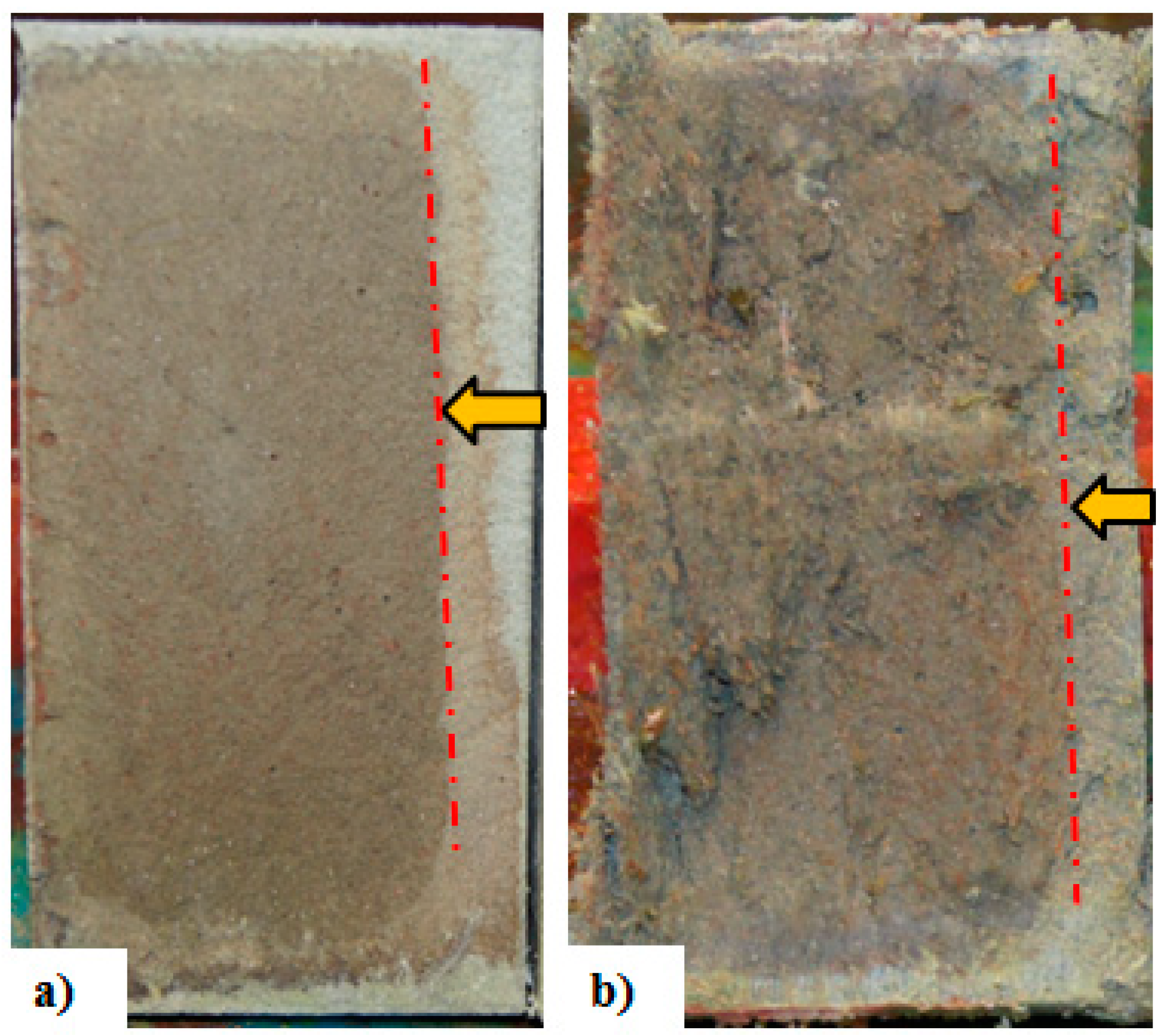

- Chen, E.; Berrocal, C.G.; Löfgren, I.; Lundgren, K. Correlation between concrete cracks and corrosion characteristics of steel reinforcement in pre-cracked plain and fibre-reinforced concrete beams. Mater. Struct. 2020, 53, 1–22. [Google Scholar] [CrossRef]

- Yuan, Q.; Shi, C.; De Schutter, G.; Audenaert, K.; Deng, D. Chloride binding of cement-based materials subjected to external chloride environment—A review. Constr. Build. Mater. 2009, 23, 1–13. [Google Scholar] [CrossRef]

- Glass, G.; Buenfeld, N. The influence of chloride binding on the chloride induced corrosion risk in reinforced concrete. Corros. Sci. 2000, 42, 329–344. [Google Scholar] [CrossRef]

- Glass, G.; Hassanein, N.; Buenfeld, N. Neural network modelling of chloride binding. Mag. Concr. Res. 1997, 49, 323–335. [Google Scholar] [CrossRef]

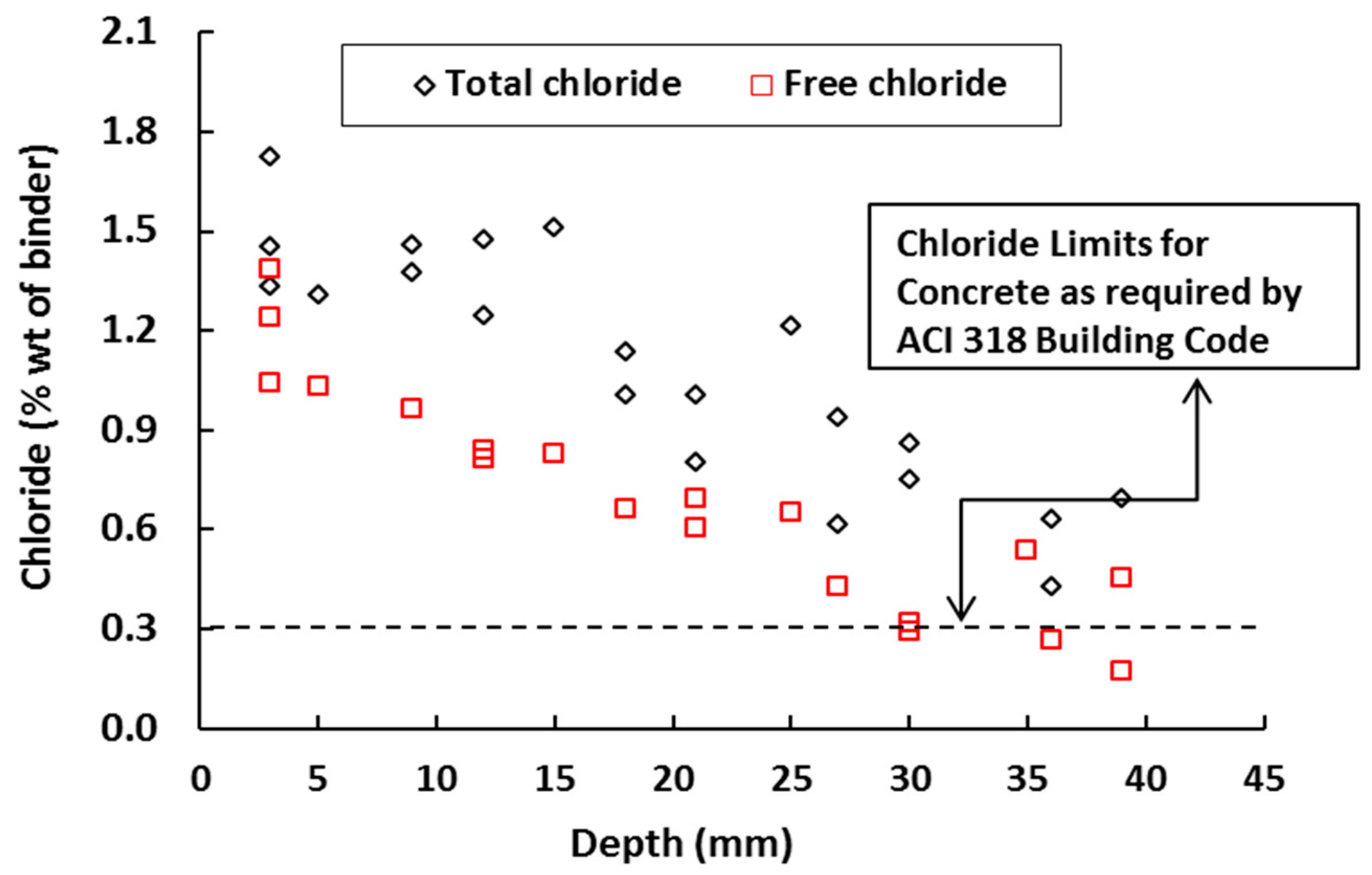

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Chloride ion penetration in reinforced concrete and steel fiber-reinforced concrete precast tunnel lining segments. Mater. J. 2014, 111, 613–622. [Google Scholar]

- Corinaldesi, V.; Moriconi, G. Mechanical and thermal evaluation of ultra high performance fiber reinforced concretes for engineering applications. Constr. Build. Mater. 2012, 26, 289–294. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Hosseini, S.A.S.; Pacheco, J.; Schlangen, E. Corrosion induced cover cracking studied by X-ray computed tomography, nanoindentation, and energy dispersive X-ray spectrometry (EDS). Mater. Struct. 2015, 48, 2043–2062. [Google Scholar] [CrossRef]

- Luković, M.; Šavija, B.; Ye, G.; Schlangen, E.; Van Breugel, K. Failure modes in concrete repair systems due to ongoing corrosion. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Paewchompoo, N.; Yodsudjai, W.; Chindaprasirt, P. Corrosion-Induced Cracking Time in Steel Fiber-Reinforced Concrete: Experiment and Finite Element Method. ACI Mater. J. 2020, 117, 3–12. [Google Scholar]

- Michel, A.; Solgaard, A.O.S.; Pease, B.J.; Geiker, M.R.; Stang, H.; Olesen, J.F. Experimental investigation of the relation between damage at the concrete-steel interface and initiation of reinforcement corrosion in plain and fibre reinforced concrete. Corros. Sci. 2013, 77, 308–321. [Google Scholar] [CrossRef]

- Bentur, A.; Diamond, S.; Mindess, S. The microstructure of the steel fibre-cement interface. J. Mater. Sci. 1985, 20, 3610–3620. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.; Camões, A.; Alves, A.C.; Rocha, L. Corrosion effects on pullout behavior of hooked steel fibers in self-compacting concrete. Cem. Concr. Res. 2016, 79, 112–122. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P. Crack formation and chloride induced corrosion in reinforced strain hardening cement-based composite (R/SHCC). J. Adv. Concr. Technol. 2014, 12, 340–351. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.; Babafemi, A.J.; Tan, M.J. Chloride ingress in cracked and uncracked SHCC under cyclic wetting-drying exposure. Constr. Build. Mater. 2016, 114, 232–240. [Google Scholar] [CrossRef]

- ACI 318-08. In Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008.

- Paul, S.C.; van Zijl, G.P. Chloride-induced corrosion modelling of cracked reinforced SHCC. Arch. Civ. Mech. Eng. 2016, 16, 734–742. [Google Scholar] [CrossRef]

- Kobayashi, K.; Iizuka, T.; Kurachi, H.; Rokugo, K. Corrosion protection performance of high performance fiber reinforced cement composites as a repair material. Cem. Concr. Compos. 2010, 32, 411–420. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Mihashi, H.; Kobayakawa, A. Corrosion durability of reinforcing steel in cracked high-performance fiber-reinforced cementitious composite beams. J. Mater. Civ. Eng. 2015, 27, 04014228. [Google Scholar] [CrossRef]

- Hansen, E.J.D.P.; Ekman, T.; Hansen, K.K. Durability of cracked fibre reinforced concrete structures exposed to chlorides. In Proceedings of the 8th International Conference on the Durability of Building Materials and Components, Vancouver, BC, Canada, 30 May–3 June 1999; pp. 280–289. [Google Scholar]

- Bernard, E. Durability of cracked fibre reinforced shotcrete. Shotcrete More Eng. Dev. Taylor Fr. Lond. Es Bernard 2004, 59–66. [Google Scholar] [CrossRef]

- Granju, J.-L.; Balouch, S.U. Corrosion of steel fibre reinforced concrete from the cracks. Cem. Concr. Res. 2005, 35, 572–577. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- Schlangen, E.; Ter Heide, N.; Van Breugel, K. Crack healing of early age cracks in concrete. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Berlin/Heidelberg, Germany, 2006; pp. 273–284. [Google Scholar]

- Huang, H.; Ye, G.; Damidot, D. Characterization and quantification of self-healing behaviors of microcracks due to further hydration in cement paste. Cem. Concr. Res. 2013, 52, 71–81. [Google Scholar] [CrossRef]

- Mangat, P.; Gurusamy, K. Permissible crack widths in steel fibre reinforced marine concrete. Mater. Struct. 1987, 20, 338–347. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Lundgren, K.; Löfgren, I. Experimental investigation on rebar corrosion in combination with fibres. In Proceedings of the XXII Nordic Concrete Research Symposium, Reykjavik, Iceland, 13–15 August 2014. [Google Scholar]

- Hwang, J.P.; Jung, M.S.; Kim, M.; Ann, K.Y. Corrosion risk of steel fibre in concrete. Constr. Build. Mater. 2015, 101, 239–245. [Google Scholar] [CrossRef]

- Masmoudi, A.; Bouaziz, J. Durability of steel fibres reinforcement concrete beams in chloride environment combined with inhibitor. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Mangat, P.; Gurusamy, K. Long-term properties of steel fibre reinforced marine concrete. Mater. Struct. 1987, 20, 273. [Google Scholar] [CrossRef]

- Lepech, M.; Geiker, M.R.; Michel, A. Multi-physics corrosion modeling for sustainability assessment of steel reinforced high performance fiber reinforced cementitious composites. In Proceedings of the 9th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Berkely, CA, USA, 28 May–1 June 2016. [Google Scholar]

- Mangat, P.; Molloy, B. Size Effect of Reinforcement on Corrosion Initiation. Available online: http://shura.shu.ac.uk/id/eprint/1052 (accessed on 10 October 2020).

- Berrocal, C.G.; Lundgren, K.; Löfgren, I. Influence of steel fibres on corrosion of reinforcement in concrete in chloride environments: A review. In Proceedings of the 7th International Conference Fibre Concrete, Prague, Czech, 12–13 September 2013. [Google Scholar]

- Wang, Y.; Niu, D.; Dong, Z. Experimental study on carbonation of steel fiber reinforced concrete. In Proceedings of the 4th International Conference on the Durability of Concrete Structures, West Lafayette, IN, USA, 24–26 July 2014. [Google Scholar]

- Miloud, B. Permeability and porosity characteristics of steel fiber reinforced concrete. Asian J. Civ. Eng. 2005, 6, 317–330. [Google Scholar]

- Zhang, H.; Rodriguez, C.R.; Dong, H.; Gan, Y.; Schlangen, E.; Šavija, B. Elucidating the effect of accelerated carbonation on porosity and mechanical properties of hydrated portland cement paste using X-ray tomography and advanced micromechanical testing. Micromachines 2020, 11, 471. [Google Scholar] [CrossRef] [PubMed]

- Ferrara, L.; Fratesi, R.; Signorini, S.; Sonzogni, F. Durability of steel-fibre reinforced concrete precast elements: Experiments and proposal of design recommendations. In Proceedings of the 6th international RILEM symposium on fibre-reinforced concretes BEFIB 2004, Varenna, Italy, 20–22 September 2004; pp. 567–576. [Google Scholar]

- Kaufmann, J. Durability performance of fiber reinforced shotcrete in aggressive environment. In Proceedings of the World Tunnelling Congress, Foz do Iguaçu, Brazil, 9–14 May 2014. [Google Scholar]

- Sanjuan, M.; Andrade, C.; Bentur, A. Effect of polypropylene fibre reinforced mortars on steel reinforcement corrosion induced by carbonation. Mater. Struct. 1998, 31, 343–349. [Google Scholar] [CrossRef]

- Böhni, H. Corrosion in Reinforced Concrete Structures; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion resistance of steel fibre reinforced concrete—A literature review. Cem. Concr. Res. 2018, 103, 1–20. [Google Scholar] [CrossRef]

- Schießl, P.; Raupach, M. Laboratory studies and calculations on the influence of crack width on chloride-induced corrosion of steel in concrete. Mater. J. 1997, 94, 56–61. [Google Scholar]

- Yazıcı, H. The effect of steel micro-fibers on ASR expansion and mechanical properties of mortars. Constr. Build. Mater. 2012, 30, 607–615. [Google Scholar] [CrossRef]

- Ponce, J.; Batic, O.R. Different manifestations of the alkali-silica reaction in concrete according to the reaction kinetics of the reactive aggregate. Cem. Concr. Res. 2006, 36, 1148–1156. [Google Scholar] [CrossRef]

- Baz̆ant, Z.P.; Steffens, A. Mathematical model for kinetics of alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 419–428. [Google Scholar] [CrossRef]

- Esposito, R.; Anaç, C.; Hendriks, M.A.; Çopuroğlu, O. Influence of the alkali-silica reaction on the mechanical degradation of concrete. J. Mater. Civ. Eng. 2016, 28, 04016007. [Google Scholar] [CrossRef]

- Esposito, R.; Hendriks, M.A. A multiscale micromechanical approach to model the deteriorating impact of alkali-silica reaction on concrete. Cem. Concr. Compos. 2016, 70, 139–152. [Google Scholar] [CrossRef]

- Andic, Ö.; Yardımcı, M.; Ramyar, K. Performance of carbon, polyvinylalcohol and steel based microfibers on alkali–silica reaction expansion. Constr. Build. Mater. 2008, 22, 1527–1531. [Google Scholar] [CrossRef]

- Haddad, R.H.; Smadi, M.M. Role of fibers in controlling unrestrained expansion and arresting cracking in Portland cement concrete undergoing alkali–silica reaction. Cem. Concr. Res. 2004, 34, 103–108. [Google Scholar] [CrossRef]

- Panesar, D.K.; Gautam, B.P. Triaxial expansion of plain, reinforced and fibre-reinforced asr-affected concrete. In Proceedings of the 24th Conference on Structural Mechanics in Reactor Technology (SMiRT 24), Busan, Korea, 20–25 August 2017. [Google Scholar]

- Turanli, L.; Shomglin, K.; Ostertag, C.; Monteiro, P. Reduction in alkali–silica expansion due to steel microfibers. Cem. Concr. Res. 2001, 31, 825–827. [Google Scholar] [CrossRef]

- Yi, C.; Ostertag, C. Mechanical approach in mitigating alkali-silica reaction. Cem. Concr. Res. 2005, 35, 67–75. [Google Scholar] [CrossRef]

- Touma, W.E.; Fowler, D.W.; Carrasquillo, R.L.; Folliard, K.J.; Nelson, N.R. Characterizing alkali-silica reactivity of aggregates using ASTM C 1293, ASTM C 1260, and their modifications. Transp. Res. Rec. 2001, 1757, 157–165. [Google Scholar] [CrossRef]

- Giaccio, G.; Bossio, M.; Torrijos, M.; Zerbino, R. Contribution of fiber reinforcement in concrete affected by alkali-silica reaction. Cem. Concr. Res. 2015, 67, 310–317. [Google Scholar] [CrossRef]

- Beglarigale, A.; Yazɩcɩ, H. The effect of alkali–silica reaction on steel fiber–matrix bond characteristics of cement based mortars. Constr. Build. Mater. 2013, 47, 845–860. [Google Scholar] [CrossRef]

- Hernández-Cruz, D.; Hargis, C.W.; Dominowski, J.; Radler, M.J.; Monteiro, P.J. Fiber reinforced mortar affected by alkali-silica reaction: A study by synchrotron microtomography. Cem. Concr. Compos. 2016, 68, 123–130. [Google Scholar] [CrossRef]

- Fernandes, B.; Gil, A.M.; Bolina, F.; Tutikian, B.F. Microstructure of concrete subjected to elevated temperatures: Physico-chemical changes and analysis techniques. Rev. Ibracon De Estrut. E Mater. 2017, 10, 838–863. [Google Scholar] [CrossRef]

- Xing, Z.; Beaucour, A.-L.; Hebert, R.; Noumowe, A.; Ledesert, B. Influence of the nature of aggregates on the behaviour of concrete subjected to elevated temperature. Cem. Concr. Res. 2011, 41, 392–402. [Google Scholar] [CrossRef]

- Mindeguia, J.-C.; Pimienta, P.; Carré, H.; La Borderie, C. On the influence of aggregate nature on concrete behaviour at high temperature. Eur. J. Environ. Civ. Eng. 2012, 16, 236–253. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Handoo, S.; Agarwal, S.; Agarwal, S. Physicochemical, mineralogical, and morphological characteristics of concrete exposed to elevated temperatures. Cem. Concr. Res. 2002, 32, 1009–1018. [Google Scholar] [CrossRef]

- Peng, G.-F.; Huang, Z.-S. Change in microstructure of hardened cement paste subjected to elevated temperatures. Constr. Build. Mater. 2008, 22, 593–599. [Google Scholar] [CrossRef]

- Novák, J.; Kohoutková, A. Fibre reinforced concrete exposed to elevated temperature. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kunming, China, 27–29 October 2017; p. 012045. [Google Scholar]

- Saad, M.; Abo-El-Enein, S.; Hanna, G.; Kotkata, M. Effect of temperature on physical and mechanical properties of concrete containing silica fume. Cem. Concr. Res. 1996, 26, 669–675. [Google Scholar] [CrossRef]

- Bhat, P.S.; Chang, V.; Li, M. Effect of elevated temperature on strain-hardening engineered cementitious composites. Constr. Build. Mater. 2014, 69, 370–380. [Google Scholar] [CrossRef]

- Akca, A.H.; Özyurt, N. Deterioration and recovery of FRC after high temperature exposure. Cem. Concr. Compos. 2018, 93, 260–273. [Google Scholar] [CrossRef]

- Jameran, A.; Ibrahim, I.S.; Yazan, S.H.S.; Rahim, S.N.A. Mechanical properties of steel-polypropylene fibre reinforced concrete under elevated temperature. Procedia Eng. 2015, 125, 818–824. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pomchiengpin, W.; Songpiriyakij, S. Post-crack (or post-peak) flexural response and toughness of fiber reinforced concrete after exposure to high temperature. Constr. Build. Mater. 2010, 24, 1967–1974. [Google Scholar] [CrossRef]

- Haddad, R.; Shannag, M.; Hamad, R. Repair of heat-damaged reinforced concrete T-beams using FRC jackets. Mag. Concr. Res. 2007, 59, 223–231. [Google Scholar] [CrossRef]

- Bezerra, A.; Maciel, P.S.; Corrêa, E.; Soares Junior, P.R.; Aguilar, M.T.; Cetlin, P.R. Effect of high temperature on the mechanical properties of steel fiber-reinforced concrete. Fibers 2019, 7, 100. [Google Scholar] [CrossRef]

- Setzer, M.J. Draft recommendation for test method for the freeze-thaw resistance of concrete Tests with water (CF) or with sodium chloride solution (CDF). Mater. Struct. 1995, 28, 175–182. [Google Scholar] [CrossRef]

- Bunke, N. Prüfung von Beton. Empfehlungen und Hinweise als Ergänzung zu DIN 1048. Dtsch. Aussch. Für Stahlbeton 1991. [Google Scholar] [CrossRef]

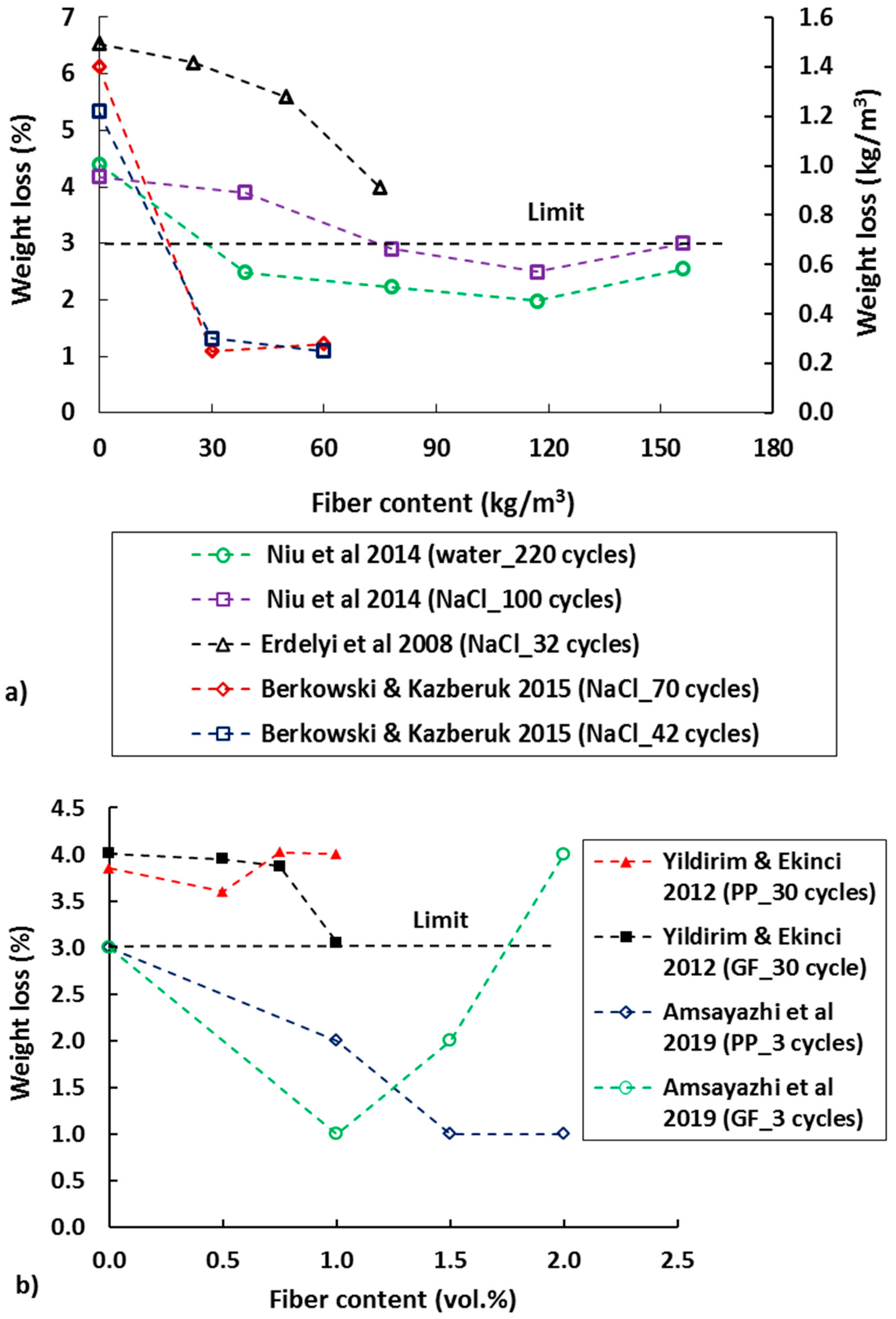

- Miao, C.; Mu, R.; Tian, Q.; Sun, W. Effect of sulfate solution on the frost resistance of concrete with and without steel fiber reinforcement. Cem. Concr. Res. 2002, 32, 31–34. [Google Scholar] [CrossRef]

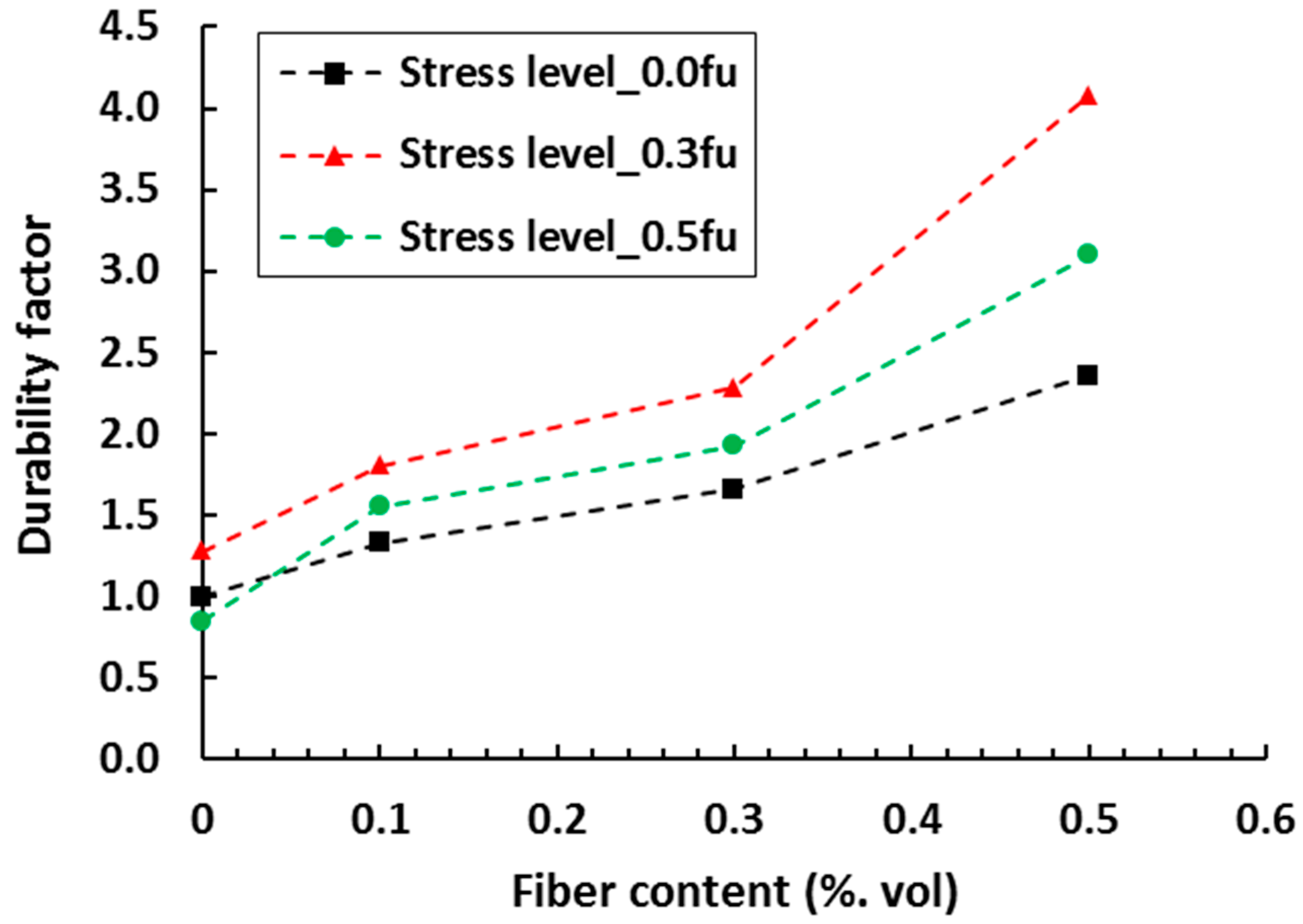

- Mu, R.; Miao, C.; Luo, X.; Sun, W. Interaction between loading, freeze–thaw cycles, and chloride salt attack of concrete with and without steel fiber reinforcement. Cem. Concr. Res. 2002, 32, 1061–1066. [Google Scholar] [CrossRef]

- Berkowski, P.; Kosior-Kazberuk, M. Effect of fiber on the concrete resistance to surface scaling due to cyclic freezing and thawing. Procedia Eng. 2015, 111, 121–127. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Ekinci, C.E. Effects on freeze-thaw durability of fibers in concrete. In Polypropylene; IntechOpen Ltd.: London, UK, 2012. [Google Scholar]

- Amsayazhi, P.; Mohan, K.S.R.; Sowmiya, R.; Kamalavani, S. Evaluation of performance of high strength fiber reinforced concrete in durability aspects. Int. J. Eng. Adv. Technol. 2009, 8, 1118–1123. [Google Scholar]

- Kopecskó, A.E.E.C.K.; Fenyvesi, A.B.O. Deterioration of steel fibre reinforced concrete by freeze-thaw and de-icing salts. Concr. Struct 2008, 9, 33–44. [Google Scholar]

- Niu, D.; Jiang, L.; Bai, M.; Miao, Y. Study of the performance of steel fiber reinforced concrete to water and salt freezing condition. Mater. Des. 2013, 44, 267–273. [Google Scholar] [CrossRef]

- Yin, L.; Yan, C.; Liu, S. Freeze-thaw durability of strain-hardening cement-based composites under combined flexural load and chloride environment. Materials 2018, 11, 1721. [Google Scholar] [CrossRef]

- Jang, S.-J.; Rokugo, K.; Park, W.-S.; Yun, H.-D. Influence of rapid freeze-thaw cycling on the mechanical properties of sustainable strain-hardening cement composite (2SHCC). Materials 2014, 7, 1422–1440. [Google Scholar] [CrossRef]

- Wang, C.; Chen, F. Durability of polypropylene fiber concrete exposed to freeze-thaw cycles with deicing salts. In Proceedings of the 2019 International Conference on Electronical, Mechanical and Materials Engineering (ICE2ME 2019), Wuhan, China, 20–21 January 2019. [Google Scholar]

- Wang, Q.; Sun, W.; Guo, L.; Gu, C.; Zong, J. Prediction of chloride ingress in steel fibre reinforced concrete under bending load. Ceram. Silikáty 2018, 62, 59–66. [Google Scholar] [CrossRef]

- Dhinakaran, G.; Gowrisankar, S.; Jeyasehar, A. Life cycle cost analysis of glass fiber reinforced polymer reinforced concrete beam. Asian J. Civ. Eng. 2016, 17, 315–323. [Google Scholar]

- Bhargava, A.; Banthia, N. Permeability of concrete with fiber reinforcement and service life predictions. Mater. Struct. 2008, 41, 363–372. [Google Scholar] [CrossRef]

- Hansen, T.C.; Jensen, H.; Johannesson, T. Chloride diffusion and corrosion initiation of steel reinforcement in fly-ash concretes. Cem. Concr. Res. 1986, 16, 782–784. [Google Scholar] [CrossRef]

- van Zijl, G.P.; Paul, S.C. A novel link of the time scale in accelerated chloride-induced corrosion test in reinforced SHCC. Constr. Build. Mater. 2018, 167, 15–19. [Google Scholar] [CrossRef]

- Huo, J.F.; Liu, D.P.; Shen, X.D.; Chu, J.J.; Song, D.T. Freeze-thaw model and service life prediction of hybrid fiber reinforced lightweight aggregate concrete. Adv. Mater. Res. 2011, 250–253, 817–821. [Google Scholar] [CrossRef]

- Purnell, P.; Cain, J.; Van Itterbeeck, P.; Lesko, J. Service life modelling of fibre composites: A unified approach. Compos. Sci. Technol. 2008, 68, 3330–3336. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Chen, S. Durability and service life prediction of GFRP bars embedded in concrete under acid environment. Nucl. Eng. Des. 2011, 241, 4095–4102. [Google Scholar] [CrossRef]

- Cusson, D.; Lounis, Z.; Daigle, L. Durability monitoring for improved service life predictions of concrete bridge decks in corrosive environments. Comput. Aided Civ. Infrastruct. Eng. 2011, 26, 524–541. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Boshoff, W.P.; Combrinck, R. Modelling the severity of plastic shrinkage cracking in concrete. Cem. Concr. Res. 2013, 48, 34–39. [Google Scholar] [CrossRef]

- Cadoni, E.; Meda, A.; Plizzari, G.A. Tensile behaviour of FRC under high strain-rate. Mater. Struct. 2009, 42, 1283–1294. [Google Scholar] [CrossRef]

- Rehacek, S.; Hunka, P.; Kolisko, J.; Kratochvile, L. Two type of impact load tests, tested on fibre reinforced concrete specimens. Procedia Eng. 2013, 65, 278–283. [Google Scholar] [CrossRef][Green Version]

- Ranade, R.; Li, V.C.; Heard, W.F.; Williams, B.A. Impact resistance of high strength-high ductility concrete. Cem. Concr. Res. 2017, 98, 24–35. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.A.; Yatim, J.B.M. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Constr. Build. Mater. 2017, 143, 147–157. [Google Scholar] [CrossRef]

- Hoff, G.C. Fire resistance of high-strength concretes for offshore concrete platforms. Spec. Publ. 1996, 163, 53–88. [Google Scholar]

- Maluk, C.; Bisby, L.; Terrasi, G.P. Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Eng. Struct. 2017, 141, 584–595. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Destree, X.; Mandl, J. Steel fibre only reinforced concrete in free suspended elevated slabs: Case studies, design assisted by testing route, comparison to the latest SFRC standard documents. In Tailor Made Concrete Structures; Walraven, J.C., Stoelhorst, D., Eds.; CRC press, Taylor & Francis Group: London, UK, 2008; pp. 437–443. [Google Scholar]

- Destree, X. Steel-fibre-only reinforced concrete in free suspended elevated slabs. Concr. Eng. 2009, 13, 47–49. [Google Scholar]

- Chiaia, B.; Fantilli, A.P.; Vallini, P. Designing cast-in-situ FRC tunnel linings. In Tailor Made Concrete Structures; Walraven, J.C., Stoelhorst, D., Eds.; CRC press, Taylor & Francis Group: London, UK, 2008; pp. 193–198. [Google Scholar]

- Briffaut, M.; Benboudjema, F.; D’aloia, L. Effect of fibres on early age cracking of concrete tunnel lining. Part I: Laboratory ring test. Tunn. Undergr. Space Technol. 2016, 59, 215–220. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Society, C. Concrete Industrial Ground Floors: A Guide to Design and Construction; Concrete Society: London, UK, 2003. [Google Scholar]

- Fib Model Code 2010; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2012.

- ACI 544.7R. Emerging Technology Report on Design and Construction of Fiber-Reinforced Precast Concrete Tunnel Segments; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- Facconi, L.; Conforti, A.; Minelli, F.; Plizzari, G. Flexural design of elevated slabs made of FRC according to fib model code 2010: A case study. In Proceedings of Italian Concrete Days 2018. ICD 2018. Lecture Notes in Civil Engineering; di Prisco, M., Menegotto, M., Eds.; Springer: Cham, Switzerland, 2018; Volme 42. [Google Scholar] [CrossRef]

- de Rivaz, B. Twenty years of FRC Tunnel final lining: Lessons learnt, design proposal and new development. In Proceedings of the 16th Australasian Tunnelling Conference 2017: Challenging Underground Space: Bigger, Better, More, Sydney, Australia, 30 October–1 November 2017; p. 467. [Google Scholar]

- Bakhshi, M.; Nasri, V. Durability design of segmental linings for intended service life of tunnels. In Proceedings of the Sixth International Conference on Durability of Concrete Structures (ICDCS 2018), West Yorkshire, UK, 18–20 July 2018. [Google Scholar]

- Chen, Z.; Koleva, D.; van Breugel, K. A review on stray current-induced steel corrosion in infrastructure. Corros. Rev. 2017, 35, 397–423. [Google Scholar] [CrossRef]

- Tang, K. Stray current induced corrosion of steel fibre reinforced concrete. Cem. Concr. Res. 2017, 100, 445–456. [Google Scholar] [CrossRef]

- Hajiesmaeili, A.; Pittau, F.; Denarié, E.; Habert, G. Life Cycle Analysis of Strengthening Existing RC Structures with R-PE-UHPFRC. Sustainability 2019, 11, 6923. [Google Scholar] [CrossRef]

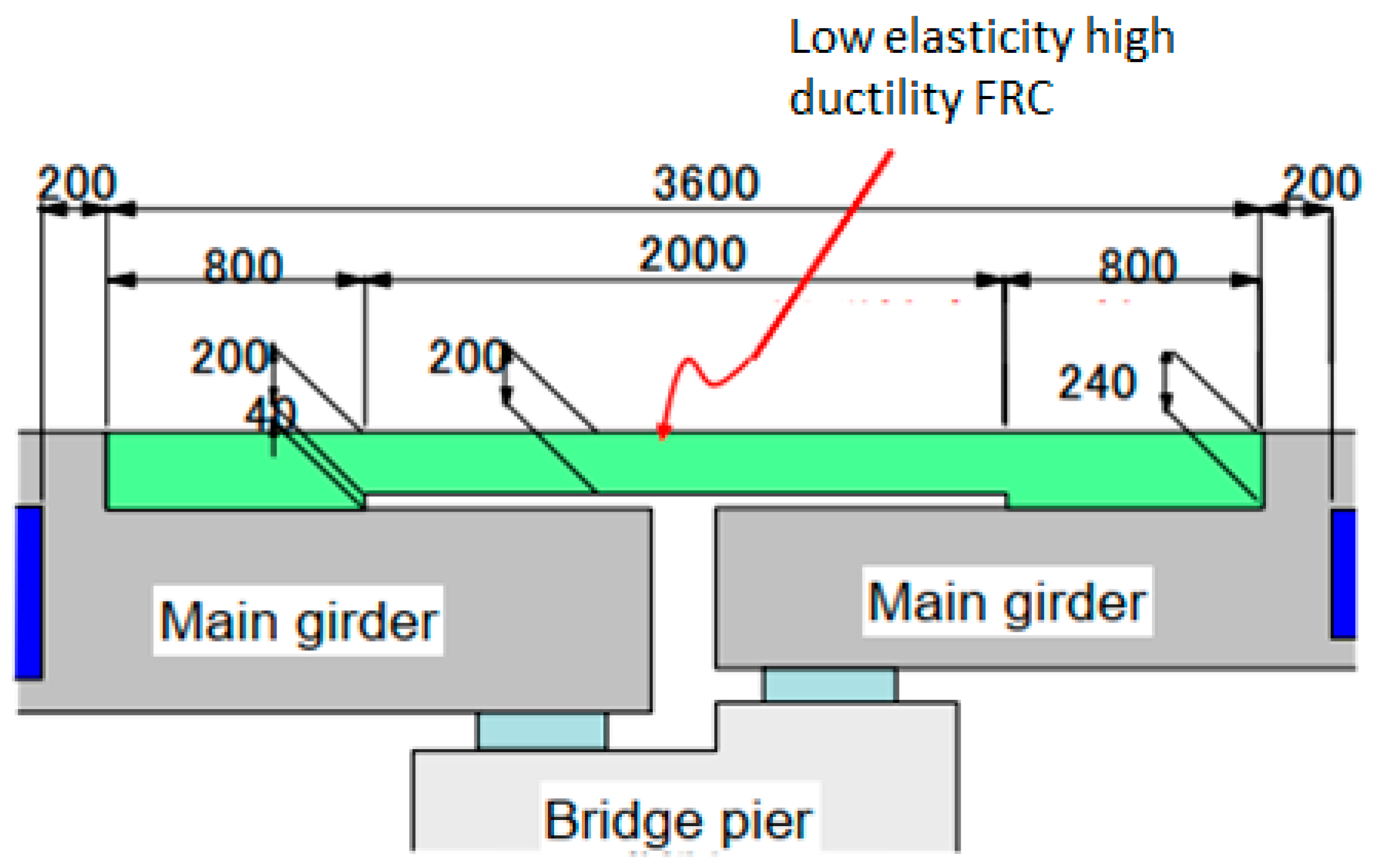

- Muroda, K.; Taira, Y.; Nabetani, Y.; Iijima, M.; Uchida, S.; Oshiro, T. Development and practical application of slab connection system for PC girders using low-elasticity high ductility fiber-reinforced cementitious composite. In Proceedings of the 3rd Sustainable Construction Materials and Technologies Conference (SCMT3), Kyoto, Japan, 18–21 August 2013. [Google Scholar]

- Ooyagi, R.; Taniguachi, H.; Sasaki, W.; Higuchi, M.; Shiina, N.; Oshiro, T. Development of low-elasticity high-ductility fiber-reinforced cementitious composite for use in PC girder connecting slabs. In Proceedings of the 3rd Sustainable Construction Materials and Technologies Conference (SCMT3), Kyoto, Japan, 18–21 August 2013. [Google Scholar]

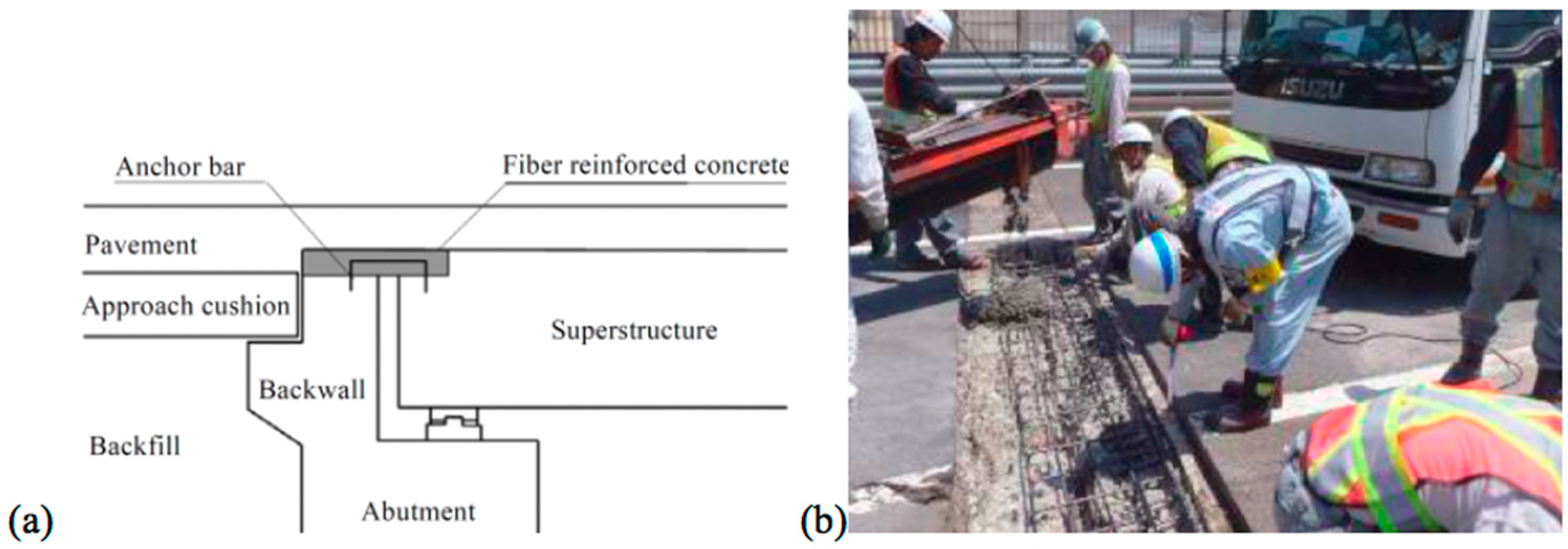

- Ishikawa, Y.; Aoyama, M.; Kuroyanagi, M.; Nagai, M.; Miyashita, T. Proposition of a new type of jointless system for existing concrete bridges. J. Phys. Sci. Appl. 2014, 4, 84–89. [Google Scholar]

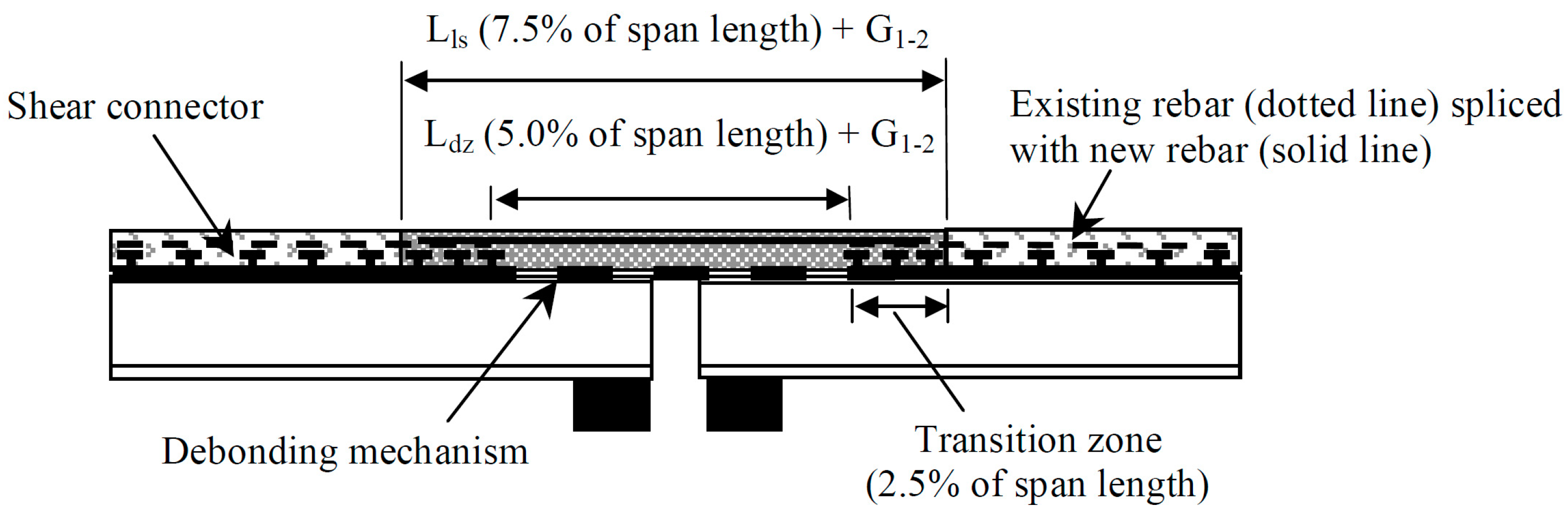

- Lepech, M.; Li, V.C. Design and field demonstration of ECC link slabs for jointless bridge decks. In Proceedings of the 3rd International Conference on Construction Materials: Performance, Innovations and Structural Implications (ConMat’05), Vancover, BC, Canada, 22–24 August 2005. [Google Scholar]

- Lepech, M.D.; Li, V.C. Application of ECC for bridge deck link slabs. Mater. Struct. 2009, 42, 1185. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Types of Fibers | Diameter (µm) | Length (mm) | Specific Gravity (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Ultimate Elongation (%) |

|---|---|---|---|---|---|---|

| Steel | 5–1000 | 10–60 | 7.85 | 200–2600 | 195–210 | 0.5–5.0 |

| Polyethylene (PE) | 25–1000 | 0.96 | 80–600 | 1.4–5 | 12–100 | |

| High modulus PE (HMPE) | 20–24 | 6–12 | 0.97 | 2500–3000 | 80–120 | 2.5–5 |

| As-spun phenylene-bensobisoxazole (PBO-AS) | 13 | 6 | 1.54 | 5800 | 180 | 3.5 |

| Polypropylene (PP) | 10–200 | 5–50 | 0.90–0.91 | 310–760 | 3.5–14.7 | 6–15 |

| Polyvinyl alcohol (PVA) | 9–760 | 6–12 | 1.2–2.5 | 800–3600 | 20–80 | 4–12 |

| Glass | 6–35 | 10–50 | 2.54–2.70 | 1500–4000 | 72–80 | 2.5–4.8 |

| Coconut | 100–400 | – | 1.12–1.15 | 120–200 | 19–25 | 10–25 |

| Jute | 100–200 | – | 1.02–1.04 | 250–350 | 25–32 | 1.5–1.9 |

| Asbestos | 0.02–25 | 5–40 | 2.55–3.2 | 200–1800 | 164 | 2–3 |

| Carbon | 7–20 | 3–12 | 1.2–2 | 600–4000 | 200–390 | 0.4–11 |

| Reference | Fibers Type/Content | Exposure Time (month) | Crack Width (mm) | Carbonation Depth (mm) | Total Chloride Content (%) | Corrosion Damage |

|---|---|---|---|---|---|---|

| Vasanelli et al. [43] | Steel, 0.6% | 17 | Wcr,ave 0.13 | 15.11–16 | – | – |

| Polyester fibers, 0.9% | 17 | Wcr,ave 0.13–0.16 | 14.87–17.47 | – | – | |

| Kobayashi & Kojima [44] | Polypropylene, 1.5% | 11 | Wcr,tot 0.04–0.26 | – | 0.38–0.63 | Mass loss, 5% |

| Polypropylene, 1.0% | 11 | Wcr,tot 0.02–0.12 | – | 0.55–0.62 | Mass loss, 8% | |

| Polypropylene, 0.75% | 11 | Wcr,tot 0.04–0.08 | – | 0.55–0.60 | Mass loss, 10% | |

| Miyazato & Hiraishi [45] | Polyethylene, 1.5% | 3 | Wcr,ave < 0.1 | 21.6 (w/c = 0.3) 28.8 (w/c = 0.6) | – | – |

| Micelli et al. [46] | Steel, 0.6% | 72 | Wcr,ave 0.19 | 39 | – | – |

| Polyester fibers, 0.9% | 72 | Wcr,ave 0.16 | 37 | – | – | |

| Chen et al. [47] | Steel, 0.5% | 36 | Wcr,ave 0.10–0.40 | – | – | Pitting area, ~17% |

| Polyvinyl alcohol, 0.75% | 36 | Wcr,ave 0.10–0.40 | – | – | Pitting area, ~20% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, S.C.; van Zijl, G.P.A.G.; Šavija, B. Effect of Fibers on Durability of Concrete: A Practical Review. Materials 2020, 13, 4562. https://doi.org/10.3390/ma13204562

Paul SC, van Zijl GPAG, Šavija B. Effect of Fibers on Durability of Concrete: A Practical Review. Materials. 2020; 13(20):4562. https://doi.org/10.3390/ma13204562

Chicago/Turabian StylePaul, Suvash Chandra, Gideon P.A.G. van Zijl, and Branko Šavija. 2020. "Effect of Fibers on Durability of Concrete: A Practical Review" Materials 13, no. 20: 4562. https://doi.org/10.3390/ma13204562

APA StylePaul, S. C., van Zijl, G. P. A. G., & Šavija, B. (2020). Effect of Fibers on Durability of Concrete: A Practical Review. Materials, 13(20), 4562. https://doi.org/10.3390/ma13204562